Patents

Literature

215results about How to "Improve bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

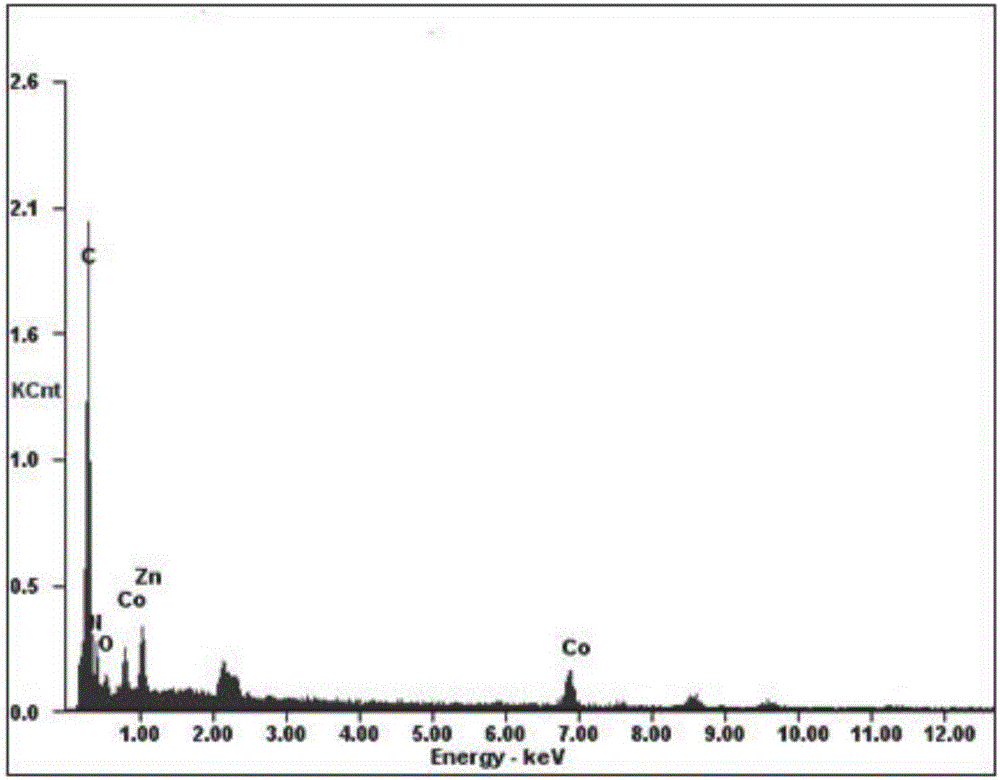

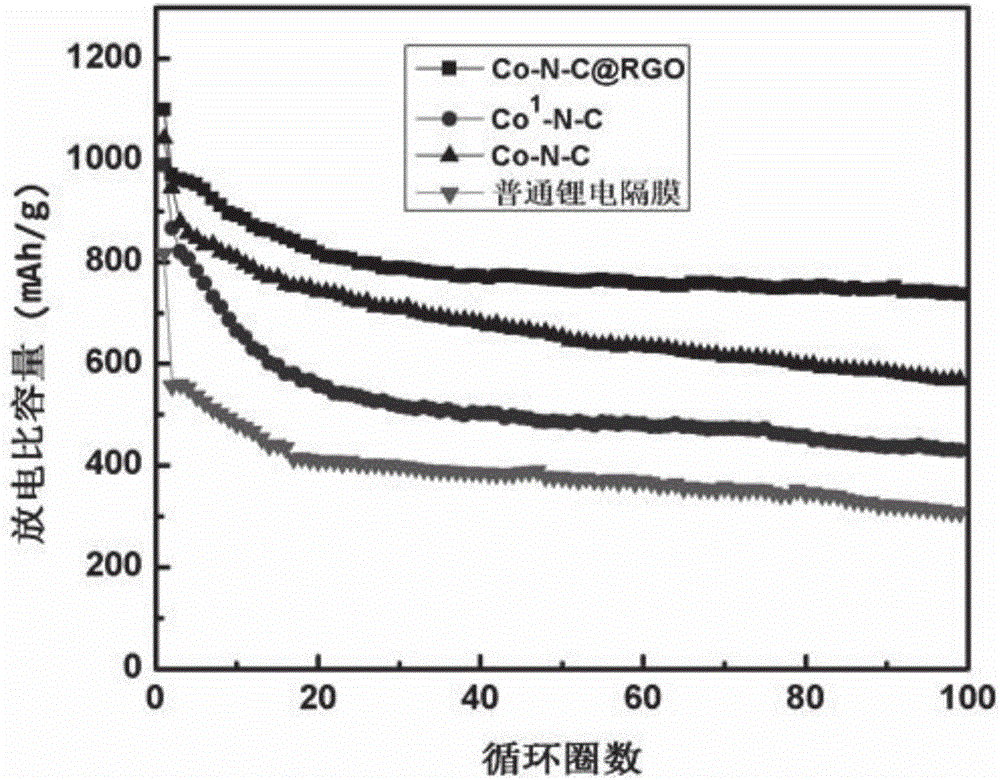

Co-N-C@RGO composite material, preparation method and application to modification of lithium-sulfur battery diaphragms

ActiveCN106784525AIncrease the areaHigh porosityLi-accumulatorsCell component detailsPorous carbonElectrical battery

The invention discloses a method for preparing porous carbon@graphene composite material by taking a bimetal organic framework material as a precursor and application to modification of lithium-sulfur battery diaphragms thereof. The preparation method comprises the following steps: taking zinc salt and cobalt salt in a certain ratio as the raw materials, synthesizing a zinc / cobalt-bimetal organic framework@graphene composite material through a room-temperature liquid phase method, taking the zinc / cobalt-bimetal organic framework@graphene composite material as the precursor, carrying out high-temperature reaction under inert atmosphere, pickling and drying to obtain a cobalt / nitrogen double-doped porous carbon@graphene (Co-N-C@RGO) composite material. Co-N-C@RGO has high conductivity; the specific surface area of Co-N-C@RGO reaches up to 750-1000m<2> / g; the content of Co is 2-4At%; the content of N is 10-20At%. When the material is applied to the modification of the lithium-sulfur battery diaphragms, the material has the function of obviously inhibiting polysulfide shuttle effect and is capable of greatly improving actual specific capacity and cyclic performance of the lithium-sulfur batteries; meanwhile, the raw materials needed for synthesizing the material are simple; the operation is convenient; the large-scale production can be achieved; the material has certain promoting effect on commercialization of lithium-sulfur battery systems.

Owner:CENT SOUTH UNIV

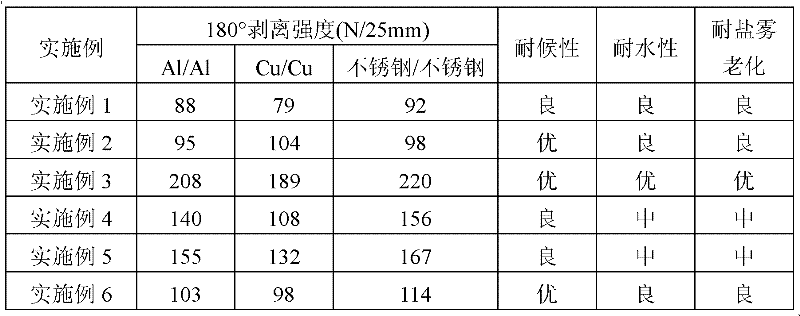

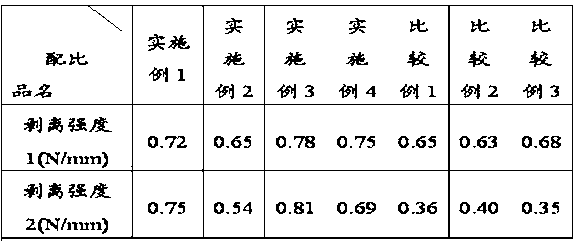

Hot melt adhesive membrane for bonding bi-metallic composite plate and preparing method thereof

InactiveCN102559078AUniform thicknessSimple bonding processFilm/foil adhesivesPolyureas/polyurethane adhesivesWeather resistanceChemistry

The invention provides a hot melt adhesive membrane for bonding a bi-metallic composite plate and a preparation method of the hot melt adhesive membrane. The adhesive membrane is prepared by the following steps: adopting one or several from polyacrylate rubber, polyethylene-acrylic acid (ester) copolymer or polyvinyl chloride-vinyl acetate esters copolymer as adhesive-based resin; adopting one or several blends from polyethylene, chloridize polyethylene, polyethylene-octene copolymer, ethylene propylene rubber, polyethylene-vinyl acetate, polymethyl methacrylate, polymethyl methacrylate-butadiene-styrene copolymer, polystyrene, thermoplastic polyurethane and polyvinyl chloride as a second matrix; adding a certain amount of thickening agents, fillers and functional additives after pre-mixing; and then casting to form the membrane. The hot melt adhesive membrane has high bonding strength and lasting stability, excellent weather resistance, aging resistance of salt mist, and water resistance, and is suitable for compounding and bonding of metal materials such as stainless steel, galvanized steel, iron, aluminum, copper, titanium alloys and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

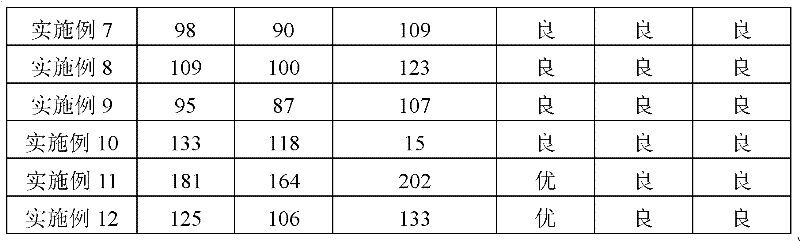

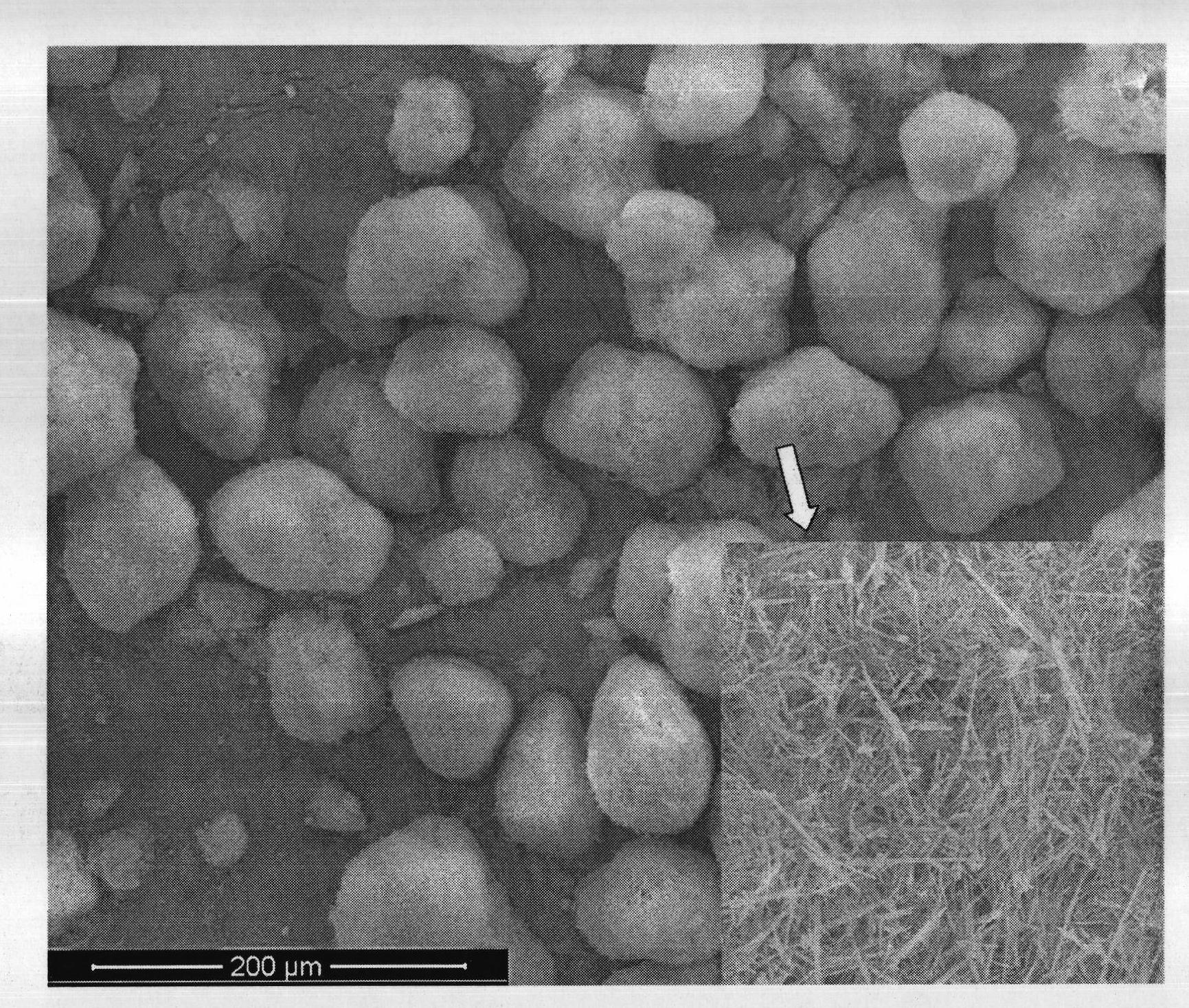

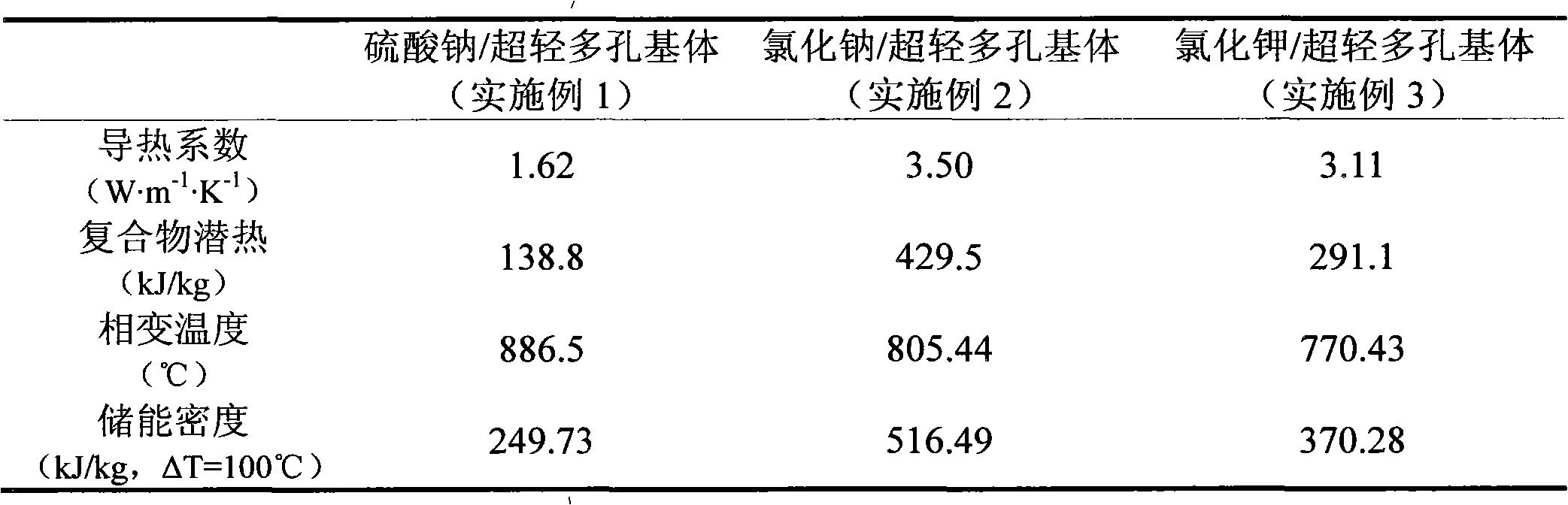

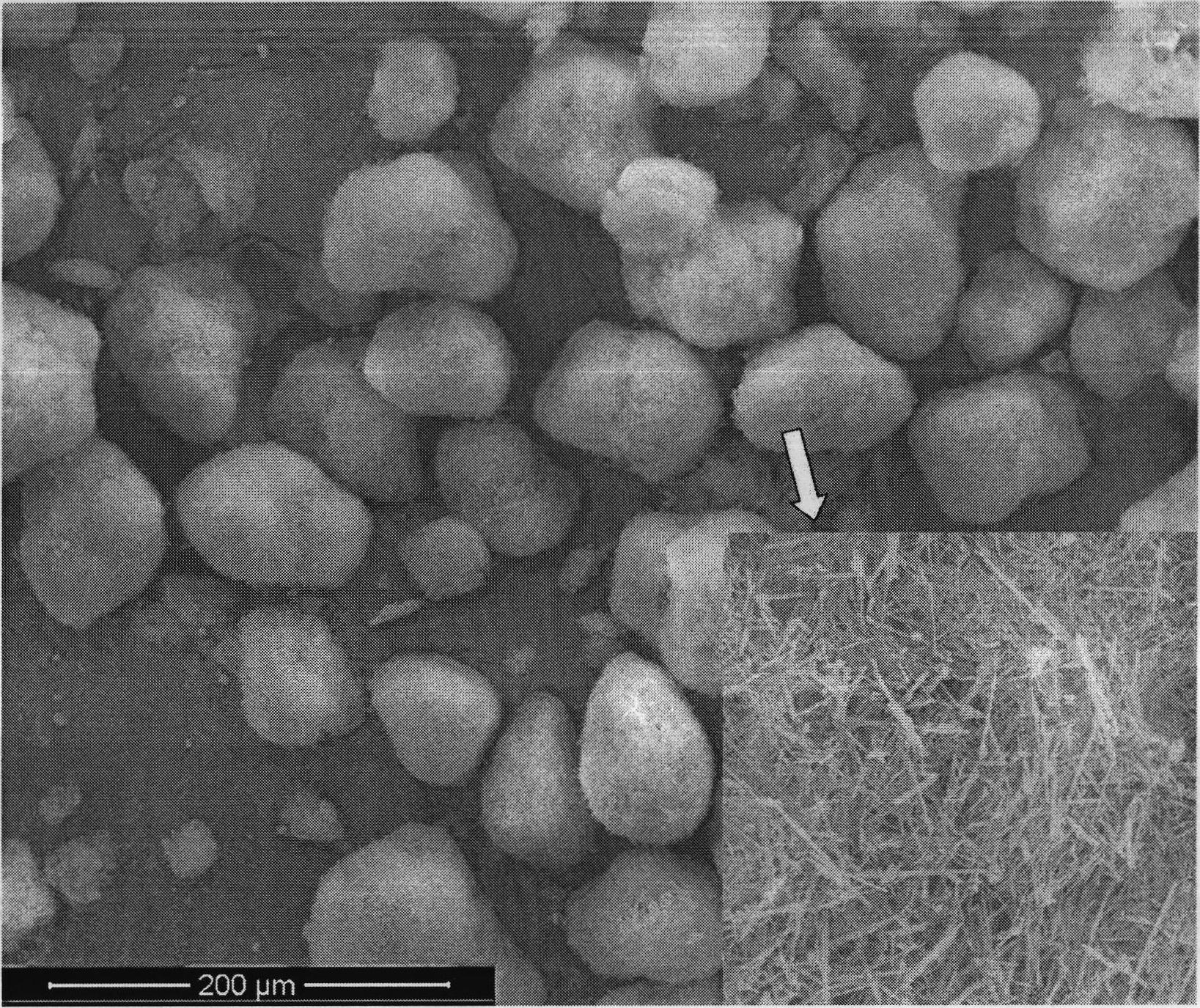

Porous material matrix and composite phase-change heat storage material and preparation methods thereof

InactiveCN102061403AIncrease contentImprove heat storage capacityHeat-exchange elementsCeramicwareWater basedHeat conducting

The invention provides a preparation method of a porous material matrix. The preparation method comprises the following steps: mixing a weighed calcium-containing raw material and a silicon-containing raw material at the mole ratio of Ca to Si of 1:(0.4-1), adding 20-40-times water based on the total weight of the raw materials, stirring and keeping the temperature of 180-320 DEG C for 4-12 hours, and obtaining porous material slurry; and adding 0%-5% of nano-metal powder after the slurry is cooled, drying and molding to obtain the porous material matrix. The preparation method of a composite phase-change heat storage material comprises the following steps: dipping the obtained porous material matrix into a fully fused inorganic salt phase-change material so that the phase-change material is completely infiltrated into a pore path of the porous material matrix; and blowing out for cooling, and then desalting the discharged sample to finally obtain the composite phase-change heat storage material. The obtained matrix material has the advantages of good infiltration property and excellent high-temperature chemical stability relative to inorganic salt; and the obtained composite phase-change heat storage material has the advantages of high heat storage density, good heat-conducting property and cheap raw material.

Owner:SOUTH CHINA UNIV OF TECH

Biodegradable PE-coated paper material and preparation method thereof

ActiveCN102558797AGood compatibilityImprove bondingSpecial paperSynthetic resin layered productsElastomerAnti ageing

The invention discloses a biodegradable PE-coated paper material which comprises the following components in percentage by weight: 60-90% of polylactic acid, 5-40% degradable toughening resin, 1-10% of elastomer, 0.1-1.0% of processing aid and 0.1-1.0% of anti-aging agent. According to the invention, the compatibility of the polylactic acid and elastic degrading resin can be improved, the adhesion of the material and paper is improved, and the cost of the existing degrading PE-coated paper raw material is greatly reduced.

Owner:SHENZHEN ESUN IND

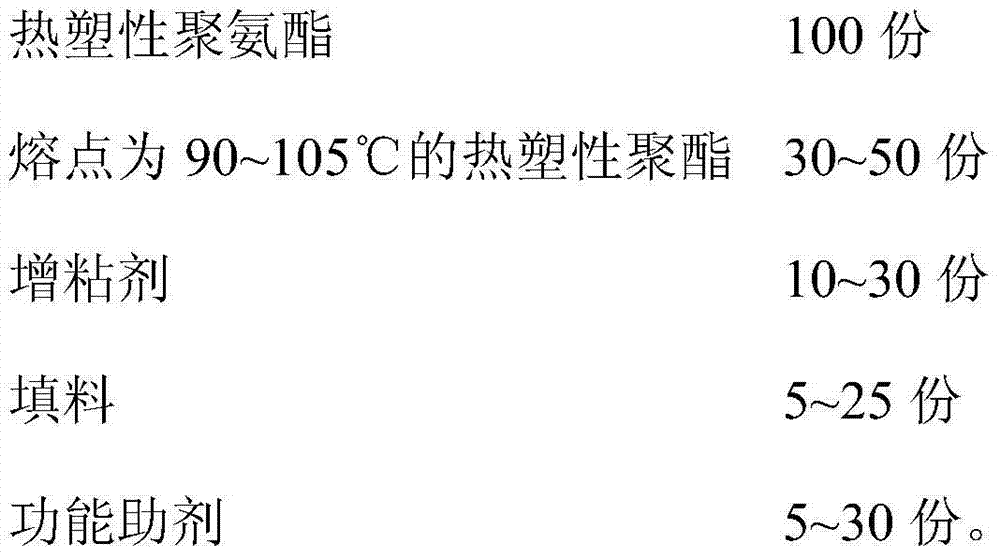

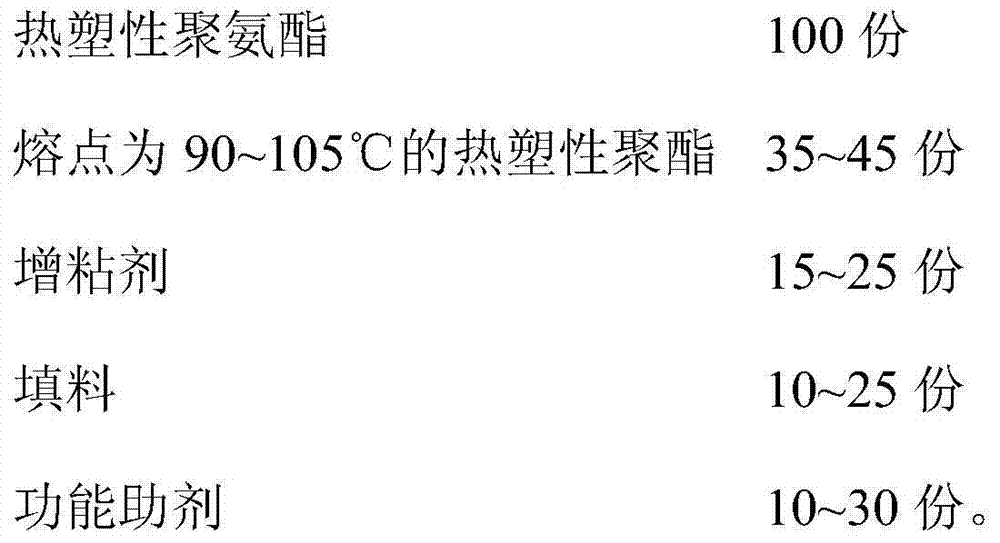

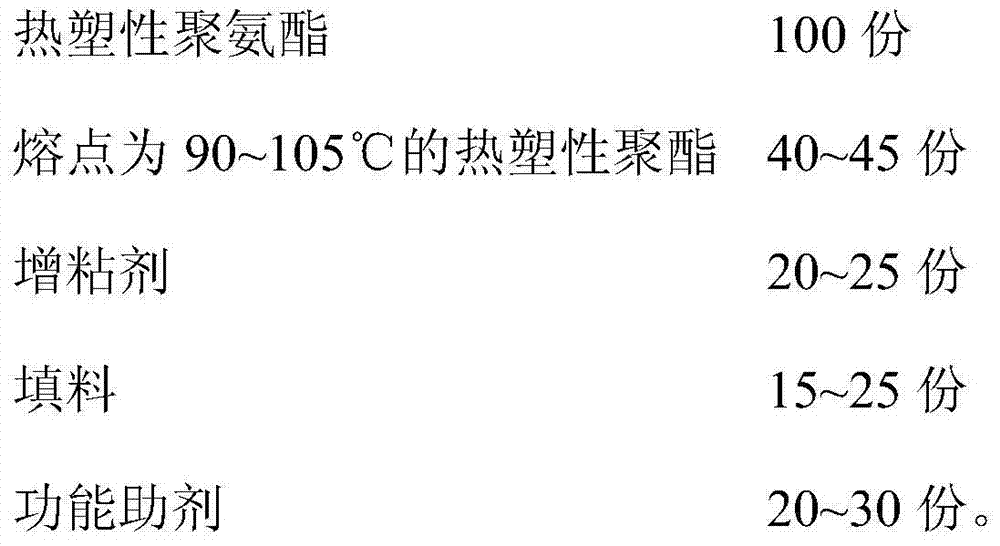

Low-melting-point and high-bonding-strength TPU (thermoplastic polyurethane) hot melt adhesive membrane and preparation method thereof

ActiveCN104263259AUniform thicknessSimple bonding processNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryPolyester

The invention provides a TPU (thermoplastic polyurethane) hot melt adhesive membrane. The TPU hot melt adhesive membrane is mainly prepared from the following raw materials in parts by weight: 100 parts of TPU, 30-50 parts of thermoplastic polyester of which the melting point is 90-105 DEG C, 10-30 parts of a tackifier, 5-25 parts of a filling material and 5-30 parts of a functional auxiliary agent. The hot melt adhesive membrane prepared by using the method provided by the invention is of a thermoplastic adhesive, is uniform in thickness and simple in bonding process, is suitable for bonding by adopting an automatic production line, is high in production efficiency and large in peeling strength after bonding, can resist water, heat and salt fog aging in an outdoor harsh environment, is durable in bonding, and can be used for significantly improving the bonding strength of the hot melt adhesive membrane adhered to fabrics.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH +1

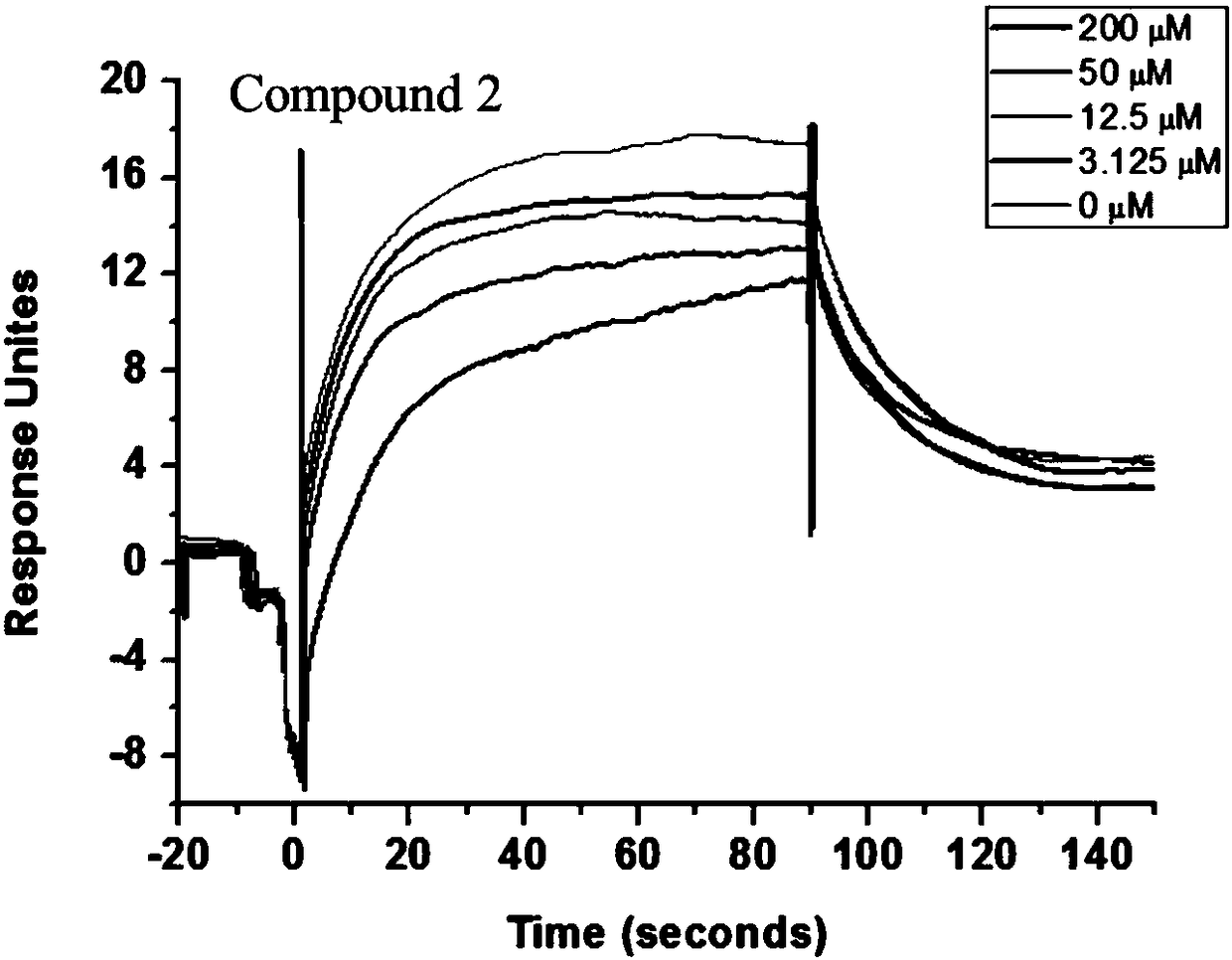

Novel PD-1 inhibitor and application thereof

PendingCN108727453AImprove bindingHigh binding affinityOrganic active ingredientsAntipyreticDiseasePharmacology

Owner:EAST CHINA UNIV OF SCI & TECH

Tunnel fire-proof slab and preparation method thereof

InactiveCN101344006AImprove flame retardant performanceLow toxicityUnderground chambersDust removalFiberAdditive ingredient

The invention discloses a tunnel fire-proof plate and a manufacture method thereof, relates to a fire-proof material and provides a fire-proof plate which is characterized by light weight, environment protection, high fire retardance, high intensity, low smoke formation and low toxicity, etc. and is applicable to the use of the tunnel and manufacture technique thereof; the tunnel fire-proof plate consists of base material, a modifying agent, reinforcing fiber and a bonding agent, wherein the base material comprises kaolinite, calcium carbonate, magnesium hydroxide and aluminium hydroxide; the modifying agent is expanded vermiculite and expanded perlite; the reinforcing fiber is the composition of inorganic fiber and polymer fiber; and the bonding agent is cement. All the ingredients are added into a high-speed disperser according to the proportion and dispersed uniformly; water is added and stirring is carried out so as to form paste; reverse mould is carried out; the obtained mixture is demoulded after being placed for one day at the room temperature, then dried after being cured for 20 to 28 days under the condition of 60 percent to 70 percent of relative humidity and the finished product is the tunnel fire-proof plate.

Owner:XIAMEN UNIV +1

Polyester hot-melt adhesive and coating method thereof

ActiveCN102703013AReduce melt viscosityExcellent film appearanceFilm/foil adhesivesLaminationEpoxyPolyester

The invention relates to the technical field of adhesives, and in particular relates to a polyester hot-melt adhesive. The polyester hot-melt adhesive comprises polyester hot-melt adhesive resin, epoxy resin and curing agents, wherein the mass ratio of the polyester hot-melt adhesive resin to the epoxy resin and to the total amount of the curing agents is 70:(30-99):1. The polyester hot-melt adhesive is low in adhesive strength attenuation, so that the adhesive strength of the polyester hot-melt adhesive on metal can be obviously improved, the melting viscosity of the polyester hot-melt adhesive is reduced, and the film-forming appearance of the polyester hot-melt adhesive is improved; and moreover, the polyester hot-melt adhesive can be prevented from being hydrolyzed, high adhesion of the polyester hot-melt adhesive at low temperature, normal temperature even high temperature is kept, and the mass production property is high.

Owner:东莞市安派电子有限公司

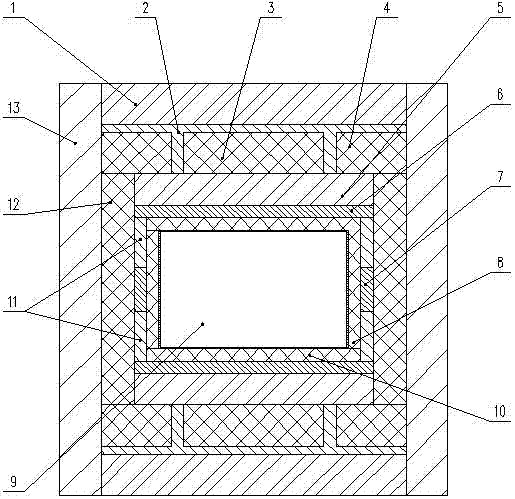

Polycrystalline diamond compact and synthetic block thereof

ActiveCN107362750AUniform distribution of temperature fieldReduce temperature differenceUltra-high pressure processesPolymer scienceNiobium

The invention provides a polycrystalline diamond compact and a synthetic block thereof. The synthetic block comprises a synthetic cavity for extruding and sintering a polycrystalline diamond blank and is characterized in that an isolation layer, a heating layer, a thermal-insulation layer and an extrusion shell are sequentially arranged outside the synthetic cavity in an encapsulated manner, the heating layer comprises a cylindrical heating element sleeving the isolation layer along an axial direction, the middle portion of the heating element corresponds to the middle portion of the synthetic cavity, and the heating quantity of the middle portion of heating element is lower than that of the two ends of the heating element; the middle portion of the heating element is preferably made of molybdenum, niobium, zirconium, titanium or tantalum, and the two ends of the heating element are preferably made of graphite. The synthetic block has the advantages that axial rigid pressure transfer is achieved, pressure loss is lowered evidently, the heating element is structurally improved, temperature gradient is avoided, the temperature in the synthetic block is even, the pressure in the synthetic block is stable and consistent, and the prepared compact is excellent in performance.

Owner:ZHONGNAN DIAMOND CO LTD

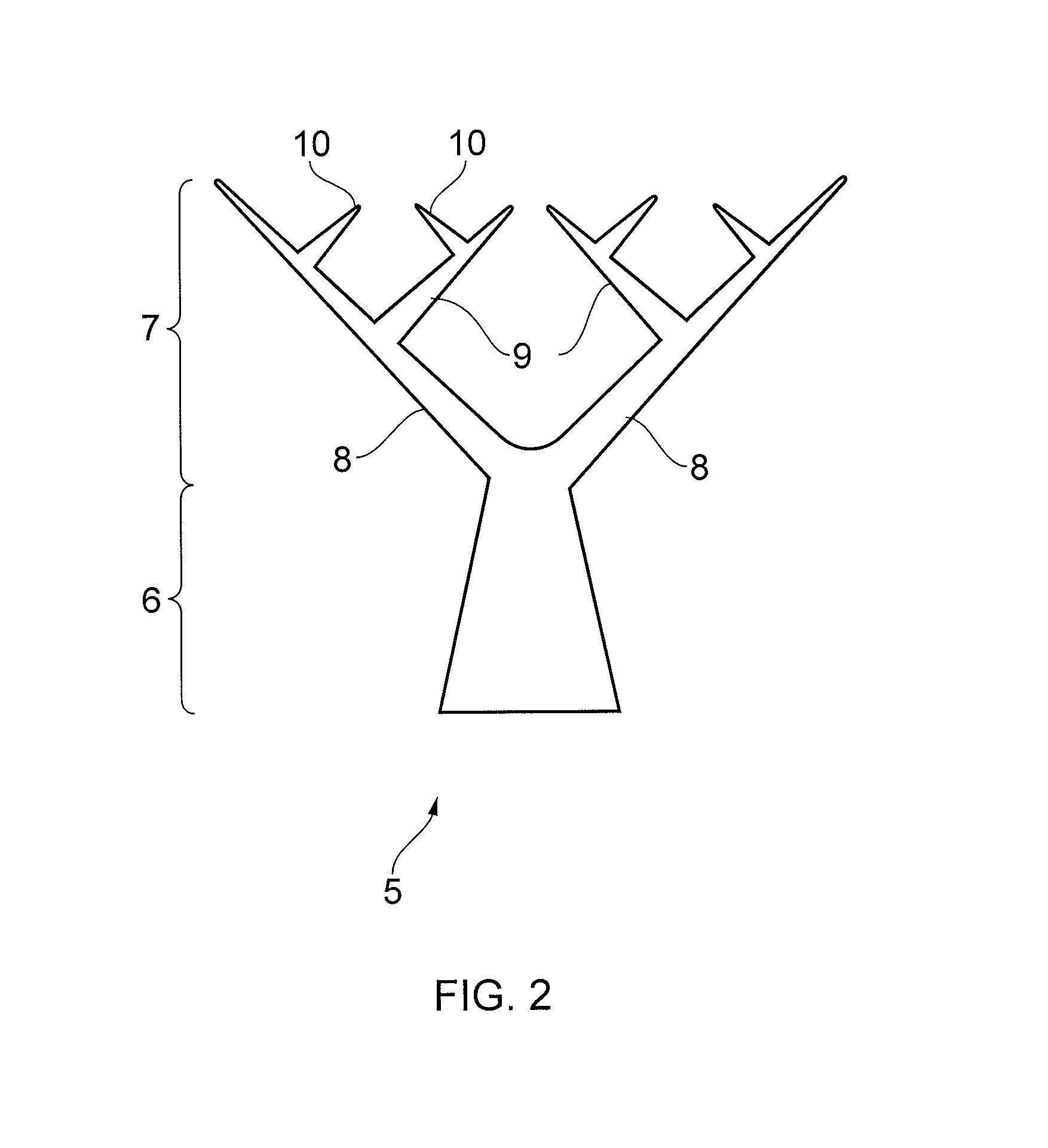

Plastic fibers for improved concrete

InactiveUS7025825B2Improve bondingImprove propertySynthetic resin layered productsBuilding reinforcementsSufficient timePolymer

A concrete article comprised of concrete having therein a reinforcing fiber, where at least about 50 percent of the reinforcing fibers are frayed only at an end or ends of the reinforcing fibers, may be made by mixing concrete, water and a reinforcing fiber for a sufficient time to fray the ends of at least 50 percent of the fibers and curing the mixture to form the concrete article. The fiber may be a reinforcing fiber comprised of at least two filaments bonded together and the filaments being comprised of a polymeric core and a polymeric sheath comprised of a fusing-fraying polymer, such that the reinforcing fiber, when mixed with inorganic particulates, frays predominately only at an end or ends of the fiber.

Owner:DOW GLOBAL TECH LLC

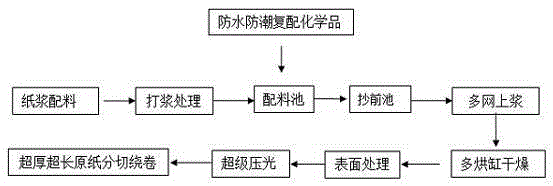

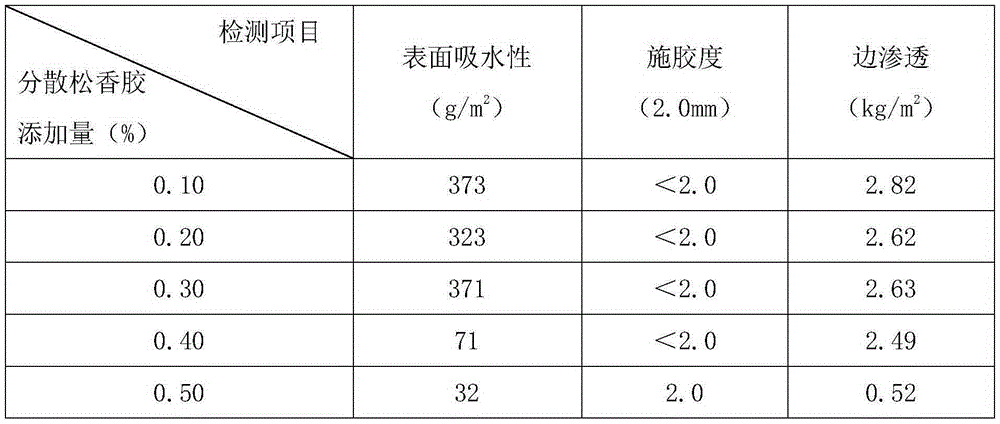

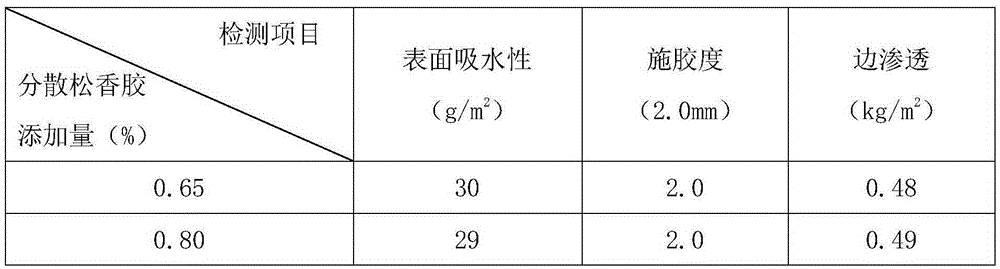

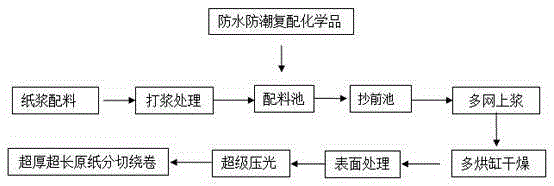

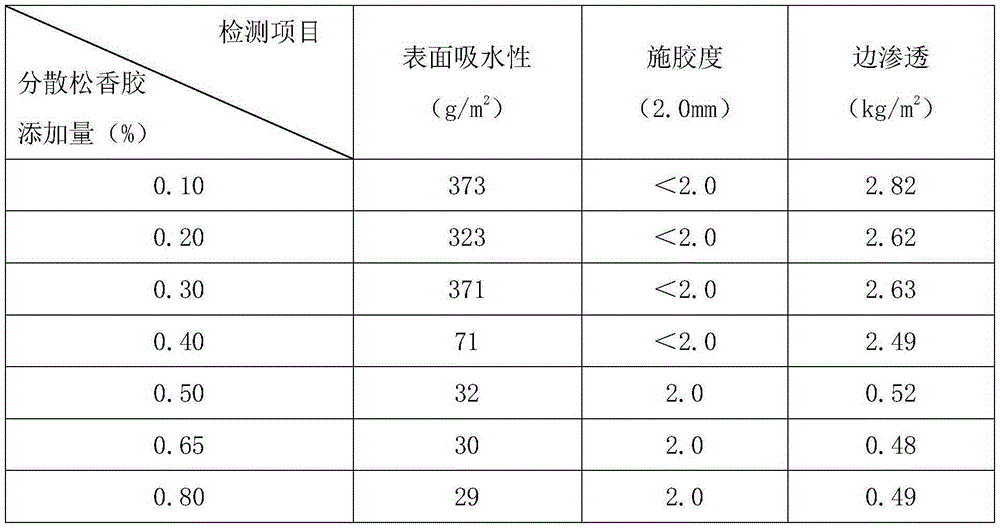

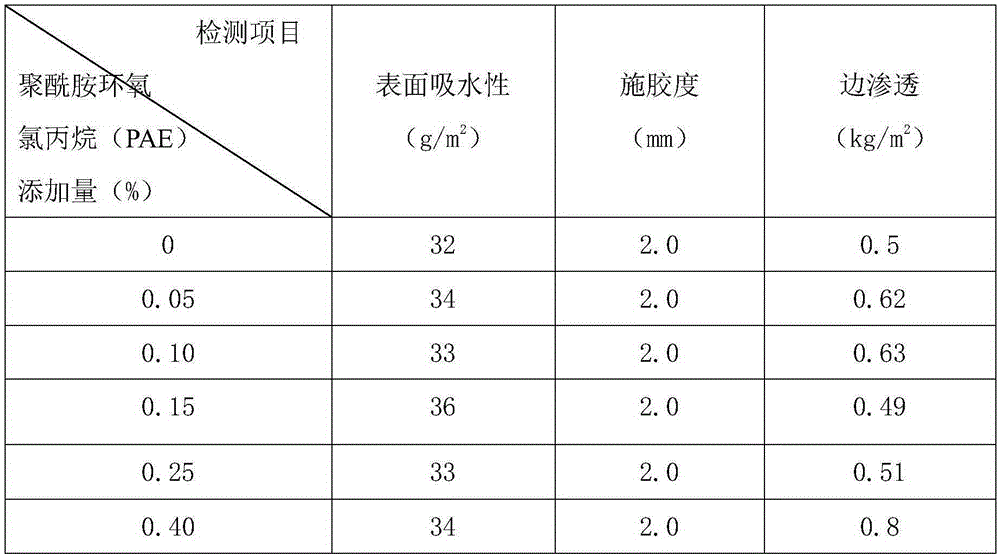

Waterproof and damp-proof raw paper dedicated for electronic paper tape, and preparation method thereof

InactiveCN105350375AGuaranteed StrengthImprove bondingWater-repelling agents additionPulp beating methodsFiberFibrillation

The present invention discloses a waterproof and damp-proof raw paper dedicated for electronic paper tapes, and a preparation method thereof. The method is characterized in that untwining and fibrillation are carried out on pulp fibers, fibrillation and cutting are further carried out so as to enable a pulp beating degree to reach 45 degree SR to 48 degree SR and a fiber wet weight to be reduced to 5.5 g to 8.0 g; and a water-resistant damp-proof composition is added in each layer, 1.0%-2.5% of the water-resistant damp-proof composition is added in relative to 100 parts of the pulp fibers, the water-resistant damp-proof composition including 0.15+-0.015 % of a wet strength agent PAE, 0.50+-0.05 % of gum rosin or an alkyl ketene dimer (AKD), 0.10+-0.01 % of silicon and fluorine type polymers, and 0.15+-0.015 % of ammonium zirconium carbonate. According to the above method, defibrination treatment is utilized, and a water-resistant damp-proof functional chemical is added in the pulp and coated on the surface of paper, surface water absorption and an edge permeation index of the raw paper are lowered than like products on the market, and water-resistance and damp-proofness of the raw paper are the best.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

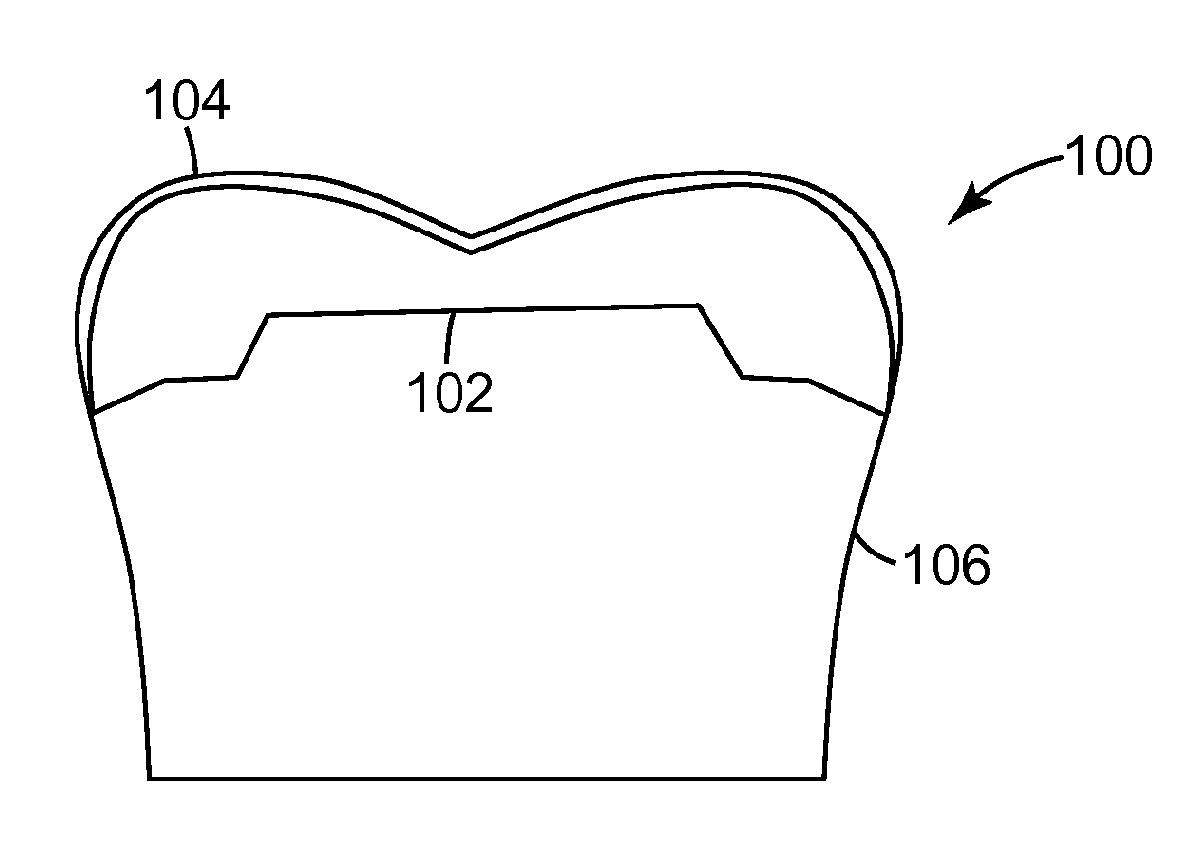

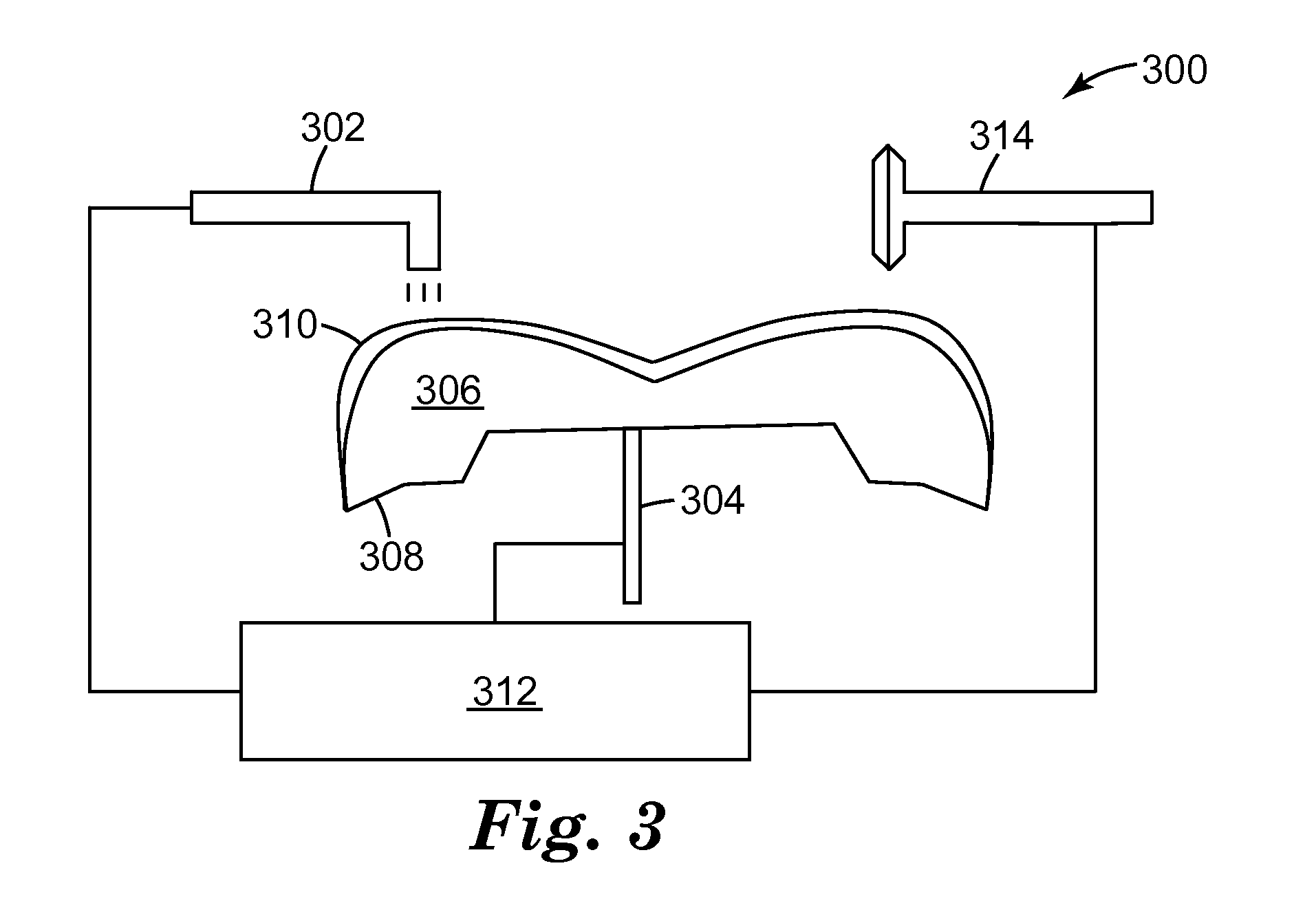

Digitally-painted dental articles

A digital painting process provides computer-controlled finishing of dental articles. The process can selectively apply different materials over portions of a dental article in one or more layers to achieve a multi-chromatic finish having a variety of colors, finishes, and surface properties that closely match the appearance and function of human dentition.

Owner:3M INNOVATIVE PROPERTIES CO

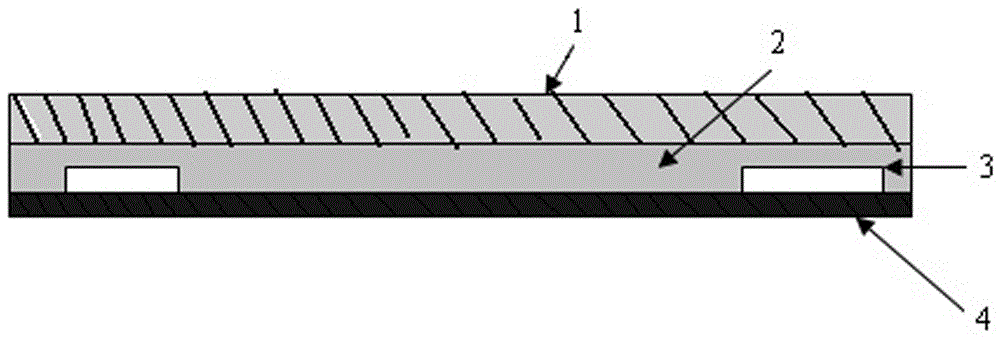

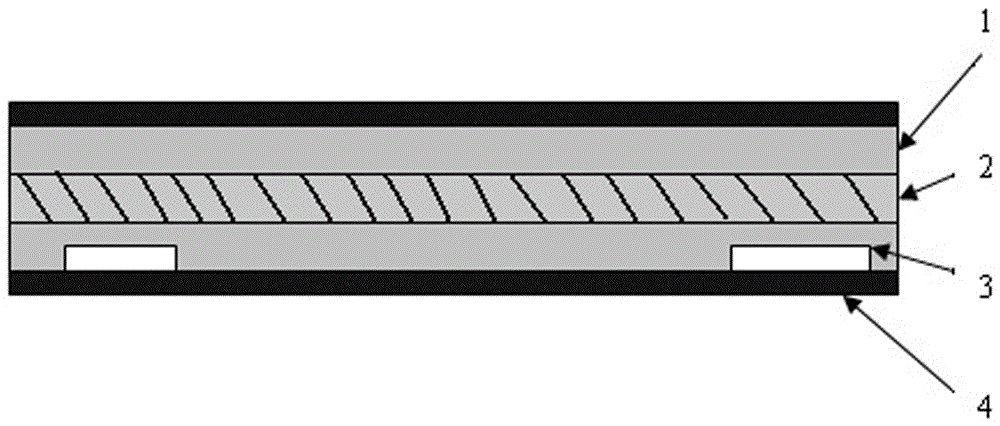

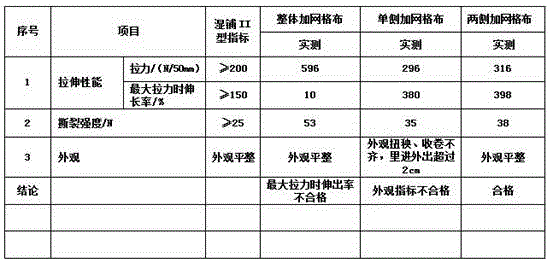

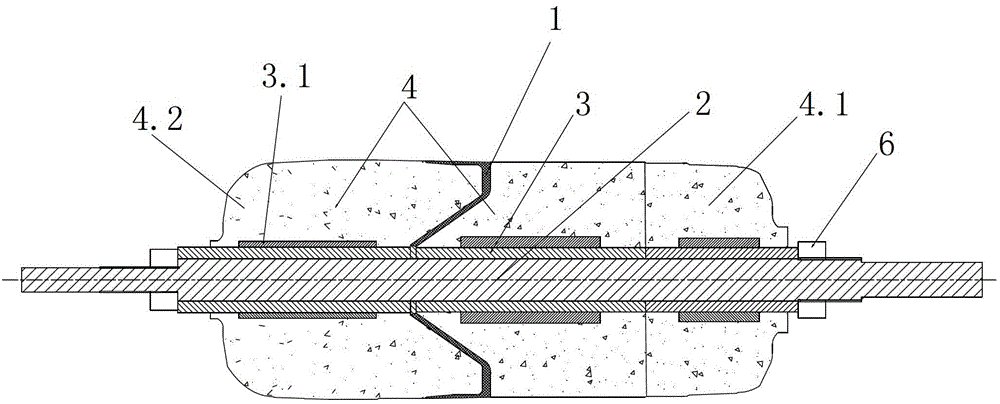

Modified asphalt waterproof coiled material with reinforced overlap edges and production method of modified asphalt waterproof coiled material

InactiveCN107175870AQuality improvementImprove mechanical propertiesRoof covering using flexible materialsSynthetic resin layered productsFiberBituminous waterproofing

The invention relates to a modified asphalt waterproof coiled material with reinforced overlap edges and a production method of the modified asphalt waterproof coiled material. The modified asphalt waterproof coiled material comprises a main body material layer, a modified asphalt layer and an isolating membrane, wherein two strips of fiber cloth are respectively embedded between the parts, which are respectively 0.1-1cm away from the edges of the two sides along the longitudinal direction of the modified asphalt layer, and the isolating membrane, so that the overlap edges are formed. After the method is adopted, the mechanical properties of the overlap edges are obviously improved after the modified asphalt waterproof coiled material is molded, so that the water resistance of the modified asphalt waterproof coiled material is more reliable; the production method provided by the invention solves the problems that in the traditional production process, due to mechanical mismatch of the left side and the right side of the coiled material, the coiled material is neat when being coiled and is twisted when being unfolded, and the like, and improves the quality of the waterproof coiled material.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

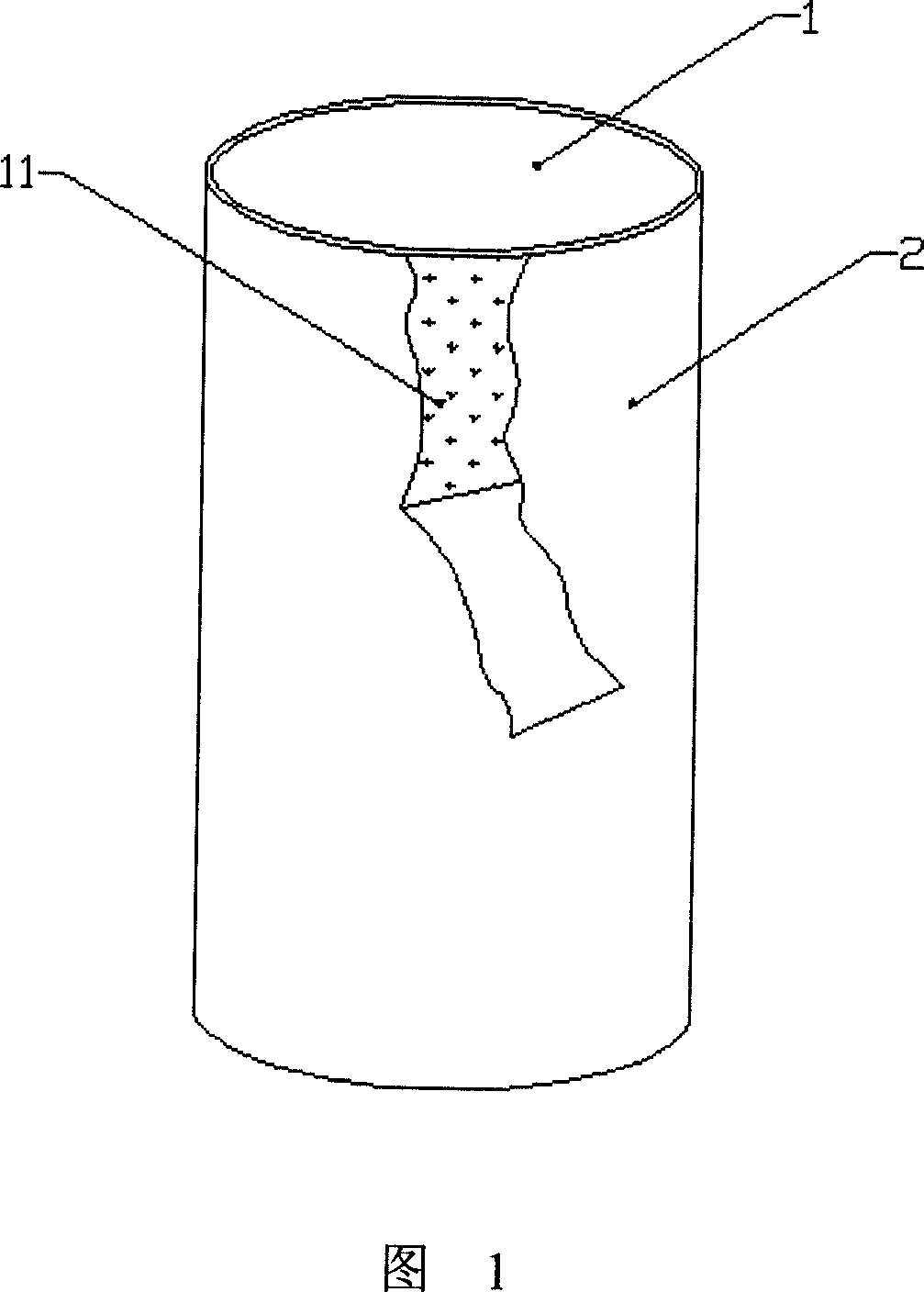

Water soluble mandrel moulding method of dipulse engine shell

The invention discloses a water soluble mandrel moulding method of a dipulse engine shell. The method comprises the following steps of: A, preparing a separator, a dabber and a shaft sleeve matched coaxially; B, preparing a quartz sand mixed cementing compound which comprises the following components in parts by weight: 350-450 parts of quartz sand, 9-10 parts of polyvinyl alcohol, 0.4-0.6 part of starch and 30-50 parts of water; first, mixing polyvinyl alcohol and starch to form mixed powder, then, mixing and stirring the mixed powder with water to form grume-free liquor, and finally, stirring and mixing quartz sand with the grume-free liquor; C, moulding the quartz sand mixed cementing compound as a sand sleeve; D, curing the sand sleeve; E, processing the external surface of the sand sleeve and the inner end face of the sand sleeve; F, assembling the dabber, the separator, the shaft sleeve and the sand sleeve; and G, performing surface treatment for the sand sleeve. The method disclosed by the invention is simple in moulding process, short in production period and low in cost, satisfies the design demand, and is suitable for being widely applied to the technical field of moulding solid rocket engine shells.

Owner:湖北三江航天江北机械工程有限公司

Electronic carrier tape special base paper with treated surface and manufacturing method thereof

ActiveCN105401481AGuaranteed StrengthImprove bondingWater-repelling agents additionPulp beating methodsPaper sheetSurface finishing

The invention discloses an electronic carrier tape special base paper with a treated surface and a manufacturing method thereof. The electronic carrier tape special base paper has two layers or more than two layers of papermaking structures. The paper is characterized in that the surface and back surface of the paper are coated with a layer of treating fluid containing a hot melting glue binding modifier, so tension for tearing the processed paper tape surface and a hot melting upper adhesive tape reaches 10 g to 70 g after hot melt adhesion, and peeling and fluffing would not occur when the hot melting upper adhesive tape is peeled. The treating fluid contains 1.5%-2.0% of polyvinyl alcohol, 1.5%-2.0% of polyacrylamide modifier, 0.7%-0.9% of acrylate copolymer, 0.02% of cyanoethyl chitosan, and 0.50%-0.80% of hot melting glue binding modifier. The tension for tearing the processed paper tape surface and the hot melting upper adhesive tape reaches 10 g to 70 g after hot melt adhesion, and peeling and fluffing would not occur when the hot melting upper adhesive tape is peeled. The electronic carrier tape special base paper satisfies requirements in industries.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

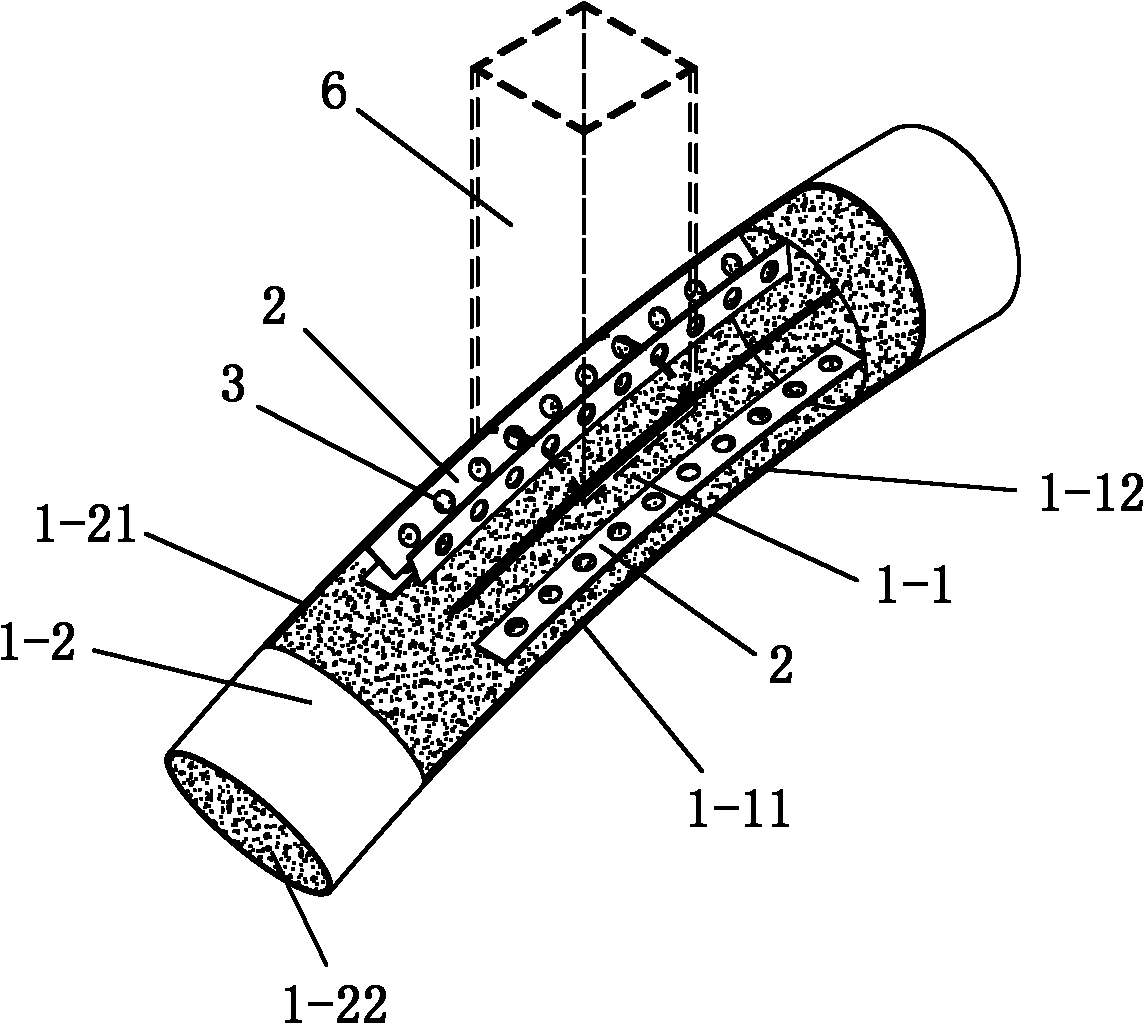

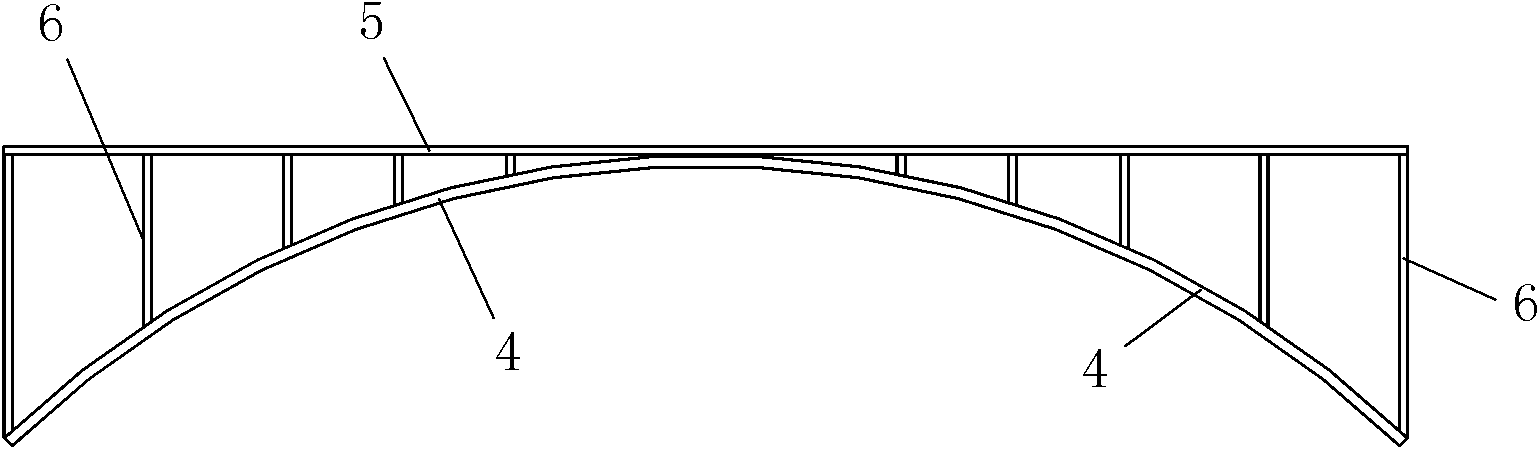

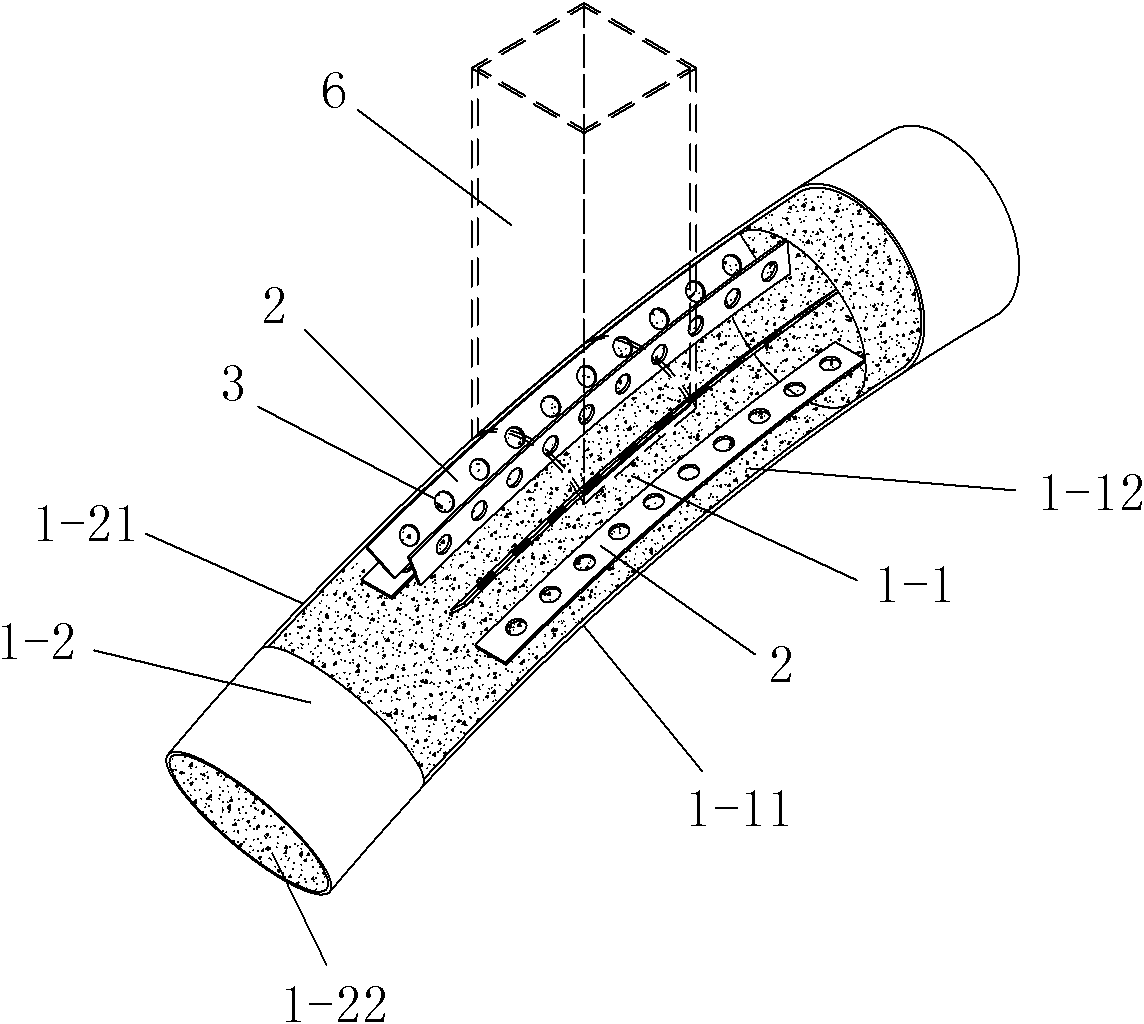

PBL (perfobond leiste) shear connector stiffened steel pipe concrete arch

InactiveCN102094386ASimple structureSimplify construction stepsBridge structural detailsArch-type bridgeMechanical propertySteel tube

The invention discloses a PBL (perfobond leiste) shear connector stiffened steel pipe concrete arch which comprises a main arch constituted by continuously assembling a plurality of steel pipe concrete arch segments, and the steel pipe concrete arch segments are divided into two types, namely stiffened steel pipe concrete arch segments provided with PBL shear connectors and ordinary steel pipe concrete arch segments which are not provided with the PBL shear connectors according to the stress situations in the positions where the steel pipe concrete arch segments are located in the main arch; and each ordinary steel pipe concrete arch segment comprises an arch-shaped steel pipe II and a concrete-filled structure II poured in the arch-shaped steel pipe II, and each stiffened steel pipe concrete arch segment comprises an arch-shaped steel pipe I, a plurality of the PBL shear connectors distributed on the inner side wall of the arch-shaped steel pipe I along the direction of the axial line and a concrete-filled structure I poured in the arch-shaped steel pipe I. The PBL (perfobond leiste) shear connector stiffened steel pipe concrete arch has simple structure, is reasonable in design, convenient to construct, excellent in mechanical properties and easy to control construction quality, and can solve the problems of void disease between steel pipes and concrete, shorter service life and the like in the existing steel pipe concrete arch structure.

Owner:CHANGAN UNIV

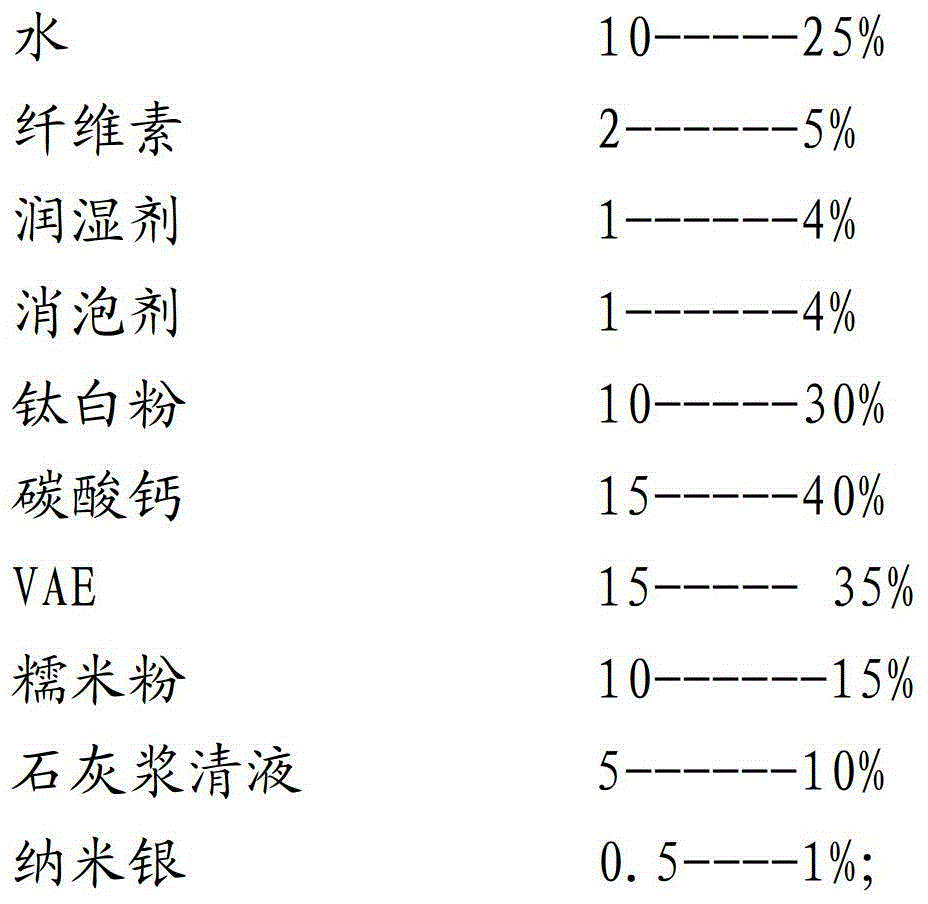

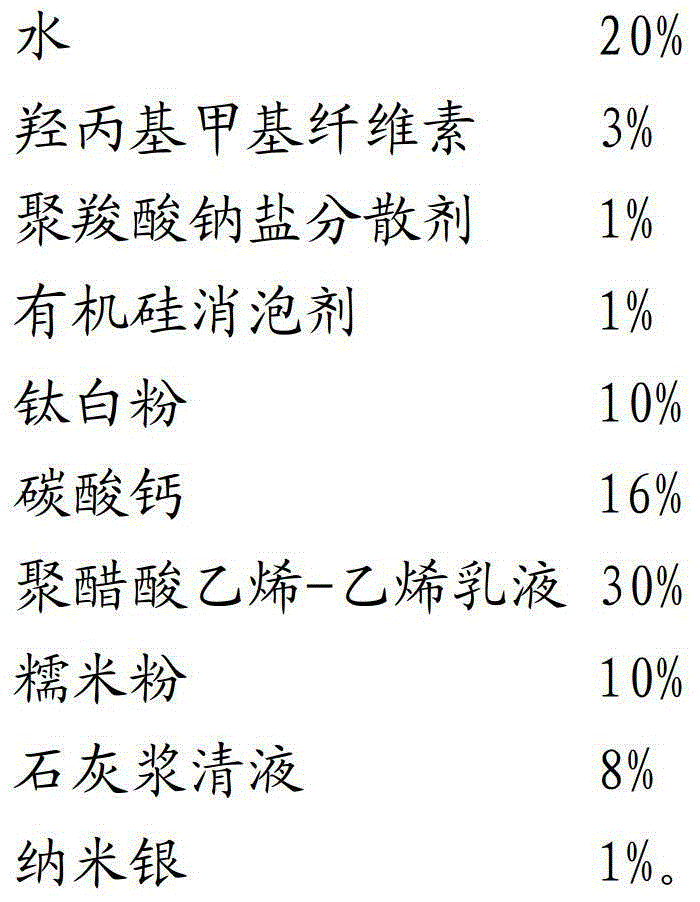

Glutinous rice flour environment-friendly water-based paint

The invention relates to paint, and in particular relates to environment-friendly, non-toxic and harmless water-based paint. The paint comprises the following components in percentage by weight: 10-25% of water, 2-5% of cellulose, 1-4% of a wetting agent, 1-4% of a defoamer, 10-30% of titanium dioxide, 15-40% of calcium carbonate, 15-35% of VAE (Vinyl Acetateethylene Emulsion), 10-15% of glutinous rice flour, 5-10% of a lime slurry clear liquid and 0.5-1% of nano-silver. With the adoption of the technical scheme, glutinous rice flour, calcium carbonate and quick lime in the formula are mixed to generate an organic-inorganic composite material which is compact in structure, high in mechanical strength, good in toughness and good in sealing performance to a base material, so that the paint obtained is excellent in weather ability and ageing resistance. Meanwhile, a plant extracting liquid is added, so that the film is more fresh and natural, and the paint is free from harmful components, safe and environment-friendly and simple to manufacture.

Owner:东莞市康博士装饰材料有限公司

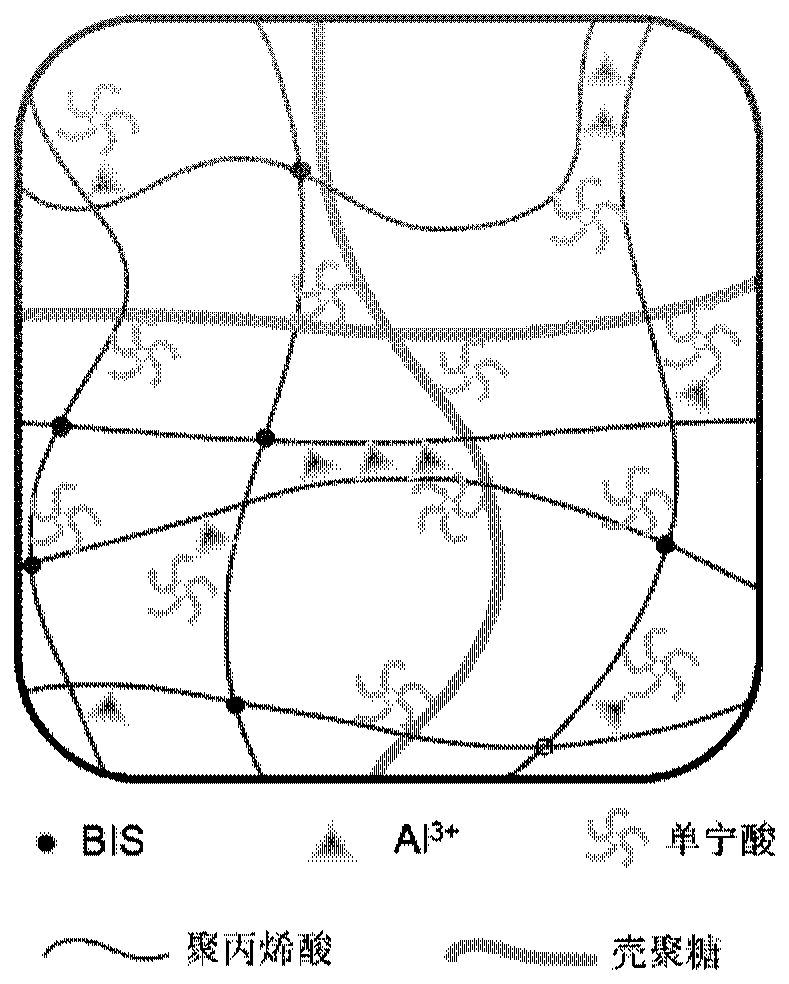

Wound adhesion hydrogel material as well as preparation method and application thereof

ActiveCN111514367AHigh bonding strengthImprove adhesion efficiencySurgical adhesivesMedicineALLYL SUCROSE

The invention discloses a wound adhesion hydrogel material as well as a preparation method and application thereof. The wound adhesion hydrogel material comprises main components including polyacrylicacid, chitosan, tannic acid and a chelating agent, wherein the polyacrylic acid and the chitosan form an interpenetrating polymer network (IPN) through an electrostatic interaction; the tannic acid is used for enhancing the viscosity and acidity of wound adhesion hydrogel; and the chelating agent is used for crosslinking the tannic acid with the polyacrylic acid and the chitosan in the IPN. The wound adhesion hydrogel material shows higher bonding strength in the air and water, can realize repeated bonding, has bonding stability, is not affected by acids or bases, shows specific bonding to biological soft tissue in water, and has antibacterial capacity and remarkable heal promoting capacity for wounds. Due to the stable bonding strength, high bonding efficiency and repeated bonding of thewound adhesion hydrogel material, the operation time can be substantially saved, the specific bonding of the wound adhesion hydrogel material to the biological soft tissue underwater also facilitatesoperation by a doctor, and the pain of a patient can be reduced. In addition, the wound adhesion hydrogel material also has the potential of being used as wearable equipment substrate.

Owner:PEKING UNIV

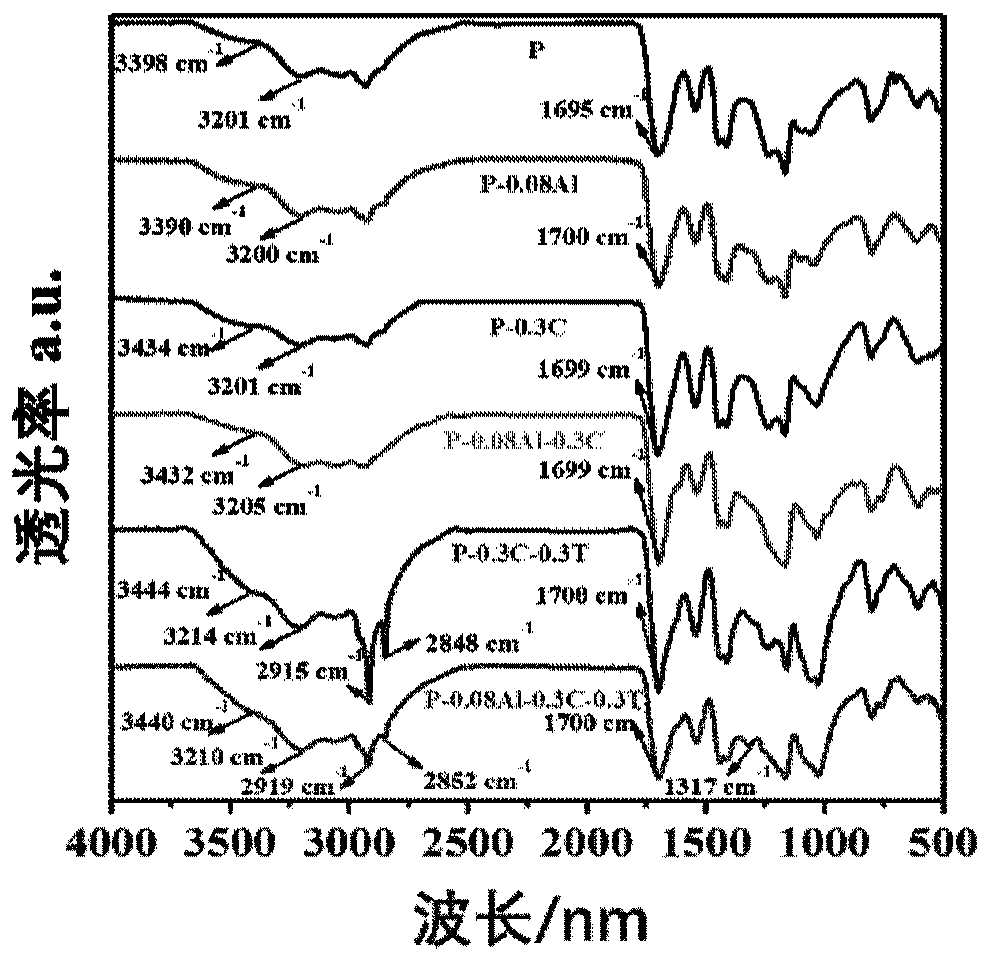

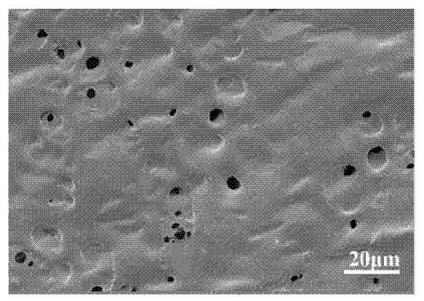

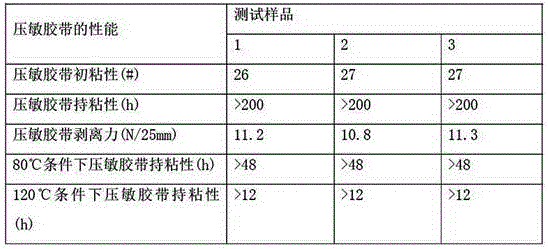

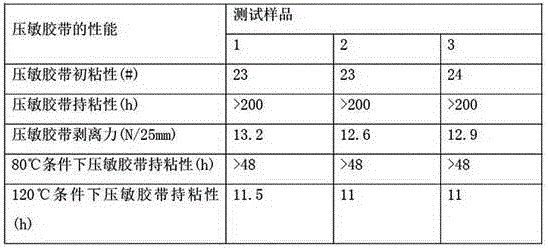

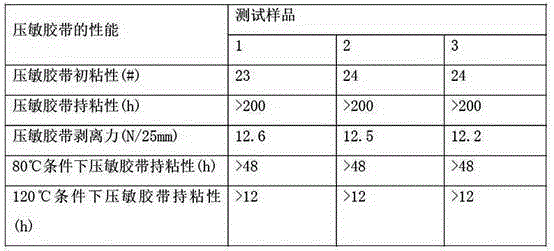

Heat-resistant polyacrylate pressure-sensitive adhesive emulsion for aluminum foil and application and preparation method thereof

InactiveCN106832104AImprove rigidityGuaranteed durabilityPressure sensitive film/foil adhesivesCross-linkDefoaming Agents

The invention discloses a heat-resistant polyacrylate pressure-sensitive adhesive emulsion for an aluminum foil and a preparation method and application thereof. An emulsion-type pressure-sensitive adhesive mainly comprises an acrylate monomer, a cross-linking monomer, an emulsifier, a buffer agent, a defoaming agent, a wetting agent, a pH modifier and an initiator. By adopting a pre-emulsification semi-continuous seed polymerization technology, a monomer and an assistant are sequentially added to a water solution for emulsification, polymerization reaction is initiated by continuously adding a pre-emulsification solution; and the assistants of the defoaming agent, the wetting agent and the pH modifier are finally added to stir evenly. The pressure-sensitive adhesive coats the surface of the aluminum foil to be dried, the thickness of the dry adhesive is 45 microns, the surface of the adhesive is uniform and transparent, and free of the defects of bubbles and sinkholes, the release force reaches 12N / 25mm, the durable viscosity is not lower than 200h, the durable viscosity is not lower than 48h under the condition of 80 DEG C / 95% and the durable viscosity is not lower than 12h under the condition of 120 DEG C / 95%.

Owner:WUXI HAITE NEW MATERIAL RES INST

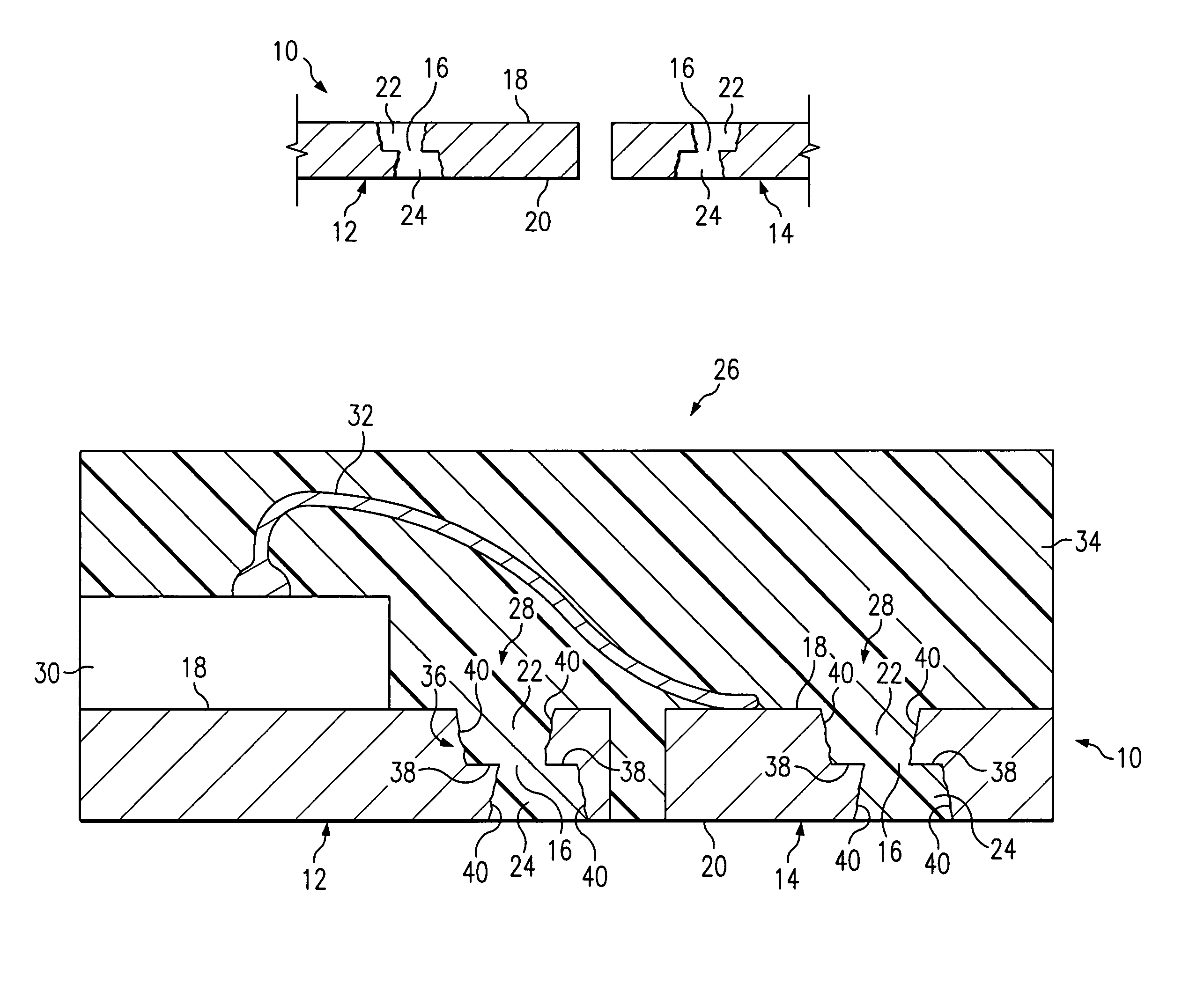

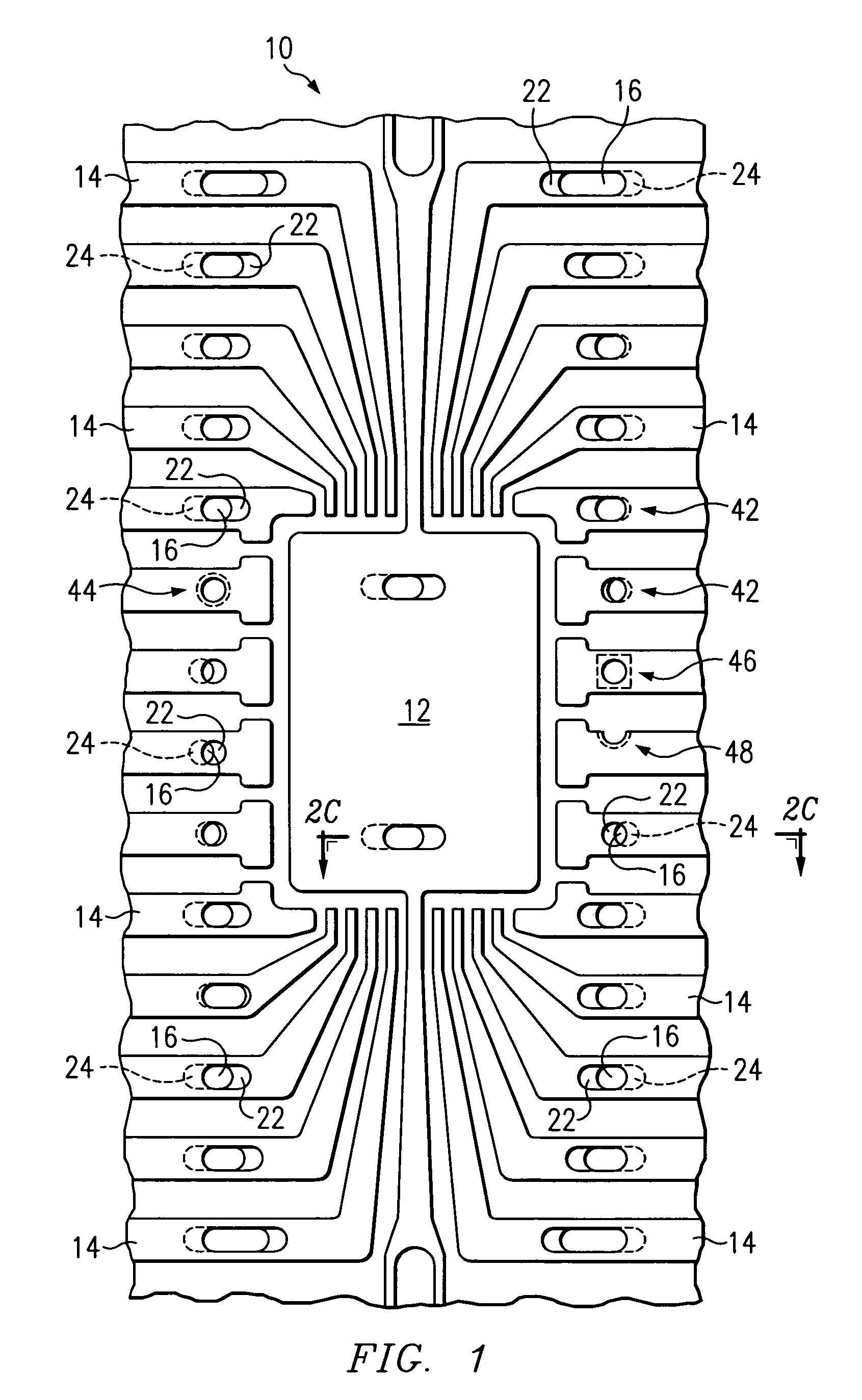

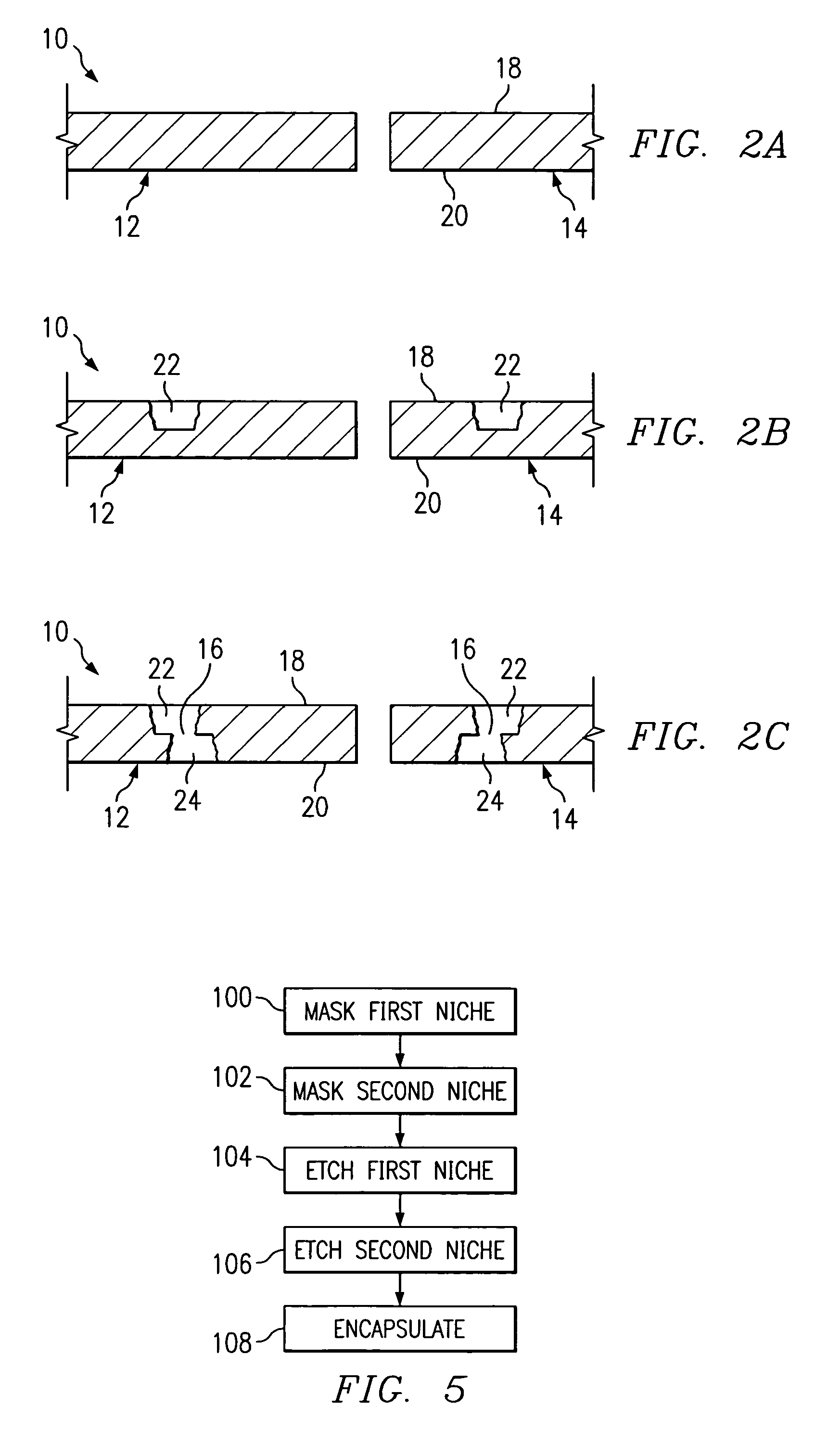

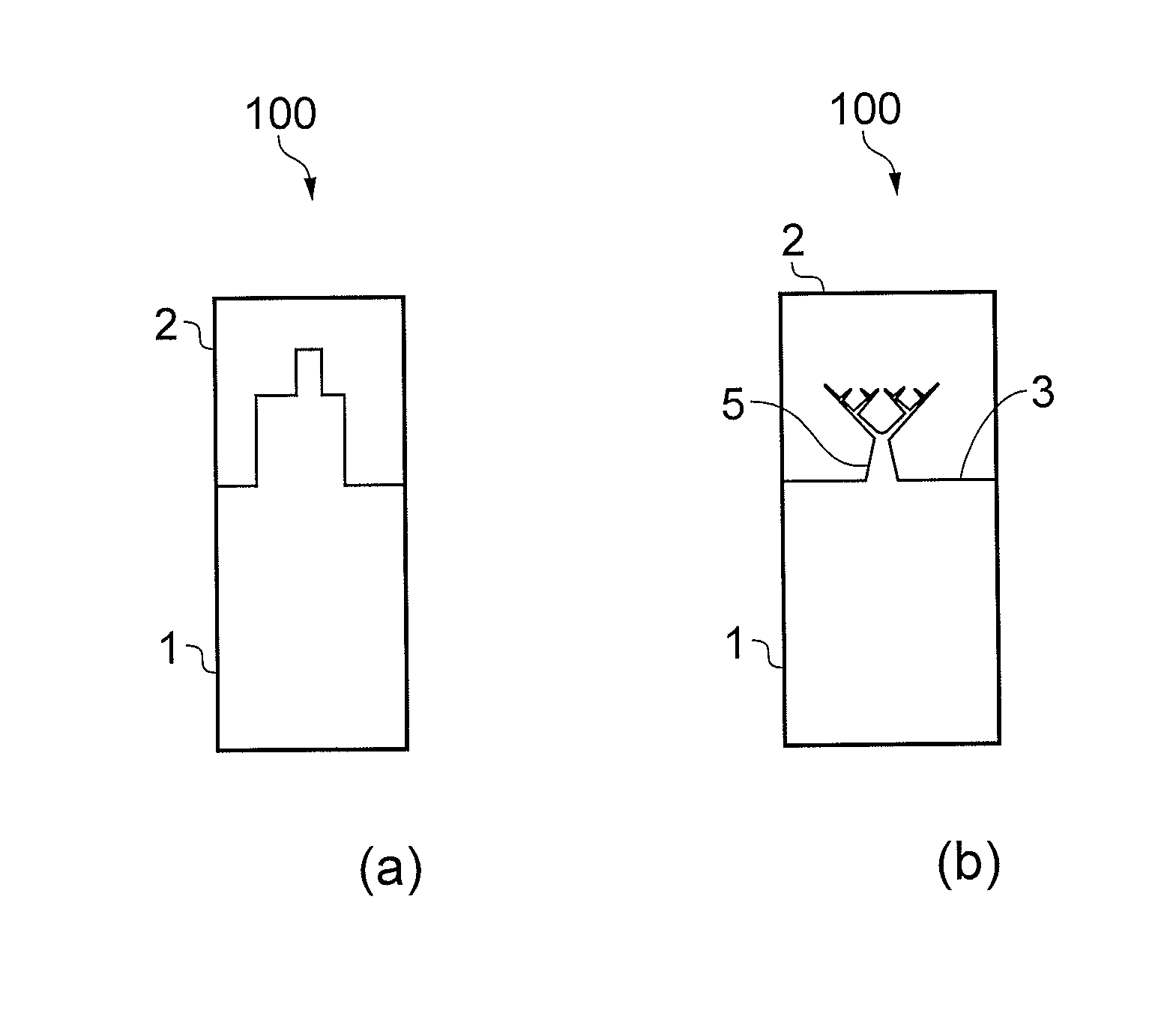

Leadframe-to-plastic lock for IC package

InactiveUS7078271B2Improve bondingSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineering

Disclosed is a method of making a mold lock for bonding leadframe-to-plastic in an IC package. Steps include providing niches from opposing sides of the leadframe. The opposing niches are arranged such that an aperture and a mechanical key are formed within the leadframe material by the partial intersection of the niches. The key is encapsulated with mold compound to form a lock. An IC package mold lock in a leadframe is also disclosed, the lock having an aperture, a key, and mold compound encapsulating the key. Additionally, an IC package employing the leadframe-to-plastic lock is disclosed.

Owner:TEXAS INSTR INC

Dry-mixed mortar prepared from industrial solid waste

The invention provides dry-mixed mortar prepared from industrial solid waste. The dry-mixed mortar is characterized by being prepared from materials in parts by weight as follows: 100 parts of cement, 300-400 parts of river sand, 50-100 parts of steel slag, 0-50 parts of iron mine tailings, 0-50 parts of glass powder, 1-2 parts of an interface reinforcing agent, 1-2 parts of an exciting agent, 0.1-0.5 parts of a water retaining agent, 1-2 parts of a water reducing agent and 0.1-0.3 parts of reinforcing fibers. According to the dry-mixed mortar, the industrial solid waste is fully utilized as aggregate to replace natural river sand, environmental protection is facilitated, resource recycling is realized, and meanwhile, performance such as the freezing resistance, the permeability resistance and the like of the dry-mixed mortar is improved through addition of the industrial solid waste.

Owner:四川震强建筑材料有限责任公司

A novel pultrude process and product thereof

InactiveCN1970279AFree from destructionImprove bondingSynthetic resin layered productsDomestic articlesRough surfaceShell molding

The pull and compression process comprises intensifying material arrangement, soaking the resin glue, performing, filling into stripping material, compressing plastics to solidify, extraction, cutting and final product. Filled with stripping material, product can have even rough surface, for the benefit of bonding of it with other materials, stable in product dimension, strict quality control, standardization with simplified process and reduced cost. It mainly uses in structural strength supplementing for all kinds of fiber intensifying plastics, distributing electric insulation core and other fields.

Owner:YASHILAN PACIFIC

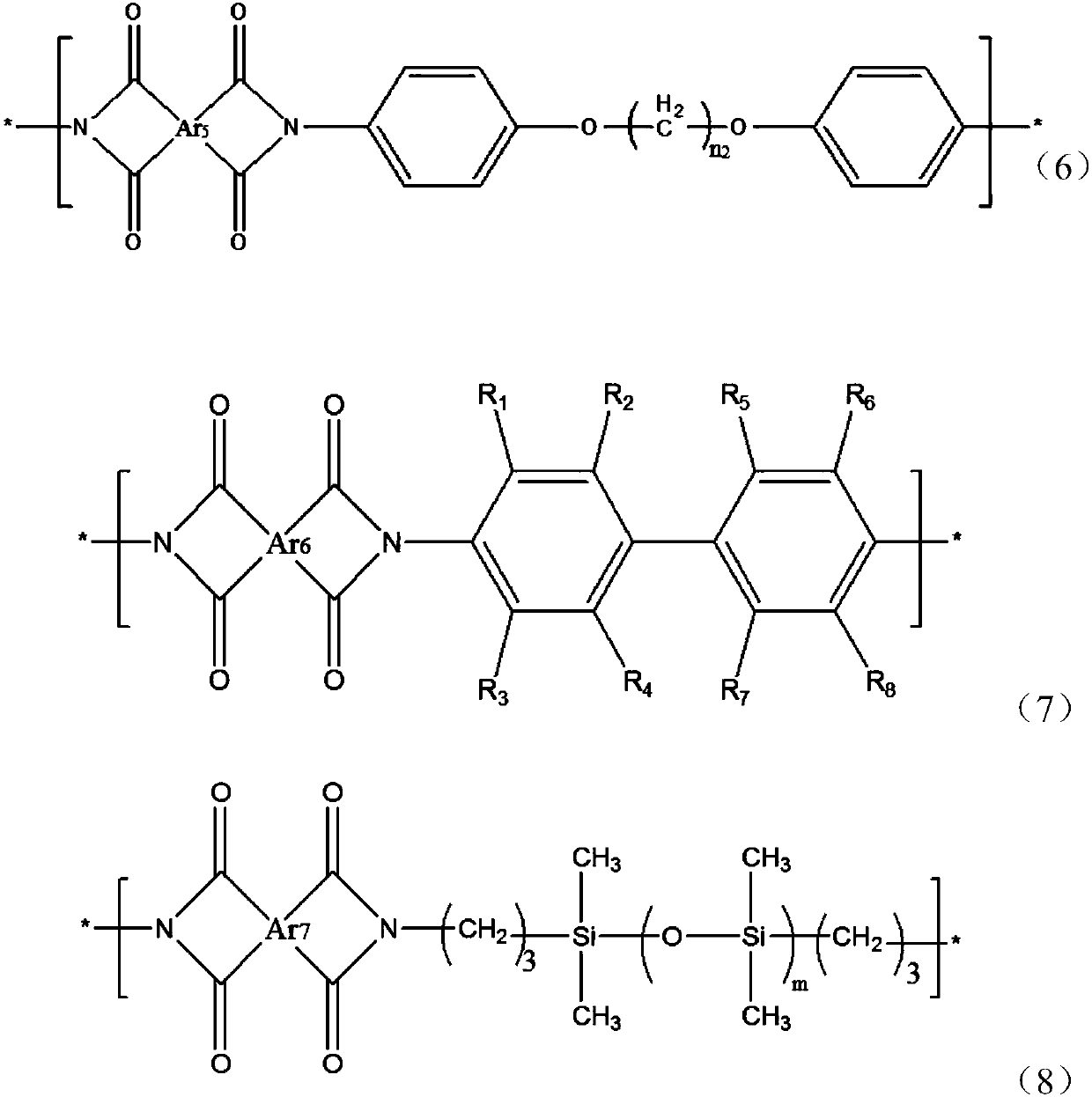

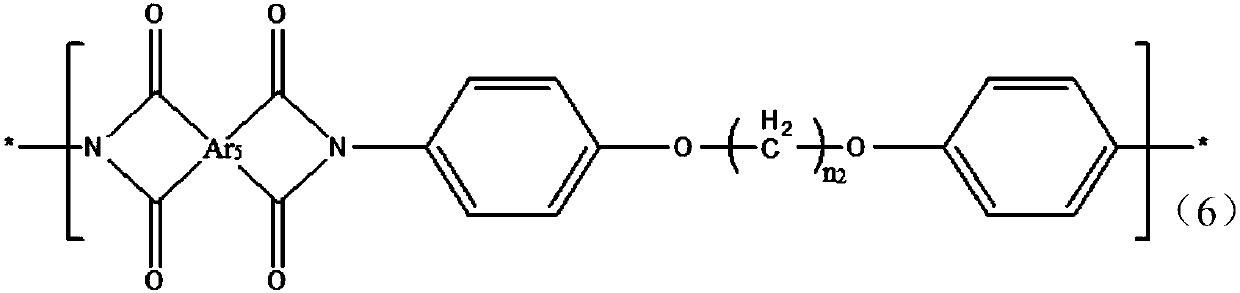

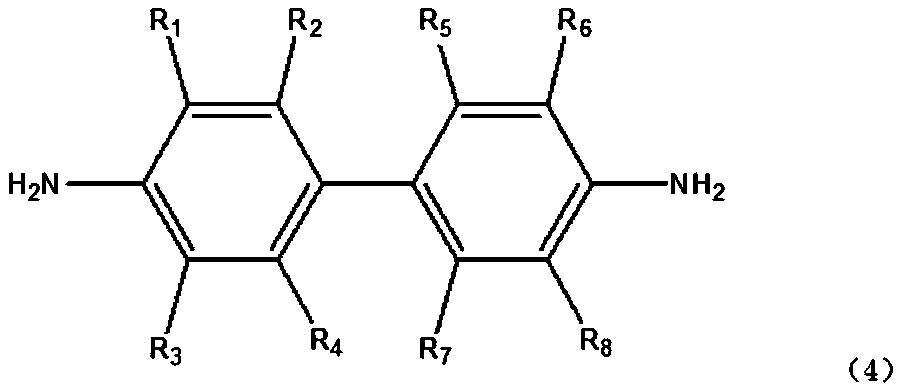

Polyimide film with ultralow dielectric loss

ActiveCN109648970AExcellent dielectric lossImprove bondingSynthetic resin layered productsCopper foilDielectric loss factor

The invention provides a polyimide film with ultralow dielectric loss and a preparation method thereof, the polyimide film is capable of being directly adhered to a copper foil, the polyimide film comprises a core layer and a surface layer, or the polyimide film comprises two surface layers and a core layer which is sandwiched between the two surface layers, the dielectric loss factor of the polyimide film at 10GHz test frequency is 0.0030-0.0060, and the dielectric constant is less than 3.0.

Owner:RAYITEK HI TECH FILM CO LTD

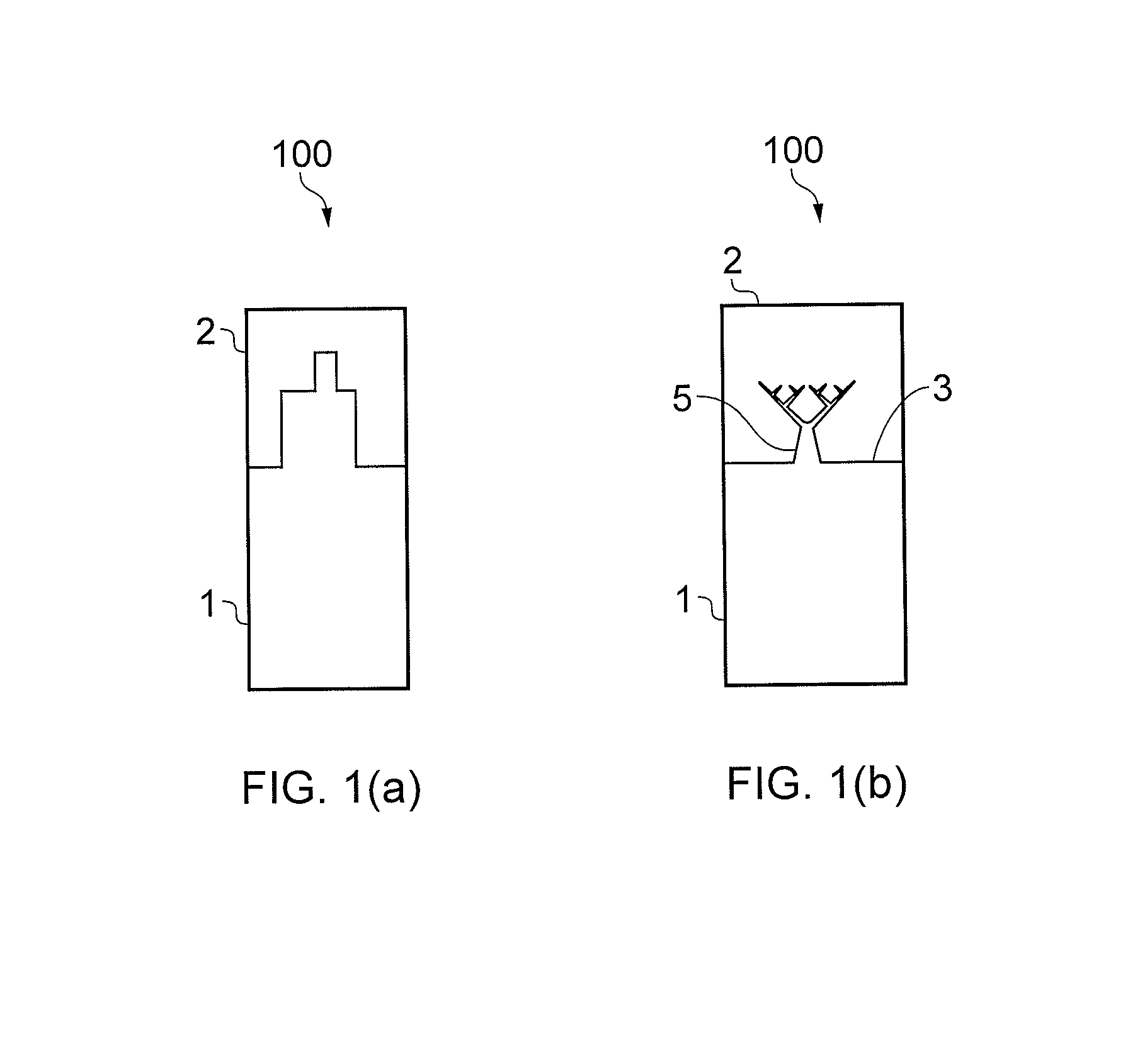

Joint structure and method

ActiveUS20140161520A1Improve bondingIncreased operating lifeTurbinesAdditive manufacturing apparatusMetal substrateMaterials science

The invention relates to a joint including a substrate, optionally a metal substrate, and a body of material joined to the substrate, the body of material typically having a composite portion. An outer surface of the substrate is provided with a fastening projection for fastening the substrate to body of material, wherein the fastening projection has a stem and a plurality of branches having dendritic geometry projecting into the material of the body.

Owner:ROLLS ROYCE PLC

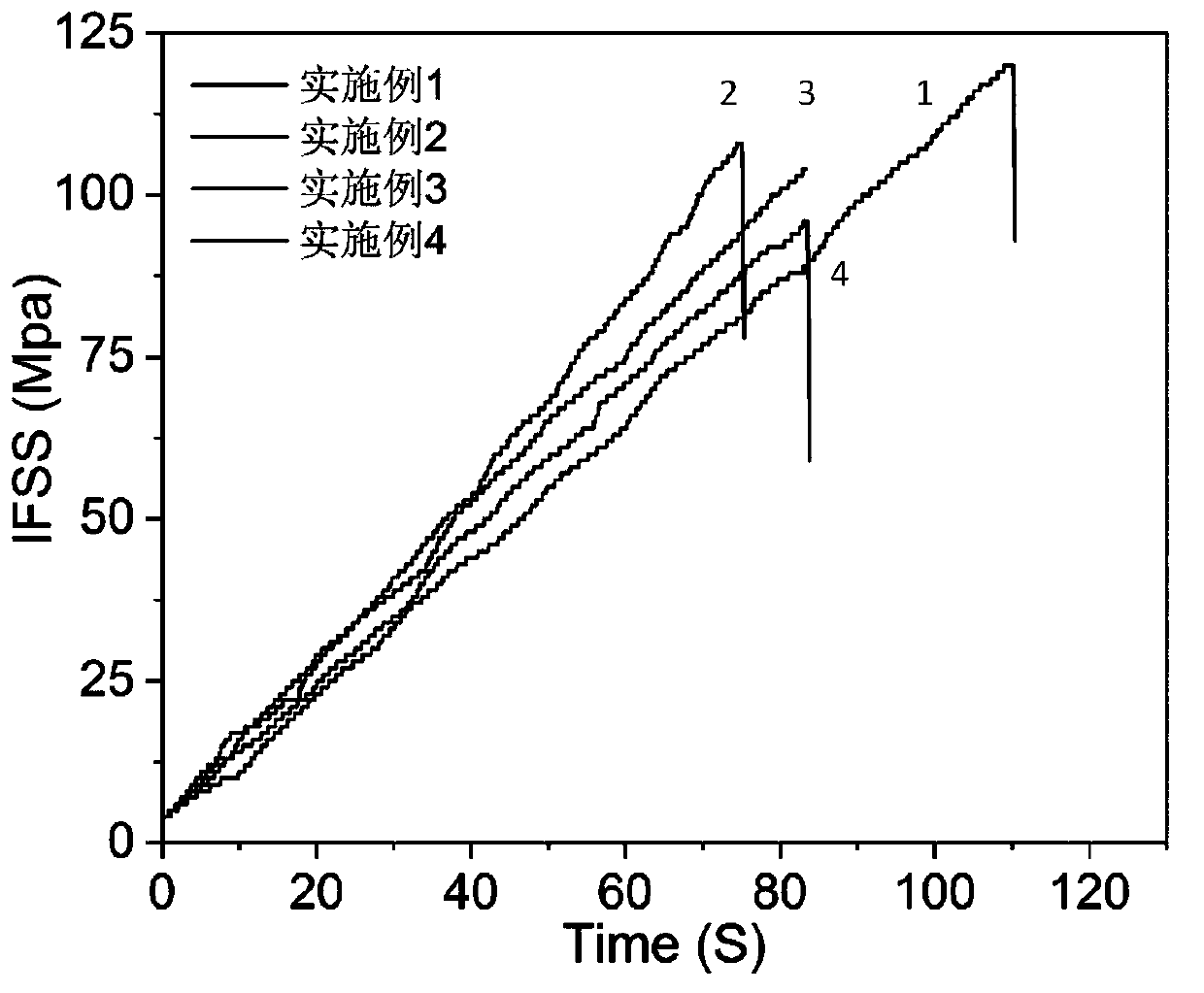

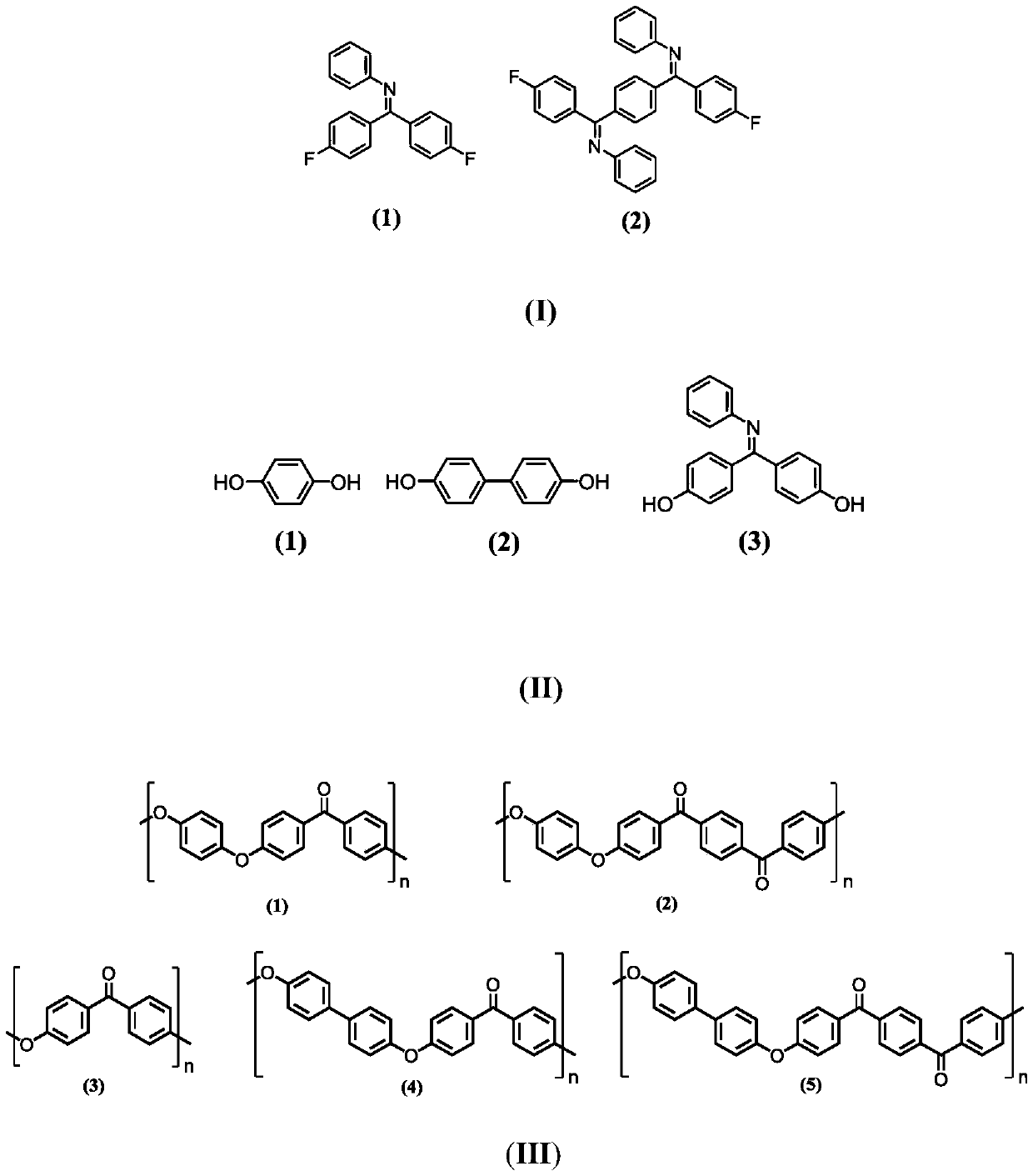

Carbon fiber modified with crystalized crosslinkable polyaryletherketone sizing agent and preparation method of carbon fiber

ActiveCN110820315ASimple structureImprove bondingPhysical treatmentCarbon fibresPolymer scienceCarbon fibers

The invention discloses a carbon fiber modified with a crystalized crosslinkable polyaryletherketone sizing agent and a preparation method of the carbon fiber and belongs to technical field of carbonfiber surface treatment. The preparation method includes subjecting double-fluorine monomer containing aniline side groups and bisphenol monomers to polymerization, or modifying crystalized polyaryletherketone, so as to obtain soluble amorphous polyaryletherketone polymer, and blocking thermotropic crosslinking groups to two terminals of the polymer; meanwhile, subjecting the carbon fiber to surface electrochemical reduction, and grafting the crosslinking groups which are the same as the mentioned to the surface of the carbon fiber; further, drafting the carbon fiber which is subjected to thesurface electrochemical reduction to pass through a sizing agent solution to size the carbon fiber, and performing acidification to recover the crystallinity of the polyaryletherketone sizing agent; finally, finishing the carbon fiber. The carbon fiber can be used for preparing a composite material, the composite material is subjected to high-heat treatment, so that the crosslinking reaction is initiated, the crystallinity of the polyaryletherketone polymer is improved, the sizing agent is allowed to have a crystalline texture and can form a chemical bonding with the surface of the carbon fiber, and further, the interference shear strength is improved, and the composite material has high temperature resistance and corrosion resistance performance.

Owner:JILIN UNIV

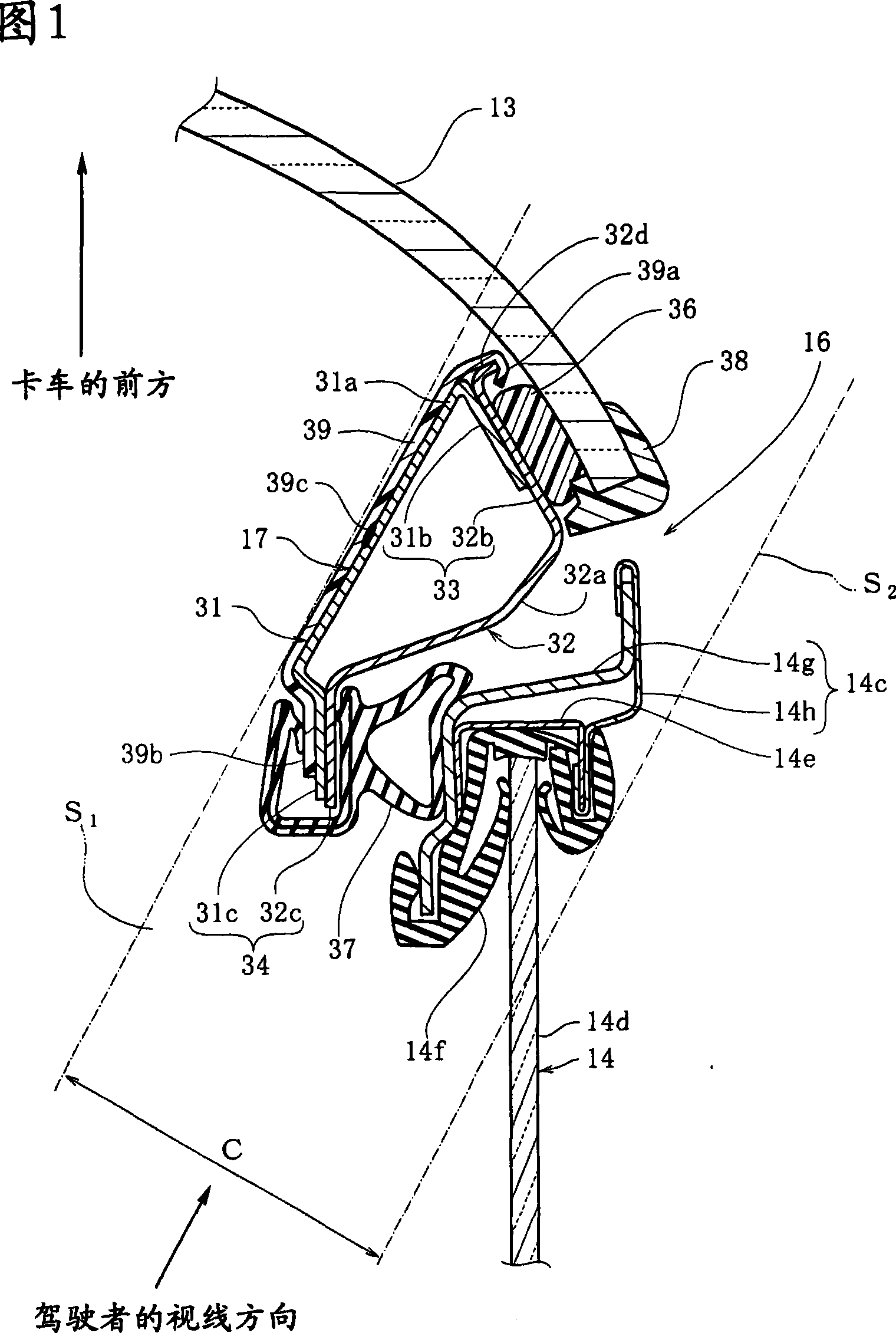

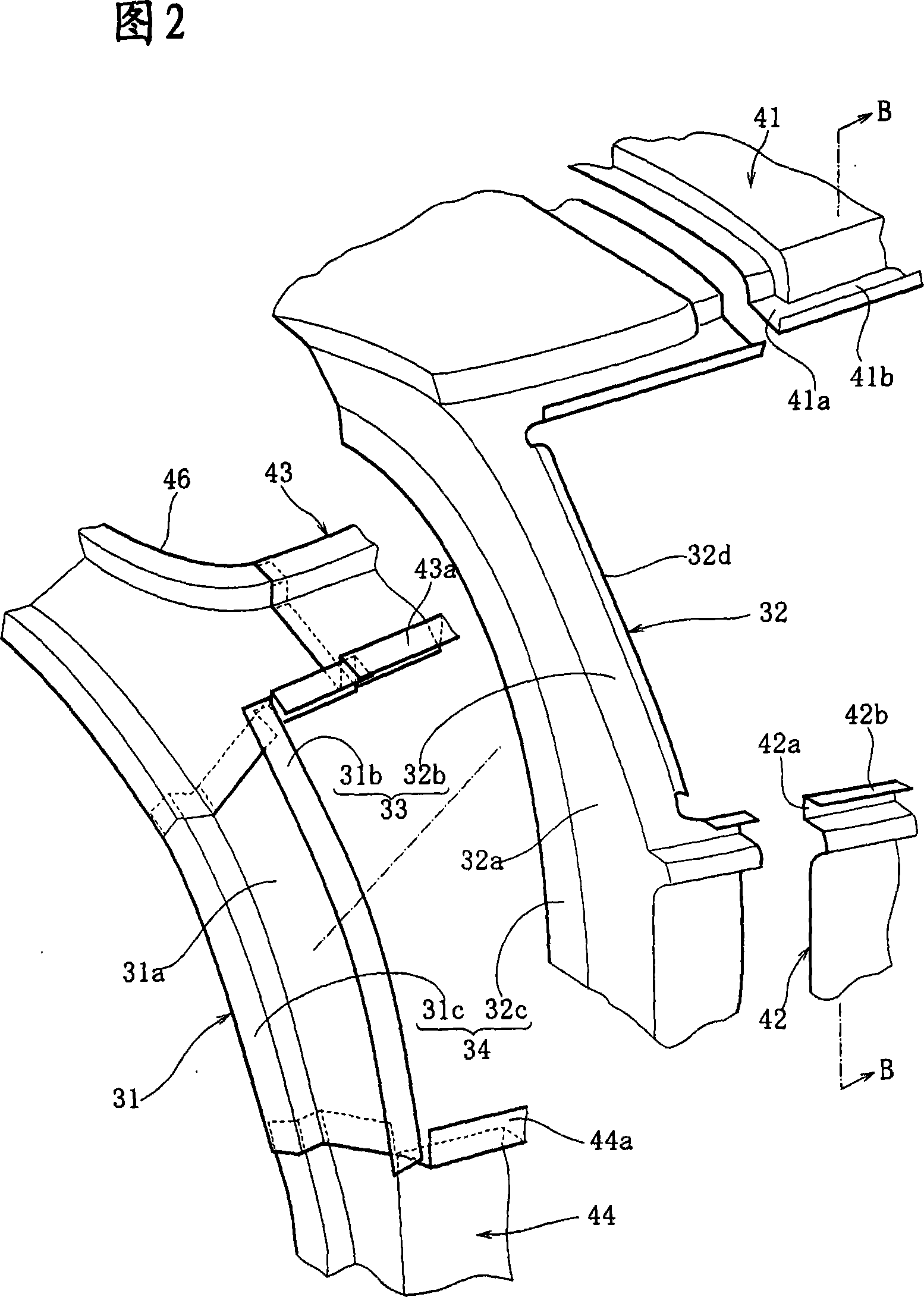

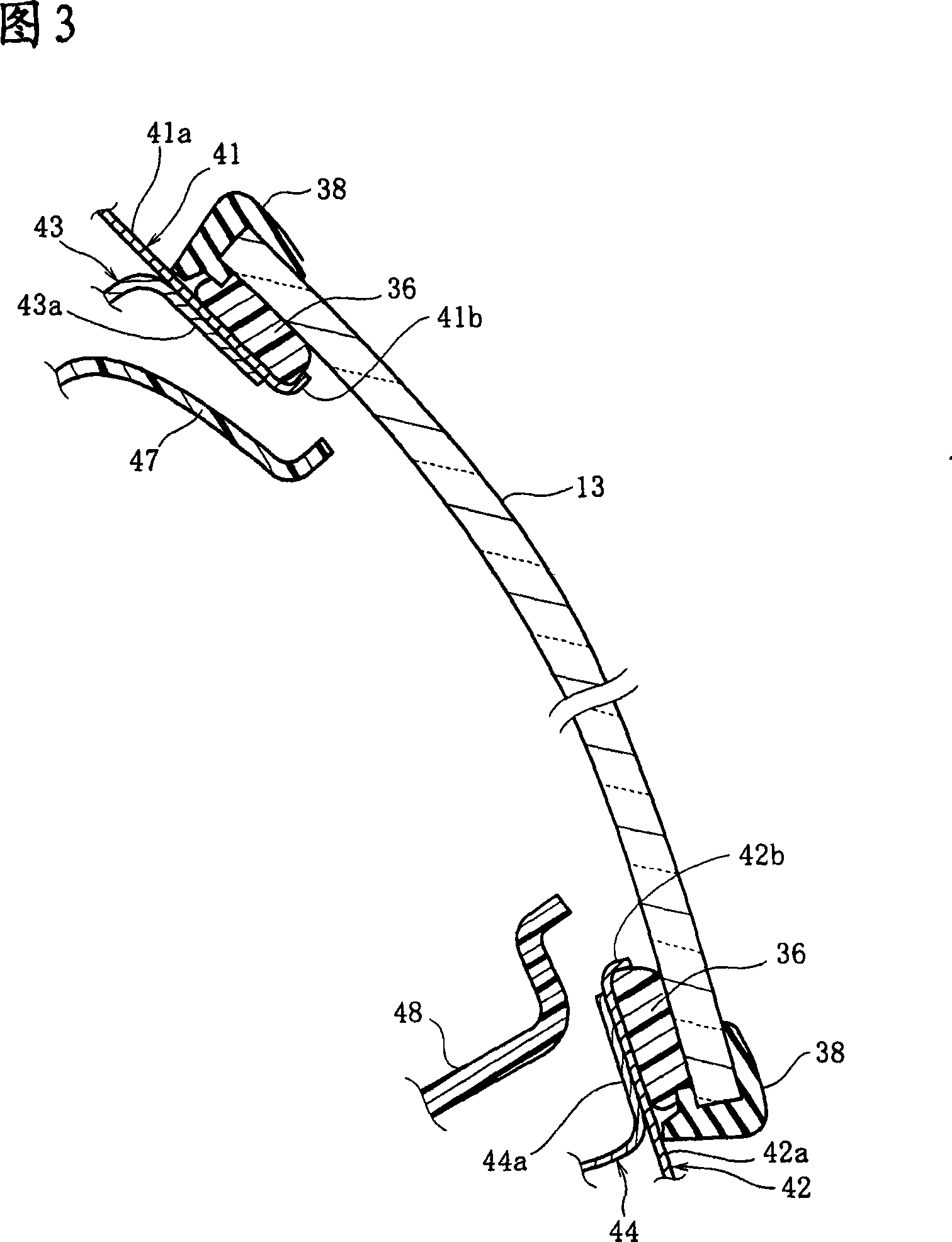

Front structure for vehicle

A front pillar (17) of a front corner member (16) provided between a side edge of a windshield (13) and a front edge of a side glass (14d) is formed in a tubular shape by joining a pillar inner panel (31) and a pillar outer panel (32). A front overlapping part (33) of the front pillar is formed by joining a pillar outer surface of a first front flange (31b) of the pillar inner panel and a pillar inner surface of a second front flange (32b) of the pillar outer panel. A rear overlapping part (34) is formed by joining a pillar inner surface of a first rear flange (31c) of the pillar inner panel and a pillar inner surface of a second rear flange (32c) of the pillar outer panel. A side edge inner surface of the windshield is fixed to the pillar outer surface of the front overlapping part. The width, as seen from a driver, of the front pillar is narrowed while its rigidity is kept, and thereby the width of a forward view field is enlarged and visibility on the far side of the front corner member is improved.

Owner:HINO MOTORS LTD

Tear-free self-adhesive rubber waterstop belt and preparation method thereof

ActiveCN104789148AWith self-adhesive functionEasy to processMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolymer scienceAdhesive

The invention belongs to the technical field water-proof materials of buildings and particularly discloses a tear-free self-adhesive rubber waterstop belt and a preparation method of the tear-free self-adhesive rubber waterstop belt. The invention adopts the major technical scheme that the rubber waterstop belt comprises a rubber base material, as well as a high polymer self-adhesive layer and an isolation layer that are pasted on one side face of the base material. The rubber base material is prepared from natural rubber, ZnO, stearic acid, an antiager, a reinforcing agent, operating oil, functional filling and a valcanizer via an extrusion technology, the high polymer self-adhesive layer is formed by melting SBS (styrene-butadiene-styrene) or / and SIS (styrene isoprene styrene) resin softening oil, an antiager, an reinforcing agent, operating oil, functional filling and an antioxidant via a stirrer, and the isolation layer is formed by stirring and mixing natural zeolite, metakaolin, wollastonite and stearic acid, and then the prepared high polymer self-adhesive layer and the isolation layer are applied on the rubber base material for calendering to form the belt. The waterstop belt has the self-adhesive layer which is securely connected with a concrete boundary layer, greatly improves adhesion between the rubber waterstop belt and concrete, and effectively solves the problems of water leakage and dampening of an expansion joint, a deformation joint and a construction joint.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

Method for preparing high-strength corrugated paper from recycled waste paper

InactiveCN107869087AHigh in fiberLow costMechanical working/deformationPulping with acid salts/anhydridesCelluloseCarboxymethyl cellulose

The invention discloses a method for preparing high-strength corrugated paper from recycled waste paper. The method sequentially includes the following steps of S1, pulping the recycled waste paper through a hydrapulper and then removing impurities; S2, conducting screening through a pressure screen and then adding phosphoric acid to be evenly stirred; S3, making pulp in the step S2 enter a pulp flowing box and adding carboxymethyl cellulose and retention aid; S4, conveying the pulp obtained in the step S3 to a paper machine to manufacture paper with pulp to obtain corrugated crude paper. In the waste paper pulping process, phosphoric acid is added first, then carboxymethyl cellulose is added, the viscosity of cellulose in the pulp is improved, the content of cellulose is improved, the retention aid is added in the pulping process, no other processing aids such as a dispersing agent, a flocculating agent, a surface sizing agent and a defoaming agent need to be added any more, the product is good in strength and high in quality, the processing technology is simple, added aids are few, and cost is lower.

Owner:GUANGDONG SONGYANG RECYCLE RESOURCES

Silicon amorphous refractory hot patching material

The invention relates to a silicon amorphous refractory hot patching material. The silicon amorphous refractory hot patching material is prepared by mixing fused quartz particles with silica sol liquid, wherein the fused quartz particles contains the following components in percentage by weight: 4%-6% of fused quartz sand with a particle size of 0.2mm-0.3mm, 18%-22% of fused quartz powder with theparticle size of 0.065mm-0.075mm and 72%-78% of fused quartz powder with the particle size of 0.035mm-0.04mm. Damaged parts with all kinds of shapes and specification of a kiln and fused parts in allsizes can be patched by virtue of the silicon amorphous refractory hot patching material from, and the damaged parts and the fused parts are firm and compact after being patched.

Owner:武汉重远炉窑工程技术服务有限公司

Cotton cloth embroidery anti-deformation processing technology

InactiveCN105040300AComplete embroideryNot offlineEmbroidering machines apparatusCotton clothHot melt

The invention relates to a cotton cloth embroidery anti-deformation processing technology. the technology comprises the following steps: (1) subjecting cotton cloth to a preshrinking treatment; (2) fixedly arranged a layer of hot melt glue on the backside of the processed cotton cloth; (3) artificially embroidering required patterns on the front side of the cotton cloth, knotting the thread residues, and after embroidery, removing the hot melt glue that face the blank area on the front side of the cotton cloth; (4) pressing and heating the residual hot melt glue, drying in the air, and cooling. In the provided technology, the patterns and hot melt glue are adhered together, the adhesion is quickly, the operation is simple, the completeness of embroidery on the cotton cloth can be guaranteed, moreover, the phenomenon of loose thread is avoided, after washing, the cotton cloth does not shrink or deform, the cotton cloth cannot be wrinkled easily, the overall cotton cloth is flat, and the technology has a good application prospect therefore.

Owner:苏州尊赢会展服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com