Glutinous rice flour environment-friendly water-based paint

A technology for water-based paint and glutinous rice flour, applied in coating and other directions, can solve the problems of glutinous rice slurry production, storage, storage difficulties, environmental pollution, and poor control of glutinous rice slurry use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First, add quicklime into water and stir for 30 minutes. After clarification, take the upper solution as lime slurry clear liquid for later use.

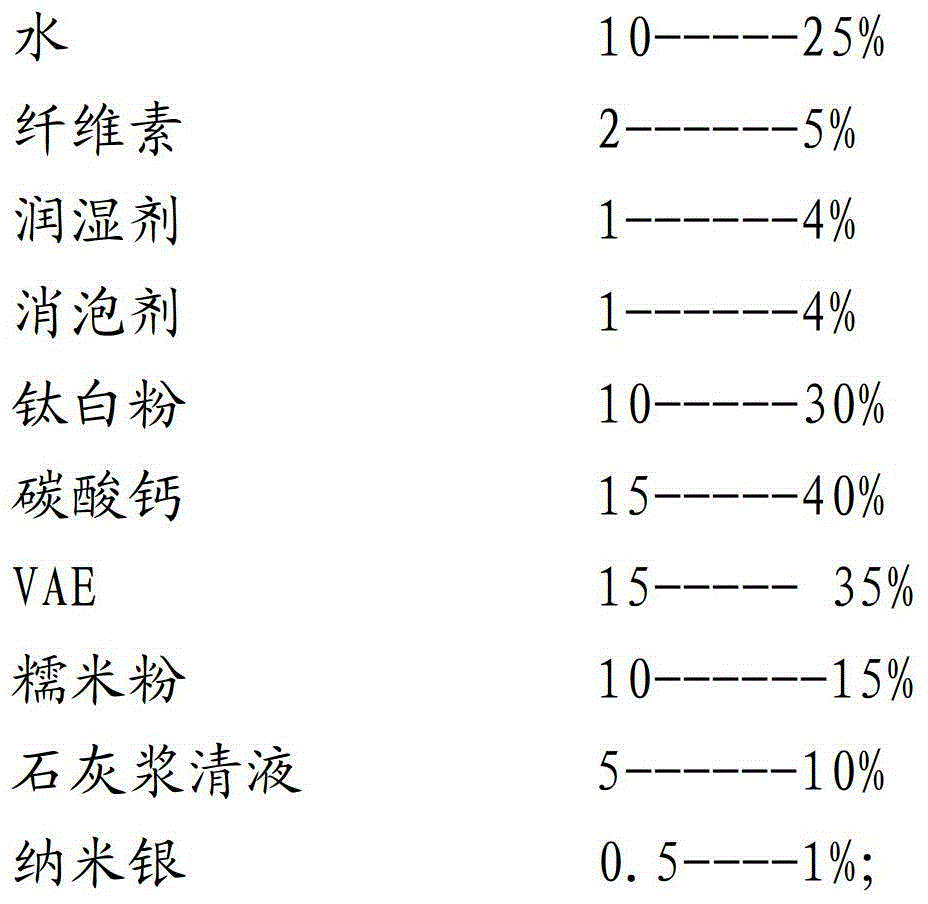

[0022] According to the following formula (according to the number of parts by mass), the following steps:

[0023]

[0024]

[0025] ① Add hydroxypropyl methylcellulose to water and stir for 30 minutes;

[0026] ② Add polycarboxylate sodium salt dispersant and silicone defoamer in sequence and stir for 30 minutes;

[0027] ③Add titanium dioxide and superfine calcium carbonate to disperse strongly for 30 minutes;

[0028] ④Add polyvinyl acetate-ethylene emulsion and glutinous rice flour and stir for 20 minutes;

[0029] ⑤ Add lime slurry and stir for 20 minutes;

[0030] ⑥Add nano-silver and stir for 20 minutes;

[0031] 7. become the finished coating of the present invention after filtering, pack.

[0032] The hydroxypropyl methylcellulose, referred to as UPMC, is produced in the United States, and the manufacture...

Embodiment 2

[0039] First, add quicklime into water and stir for 30 minutes. After clarification, take the upper solution as lime slurry clear liquid for later use.

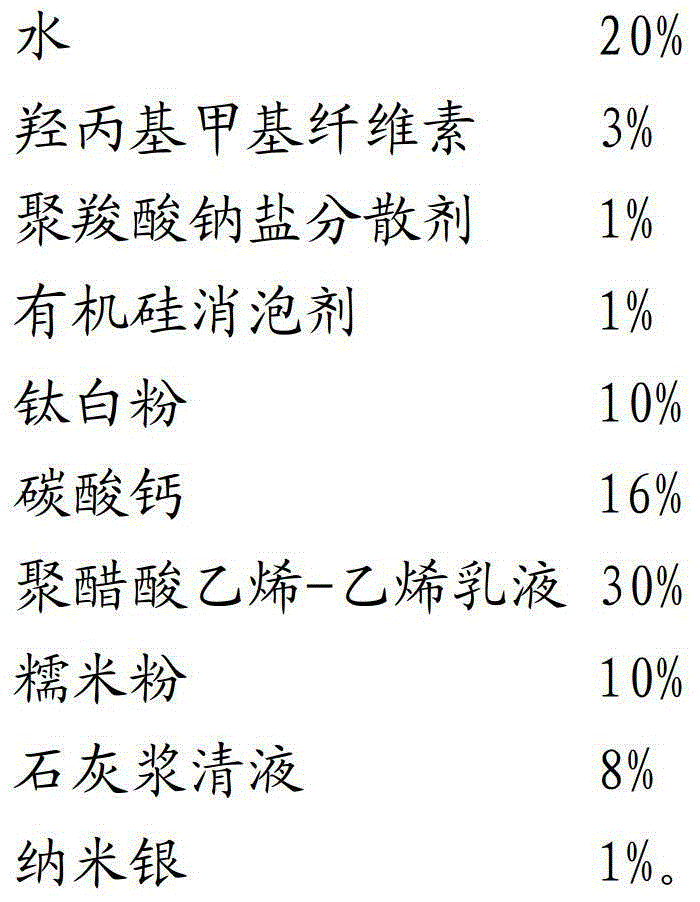

[0040] According to the following formula (according to the number of parts by mass), the following steps:

[0041]

[0042]

[0043] Adopt this formula, produce 10 batches of coatings according to the production method of embodiment one, its main technical index is all in the scope of following table:

[0044] pH value

Embodiment 3

[0046] First, add quicklime into water and stir for 30 minutes. After clarification, take the upper solution as lime slurry clear liquid for later use.

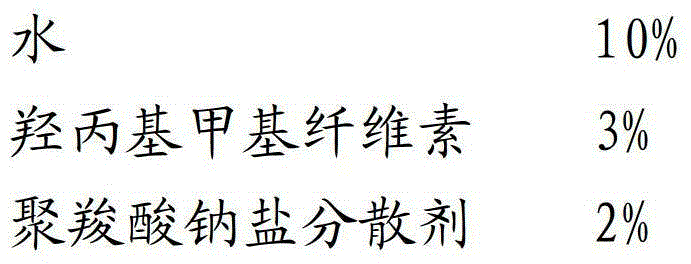

[0047] According to the following formula (according to the number of parts by mass), the following steps:

[0048]

[0049] Adopt this formula, produce 10 batches of coatings according to the production method of embodiment one, its main technical index is all in the scope of following table:

[0050] pH value

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com