Water soluble mandrel moulding method of dipulse engine shell

The invention relates to a technology of an engine casing and a forming method, which is applied in the field of water-soluble core mold forming of a double-pulse engine casing, and can solve the problems of complex manufacturing technology of the core mould of the engine casing, damage to the metal part of the engine casing, long production cycle, and the like. Achieve the effect of low cost, short production cycle and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

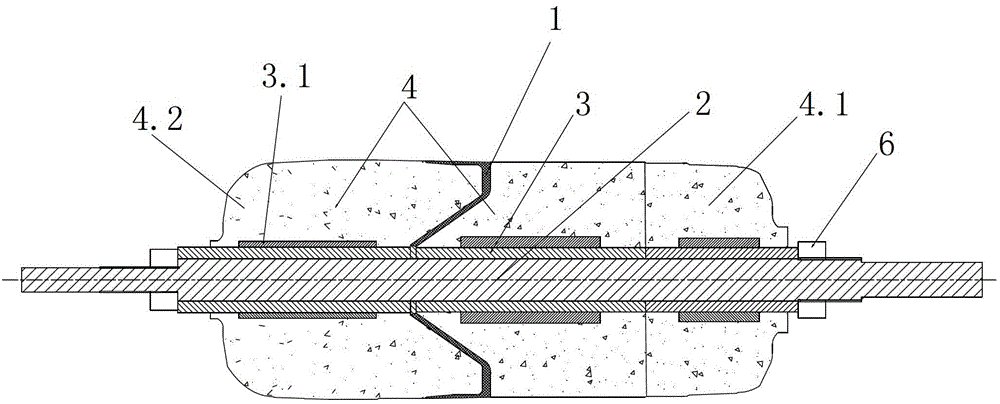

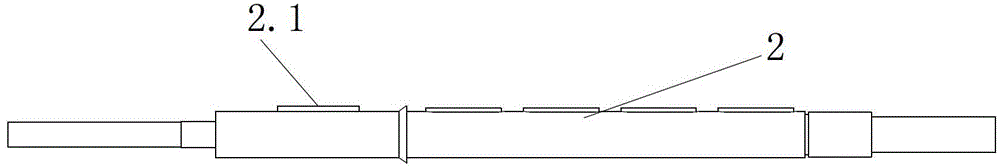

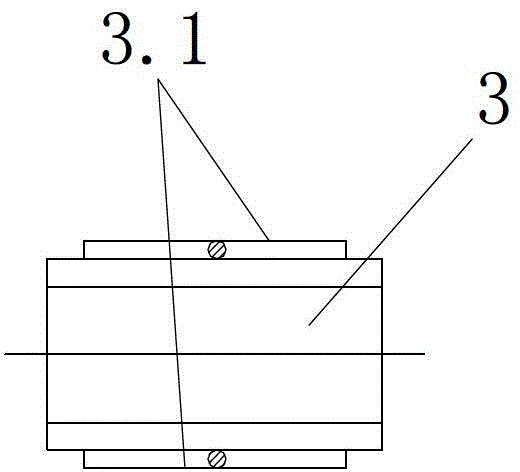

[0024] see Figure 1 to Figure 5 , the water-soluble mandrel of the dual-pulse engine casing involved in the method of the present invention includes a partition plate 1, a mandrel 2, a shaft sleeve 3, a sand sleeve 4 and a lock nut 6.

[0025] The mandrel 2, the shaft sleeve 3 and the sand sleeve 4 are coaxially matched from the inside to the outside, and the sand sleeve 4 is divided into two parts, respectively corresponding to the first pulse zone (not shown in the figure) and the second pulse zone of the engine. The first pulse zone sand jacket 4.1 and the second pulse zone sand jacket 4.2 in the zone (not shown in the figure), the partition 1 is arranged between the first pulse zone sand jacket 4.1 and the second pulse zone sand jacket 4.2. Since the sand sleeve 4.1 in the first pulse area is relatively long, it is divided into two parts in the present embodiment, so that the sand sleeve 4 is divided into three sections on the whole, and the axle sleeve 3 is also divided ...

Embodiment 2

[0037] The present embodiment is basically the same as Example 1, the difference being: B, preparation of quartz sand mixed adhesive, said quartz sand mixed adhesive comprises the following components and parts by weight: 400 grams of quartz sand, 9.5 grams of polyvinyl alcohol, 0.5 grams of starch grams, 40 grams of water; when preparing the quartz sand mixed adhesive, first mix polyvinyl alcohol and starch to form a mixed powder, then mix the mixed powder with 60°C water and stir until a non-sticky solution is formed, and finally the particle size is 140 mesh quartz sand Stir to combine with the non-sticky solution.

Embodiment 3

[0039] The present embodiment is basically the same as Example 1, except that: B, prepare the quartz sand mixed adhesive, which includes the following components and parts by weight: 450 grams of quartz sand, 10 grams of polyvinyl alcohol, 0.6 grams of starch 50 grams of water; when preparing the quartz sand mixed adhesive, first mix polyvinyl alcohol and starch to form a mixed powder, then mix the mixed powder with 80°C water and stir until a non-sticky solution is formed, and finally the particle size is 180 mesh quartz sand Stir to combine with the non-sticky solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com