Internal-division-type fender injection mold and injection molding method of fender

A technology for injection molds and fenders, which is applied in the field of injection molds and can solve problems such as deformation, R corner strain, and damage to the integrity of the fillet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

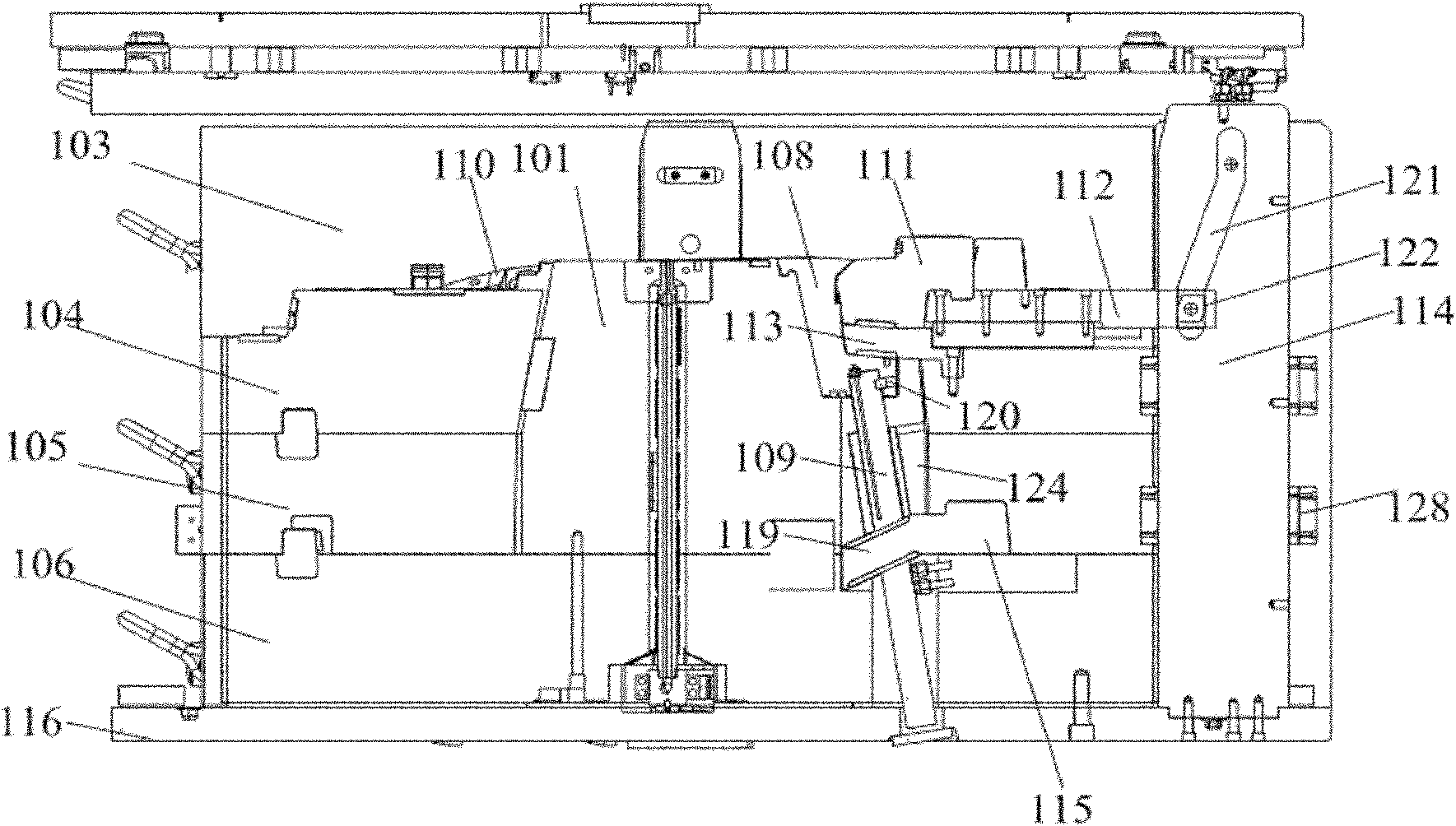

[0029] An embodiment of the present invention provides an injection mold for an inner split fender, which will be described in detail below with reference to the accompanying drawings.

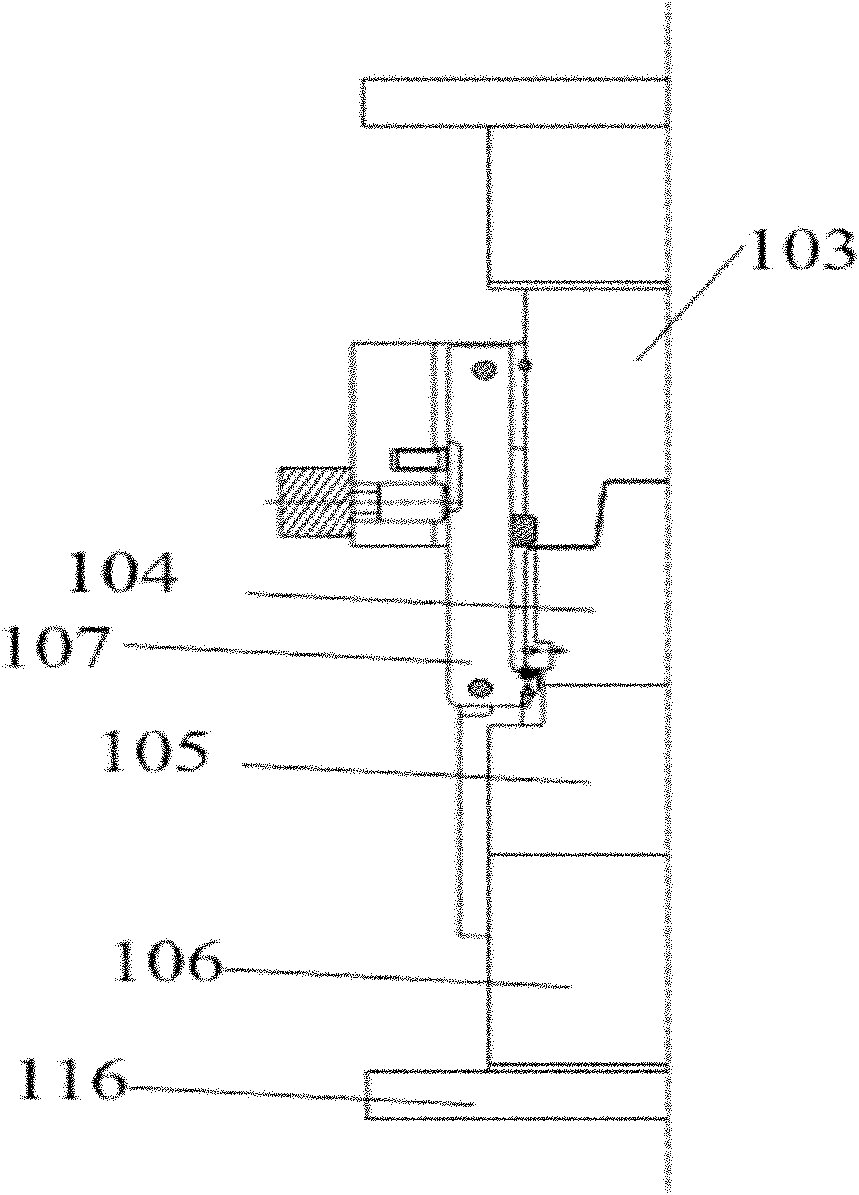

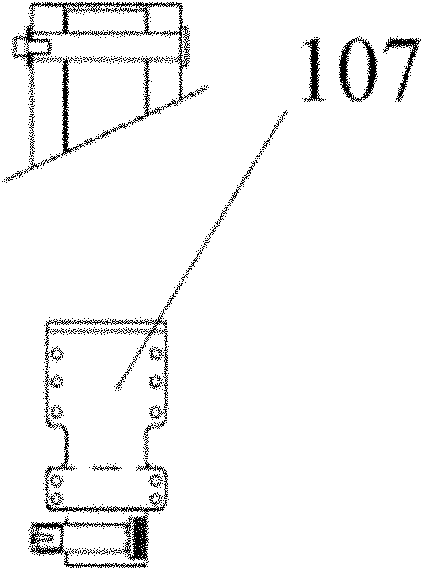

[0030] see figure 1 and figure 2 , A-A cross-sectional schematic diagram and B-B cross-sectional schematic diagram of the internal split injection mold of the embodiment of the present invention, the inner split fender injection mold includes a bottom plate 116, a main body punch core 101, a die cavity 102, a movable mold seat plate 103, a fixed Die seat plate 104, push plate 105, fixed die seat plate main body support plate 106, heavy-duty hook 107 and ejection mechanism, main body punch core 101 is installed on the fixed die seat plate main body support plate 106, fixed die seat plate 104 and push The plate 105 is set on the main body punch core 101, the fixed mold seat plate 104 and the push plate 105 are fixed together by a fixing device, the fixed device can be screws, bolts, etc., and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com