Oil pump gear shaft precision forging forming die and forming method

A technology for oil pump gears and forming dies, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. Reduced life, high production cost, long processing time and other problems, to achieve the effect of solving the difficulty of mold release, improving product performance and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

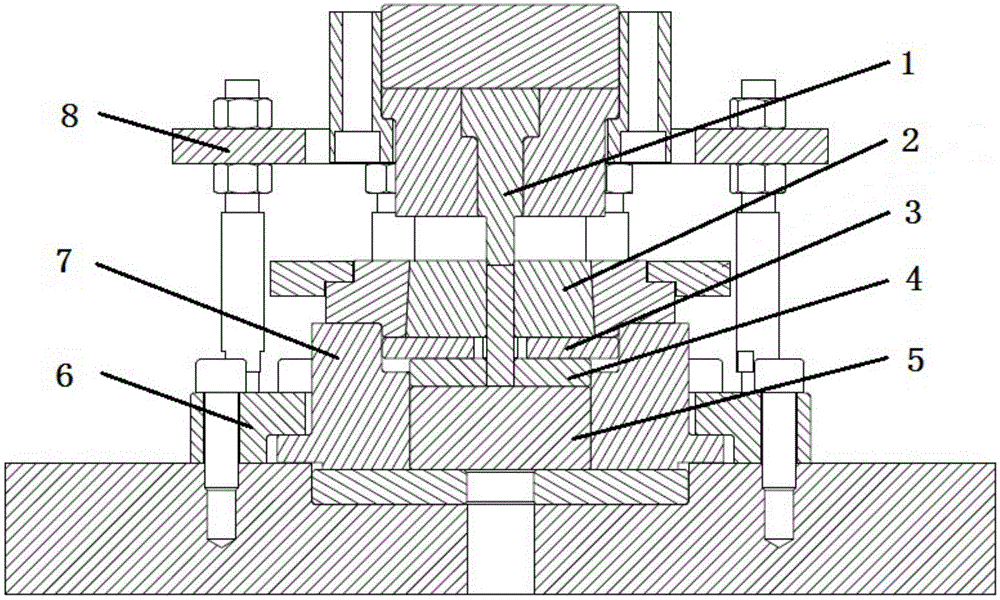

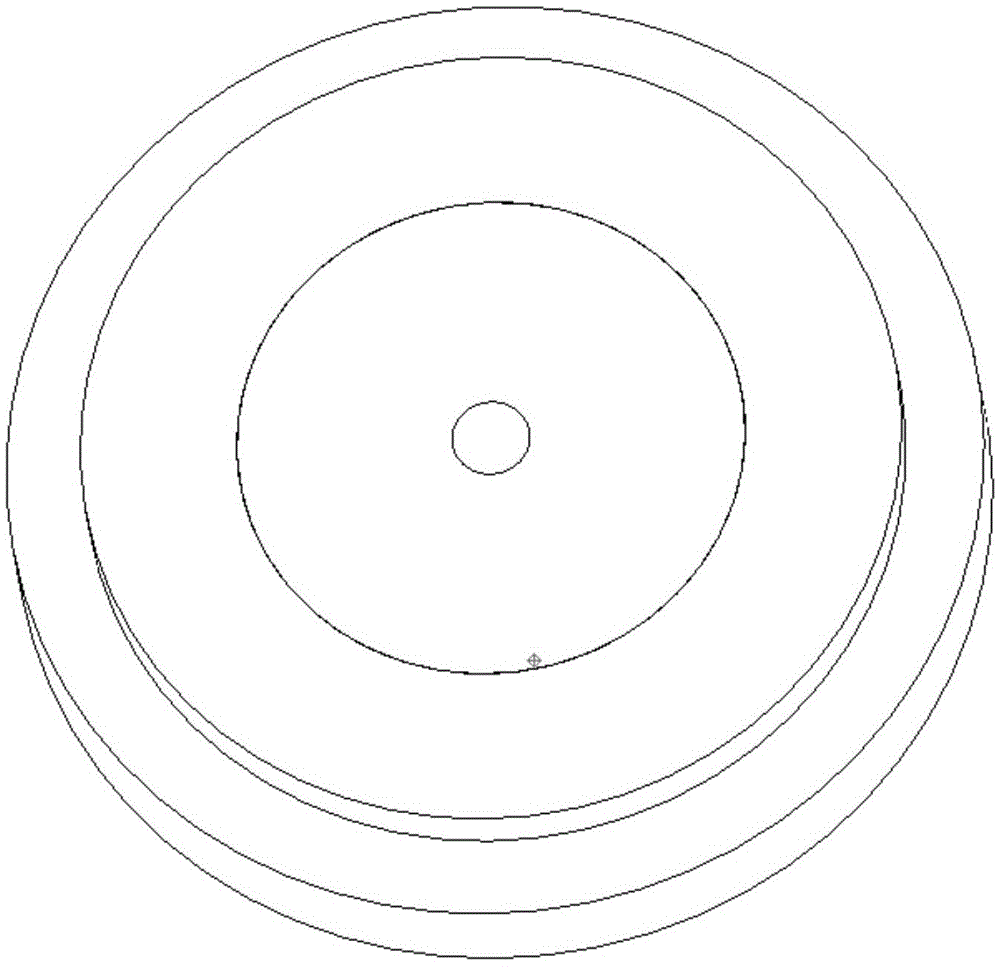

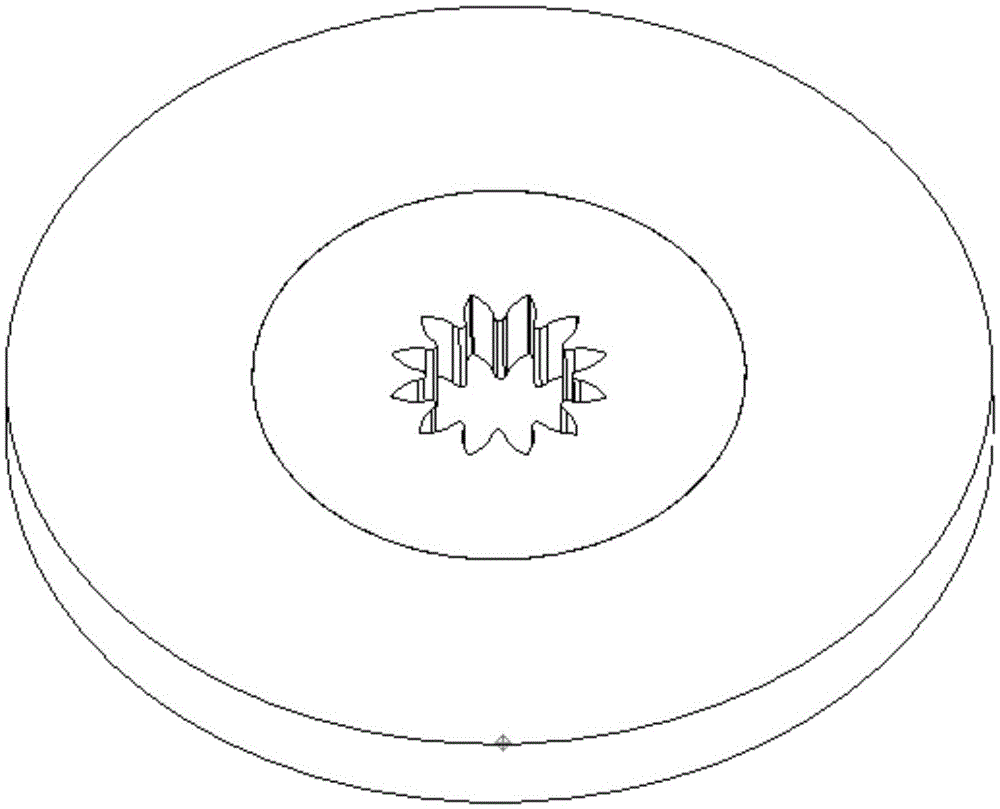

[0024] Such as Figure 6 As shown, the oil pump gear shaft forged by the example of the present invention includes a toothed part and a shaft part on both sides; The lower layer of the mold is assembled by the interference of the inner and outer rings; each part of the mold is pressed figure 1 The structural assembly shown: the upper mold 1 is installed under the upper slider of the press, the base 5, the lower layer of the lower mold 4, and the toothed mold 3 ( image 3 ), lower mold upper layer 2 ( figure 2 ) into the lower mold base 7 in turn, and fixed on the press frame by the lower mold outer ring 6; the demoulding ring 8 is fixed on the lower mold outer ring 6 by nuts.

[0025] In this example, the mold is installed on a 1000T double-disc friction press for precise forging of the oil pump gear shaft. The forging speed is about 200mm / s. Both the forging mold and the forging are coated with water-based graphite lubricant.

[0026] The precision forging of the oil pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com