Patents

Literature

892 results about "Gear oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gear oil is a lubricant made specifically for transmissions, transfer cases, and differentials in automobiles, trucks, and other machinery. It is of a high viscosity and usually contains organosulfur compounds. Some modern automatic transaxles (integrated transmission and differential) do not use a heavy oil at all but lubricate with the lower viscosity hydraulic fluid, which is available at pressure within the automatic transmission. Gear oils account for about 20% of the lubricant market.

Lubricating fluids with enhanced energy efficiency and durability

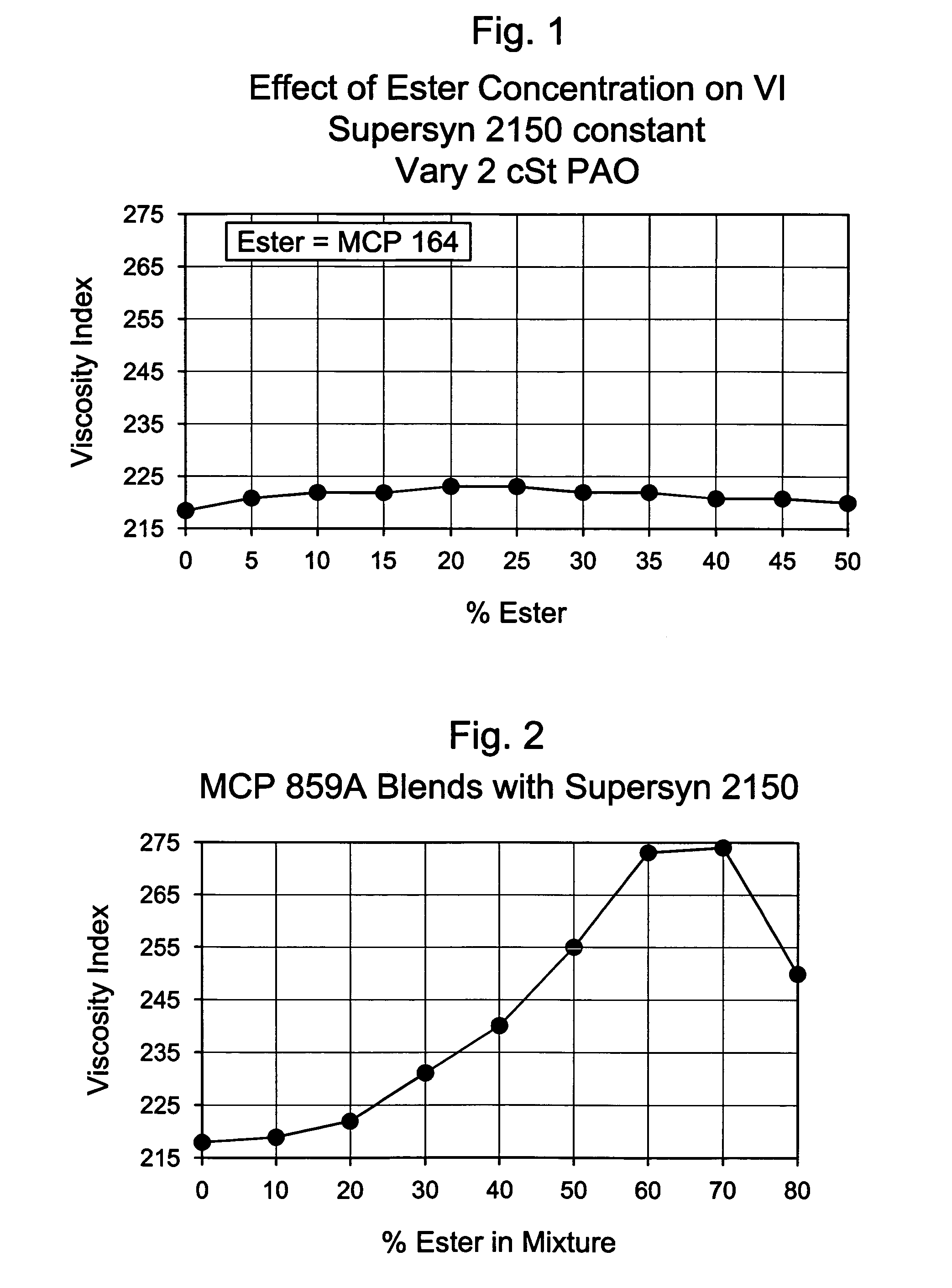

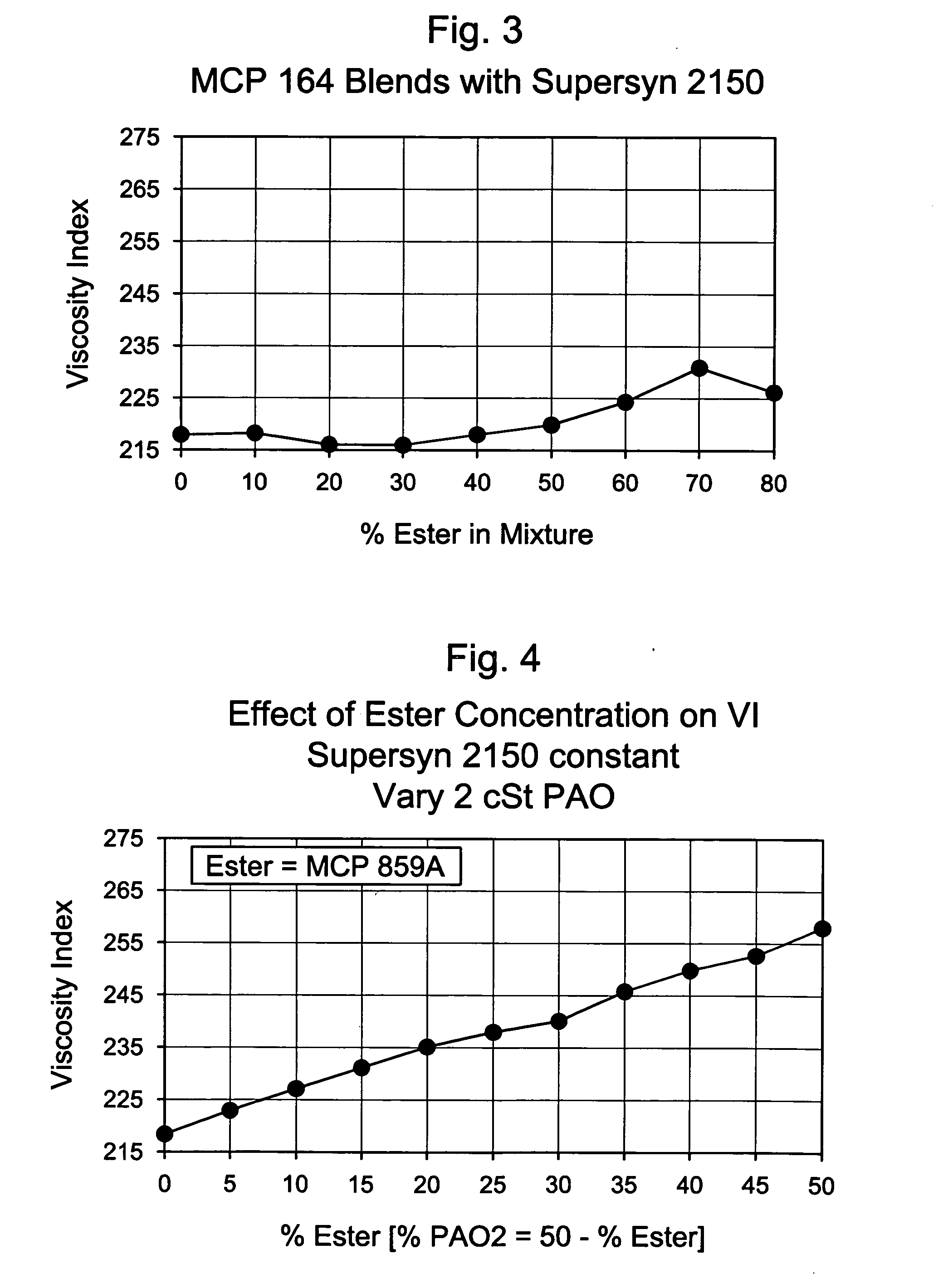

The present invention comprises novel lubricating compositions, automotive gear lubricating compositions, and fluids useful in the preparation of finished automotive gear lubricants and finished gear oils, and methods of preparation thereof. One embodiment of the present invention comprises a lubricating composition comprising a blend of a PAO having a viscosity of greater than or equal to about 40 cSt. at 100° C. and less than or equal to about 1,000 cSt. at 100° C. and an ester having a viscosity of less than or equal to about 2.0 cSt. at 100° C., wherein said blend of said PAO and said ester has a viscosity index greater than or equal to the viscosity index of the PAO.

Owner:EXXONMOBIL CHEM PAT INC

Biodegradable non-toxic gear oil

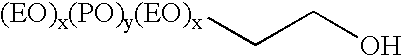

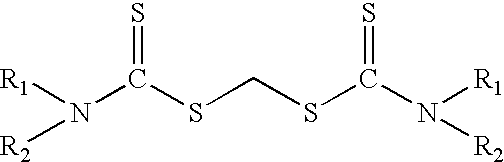

A biodegradable lubricating oil composition especially useful as a gear oil employs a synthetic alcohol ester basestock formed from mono- and dipentaerythritol with certain mono- and dicarboxylic acids or dicarboxylic acid anhydrides and an effective amount of a polyoxyalkylene alcohol demulsifying agent, a combination of alkylated organic acid and ashless succinimide rust inhibitors and an ashless dithiocarbamate antiwear and extreme pressure agent.

Owner:EXXON RES & ENG CO

Open-type gear grease composition

The invention provides an open gear grease composition, which comprises the following components and the weight percentage contents are that gelatinizer 2-6%, mineral oil 20-60%, synthetic oil 20-60%, antioxidant 0.3-1%, oil solubility anti-wear extreme pressure additive 1-15%, solid additive 3-20% and rust inhibitor 1-3%. The open gear grease composition of the invention does not contain dissolvent and bitumen, which has no harmless to environment, and solves the problems that bitumen-type open gear oil has bad pollution and low-temperature performance, and the flowability of open gear grease is bad. The open gear grease composition has outstanding water resistance, adhesiveness and antiwear and extreme pressure property.

Owner:益田润石(北京)化工有限公司

Extreme-pressure abrasion-resistant open gear oil

ActiveCN102690702ASolve the problem of clogged equipmentGood extreme pressure and anti-wear propertiesAdditivesFoaming agentAdhesive

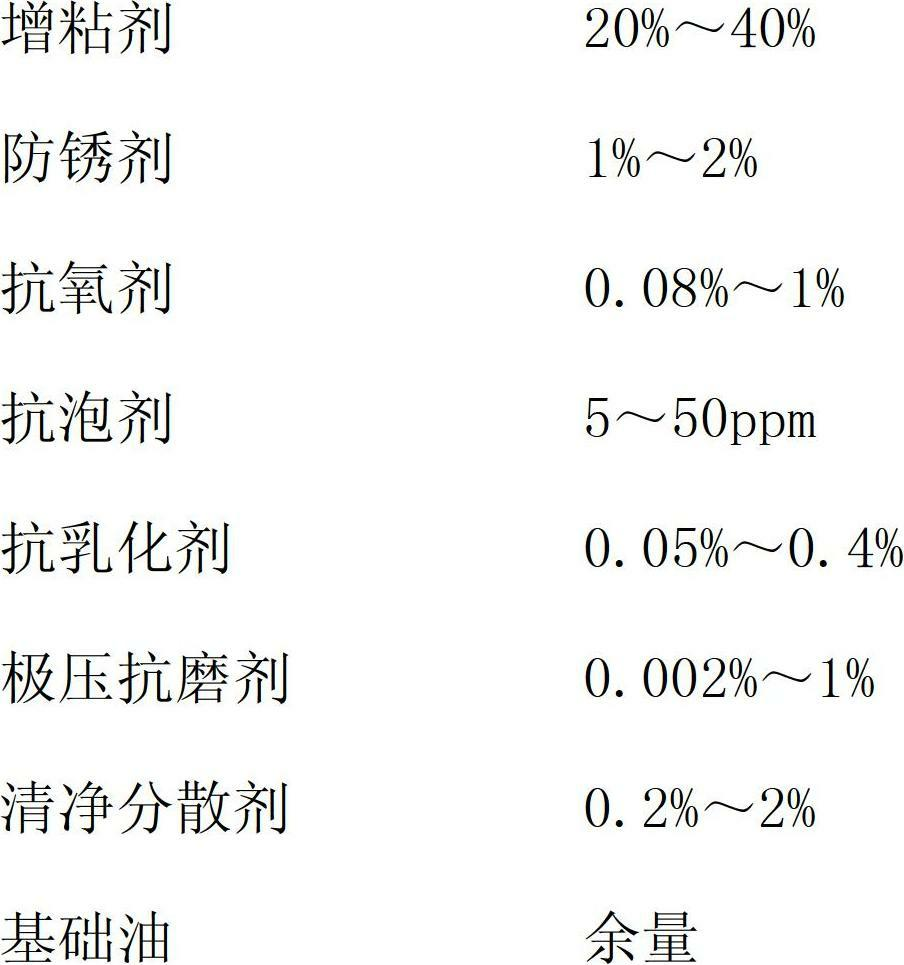

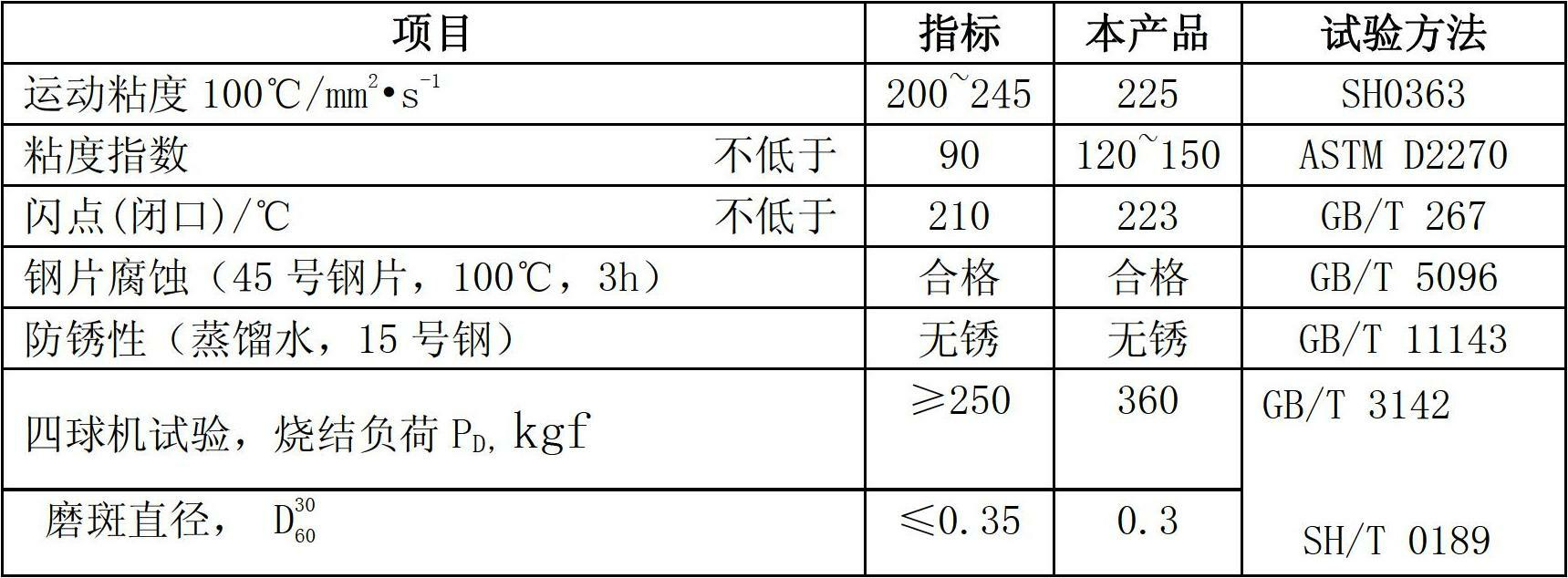

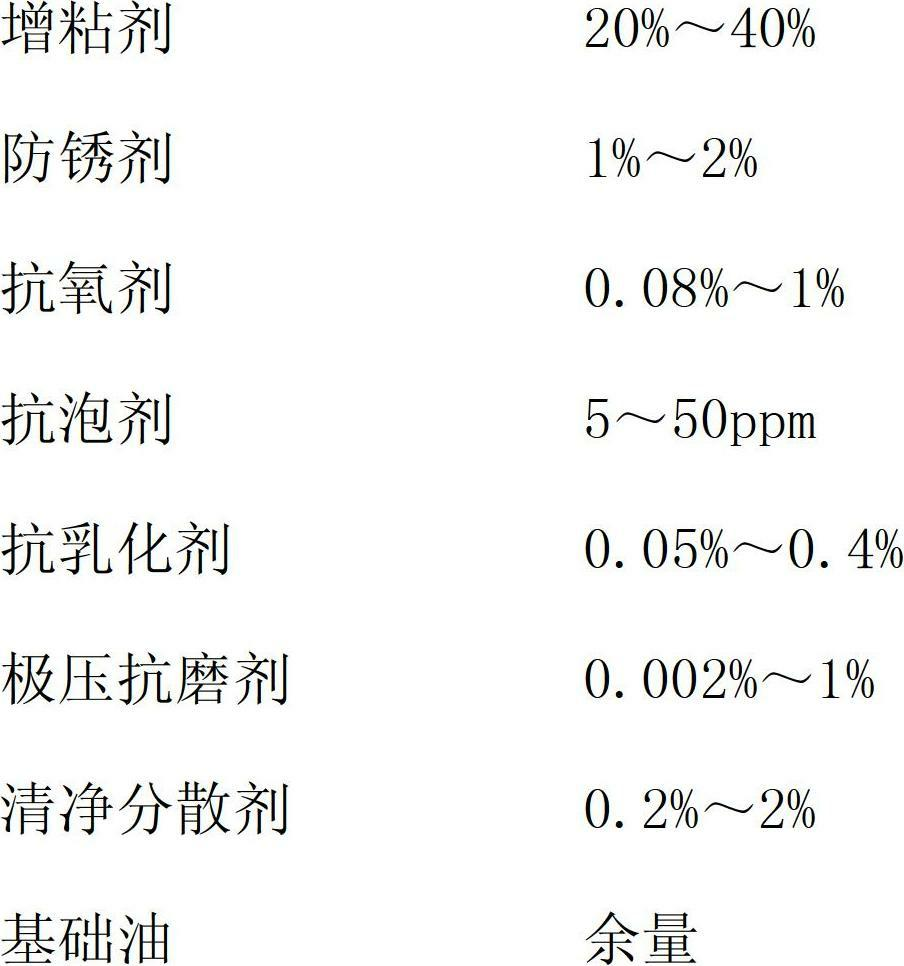

The invention discloses extreme-pressure abrasion-resistant open gear oil which is prepared from the following components by weight: 20-40% of tackifier, 1-2% of rust inhibitor, 0.08-1% of antioxygen, 5-50ppm of anti-foaming agent, 0.05-0.4% of demulsifying agent, 0.002-1% of extreme-pressure abrasion-resistant agent, 0.2-2% of purification dispersant and the balance being base oil, wherein the extreme-pressure abrasion-resistant agent refers to nanometer grapheme. By adding the nanometer grapheme to serve as the extreme-pressure abrasion-resistant agent, the extreme-pressure abrasion resistance of the gear oil is improved, an abrasion-resistant effect is remarkable and the abrasion loss can be reduced by 52%; by utilizing effective adhesive, clearing agent, antirust corrosion-resistant additive and the antioxygen, the adhesion, viscosity-temperature characteristic and antioxidant rust resistance of the oil are ensured; and by adding the dispersant, the problem of blockage caused by poor dispersibility of the nanometer grapheme which serves as a solid extreme-pressure agent is solved.

Owner:上海福岛新材料科技有限公司

Gear oil composition containing nanomaterial

ActiveUS7449432B2High indexImprove propertiesMaterial nanotechnologyAdditivesNanoparticleEngineering

Owner:VGP IPCO LLC

Combination of general gear oil

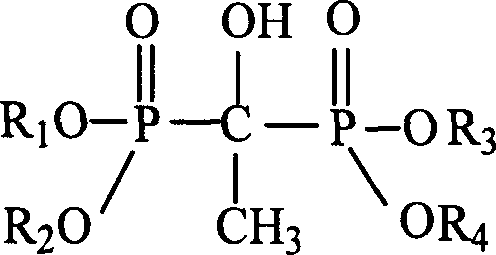

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Universal oil composition for environment-friendly energy-saving engineering machinery

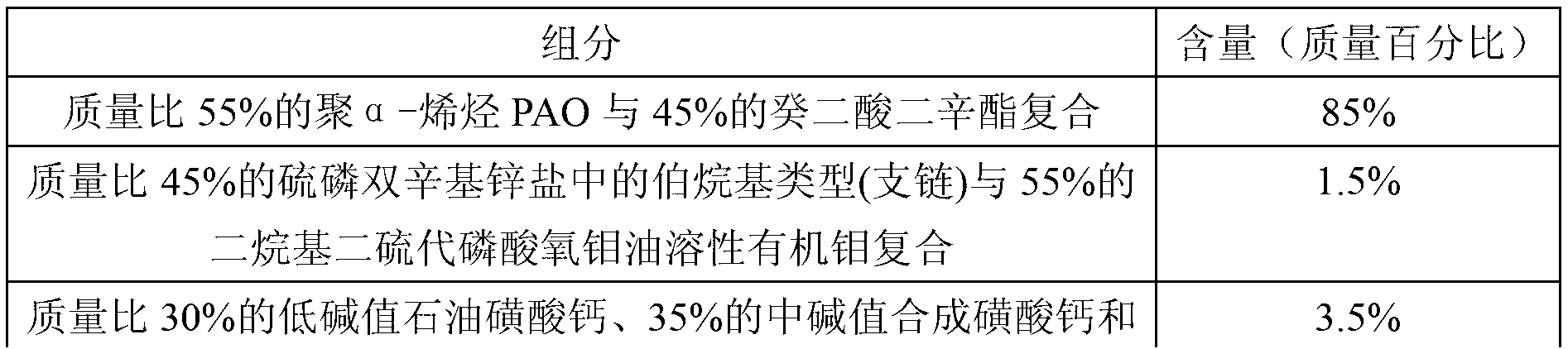

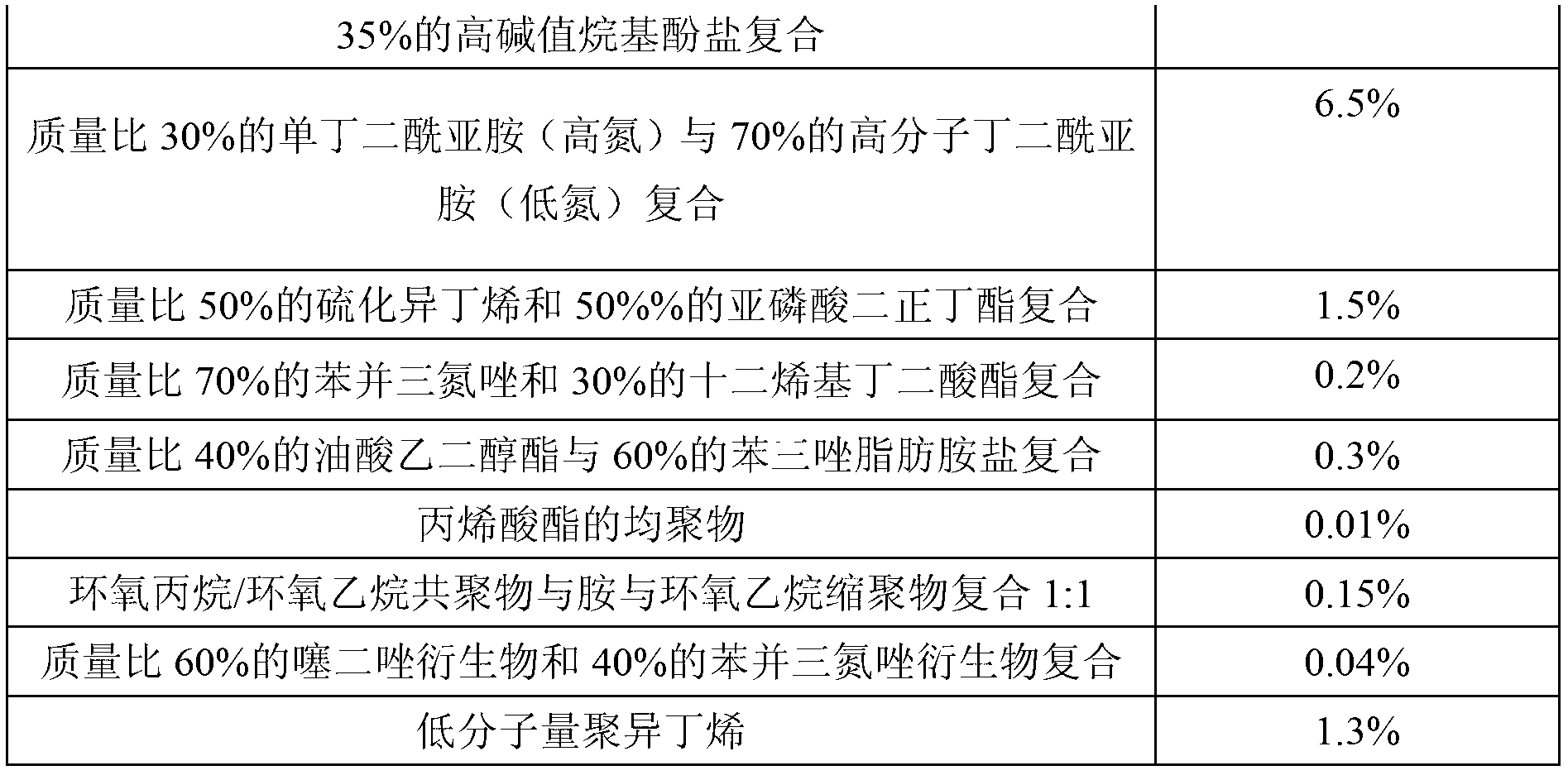

The invention discloses a universal oil composition for environment-friendly energy-saving engineering machinery. The universal oil composition comprises the following components according to mass percent: 85%-90% of composite base oil and 15%-10% of other additives. The universal oil composition for the environment-friendly energy-saving engineering machinery adopts a poly-alpha-olefin (PAO) and dioctyl sebacate composition as the base oil, is good in comprehensive performance, can replace diesel engine oil, hydraulic oil, gear oil, hydraulic transmission fluid and other various unit oil used in the engineering machinery, achieves multiple purposes, increases the power of a diesel engine, improves the reliability, the fuel economy and the low-temperature start performance of the diesel engine and the working efficiency and the precision of a hydraulic system, and effectively prolongs the service life and the oil draining period of the hydraulic system, the diesel engine, a gear system, a hydraulic transmission system and other various units.

Owner:GUANGXI UNIV

Open type gear oil composition

The invention discloses an open gear oil composition, which comprises the following parts: 10-70% thickener, 0.1-5% extreme-pressure antiwear agent, 0.005-0.5% anti-emulsifier and mineral oil typed and or synthetic basic oil. The invention improves open gear oil viscosity-temperature property, which modifies oil stability and reserving property.

Owner:CHINA PETROLEUM & CHEM CORP

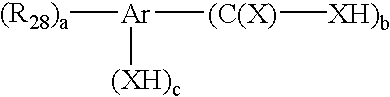

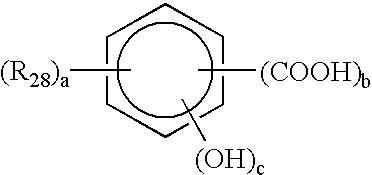

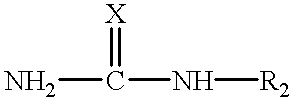

Lubricative Composition for Industrial Machinery and Equipment

InactiveUS20080058235A1Excellent in sludge resistance and extreme pressure propertyMaintain good propertiesGroup 5/15 element organic compoundsAdditivesViscosity indexCarboxylic acid

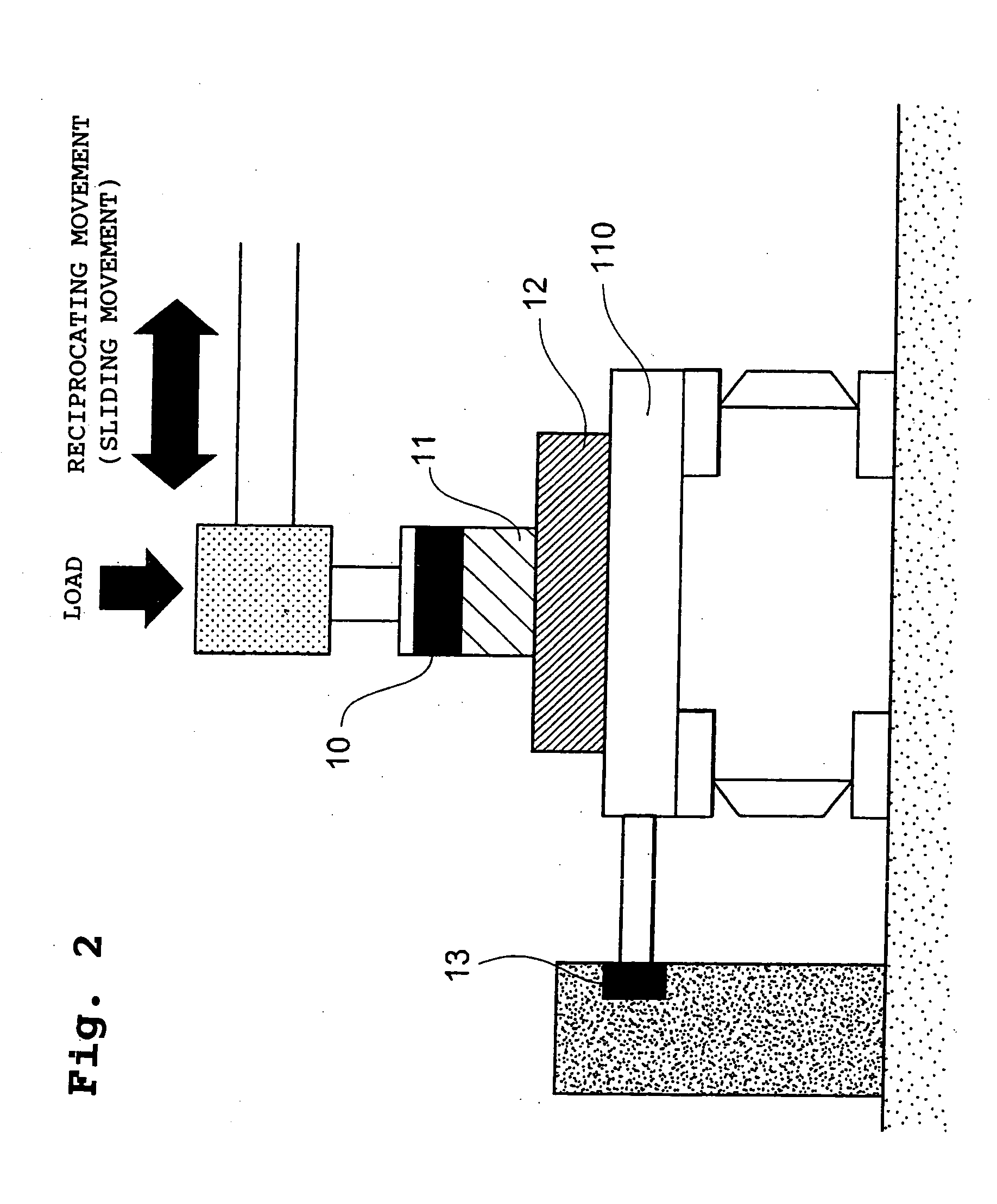

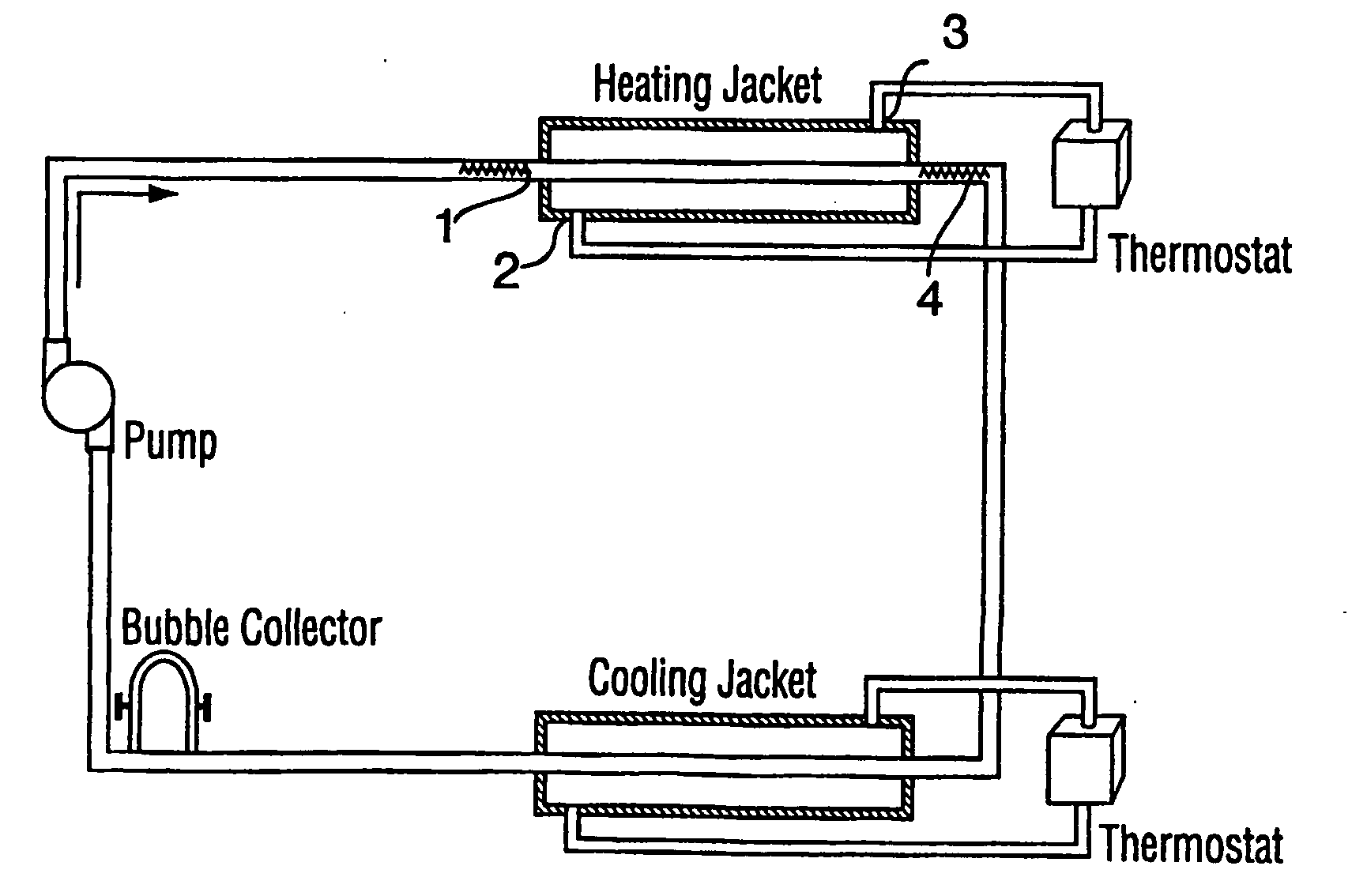

A lubricative composition for industrial machinery and equipment which comprises a base oil selected from among mineral oils, fats and oils, synthetic oils and mixture of two or more of them, and at least one additive selected from among the following components (A) to (D): component (A): (A-1) a phosphorus-containing carboxylic acid and / or (A-2) a thiophosphoric ester, component (B): a dispersant viscosity index improver, component (C): (C-1) a specific amidocarboxylic acid compound and / or (C-2) a specific carboxylic acid compound, and component (D): an ester oiliness improver. The composition is favorable as a lubricating oil composition and useful as a gear oil composition, a lubricating oil composition for paper machines or a lubricating oil composition for slide guides, a hydraulic oil, or the like.

Owner:NIPPON OIL CORP

Gear oil composition containing nanomaterial

ActiveUS20080242566A1Add friction propertiesHigh indexMaterial nanotechnologyLubricant compositionNanoparticleEngineering

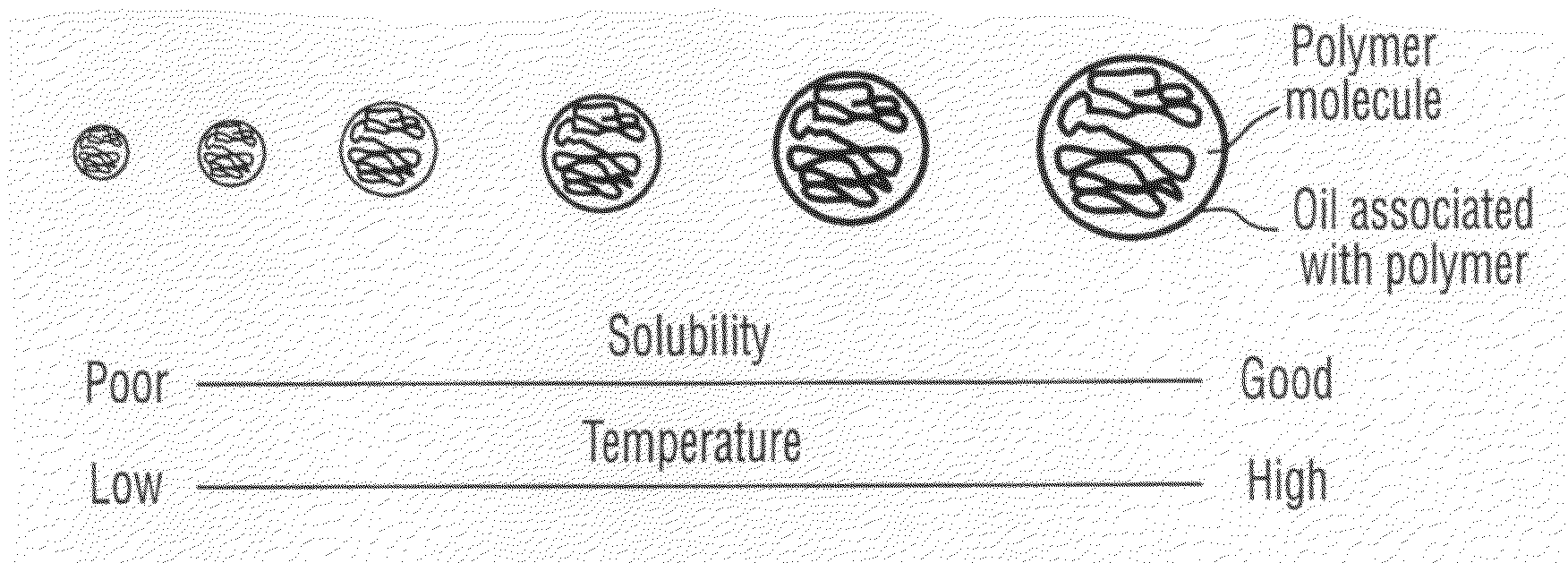

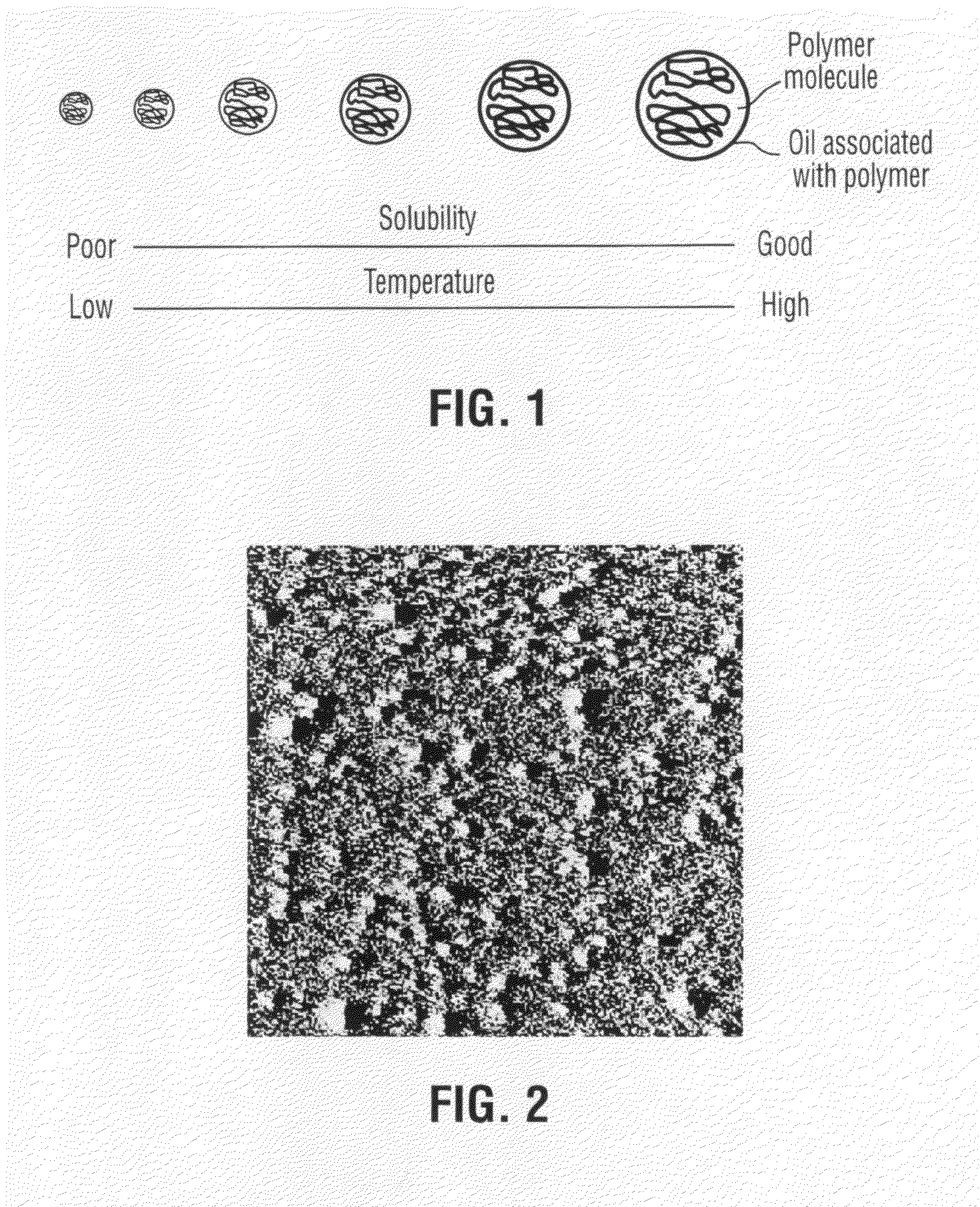

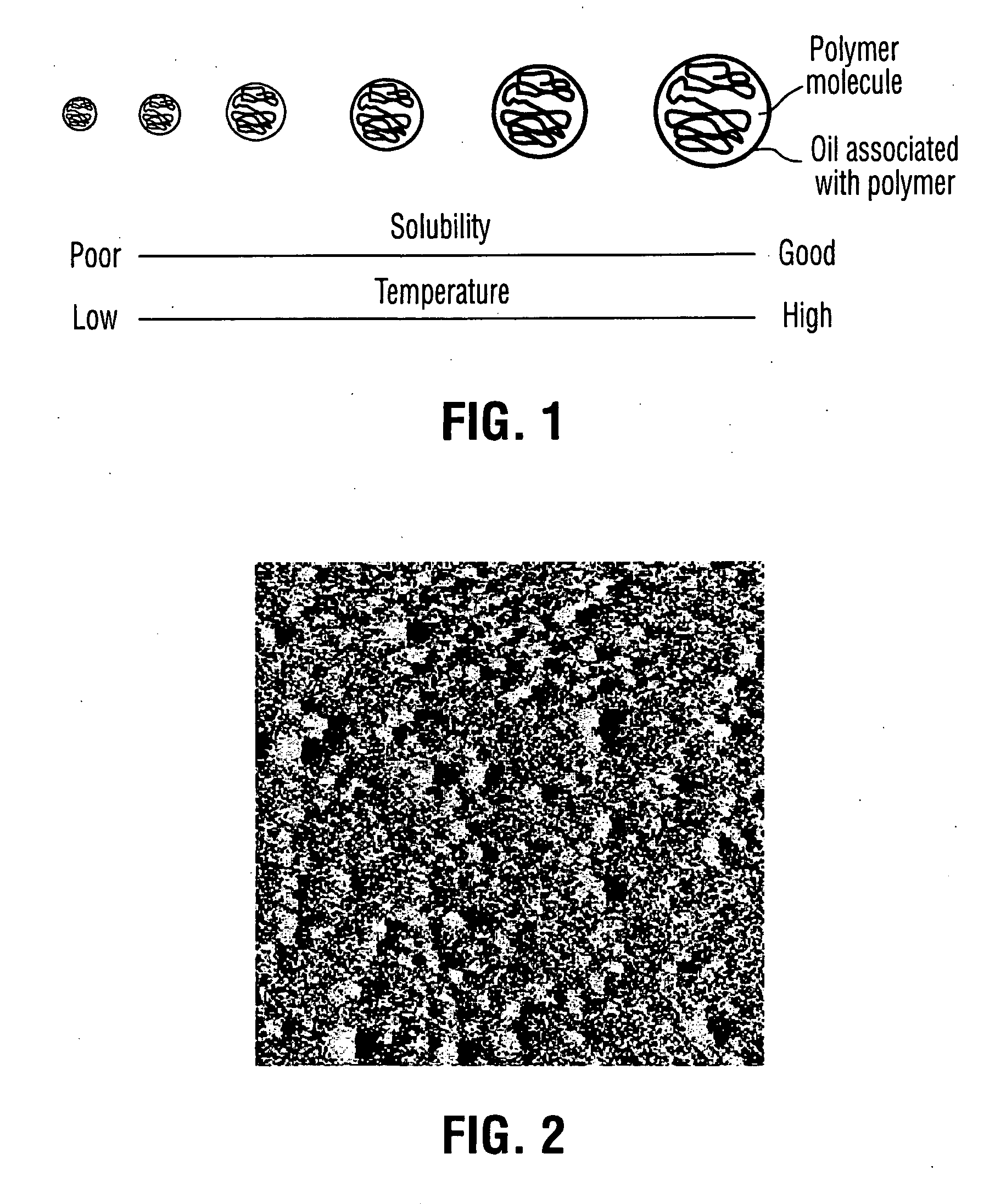

The present invention relates to a novel use of nanomaterials as a viscosity modifier and thermal conductivity improver for gear oil and other lubricating oil compositions. The gear oils of the instant invention have a higher viscosity index, higher shear stability, and improved thermal conductivity compared to currently available gear oils. The preferred nanoparticles also impart a reduction in the coefficient of friction, including reduced friction in the boundary lubrication regime. These properties are obtained by replacing part or all of the polymer thickener or viscosity index improver or some other part of the composition normally used in gear oils with nanomaterials of suitable shape, size, and composition.

Owner:VGP IPCO LLC

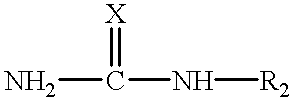

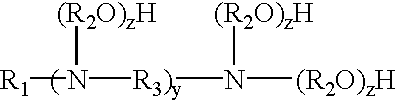

Friction modified lubricants

Mixtures of the reaction product of at least one C5-C60 carboxylic acid and at least one amine selected from the group consisting of guanidine, aminoguanidine, urea, thioruea and salts thereof and a phosphorus-containing dispersant are useful as gear oil additives. Lubricant formulations containing said mixtures exhibit excellent low and high temperature rheology and are particularly suited for use in automotive and industrial gear applications. Lubricants of the present invention exhibit improved performance properties such as increased axle efficiencies and lower axle temperatures compared to lubricant formulations that do not contain said mixtures.

Owner:AFTON CHEM INTANGIBLES

Mineral gear oils and transmission fluids

InactiveUS6872693B2High viscosityPromote oxidationSolid fuelsLiquid carbonaceous fuelsEngineeringFluid composition

This invention relates to mineral oil based gear oils and transmission fluids which comprise a major amount of a mineral oil having an iodine number of less than 9 and where at least 55% of the saturates are aliphatic, and gear oil or transmission fluid additives. In one embodiment, the invention relates to a gear oil or transmission fluid composition comprising a major amount of lubricant basestock and at least one functional additive wherein a major amount of the lubricant basestock comprises a mineral oil having an iodine number of less than 9 and comprising at least 45% by weight of aliphatic saturates. These gear oils and transmission fluids have good viscosity and oxidation properties.

Owner:THE LUBRIZOL CORP

Low-temperature and over-loading synthetic gear oil

ActiveCN107312598AGood low temperatureGood thickening effectLubricant compositionViscosity indexBase oil

The invention relates to low-temperature and over-loading synthetic gear oil comprising at least the following components: an anti-wear reagent at extreme pressure, a friction modifier, a viscosity index improver, and base oil, wherein the anti-wear reagent at extreme pressure at least comprises an oil-soluble nano-borate, the viscosity index improver at least comprises a modified polymethacrylate tackifier, the friction modifier at least comprises organic molybdenum, the base oil is mixed base oil comprising polyalphaolefin and ester oil, the mass percentage of the mixed base oil is 78.4%, the mass percentage of the modified polymethacrylate tackifier is 7.5%, the mass percentage of the oil-soluble nano borate is 2%, and the mass percentage of organic molybdenum is 0.2-0.3%. The gear oil disclosed by the invention has excellent low temperature performance and can effectively prolong the life cycle of oil products, and a solid borate film formed by the borate has excellent extreme pressure resistance, can bear huge load and has excellent anti-wear and anti-friction performances.

Owner:北京雅士科莱恩石油化工有限公司

Gear oil composition and applications thereof

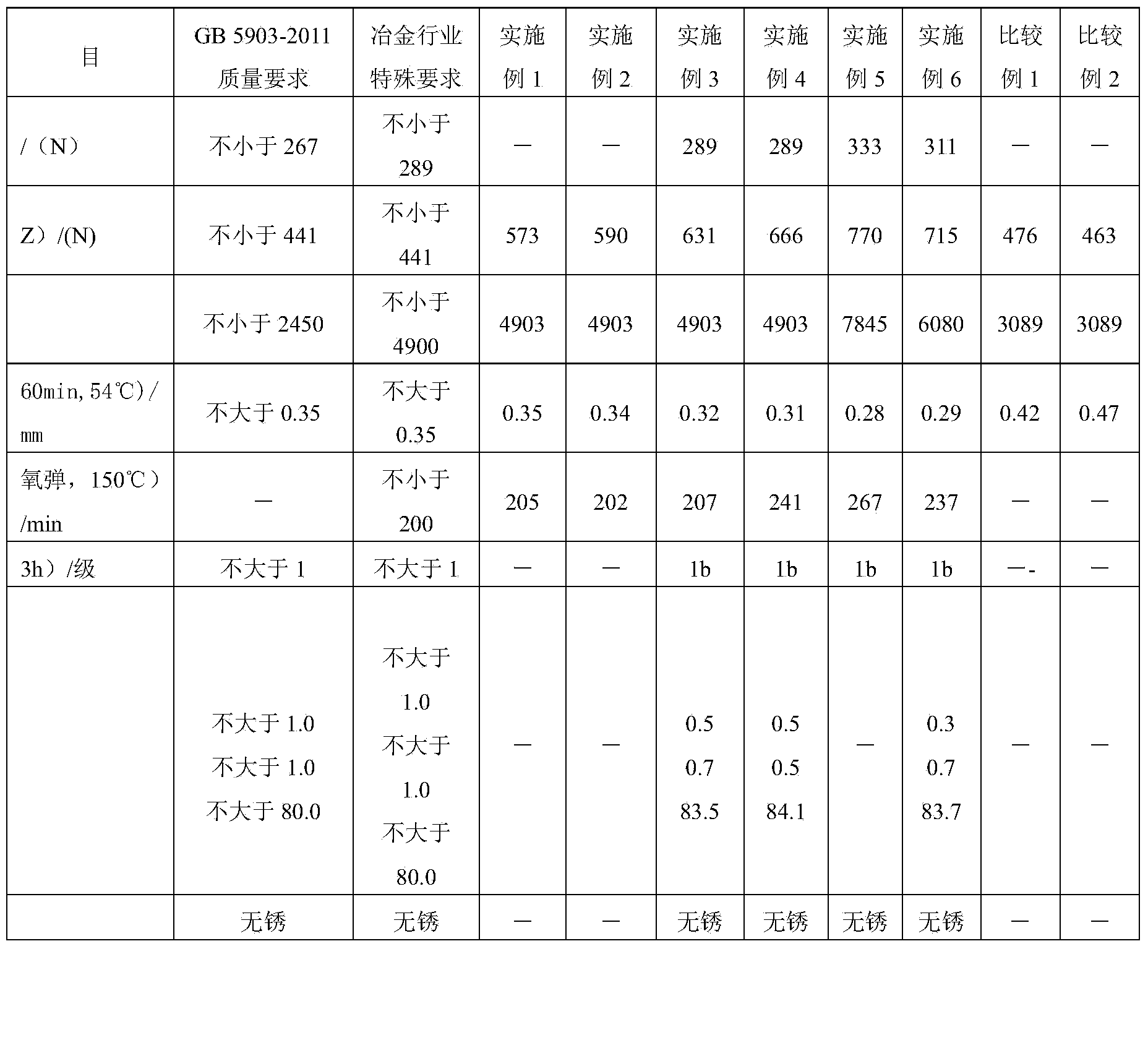

The invention relates to a gear oil composition and applications thereof, mainly solving problems of abnormal gear wear and poor oxidation stability of an oil product which are caused by that the extreme pressure property of industrial gear oil in the prior art fails to satisfy a part of using requirements of the metallurgy industry. According to the technical scheme adopted by the gear oil composition, the gear oil composition comprises following components by weight: a) 100 parts of mineral base oil; b) 0.1-10.0 parts of an anti-wear reagent at extreme pressure; c) 0.01-2.0 parts of an antioxidant; d) 0.01-0.5 part of a metal deactivator and e) 0.01-1.5 parts of an oiliness agent, wherein the anti-wear reagent at extreme pressure is a mixture of sulfurized isobutylene and at least one selected from sulfurized olefin, phenyl sulfide, sulfurized aliphatic ester or amine thiophosphate diester; and the antioxidant is at least one selected from 2,6-di(tertbutyl)-p-cresol, 3.5-di(tertbutyl)-4-hydroxy phenyl acrylate, pentaerythrite tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], N-phenyl-1-naphthylamine or alkylated diphenylamine. By the technical scheme, the problems are solved well and the gear oil composition can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

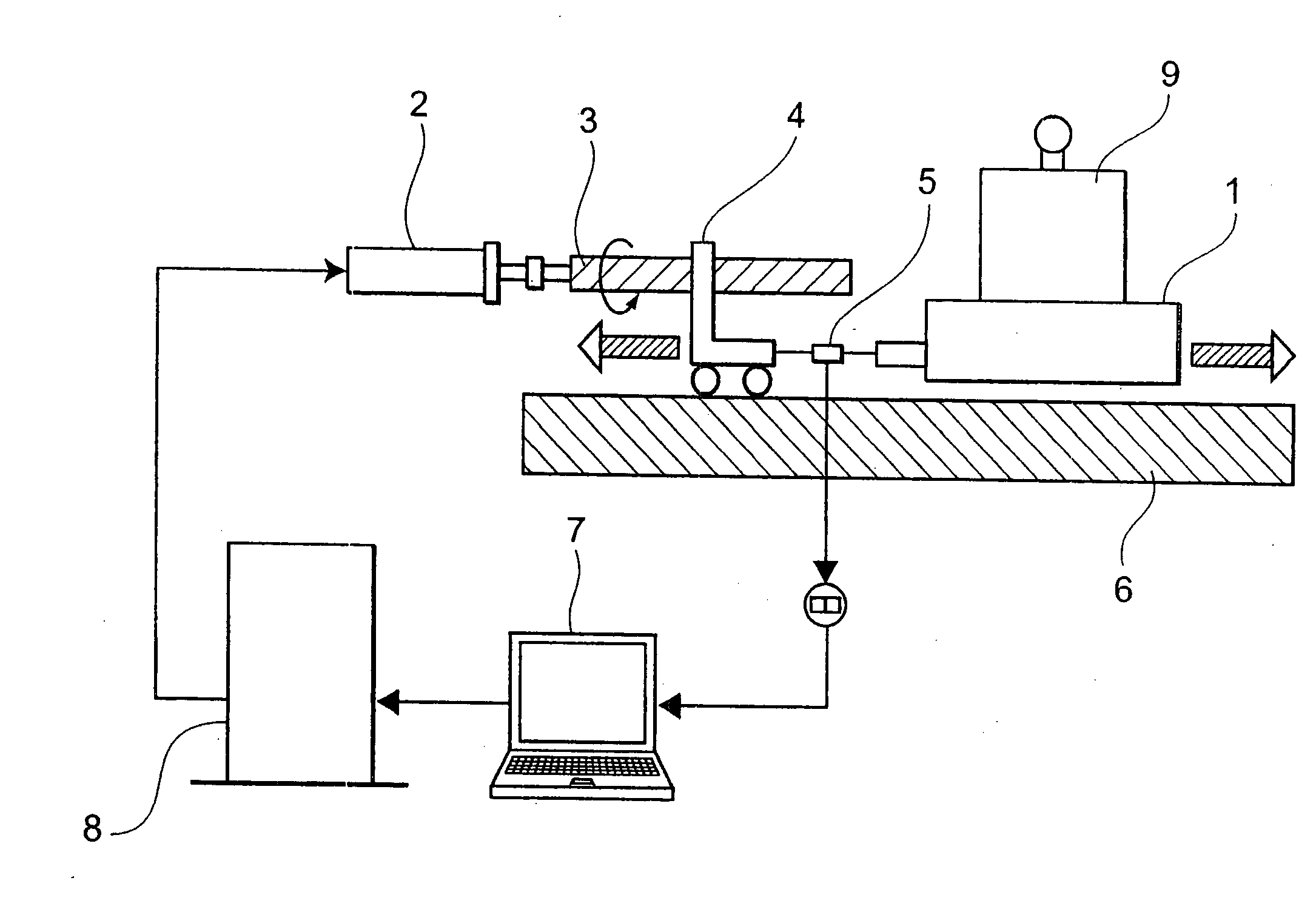

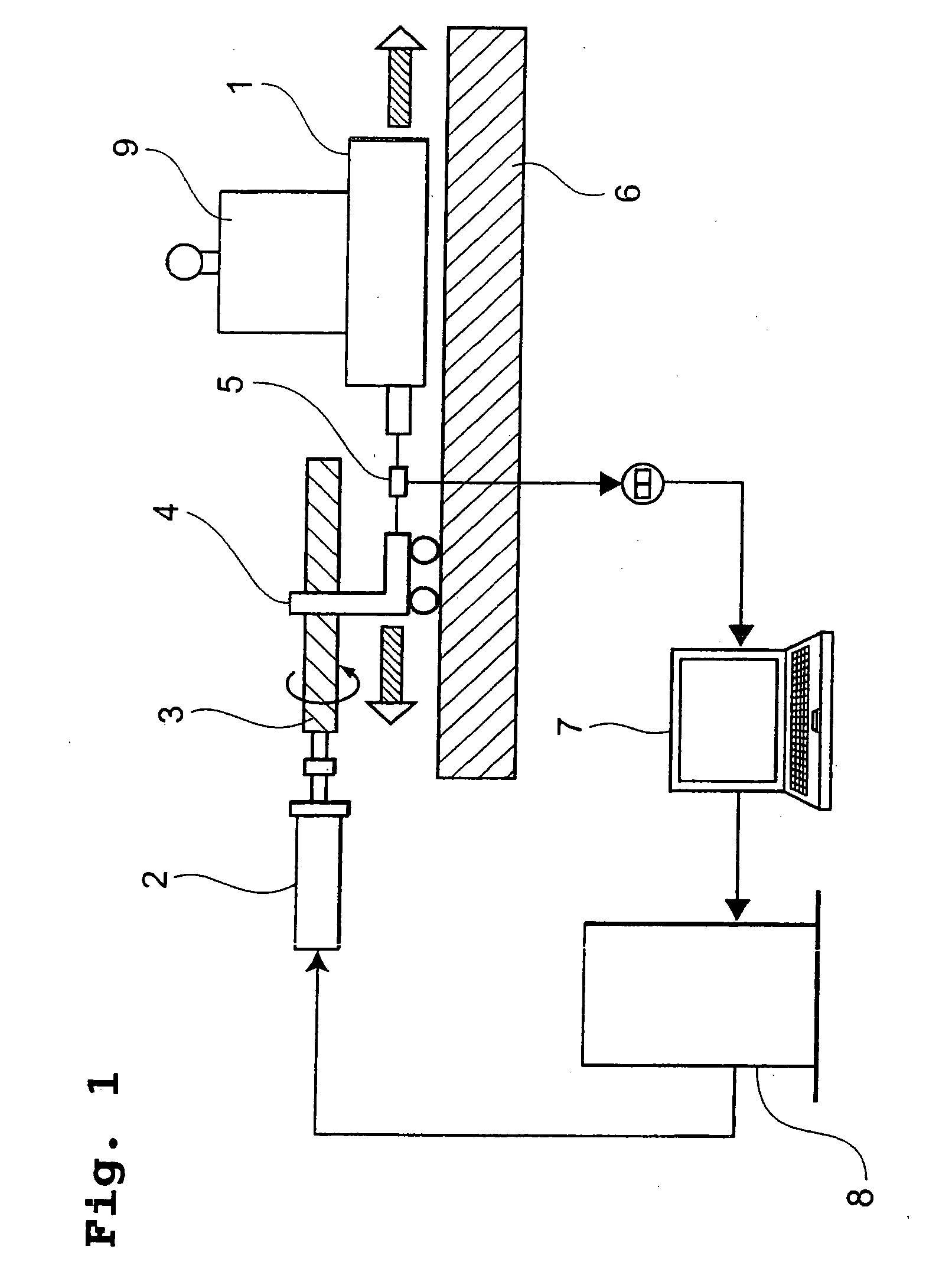

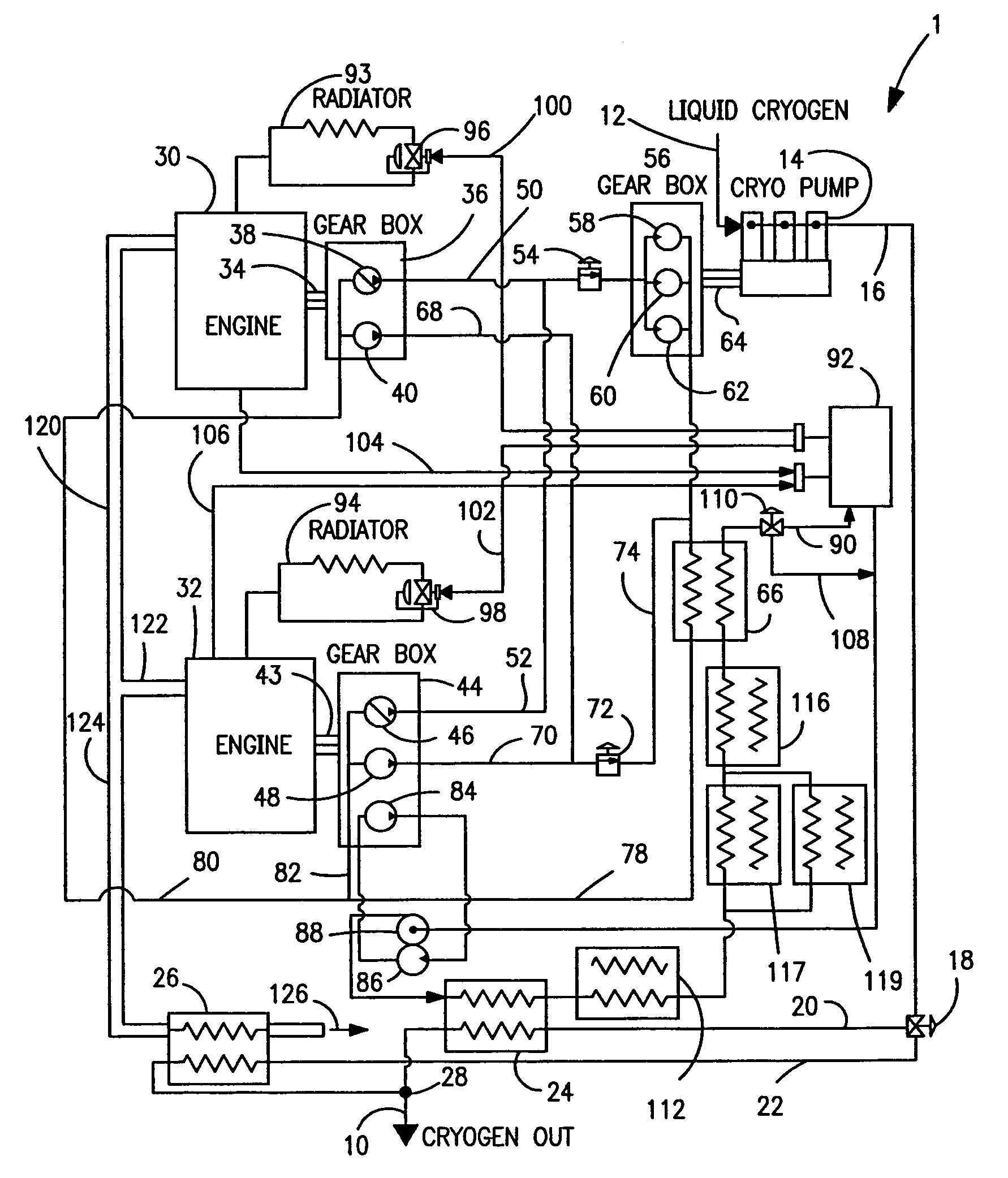

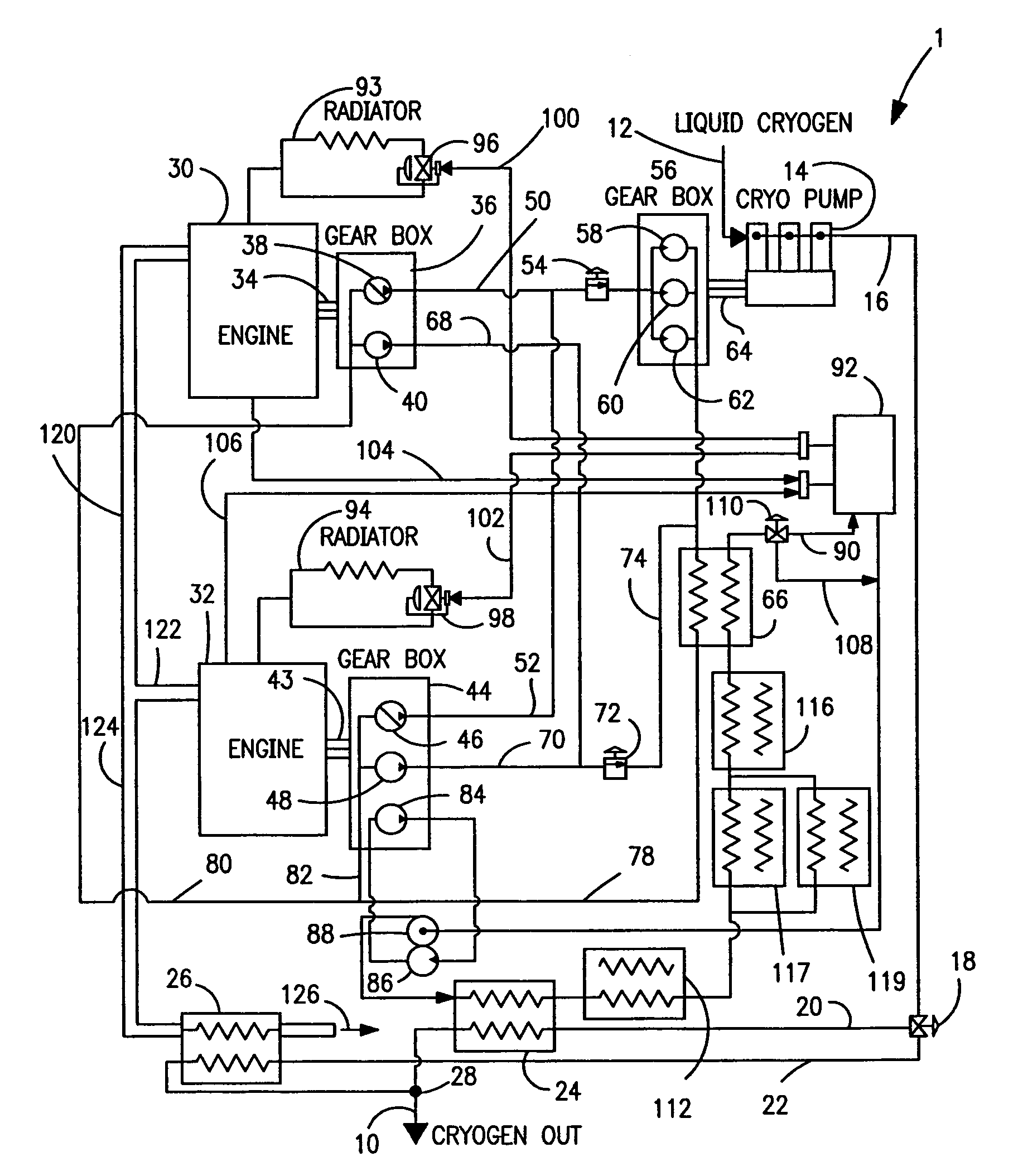

Apparatus and method for producing a pressurized vapor stream

ActiveUS6981850B1Less complex and expensive devicesEasy to controlFluid couplingsContainer filling methodsHydraulic pumpEngineering

A cryogenic stream is pumped by a cryopump and then vaporized in a vaporizer to produce the pressurized vapor stream. The cryopump is driven by a transmission that is in turn driven by a hydraulic fluid. The hydraulic fluid flows within a hydraulic fluid circuit having first and second hydraulic fluid flow paths. The first of the flow paths is used to drive the hydraulic transmission. The second of the flow paths is dedicated to raising heat. Hydraulic fluid is circulated within the flow path by hydraulic fluid pumps and the amount of heat generated is controlled by adjustable back pressure valves. The adjustable back pressure valves in both fluid flow paths can be adjusted to control the degree to which heat is added to the vaporizer and therefore the pressurized vapor stream. The hydraulic fluid pumps can be driven by diesel engines. Heat may also be recovered from the diesel engines and gear oil used in pumps and the cryopump to also help vaporize the pressurized liquid stream. The aforesaid system of first and second pumps driven by an engine and first and second flow paths can be replicated to allow for expansion of pumping capacity.

Owner:PRAXAIR TECH INC +1

Oil-gas lubricating oil and production method thereof

The invention provides oil-gas lubricating oil which comprises the following components in percentage by weight: 75-90% of polyester type base oil, 6-20% of other types of base oil, 0.3-3% of antioxidant, 0.01-2% of antirusting agent, 0.5-3% of oiliness improver, 1-5% of extreme pressure antiwear agent and 0.01-0.5% of anti-foaming agent, wherein other types of base oil is one or more than one of synthetic ester, alkyl benzene and alkyl naphthalene. The provided oil-gas lubricating oil has strong universality, is not easy to coke at high temperature and has excellent high temperature performance and good lubricating property. The oil-gas lubricating oil not only can be applied to various bearings of an oil-gas lubricating device, gear cases with various loads, worm gears, worms, locomotive wheel rims, rail cases and the like, but also can be used as ordinary gear oil. Moreover, the oil-gas lubricating oil can be used both in summer and in winter and in southern region and northern region. The oil-gas lubricating oil has strong cleaning performance and can effectively prevent coked matter from blocking oil pipelines.

Owner:CHINA PETROLEUM & CHEM CORP

Sedan hand gearshift case gear lubricating oil composition

ActiveCN101298578AMeet lubricationMeet lubrication requirementsAdditivesBase-materialsGear wheelBench test

The invention provides a gear lubricant composite for manual transmissions of the light cars, comprising (A) at least one type of refining mineral oil with high viscosity index, or polyolefin synthesis oil, or ester lubricants, or a free composite of the above components, (B) at least one type of viscosity index improver, (C) at least one type of pour point depressant, (D) at least one type of extreme pressure additive with sulfurs, (E) at least one type of anti-wear additive with phosphorus, (F) at least one type of wear, oxygen, and corrosion-preventing multifunctional additive with phosphorus, (G) at least one type of anti-rusting additive, and (H) at least one type of friction modifier. The lubricant composite has excellent performance of high and low temperature, which can meet the requirements of gear oil with a viscosity grade of 75W / 90. Moreover, passing the full-size gear bench tests as CRCL-42, L-37, L-33, L-60, and L-60-1 as well as cycle bench tests for the manual transmissions of the light cars, the gear lubricant composite can meet lubrication requirements of the manual transmissions of the light top-grade cars.

Owner:PETROCHINA CO LTD

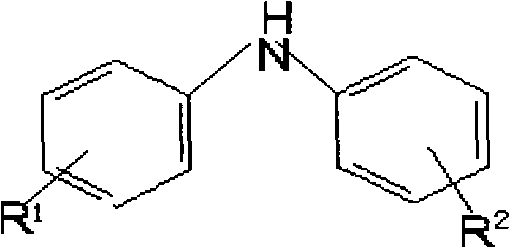

Amine tungstates and lubricant compositions

InactiveUS20090029888A1Improved performance characteristicsEasy to controlAdditivesGroup 6/16 organic compounds without C-metal linkagesChemical compositionAntioxidant

This invention relates to lubricating oil additives, and to lubricating oil compositions, their method of preparation, and use. More specifically, this invention relates to several novel lubricating oil additives and compositions which contain a tungsten compound and an antioxidant, namely aminic antioxidants such as a secondary diarylamine or an alkylated phenothiazine. The use of the tungsten compound with the secondary diarylamine and / or the alkylated phenothiazine provides improved oxidation and deposit control to lubricating oil compositions. The lubricating oil compositions of this invention are particularly useful as crankcase and transmission lubricants, gear oils and other high performance lubricant applications.

Owner:KING INDUSTRIES INC

Rubber framework grease seal for automobile gear box and manufacturing method thereof

InactiveCN101319082APrevent leakageSolve the problem of oil leakageEngine sealsDomestic articlesSodium stearateSulfur

The invention provides a rubber framework oil seal used for a gear box of an automobile and a manufacturing method thereof. The rubber framework oil seal comprises the following compositions in weight portion: 100 portions of activated chlorine type acrylate adhesive AR840, 0.5 to 1 portion of a vulcanizing activator stearic acid, 1.5 to 2 portions of a process additive TM-80, 2 to 3 portions of a vulcanizing agent sodium stearate, 0.5 to 0.6 portion of an accelerating agent sulfur and potassium stearate, 1 to 2 portions of an age inhibitor 445, 1 to 2 portions of MB, 4 to 6 portions of a strengthening agent carbon soot and 22 to 28 portions of a siliceous reinforcing agent. The rubber framework oil seal has the characteristics of stable size of hypoid gear oil of the gear box, oil resistance, anti-aging property, and sealing reliability, etc.

Owner:青岛茂林橡胶制品有限公司

Modified gear oil

A modified gear oil can be used for extreme worm oil, open industrial gear oil and closed industrial gear oil in traffic transportation, machinery, metallurgical, chemical industries. In the mineral lube-oil or synthetic lube-oil, modified nano-carbon with average grain size 2-6nm is added as extreme anti-scuff agent and oily agent, quality fraction is 2X10-5-1X10-2, nano-diamond occupies 10-99%, wear rate is decreased by 46.7%, mechanical efficiency improves by 2.84%, polishing scratch depth is decreased from 4.94 mu m to 0.07 mu m.

Owner:TIANJIN CHANYU SUPERHARD SCI TECH CO LTD

Special castor-oil-based gear oil for wind power generation

InactiveCN103131525AExtended service lifeReduce the number of oil changesLubricant compositionFoaming agentEngineering

The invention provides special castor-oil-based gear oil for wind power generation. The special castor-oil-based gear oil for wind power generation is formed through combination of castor-oil-based base oil and other additives. The special castor-oil-based gear oil comprises the following components in percentage by mass: 0-30% of other types of base oil, 0.1-2% of friction modifier, 0.1-3% of extreme pressure anti-wear agent, 0.01-0.3% of metal passivator, 0.1-2% of antioxidant agent, 0.001-0.5% of demulsification agent, 0.01-0.5% of anti-rust agent, 0.001-0.3% of anti-foaming agent and the balance of castor-oil-based base oil. The special castor-oil-based gear oil provided by the invention has the advantages of having excellent biological degradability, being capable of being decomposed under the effect of microorganisms even if leaking into environments, having no pollution to environments, and having excellent extreme pressure anti-wear performance, good thermal oxidation stability, low-temperature performance, viscosity-temperature performance, anti-emulsification property and long service life.

Owner:TIANJIN NANKAI UNIV CASTOR ENG SCI & TECH

Lubricating oil composition for industrial machinery and equipment

InactiveCN1938408AExcellent sludge resistanceImprove extreme pressure performanceAdditivesChemical compositionCarboxylic acid

A lubricative composition for industrial machinery and equipment which comprises a base oil selected from among mineral oils, fats and oils, synthetic oils, and mixtures of two or more of them, and at least one additive selected from among the following components (A) to (D): (A): (A-1) a phosphorus-containing carboxylic acid and / or (A-2) a thiophosphoric ester (B): a dispersant viscosity index improver, (C): (C-1) a specific amidocarboxylic acid and / or (C-2) a specific carboxylic acid, and (D): an ester oiliness improver. The composition is favorable as a lubricating oil composition and useful as a gear oil composition, a lubricating oil composition for paper machines or slide guides, a hydraulic oil, or the like.

Owner:NIPPON OIL CO LTD

Lubricating oil wear resistant additive, and preparation method and application thereof

InactiveCN104711077AImprove anti-wear performanceWith repair functionAdditivesMolybdateWear resistant

The invention discloses a lubricating oil wear resistant additive. The lubricating oil wear resistant additive comprises, by mass, 70-80% of base oil, 5-10% of organic molybdate, 1-3% of sorbitan monooleate, 0.7-0.8% of zinc diamyldithiocarbamate, 1-3% of nanometer graphene, and the balance of additives. The lubricating oil wear resistant additive has wear resistance and reduction effects on various lubricating oils, has a restoration function, can reduce the mechanical work noise and power loss, and is suitable for any brand of machine oils, gear oils, hydraulic oils, track oils and other lubricating oils. The invention also discloses a preparation method of the lubricating oil wear resistant additive. The method comprises the following steps: mixing nanometer graphene with sorbitan monooleate, carrying out ultrasonic dispersion, adding base oil, organic molybdate, zinc diamyldithiocarbamate and the additives, and uniformly stirring. The preparation method has the advantages of simple process steps, low cost, and suitableness for industrial production.

Owner:上海恒扬新能源科技发展有限公司

Truck fleet fuel economy by the use of optimized engine oil, transmission fluid, and gear oil

InactiveUS20090011963A1Improve fuel economyLiquid carbonaceous fuelsAdditivesAntioxidantViscosity index

The lubricant system of the present disclosure comprises an engine oil comprising at least one additive chosen from a viscosity index improver, a dispersant, a detergent, an antioxidant, and an antiwear compound; a transmission fluid comprising at least one additive chosen from a dispersant and a pour-point depressant; and a gear oil comprising at least one additive chosen from a viscosity index improver, an extreme pressure agent, and a dispersant. There is also disclosed a method of improving fuel economy of a vehicle comprising providing to the vehicle the disclosed lubricant system.

Owner:AFTON CHEMICAL

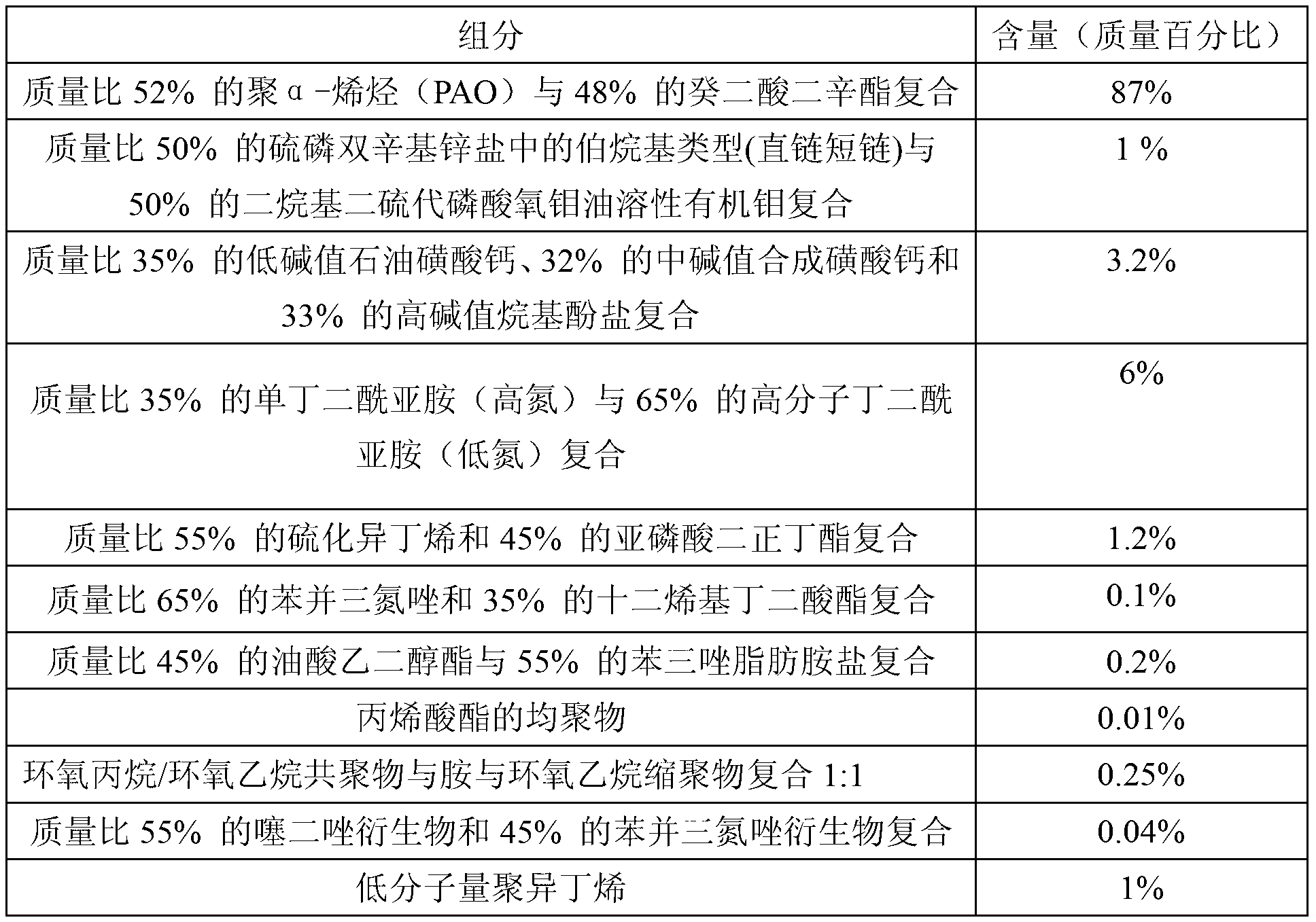

Biodegradable industrial gear oil composition

ActiveCN105132104AImprove performanceImprove compatibilityLubricant compositionEmulsionFoaming agent

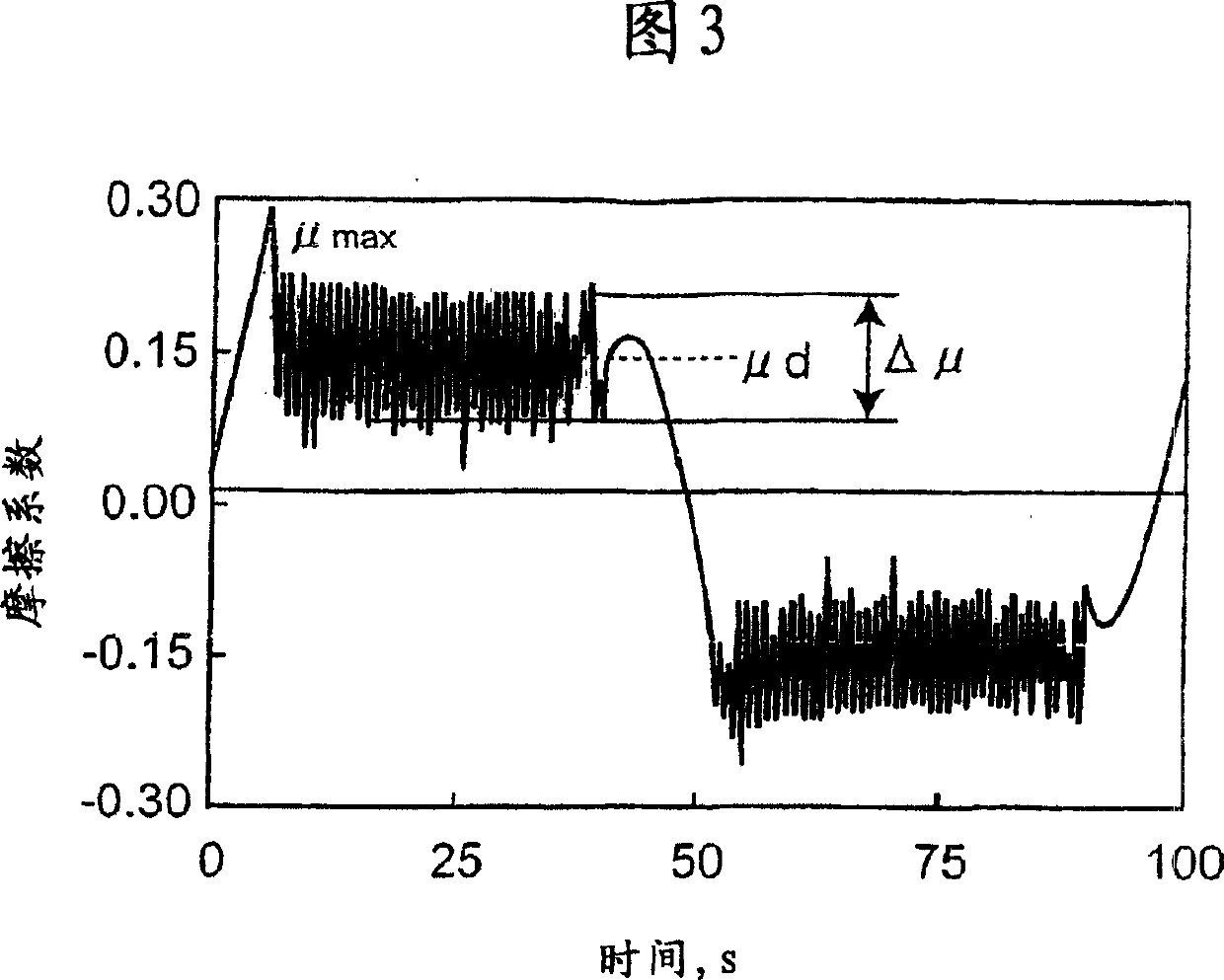

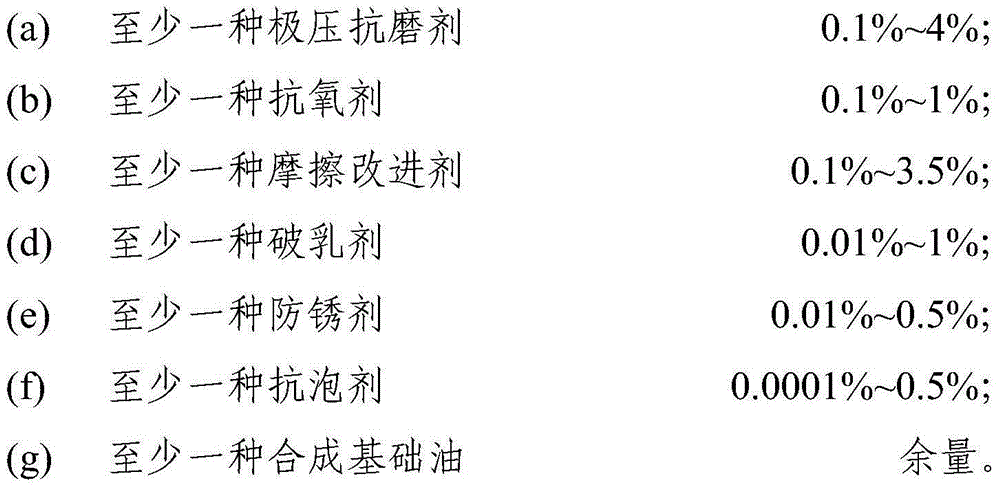

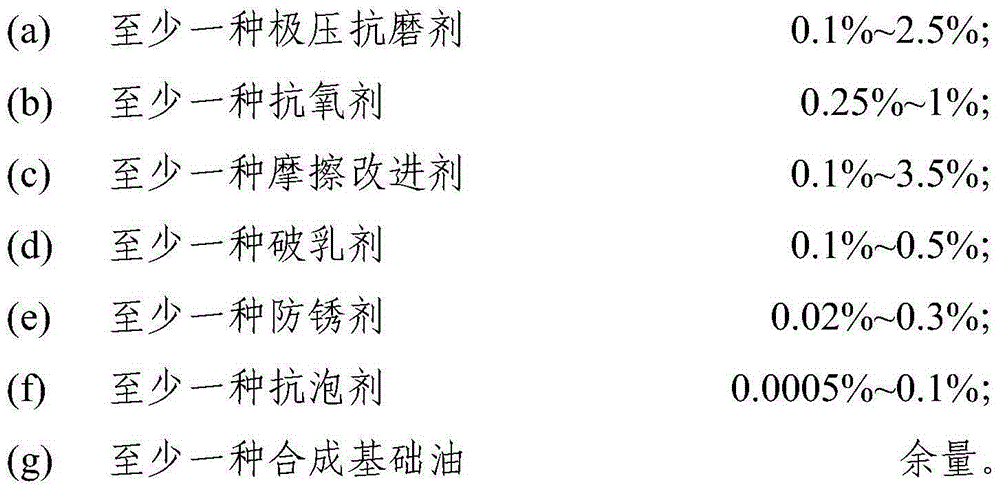

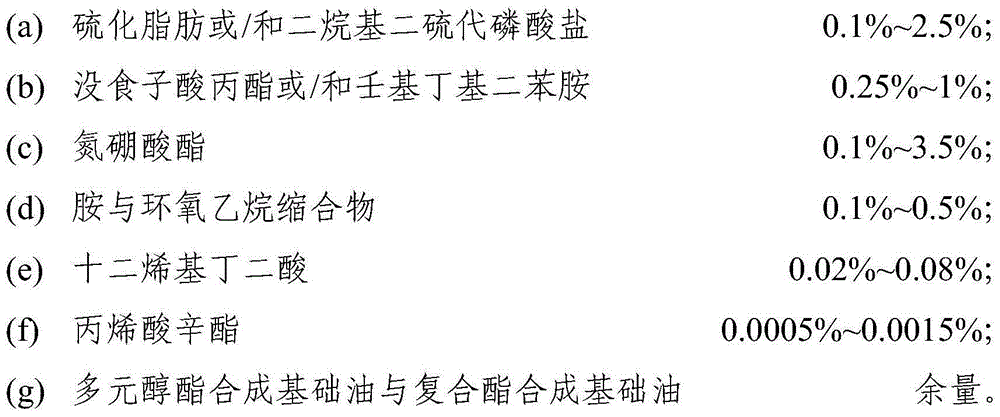

The invention relates to a biodegradable industrial gear oil composition which is composed of at least one extreme pressure wear-resistant agent (a), at least one antioxidant (b), at least one friction improver (c), at least one demulsifying agent (d), at least one antirust agent (e), at least one anti-foaming agent (f) and at least one synthesis base oil (g). Biodegradable industrial gear oil has outstanding biodegradable performance, outstanding extreme pressure wear-resistant performance, excellent sealing material compatibility, excellent emulsion resistance, good oxidation stability and good corrosion resistant performance. The composition can be used for lubricating various gear devices comprising spur gears, helical gears, bevel gears and the like in environmentally sensitive areas, and can completely meet the requirement of environmental protection for the biodegradable performance of oil products.

Owner:CHINA PETROLEUM & CHEM CORP

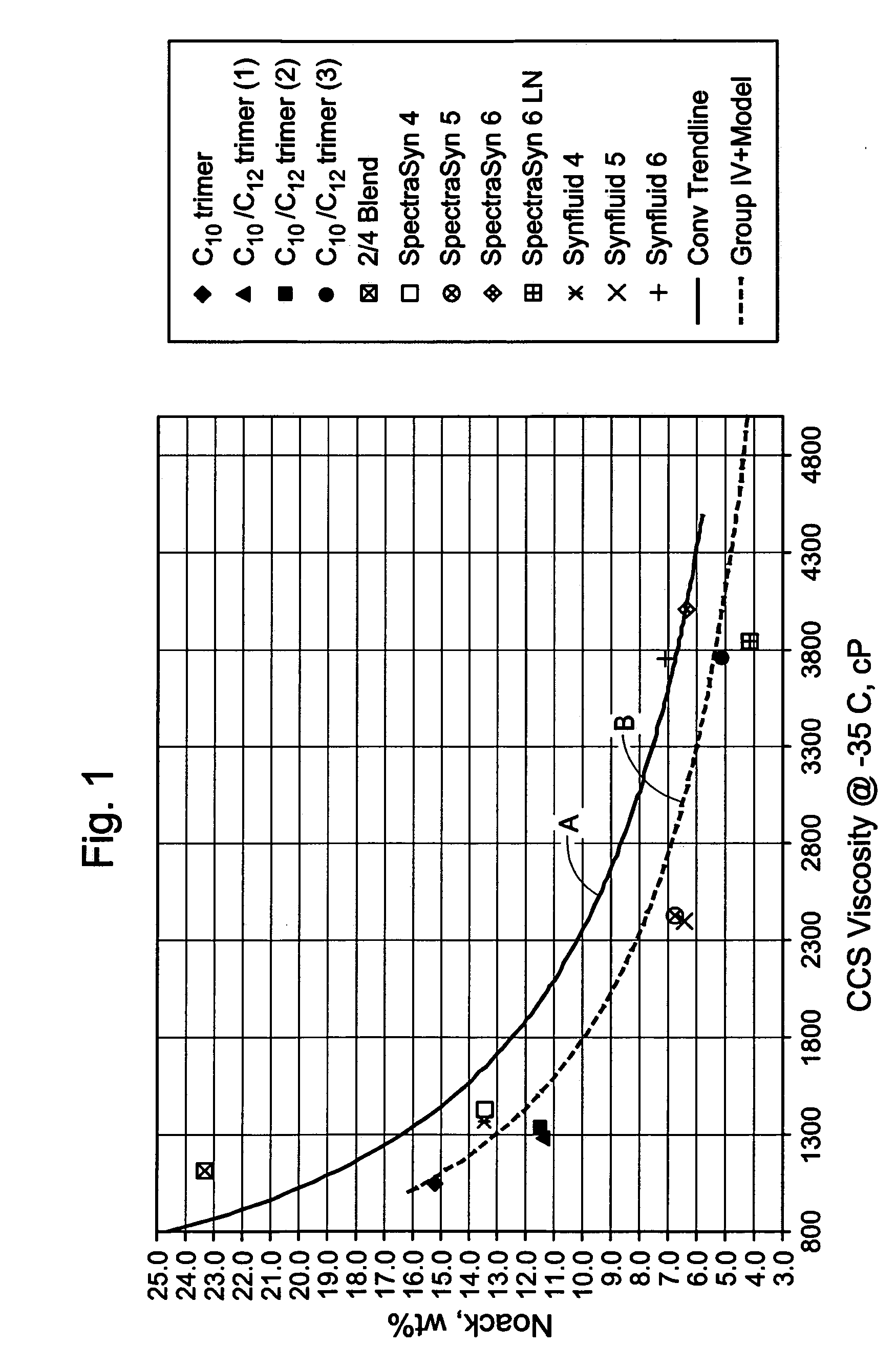

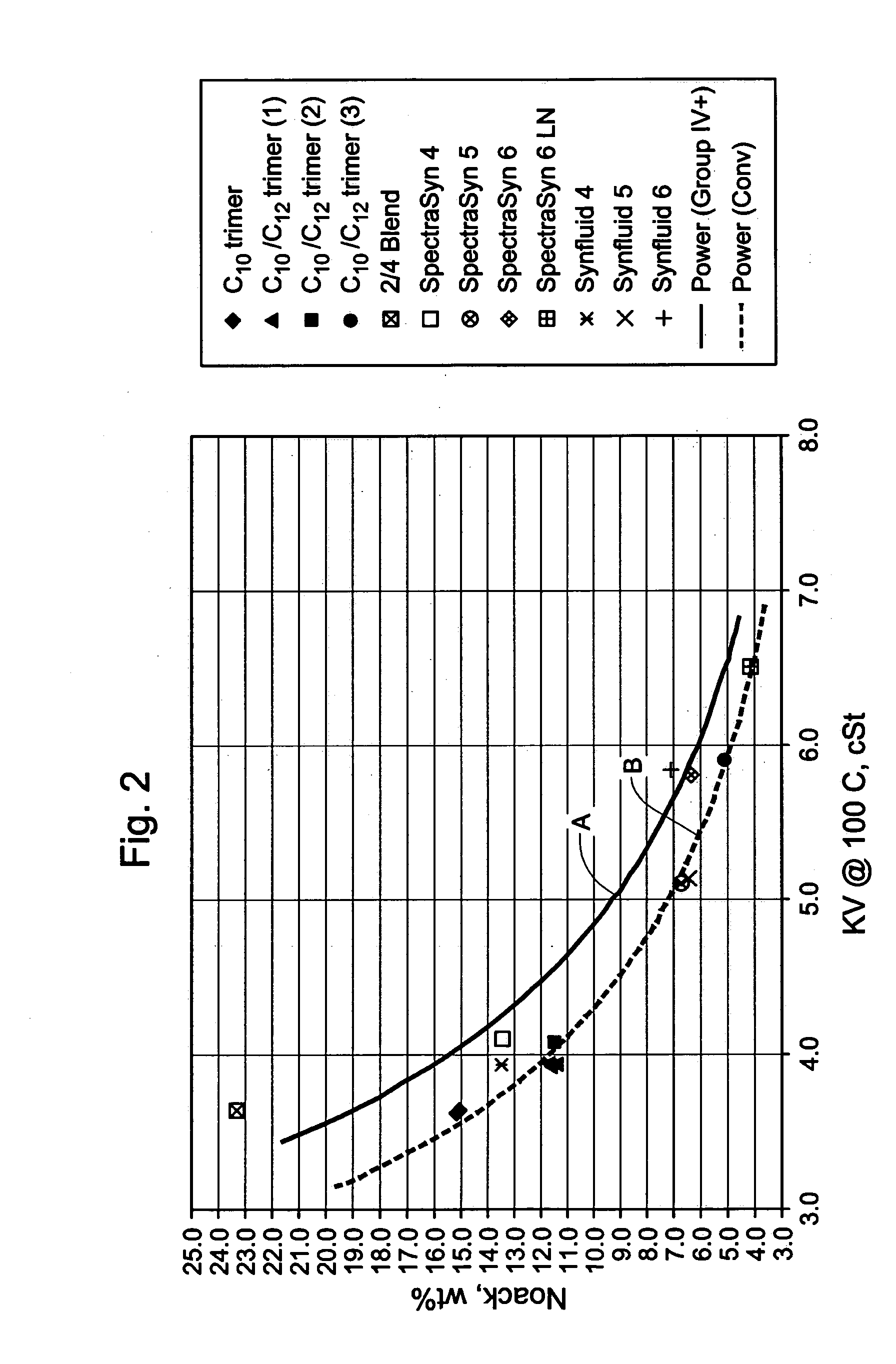

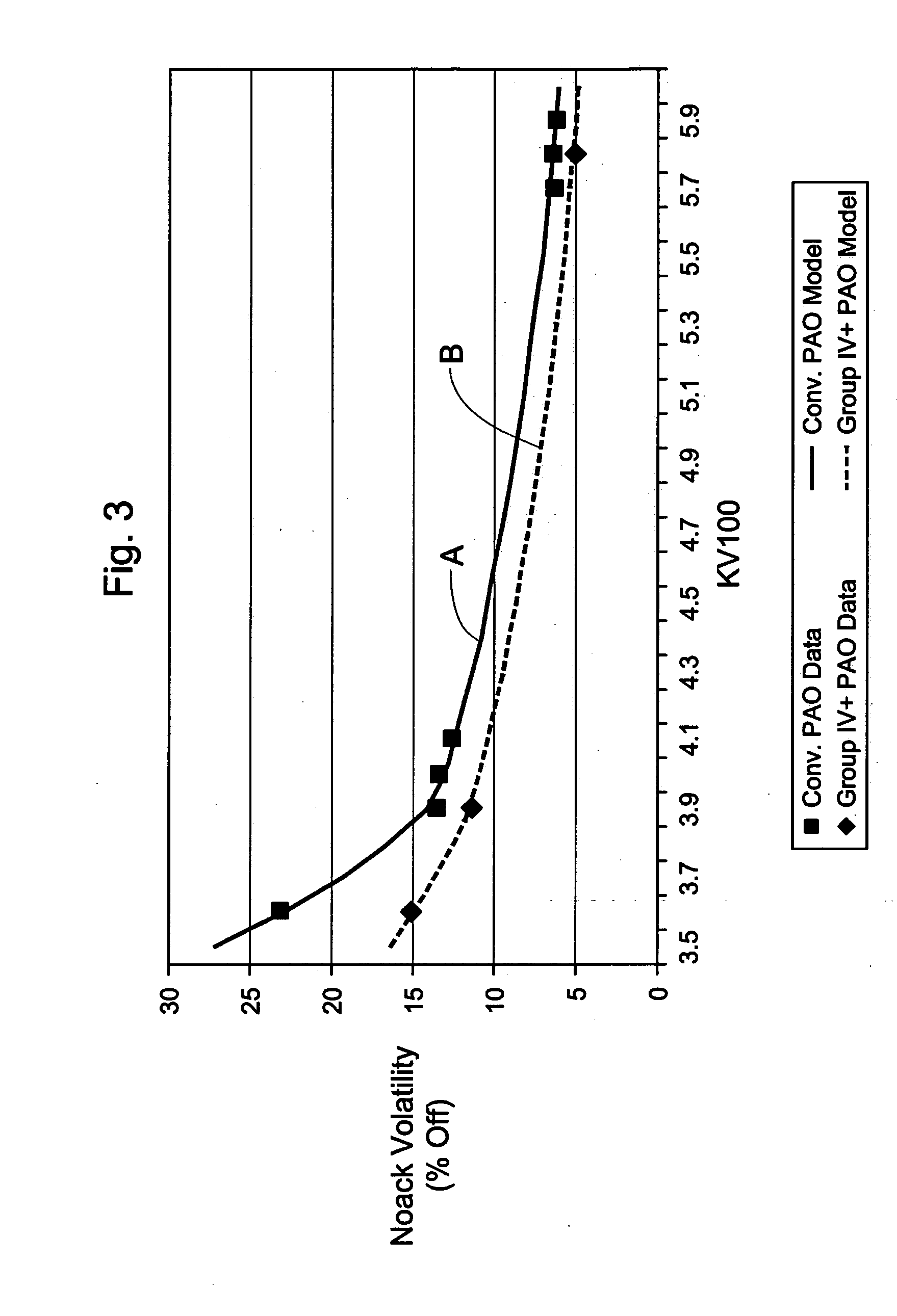

Blend comprising group III and group IV basestocks

InactiveUS20060211581A1Liquid hydrocarbon mixtures productionTreatment with hydrotreatment processesHydraulic fluidViscosity

The invention relates to compositions comprising a blend of Group III basestocks and low volatility, low viscosity PAO basestocks. The blend is particularly useful for preparing finished lubricants that meet or even exceed the criteria for SAE Grade 0 W multi-grade engine oils. The combination of these low volatility, low viscosity PAOs with Group III basestocks provide, in embodiments, the necessary performance criteria in automatic transmission fluids, automotive or industrial gear oils, hydraulic fluids, or any other high performance lubricant requiring a combination of excellent low fluidity and low volatility.

Owner:EXXONMOBIL CHEM PAT INC

Open type gear oil composition

ActiveCN1962835AGuaranteed adhesionGuaranteed viscosity-temperature characteristicsAdditivesEngineeringBase oil

The invention discloses a new open-typed gear oil composition, which comprises the following parts: 0.2-70% thickener, 0.1-5% extreme-pressure antiwear agent, 0.005-0.5% anti-emulsifier, 0.5-8% oil-soluble friction modifier and basic oil. The invention expands the application scale of oil, which satisfies the lubricating need of different equipments.

Owner:CHINA PETROLEUM & CHEM CORP

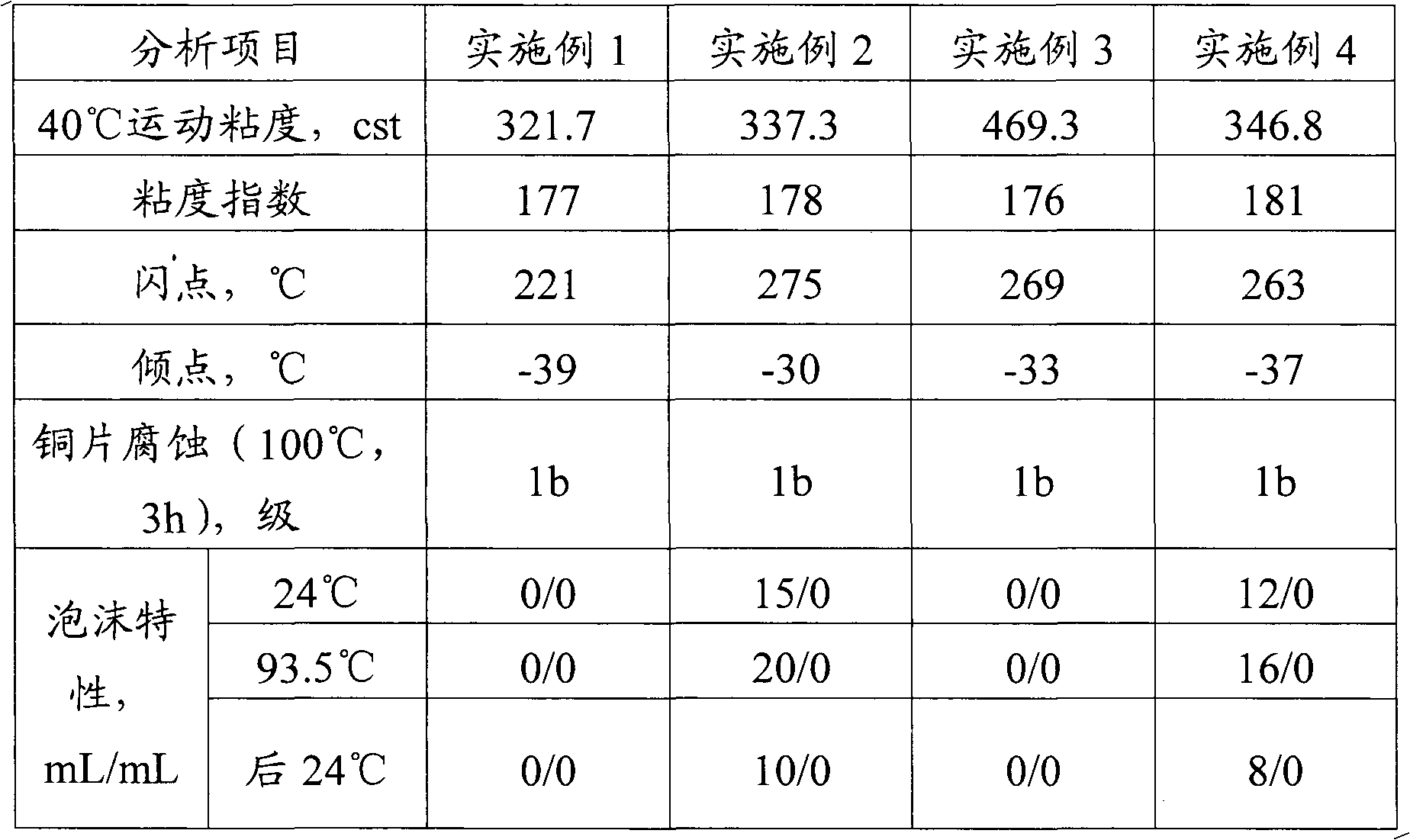

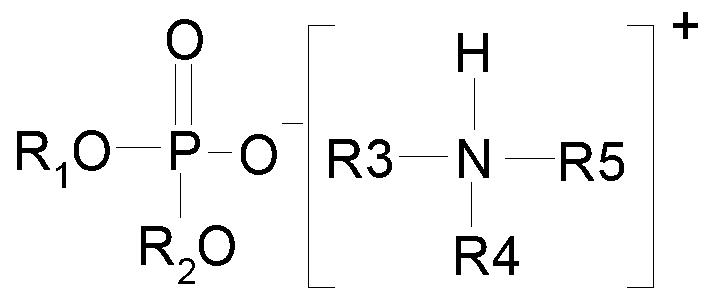

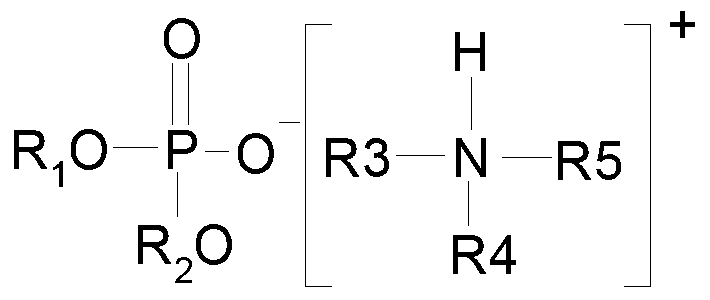

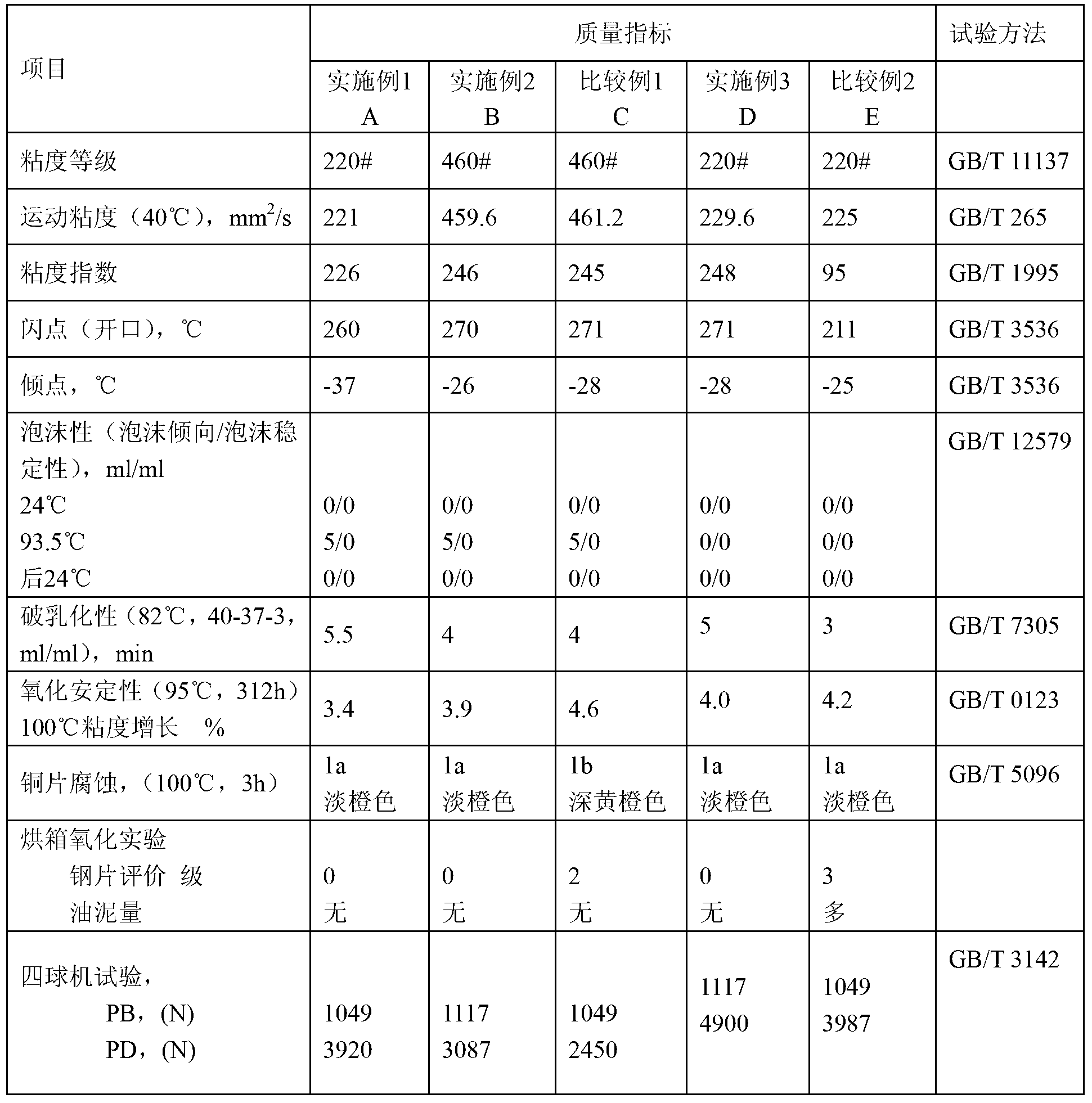

Worm and gear oil composition and preparation method thereof

ActiveCN103289797AWill not corrodeFree from chafingLubricant compositionDemulsifierChemical composition

The invention provides a worm and gear oil composition and a preparation method thereof. The worm and gear oil composition comprises at least one polyether base oil, at least one extreme-pressure anti-wear agent, at least one oiliness agent or friction modifier, at least one antioxidant of amine, phenolic or a mixture of the two, at least one metal deactivator, at least one demulsifier, and at least one anti-foam agent, wherein the viscosity of the polyether base oil at 40 DEG C is 40mm<2> / s-680mm<2> / s according to measurement with GB / T265, and the extreme-pressure anti-wear agent comprises phosphate amine salt with a specific structure. The worm and gear oil composition provided by the invention has an excellent extreme-pressure anti-wear property, causes no corrosion to non-ferrous metals and particularly copper, and has excellent high-temperature detergency, oxidation stability, lubricating oil properties and viscosity-temperature properties, a simple preparation method and a wide application range.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Friction modified lubricants

Mixtures of the reaction product of at least one C5-C60 carboxylic acid and at least one amine selected from the group consisting of guanidine, aminoguanidine, urea, thioruea and salts thereof and a phosphorus-containing dispersant are useful as gear oil additives. Lubricant formulations containing said mixtures exhibit excellent low and high temperature rheology and are particularly suited for use in automotive and industrial gear applications. Lubricants of the present invention exhibit improved performance properties such as increased axle efficiencies and lower axle temperatures compared to lubricant formulations that do not contain said mixtures.

Owner:AFTON CHEM INTANGIBLES

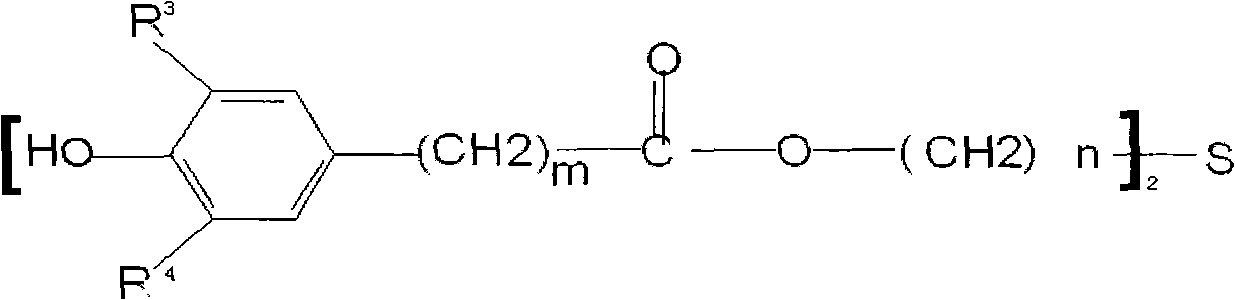

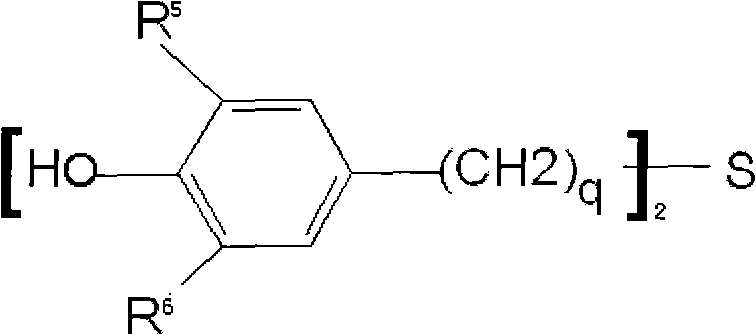

Anti-oxidation lubricating oil composition

The invention provides a lubricating oil composite antioxidant by using synergy generated by compounding among antioxidants of different types. The composite antioxidant at least comprises the following components: (1) alkylated diphenylamine antioxidant; (2) thiophenolic ester antioxidant; and (3) thioether phenolic antioxidant. The invention also provides a lubricating oil composition with oxidation stability. The invention also provides a method for improving oxidation stability of lubricating oil. The composite antioxidant does not contain diluent, can partially replace the consumption of zinc dialkyldithio-phosphate (ZDDP), has predominant effect of controlling the viscosity increment of oil, has obvious inhibiting effect on generation of sediments, and particularly has cleaning effect on the surface of a piston. The composite antioxidant has good compatibility with other component additives, and can be prepared into the lubricating oil composition such as hydraulic oil, steam turbine oil, gear oil, heat conducting oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com