Low-temperature and over-loading synthetic gear oil

A gear oil and load technology, applied in the field of lubricating oil, can solve problems such as difficult start, failure to meet gear oil viscosity and fluidity requirements, poor low temperature performance of mineral oil, etc., to achieve reduced dosage, strong shear resistance and adsorption strength , the effect of high thickening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

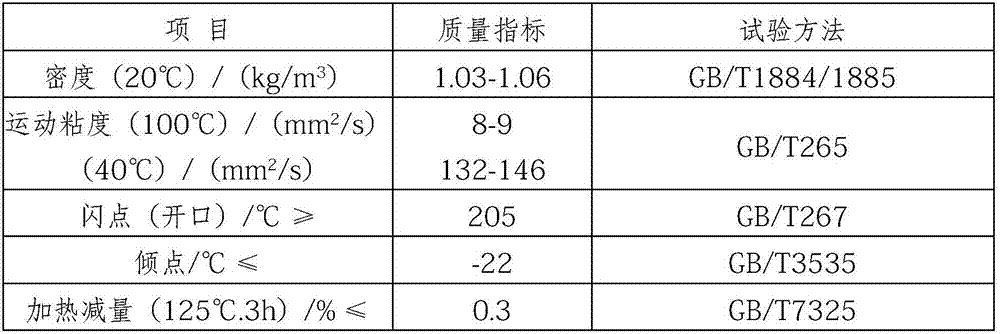

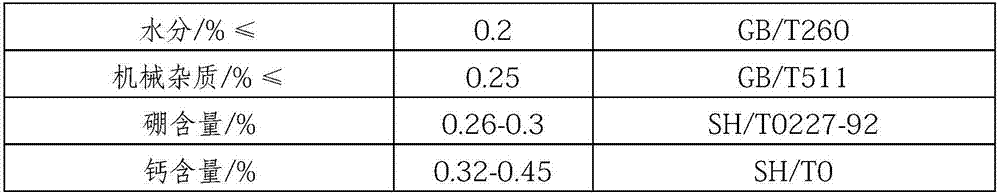

Method used

Image

Examples

Embodiment approach

[0055] According to a preferred embodiment, the mass percentage of the antioxidant in the synthetic gear oil is 2.5%, the mass percentage of the rust inhibitor is 0.1%, and the mass percentage of the metal deactivator is 1.0%, and the The mass percentage of the anti-emulsion agent is 0.5%, and the mass percentage of the anti-foaming agent is an additional 0.001%.

[0056] The present invention also provides a method for preparing low-temperature super-heavy-duty synthetic gear oil, the method comprising:

[0057] Add one-half of the mixed base oil into the blending kettle, raise the temperature to 85°C±5°C, add polymethacrylate viscosity index improver and stir continuously for 1h;

[0058] Add the remaining mixed base oil and keep the temperature at 60°C,

[0059] Add antioxidant, anti-rust agent, extreme pressure anti-wear agent, metal deactivator, anti-emulsifier, friction modifier, friction modifier, anti-foaming agent in sequence and continue to circulate and stir for 2-...

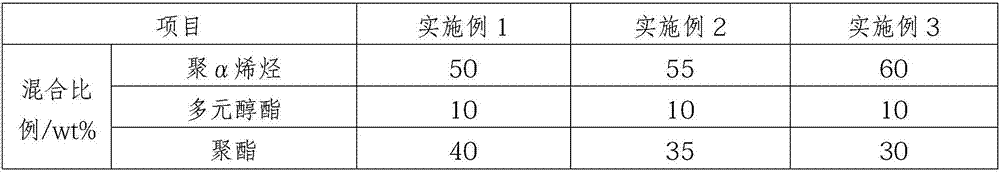

Embodiment 1

[0067] Add 1 / 2 base oil into the blending kettle, raise the temperature to 85°C±5°C, add polymethacrylate viscosity index improver (7.5%) and keep stirring for 1h. Add the remaining 2 / 3 base oil, keep the temperature at 60°C and add antioxidant L57 (1.0%), antioxidant N531 (1.5%), rust inhibitor T747A (0.1%), sulfurized isobutylene T2040 (5.5%), Phosphothioate amine salt T307 (2%), calcium hexadecyl borate (2%), liquid benzotriazole derivative L39 (0.5%), thiadiazole derivative RHY581 (0.5%), anti-emulsification Agent DL32 (0.5%), friction modifier M807 (0.3%), friction modifier G-204 (0.2%), antifoaming agent C-402 (0.001%), continue to circulate and stir for 2-3 hours, add the remaining 1 / 3 base oil, cooling to get the finished product.

Embodiment 2

[0069] Add 1 / 2 base oil into the blending kettle, raise the temperature to 85°C±5°C, add polymethacrylate viscosity index improver (7.5%) and keep stirring for 1h. Add the remaining 2 / 3 base oil, keep the temperature at 60°C and add antioxidant L57 (1.0%), antioxidant N531 (1.5%), rust inhibitor T747A (0.1%), sulfurized isobutylene T2040 (5.0%), Phosphothioate amine salt T307 (2.5%), calcium hexadecyl borate (2.0%), liquid benzotriazole derivative L39 (0.5%), thiadiazole derivative RHY581 (0.5%), anti-emulsification Agent DL32 (0.5%), friction modifier M807 (0.25%), friction modifier G-204 (0.25%), and added antifoaming agent C-402 (0.001%) continue to circulate and stir for 2-3 hours, and add the remaining 1 / 3 base oil, cooling to get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com