Silicone modified acrylic-polyurethane heterocomplexing water dispersion and preparing method thereof

A technology of acrylic polyurethane and acrylate, which is applied in the field of organosilicon-modified acrylic polyurethane hybrid aqueous dispersion and its preparation, can solve the problems of poor heat resistance and solvent resistance, poor stability, and unstable products, and achieve good durability Effect of thermal performance and chemical resistance, good heat resistance and solvent resistance, good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

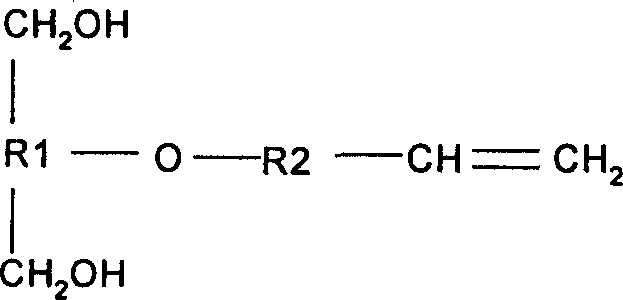

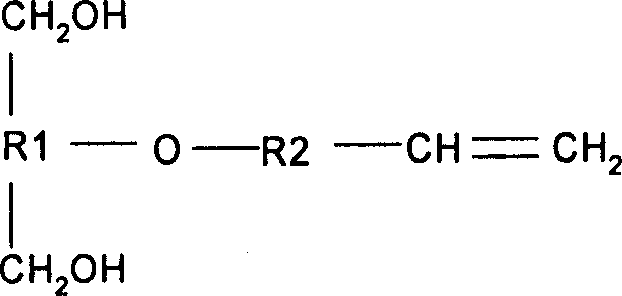

Method used

Image

Examples

Embodiment 1

[0038] The weight of each reaction raw material is as follows:

[0039] quality

[0040] No. Raw material name

[0041] (g)

[0042] 1 Isophorone diisocyanate 100.7

[0043] 2 polycaprolactone diol (Mn=1000) 26.3

[0044] 3 polyoxypropylene ether glycol (Mn=1000) 26.3

[0045] 4 Dibutyltin dilaurate 0.05

[0046] 5 1,4-butanediol 21.1

[0047] 6 2,2-di(hydroxymethyl)propionic acid 11.9

[0048] 7 N-methyl-2-pyrrolidinedione 14.6

[0049] 8 1,4-cyclohexyl dimethanol vinyl ether 8.2

[0050] 9 Triethylamine 8.4

[0051] 10 Methyl methacrylate 148.1

[0052] 11 Hexamethylenediamine 8.8

[0053] 12 Isopropanol 0.05

[0054] 13 Deionized water 766.6

[0055] 14 Initiator solution 21.5

[0056] 15 Butyl Acrylate 16.8

[0057] 16 γ-methacryloxypropyltriisopropoxysilane 3.8

[0059] Note: The initiator solution is prepared by dissolving 1.5g of azobisisobutyro...

Embodiment 2

[0079] Each reaction raw material and its weight composition are basically the same as Example 1, only the weight of 1,4-cyclohexyl dimethanol vinyl ether is increased, from 8.4g to 10.6g, 12.9g, 16.7g respectively, in order to maintain the overall The ratio of the amount of isocyanate group to hydroxyl group substance remains unchanged, and the mass parts of 1,4-butanediol are correspondingly reduced, and the reaction steps of Example 1 are used to prepare three organosilicon modifications with numbers A, B, and C respectively. Aqueous dispersion samples of acrylic polyurethane hybrids. The specific performance comparison of the three samples is as follows:

[0080] project result

[0081] A B C

[0082] Translucent None Translucent None Translucent None

[0083] Appearance of emulsion Mechanical impurities, no coagulation Mechanical impurities, no coagulation Mechanical impurities, no coagulation

[0084] ...

Embodiment 3

[0102] Each reaction raw material and its weight composition are basically the same as in Example 1, only the mass parts of functional organosiloxane γ-methacryloxypropyltriisopropoxysilane are increased from 3.8g to 4.3g, 6.1g, 10.2g, in order to keep the total amount of monomers unchanged, reduce the mass parts of methyl methacrylate correspondingly, and prepare three organic compounds with numbers D, E, and F respectively with the reaction steps of Example 1. Aqueous dispersion sample of silicon-modified acrylic polyurethane hybrid. The specific performance comparison of the three samples is as follows:

[0103] result

[0104] project

[0105] D E F

[0106] Translucent None Translucent None Translucent None

[0107] Appearance of emulsion Mechanical impurities, no coagulation Mechanical impurities, no coagulation Mechanical impurities, no coagulation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com