Patents

Literature

37results about How to "Strong resistance to extreme pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

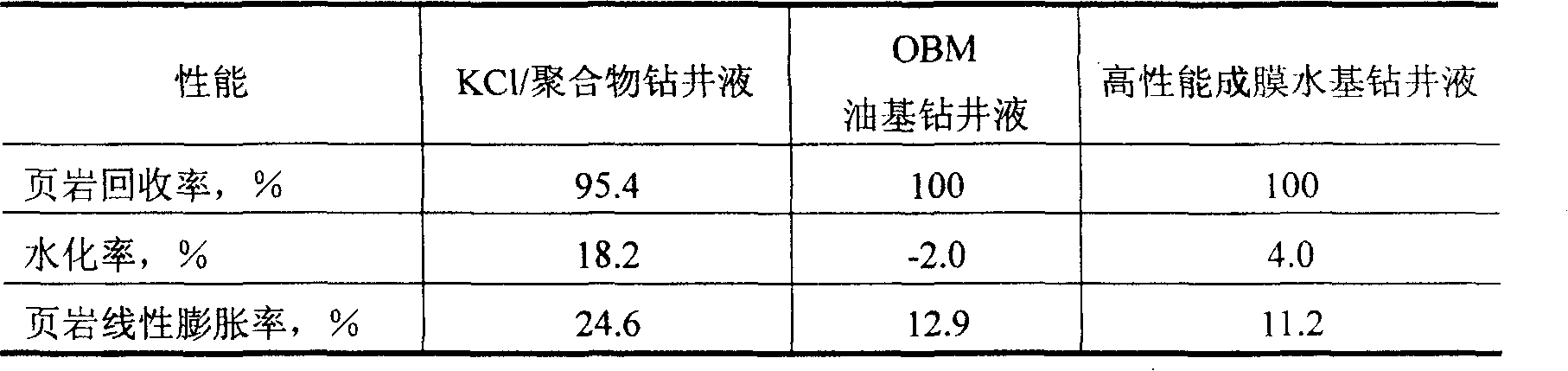

Method for preparing high-performance filming water-base drilling fluid

InactiveCN101200631AImprove the lubrication effectReduce frictionDrilling compositionWater basedFilm-forming agent

The present invention relates to a preparation method of a high-performance film-forming water-based drilling fluid system, which is characterized in that brine is used for confecting THE typical prescription of the high-performance film-forming water-based drilling fluid system, which is 10 percent of saturant NaCl solution, 1 percent to 3 percent of fluid loss additive, 0.3 percent to 0.5 percent of polymer viscosity increaser, 0.5 percent to 1 percent of coating agent, 2.5 percent to 5 percent of amine shale inhibitor, 3 percent to 4 percent of lubricant and 7 percent to 8 percent of film-forming agent. The drilling fluid system has the good performances of good film-forming character and strong inhibiting capability and is a novel drilling fluid system which can satisfy the requirement of the environmental protection and can replace oil-based drilling fluid (OBM).

Owner:张金波 +1

Nanometer lubricant for drilling fluid and preparation method of nanometer lubricant

InactiveCN108753269AGood dispersionLarge specific surface areaMaterial nanotechnologyDrilling compositionWater in oil emulsionSURFACTANT BLEND

The invention discloses a nanometer lubricant for a drilling fluid and a preparation method of the nanometer lubricant in the petroleum industry. The lubricant is added to the drilling fluid to improve the lubricity of the drilling fluid, and then the friction and the torque in the drilling process are reduced. The nanometer lubricant for the drilling fluid comprises linear alpha-olefin, nanosilicon dioxide, sulfide fatty acid ester, a surfactant and water, the preparation method comprises putting the linear alpha-olefin into a stirring kettle, controlling the temperature of the kettle to 25-30 DEG C, then proportionally adding the surfactant, stirring for 4 hours, proportionally adding the nanosilicon dioxide, stirring for 2 hours, then proportionally adding the sulfide fatty acid ester,stirring for 2 hours, proportionally adding water, controlling the water addition speed to be lower than or equal to 2 m<3> / h, and continuously stirring for 4 hours until an even water-in-oil emulsionis formed, wherein the water-in-oil emulsion is the nanometer lubricant for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

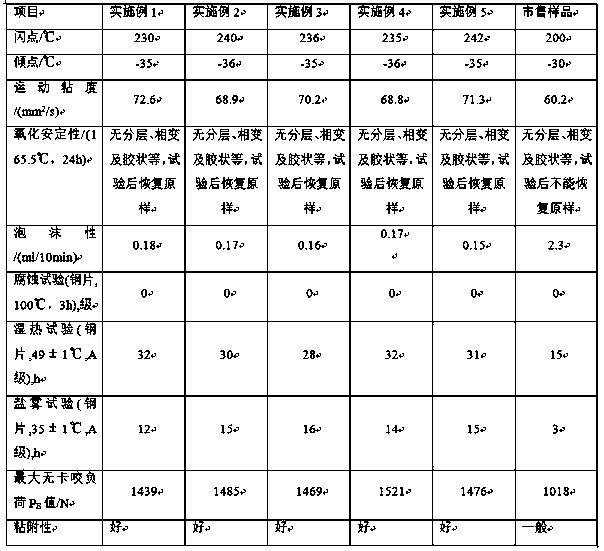

Preparation method of lubricating rust-preventive oil

InactiveCN108587737AImprove stabilityGood lubrication and anti-rust effectOrganic-compounds/hydrides/coordination-complexes catalystsAdditivesRosinFatty alcohol

The invention belongs to the technical field of lubricating oil processing, and concretely relates to a preparation method of lubricating rust-preventive oil. The preparation method comprises the following steps: phospho-tungstic acid and benzothiazoles ionic liquid are grafted to prepare an immobilized ionic liquid catalyst which is used for catalyzing a catalytic reaction of rosin borate, the lubrication anticorrosion performance of the cutting fluid is effectively increased, tallol is used as a raw material, liquid SO3 is taken as the catalyst, the material and monoethanolamine are subjected to a reaction to generate tall oil acid monoethanolamine, finally, rosin borate, tall oil acid monoethanolamine, butyl stearate, white oil, tung oil, sodium hexametaphosphate, phenoxy-1-propanol , fatty alcohol polyoxyethylene ether, sodium dodecyl benzene sulfonate, an anti-oxidant, and a bactericide are used as the raw materials to prepare the lubricating rust-preventive oil.

Owner:周文辽

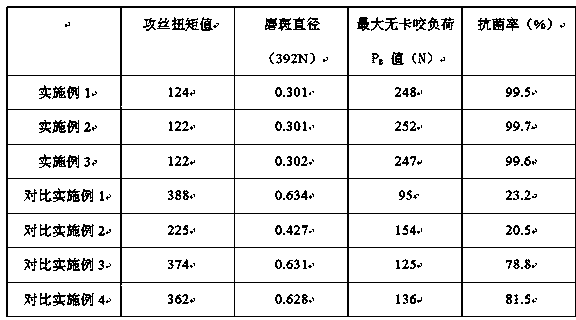

Metal cutting fluid containing nanometer titania of different particle sizes and preparation method of metal cutting fluid

InactiveCN109370717ALow tapping torque valueImprove the lubrication effectLubricant compositionVegetable oilSubstance.toxic

The invention discloses metal cutting fluid containing nanometer titania of different particle sizes and a preparation method of the metal cutting fluid. The prepared metal cutting fluid has low tapping torque and is excellent in lubricating property and low in grinding spot diameter, the wear resistance of the metal cutting fluid is excellent, the maximum non-seizure load PB value is great, the extreme pressure resistance is obvious, and the antibacterial property is outstanding. The metal cutting fluid does not contain sodium nitrite or any other substance toxic and harmful to the environment, takes vegetable oil as a main ingredient, is added with some high-efficiency additives, and is green, environmental-friendly, high-efficiency, simple in formula, excellent in antibacterial propertyand difficult to deteriorate. Due to the addition of silver-loaded graphene, silver particles are loaded among graphene sheet layers, so that the dispersion property of the graphene is further enhanced, the sheet stripping is full, and the anti-wear and friction reducing properties of the prepared cutting fluid are enhanced. Meanwhile, the cutting fluid is endowed with an antibacterial effect, the cutting fluid is difficult to deteriorate, and the storage period is prolonged.

Owner:五河富强鑫金属制品有限公司

Method for preparing metal cutting fluid with high extreme pressure resistance

InactiveCN102703197AStrong resistance to extreme pressureImprove rust resistanceLubricant compositionCarboxylic acidOleic Acid Triglyceride

The invention discloses a method for preparing a metal cutting fluid with high extreme pressure resistance. The method for preparing the metal cutting fluid with high extreme pressure resistance comprises the following steps of: 1) synthesizing diethanolamine-boric acid-polycarboxylic acid complex ester, namely performing esterification reaction of diethanolamine, polycarboxylic acid and boric acid in a molar ratio of 3:1:1 at the temperature of 150 to 155 DEG C for 2 to 4 hours; 2) synthesizing diethanolamine-boric acid-maleic anhydride complex ester, namely performing esterification reaction of diethanolamine, maleic anhydride and boric acid in a molar ratio of 3:1:1 at the temperature of 150 to 155 DEG C for 2 to 4 hours; 3) raising the temperature of water to 70 to 80 DEG C, sequentially adding lead naphthenate, oleic acid, barium petroleum sulfonate, triethanolamine, borax, sodium silicate and nitrobenzoic acid under stirring, continuing to stir for 20 to 40 minutes, reducing the temperature to 50 to 60 DEG C, adding sodium molybdate and boric acid under the condition of constant stirring, stirring for 20 to 30 minutes, adding methylsilicone oil, and stirring for 10 to 20 minutes; and 4) mixing products obtained in step 1)-3), and stirring at the temperature of 50 to 60 DEG C for 60 to 90 minutes to obtain the metal cutting fluid.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Efficient wear-resistant lubricating oil and preparation method thereof

InactiveCN107384551AImprove antioxidant capacityReduce wearLubricant compositionWear resistantAntioxidant

The invention discloses efficient wear-resistant lubricating oil. The efficient wear-resistant lubricating oil is prepared from components in parts by weight as follows: 40-60 parts of base oil, 30-40 parts of chlorinated paraffin, 20-30 parts of triphenyl phosphate, 10-30 parts of nano-graphite, 10-20 parts of nano-metal oxide, 5-15 parts of nano-aluminum, 3-8 parts of sepiolite, 5-10 parts of mica powder, 2-8 parts of sodium bentonite, 4-10 parts of calcium carbonate, 1-5 parts of an antioxidant, 0.5-3 parts of an antirust agent, 0.4-0.8 parts of an antifoaming agent and 0.2-0.8 parts of a pour point depressant. According to the efficient wear-resistant lubricating oil, defects of poor stability, weak oxidation resistance and poor wear-resistant effect in the prior art can be overcome, the lubricating oil with good stability, high anti-oxidative capacity and remarkable wear-resistant effect is provided, so that mechanical wear is reduced, and service life of machinery is prolonged.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Lubricating oil for gears

ActiveCN106221871AImprove resistance to decompositionImprove wear resistanceLubricant compositionParticulatesGear wheel

The invention discloses a lubricating oil for gears. The lubricating oil is prepared from modified base oil, succinate, diethylenetriamine penta(methylene phosphonic acid), octyl diphenylamine, sorbitol, nano copper powder, C12 dibasic acids, beta-sitosterol, cholesteryl nonanoate, ethanediol amide cocoate and auxiliary additives. The lubricating oil for gears has the characteristics of favorable oxidation resistance, favorable corrosion resistance, favorable rust resistance, favorable wear resistance, favorable anti-friction property, high torque, favorable high-temperature stability, favorable demulsibility, long oil change period, favorable biodegradability and lower price than the traditional lubricating oil, and reduces the emissions of waste oil, waste gas and particles. The lubricating oil has the advantages of favorable viscosity, favorable lubricating property, favorable cooling property, excellent viscosity-temperature characteristics, high viscosity index, low condensation point and high flash point, and well reduces the friction between gear pairs.

Owner:东营国安化工有限公司

Multifunctional oil cutting fluid for metal finish machining and preparation method thereof

InactiveCN108048178AImprove antioxidant capacitySmall smellLubricant compositionNonferrous metalBase oil

The invention provides a multifunctional oil cutting fluid for metal finish machining. The multifunctional oil cutting fluid comprises the following raw materials by weight percentage: 75-98% of baseoil; 1-8% of an extreme pressure agent; 1-10% of a lubricant; and 0.1-7% of a compound agent. The base oil is class II hydrogenated oil. The extreme pressure agent is the sulfur-containing extreme pressure agent and high alkali value calcium petroleum sulfonate, wherein the sulfur-containing extreme pressure agent contains 10-30% of sulfur, has excellent anti-extreme pressure properties, and has negligible smell compared with that of sulfurized olefin, sulfur is inactive at a temperature of 100DEG C or below, is non-corrosive to nonferrous metals and black metals, and at the same time the additive also has good lubrication performance. High alkali value calcium petroleum sulfonate can provide very high extreme pressure resistance, and also has certain detergency.

Owner:CHANGHONG PRECISION TOOL DONGGUAN CO LTD

Lubricating oil for bearings

The invention discloses lubricating oil for bearings. The lubricating oil is prepared from the following components of modified base oil, succinate, dodecenylsuccinic acid ester, octyl diphenylamine, sorbitol, nanometer copper powder, lignin sodium sulphate, beta-sitosterol, cholesteryl nonanoate and poly(paraphenylene) terephthalamide. The lubricating oil disclosed by the invention is good in cooling properties and excellent in lubrication effects, and can be adapted to most application occasions, the antirust property of the lubricating oil can be greatly improved, the lubrication effects of the lubricating oil are also improved, the pour point is low, the friction coefficient of the lubricating oil at high temperature cannot be greatly changed, and the lubricating oil is high in stability, low in cost, good in viscosity index, high in abrasion resistant properties and long in service life. The lubricating oil disclosed by the invention has the characteristics of being light in color, high in polarity, good in fluidity and good in storage capability. The lubricating oil can be widely applied to mechanical lubrication, machinery can be well protected, besides, energy is saved, and consumption is reduced, so that the lubricating oil has wide application prospects.

Owner:深圳市龙威科技发展有限公司

Lubricating oil special for gears

InactiveCN104371813AImprove wear resistanceImprove cooling effectLubricant compositionSulfite saltMethyl benzoate

The invention relates to lubricating oil for gears. The lubricating oil comprises, by weight, 50-70 parts of 650SN base oil, 5-15 parts of 250BS base oil, 15-25 parts of 150BS base oil, 3-6 parts of polyvinyl ether, 4-8 parts of calcium alkylbenzene sulfonate, 3-7 parts of ethylene-propylene copolymer, 1-4 parts of sodium sulfite, 4-6 parts of sodium dodecyl benzene sulfonate, 7-11 parts of trichloromethane, 2-6 parts of methyl benzoate, 3-5 parts of antioxidant, 2-4 parts of triethanolamine, 1.5-3 parts of dispersing agent, 0.2-1.5 parts of extreme pressure anti-wear agent and 1.0-3.5 parts of metal deactivator, wherein the metal deactivator contains benzotriazole or thiadiazole. The lubricating oil is good in wear resistance, capable of bearing high temperature generated by the high-speed rotation and the meshing of the gears, good in cooling performance, high in extreme pressure resistance, and suitable for engines and large machinery.

Owner:CHONGQING JIAZHOU LUBRICATING OIL

Wearing-resistant vehicle lubricating oil and preparation method thereof

InactiveCN108485764AGood extreme pressure resistanceGood wear resistanceLubricant compositionParaffin waxLubrication

The invention discloses wearing-resistant vehicle lubricating oil which comprises the following raw materials in parts by weight: 20-30 parts of polybutylene synthetic oil, 15-30 parts of corn oil, 8-15 parts of nano diamonds, 1-3 parts of poly-boron amine, 7-11 parts of oxymolybdenum dialkydithiophosphate, 2-6 parts of sodium citrate, 4-9 parts of polyimide, 6-12 parts of modified bentonite, 8-13parts of liquid paraffin, 9-15 parts of pentaerythritol, 5-14 parts of an antioxidant and 3-7 parts of an anti-corrosion anti-rusting agent. The wearing-resistant vehicle lubricating oil is scientific and reasonable in formula, a product made of the lubricating oil is excellent in extreme pressure resistance, high in bearing capability, high in wearing resistance and in addition high in low-temperature flowability, and excellent long-lasting lubrication properties can be achieved.

Owner:合肥市闵葵电力工程有限公司

An environmentally friendly anti-wear lubricant

The invention discloses eco-friendly anti-wear lubricating oil, which is made from the following components: modified base oil, succinate, a cleanup agent, octyl diphenylamine, an antifoaming agent, an anti-friction and anti-wear synergist, dodecanedioic acid, beta-sitosterol, cholesteryl nonanoate, castor oil and auxiliary additives. The lubricating oil is excellent in antioxidant corrosion resistance, anti-rust property, anti-wear property, anti-friction property, bearing property, corrosion resistance and emulsion resistance, and is high in torque, long in oil change period, reduced in waste oil, and low in price when compared with conventional lubricating oil. The lubricating oil is good in chemical stability and lubricating property and excellent in high and low temperature resistance, can be totally biodegraded and is free of toxicity. The lubricating oil causes no effect on operators' health during research and development, production and use processes, has no effect on the environment, and is a green product conforming to environmental requirements. The lubricating oil is low in production cost, simple in preparation technology, and suitable for industrial production.

Owner:杭州高翔润滑油有限公司

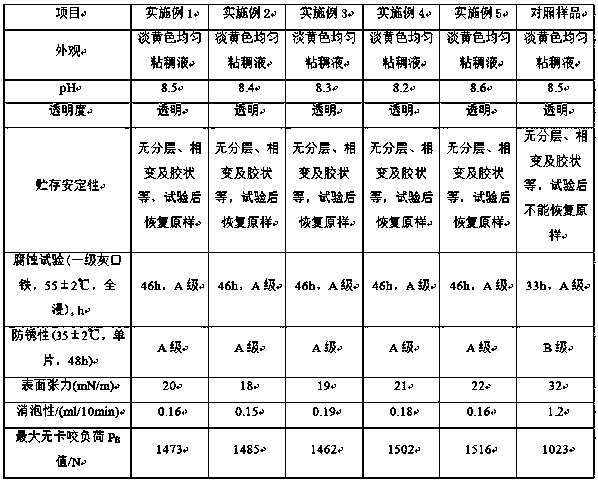

Preparation method of microemulsified cutting fluid

InactiveCN108329984AImprove easy oxidationImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsLubricant compositionRosinLubrication

The invention belongs to the technical field of cutting fluid processing, and in particular, relates to a preparation method of microemulsified cutting fluid. The preparation method includes the preparation steps: grafting phosphotungstic acid with a benzothiazole ionic liquid to prepare an immobilized ionic liquid catalyst for catalyzing a catalytic reaction of rosin borate, so as to effectivelyimprove the lubricating and anticorrosion properties of the cutting fluid; then with toll oil as a raw material and liquid SO3 as a catalyst, carrying out a reaction with monoethanolamine to produce tall oil acid monoethanolamine; and finally, with rosin borate, tall oil acid monoethanolamine, tung oil, mineral oil, swill-cooked dirty oil, fatty alcohol-polyoxyethylene ether, polydimethylsilane, polyacrylate, water and a bactericide as raw materials, preparing the microemulsified cutting fluid. The prepared microemulsified cutting fluid has excellent various properties and good lubrication andrust resistance.

Owner:周文辽

High basicity boron-containing composite mahogany sulfonate and its preparation method and use

ActiveCN1990466AHigh Total Base NumberImprove detergencyAdditivesSulfonic acid preparationAlkalinitySulfonate

The invention provides a boron-containing compound sulfonate with high alkalinity, sodium and magnesium containing alkylbenzenesulfonate, preparing method, and the application of said boron-containing compound sulfonate as lubricant additive. The method comprises following steps: mixing alkylbenzene sulfonic acid, sodium alkali compound, magnesium alkali compound with low carbon alchol, water, diluting oil and accelerator for reaction; feeding carbon dioxide for carbonation, adding boron compounds, separating and getting final product. The said boron containing sulfonate is characterized by good anti-extreme pressure, anti-oxygen and cleaness, high total alkalinity and adjustable sodium and magnesium content. The content of said boron-containing compound sulfonate used as lubricatant additive in oil should be less than 5% by weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antifriction lubricating oil for lead pig cold granulating machine

InactiveCN106867636AImprove cooling effectImprove the lubrication effectLubricant compositionTurpentineSodium sulfate

The invention discloses antifriction lubricating oil for a lead pig cold granulating machine. The antifriction lubricating oil is prepared from base oil, zinc naphthenate, trisodium phosphate, octyl diphenylamine, turpentine, lignin sodium sulfate, attapulgite, nanometer sericite, cholesteryl nonanoate and coconut oil acid glycol amide. The antifriction lubricating oil provided by the invention has the advantages of excellent cooling property, excellent lubricating effect, capability of greatly promoting the anti-rusting property and lubricating effect of the lubricating oil, low flow point, no huge change in friction coefficient under high temperature, high stability and low cost.

Owner:蚌埠市华鼎机械科技有限公司

Corrosion resistant cast iron cutting fluid

InactiveCN104845719AStrong resistance to extreme pressureReduce wearAdditivesDodecylsulfonic acidSulfonic acid ester

A corrosion resistant cast iron cutting fluid is formed by the following raw materials in parts by weight: 1-4 parts of petroleum sodium sulfonate, 2-5 parts of glycerinum, 4-5 parts of dodecyl trimethyl ammonium chloride, 5-6 parts of sodium dodecyl sulfate, 3-6 parts of sebacic acid, 6-8 parts of polyacrylate, 2.4-3.5 parts of sodium carbonate, 1-5 parts of dodecylbenzene sulfonic acid, 2-3 parts of per-fluororated poly ethers, 4-5 parts of sodium tripolyphosphate, 2-6 parts of zirconium fluoride, 3-5 parts of laurate polyoxyethylene ester, and 7-11 parts of engine oil. The corrosion resistant cast iron cutting fluid has the beneficial effects that the corrosion resistant cast iron cutting fluid is very strong in extreme pressure resistance, abrasion is reduced and the machining precision of a workpiece is high.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

A kind of guide rail oil and production method thereof

ActiveCN104371807BRapid cooling of working contact surfacesAvoid slight deformationAdditivesAntioxidantDepressant

The invention discloses a guide rail oil and a production method thereof. The main points of the technical solution of the present invention are: a guide rail oil, which is mainly prepared from the following components in weight percentage: base oil 75%-90%, antirust agent 1%-5%, anticorrosion agent 1% ‑5%, antioxidant 1%‑10%, fungicide 0.1%‑2%, pour point depressant 1%‑10% and anti-emulsifier 0.1%‑2%. The invention also discloses a production method of the rail oil. The invention has the characteristics of good extreme pressure performance, good emulsification resistance, long service life and excellent lubricating, cooling and antirust functions.

Owner:HENAN NORMAL UNIV

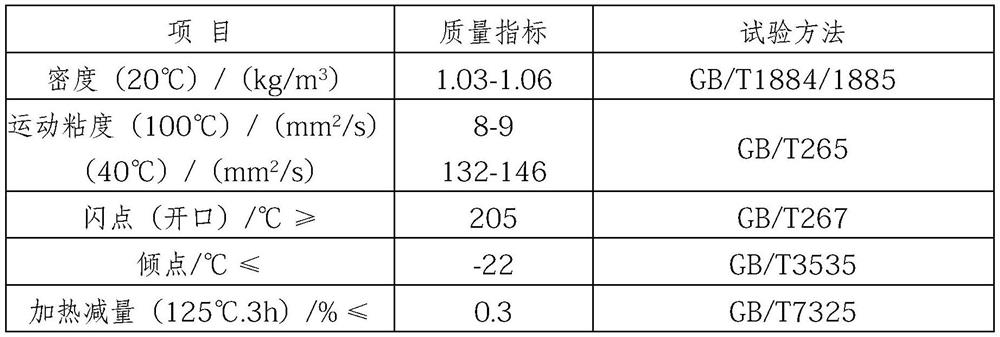

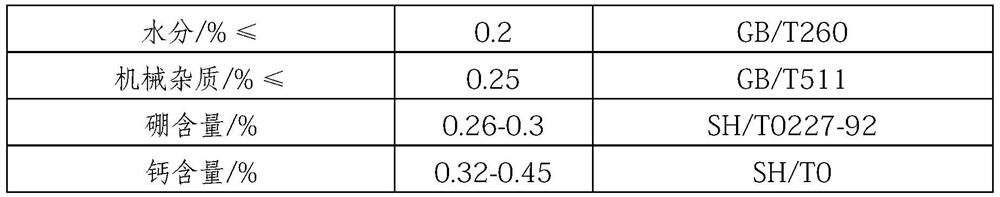

Lubricating oil, with high bearing force, for automobile absorber

The invention discloses lubricating oil, with high bearing force, for an automobile absorber and relates to the technical field of automobile components. The lubricating oil, with high bearing force,for the automobile absorber is prepared from the following components in percentage by mass: 2.55-2.59 percent of camellia-seed oil-maleic anhydride copolymer and 0.012-0.014 percent of maleic anhydride modified nanometer diatomite. The lubricating oil, with high bearing force, for the automobile absorber is good in cooling performance and lubricating effect, can greatly improve the anti-rust property and the lubricating effect of the lubricating oil, is low in pour point, cannot be changed too much in friction coefficient at high temperature and is strong in stability, high in bearing abilityand low in cost.

Owner:安徽东星主动减振科技有限公司

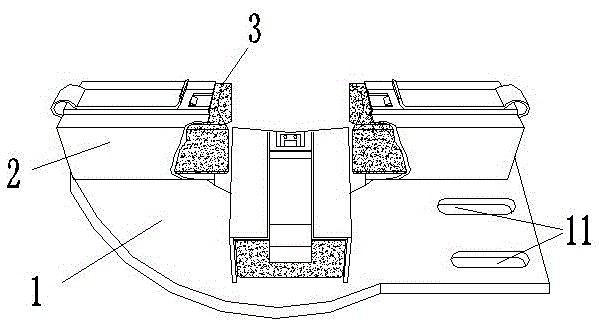

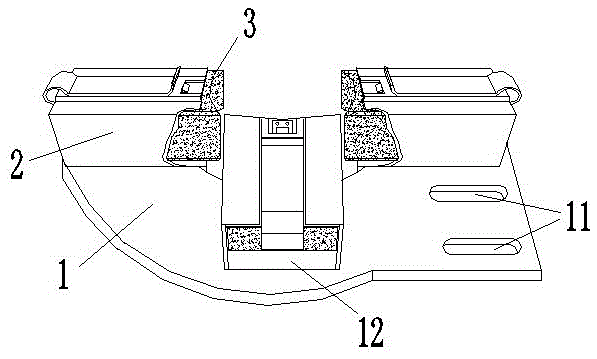

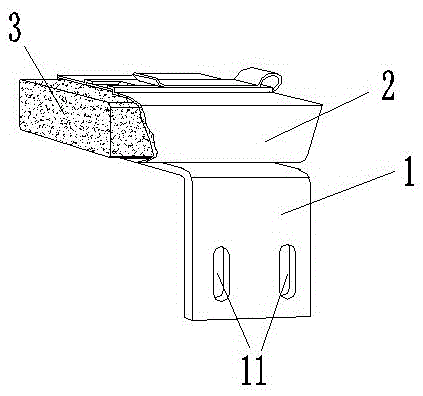

Solid lubricator

The invention discloses a solid lubricator. The solid lubricator comprises a fixed base; a solid lubricating device is arranged on the fixed base and comprises a solid lubricating block storage box; the solid lubricating block storage box is arranged on the fixed base; a solid lubricating block is mounted in the solid lubricating block storage box; a solid lubricating block propelling device is arranged on the solid lubricating block storage box and is connected with the solid lubricating block in a resisting manner. The solid lubricator disclosed by the invention is simple in structure, green, environment-friendly, clean and sanitary, is easy and convenient to repair, replace and maintain, and is low in using cost.

Owner:ZHEJIANG BAOSHENG RAILWAYNEW MATERIALS TECH

Cylinder sleeve and preparation method thereof

ActiveCN110791701AFill dendrite voidsGood self-lubricating performanceFurnace typesQuenching agentsWear corrosionThermal fatigue

The invention provides a cylinder sleeve. The cylinder sleeve comprises the following components including, by weight, 2.3%-3.0% of C, 1.5%-2.5% of Si, 0%-0.15% of P, 0.05%-0.1% of S, 2.1%-3.0% of Mn,3.5%-4.0% of Cu, 0.05%-0.1% of Pb and the balance Fe. According to the cylinder sleeve, the cylinder sleeve prepared through a cylinder sleeve formula adopting the specific components has high tensile strength and elastic modulus, good thermal conductivity and good corrosion resistance, and the inner wall wear surface has good wear resistance, abrasion reduction and thermal fatigue resistance; moreover, the component composition and the production process of the cylinder sleeve are simple, and the cost is low; and the cylinder sleeve can effectively reduce the frequency of cylinder sleeve replacing due to failures caused by wear, corrosion, thermal fatigue and the like, so that the service life of the cylinder sleeve is prolonged, and the production cost of the cylinder sleeve is obviously reduced.

Owner:ZYNP GRP

Special gear lubricating oil high in oxidation resistance

The invention relates to a special gear lubricating oil high in oxidation resistance. The special gear lubricating oil is composed of, by weight, 50-70 parts of 650SN base oil, 5-15 parts of 250BS base oil, 15-25 parts of 150BS base oil, 3-6 parts of polyvinyl ether, 4-8 parts of alkyl benzene sulfonic acid, 3-7 parts of ethylene-propylene copolymer, 1-4 parts of sodium sulfite, 4-6 parts of sodium dodecyl benzene sulfonate, 2-6 parts of methyl benzoate, 0.7-2.5 parts of complex antioxidant, 2-4 parts of triethanolamine, 0.2-1.5 parts of extreme-pressure antiwear agent, 1.0-3.5 parts of metal deactivator, 1.0-3.0 parts of detergent and 1.5-3 parts of dispersing agent. The special gear lubricating oil has the advantages of excellent wear resistance, capability of bearing high temperature generated by high-speed gear rotation and engagement, excellent cooling performance, high extreme pressure resistance and applicability to engines and large machines.

Owner:CHONGQING JIAZHOU LUBRICATING OIL

Method for preparing composite lithium-calcium based grease by using waste lithium based lubricating grease as raw materials

The invention belongs to the technical field of recovery or processing of carboxylic ester containing waste materials, and particularly relates to a method for preparing composite lithium-calcium based grease by using waste lithium based lubricating grease as raw materials. The method comprises the following steps that A, the recovered waste lithium based lubricating grease is diluted by mineral oil until the penetration degree is 420 to 480; mechanical impurities are removed; then, 12-oxystearic acid and stearic acid are added; heating is performed to 80 DEG C; then, a calcium hydroxide watersolution is added; stirring reaction is performed for 4 to 6h under the condition of 80 DEG C to 100 DEG C; the temperature is raised to 160 DEG C; dehydration is performed until the water mass content is smaller than or equal to 0.05 percent; cooling is performed to be smaller than or equal to 60 DEG C; B, anti-oxidizing preservatives, anti-wear reagents at extreme pressure, benzotriazole and benzotriazole derivatives are added into the mixture obtained in the step A; stirring, homogenating and desaeration are performed to obtain the composite lithium-calcium based grease. The composite lithium-calcium based grease prepared by the method has excellent high temperature resistant performance, excellent compressive performance and excellent water sprinkling loss performance.

Owner:重庆化工职业学院

Extreme pressure-resistant cutting fluid

InactiveCN104152233AStrong resistance to extreme pressureLubricant compositionButanedioic acidSuccinic acid

The invention discloses an extreme pressure-resistant cutting fluid, which is prepared from the following raw materials in parts by weight: 6-14 parts of barium petroleum sulfonate, 2-6 parts of oleic acid, 1.2-5 parts of sodium molybdate, 3-6 parts of diethanolamine borate-maleic anhydride complex ester, 5-11 parts of alkenyl succinic acid, 1.5-2.5 parts of film forming additive, 2-3.5 parts of sebacic acid, 1.3-3.4 parts of naphthenic oil, and 20 parts of water. The extreme pressure-resistant cutting fluid has the beneficial effects of being excellent in extreme pressure resistance, and good in cooling and lubrication functions.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

Lubricating oil for bearings

Owner:深圳市龙威科技发展有限公司

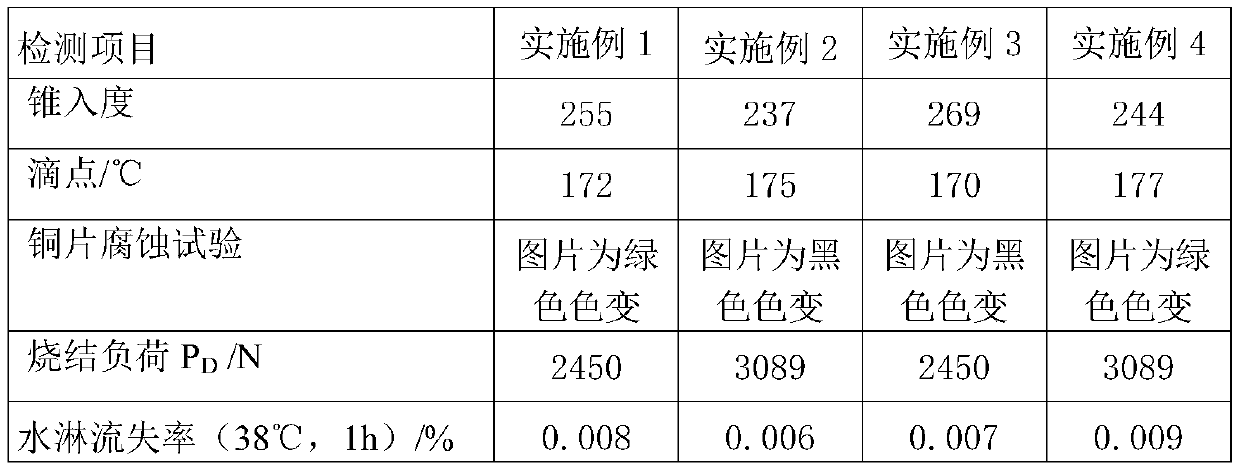

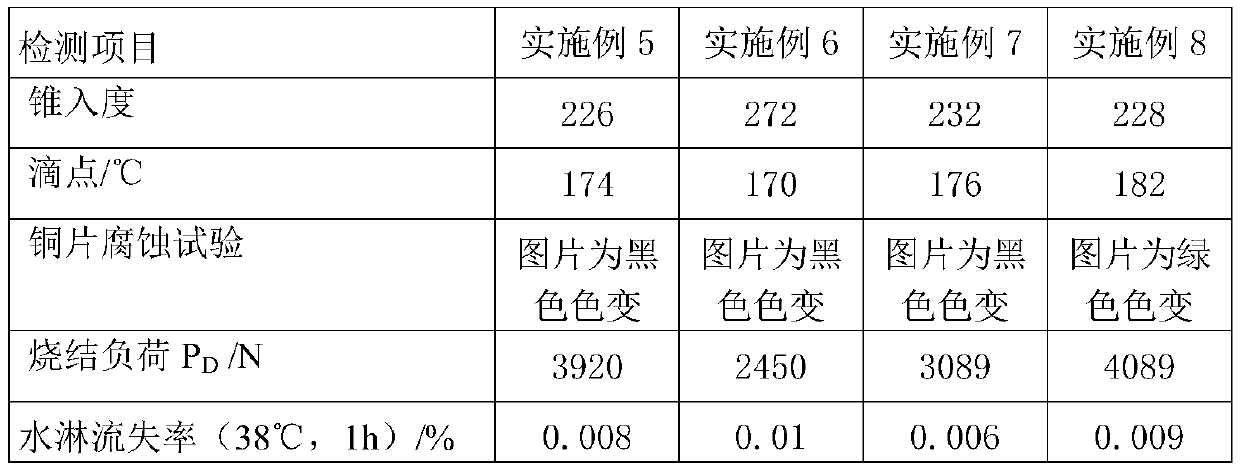

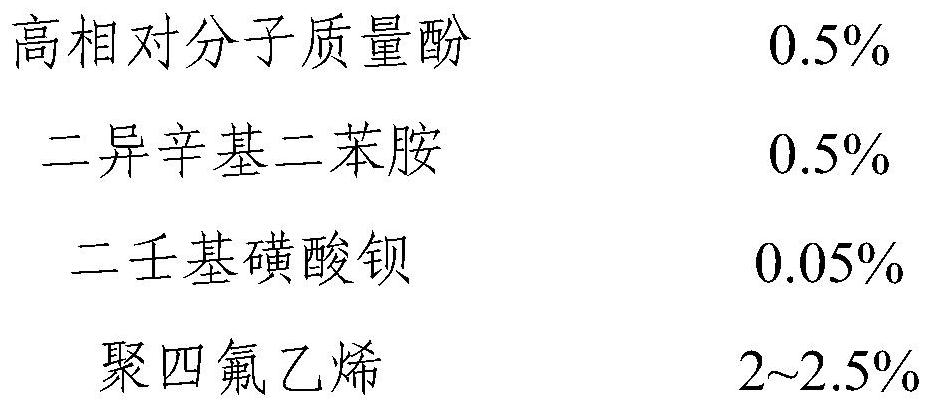

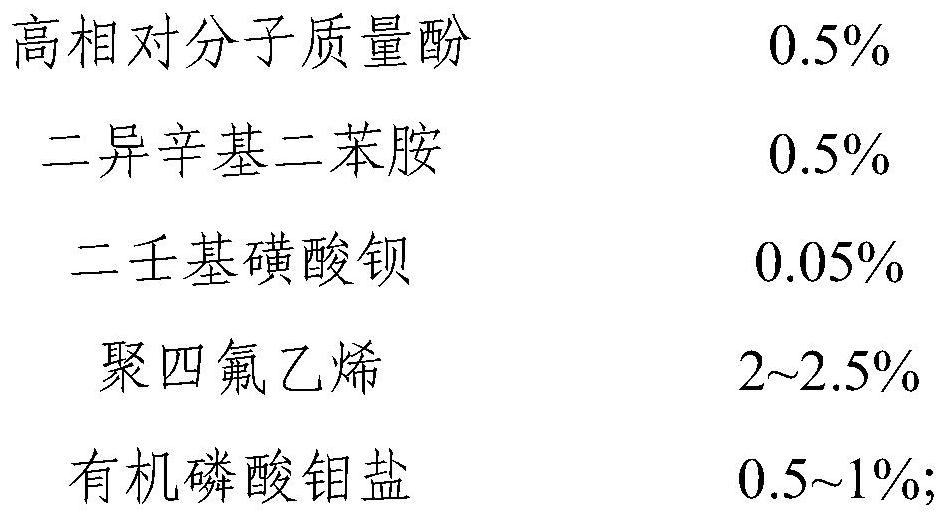

Transmission shaft spline lubricating grease composition and preparation method and application thereof

InactiveCN111808657AImprove water resistanceImprove antioxidant capacityBiocideAnimal repellantsSulfonatePhosphate

The invention relates to the technical field of lubricating grease, in particular to a transmission shaft spline lubricating grease composition and a preparation method and application thereof. The main components of the transmission shaft spline lubricating grease composition comprise base oil, a thickening agent, an antioxidant, an antirust agent and an extreme pressure anti-wear agent, whereinthe thickening agent is a composite lithium thickening agent; the viscosity of the base oil at 100 DEG C is 9-30 mm < 2 > / s; the antioxidant is an amine antioxidant and / or a phenol antioxidant; the antirust agent is barium sulfonate; the extreme pressure anti-wear agent is organic molybdenum phosphate and / or polytetrafluoroethylene; the thickening agent accounts for 10-15% of the total mass of themain components; and based on the total mass of the main components, the use amount of the extreme pressure anti-wear agent is 2.5-5%. Various properties of the transmission shaft spline lubricatinggrease composition are superior to those of products in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP

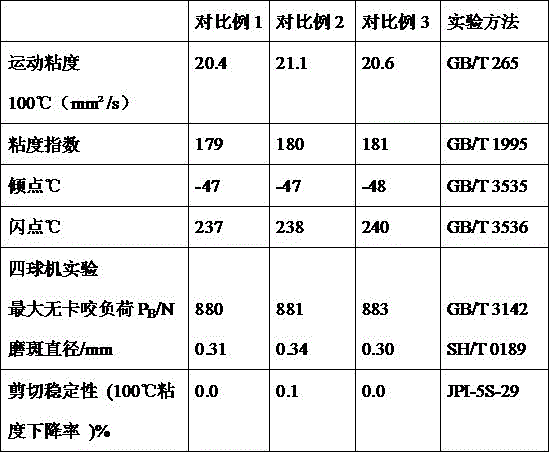

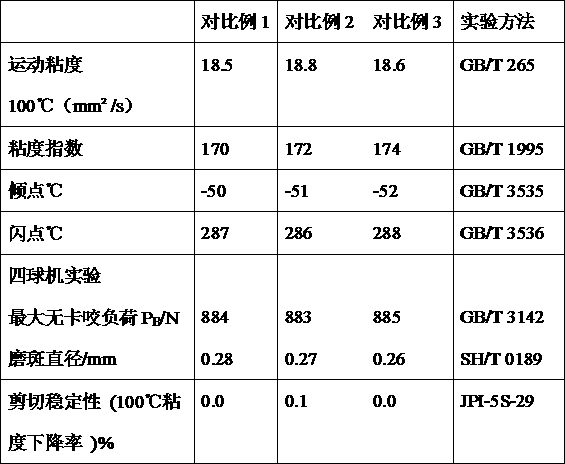

A low-temperature super-heavy-duty synthetic gear oil

ActiveCN107312598BImprove liquidityStrong resistance to extreme pressureLubricant compositionPolyolefinEngineering

The present invention relates to a low-temperature super-heavy duty synthetic gear oil, the synthetic gear oil at least comprises the following components: extreme pressure antiwear agent, friction modifier, viscosity index improver and base oil, wherein the extreme pressure antiwear agent is at least Including oil-soluble nano-borate, the viscosity index improver includes at least modified polymethacrylate tackifier, and the friction modifier includes at least organic molybdenum; wherein the base oil includes polyalphaolefin and esters The mixed base oil of oil, the mass percentage of described mixed base oil is 78.4%, the mass percentage of described improved methacrylate tackifier is 7.5%, the mass percentage of described oil-soluble nano borate is 2%, The mass percentage of the organic molybdenum is 0.2-0.3%. The gear oil of the present invention has excellent low-temperature performance, can effectively extend the service life of the oil, and the solid borate film formed by the borate has good extreme pressure resistance, can withstand a huge load, and has excellent Anti-wear and anti-friction properties.

Owner:北京雅士科莱恩石油化工有限公司

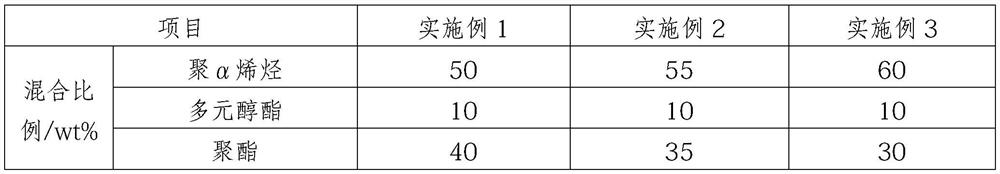

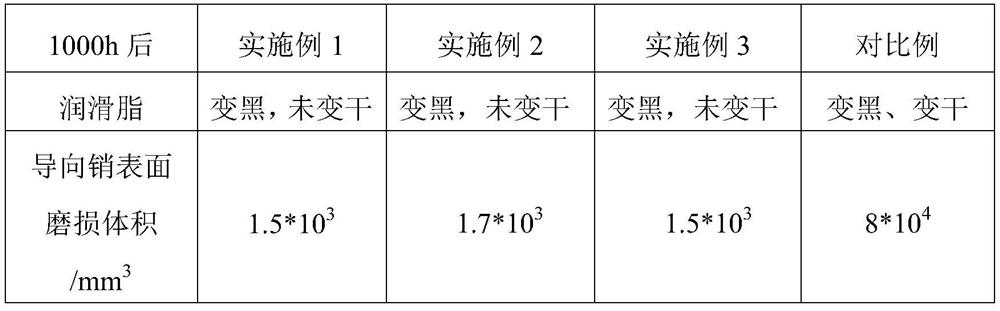

Special lubricating grease for caliper guide pin

ActiveCN114276854AStrong resistance to extreme pressureIncrease the extreme pressure valueLubricant compositionChemical reactionAntioxidant

The invention discloses special lubricating grease for a caliper guide pin, which is prepared from the following components in parts by mass: 80 to 90 parts of base oil, 0.1 to 0.5 part of nanoscale sulfide additive, 1.65 to 3 parts of extreme pressure agent, 1 to 2 parts of corrosion inhibitor, 5.5 to 7 parts of thickening agent, 0.1 to 0.5 part of peptizing agent and 0.1 to 0.5 part of antioxidant, the nanoscale sulfide additive is one or more of copper sulfide nanoparticles, nickel sulfide nanoparticles and zinc sulfide nanoparticles, and the thickening agent is formed by compounding lithium 12-hydroxystearate, dilithium azelate and palmitic acid. The nano-scale sulfide additive is added in the formula, nano-particles are large in surface area and active in chemical property, the nano-particles and the abraded surface are prone to chemical reaction, a sediment film and a chemical reaction film are formed, and the fretting wear of the caliper guide pin can be obviously improved.

Owner:DONGFENG MOTOR GRP

Lubricating oil specially used for automotive chassis

InactiveCN108034481AExtended service lifeReduce maintenance costsLubricant compositionCarrying capacityAntioxidant

The invention discloses lubricating oil specially used for automotive chassis. The lubricating oil is prepared from the following raw materials in parts by weight: 60-80 parts of high viscosity base oil, 15-25 parts of modified nano-graphite, 3-7 parts of an antioxidant, 1-5 parts of an anti-wear agent, 18-28 parts of a pour point depressant and 14-20 parts of molybdenum thiophosphate. The lubricating oil is specially used for the automotive chassis; by adding additives in to the lubricating oil in a matching way, the lubricating oil can effectively remove thick black carbon mud particles on bearing parts, thus prolonging the service lives of bearings of the automotive chassis and reducing the maintenance cost of equipment; furthermore, the antioxidant is also added into the lubricating oil, so that the oxidation resistance of the oil product is improved, and the storage and service lives of the oil product are prolonged. The prepared lubricating oil shows excellent extreme pressure resistance and high carrying capacity, is good in wear resistance, and also can provide excellent long-acting lubricating property.

Owner:徐州瀚德机械有限公司

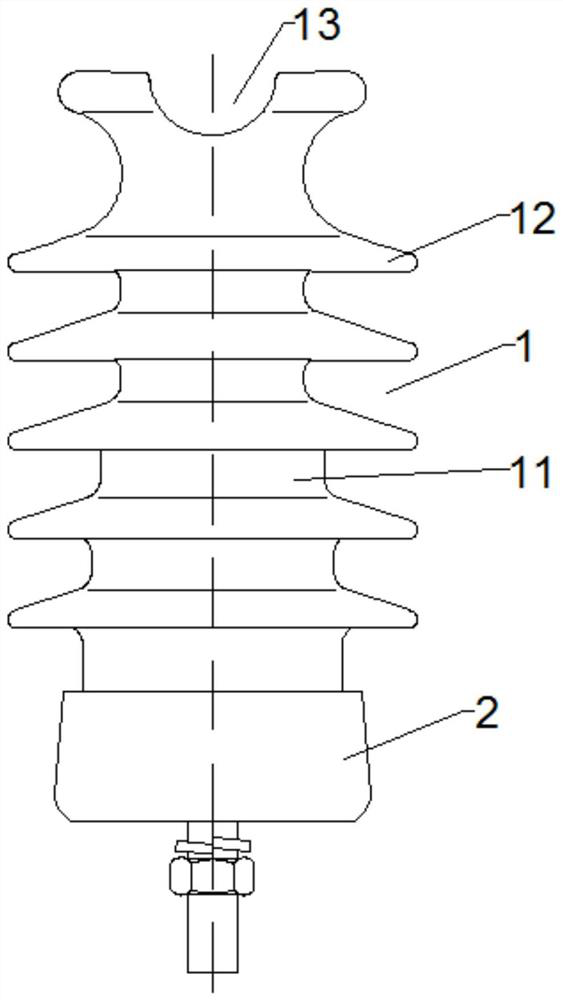

Line column type porcelain insulator and preparation method thereof

PendingCN114141443AImprove wettabilityGood dispersionSupporting insulatorsCeramic materials productionZincThermal shock

The invention relates to the technical field of insulators, and provides a line column type porcelain insulator and a preparation method thereof. And by carrying out zinc-nickel permeation layer treatment on the metal accessory, the corrosion resistance is greatly improved, the insulator can adapt to complex environmental conditions, and the service life of the insulator is prolonged. The composition of the mud blank is reasonable, the compactness and hardness of a network can be improved, the strength and thermal shock resistance of an insulator are improved, and the insulator is high in mechanical strength and can adapt to harsh weather conditions. And the sintering process of temperature programming is adopted, so that formation of various crystals and functional products in the insulator is facilitated, and various properties of the insulator are improved.

Owner:江西新龙电瓷电器制造有限公司

First grinding liquid of steel ball and preparation method of first grinding liquid

InactiveCN103436344AGood water solubilityNo stratificationInorganic pigment treatmentLubricant compositionMetallurgySteel ball

The invention discloses first grinding liquid of a steel ball, which is prepared by mixing the following raw components by weight percentage: 8-12% of oleic acid, 7-9% of sodium carbonate, 14-16% of detergent 105, 1-2% of antifoaming agent, 1-2% of caustic soda flake and the balance of water. A preparation method comprises the steps of adding the raw components in a formula to hot water in a reaction kettle, sufficiently stirring and obtaining the first grinding liquid. The first grinding liquid of the steel ball has the characteristics of simplicity in preparation, low raw material cost and good using effect, and has the advantage of less environmental pollution.

Owner:安徽舒城云飞工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com