Metal cutting fluid containing nanometer titania of different particle sizes and preparation method of metal cutting fluid

A technology of nano-titanium dioxide and metal cutting fluid, which is applied in the petroleum industry, lubricating compositions, etc., can solve environmental pollution and other problems, and achieve the effects of outstanding antibacterial performance, extended shelf life, and low wear spot diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

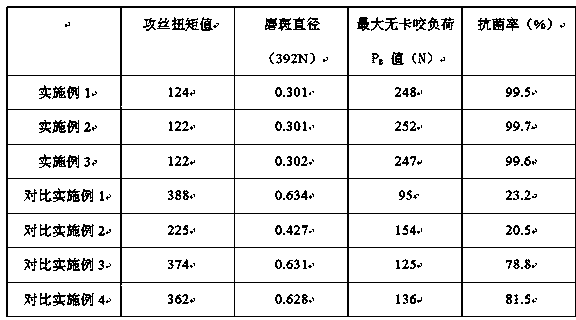

Examples

Embodiment 1

[0023] A metal cutting fluid containing nano-titanium dioxide with different particle sizes is made from the following raw materials in parts by weight:

[0024] Nano-titanium dioxide with large particle size 8, nano-titanium dioxide with small particle size 10, silver-loaded graphene 5, sodium dodecylbenzenesulfonate solution 3, palm oil 30, camellia oil 20, diethanolamine 40, maleic anhydride 10, lauric acid 10, Tween 80 3, PTFE emulsion 4.

[0025] Further, its preparation method comprises the following steps:

[0026] (1) Add nano-titanium dioxide with large particle size and nano-titanium dioxide with small particle size to 20 times its volume of acetone solution, and then add silver-loaded graphene and dodecylbenzenesulfonic acid with a mass fraction of 2% Sodium solution, ultrasonically treated at 180Hz for 30min to obtain an aqueous phase dispersant;

[0027] (2) Mix palm oil, camellia oil, diethanolamine, maleic anhydride, and lauric acid, and react at 90°C and 300 ...

Embodiment 2

[0038] A metal cutting fluid containing nano-titanium dioxide with different particle sizes is made from the following raw materials in parts by weight:

[0039] Large particle size nano-titanium dioxide 10, small particle size nano-titanium dioxide 13, silver-loaded graphene 6, sodium dodecylbenzenesulfonate solution 4, palm oil 50, camellia oil 30, diethanolamine 50, maleic anhydride 15, lauric acid 12, Tween 80 4, PTFE emulsion 5.

[0040] Further, its preparation method comprises the following steps:

[0041] (1) Add nano-titanium dioxide with large particle size and nano-titanium dioxide with small particle size to 25 times its volume of acetone solution, and then add silver-loaded graphene and 3% dodecylbenzenesulfonic acid by mass fraction Sodium solution, ultrasonically treated at 190Hz for 40min to obtain an aqueous phase dispersant;

[0042] (2) Mix palm oil, camellia oil, diethanolamine, maleic anhydride, and lauric acid, and react at 100°C and 350 rpm for 140 min...

Embodiment 3

[0053] A metal cutting fluid containing nano-titanium dioxide with different particle sizes is made from the following raw materials in parts by weight:

[0054] Large particle size nano-titanium dioxide 12, small particle size nano-titanium dioxide 16, silver-loaded graphene 8, sodium dodecylbenzenesulfonate solution 6, palm oil 60, camellia oil 40, diethanolamine 60, maleic anhydride 20, lauric acid 15, Tween 80 5, PTFE emulsion 6.

[0055] Further, its preparation method comprises the following steps:

[0056] (1) Add nano-titanium dioxide with large particle size and nano-titanium dioxide with small particle size to 30 times its volume of acetone solution, and then add silver-loaded graphene and 4% dodecylbenzenesulfonic acid by mass fraction Sodium solution, ultrasonic treatment at 200Hz for 60min, to obtain an aqueous phase dispersant;

[0057] (2) Mix palm oil, camellia oil, diethanolamine, maleic anhydride, and lauric acid, and react at 120°C and 400 rpm for 160 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com