Vegetable oil-based environmentally-friendly metal cutting fluid and preparation method thereof

A metal cutting fluid and vegetable oil-based technology, applied in the field of metal cutting fluid, can solve the problems of poor cooling and cleaning capabilities, poor anti-rust and anti-corrosion performance, insufficient anti-extreme pressure performance, etc., to improve anti-wear and anti-friction performance And the effect of anti-rust performance, improved anti-rust performance and good anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

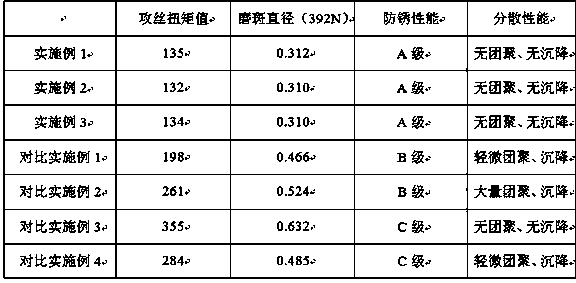

Examples

Embodiment 1

[0019] A vegetable oil-based environment-friendly metal cutting fluid is characterized in that it is made of the following raw materials in parts by weight:

[0020] Nano cubic boron nitride 5, sodium dodecylbenzene sulfonate 2, octadecylamine 4, polyaniline 20, soybean oil 40, castor oil 10, coconut oil 5, anionic surfactant 3, aqueous dispersion 30.

[0021] Further, its preparation method comprises the following steps:

[0022] (1) The nano-cubic boron nitride is subjected to the following pretreatment: place it at -30°C and 2MPa for 4 hours, then take it out and perform ball milling. After forward ball milling at 120°C for 20 minutes, reverse ball milling at -20°C for 40 minutes. Then place it at 100°C for 1 hour, then place it in an ethanol solution 30 times its volume, ultrasonically disperse at 50°C for 20 minutes, filter, and dry at 80°C;

[0023] (2) Add the product obtained in step (1) to 50 times its volume of deionized water, then add sodium dodecylbenzenesulfonat...

Embodiment 2

[0030] A vegetable oil-based environment-friendly metal cutting fluid is characterized in that it is made of the following raw materials in parts by weight:

[0031] Nano cubic boron nitride 10, sodium dodecylbenzene sulfonate 3, octadecylamine 5, polyaniline 22, soybean oil 50, castor oil 13, coconut oil 7, anionic surfactant 5, aqueous dispersion 40.

[0032] Further, its preparation method comprises the following steps:

[0033] (1) The nano-cubic boron nitride is subjected to the following pretreatment: place it at -32°C and 2.2MPa for 4 hours, then take it out and perform ball milling. After forward ball milling at 122°C for 25 minutes, reverse ball milling at -23°C for 45 minutes , and then placed at 102°C for 2 hours, then placed in 40 times its volume of ethanol solution, ultrasonically dispersed at 55°C for 25 minutes, filtered, and dried at 90°C;

[0034] (2) Add the product obtained in step (1) to 70 times the volume of deionized water, then add sodium dodecylbenze...

Embodiment 3

[0041] A vegetable oil-based environment-friendly metal cutting fluid is characterized in that it is made of the following raw materials in parts by weight:

[0042] Nano cubic boron nitride 15, sodium dodecylbenzene sulfonate 3, octadecylamine 7, polyaniline 25, soybean oil 60, castor oil 15, coconut oil 10, anionic surfactant 6, aqueous dispersion 60.

[0043] Further, its preparation method comprises the following steps:

[0044](1) The nano-cubic boron nitride is subjected to the following pretreatment: place it at -35°C and 2.6MPa for 5 hours, then take it out and perform ball milling. After forward ball milling at 125°C for 30 minutes, reverse ball milling at -25°C for 50 minutes , and then placed at 105°C for 2 hours, then placed in 50 times its volume of ethanol solution, ultrasonically dispersed at 60°C for 30 minutes, filtered, and dried at 100°C;

[0045] (2) Add the product obtained in step (1) to 100 times the volume of deionized water, then add sodium dodecylben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com