Patents

Literature

109results about How to "Improve anti-wear and anti-friction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

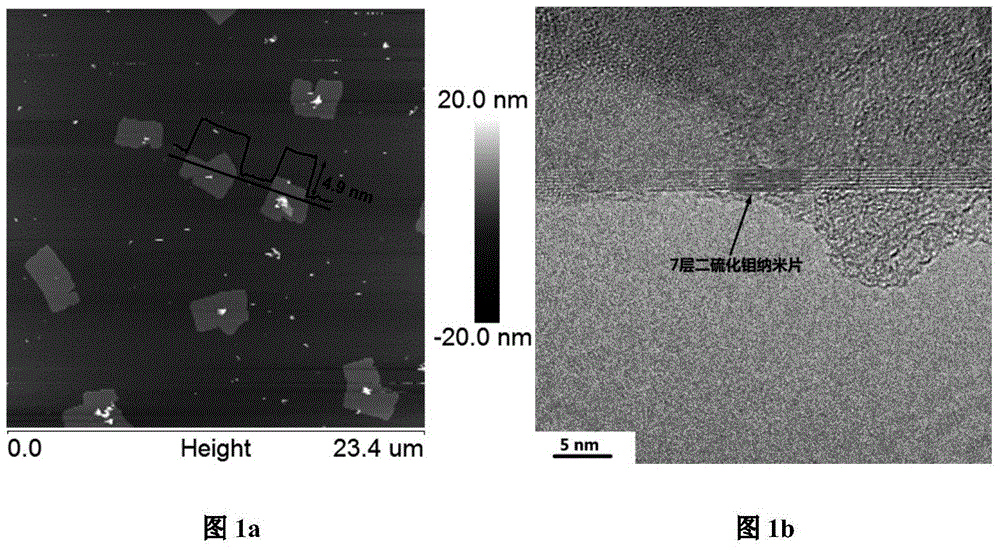

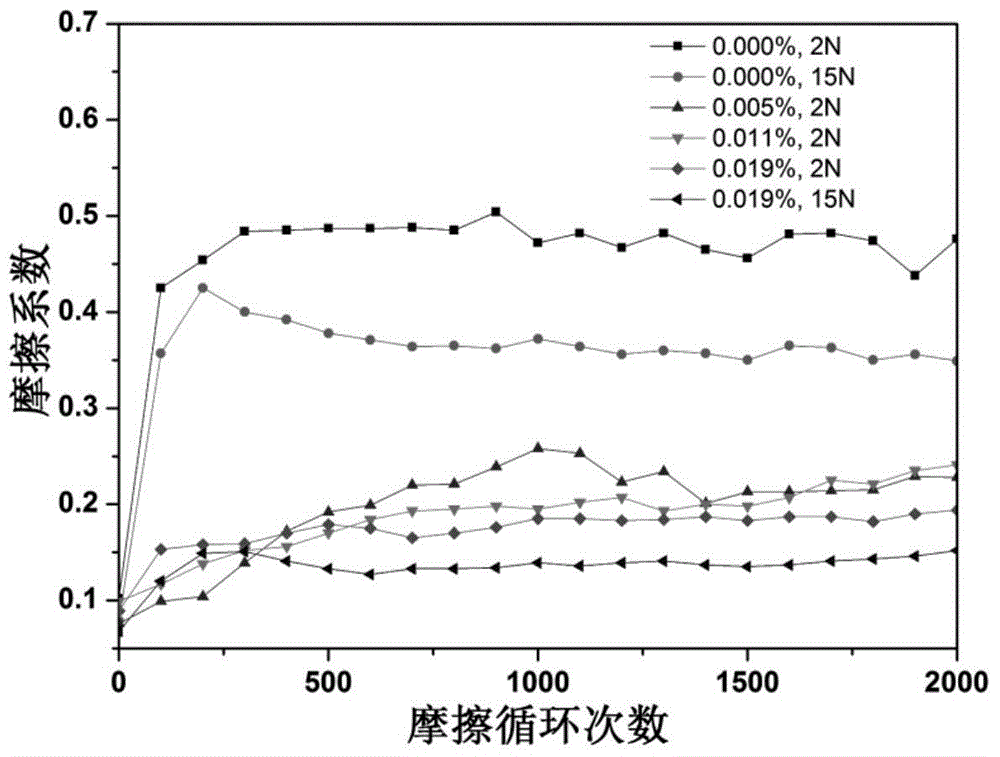

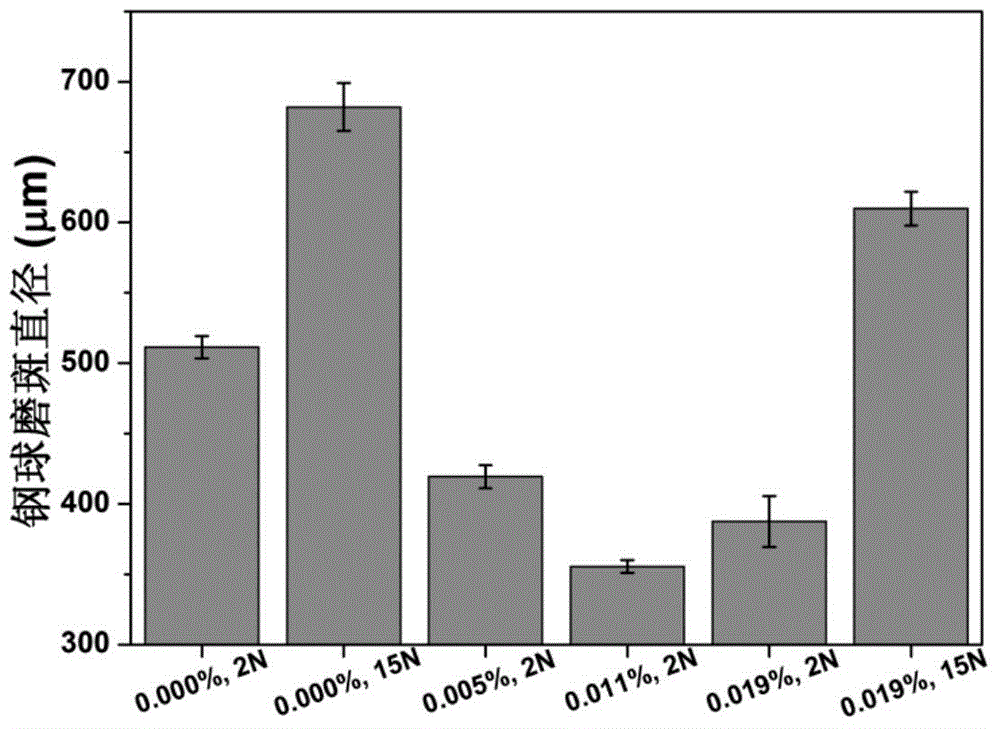

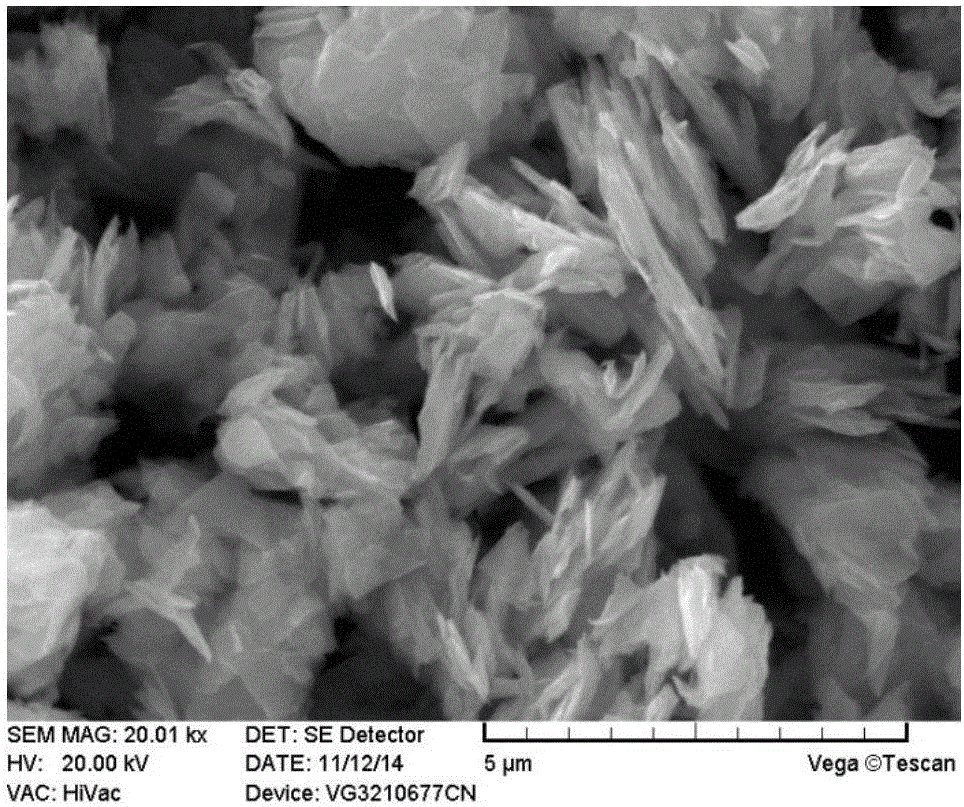

In-situ preparation method of water-based lubricant containing molybdenum disulfide nanosheet

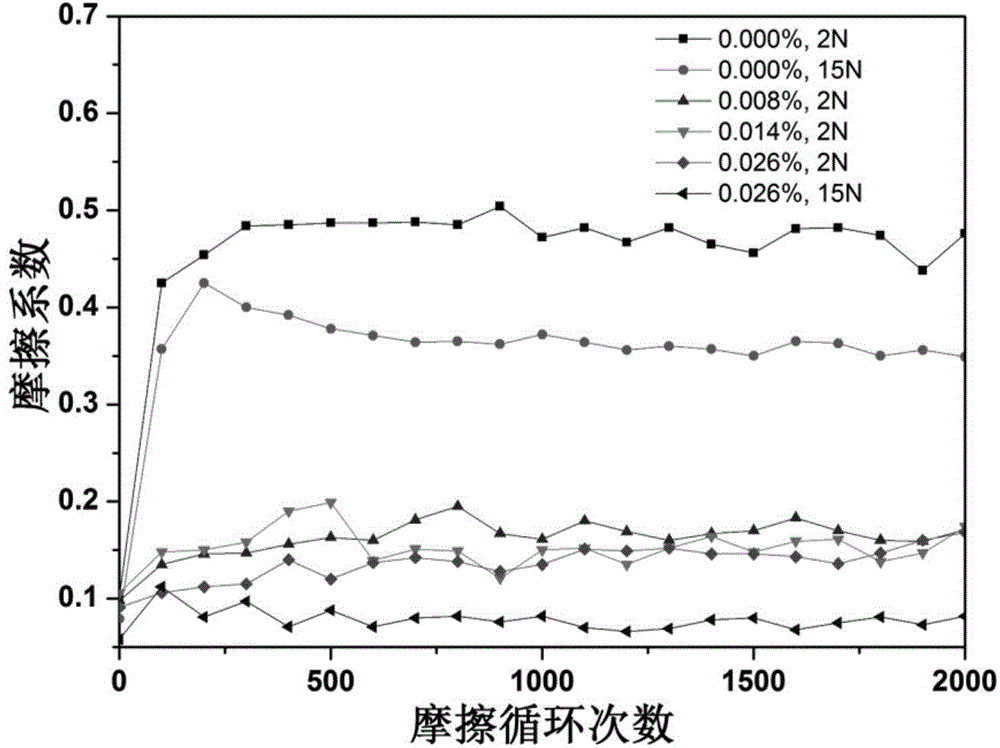

An in-situ preparation method of a water-based lubricant containing a molybdenum disulfide nanosheet comprises six steps as follows: (1), a surface active agent is dissolved in deionized water in a proportion to obtain a solution; (2), molybdenum disulfide powder is uniformly dispersed into the solution; (3), a molybdenum disulfide dispersion liquid is subjected to ultrasonic cavitation processing; (4), the solution is left to stand for a certain period of time, and a supernatant liquid of the solution is taken; (5), the obtained solution is subjected to centrifugal separation processing; (6) the supernatant liquid of the centrifugal solution is collected, and the water-based lubricant containing the in-situ prepared molybdenum disulfide nanosheet is obtained. The method is easy, convenient and feasible, and the dispersion stability of the molybdenum disulfide nanosheet is good. A friction experiment result indicates that the wear-resistant and anti-friction performance of the lubricant can be greatly improved by adding a small quantity of the molybdenum disulfide nanosheet on the premise that the original excellent characteristics of good cooling performance and processability and the like of the water-based lubricant are not influenced, and the addition quantity of the molybdenum disulfide nanosheet ranges from 0.001% to 1%.

Owner:BEIHANG UNIV

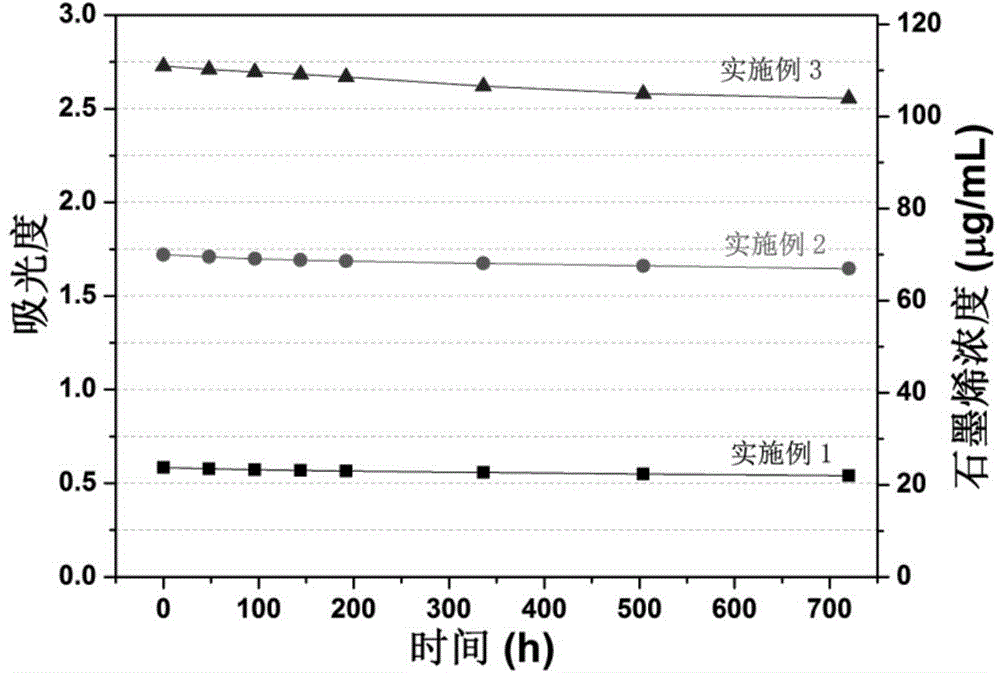

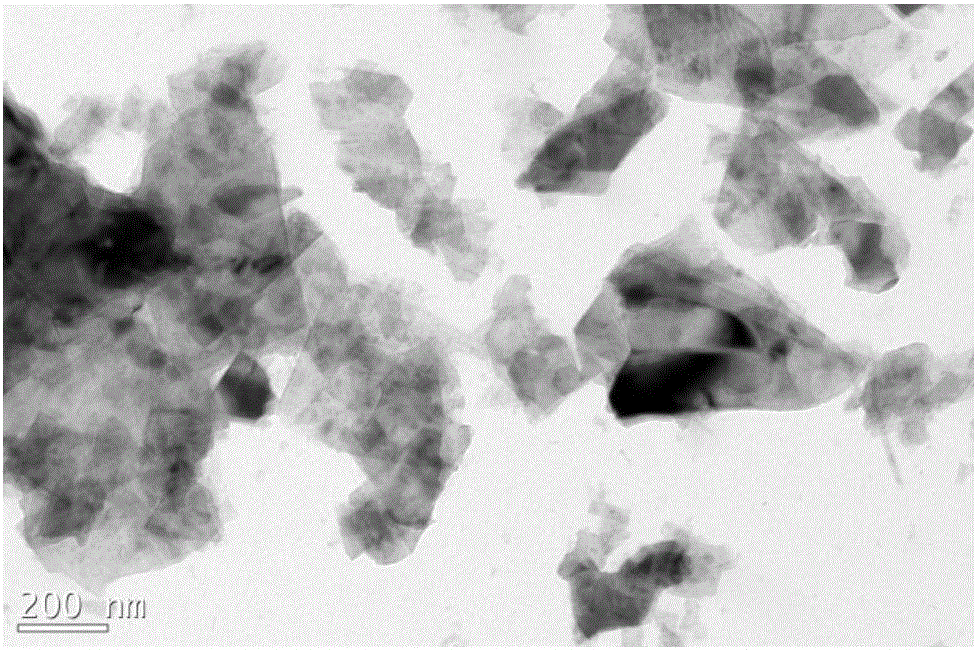

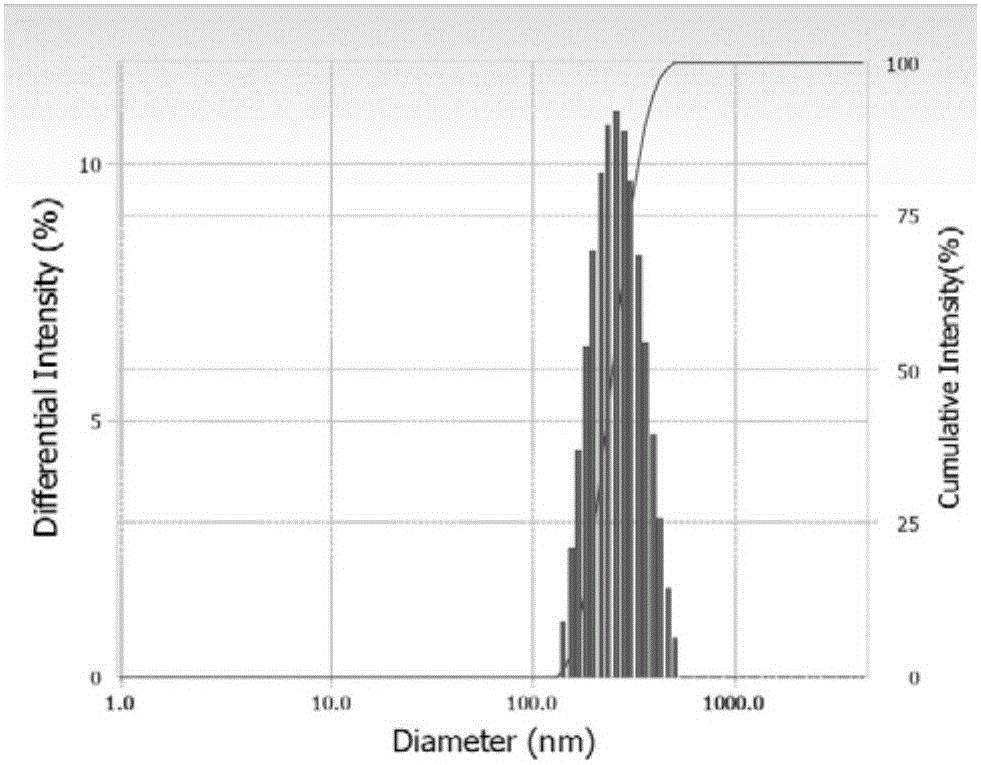

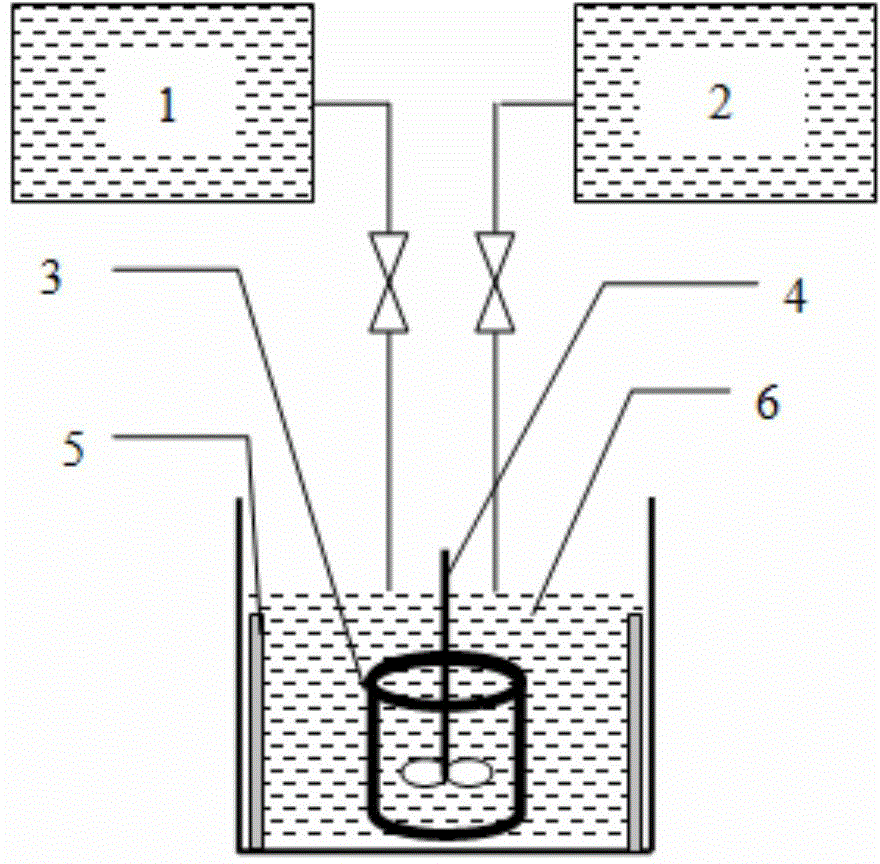

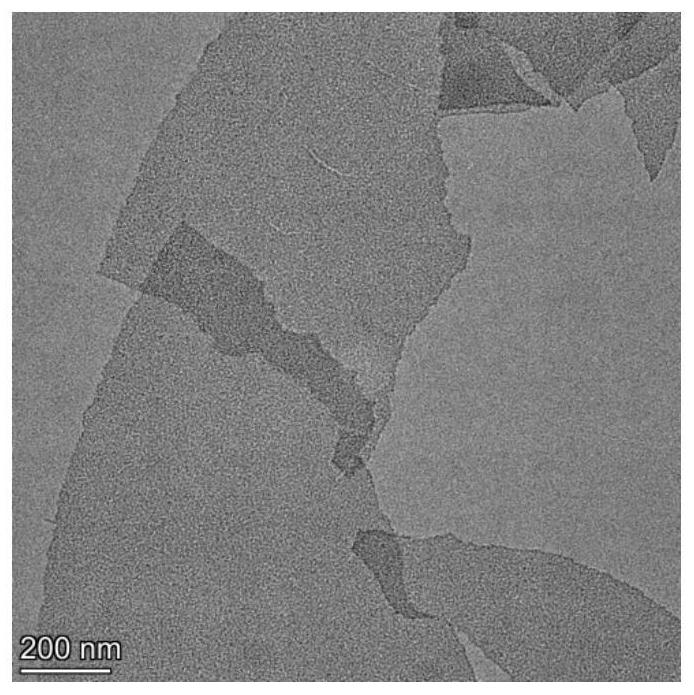

Method for preparing graphene water-based lubricating agent in situ

InactiveCN104593130ASimple preparation processEasy to prepareLubricant compositionWater basedFriction reduction

The invention discloses a method for preparing a graphene water-based lubricating agent in situ, belonging to the field of application of graphene serving as a nanometer lubricating additive. The lubricating agent consists of graphene nanoparticles, a surface modifier and purified water. The method comprises the following preparation steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing graphene powder in the liquid; 3, performing ultrasonic cavitation treatment on the graphene dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation treatment on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing graphene prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the graphene is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the graphene, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property, high machinability and environment friendliness of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

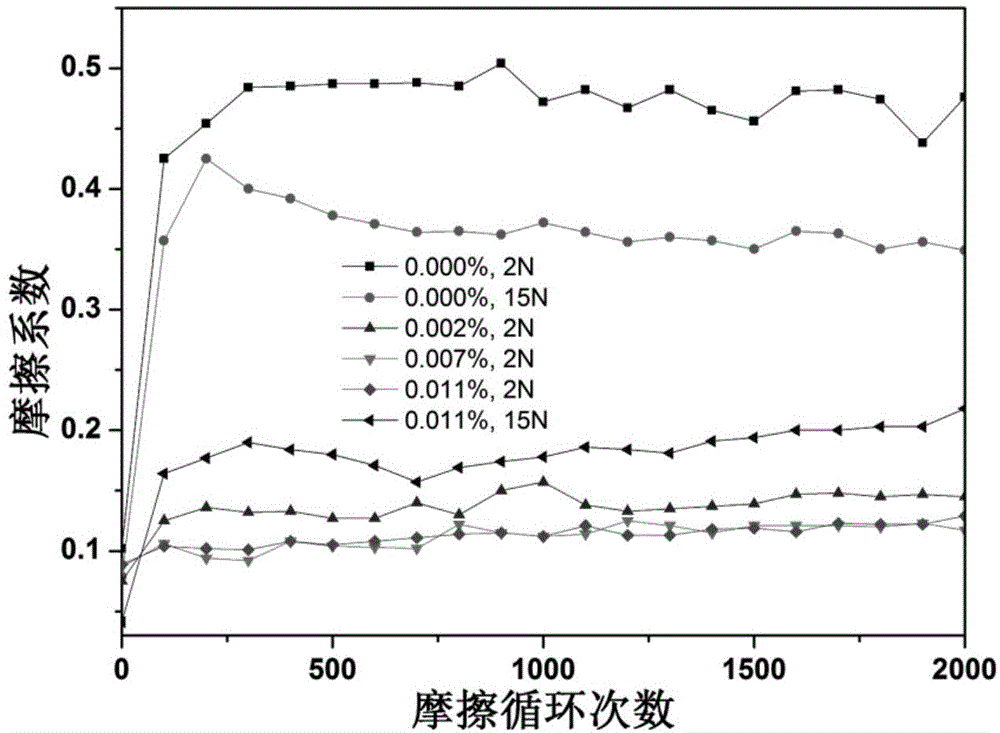

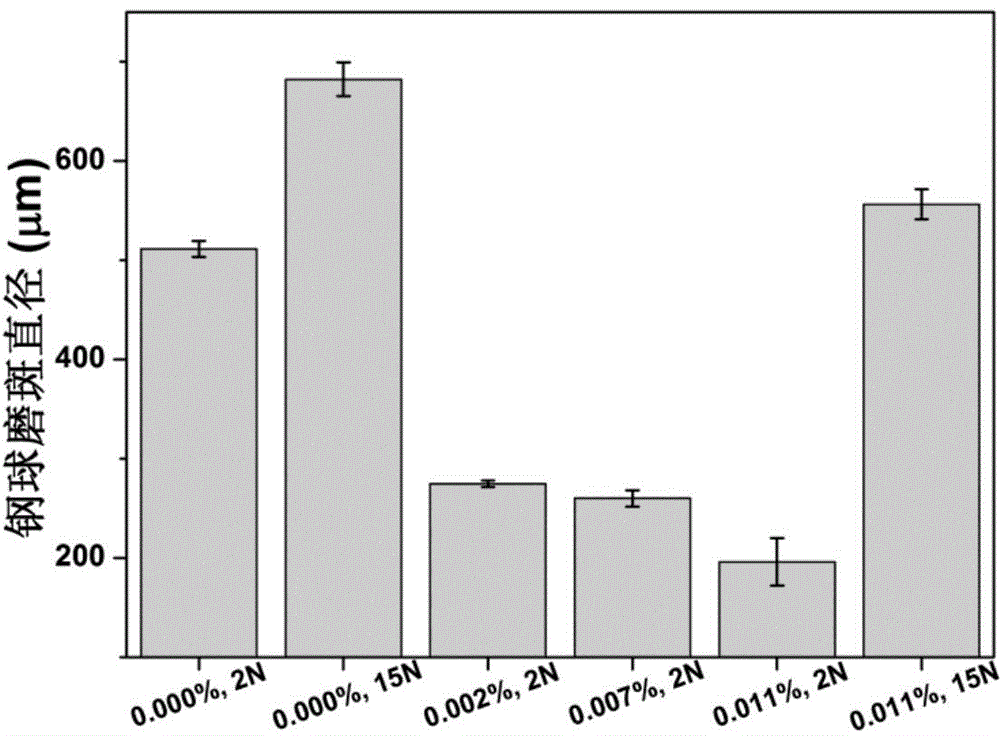

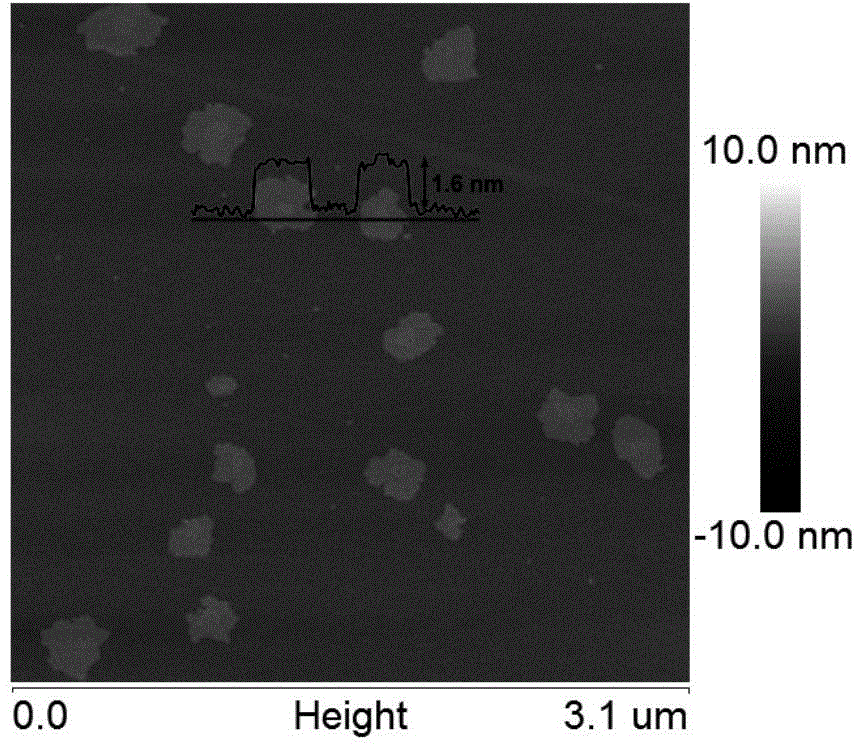

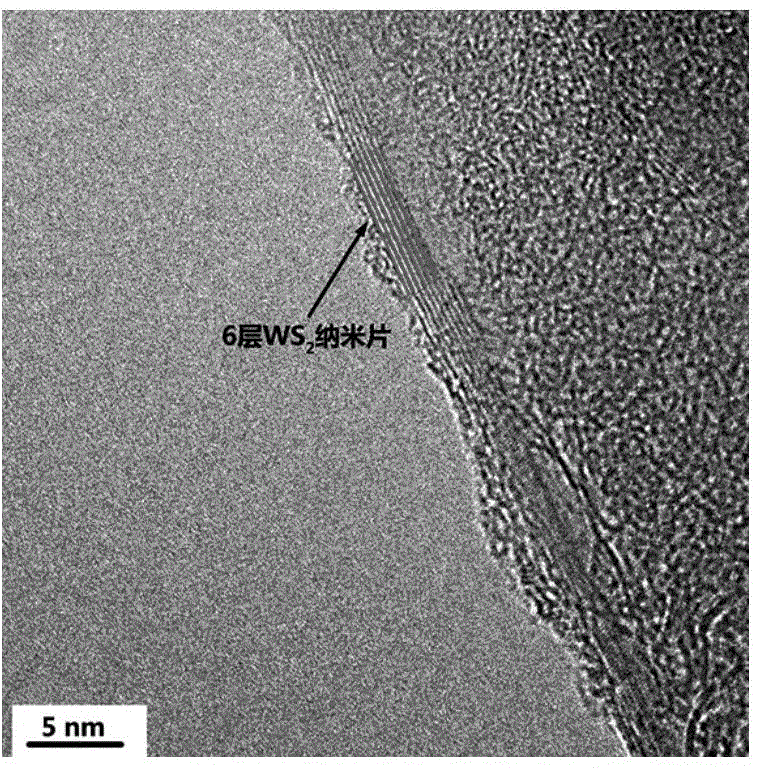

Method for preparing tungsten disulfide nanosheet water-based lubricating agent in situ

The invention discloses a method for preparing a tungsten disulfide nanosheet water-based lubricating agent in situ. The method comprises the following six steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing tungsten disulfide powder in the liquid; 3, performing ultrasonic cavitation treatment on the tungsten disulfide dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing tungsten disulfide nanosheets prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the tungsten disulfide nanosheets is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the tungsten disulfide nanosheets, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property and high machinability of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

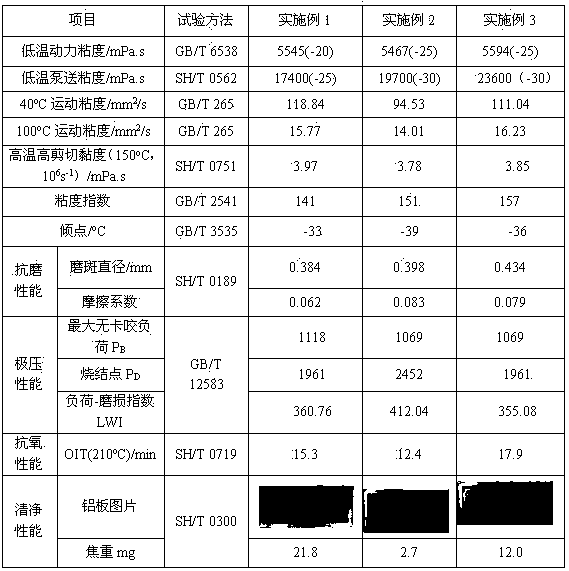

Gasoline engine lubricating coil composition and preparation method thereof

InactiveCN107760419AReduce usageGive full play to the synergistic effectLubricant compositionChemical compositionBoron containing

The invention discloses a gasoline engine lubricating coil composition and a preparation method thereof. The gasoline engine lubricating coil composition comprises the following components in percentby weight: (A) 0.1 to 6.0 percent of an ashless dispersing agent, (B) 0.1 to 8.0 percent of a clearing agent, (C) 0.01 to 1.5 percent of oil-soluble or dispersible oil stability boron-containing compound, (D) 0.003 to 0.5 percent of oil-soluble or dispersible oil stability molybdenum-containing compound, (E) 0.02 to 3.2 percent of zinc dialkyl dithiophosphate, (F) 0.01 to 3.0 percent of an antioxidant and (G) lubricating oil base oil with a main amount, wherein the boron molybdenum mass ratio of the component (C) to the component (D) ranges from 1:5 to 10:1. The blended gasoline engine oil composition contains all of the boron-containing compound, the molybdenum-containing compound and the zinc dialkyl dithiophosphate, completely exerts the synergistic effect between the additives, improves the anti-oxidation property, the anti-wear and friction-reducing properties and the extreme pressure property of the lubricating oil composition and reduces the ash content and the thionazin contentof the lubricating oil composition.

Owner:江西福安路润滑材料有限公司 +1

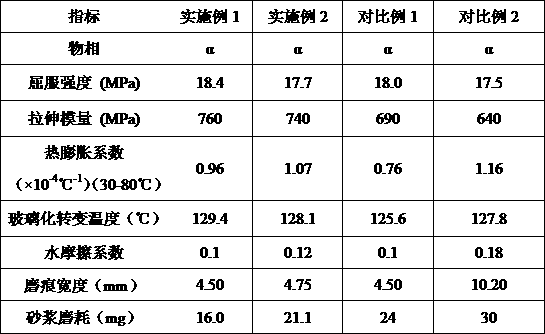

Preparation method of carbon fiber and silicon dioxide nanosphere synergically filled ultra-high molecular weight polyethylene wear-resistant material

ActiveCN107663328AImprove anti-wear and anti-friction performanceImprove mechanical propertiesFiberCarbon fibers

The invention discloses a preparation method of a carbon fiber and silicon dioxide nanosphere synergically filled ultra-high molecular weight polyethylene wear-resistant material and relates to the field of nanotribology, in particular dispersion of a nano material in high molecular resin and tribological properties thereof. The preparation method comprises the following steps: firstly, modifyingthe carbon fibers with nitric acid to obtain nitric acid modified carbon fibers; loading silicon dioxide nanospheres on the surfaces of nitric acid modified carbon fibers by means of a sol-gel processto obtain a composite material of silicon dioxide nanospheres and carbon fibers, and performing surface coupling treatment to obtain coupled composite packing; and finally, mixing the coupled composite packing with ultra-high molecular weight polyethylene, and performing hot pressing and sulfidizing to obtain the carbon fiber and silicon dioxide nanosphere synergically filled ultra-high molecularweight polyethylene wear-resistant material. The composite material has relatively good mechanical property, frictional wear-resistant property, mortar wear property and machine shaping property.

Owner:YANGZHOU UNIV

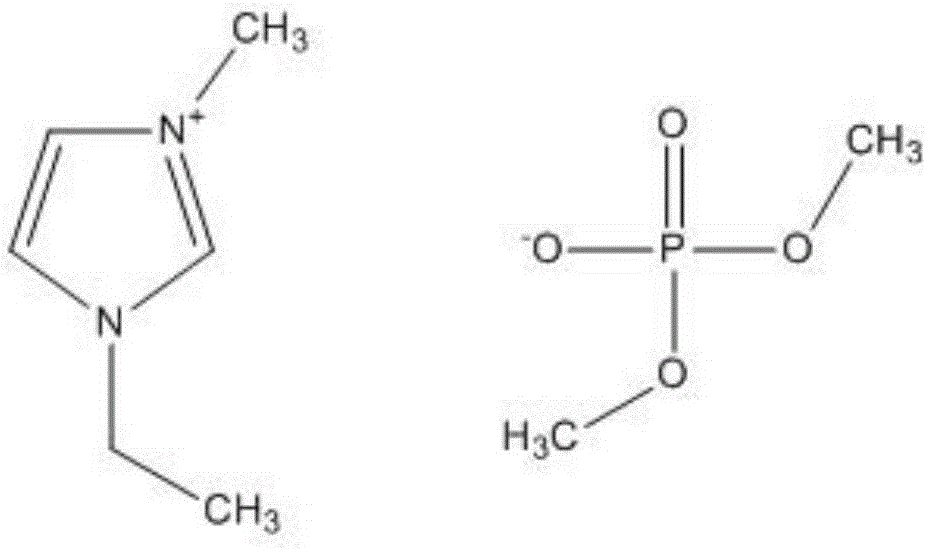

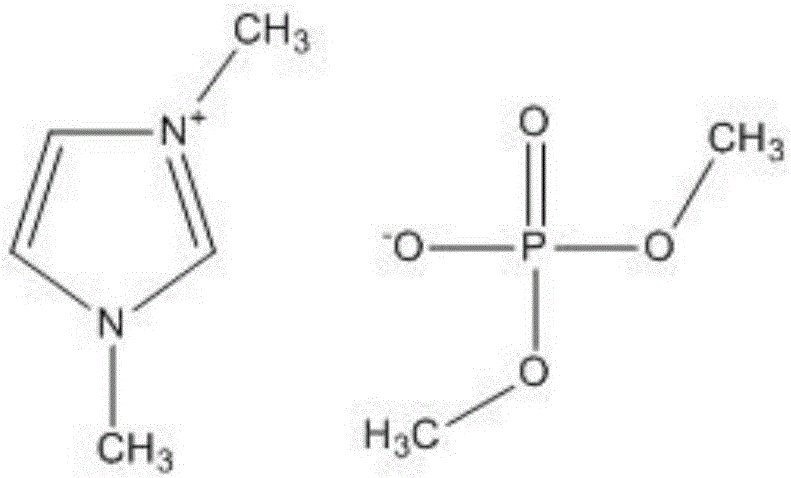

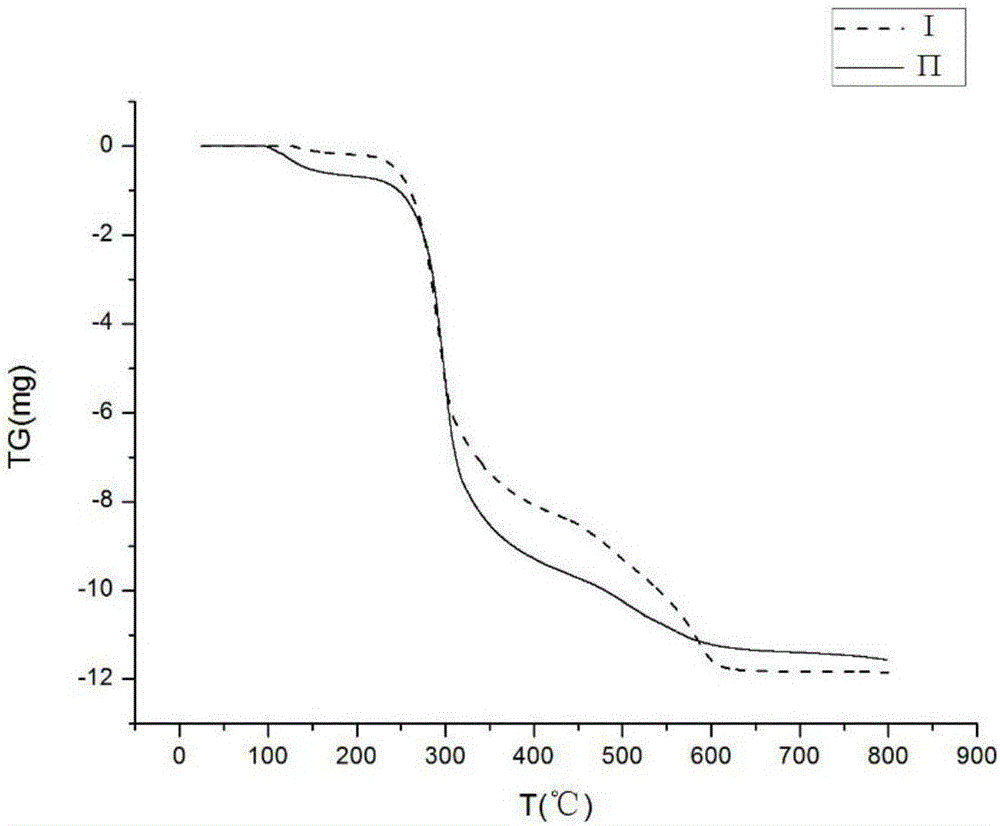

High-temperature environment-friendly water-based ionic liquid lubricant

The invention discloses a high-temperature environment-friendly water-based ionic liquid lubricant and belongs to the technical field of liquid lubricants. The lubricant comprises the following raw materials in percentage by mass: 0.5-1% of 1-ethyl-3-methylimidazole dimethyl phosphate; 0.1-0.5 % of 1,3-dimethylimidazolium dimethyl phosphate; 1-2% of a corrosion inhibitor; 0.01-2% of a bactericide, and 90-95% of water to prepare the water-based solution. According to the invention, the high-temperature environment-friendly water-based ionic liquid lubricant has very high thermal stability, extremely low volatility and excellent high-temperature antifriction and anti-wear properties. Performance detection is carried out on the lubricant provided by the invention, and the result shows that the thermal decomposition temperature of the lubricant is about 300 DEG C and the metal has good oxidation resistance, friction resistance and wear resistance. According to the invention, no pollution is caused to the environment, so that the lubricant has good popularization and application prospect.

Owner:UNIV OF SCI & TECH BEIJING

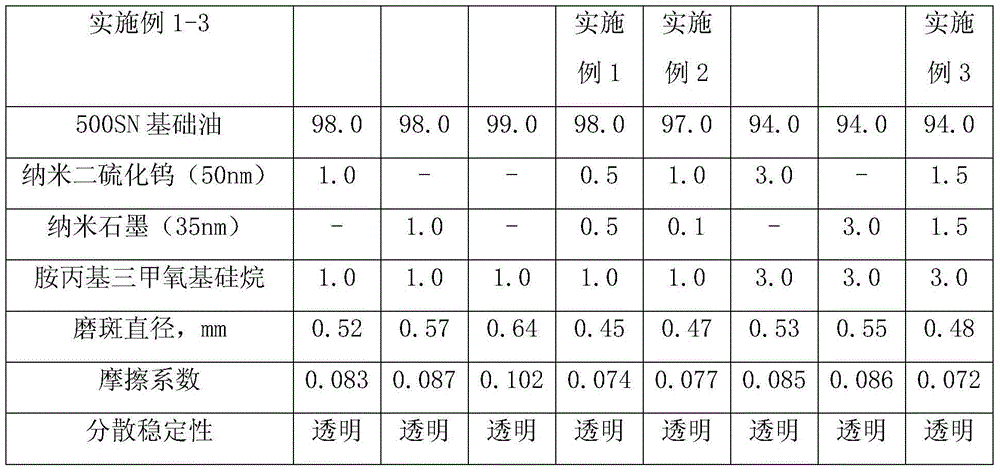

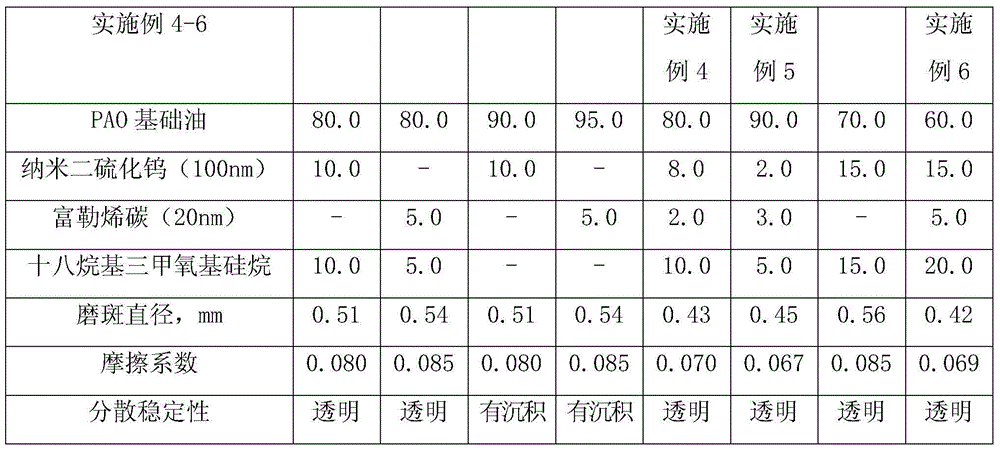

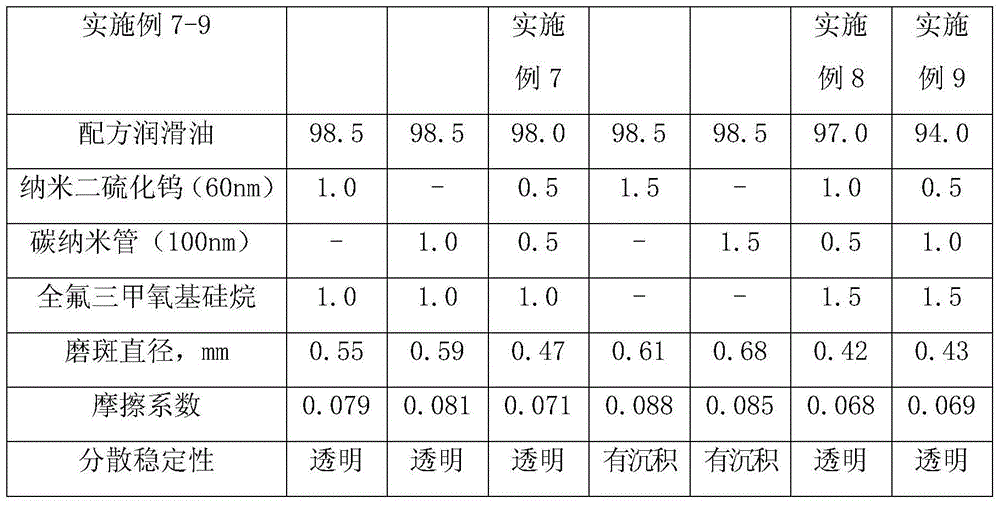

Antifriction and antiwear lubricant oil additive containing nano tungsten disulfide

InactiveCN104560307AImprove dispersion stabilityImprove anti-wear and anti-friction performanceAdditivesDispersion stabilityOil additive

The invention discloses an antifriction and antiwear lubricant oil additive containing nano tungsten disulfide, and belongs to the technical field of lubricant oil. The lubricant oil additive comprises the following components in percentage by weight: 0.5-15% of nano tungsten disulfide, 0.1-5% of a carbon nano additive, 1-20% of a surface modifier and 60-98.4% of basic lubricant oil. The lubricant oil additive disclosed by the invention can remarkably improve antifriction and antiwear performances of the basic lubricant oil, has relatively good dispersion stability in the basic lubricant oil, can be widely applied to lubricant grease of various vehicles and large-sized mechanical equipment, and can contain an extreme-pressure antiwear agent, an antioxidant, a purification dispersant, a corrosion inhibitor and the like.

Owner:中国人民解放军空军勤务学院

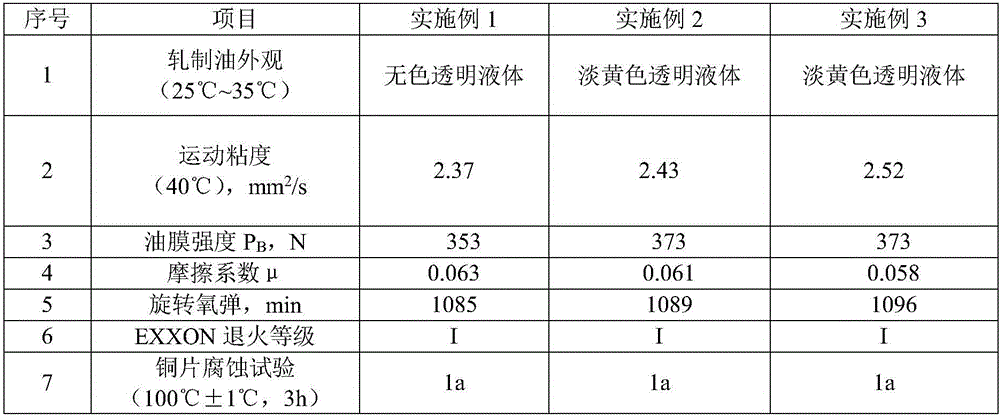

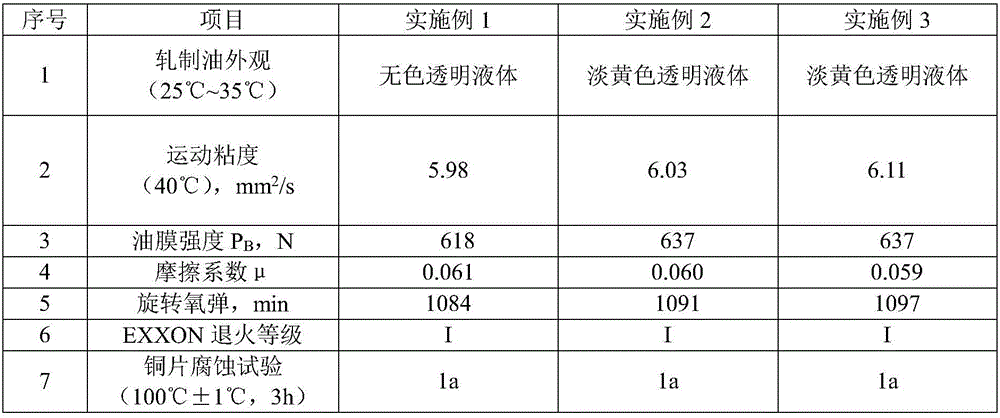

Universal nonferrous metal and stainless steel cold rolling oil composite additive and preparation method thereof

ActiveCN106566598AImprove anti-friction and anti-wear effectImprove anti-wear and anti-friction performanceAdditivesAntioxidantSolvent

The invention provides a universal nonferrous metal and stainless steel cold rolling oil composite additive and a preparation method thereof and belongs to the field of lubricating agents. According to the universal nonferrous metal and stainless steel cold rolling oil composite additive, lauryl alcohol, butyl stearate, pentaerythritol oleate and lauric acid are selected as oily agents; 2,6-di-tert-butyl-4-methylphenol is selected as an antioxidant; benzotriazole and thiadiazole derivatives are used as metal deactivators; dialkyl phosphorodithioate serves as an antiwear agent; and hydrogenated base oil serves as a solvent. The alcohol-ester type oily agents are mainly used for compounding with a little amount of acid oily agents as supplementation; a little amount of dialkyl phosphorodithioate is used as the antiwear agent to reinforce an oil film so as to improve the surface quality of a rolled stock; the service life of rolling oil is prolonged through a little amount of the antioxidant and the metal deactivators, the cyclic use frequency is increased, and rolled pieces are protected against corrosion. The universal nonferrous metal and stainless steel cold rolling oil composite additive is convenient to use, low in cost and little in dosage, and has the characteristics of high oil film strength, good antiwear and antifriction effect, high oxidation resistance and excellent annealing performance.

Owner:UNIV OF SCI & TECH BEIJING

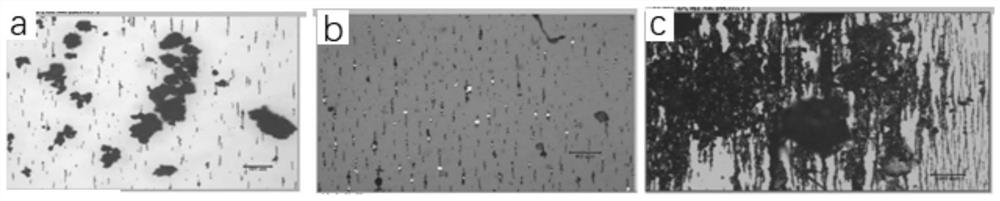

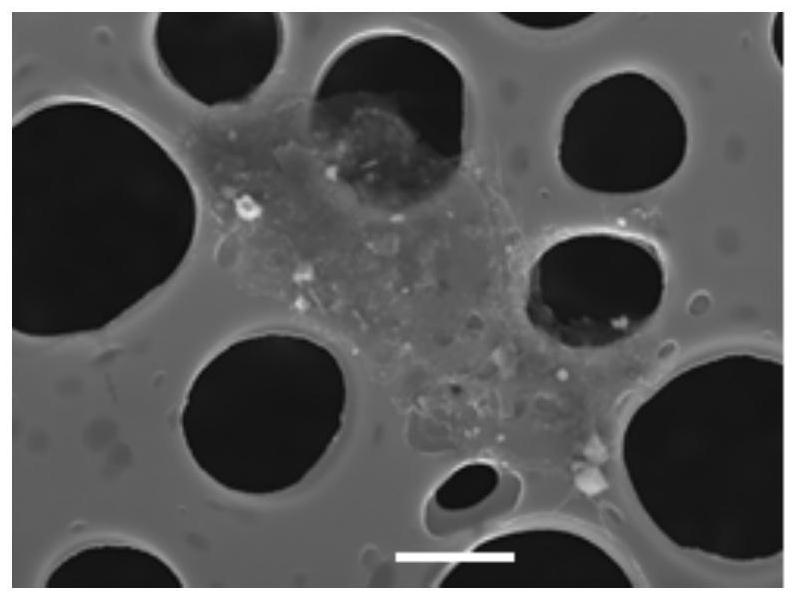

Application of aminated mesoporous silica nanomaterial as lubricating oil antiwear agent

InactiveCN108165341AImprove anti-wear and anti-friction performanceImprove carrying capacityAdditivesWear resistantMesoporous silica

The invention relates to an application of an aminated mesoporous silica nanomaterial as a lubricating oil antiwear agent. The aminated mesoporous silica nanomaterial with an ordered pore passage structure can be used as the lubricating oil antiwear agent, can significantly improve the wear resistant and friction reducing properties and the bearing capacity of the lubricating oil. The interior ofthe mesoporous silica nanomaterial has a highly ordered pore passage structure, and can provide good oil absorption and oil storage functions. In the process of friction, the lubricating oil stored inpores is released to form an oil film, cracks of the friction surface are filled, the wear can be further reduced and excellent lubrication effect is achieved. With application of the aminated mesoporous silica nanomaterial, the lubricating oil has the advantages of no corrosion of friction pair materials, environmental protection, no pollution, good chemical stability and the like. The preparation method of the aminated mesoporous silica nanomaterial has the advantages of high efficiency, rapidness, wide sources of raw materials and low cost. After the mesoporous silica nanomaterial is aminated, the mesoporous silica nanomaterial is dispersed evenly in the lubricating oil, and the antiwear property is more uniform.

Owner:北京天元陆兵汽车科技有限公司

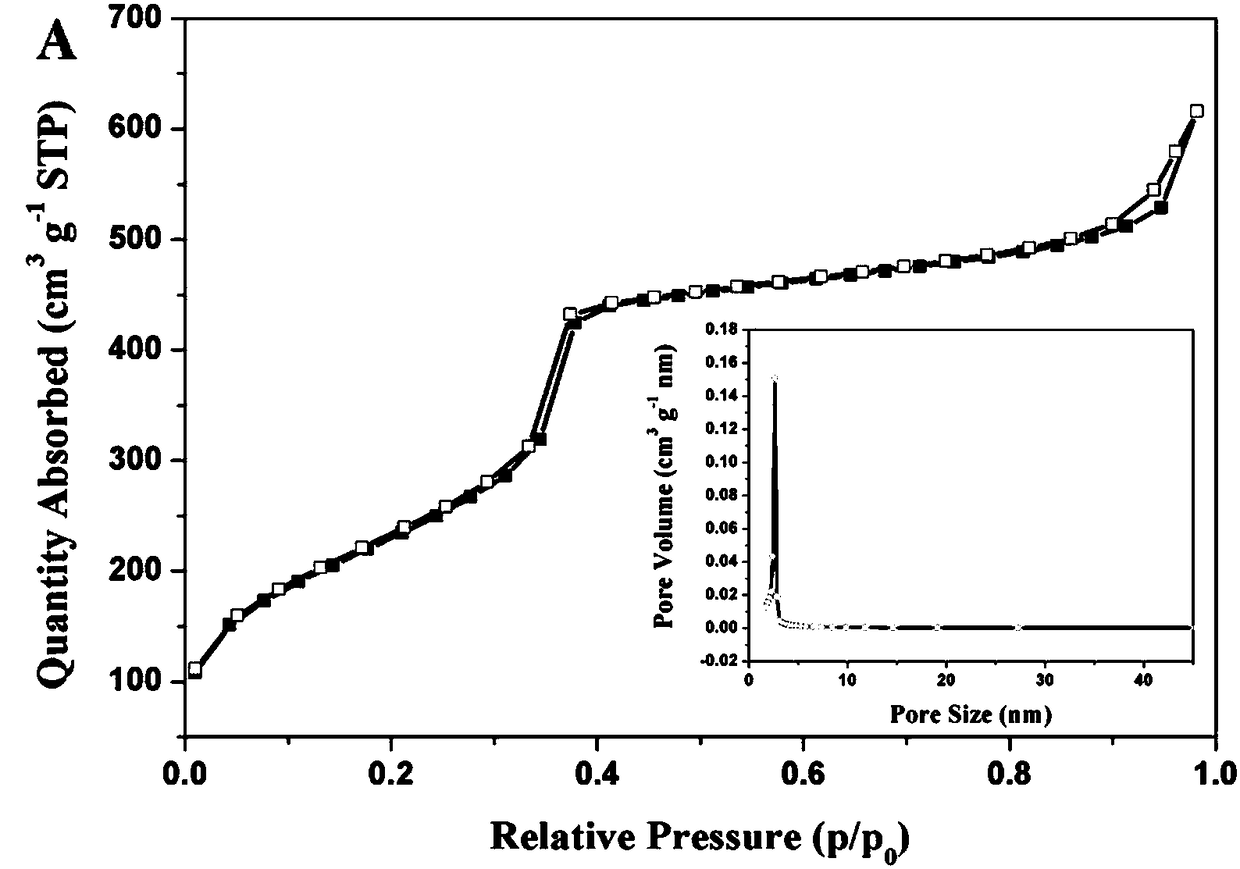

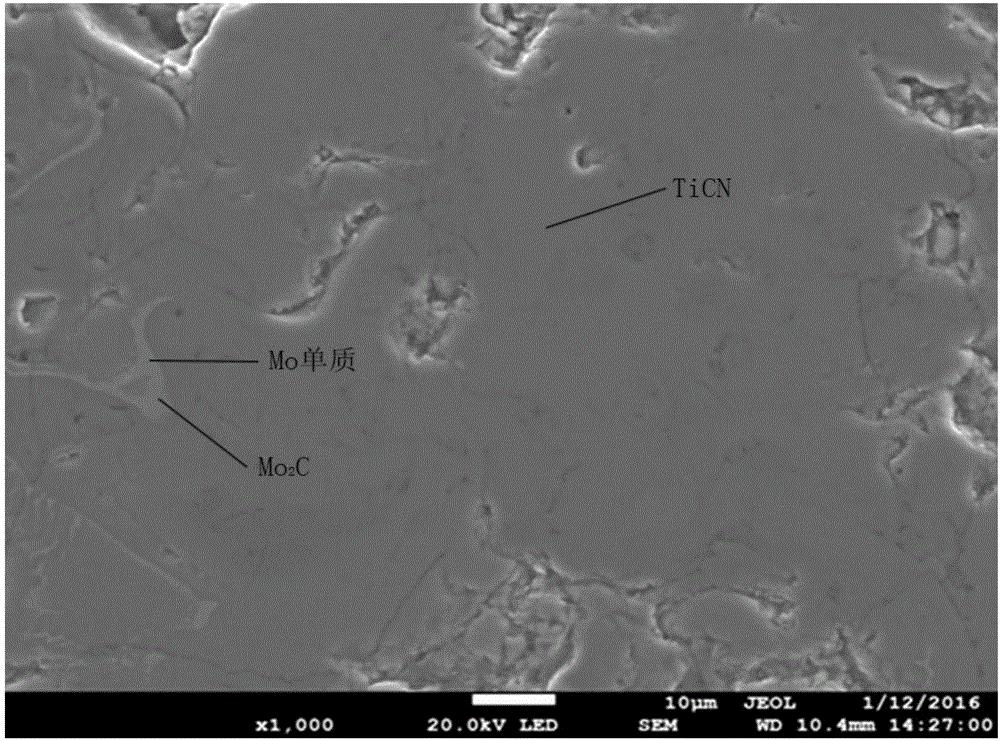

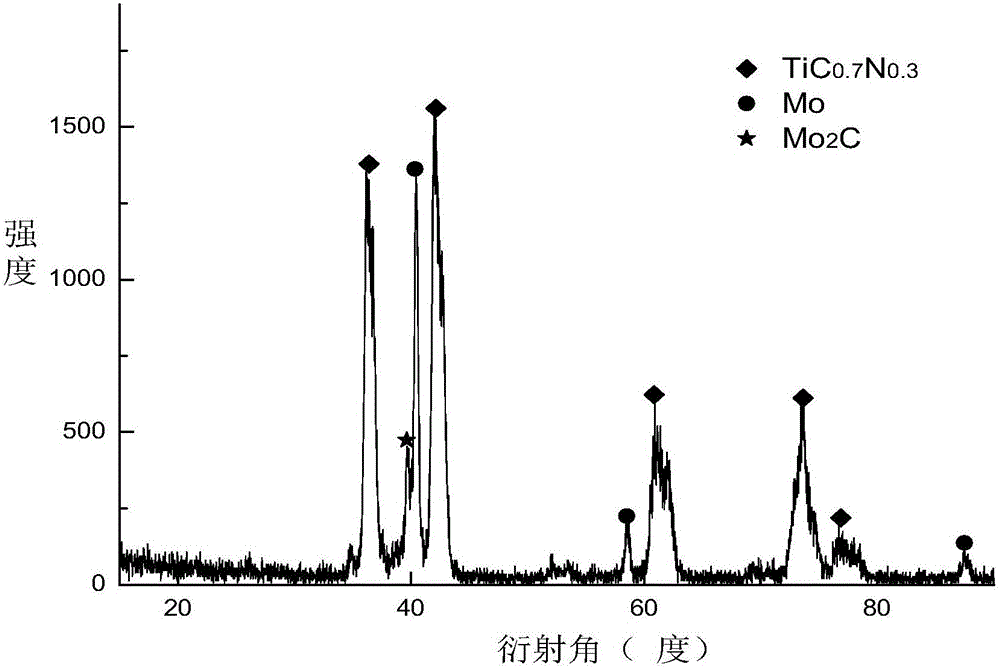

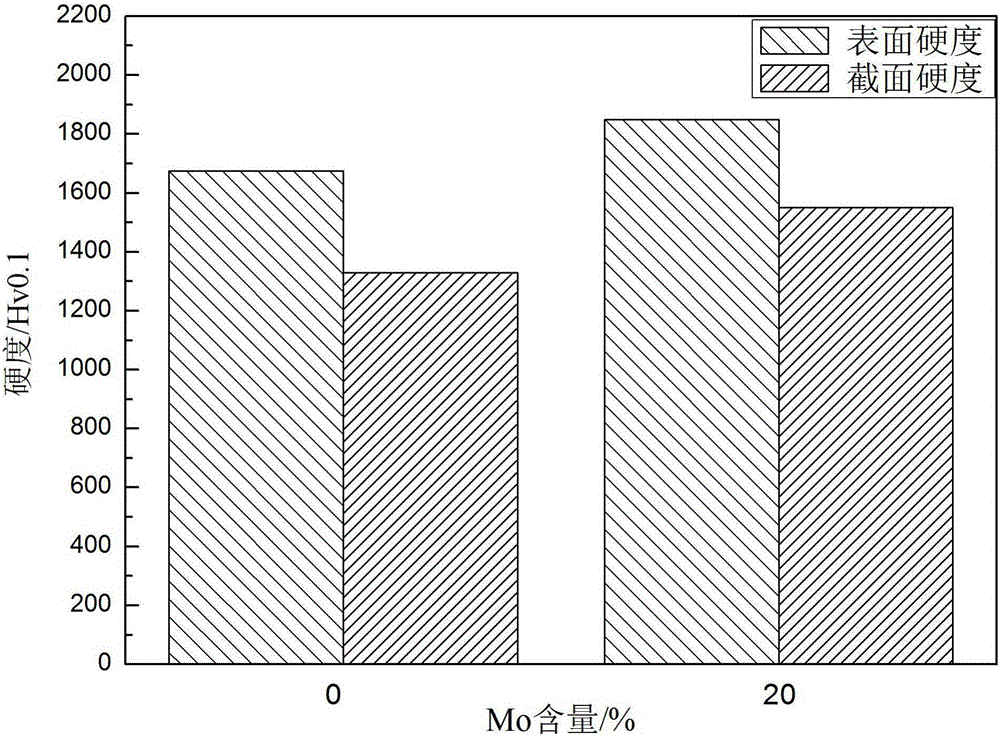

Preparation method of Mo-containing TiCN-based composite coating

InactiveCN106435444AHigh hardnessImprove wear resistanceMolten spray coatingCeramic compositeHardness

The invention discloses a preparation method of a Mo-containing TiCN-based composite coating. The method comprises the following steps that firstly, the surface of a substrate sample is roughened; secondly, Ti / C composite powder and Mo powder are mechanically blended to obtain original feed composite powder; thirdly, the surface of a substrate is pre-coated with Ni-10%wtAl self-refluxing alloy power, so that a base layer with the thickness being 90-120 [mu]m is obtained; and fourthly, the surface of the base layer is coated with the original feed composite powder, so that a TiCN-Mo metal-based ceramic composite coating with the thickness being 300-500 [mu]m is obtained. The plasma-spraying TiCN-Mo metal-based ceramic composite coating is high in hardness, good in abrasion resistance and corrosion resistance, suitable for workpieces, such as cutters, drill bits, moulds and the like in the fields of machinery, automobile making, aerospace and the like, under abrasive and corrosive environment conditions, and the plasma-spraying TiCN-Mo metal-based ceramic composite coating has extremely wide application prospects.

Owner:HEBEI UNIV OF TECH

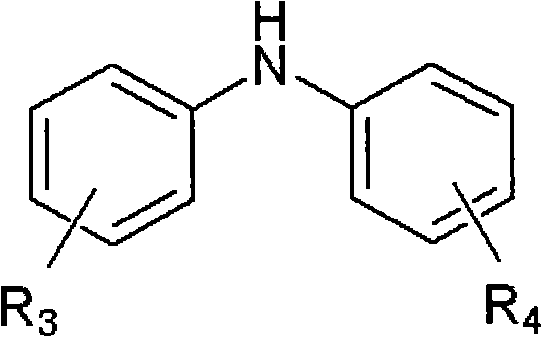

Antioxidant composition and lubricating oil composition

ActiveCN103060059AEasy to prepareImprove conversion rateAdditivesChemical compositionFatty acid amide

The invention provides an antioxidant composition and a lubricating oil composition containing the antioxidant composition; and the antioxidant composition comprises aromatic amine antioxidant and organic molybdenum additive, wherein the organic molybdenum additive is prepared by the reaction of fatty acid amide, polyisobutylene succinimide and inorganic molybdenum compound under the condition that unnecessary dilute oil exists. The antioxidant composition and the lubricating oil composition have excellent antioxidant performance, wear resistance and antifriction performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alloy drill bit for geological exploration

The invention belongs to the field of machining and discloses an alloy drill bit for geological exploration. The alloy drill bit is composed of a cutter head and a base body. The cutter head is prepared, by weight, from 100 parts of steel powder, 30 parts of nickel powder, 20 parts of copper powder, 8 parts of modified silicon carbide, 6 parts of manganese powder, 4 parts of molybdenum powder, 3 parts of tungsten carbide powder, 2 parts of modified kaolin, 2 parts of modified attapulgite, 1 part of nanometer yttrium oxide, 1 part of nanometer cerium oxide, 1 part of glass fiber and 1 part of graphite fiber. The alloy drill bit for geological exploration has the good performance in bending strength, impact toughness, the wearing and tearing ratio and corrosion resistance.

Owner:QIDONG CHUANGLYU GREENING ENG CO LTD

Method for obtaining lubricating oil containing lubrication-friendly MoS2 nano-particles

The invention discloses a method for obtaining lubricating oil containing lubrication-friendly MoS2 nano-particles. The method comprises the following steps: adding an anti-wear and antifriction additive to a ball milling tank as a modifier, and adding a MoS2 particle raw material and a proper amount of balls to the ball milling tank according to a certain ratio; and starting a high-energy ball mill, and carrying out ball milling for an appropriate time; and carrying out ultrasonic treatment or stirring on nano-particles prepared after the ball milling completes to fully disperse the nano-particles in finished oil in order to obtain the lubricating oil containing lubrication-friendly MoS2 nano-particles. The method realizes preparation of the lubrication-friendly MoS2 nano-particles, guarantees the lubrication validity of MoS2 nano-particles and realizes the compatibility of the MoS2 particles and a lubricant / additive system through adopting a high-energy ball milling technology by adopting the common lubricating oil anti-wear and antifriction additive as the modifier, and allows the lubricating oil containing lubrication-friendly MoS2 nano-particles to be obtained.

Owner:XI AN JIAOTONG UNIV

Surface anticorrosion wear-resistant composite coating for cylinder sleeve of automobile engine applying bio-oil

ActiveCN104313554AReduce concentrationRealize the effect of degreasing and derustingLiquid/solution decomposition chemical coatingChemical platingWear resistant

A surface anticorrosion wear-resistant composite coating for a cylinder sleeve of an automobile engine applying bio-oil is disclosed. The coating comprises a Ni-Cu-Ce-La-P-Graphene composite material, and can be prepared by adopting a gradient chemical plating coating process. The coating is characterized in that: Ni, Cu, Ce, La and P in a special ratio, and Graphene are simultaneously deposited on the surface of the cylinder sleeve, and the composite coating with good anticorrosion and wear-resistant functions is prepared. The coating is advantageous in that: the binding force of the coating and a substrate is strong, compactness of the coating is high, the coating has excellent anticorrosion and wear-resistant effects especially for the bio-oil, a preparing method of the coating is simple, convenient, and prone to industrial production, and the coating can be widely used in the fields of metal material protection, mechanical surface treatment, energy-saving and environmental friendly automobiles, and the like.

Owner:黄山市开发投资集团有限公司

Antioxidant corrosion inhibitor composition and lubricating oil composition

ActiveCN103060058AAccelerated corrosionImprove anti-friction and anti-wear effectAdditivesChemical compositionWear resistance

The invention provides an antioxidant corrosion inhibitor composition and a lubricating oil composition containing the antioxidant corrosion inhibitor composition; and the antioxidant corrosion inhibitor composition comprises aromatic amine antioxidant, thiadiazole derivative and organic molybdenum additive, wherein the organic molybdenum additive is prepared by the reaction of fatty acid amide, polyisobutylene succinimide and inorganic molybdenum compound under the condition that unnecessary dilute oil exists. The antioxidant corrosion inhibitor composition and the lubricating oil composition have excellent antioxidant performance, corrosion resistance, wear resistance and antifriction performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

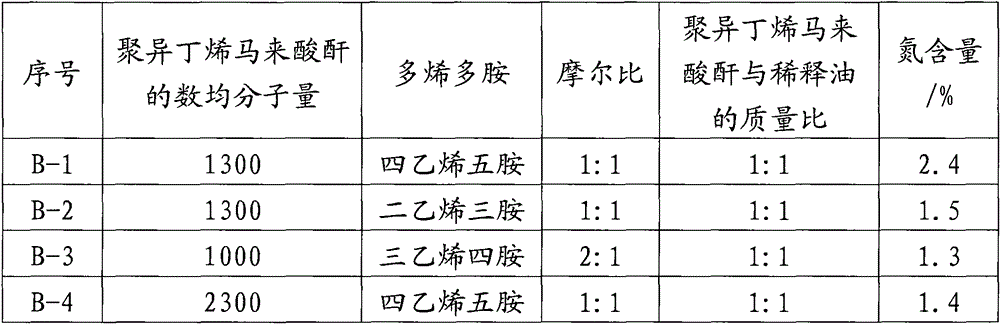

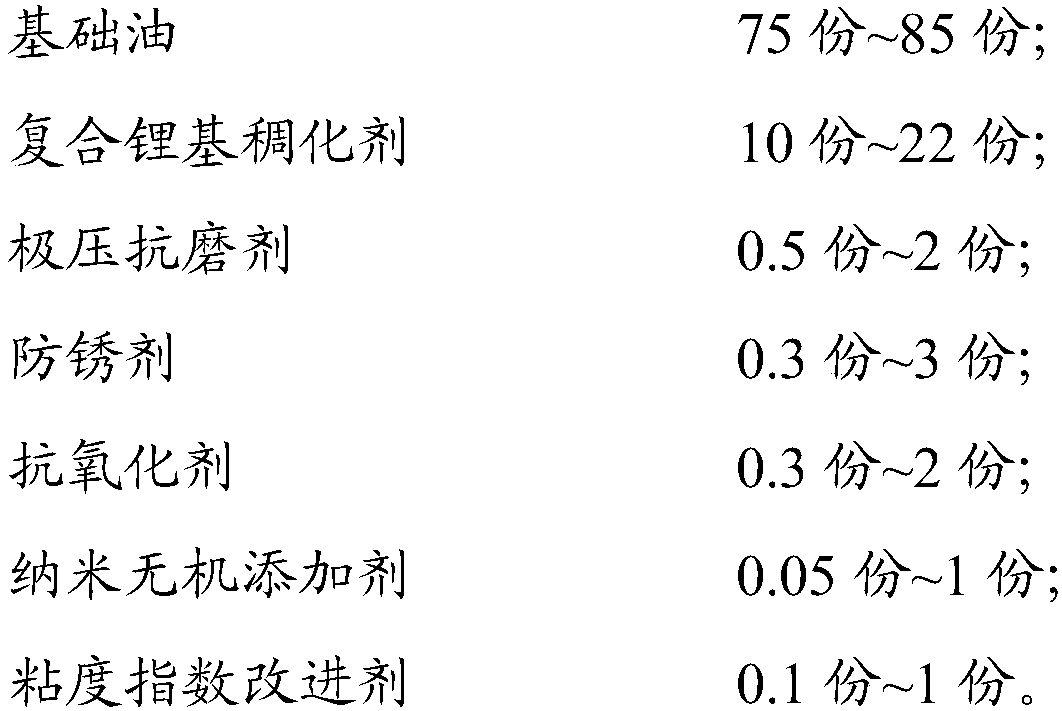

Lubricating grease for automobile ball joint and preparation method of lubricating grease

ActiveCN108384605AImprove adsorption capacityAchieve anti-wearLubricant compositionLithiumOxidation resistant

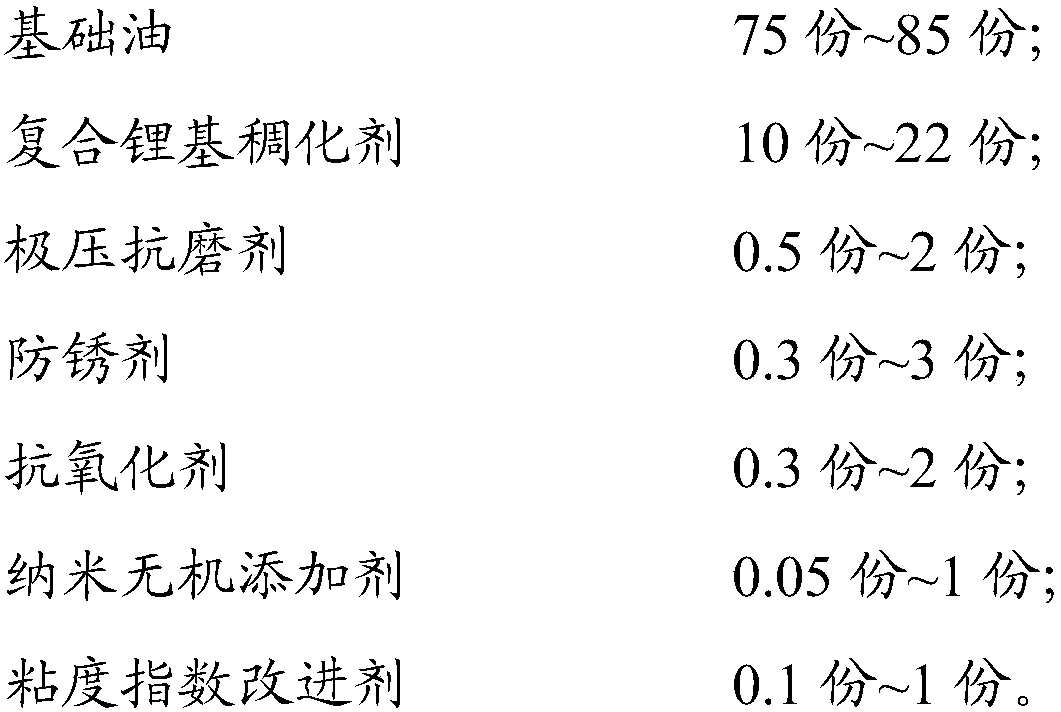

The invention discloses lubricating grease for an automobile ball joint. The lubricating grease comprises the following components of: in parts by mass, 75-85 parts of base oil, 10-22 parts of a compound lithium-based thickener, 0.5-2 parts of an extreme-pressure anti-wear agent, 0.3-3 parts of a rust inhibitor, 0.3-2 parts of an antioxidant, 0.05-1 part of a nano inorganic additive and 0.1-1 partof a viscosity index improver. The lubricating grease has the advantages that the lubricating grease for the automobile ball joint has excellent high-and-low temperature performance, small change with the temperature, small low-temperature torque and small starting torque, and the anti-wear anti-friction performance is improved to a certain extent; furthermore, not only can good adsorption capacity between the lubricating grease and a ball joint friction pair be achieved, but also wear resistance, rust prevention, oxidation resistance and other functions can be achieved; in addition, the lubricating grease has a simple preparation method and low cost; besides, the invention also discloses a preparation method of the lubricating grease for the automobile ball joint.

Owner:广东阿特斯新材料科技有限公司

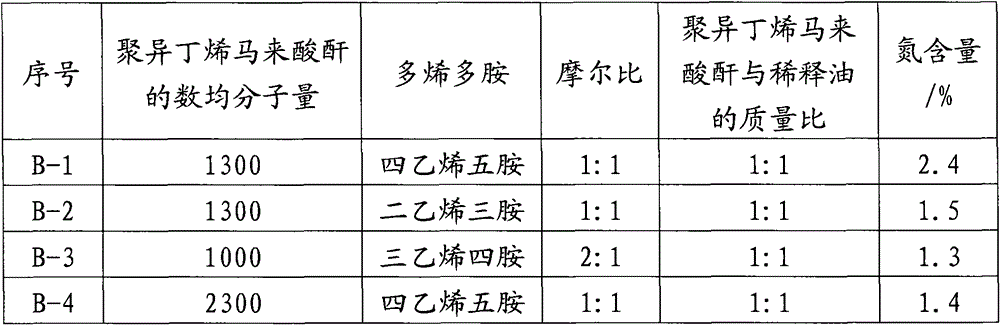

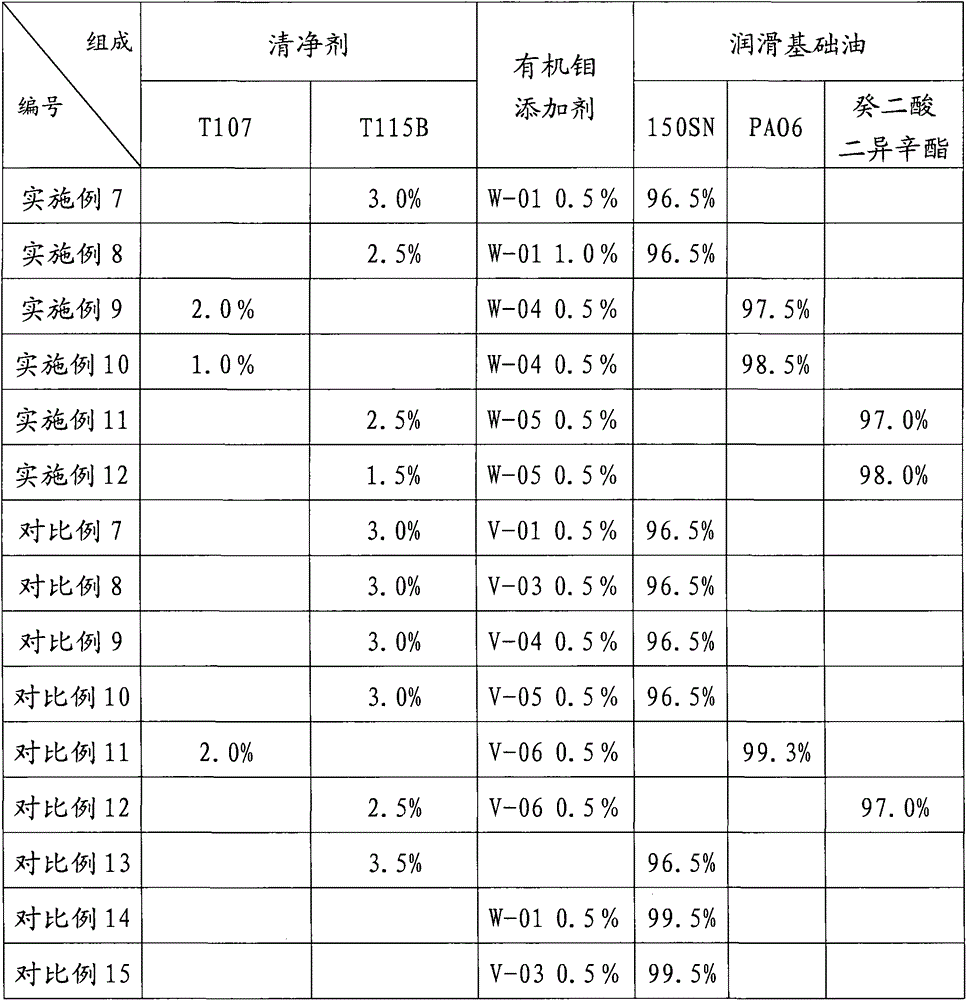

Clean anti-friction composition and lubricating oil composition

ActiveCN103060060AImprove cleanlinessImprove anti-wear and anti-friction performanceAdditivesClearing AgentPolyisobutylene succinimide

The invention provides a clean anti-friction composition, and a lubricating oil composition containing the clean anti-friction composition. The clean anti-friction composition comprises a clearing agent and an organic molybdenum additive, wherein the organic molybdenum additive is prepared from fatty acid amide, polyisobutylene succinimide and inorganic molybdenum compound by reaction in the presence of unessential cutback oil. The clean anti-friction composition and the lubricating oil composition have excellent clearing property and anti-wear and friction reducing properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

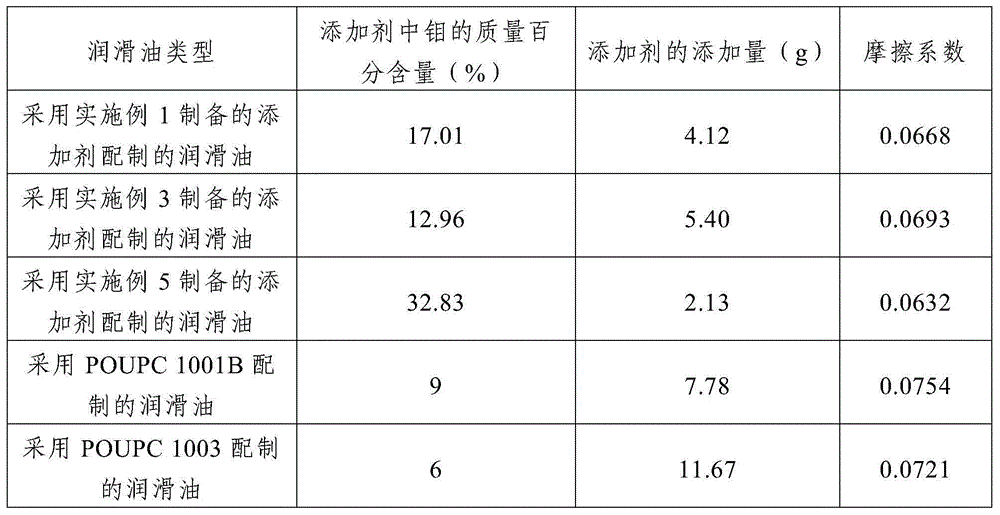

Preparation method of molybdenum-sulfur complex lubricating oil additive with high molybdenum content

The invention discloses a preparation method of a molybdenum-sulfur complex lubricating oil additive with high molybdenum content. The preparation method comprises the following steps: I, preparing a mixed liquid A from a hexavalent molybdenum compound, a sulfur-containing compound and distilled water, and then adjusting a pH value; II, adding dialkyl amine into the mixed liquid A which is subjected to pH value adjustment, then stirring, and then adding a phase transfer catalyst to obtain a mixed liquid B; III, under the protection of a nitrogen atmosphere, dropwise adding carbon disulfide into the mixed liquid B to obtain a mixed liquid C; and IV, standing the mixed liquid C till the mixed liquid C is layered, removing a water phase, washing an organic phase by virtue of an alkaline solution and an organic solvent, then distilling, and drying to obtain the high-molybdenum-content molybdenum-sulfur complex lubricating oil additive of which the mass percentage content of molybdenum is not less than 10%. The preparation method disclosed by the invention is simple in preparation process, and is favorable for industrial production; and the prepared molybdenum-sulfur complex lubricating oil additive has relatively high molybdenum content and good oil solubility, and after the additive is added into lubricating oil, the anti-wear and friction reduction properties of the lubricating oil can be greatly improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

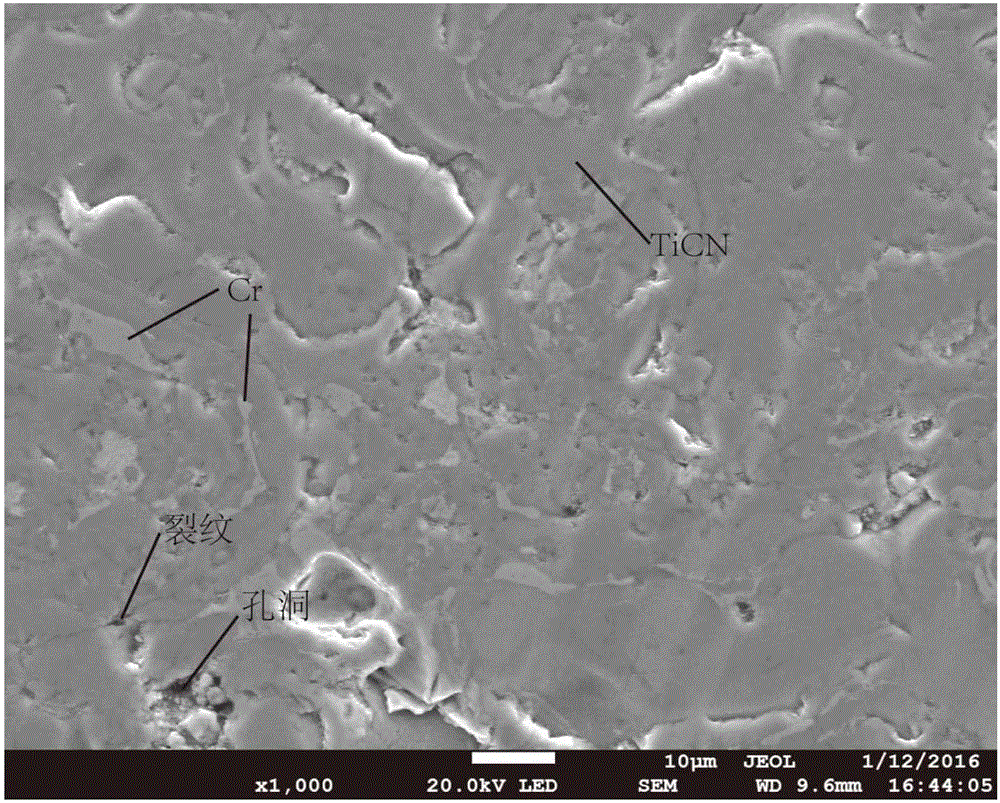

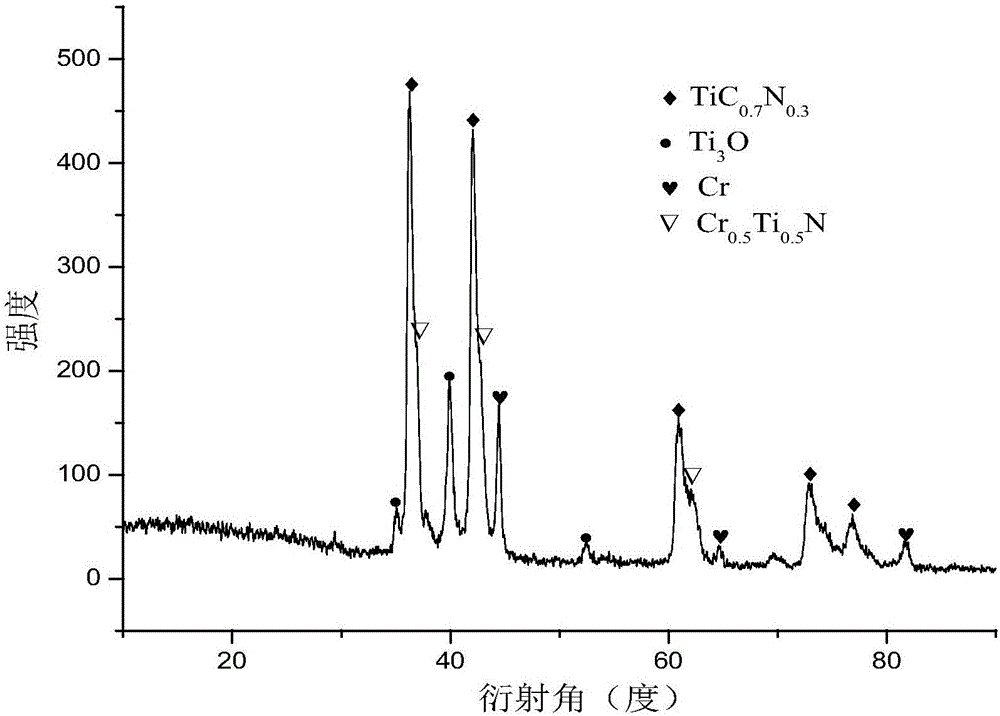

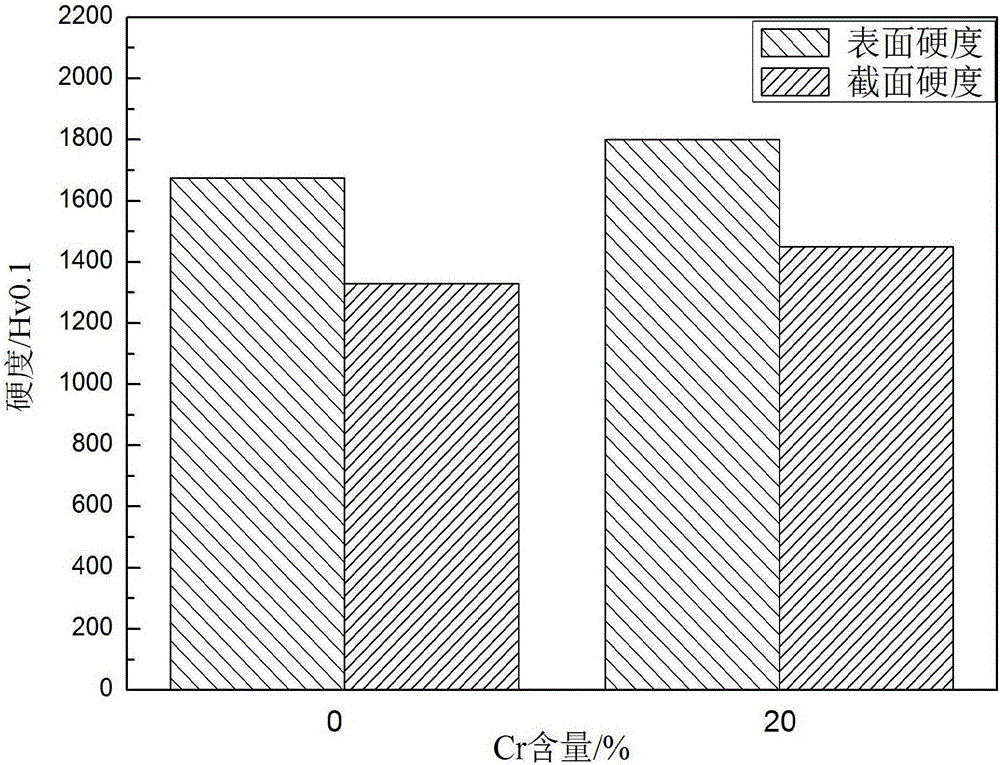

Preparation method of Cr-containing TiCN-based composite coating

The invention discloses a preparation method of a Cr-containing TiCN-based composite coating. The method comprises the steps of step 1, carrying out roughening treatment on the surface of a matrix sample; step 2, mechanically mixing Ti / C composite powder with Cr powder to obtain original feeding composite powder; step 3, spraying Ni-Al self-fluxing alloy powder on the surface of a matrix in advance to obtain a bottom layer of which the thickness is 90 to 120 <mu>m, wherein the weight percent of Al in the Ni-Al self-fluxing alloy powder is 10 wt%; and step 4, spraying the original feeding composite powder on the surface of the bottom layer to obtain a TiCN-Cr metal-based ceramic composite coating of which the thickness is 300 to 500 <mu>m. The plasma spraying TiCN-Cr metal-based ceramic composite coating provided by the invention has relatively high hardness and good abrasion resistance and corrosion resistance, is suitable for working under abrasive and corrosive environment conditions like the fields of machinery manufacturing of cutting tools, drills and molds, automobile manufacturing and aerospace, and has quite wide application prospect.

Owner:HEBEI UNIV OF TECH

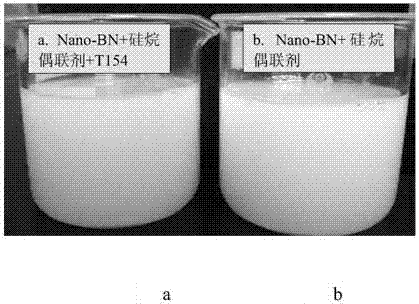

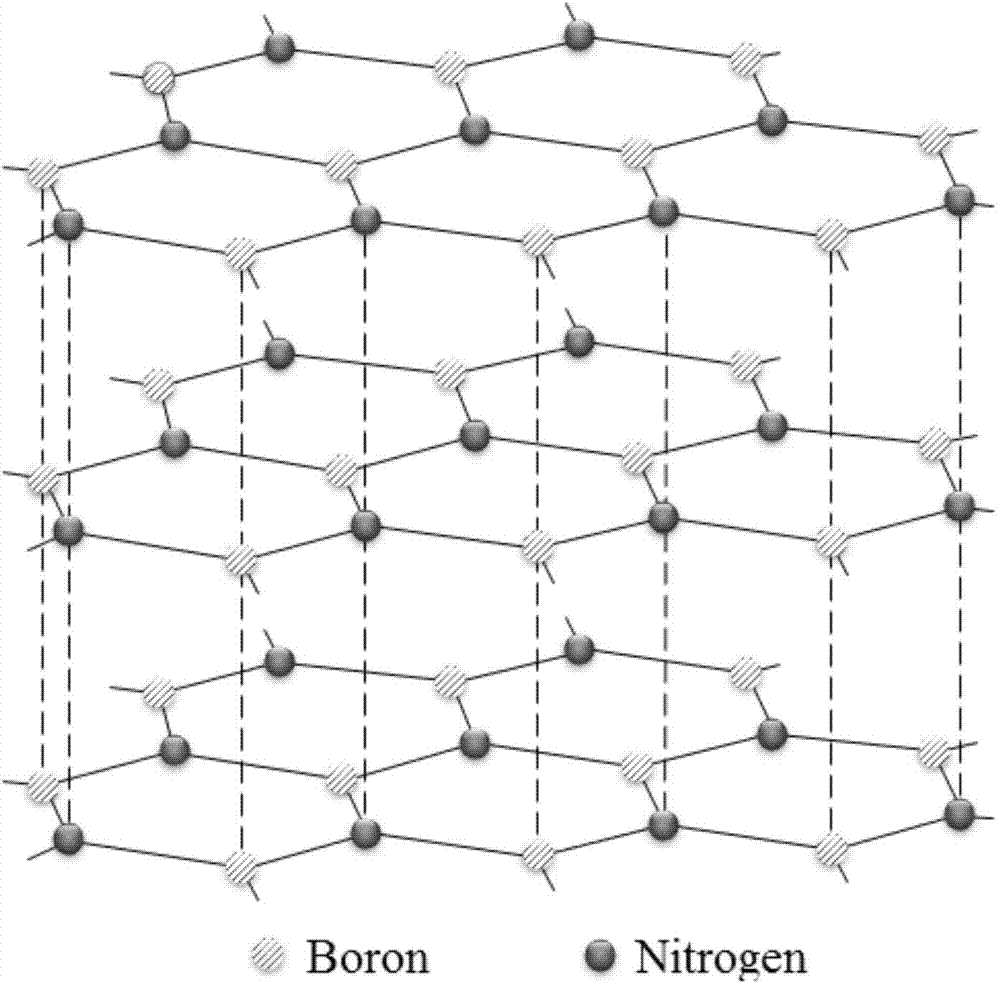

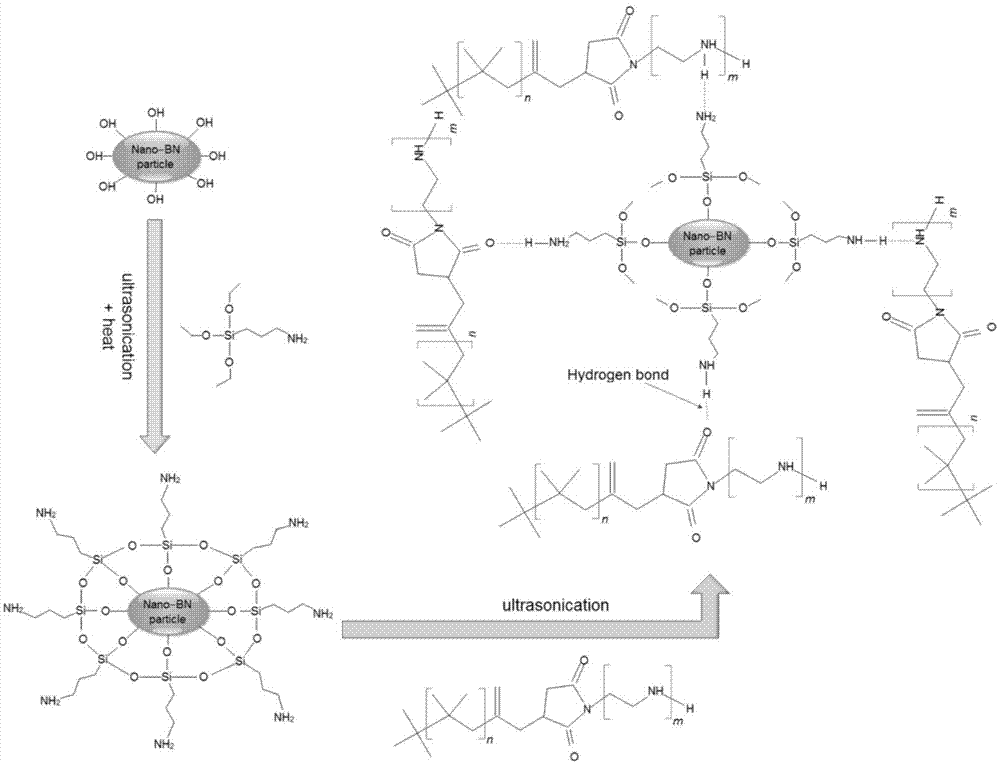

Method to realize stable dispersion of nano BN powder in lubricating oil

A method to realize stable dispersion of nano BN in the lubricating oil. The method is as below: first adding BN nanoparticles and a silane coupling agent in the lubricating oil, fully shocking and dispersing by using ultrasonic and heating in a water bath for reaction; adding Isobutylene polyisobutylene succimide (T154) to the solution, fully shocking and dispersing by using ultrasonic, so as to obtain a nano boron nitride oil solution with long time stable dispersion after the reaction. The invention realizes the rapid preparation of the nano BN oil solutionby using silane coupling agent as a dispersant and T154 as a stabilizer, prepares nano BN oil solution with good dispersion and stability, and lays the foundation for industrial application of BN nanoparticles as a lubricating oil additive.

Owner:XI AN JIAOTONG UNIV

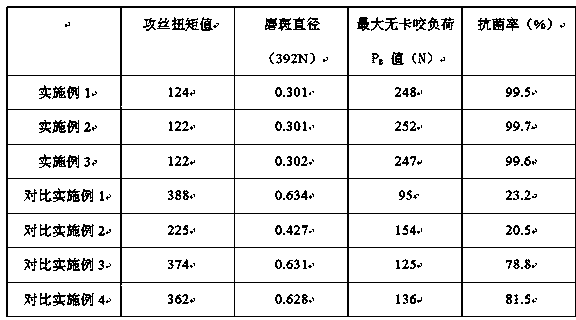

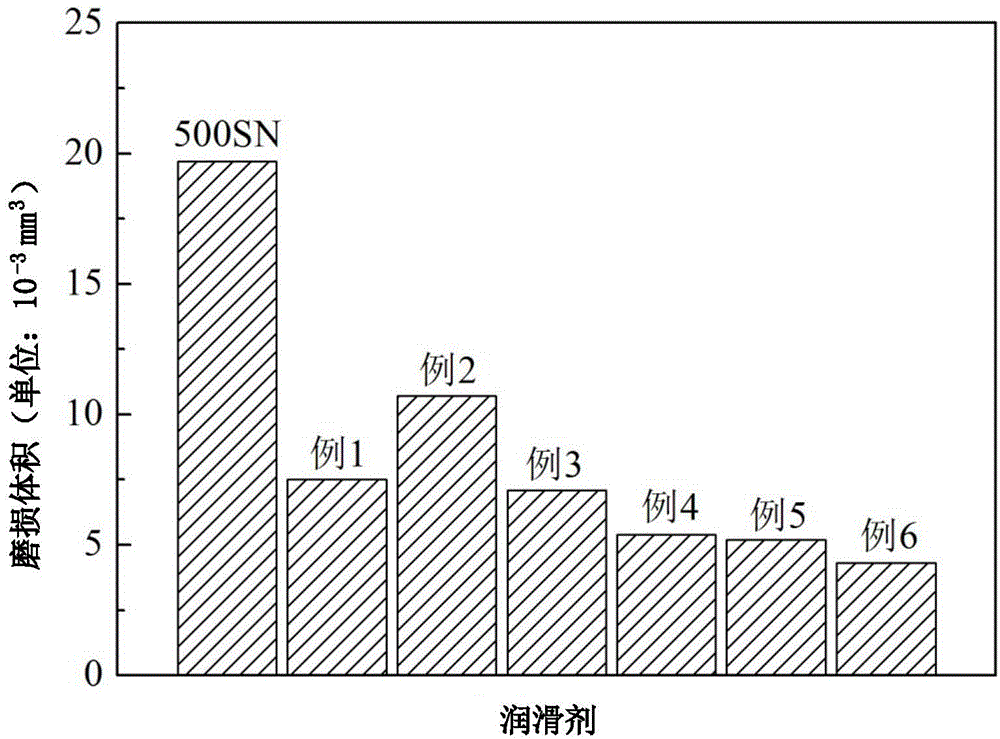

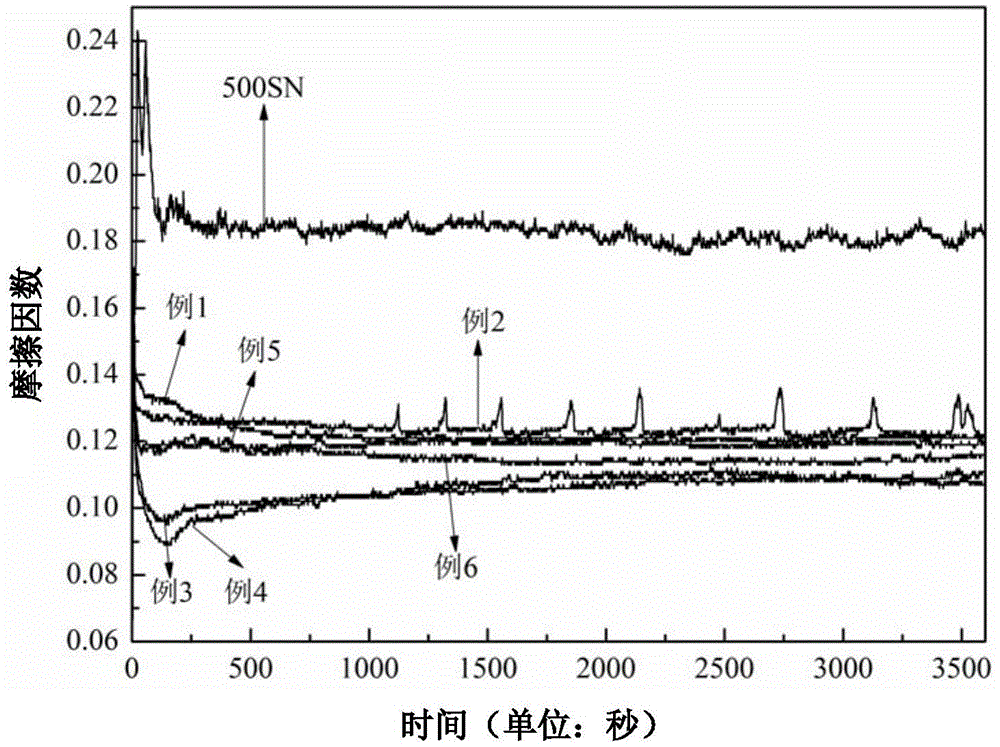

Metal cutting fluid containing nanometer titania of different particle sizes and preparation method of metal cutting fluid

InactiveCN109370717ALow tapping torque valueImprove the lubrication effectLubricant compositionVegetable oilSubstance.toxic

The invention discloses metal cutting fluid containing nanometer titania of different particle sizes and a preparation method of the metal cutting fluid. The prepared metal cutting fluid has low tapping torque and is excellent in lubricating property and low in grinding spot diameter, the wear resistance of the metal cutting fluid is excellent, the maximum non-seizure load PB value is great, the extreme pressure resistance is obvious, and the antibacterial property is outstanding. The metal cutting fluid does not contain sodium nitrite or any other substance toxic and harmful to the environment, takes vegetable oil as a main ingredient, is added with some high-efficiency additives, and is green, environmental-friendly, high-efficiency, simple in formula, excellent in antibacterial propertyand difficult to deteriorate. Due to the addition of silver-loaded graphene, silver particles are loaded among graphene sheet layers, so that the dispersion property of the graphene is further enhanced, the sheet stripping is full, and the anti-wear and friction reducing properties of the prepared cutting fluid are enhanced. Meanwhile, the cutting fluid is endowed with an antibacterial effect, the cutting fluid is difficult to deteriorate, and the storage period is prolonged.

Owner:五河富强鑫金属制品有限公司

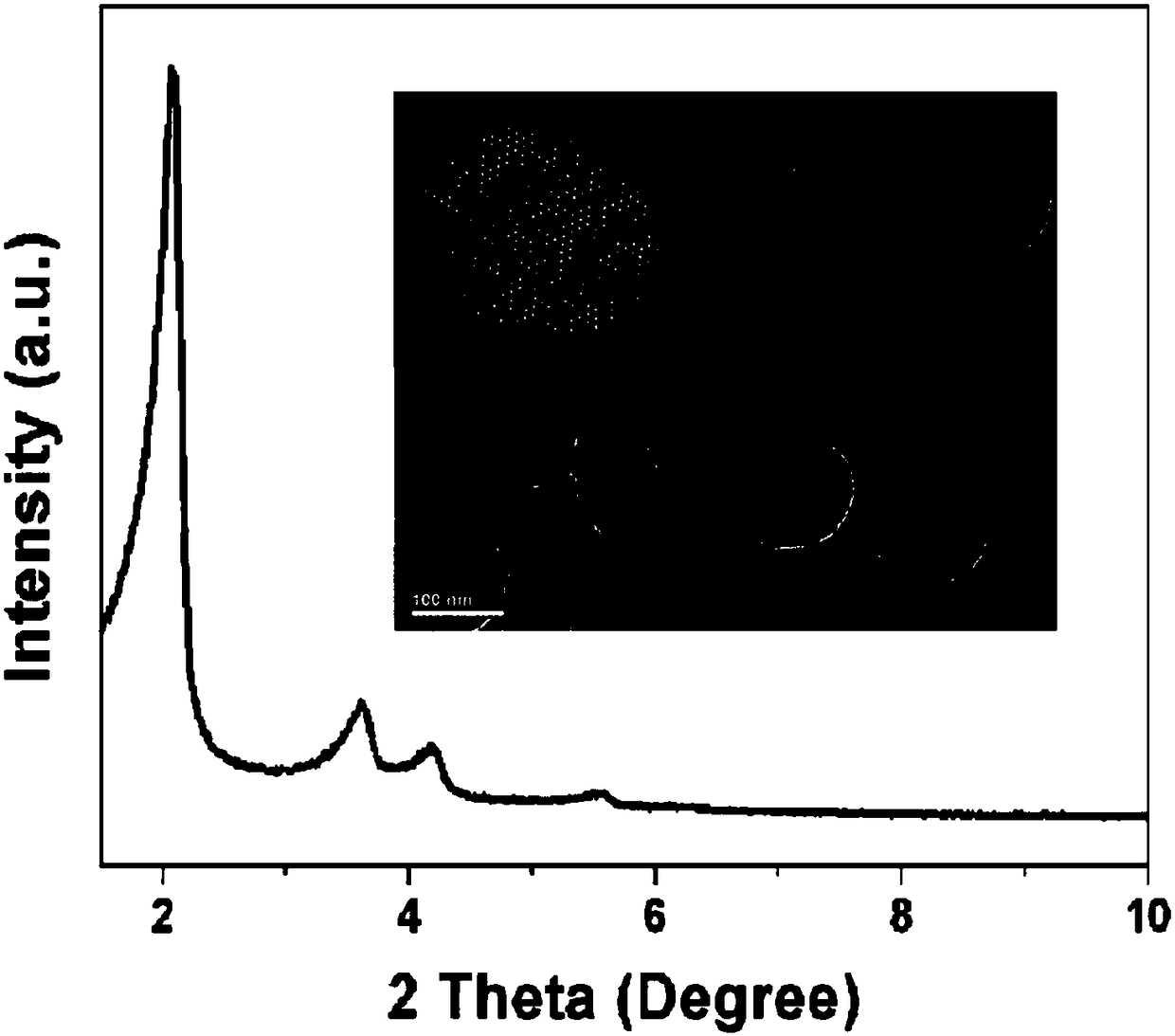

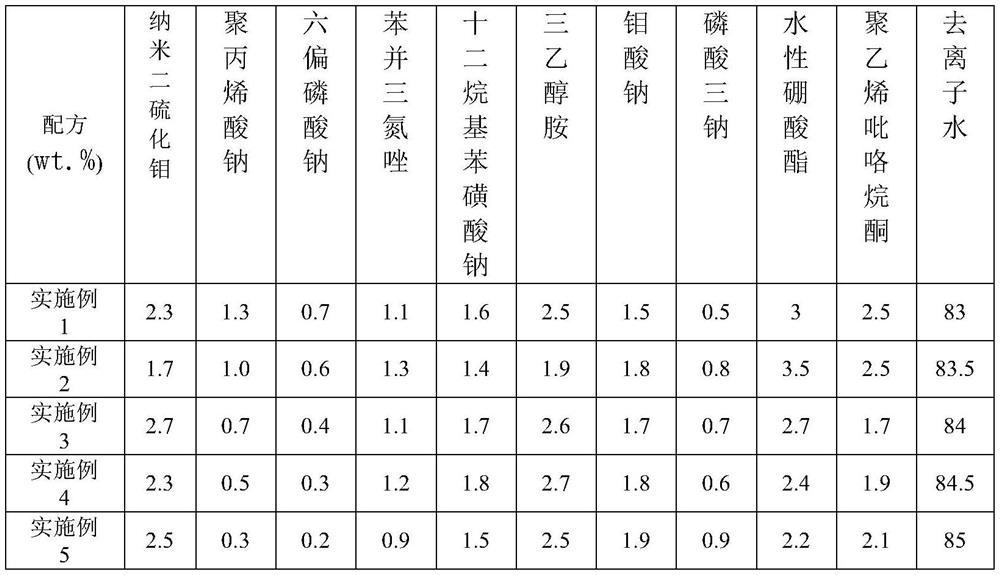

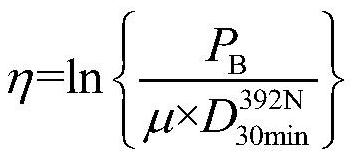

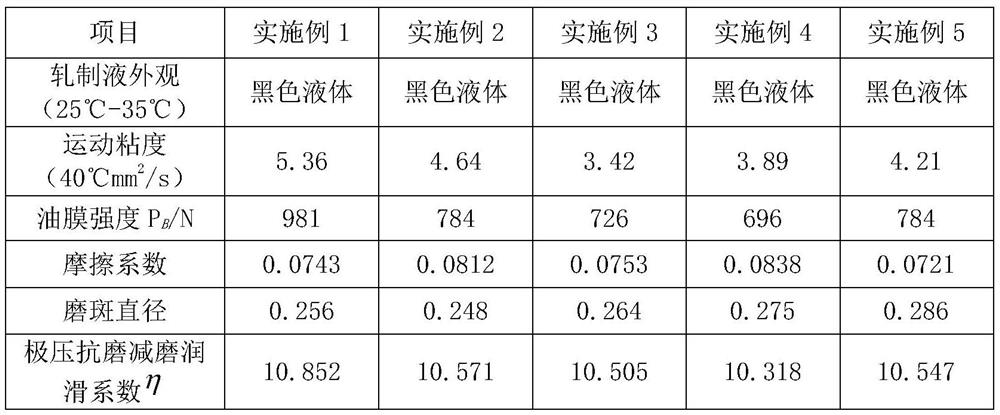

High-dispersity nano molybdenum disulfide water-based rolling liquid and preparation method thereof

ActiveCN112940836AImprove stabilityGood film-forming structural propertiesLubricant compositionSodium phosphatesPyrrolidinones

The invention relates to a high-dispersity nano molybdenum disulfide water-based rolling fluid and a preparation method thereof. Nano molybdenum disulfide with the particle size smaller than 50 nm, sodium polyacrylate and sodium hexametaphosphate are selected as a surface modifier and a dispersing agent, benzotriazole, sodium dodecyl benzene sulfonate, triethanolamine, sodium molybdate and trisodium phosphate are compounded to serve as an anti-rust agent, water-based boric acid ester and polyvinylpyrrolidone are used as extreme pressure agents, and deionized water is added to form the water-based nano rolling liquid with high dispersity and lubricating property. The novel molybdenum disulfide water-based nano rolling liquid is adopted to replace a traditional oil-in-water (O / W) emulsion, the development direction of energy conservation, consumption reduction, clean production and environmental protection of current metallurgical enterprises is better met, and the overall level of the steel industry in China can be improved.

Owner:ANGANG STEEL CO LTD

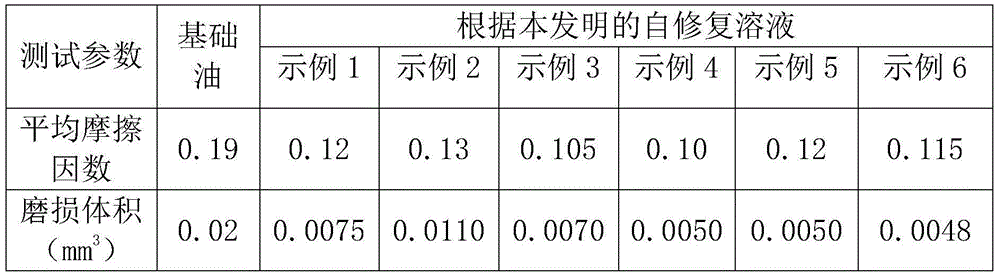

Self-repair solution, preparation method and use method thereof

ActiveCN105419907AImprove dispersion stabilityLow costAdditivesReduced propertiesOleic Acid Triglyceride

The present invention provides a self-repair solution, a preparation method and a use method thereof. The self-repair solution comprises, by mass, 2-30% of nanometer attapulgite powder, 1-30% of nanometer copper alloy, 0.5-5% of nanometer lanthanum oxide, 0.5-5% of oleic acid, 1-10% of a dispersant, and 50-95% of base oil, wherein the dispersant is one selected from dialkenyl succinimide, mono succinimide, and poly succinimide, the base oil is synthetic ester base oil or mineral base oil, and the nanometer attapulgite powder adopts natural attapulgite as a raw material, is subjected to industrial purification, and has a purity of more than or equal to 75%. The self-repair solutions of the present invention has high anti-wear shocking reducing property so as to substantially reduce the surface roughness of parts and reduce friction, such that the purposes of energy saving, consumption reducing, and equipment service life prolonging can be achieved.

Owner:张晓梅 +2

Anti-wear, anti-friction and stable-dispersion lubricating oil or lubricating grease and preparation method thereof

ActiveCN111808656AImprove anti-wear and anti-friction performanceImprove dispersion stabilityAdditivesChemistryCarbon chain

The invention relates to an anti-wear, anti-friction and stable-dispersion lubricating oil or lubricating grease. The anti-wear, anti-friction and stable-dispersion lubricating oil or lubricating grease comprises a lubricating oil or lubricating grease main component and long carbon chain grafted sulfonated graphene. A preparation method of the anti-wear, anti-friction and stable-dispersion lubricating oil or lubricating grease comprises the following steps: mixing the lubricating oil or lubricating grease main component with the long carbon chain grafted sulfonated graphene, stirring, and dispersing to obtain the lubricating oil or lubricating grease. According to the lubricating oil or lubricating grease provided by the invention, the long carbon chain grafted sulfonated graphene is added into the main components, so the long-term dispersion stability and the complex environment dispersion stability of the lubricating oil or lubricating grease are remarkably improved, the friction coefficient can be remarkably improved, the wear resistance and friction reduction performance of the lubricating oil or lubricating grease can be remarkably improved, the wear spot diameter is reduced,and the wear of copper and iron is reduced.

Owner:GUANGXI LIUGONG MASCH CO LTD +1

Hydroxyl magnesium silicate nanotube anti-wear material doped with organic silicon

InactiveCN109439388AImprove anti-wear and anti-friction performanceExtended service lifeAdditivesMicrometerMechanical equipment

The invention relates to the field of materials, in particular to a magnesium silicate nanotube anti-wear material doped with organic silicon. The material is prepared by doping an organic silicon material into a hydroxyl magnesium silicate nanotube according to the mass concentration of 1: 30-50 to form the hydroxyl magnesium silicate anti-wear nano material doped with the organic silicon, wherein the hydroxyl magnesium silicate nanotube is obtained by heating a magnesium compound containing magnesium element and a silicon compound containing silicon element in an alkali solution for reaction, and then centrifuging, washing and drying in sequence. The hydroxyl magnesium silicate nanotube anti-wear material doped with the organic silicon is in a nanotube shape, has a tube diameter of 15-55nanometers and a length of 100 nanometers to 5 micrometers, and has relatively regular products, uniform fineness and even dispersion. As an additive of lubricating oil, the anti-wear and anti-friction performance of lubricating oil can be greatly improved, the lubricating function is excellent, and the service life of mechanical equipment is prolonged.

Owner:科特龙环境科技江苏有限公司

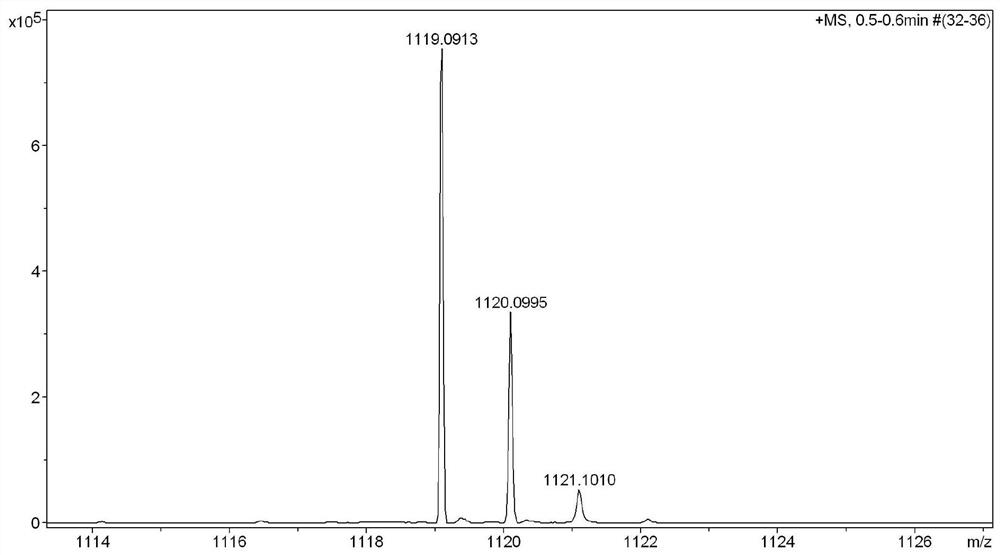

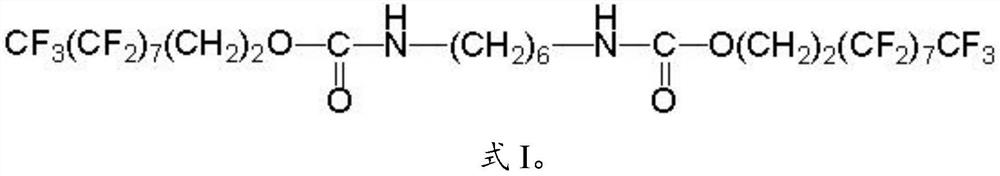

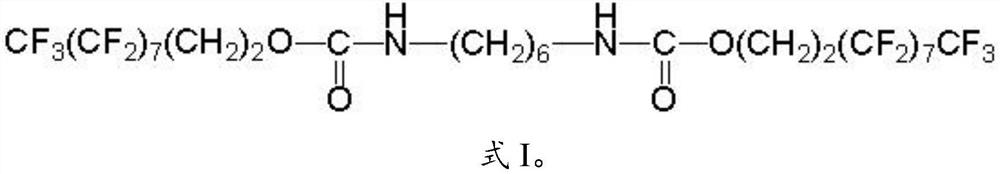

Perfluoropolyether supermolecular gel composite nano-particle lubricant as well as preparation method and application thereof

ActiveCN111635804AImprove anti-wear and anti-friction performanceImprove bearing capacityLubricant compositionFriction reductionPolymer science

The invention relates to the technical field of lubricating materials, and provides a perfluoropolyether supermolecular gel composite nano-particle lubricant as well as a preparation method and application thereof. According to the invention, the perfluoropolyether lubricating oil forms the supermolecular gel lubricant by using a gelator; the nano-particles are limited by using the limiting effectof supermolecular gel, so that the nano-particles are stably dispersed in the perfluoropolyether lubricating oil, and the nano-particles are used as an additive to effectively improve the wear resistance and friction reduction performance of the supermolecular gel lubricating oil and greatly improve the bearing capacity of the supermolecular gel. According to the perfluoropolyether supermoleculargel composite nano-particle lubricant provided by the invention, the problem of poor dispersion stability of nano-particles in perfluoropolyether lubricating oil is solved; a good solution is provided for the application of the nano-particles in the lubricant under the caustic conditions of aerospace and the like, and the method has important significance for prolonging the service life of mechanical equipment in the high-end fields of aerospace and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lubricating oil and preparation method thereof

InactiveCN107267266AExtended service lifeImprove anti-friction and anti-wear effectLubricant compositionThermal stabilityBase oil

The invention discloses lubricating oil. The lubricating oil is prepared from 70 to 80 portions by weight of base oil, 5 to 10 portions by weight of magnetic powder, 2 to 8 portions by weight of a viscosity improver, 1 to 5 portions by weight of a surface modifier, 2 to 5 portions by weight of a dispersant aid, 5 to 15 portions by weight of an anti-wear agent and 0.4 to 1 portion by weight of a wetting reinforcing agent. The preparation method comprises weighing the base oil, the viscosity improver, the surface modifier, the dispersant aid, the anti-wear agent and the wetting reinforcing agent in a mixer according to the weight part ratio, uniformly mixing the materials to obtain a mixture, heating the mixture to 200-250 DEG C, adding magnetic powder into the mixture, stirring the mixture until all the materials are completely dissolved, stopping stirring, cooling the mixture to the normal temperature, and standing the mixture for 3-5h to obtain lubricating oil. The novel lubricating oil greatly improves anti-wear and antifriction performances and improves thermal stability.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Motor shell for oil-electricity hybrid four-wheeled vehicles and preparation process of motor shell

The invention belongs to the field of new-energy vehicles and discloses a motor shell for oil-electricity hybrid four-wheeled vehicles and a preparation process of the motor shell. The motor shell is prepared from talcum powder, nano cerium oxide, nano titanium dioxide, diatomite, graphite fibers, glass fibers, molybdenum disulfide, manganese, nickel, aluminum and magnesium. The motor shell has the advantages of excellent mechanical performances, high corrosion resistance and applicability to the oil-electricity hybrid vehicles.

Owner:山东金立车业有限公司

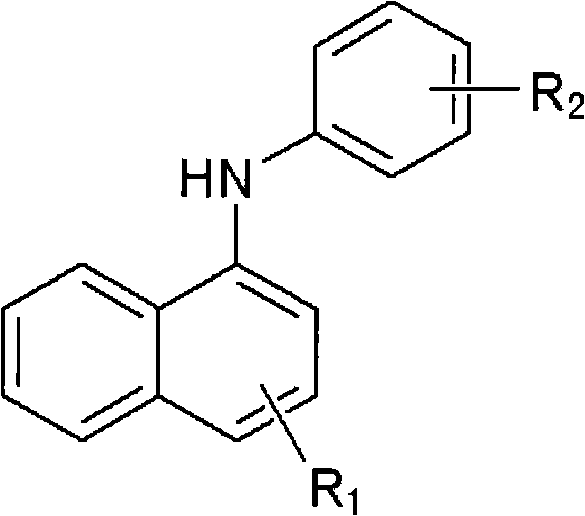

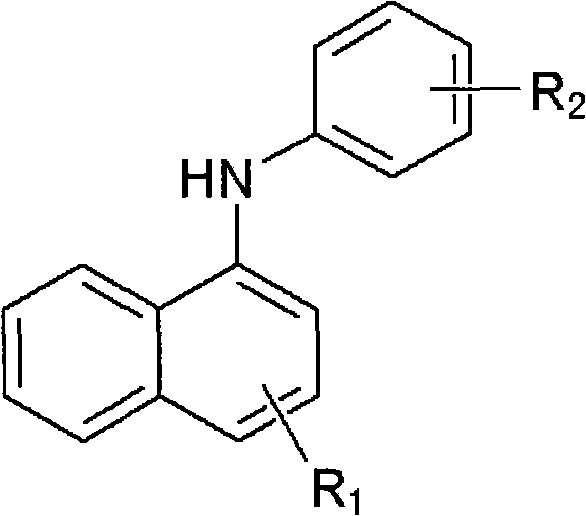

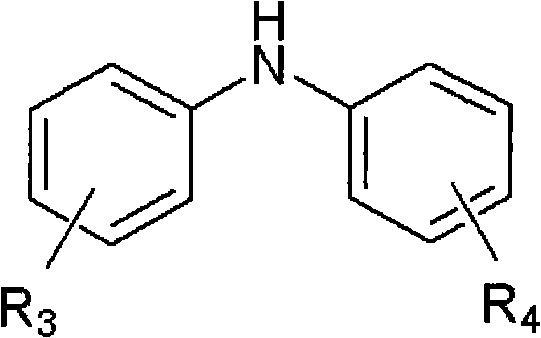

Lubricant composition and method for improving anti-wear and friction reduction properties of lubricant

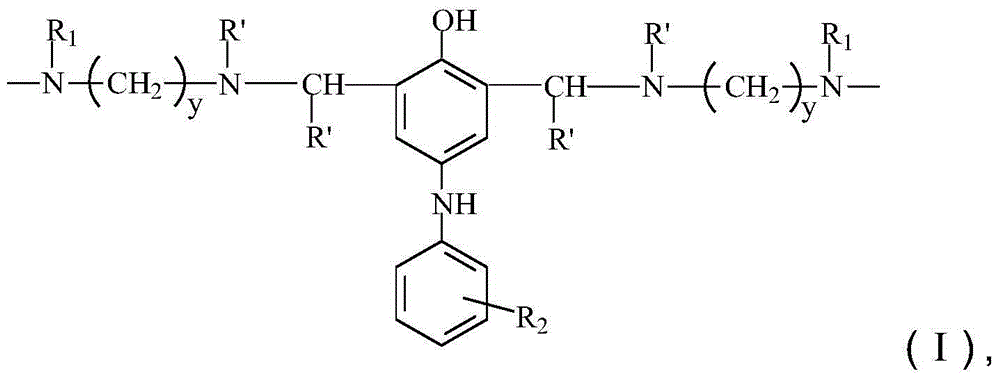

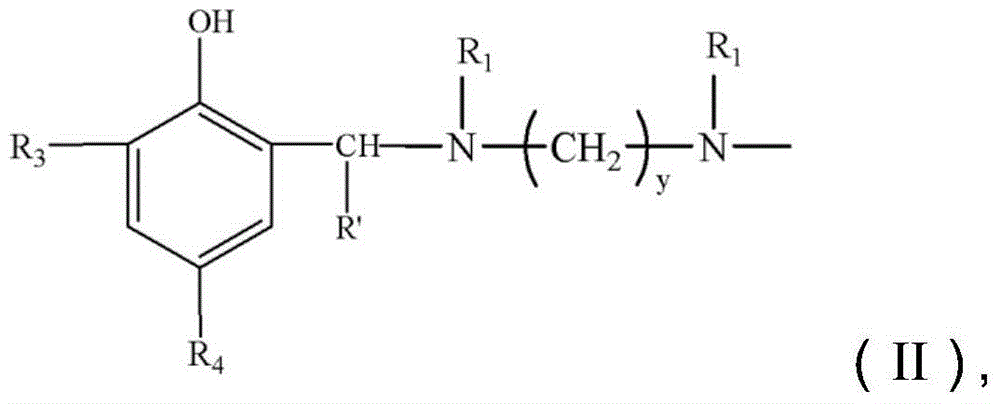

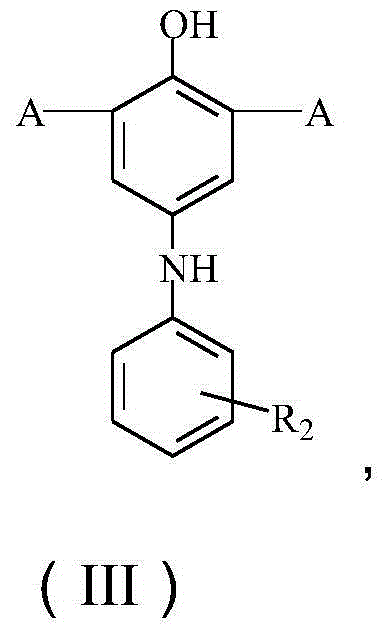

The invention provides a lubricant composition and a method for improving anti-wear and friction reduction properties of a lubricant. The composition contains a Mannich base, an alkyl-naphthalene sulfonate, phenolic ester and / or a thio-phenolic ester antioxidant, alkyl monosulfide phenoxide and lubricant base oil, wherein the Mannich base contains a structural unit (I) and a structural unit (II) shown in the specification, wherein each R1 is same or different and is independently selected from hydrogen, C1-4 straight chain or branched chain alkyl and a single bond respectively; each R' is same or different and is independently selected form hydrogen and C1-6 straight chain or branched chain alkyl respectively; R2 is selected from H, C1-8 alkyl, hydroxyl or nitryl; R3 is selected from C1-6 straight chain or branched chain alkyl; R4 is selected from hydrocarbyl of which the number-average molecular weight Mn is 300-3000; and each y is same or different and is independently selected from an integer from 2 to 5 respectively. The lubricant composition provided by the invention is excellent in clean dispersion property, anti-wear and friction reduction properties and antirust property.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-wear-resistance lubricating oil and preparation method thereof

InactiveCN110835574AIncrease activationImprove anti-wear and anti-friction performanceRotary stirring mixersTransportation and packagingVulcanizationActive agent

The invention discloses high-wear-resistance lubricating oil, which is prepared from the following raw materials by weight: 80 to 90 parts of base oil, 2 to 3 parts of nano tungsten disulfide, 0.4 to0.6 part of a surfactant, 0.8 to 1 parts of a defoamer and 1.5 to 2 parts of an antiwear additive. The invention also discloses a preparation method of the lubricating oil. According to the lubricating oil, the nano tungsten disulfide is uniformly dispersed in the lubricating oil through the compounding of the nano tungsten disulfide and the surfactant, and the anti-wear and anti-friction effect of the nano-particles is exerted; by adding the anti-wear additive, a composite protective film is generated at the bearing friction interface and has excellent anti-wear and anti-friction performance;the lubricating oil is processed through special processing equipment, the lubricating oil can be fully, thoroughly and efficiently blended and processed so that components are evenly dispersed in the lubricating oil to exert corresponding effects and to ensure quality of the lubricating oil. The wear-resistant high-quality lubricating oil is obtained and suitable for tapered roller bearings, heavy-duty gear and other fields.

Owner:安徽中天石化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com