Lubricating grease for automobile ball joint and preparation method of lubricating grease

A technology of lubricating grease and ball joint is applied in the field of lubricating grease for automobile ball joint and its preparation field, which can solve the problems of metal rod corrosion, grease detachment, oxidation, etc., and achieve the effects of low cost, good adsorption capacity and simple production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

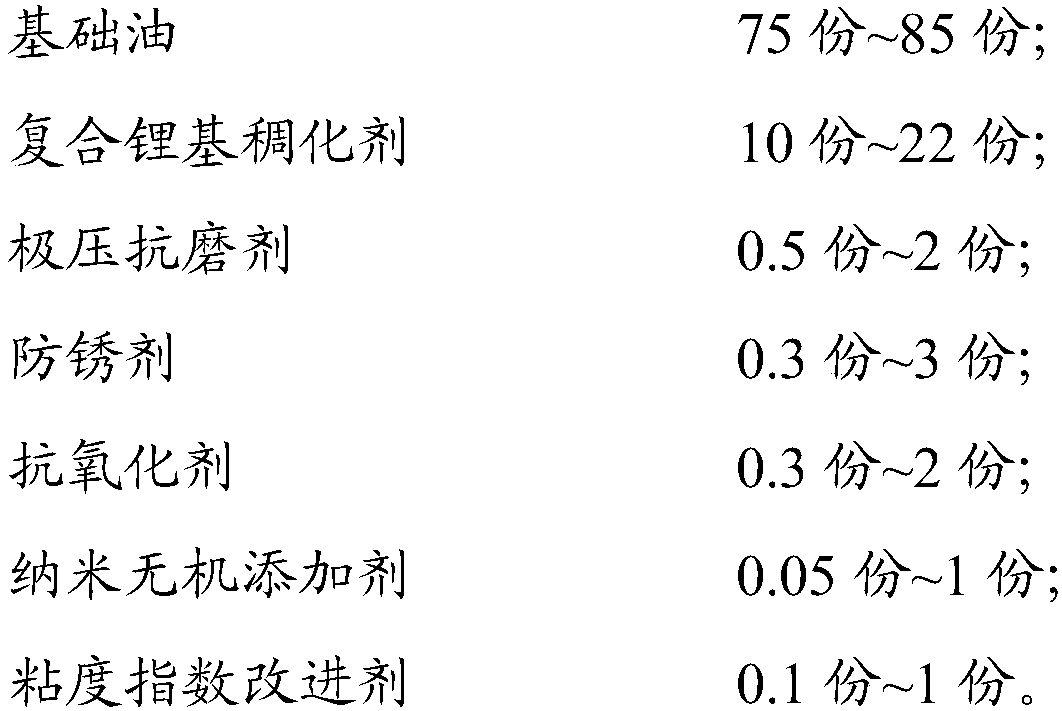

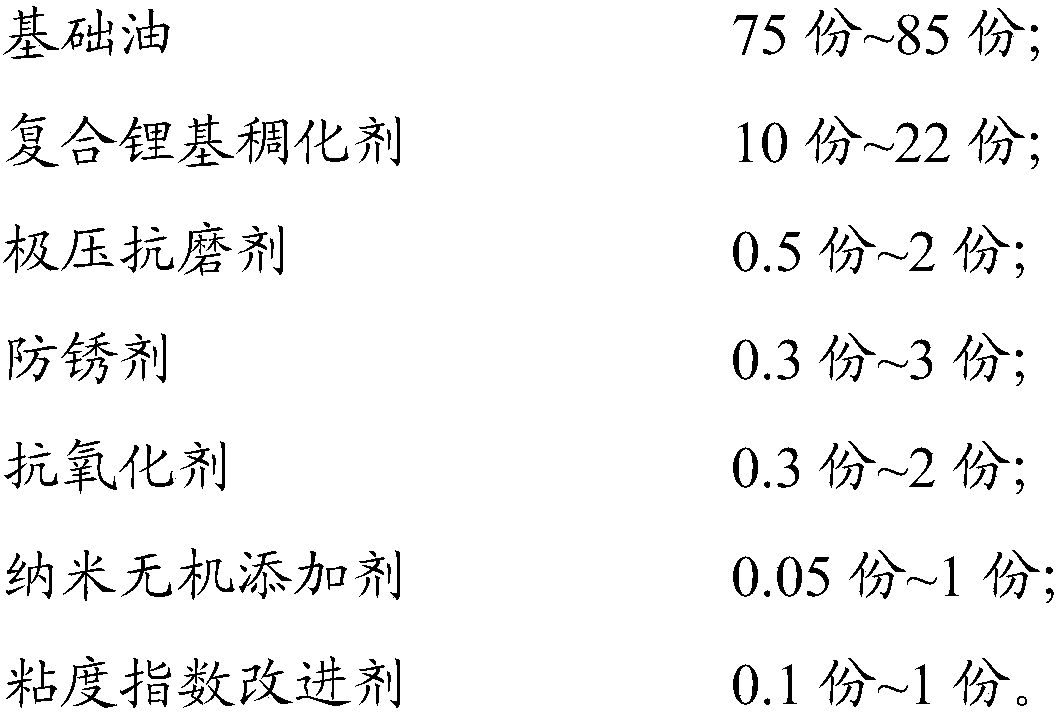

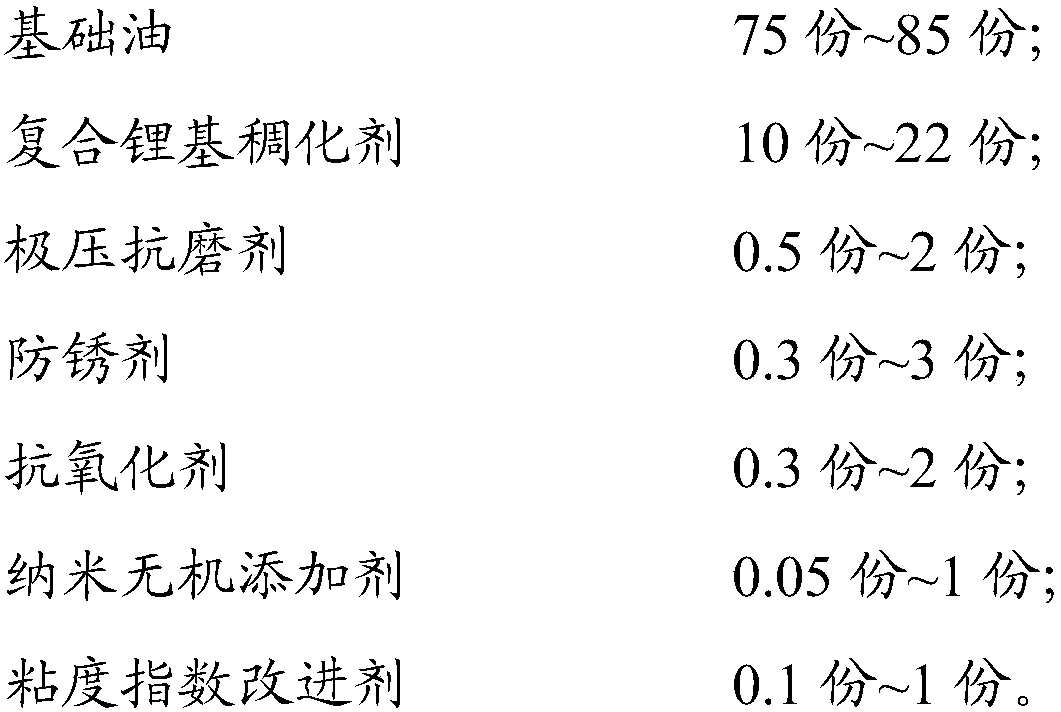

[0048] The preparation method of the above-mentioned lubricating grease for automobile ball joints in one embodiment specifically includes the following steps:

[0049] Step S10: mixing the complex lithium-based thickener with the base oil, heating and stirring, and cooling at a constant temperature to obtain an intermediate product;

[0050] Mixing the complex lithium-based thickener with a certain amount of base oil through step S10 can enable the thickener to be quickly and evenly dispersed in the base oil in the subsequent fat-making process. The more intense the mechanical stirring in the reaction process, the faster the reaction rate. Also faster, for example, after mixing 10 to 22 parts of the lithium complex thickener with 30 to 40 parts of the base oil, heat to 150°C to 200°C, and stir for 1h to 3h. After cooling in a constant temperature box at ~40°C, an intermediate product is obtained; as another example, after mixing 12 parts of the complex lithium-based thickener...

Embodiment 1

[0058] With 15 parts of 12-hydroxystearic acid-azelaic acid lithium base thickener and 35 parts of high viscosity silicone oil (viscosity is 550mm at normal temperature 2 / s) After mixing, heat to 180° C. and stir for 2 h, then perform constant temperature cooling at 25° C. to obtain an intermediate product. Get 0.5 parts of molybdenum disulfide and add it to 200 mL of oleic acid, react at 80°C for 2 hours to obtain modified molybdenum disulfide, add 0.3 parts of modified molybdenum disulfide to 46.6 parts of high-viscosity silicone oil (viscosity at room temperature 550mm 2 / s) after ultrasonic mixing for 2h, mixed with the intermediate product, and added 1 part of phosphite, 0.8 part of dodecenyl succinic acid, 1 part of diphenylamine and 0.3 part of polyisobutylene, at 50 After stirring at ℃ for 2 hours, it was naturally cooled to room temperature to obtain lubricating grease for automobile ball joints. The performance index of grease is shown in Table 1.

Embodiment 2

[0060] With 13 parts of 12-hydroxystearic acid-azelaic acid lithium base thickener and 40 parts of high viscosity silicone oil (viscosity is 800mm at normal temperature 2 / s) After mixing, heat to 190° C. and stir for 2.5 hours, then perform constant temperature cooling at 25° C. to obtain an intermediate product. Get 1 part of graphene and add it to 100 mL of oleic acid. After reacting for 2 hours at 85 ° C, modified graphene is obtained. 0.5 parts of modified graphene are added to 43.4 parts of high-viscosity silicone oil (viscosity at room temperature is 800mm 2 / s) after ultrasonic mixing for 2.5h, mixed with the intermediate product, and added 1 part of superbasic calcium sulfonate, 0.8 part of sodium carboxylate, 1 part of phenyl-α-naphthylamine and 0.3 part The ethylene-propylene copolymer was stirred at 55°C for 2 hours, and then naturally cooled to room temperature to obtain lubricating grease for automobile ball joints. The performance index of grease is shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com