Method to realize stable dispersion of nano BN powder in lubricating oil

A kind of lubricating oil, nano technology, applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of unsuitable industrial application, no research on the stability of BN oil solution stability of nano BN oil solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

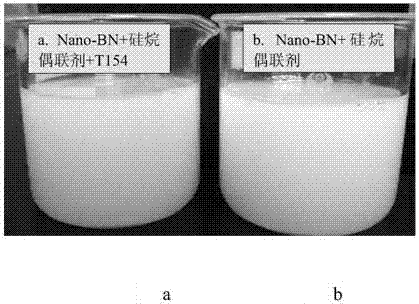

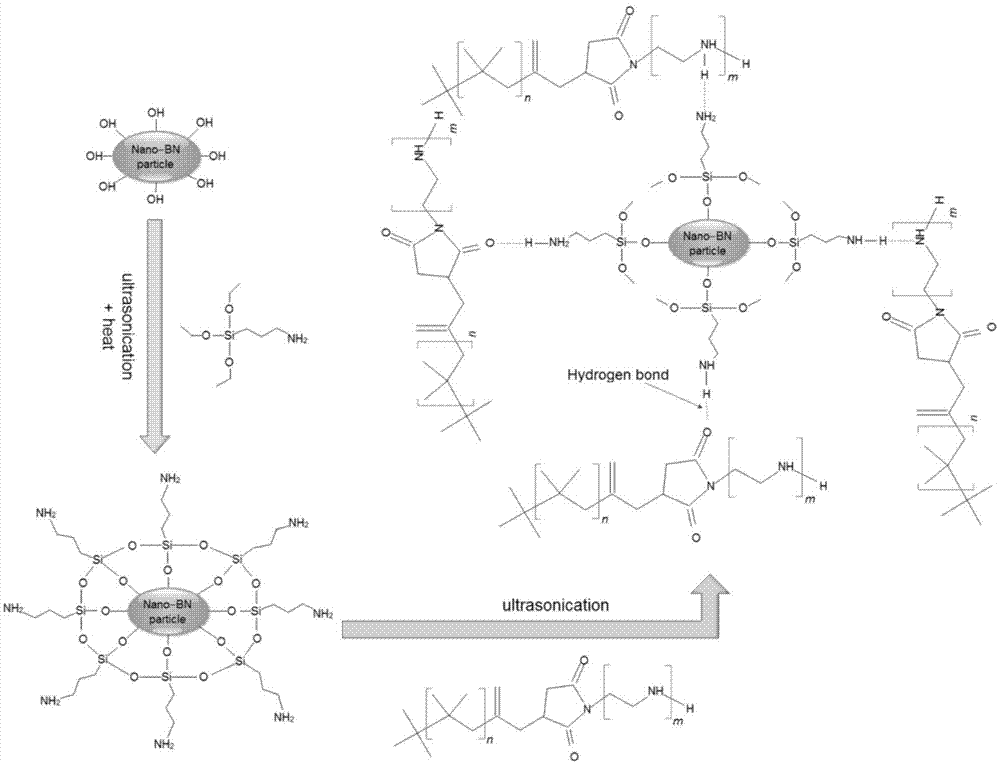

[0030] refer to figure 2 , this embodiment includes the following steps:

[0031] In the first step, ultrasonically disperse 0.04g of nano-BN particles with an average particle size of 80nm and 0.0016g of silane coupling agent KH-550 (γ-aminopropyltriethoxysilane) in 40g of paraffin oil to make milky white nano BN oil solution, obtaining concentration is the BN dispersion oil solution of 0.1wt%;

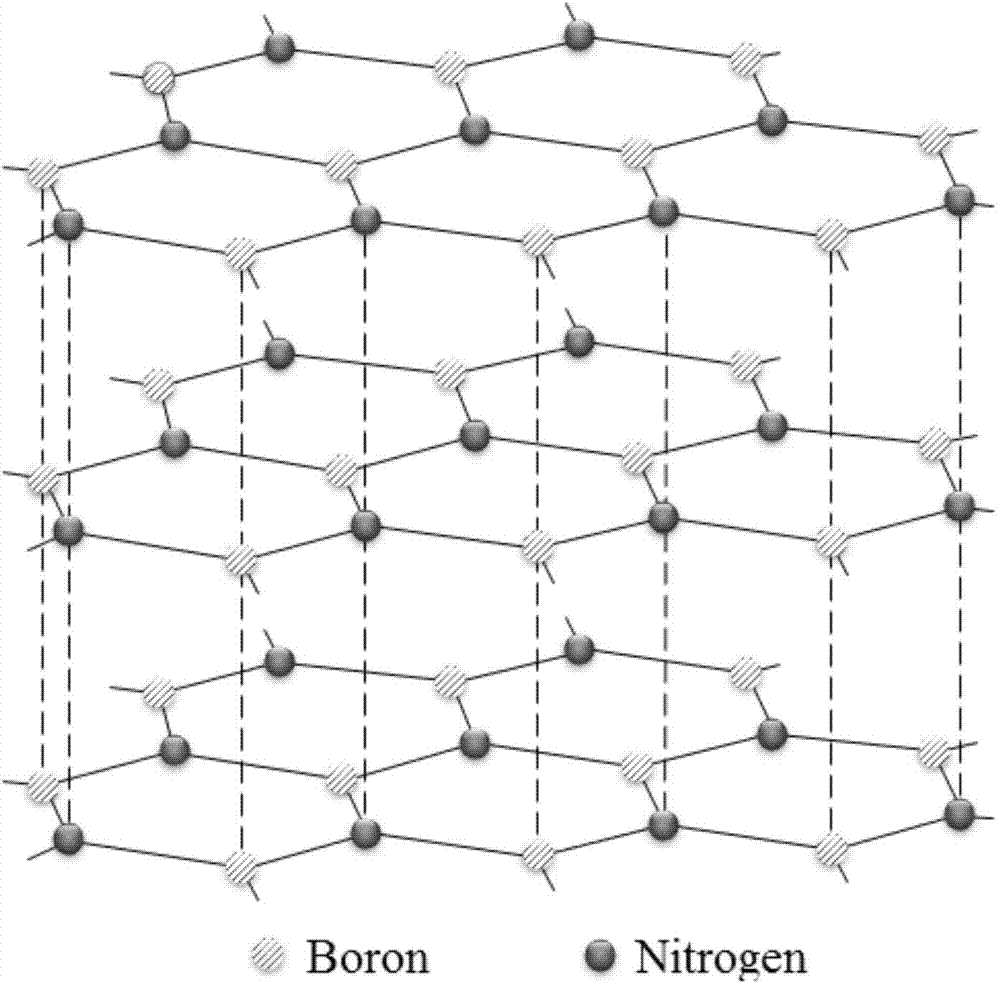

[0032] refer to figure 1 , the nano-BN refers to hexagonal boron nitride, which has a hexagonal layered structure,

[0033] The ultrasonic dispersion refers to: working frequency 40kHz; ultrasonic power 100W; ultrasonic time 30min;

[0034] In the second step, a constant temperature water bath is used to heat the reaction and fully stirred to obtain surface-modified nano-BN particles after the reaction is completed;

[0035] The water bath heating reaction, full stirring is: using magnetic stirring, the frequency is 50Hz, the set temperature is 80°C, and the stirring time is 30m...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040]In the first step, 0.04g of nano-BN particles with an average particle size of 80nm, 0.0008g of silane coupling agent KH-550 (γ-aminopropyltriethoxysilane) and 0.0008g of KH-560 silane coupling agent were ultrasonically dispersed in 10g 32# machine oil, 30g white oil, make milky white nano BN oil solution;

[0041] The ultrasonic dispersion is: working frequency 40kHz; ultrasonic power 100W; ultrasonic time 40min;

[0042] In the second step, a constant temperature water bath is used to heat the reaction and fully stirred to obtain surface-modified nano-BN particles after the reaction is completed;

[0043] The water bath heating reaction, full stirring is: using magnetic stirring, the frequency is 50Hz, the set temperature is 80°C, and the stirring time is 20min;

[0044] In the third step, 1.2 g of stabilizer polyisobutylene succinimide T154 is added to the nano-BN oil solution, and fully ultrasonically oscillate...

Embodiment 3

[0047] This embodiment includes the following steps:

[0048] In the first step, ultrasonically disperse 0.04g of nano-BN particles with an average particle size of 80nm and 0.0016g of silane coupling agent KH-550 (γ-aminopropyltriethoxysilane) in 40g of paraffin oil to make milky white nano BN oil solution, obtaining concentration is the BN dispersion oil solution of 0.1wt%;

[0049] The ultrasonic dispersion is: working frequency 40kHz; ultrasonic power 100W; ultrasonic time 30min;

[0050] In the second step, a constant temperature water bath is used to heat the reaction and fully stirred to obtain surface-modified nano-BN particles after the reaction is completed;

[0051] The water bath heating reaction, full stirring is: using magnetic stirring, the frequency is 50Hz, the set temperature is 80°C, and the stirring time is 30min;

[0052] In the third step, the stabilizer polyisobutylene succinimide T154, which accounts for 2wt%, 5wt%, and 15wt% of the nano-BN content, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com