Patents

Literature

69results about How to "Increase activation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

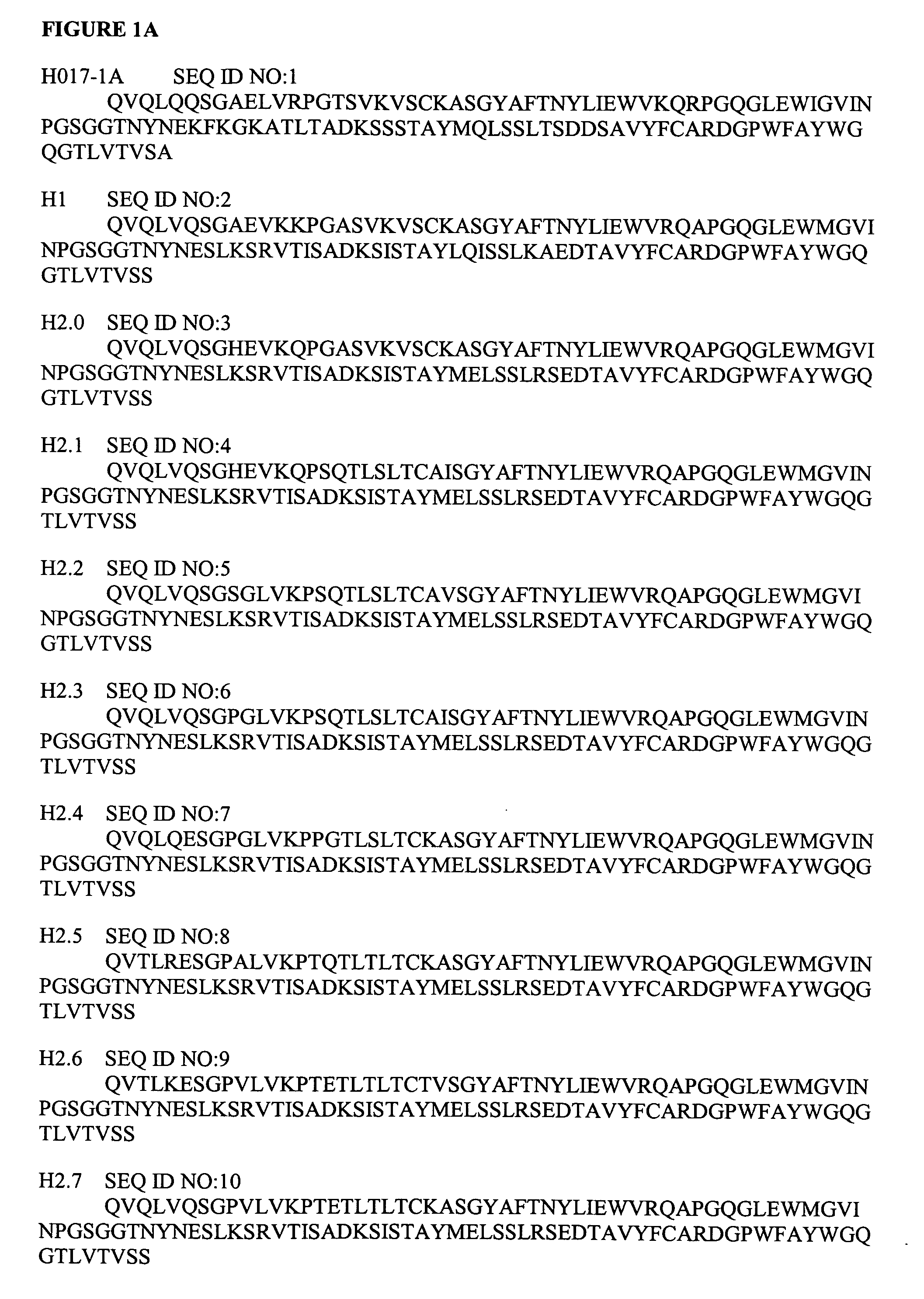

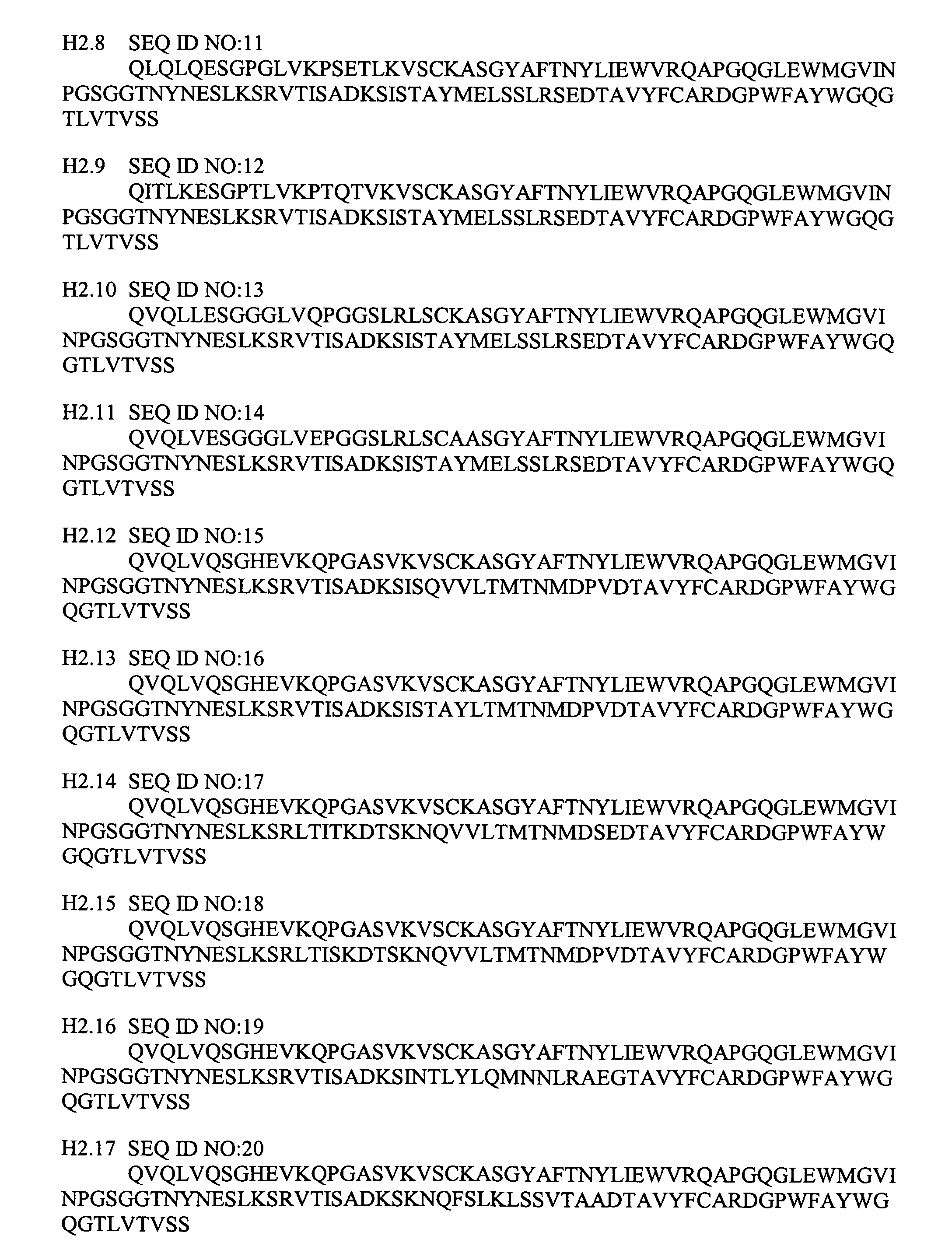

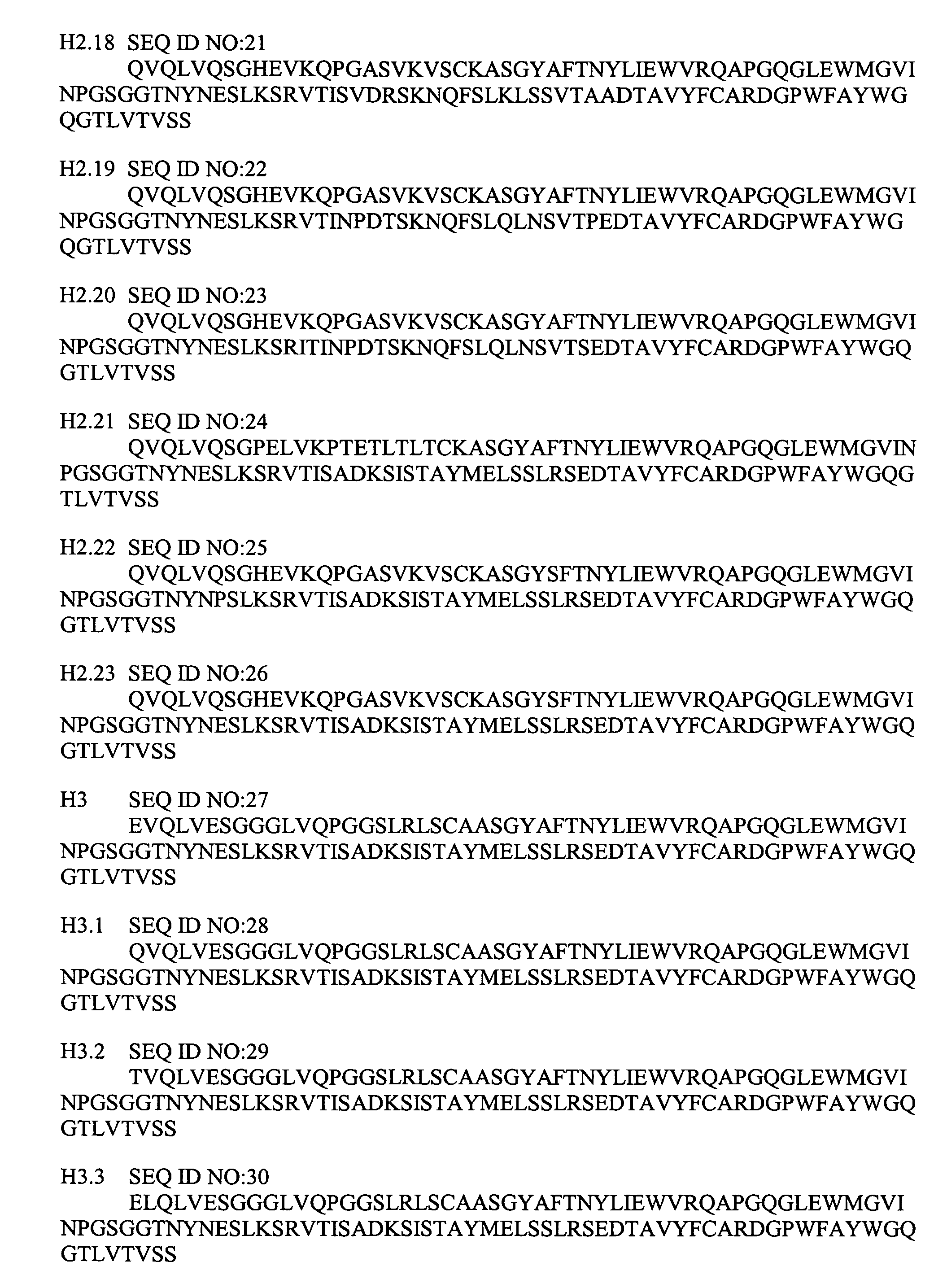

Optimized proteins that target Ep-CAM

InactiveUS20070122406A1Increase activationIncreased activationImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsAntibodyMolecular biology

Owner:XENCOR

Processing technology of modified calcium carbonate

InactiveCN106118136AGood dispersionIncrease activationCoatingsPigment treatment with non-polymer organic compoundsDispersityHigh activation

The invention discloses a processing technology of modified calcium carbonate. The processing technology includes the following steps that 1, by mass, 90-110 parts of calcium carbonate, 1.5-2.5 parts of a titanate coupling agent and 2-3 parts of stearic acid are selected; 2, calcium carbonate is put into a high-speed mixer, heating and mixing are carried out, and dewatering is carried out for 5-10 min when the temperature reaches 100 DEG C; 3, the titanate coupling agent is put into the high-speed mixer, calcium carbonate is activated for 5-10 min at 110-130 DEG C, and stearic acid is added for 10-20 min of modification treatment; 4, modified calcium carbonate is discharged out of the high-speed mixer at 110 DEG C and cooled, and powdery hydrophobic calcium carbonate with a high activation degree and good dispersity is obtained. According to the processing technology of modified calcium carbonate, the dispersity of modified calcium carbonate is improved, the surface of calcium carbonate is hydrophobic, and modified calcium carbonate has good adsorbability.

Owner:ANHUI HUAYU PIPELINE MFG

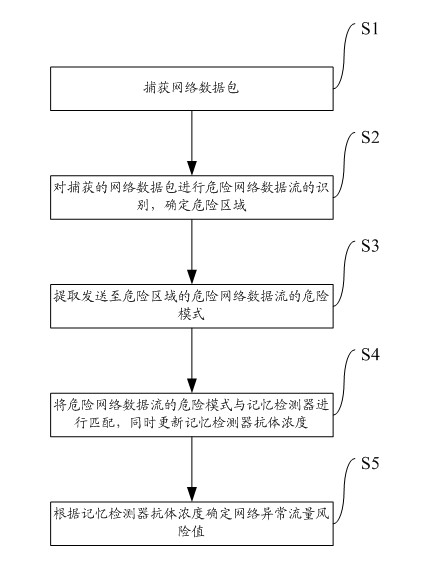

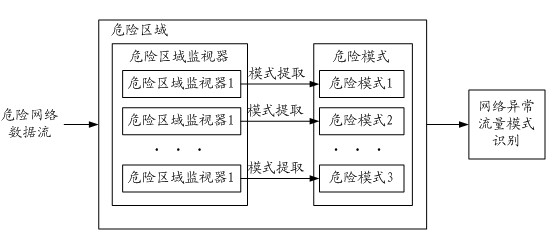

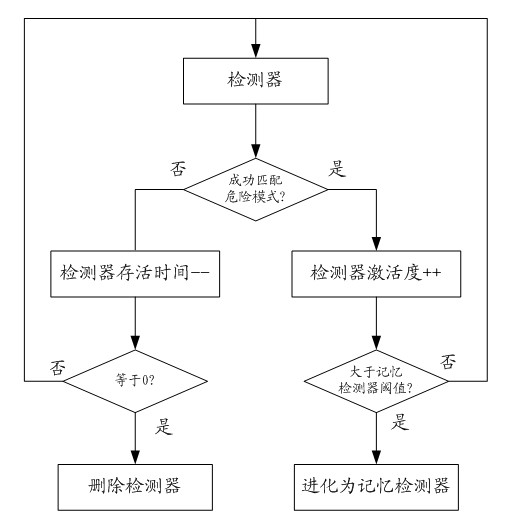

ISP anomalous traffic detection method and system

ActiveCN101945112AReduce false recognition rateShorten survival timeData switching networksData streamNetwork packet

The invention discloses an ISP anomalous traffic detection method and a system, belonging to the field of information safety. The method comprises the following steps: capturing a network data packet; distinguishing a dangerous network data stream to determine a dangerous area; extracting the dangerous mode of the dangerous network data stream sent to the dangerous area; matching the dangerous mode with a memory detector, and meanwhile updating the antibody concentration of the memory detector; and according to the antibody concentration of the memory detector, determining the value at risk of the anomalous traffic of a network. The system of the invention comprises a network data packet acquisition module, a danger identification module, a dangerous area identification module, a network anomalous traffic mode identification module and a danger assessment module. The invention can solve the problems of low misinformation rate, poor self-adaption ability or no self-adaption ability. The invention also adopts the tolerance mechanism of the network anomalous traffic to cause the system to have the ability of detecting the anomalous network traffic caused by a large number of sudden normal network accesses.

Owner:四川通信科研规划设计有限责任公司

Stone-plastic wallboard

InactiveCN107244868AHigh activityIncrease activationAnti-corrosive paintsElectrically-conductive paintsFiberCrack resistance

The invention provides a stone-plastic wallboard which comprises 50-80 parts of calcite powder, 40-60 parts of PVC (Polyvinyl Chloride) resin, 20-30 parts of chloroprene rubber, 33-43 parts of butadiene-acrylonitrile rubber, 3-5 parts of conductive fibers, 30-50 parts of marble powder, 4-8 parts of processing aids, 4-8 parts of a modifier, 1-3 parts of a stabilizer, 2-5 parts of a foaming agent, 1-5 parts of a lubricating agent, 90-100 parts of semi-hydrated gypsum, 1-3 parts of bamboo charcoal fibers, 2-5 parts of methyl cellulose, 3-7 parts of ethyl cellulose, 20-30 parts of a stone-like coating and 3-6 parts of polyvinyl alcohol. According to the stone-plastic wallboard disclosed by the invention, the calcite powder, the marble powder, the semi-hydrated gypsum, the PVC resin, chloroprene rubber and the butadiene-acrylonitrile rubber are mixed, so that the prepared stone-plastic wallboard has excellent mechanical strength, tensile strength and crack resistance, the activity of the semi-hydrated gypsum is improved, the content of soluble impurities in the semi-hydrated gypsum is reduced, a pulverization phenomenon on the surface of a gypsum base material is further avoided, and the strength and toughness of the semi-hydrated gypsum base material are improved, so that the gypsum is applied to the field of building materials in a wide range, the inventory of phosphogypsum in the natural world is reduced, and the environmental pollution is reduced.

Owner:合肥易美特建材有限公司

Solvent-free epoxy heavy-duty anticorrosive coating and preparation method thereof

InactiveCN110157293AReduce pollutionExcellent chemical stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

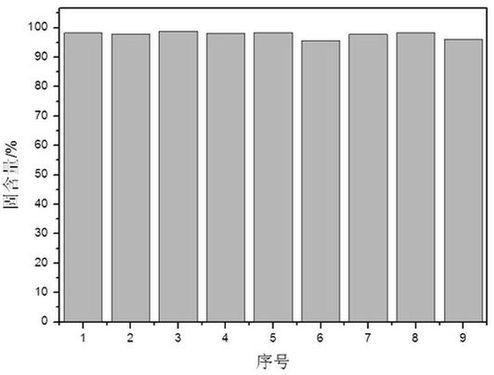

The invention relates to the field of anticorrosive coatings, in particular to a solvent-free epoxy heavy-duty anticorrosive coating and a preparation method thereof. The solvent-free epoxy heavy-dutyanticorrosive coating comprises a component A and a component B; the component A comprises 100 parts of a solvent-free epoxy resin, 8-16 parts of a active diluent, 70-115 parts of a pigment and filler, 1.5-2.6 parts of a coupling agent, 1.5-2.6 parts of a dispersing agent, and 0.8-1.3 parts of a thixotropic agent; and the component B is a curing agent, and the mass ratio of the component B to theliquid epoxy resin in the component A is (1.5:1)-(3.5:1). The solid content of the heavy-duty anticorrosive coating is 98% or more, and the coating is an environment-friendly coating; the coating contains only a very small amount of a volatile organic solvent, so that only a small amount of shrinkage cavities and pinholes are formed after the coating is cured, and the compactness of the coating effectively increases the barrier properties and permeability resistance of an anticorrosive coating layer.

Owner:HENAN UNIV OF URBAN CONSTR

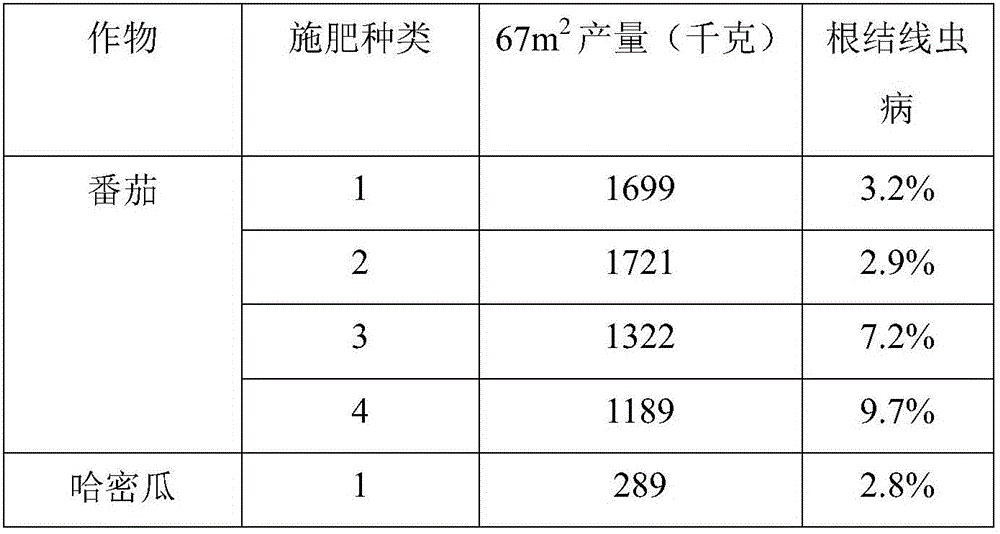

Preparing method of farm-oriented bacterial manure with activated oyster shell powders as a carrier

InactiveCN106365829AIncrease physical and chemical propertiesIncrease productionAnimal corpse fertilisersNitrogenous fertilisersAzotobacter chroococcumOyster

The invention discloses a preparing method of a farm-oriented bacterial manure with activated oyster shell powders as a carrier. The method comprises the steps of cultivating azotobacter chroococcum, bacillus megatherium, jelly bacillus, bacillus subtilis, 5406 antibiotic bacteria and trichoderma viride in each suitable culture medium respectively and making living bacteria counts in each bacteria solution which has been cultured reach 3-5 hundred million / g to be used for standby applications; measuring cultured azotobacter chroococcum bacteria solution, bacillus megatherium bacteria solution, jelly bacillus bacteria solution, bacillus subtilis bacteria solution, 5406 antibiotic bacteria bacteria solution and trichoderma viride bacteria solution respectively according to a volume ratio of 2 : 2: 2: 2: 1: 1, mixing the mixtures evenly to obtain a mixed bacteria bacteria solution; mixing the activated oyster shell powders with the mixed bacteria bacteria solution evenly according to a mass ratio of 3: 3-5 to obtain a mixed fertilizer, airing the mixed fertilizer to obtain the farm-oriented bacterial manure. According to the preparing method of the farm-oriented bacterial manure with activated oyster shell powders as a carrier, soil physical and chemical properties can be improved, crop yield can be increased and disease-resistant performance of plants can be strengthened.

Owner:陈景河

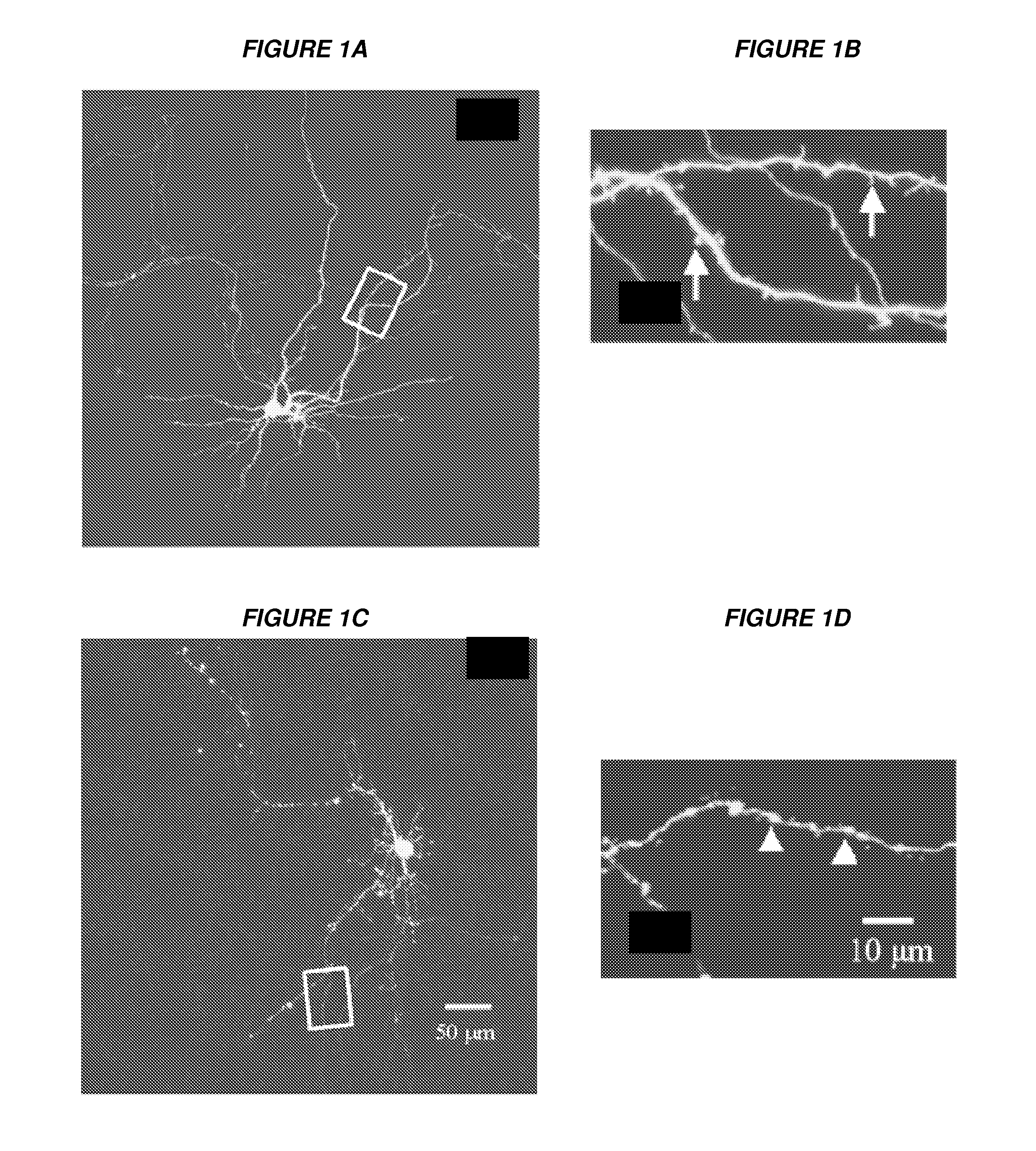

Methods to inhibit neurodegeneration

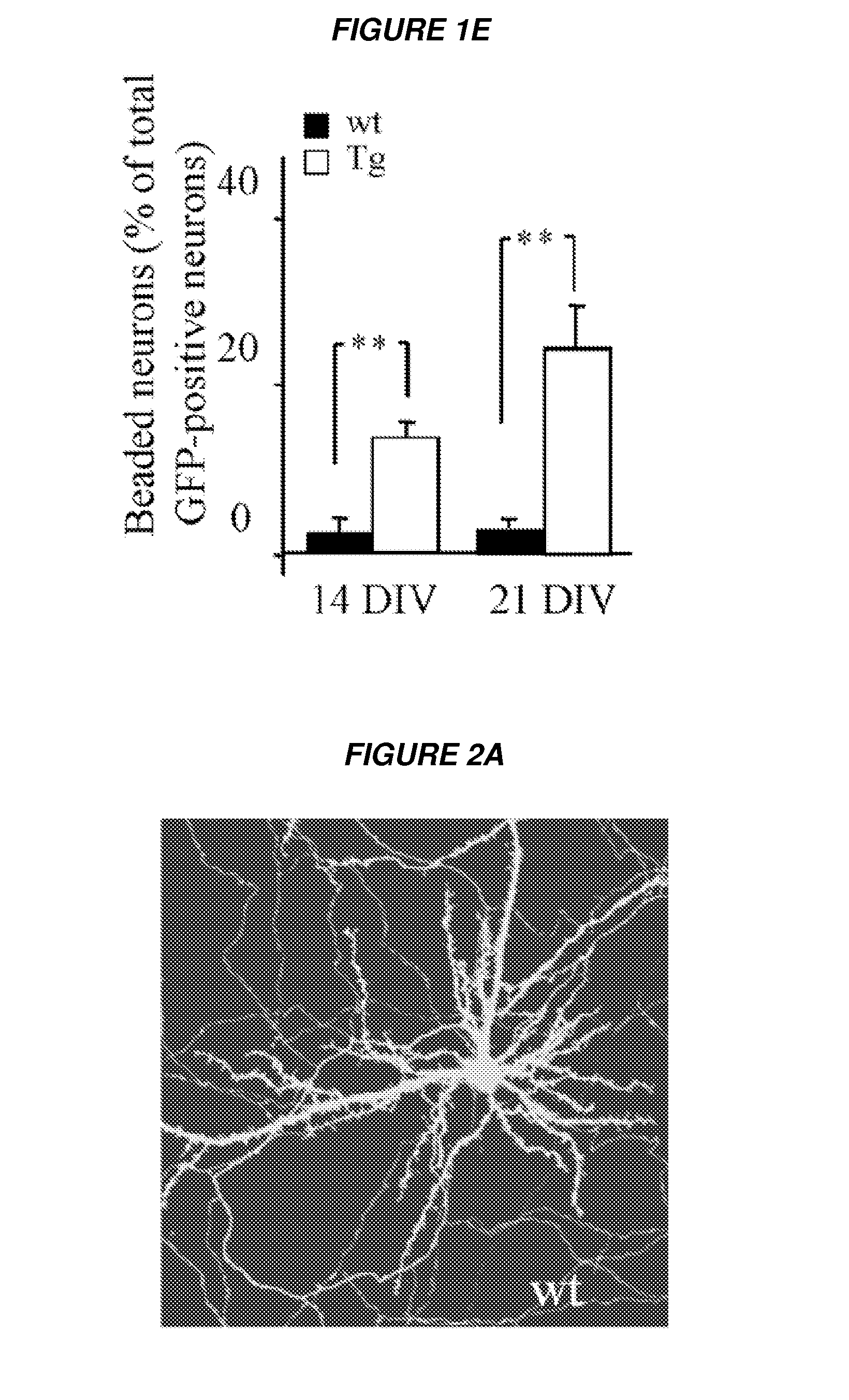

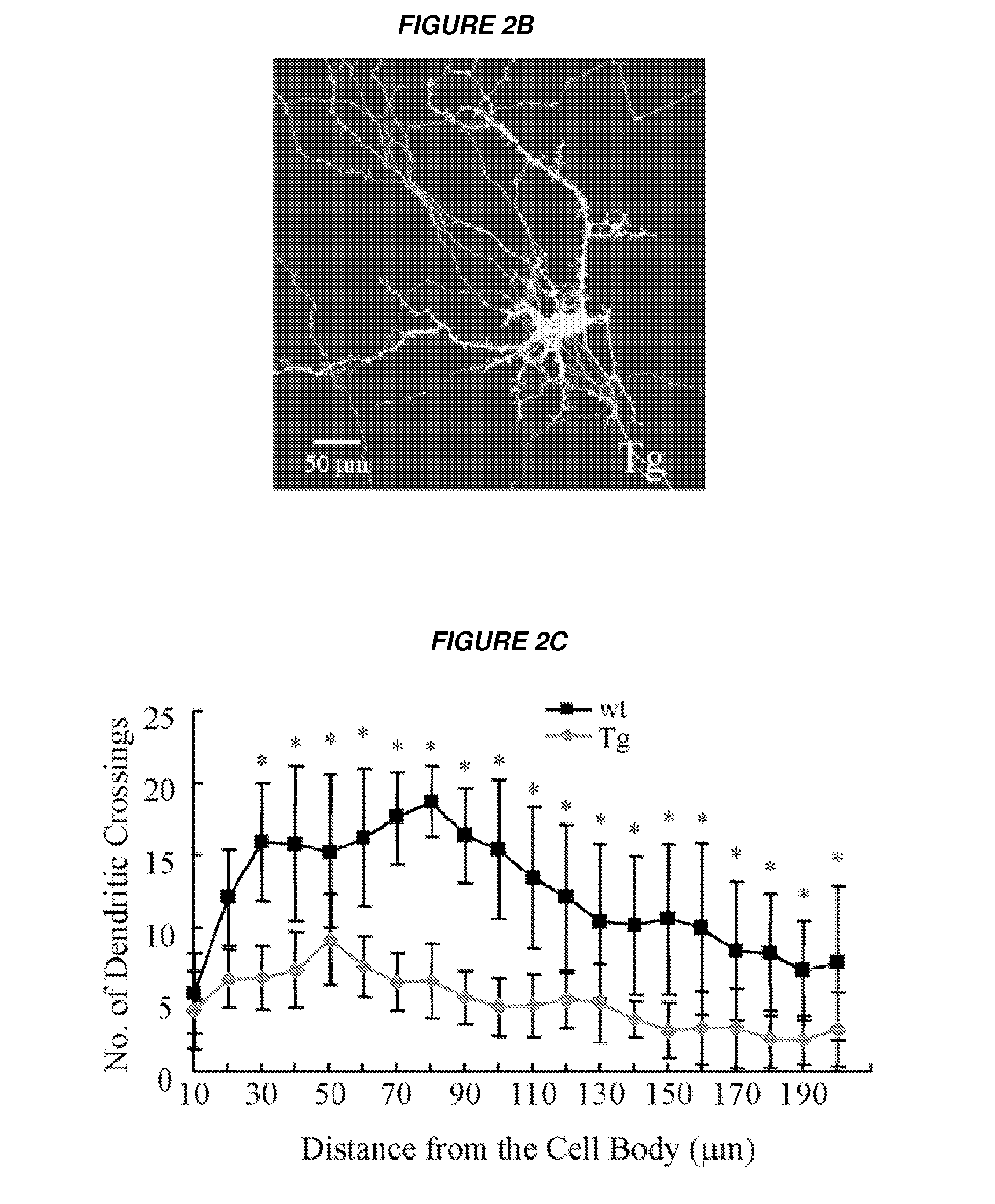

InactiveUS20130195866A1Increase activationDecrease NFAT activityNervous disorderPeptide/protein ingredientsEncephalitisSynapse

Disclosed herein are methods, and compositions for inhibiting neurodegeneration, e.g., in neuronal cells. The methods and compositions the invention can be used to treat a neurodegenerative disorder, e.g., Alzheimer's disease, Parkinson's disease, Huntington's disease, and frontotemproal dementia. In some embodiments, the methods and compositions can be used to inhibit neurodegeneration, e.g., caused by tau-mediated synaptic neurodegeneration, encephalitis, brain trauma, or any disorder suffering from weakening synapses.

Owner:THE GENERAL HOSPITAL CORP

Preparation method of modified nano calcium carbonate

The invention discloses a preparation method of modified nano calcium carbonate. The method comprises the following steps: adding nano calcium carbonate, phosphate, sodium stearate and sodium dodecylsulfate into a high-speed mixer, and carrying out activating treatment on the powdery hydrophobic nano calcium carbonate with high activation degree and favorable dispersity. By using the method, the modified nano calcium carbonate has hydrophobic surface, can be uniformly dispersed in an organic medium, has higher binding force with polymers, has improved dispersity and stability in the polymer matrix, and can be easily dispersed in the resin and rubber.

Owner:ANHUI HUAYU PIPELINE MFG

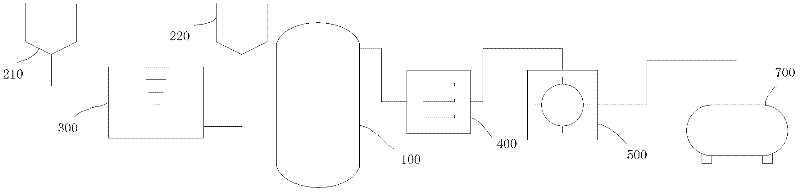

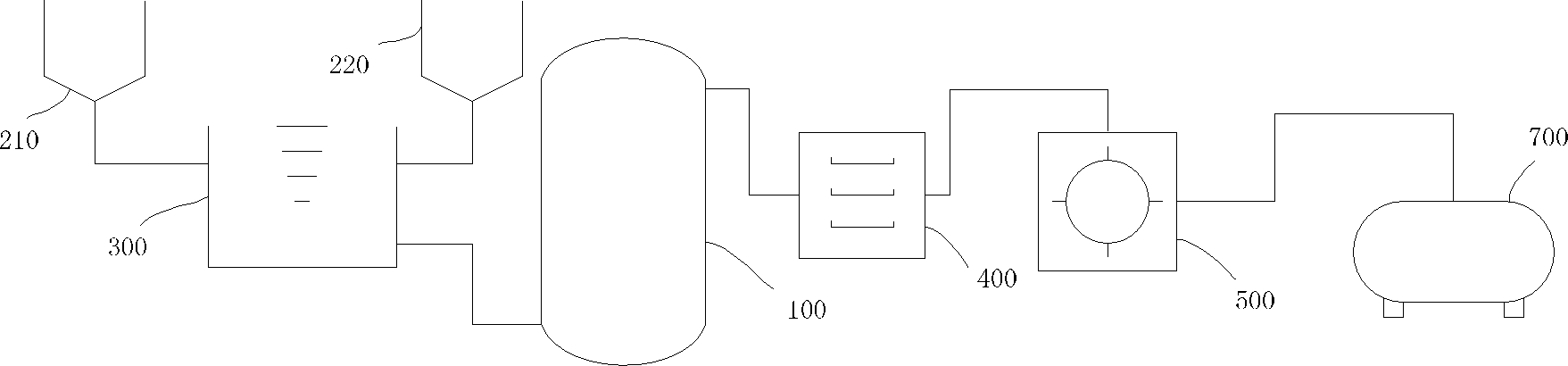

Wet grinding system for nonmetal mineral powder and grinding method thereof

The invention provides a wet grinding system for nonmetal mineral powder and a grinding method thereof. The wet grinding system for nonmetal mineral powder provided by the invention comprises a blade type stirring grinder, a continuous modifying machine and a drying machine. After the nonmetal mineral powder is prepared into first slurry, the first slurry is ground in the blade type stirring grinder and then enters into the drying machine. After the first slurry is dried in the drying machine, the first slurry enters into the continuous modifying machine so as to be modified. An obtained product has a fine grain size; the grain size of brucite can reach 8000 meshes; the grain size of barite can reach 10000 meshes; the grain size distribution is narrow; the cycling grinding is unnecessary during a production process; a plurality of grinding devices need not be serially connected; the energy consumption is low; and the excessive grinding phenomenon of the powder is avoided.

Owner:内蒙古超牌新材料股份有限公司

Calcium carbonate inhibitor for fluorite ore flotation and preparation method thereof

The invention discloses a calcium carbonate inhibitor for fluorite ore flotation. The inhibitor is composed of the following raw materials in parts by weight: 40-50 parts of water glass, 15-25 parts of sulfuric acid, 8-15 parts of sodium hexametaphosphate, 8-15 parts of sodium sulfate and 5-10 parts of alums. The inhibitor disclosed by the invention has the advantages of small dosage, low cost, stable performance and wide application range, can effectively improve the floatation rate of fluorite ores, can effectively eliminate coagulated and activated fluorite ores by adding the water glass, the sulfuric acid, the sodium hexametaphosphate, the sodium sulfate and the alums, and can inhibit silicon dioxide and carbonate in the ores, so that the concentrate output grade and quality of the ores can be improved, and the CaF2 recovery rate is obviously improved.

Owner:洛阳丰瑞氟业有限公司

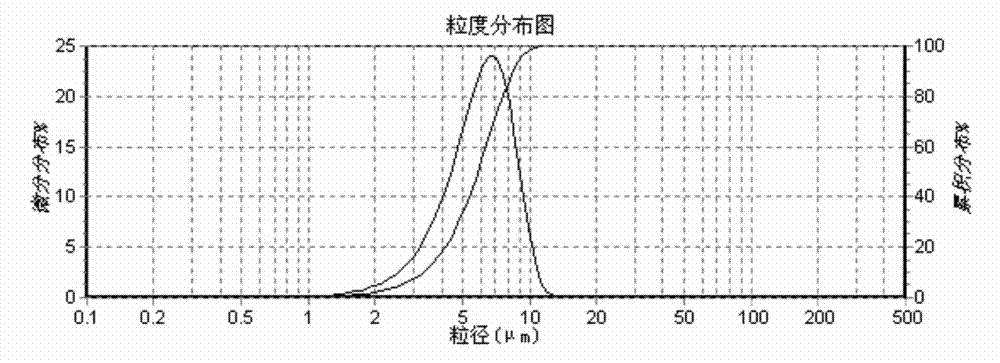

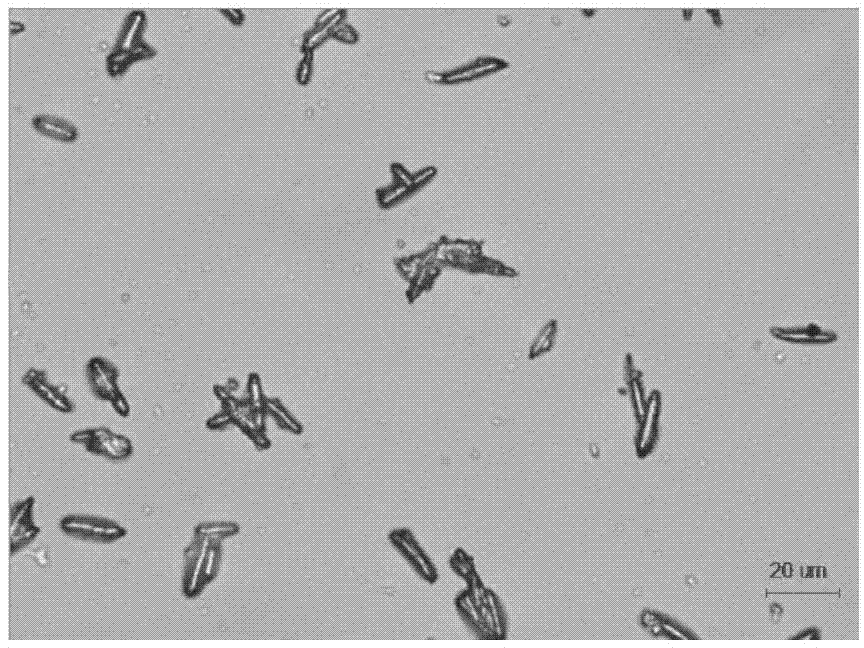

Preparation method of calcium carbonate whiskers by aluminic acid ester and sodium stearate in situ modification

ActiveCN104497638AConcentrated particle sizeIncrease activationPigment treatment with non-polymer organic compoundsSodium stearateFiltration

The invention discloses a preparation method of calcium carbonate whiskers by aluminic acid ester and sodium stearate in situ modification. The preparation method of the calcium carbonate whiskers comprises the following steps: adding a magnesium chloride solution into a calcium hydroxide slurry with a mass concentration of 0.5-1.5% under the condition with the temperature of 70-80 DEG C and a stirring rotation rate of 600-900 rotations per minute, enabling a mole ratio of calcium to magnesium in a mixture to be 1 to 2.5, stirring for 10 minutes, introducing gas with carbon dioxide and nitrogen according to a volume ratio of 1 to 3 under the condition with a rate of 10-100 liters per minute, adding aluminic acid ester and sodium stearate to modify, further introducing gas for 30 minutes when the pH value of a reaction solution reaches 7, then ending the reaction; washing, carrying out suction filtration and drying the reaction solution to obtain functional calcium carbonate whiskers, wherein the adding amount of aluminic acid ester is 0.5%-3% of the mass of the calcium hydroxide slurry, and the adding amount of sodium stearate is 0.5%-1.5% of the calcium hydroxide slurry. The whiskers prepared by the method are needle-shaped, and are intensive in particle diameter distribution and high in activation grade; when the whiskers are used as papermaking fillers, the performance of paper can be improved; a high retention rate is retained; the preparation process is simple; the reaction conditions are mild; the industrial production is liable to implement.

Owner:GUANGXI UNIV

Method for preparing mixed filler-modified heat-resistant anticorrosive coating

InactiveCN108424710AIncrease activationImprove heat resistanceFireproof paintsAnti-corrosive paintsEpoxyFiltration

The invention discloses a method for preparing a mixed filler-modified heat-resistant anticorrosive coating. The method comprises the following steps: performing ultrasonic treatment on a graphene oxide-polypyrrole solution; regulating the pH; adding hydrazine to be stirred and mixed uniformly; condensing and refluxing in an oil bath; performing suction filtration; adding acetone and deionized water for centrifugal washing; drying to obtain a graphene-polypyrrole compound; stirring a barium sulfate suspension in a constant-temperature bath; adding a compound modifier to be stirred; filtering when the mixture is hot; drying, grinding and screening to obtain modified barium sulfate; drying calcium carbonate in a vacuum oven; adding a coupling agent; modifying calcium carbonate with a heatingdry method; drying talc powder in a hot air oven; adding an aluminate coupling agent; melting and blending at a high speed to prepare the coupled modified talc powder; uniformly mixing waterborne epoxy resin with deionized water; performing ultrasonic separation; adding the modified filler; mixing and ball-milling; ultrasonically stirring and dispersing uniformly; mixing with a waterborne epoxy curing agent; ultrasonically stirring; adding an emulsifying agent, a dispersing agent, a defoaming agent and a wetting agent; stirring and mixing uniformly to obtain the heat-resistant anticorrosive coating.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Modifying method of potassium titanate fiber for carbon-based ceramic friction material

The invention relates to the technical field of raw material treatment of a carbon-based ceramic friction material, in particular to a modifying method of potassium titanate fiber for the carbon-based ceramic friction material. The modifying method comprises the following steps of pretreating the potassium titanate fiber by clarification limewater, using trench oil, vegetable oil and pine oil, and performing ultrasonic treatment, so as to enhance the activity of the potassium titanate fiber, and promote the activating degree of the potassium titanate fiber; adding a composite alkaline catalyst, supplementing titanium and potassium elements, adding pine oil and diesel oil, and performing ultrasonic treatment, so as to improve the quality of the potassium titanate fiber, promote the potassium titanate fiber to generate chemical reaction with other raw materials within shorter time after the potassium titanate fiber is added into the raw material of the carbon-based ceramic friction material, improve the toughness, abrasion-resistant property, heat stability, and dynamic and static friction coefficient ratio of the carbon-based ceramic friction material, and further improve the safety.

Owner:WANSHAN SPECIAL ZONE HONG AN FRICTION MATERIAL

Preparation method of barium sulfate-calcium carbonate compound modified epoxy resin coating

InactiveCN108559360AIncrease activationImprove heat resistanceEpoxy resin coatingsEpoxyResin coating

The invention discloses a preparation method of a barium sulfate-calcium carbonate compound modified epoxy resin coating. The preparation method is characterized in that the compound modified epoxy resin coating is prepared by heating a graphene oxide dispersion liquid, adding p-phenylenediamine dropwise, stirring, dissolving, reacting at the constant temperature, filtering, centrifuging and washing with deionized water and absolute ethyl alcohol, drying to obtain a graphene oxide-p-phenylenediamine composite; stirring a barium sulfate suspension liquid in a thermostatic bath, adding a compound modifier, stirring, filtering while the mixture is hot, drying, grinding, and screening to obtain modified barium sulfate; drying calcium carbonate in a vacuum drying oven, adding a silane couplingagent and a titanate coupling agent, heating and modifying calcium carbonate through a dry method; mixing and stirring deionized water ultrasonic dispersion liquid of the graphene oxide-p-phenylenediamine composite and deionized water ultrasonic dispersion liquid of a waterborne epoxy resin, ultrasonically treating, layering, pouring out water, heating the mixed solution in the drying oven, mixingwith a waterborne epoxy hardener, ultrasonically stirring, adding an emulsifier, a dispersing agent, a defoamer and a wetting agent, and ultrasonically treating.

Owner:WUHU BAOYI AMUSEMENT EQUIP

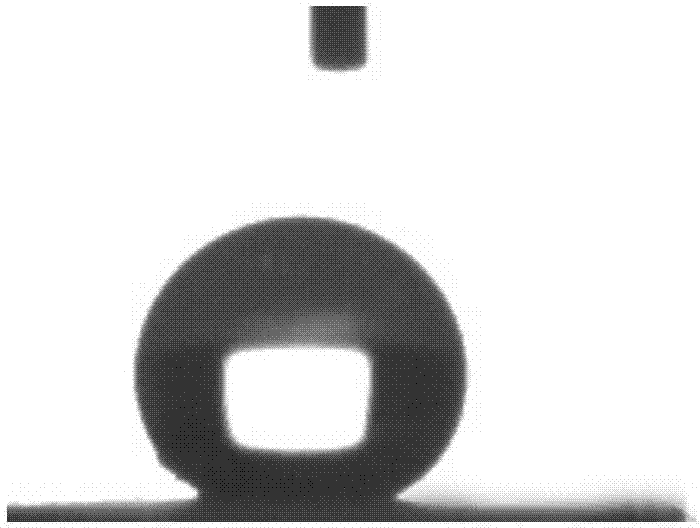

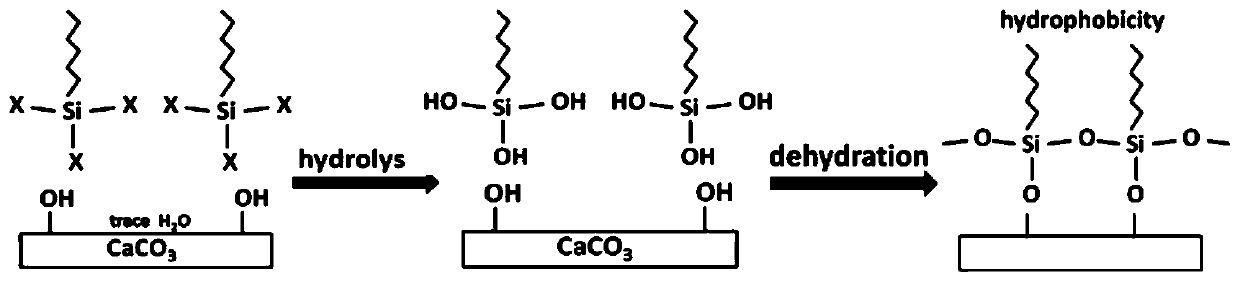

CaCO3 surface treatment method for high-filling PBAT biodegradable film and preparation method of film

The invention discloses a CaCO3 surface treatment method for a high-filling PBAT biodegradable film and a preparation method of the film. The invention belongs to the technical field of high polymer materials. The high-filling PBAT biodegradable film is prepared from the following raw materials: 50 to 90 percent of PBAT, 10 to 50 percent of CaCO3, 0 to 3 percent of a surfactant, 0 to 1 percent ofa dispersing agent, 0 to 1 percent of a chain extender, 0 to 1 percent of a lubricating agent and 0 to 1 percent of an antioxidant. CaCO3 is modified through a surfactant and then mixed with PBAT andother auxiliaries, twin-screw granulation is conducted, and then film blowing is conducted through a film blowing machine. The surfactant organic silicon material reacts with a trace amount of water on the surface of CaCO3 to be hydrolyzed so that a Si-X bond forms a Si-OH bond, and the Si-OH bond and -OH on the CaCO3 surface undergo polycondensation dehydration to form a monomolecular film, thereby promoting the hydrophilicity of the modified CaCO3 surface to be changed into hydrophobicity, effectively enhancing the compatibility between CaCO3 and PBAT, and ensuring that the activation degreeof the modified CaCO3 is up to 90% or above.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

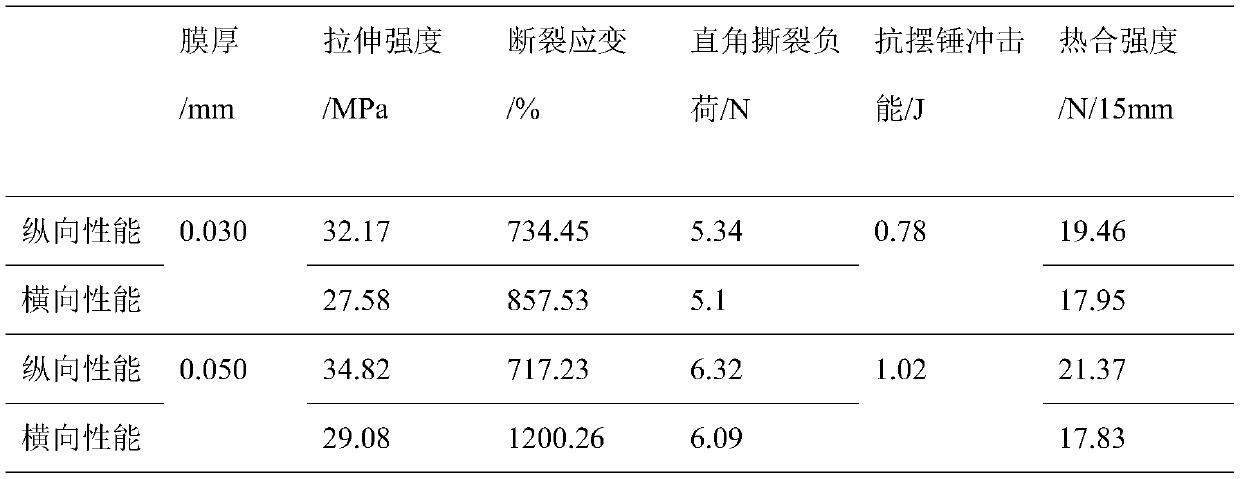

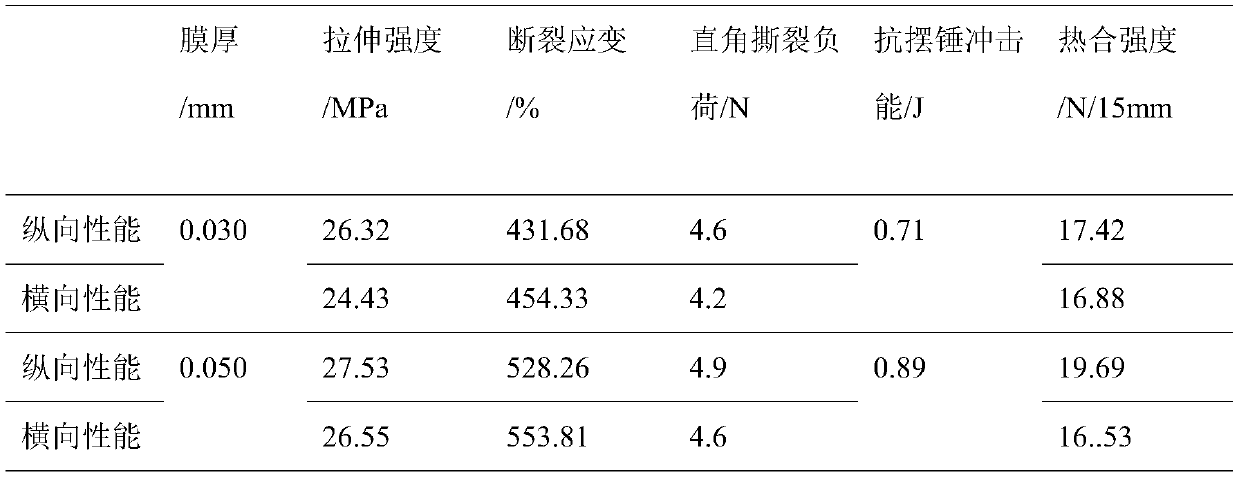

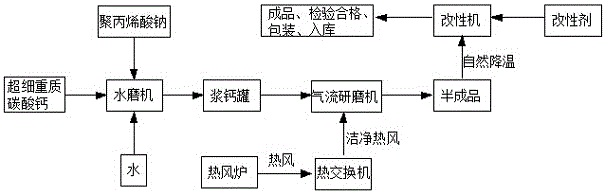

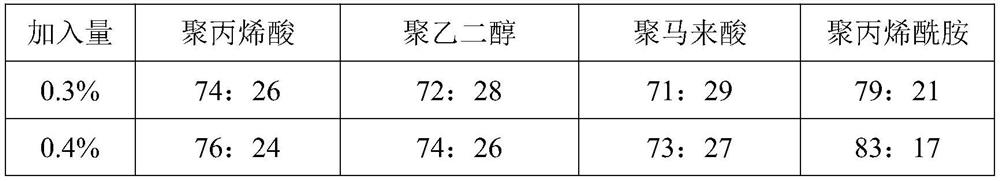

Production process for heavy nano calcium carbonate

ActiveCN105753032AFast granularityReduce liquidityCalcium/strontium/barium carbonatesEnergy inputGranularityBiological activation

The invention discloses a production process for heavy nano calcium carbonate. A certain amount of superfine heavy calcium carbonate, water and sodium polyacrylate in a ratio are ground and mixed by a levigator, therefore, the granularity of calcium carbonate can effectively reach 1000 nm or smaller, and calcium carbonate is in a runny paste state; then under the combined action of thermal airflow and a preheated airflow grinding machine, effective grinding is performed while moisture is dried, the mobility of calcium carbonate is reduced while the moisture is reduced, the granularity of calcium carbonate can effectively reach 100 nm or smaller during grinding in the process, and calcium carbonate has uniform and round granules and excellent performance; finally, a modifier in a certain proportion is added, so that various performance such as the activation grade, the dispersing performance and the like of nano calcium carbonate is greatly improved, and the comprehensive performance of nano calcium carbonate is remarkably improved. The production process is simple, convenient to operate, high in efficiency and low in overall energy consumption; the cost is effectively saved, the quality and the performance of products are considerable, and the application space of the products is greatly increased.

Owner:NANZHAO XINTAI CALCIUM IND

Method for reducing production energy consumption of nano calcium carbonate

InactiveCN113247936AShorten the carbonization reaction timeImprove energy utilizationCalcium/strontium/barium carbonatesMaterial nanotechnologyCalcium hydroxideProcess equipment

The invention discloses a method for reducing energy consumption in nano calcium carbonate production, and belongs to the field of nano calcium carbonate preparation, the method for reducing the energy consumption in nano calcium carbonate production comprises the following steps: S1, adding water to dilute refined lime milk, adjusting to a suspension with calcium hydroxide concentration of 7-12%, and adding into a carbonization reactor; s2, adjusting the temperature of the calcium hydroxide suspension to 10-40 DEG C, then adding an additive 1 and an additive 2 into the suspension, and uniformly mixing; and S3, introducing carbonization gas with the CO2 volume concentration of 10-100% into the suspension liquid to carry out carbonization reaction, continuously introducing the carbonization gas for 10-30 minutes to carry out over-carbonization when the pH value of the suspension liquid is reduced to 7.0, and obtaining a nano calcium carbonate suspension liquid at the temperature of 30-70 DEG C after the carbonization is finished. According to the method, the productivity and the equipment utilization rate are improved, the production energy consumption is reduced, the produced nano calcium carbonate product is high in activation degree and low in oil absorption value, the process is simple and feasible, existing process equipment does not need to be changed, the production cost is low, and good economic benefits and social benefits are achieved.

Owner:安徽前江超细粉末科技有限公司

High-wear-resistance lubricating oil and preparation method thereof

InactiveCN110835574AIncrease activationImprove anti-wear and anti-friction performanceRotary stirring mixersTransportation and packagingVulcanizationActive agent

The invention discloses high-wear-resistance lubricating oil, which is prepared from the following raw materials by weight: 80 to 90 parts of base oil, 2 to 3 parts of nano tungsten disulfide, 0.4 to0.6 part of a surfactant, 0.8 to 1 parts of a defoamer and 1.5 to 2 parts of an antiwear additive. The invention also discloses a preparation method of the lubricating oil. According to the lubricating oil, the nano tungsten disulfide is uniformly dispersed in the lubricating oil through the compounding of the nano tungsten disulfide and the surfactant, and the anti-wear and anti-friction effect of the nano-particles is exerted; by adding the anti-wear additive, a composite protective film is generated at the bearing friction interface and has excellent anti-wear and anti-friction performance;the lubricating oil is processed through special processing equipment, the lubricating oil can be fully, thoroughly and efficiently blended and processed so that components are evenly dispersed in the lubricating oil to exert corresponding effects and to ensure quality of the lubricating oil. The wear-resistant high-quality lubricating oil is obtained and suitable for tapered roller bearings, heavy-duty gear and other fields.

Owner:安徽中天石化股份有限公司

Surface-modified ground calcium carbonate suitable for artificial stone fillers

ActiveCN110877962BWide particle size distributionLarge specific surface areaPhysical chemistryArtificial stone

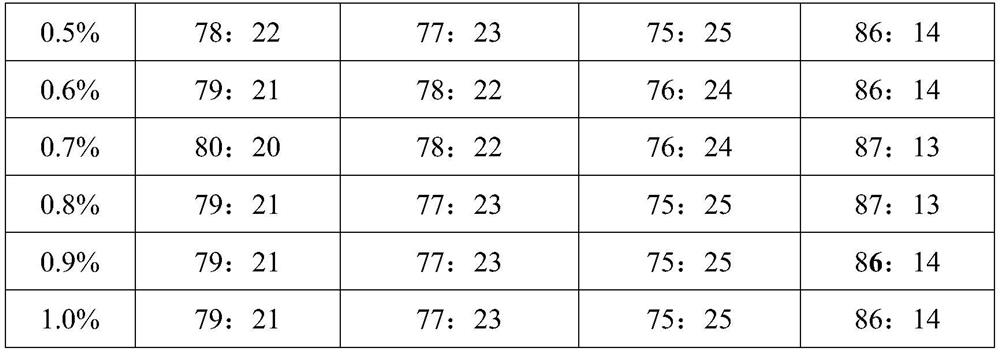

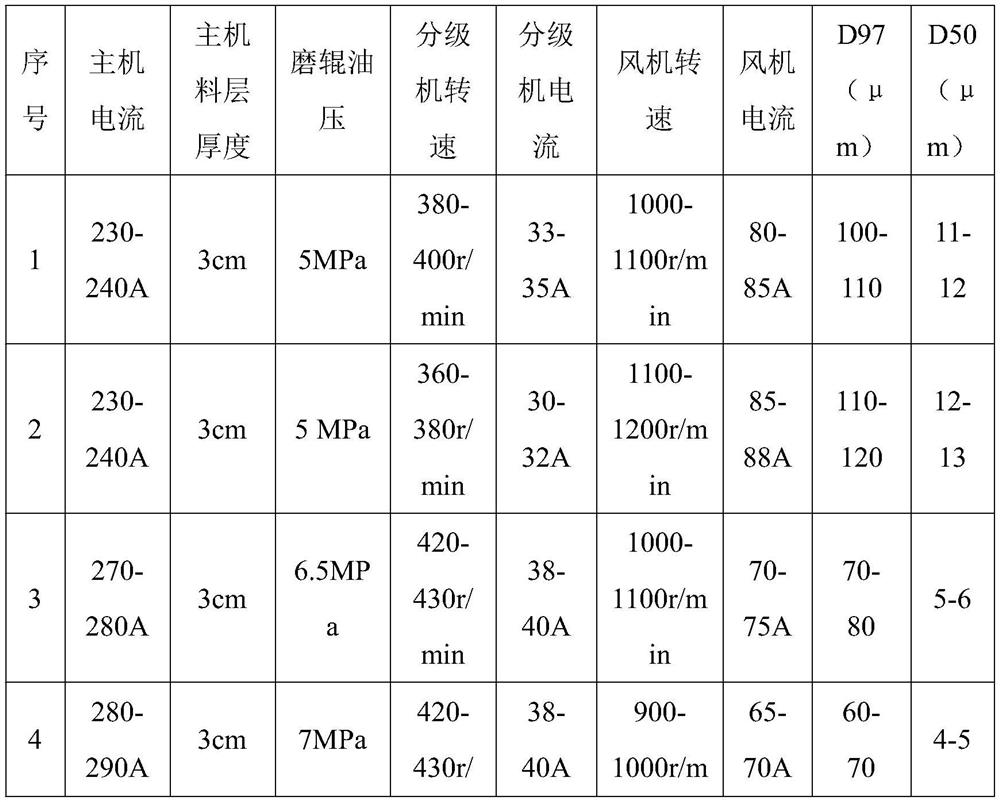

The invention discloses a surface-modified heavy calcium carbonate suitable for artificial stone filler, which comprises the following raw materials: ore, auxiliary agent A and auxiliary agent B, and is obtained by controlling specific production parameters by using vertical mill equipment. The present invention adds auxiliary agent A and auxiliary agent B on the basis of existing heavy calcium carbonate, adopts vertical mill to grind, controls through specific production parameters, and the obtained modified calcium carbonate has wide particle size distribution and large specific surface area, High activation degree, low oil absorption value, and application performance are much better than ordinary calcium carbonate. The obtained modified calcium carbonate has good dispersibility and compatibility in the production of artificial stone, and the filling amount of calcium carbonate accounts for more than 81% of the mass of artificial stone. , the production cost is greatly reduced, and it is more environmentally friendly.

Owner:广西贺州市科隆粉体有限公司

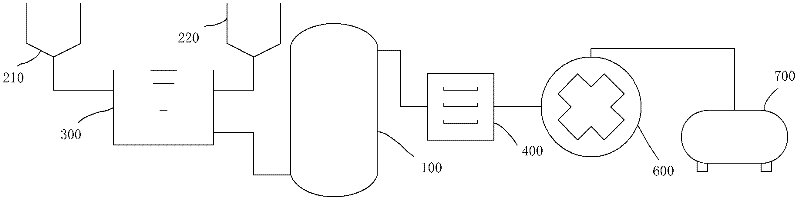

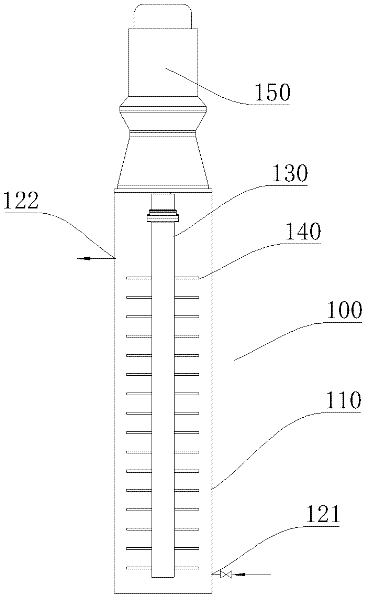

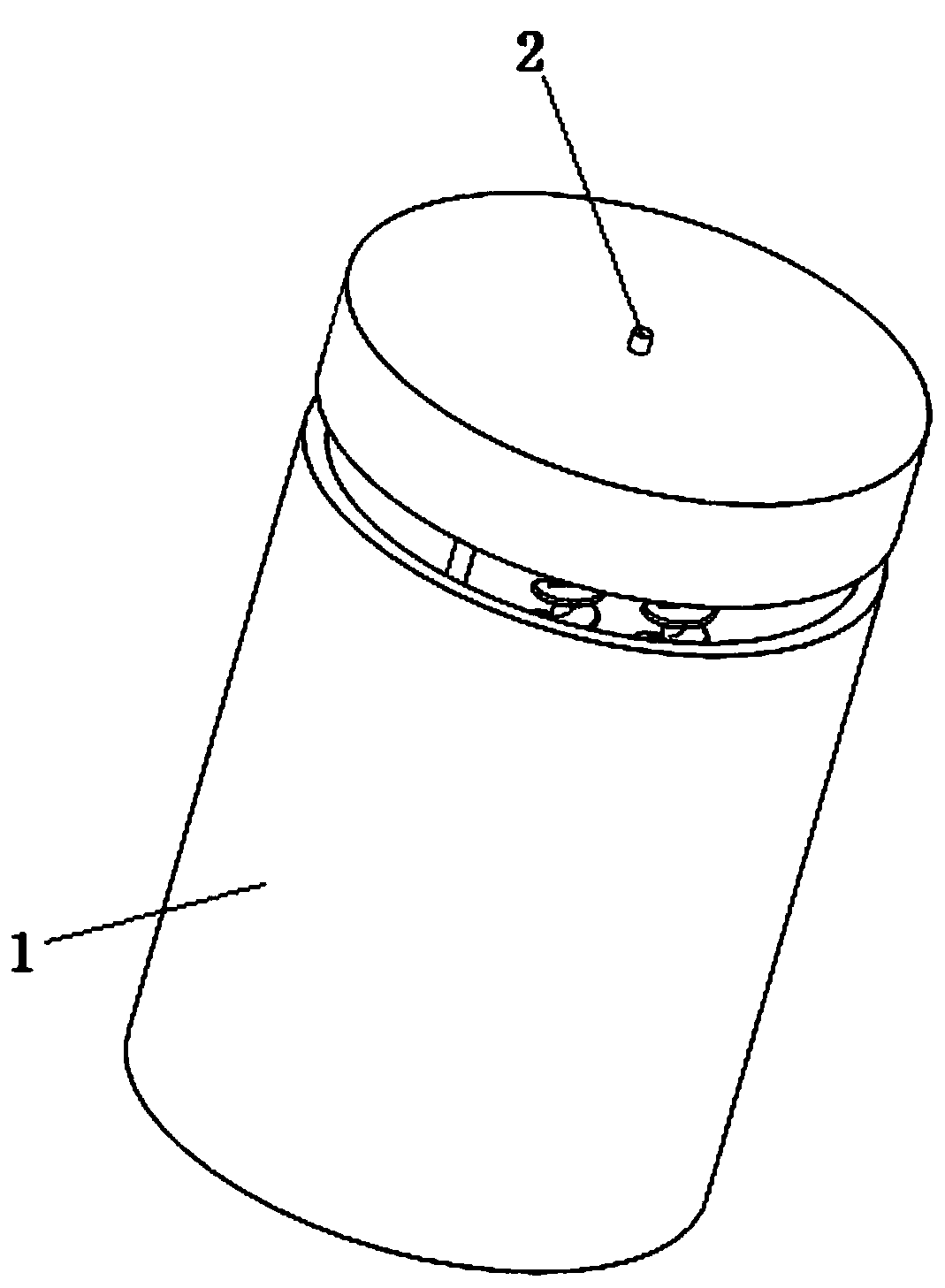

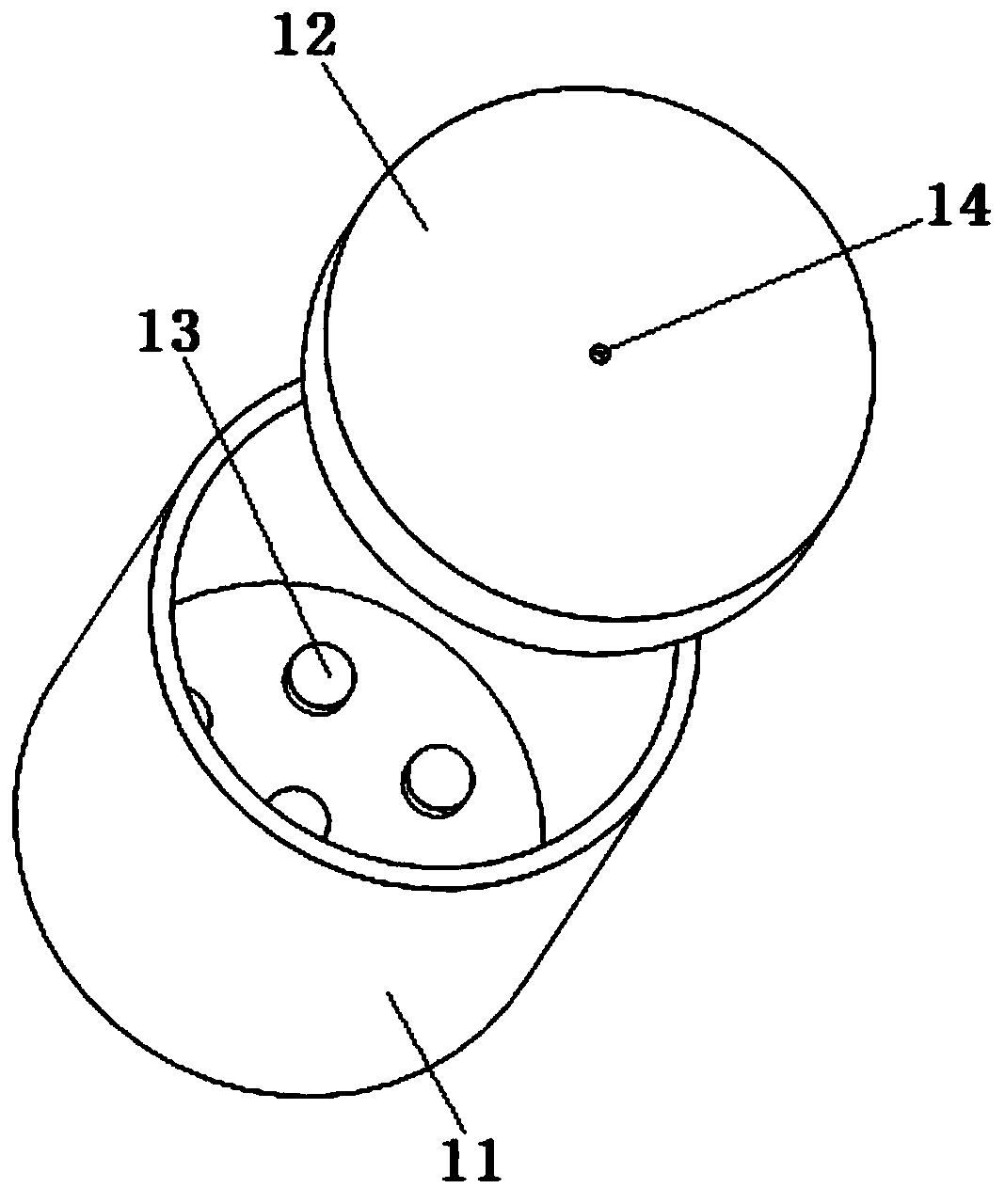

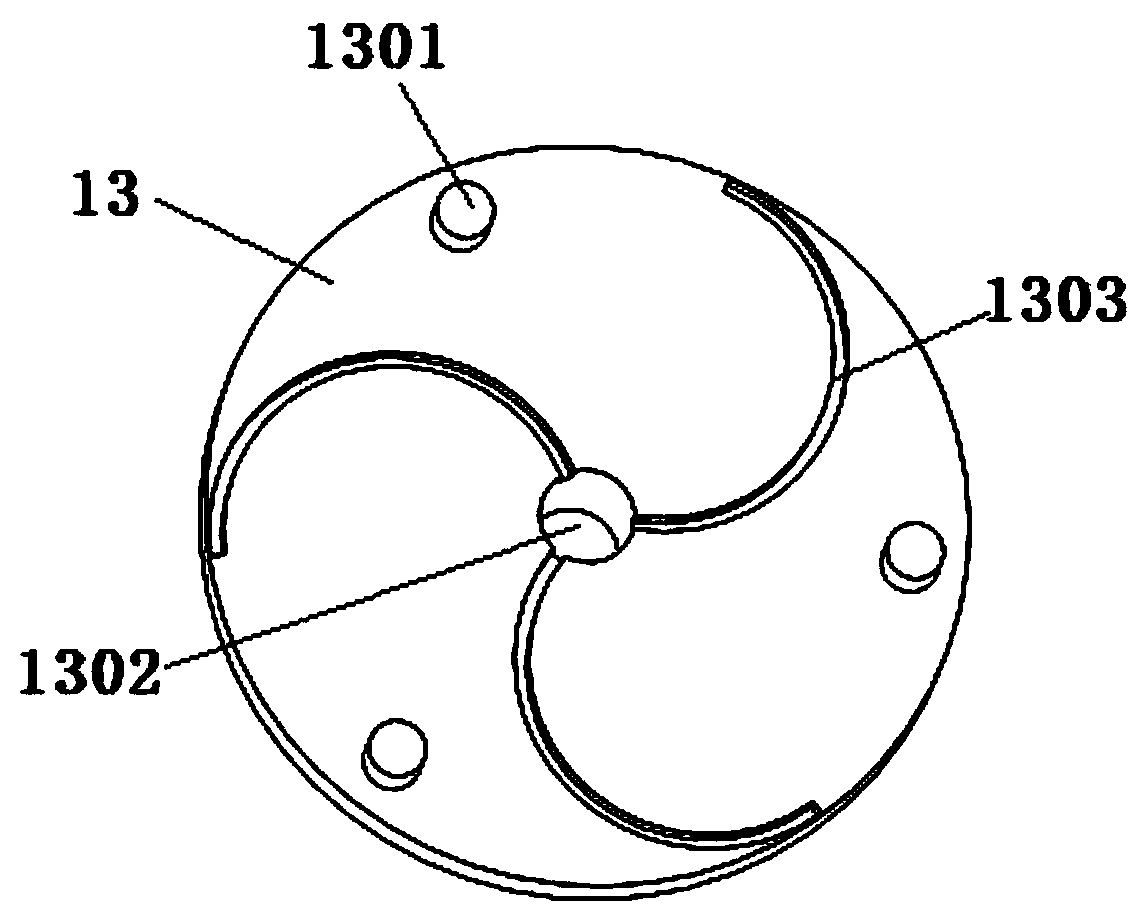

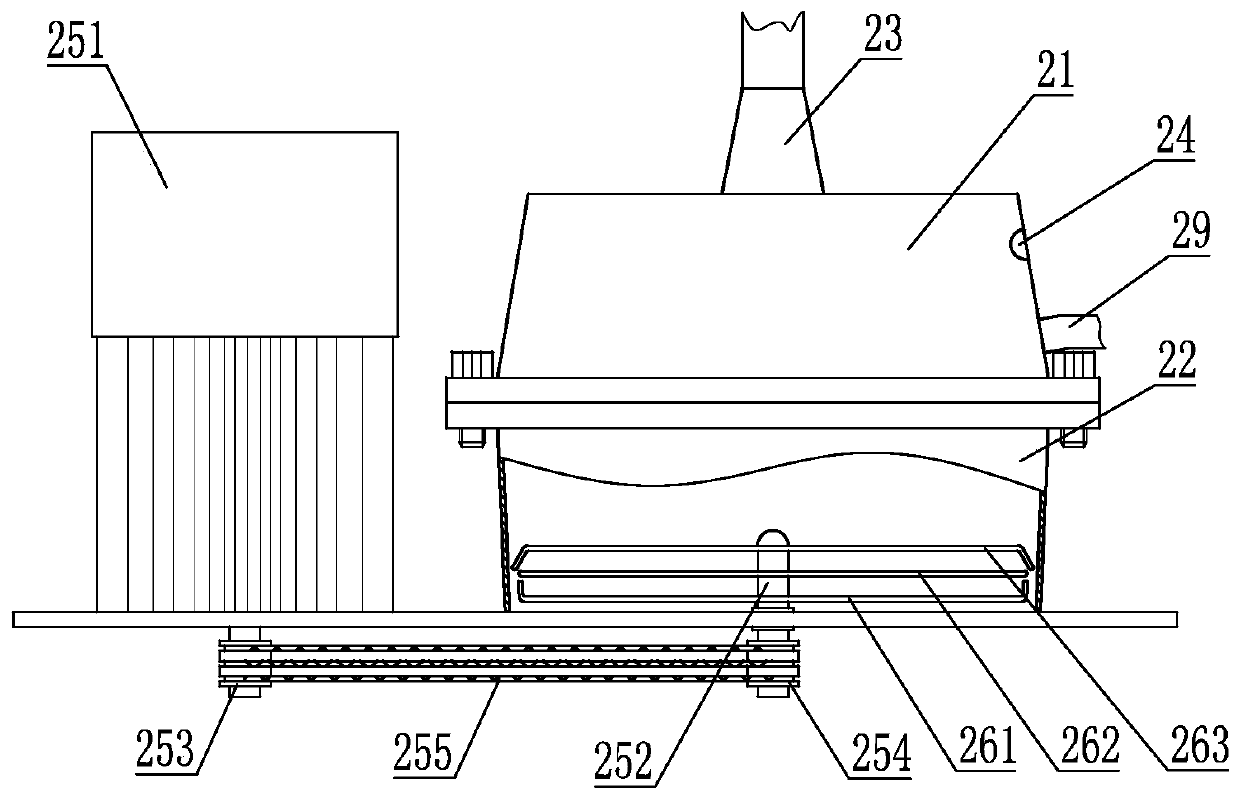

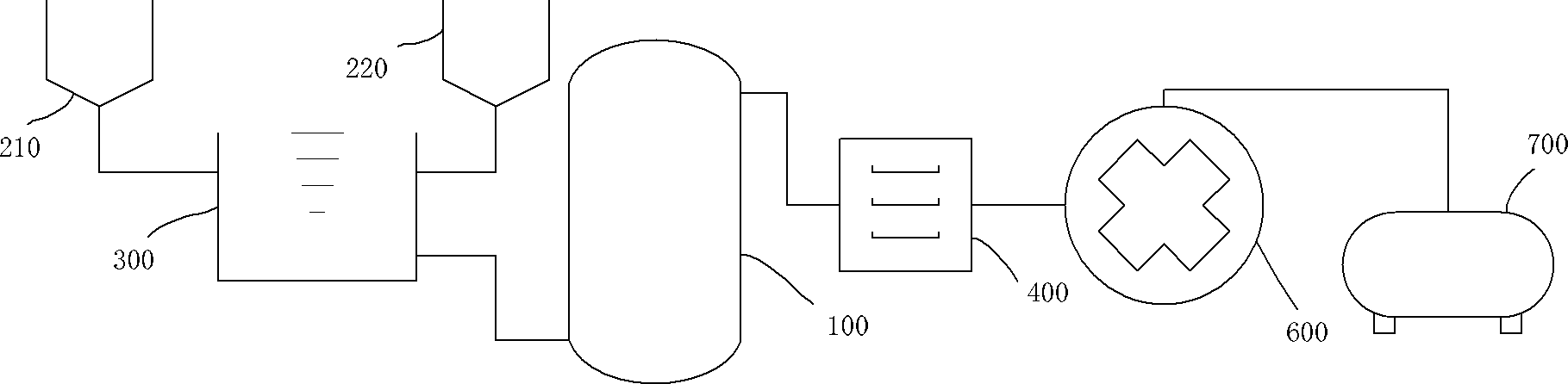

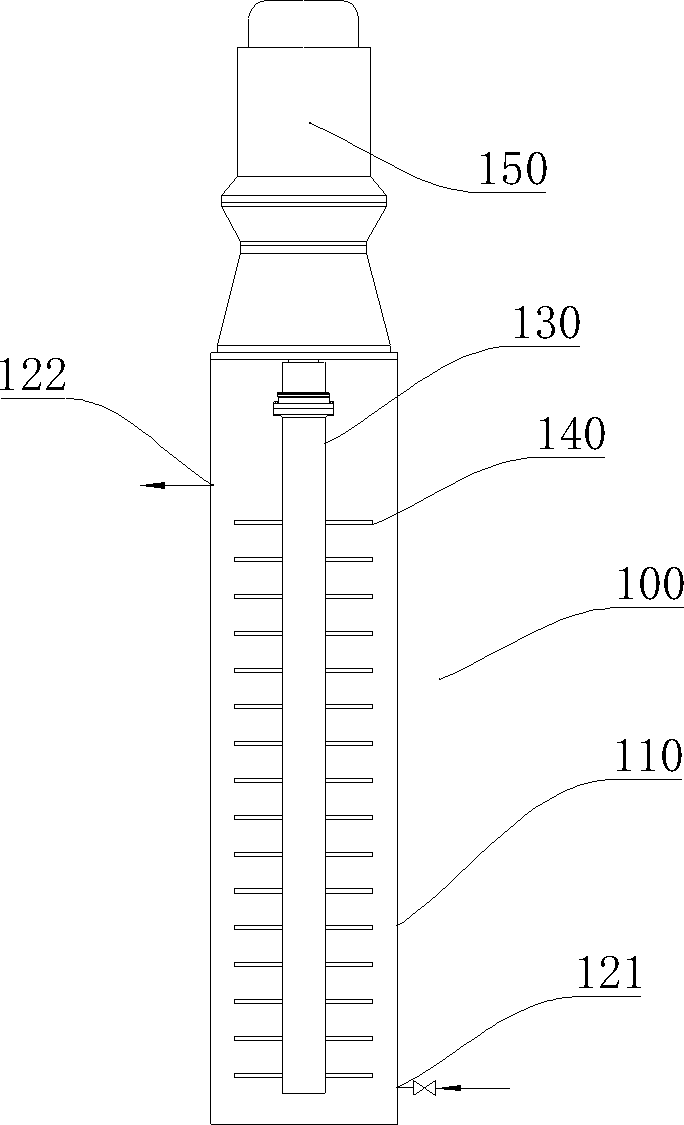

Powder activation device

PendingCN111437787AReduce noiseReduce energy consumptionPigmenting treatmentChemical/physical/physico-chemical stationary reactorsProcess engineeringMechanical engineering

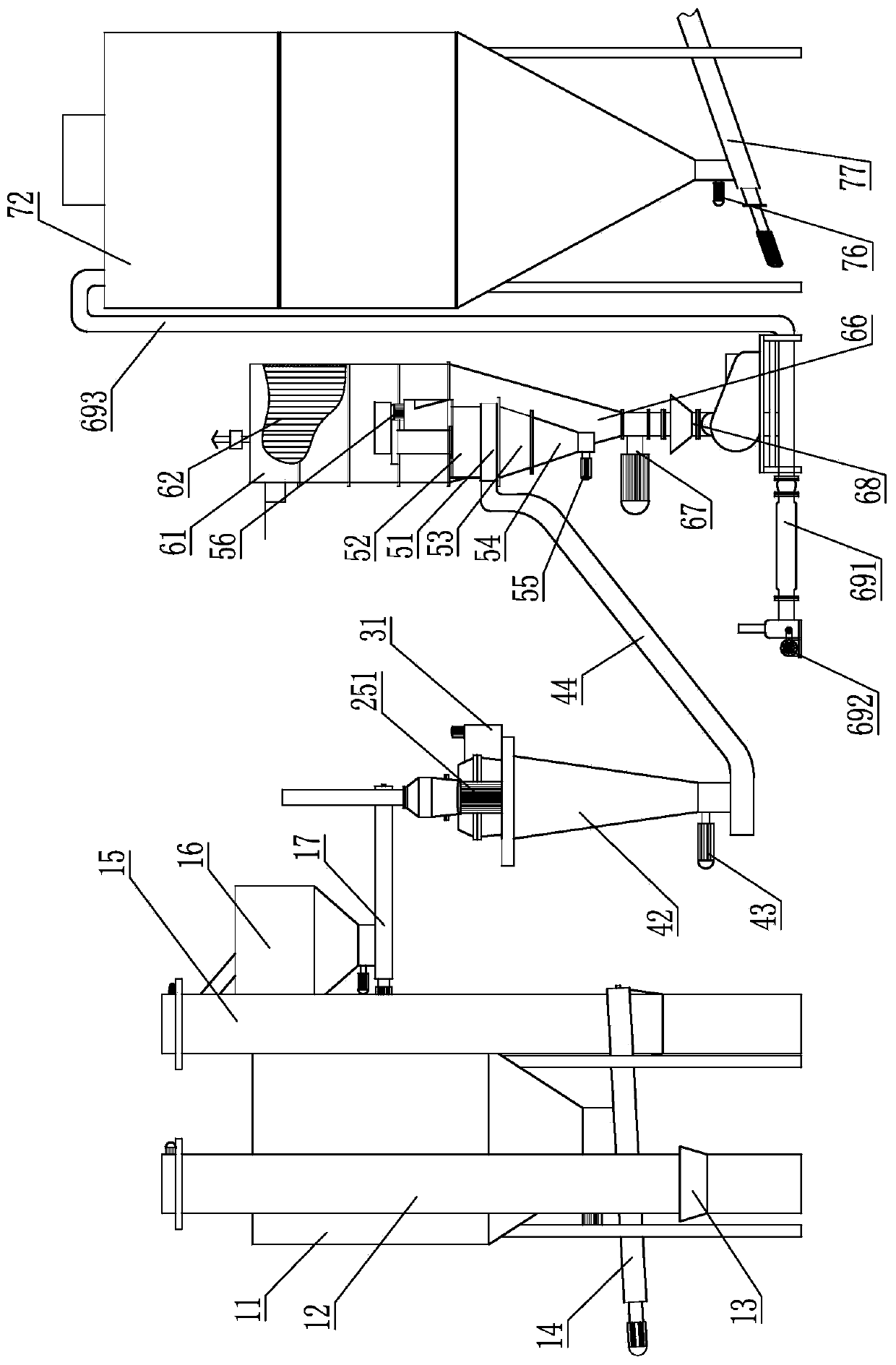

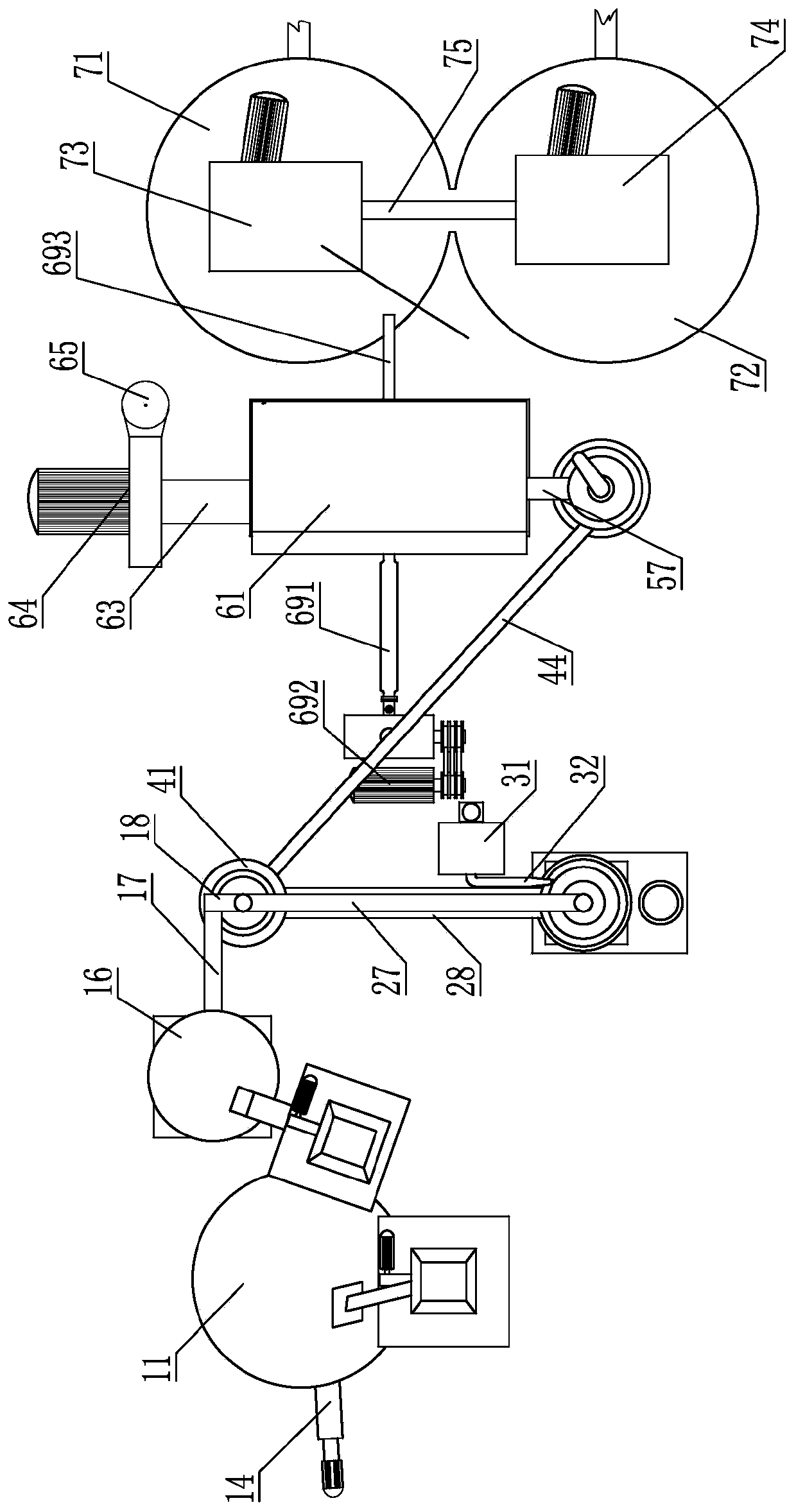

The invention discloses a powder activation device. The powder activation device comprises a feeding device, the feeding device is connected with an activating machine, the activating machine is connected with a searching device through a raw material discharging pipe, the searching device is connected with a graded discharging device through an activating material conveying pipeline, the graded discharging device is connected with a dust collecting discharging device, and the dust collecting discharging device is connected with a finished product warehousing and sub-packaging device through afinished product material conveying pipeline; a raw material feeding hole of the activating machine is connected with one end of the raw material discharging pipe; a search air outlet of the searching device is communicated with the other end of the raw material discharging pipe; the discharging end of the feeding device is connected with the end, close to the searching device, of the raw material discharging pipe, the activating machine is communicated with a searching feeding port of the searching device through an activating material inlet pipeline, an activating material discharging portis formed in the bottom end of the searching device, and the activating material discharging port is communicated with an activating material conveying pipeline; the powder activation device has the characteristics of full sealing, low noise, low energy consumption, no dust, no waste gas emission, no agglomerated particles, high activation degree, high efficiency and continuous production, and isa preferred product for powder activation.

Owner:浙江钦堂钙业有限公司

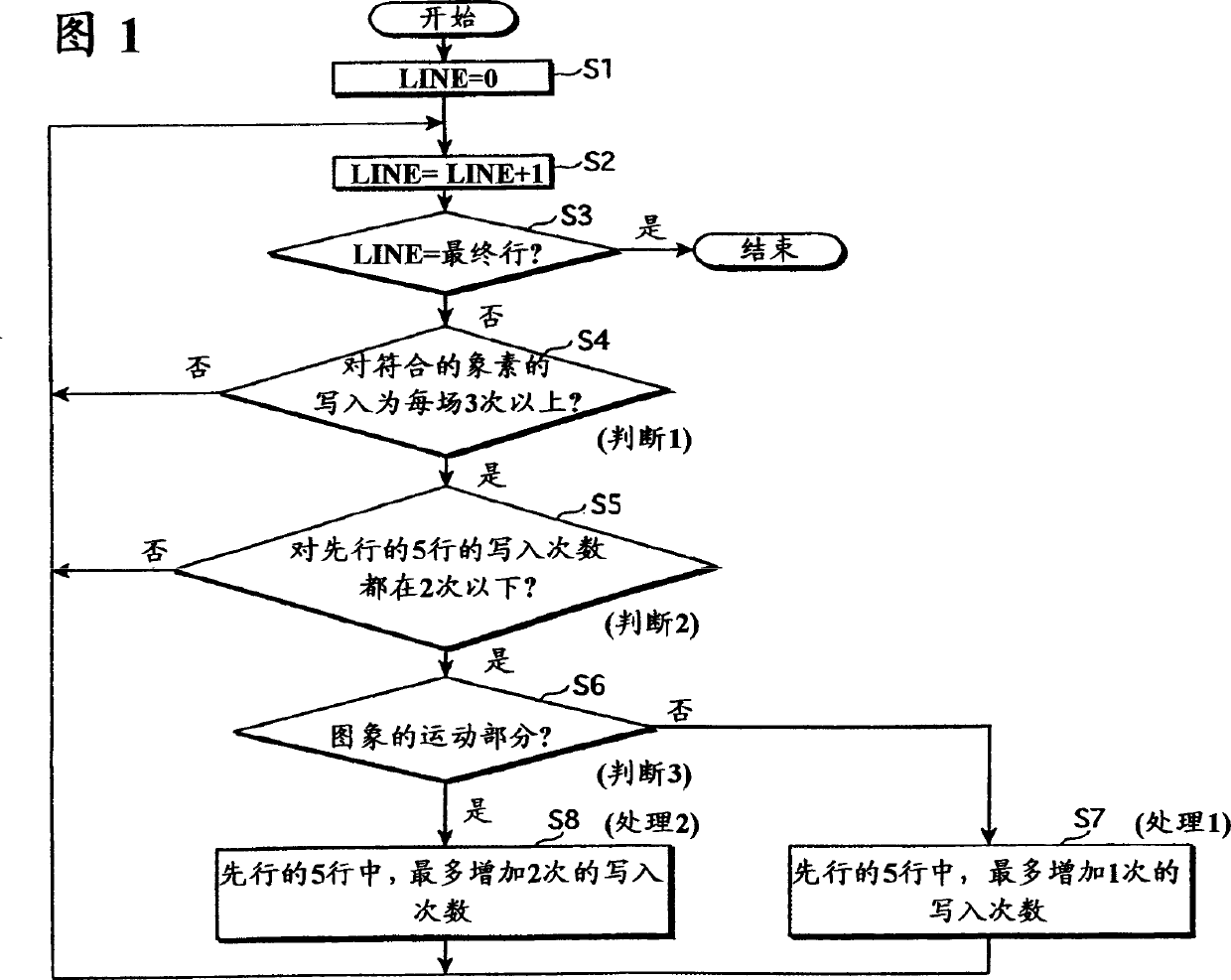

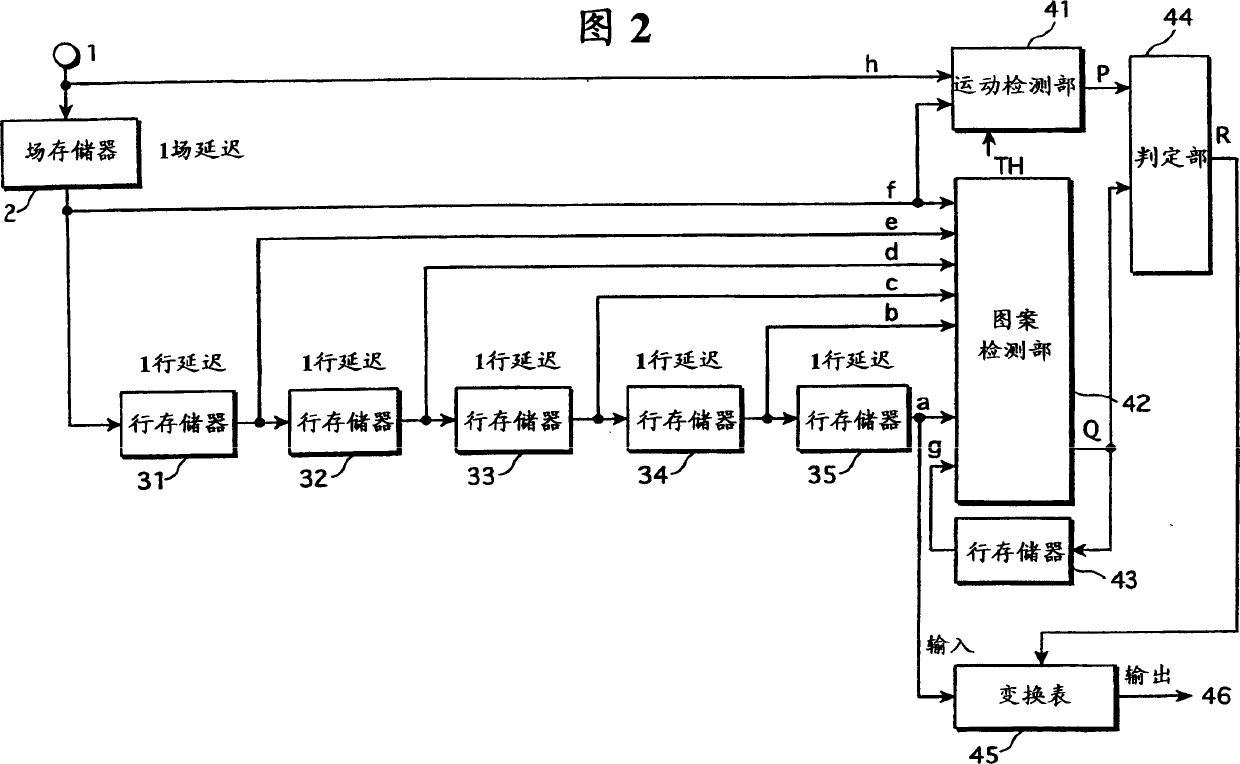

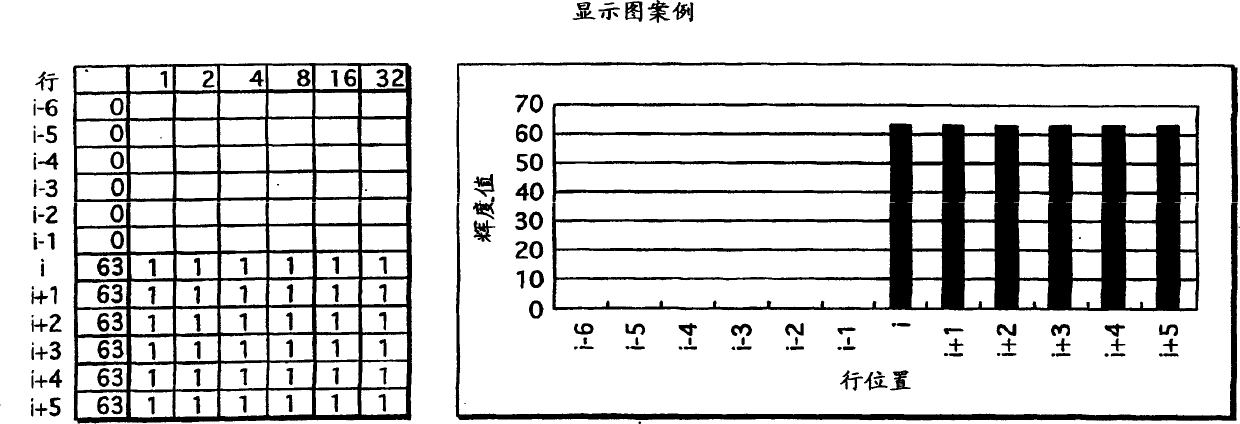

Signal processor

InactiveCN1608279AIncrease writing frequencyImprove reliabilityTelevision system detailsStatic indicating devicesLeading edgeAnalog processor

In writing scanning using subfields, writing errors may occur due to movement of patterns or images. In patterns prone to writing errors, corrections are made differently for still images and moving images. In particular, for a moving image portion, the writing operation is reliably performed by first performing low-intensity writing in the leading edge portion of the image to activate the pixels.

Owner:PANASONIC CORP

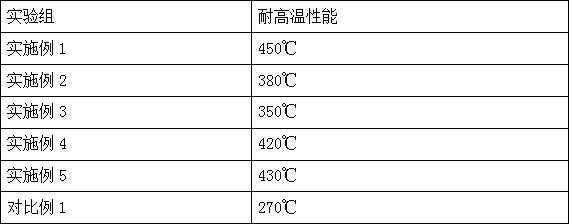

High-temperature-resistant release ink

InactiveCN110760216ANarrow particle size distributionSmall specific surface areaInksPolymer sciencePolymer chemistry

The invention provides high-temperature-resistant release ink. The high-temperature-resistant release ink is characterized by comprising the following components in parts by weight: 40 to 58 parts ofresin, 15 to 27 parts of solvent, 5 to 10 parts of curing agent, 3 to 5 parts of assistant and 12 to 33 parts of functional filler. The invention provides the ink which can resist to a high temperature and be easy to release in the forming process in the manufacture procedure of a mobile phone back cover. The high-temperature-resistant release ink can resist to a high temperature of over 300 DEG C, and is superior to existing similar products in the market.

Owner:惠州市韵点新材料科技股份有限公司

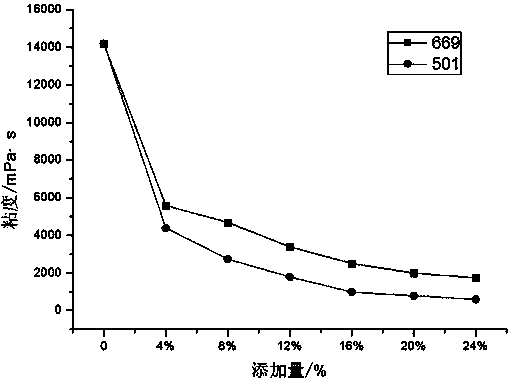

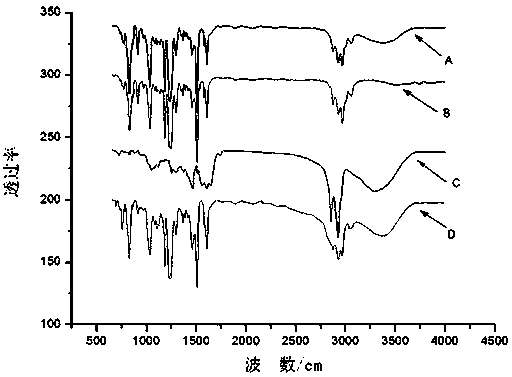

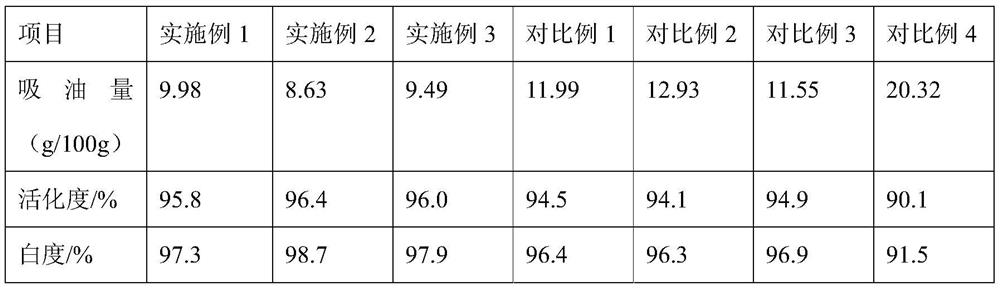

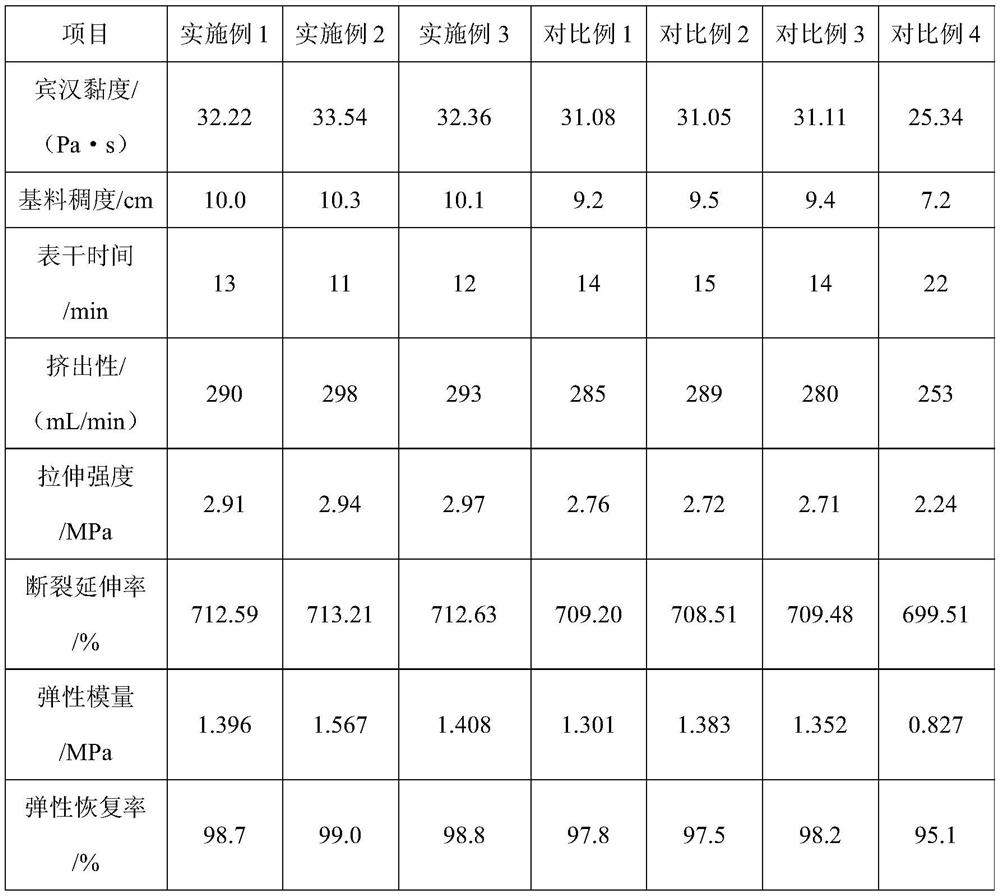

Preparation method of heavy calcium carbonate for high-activation-degree silicone adhesive

ActiveCN113088102AGood dispersionIncrease activationNon-macromolecular adhesive additivesPigment flushingHigh activationPhysical chemistry

The invention discloses a preparation method of heavy calcium carbonate for a high-activation-degree silicone adhesive. The preparation method sequentially comprises the steps of ore storage, cleaning, mineral separation, crushing and homogenizing, grinding, grading, powder collection, quality inspection I, activation, cooling and quality inspection II. The preparation method disclosed by the invention is simple and easy to implement, the prepared calcium carbonate powder has good dispersity, extremely high activation degree, relatively high whiteness and extremely low oil absorption value, and the thixotropy and tensile strength of a silicone adhesive can be effectively improved.

Owner:广西贺州市科隆粉体有限公司 +1

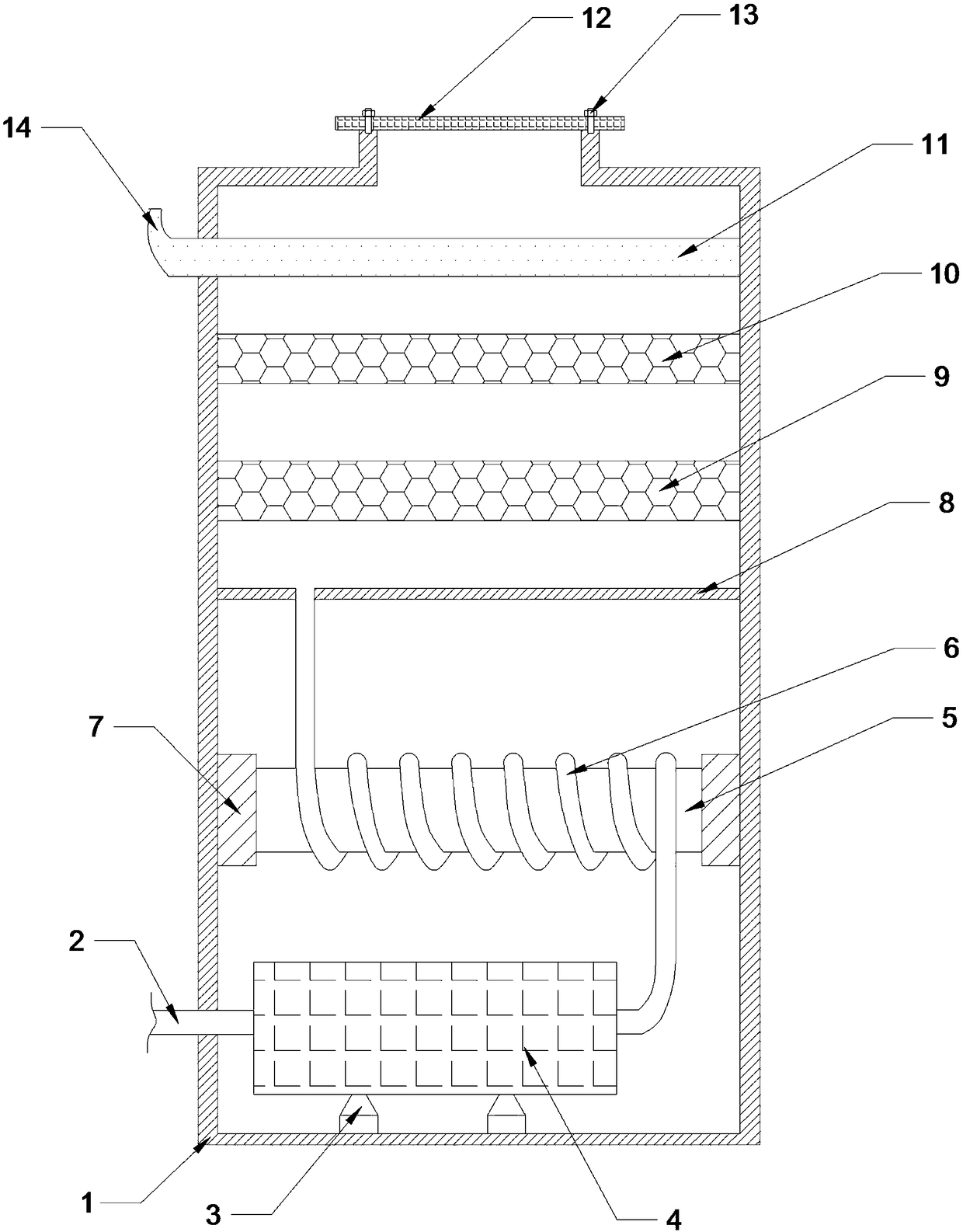

Automobile exhaust treatment device

PendingCN108533367AImprove the living environmentExtension of timeExhaust apparatusSilencing apparatusHazardous substanceEngineering

The invention relates to the field of automobile spare parts and discloses an automobile exhaust treatment device. The automobile exhaust treatment device comprises a box body. The box body is internally of a hollow structure. One side of the box body is provided with a gas inlet pipe communicating with the box body. The gas inlet pipe is connected with an inlet of a spiral glass pipe. The spiralglass pipe winds around the outer wall of an ultraviolet lamp pipe. The ultraviolet lamp pipe is fixed to a lamp holder. The lamp holder is fixed to the box body. An outlet of the spiral glass pipe communicates with an opening of a partition plate. The partition plate divides an inner cavity of the whole box, the space above the partition plate is a hazardous substance treatment chamber, the hazardous substance treatment chamber is internally provided with reducing honeycomb ceramic and oxidizing honeycomb ceramic which divide the whole hazardous substance treatment chamber into three parts, the reducing honeycomb ceramic is located above the partition plate, the oxidizing honeycomb ceramic is arranged above the reducing honeycomb ceramic, and a gas outlet pipe is arranged above the oxidizing honeycomb ceramic. According to the automobile exhaust treatment device, the purpose of filtering substances harmful to the human body in the automobile exhaust can be achieved.

Owner:NEIJIANG ZHICHENG PLATINUM TECH CO LTD

Preparation method of high-quality hemp softening liquid for softening hemp material

InactiveCN110230192AImprove abilitiesUniform and rapid softening treatmentGrip property fibresVegetal fibresCelluloseWhite oil

The invention relates to the technical field of hemp material softening, and provides a preparation method of high-quality hemp softening liquid for softening a hemp material. The method comprises thefollowing steps: step 1, preparation of an osmotic modifier: adding a penetrant JFC with a mass fraction of 0.5-1% into a sodium alginate solution with a mass fraction of 3-5%, ultrasonically dispersing for 10-20 min, wherein the ultrasonic power is 100-200 W, then adding powdery cellulose and isopropyl myristate, and stirring at 500-600r / min for 10-20min until the reaction is over. According tothe invention, white oil and diesel oil are adopted as main agents of the softening liquid, the hemp material comprises the compositions such as linen or ramie short fibers, and the osmotic modifier carries the main agents of the softening liquid to penetrate into the internal structure of the short fibers, so that the hemp material is uniformly and rapidly softened, and the softening effect is improved; and the white oil and diesel oil are mixed with a softening dispersing agent.

Owner:重庆市远康纺织品有限公司

High compatibility modifier for plastic processing

The invention provides a high compatibility modifier for plastic processing. The high compatibility modifier for plastic processing comprises, by weight parts, 5-15 parts of nano calcium carbonate, 5-10 parts of chlorinated polyethylene, 5-10 parts of silicone acrylic emulsion, 2-5 parts of dimethicone copolyol, 0.5-2 parts of grafted polyether polyol, 3-10 parts of polyethylene glycol, 0-1 part of ethyl p-aminobenzoate, 0-1 part of heat stabilizer, 0-1 part of coupling agent and 0-0.5 part of surfactant. Through the reasonable raw material ratio, the made modifier has excellent dispersibilityand compatibility for plastic processing and improves plastic product quality stability. In addition, the high compatibility modifier also has excellent weather resistance, UV resistance and toughness, the comprehensive quality is obviously improved, the practical benefit is improved, and the high compatibility modifier is worth promoting.

Owner:NANJING CONCORD FERTILIZER CHEM

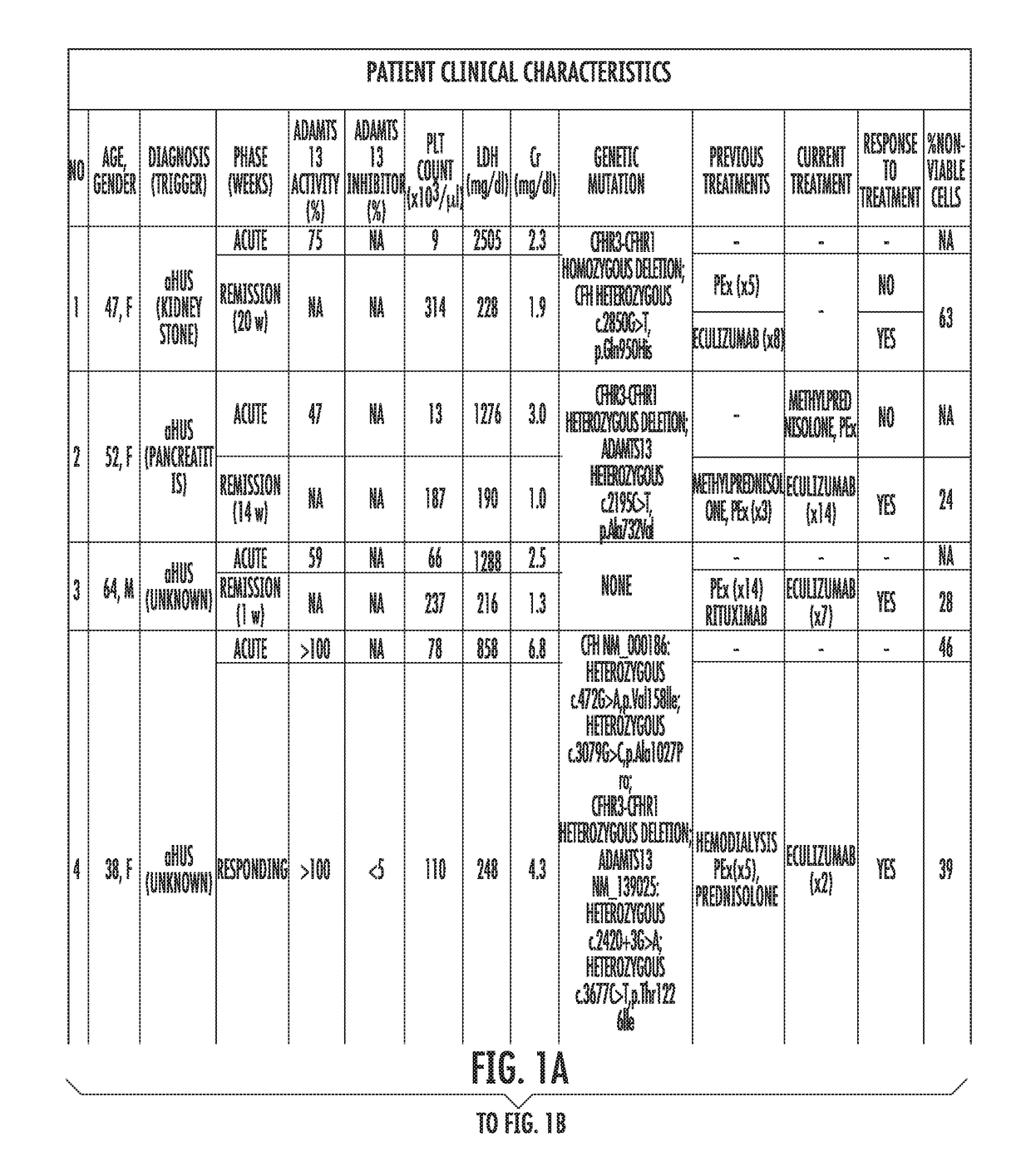

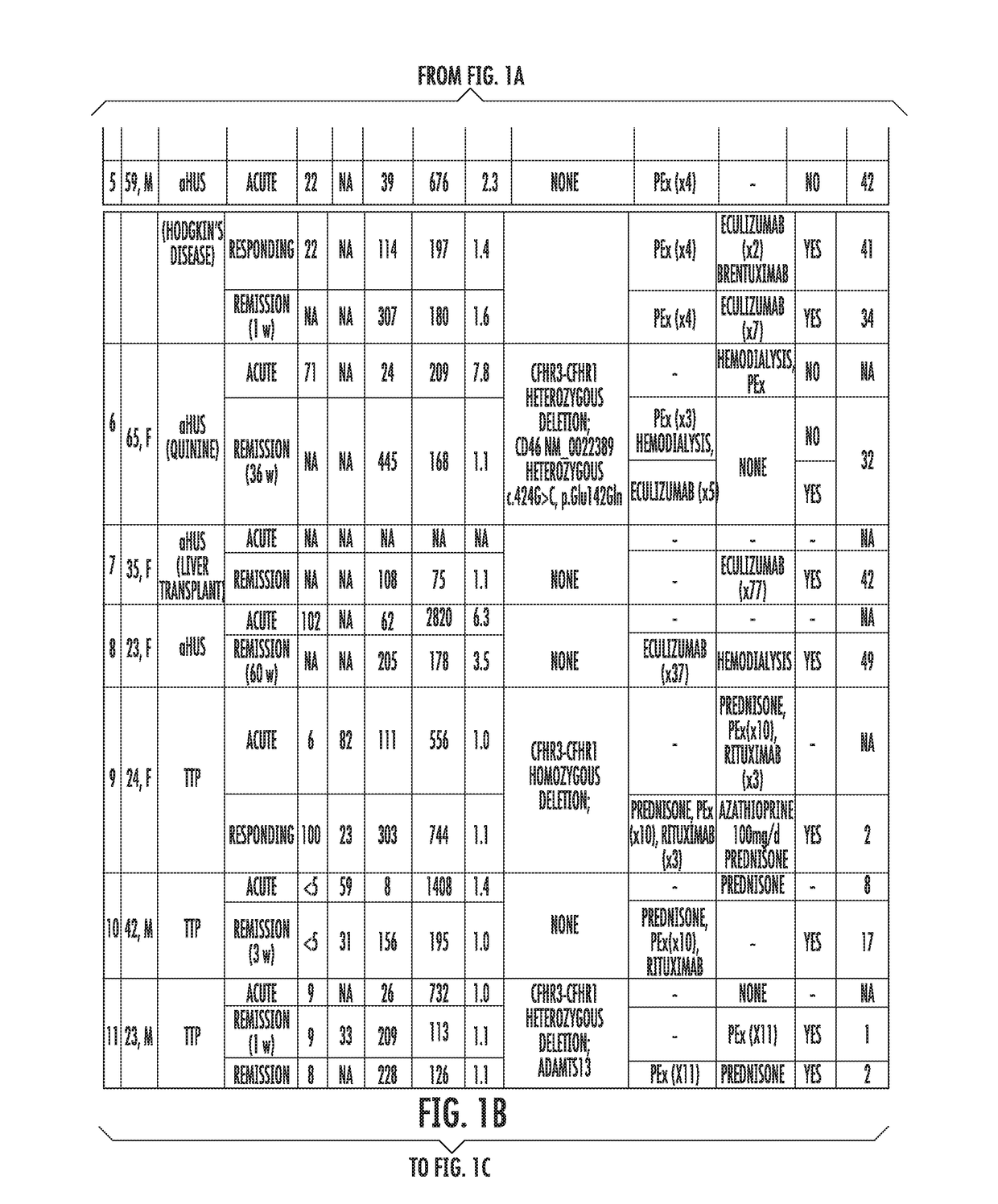

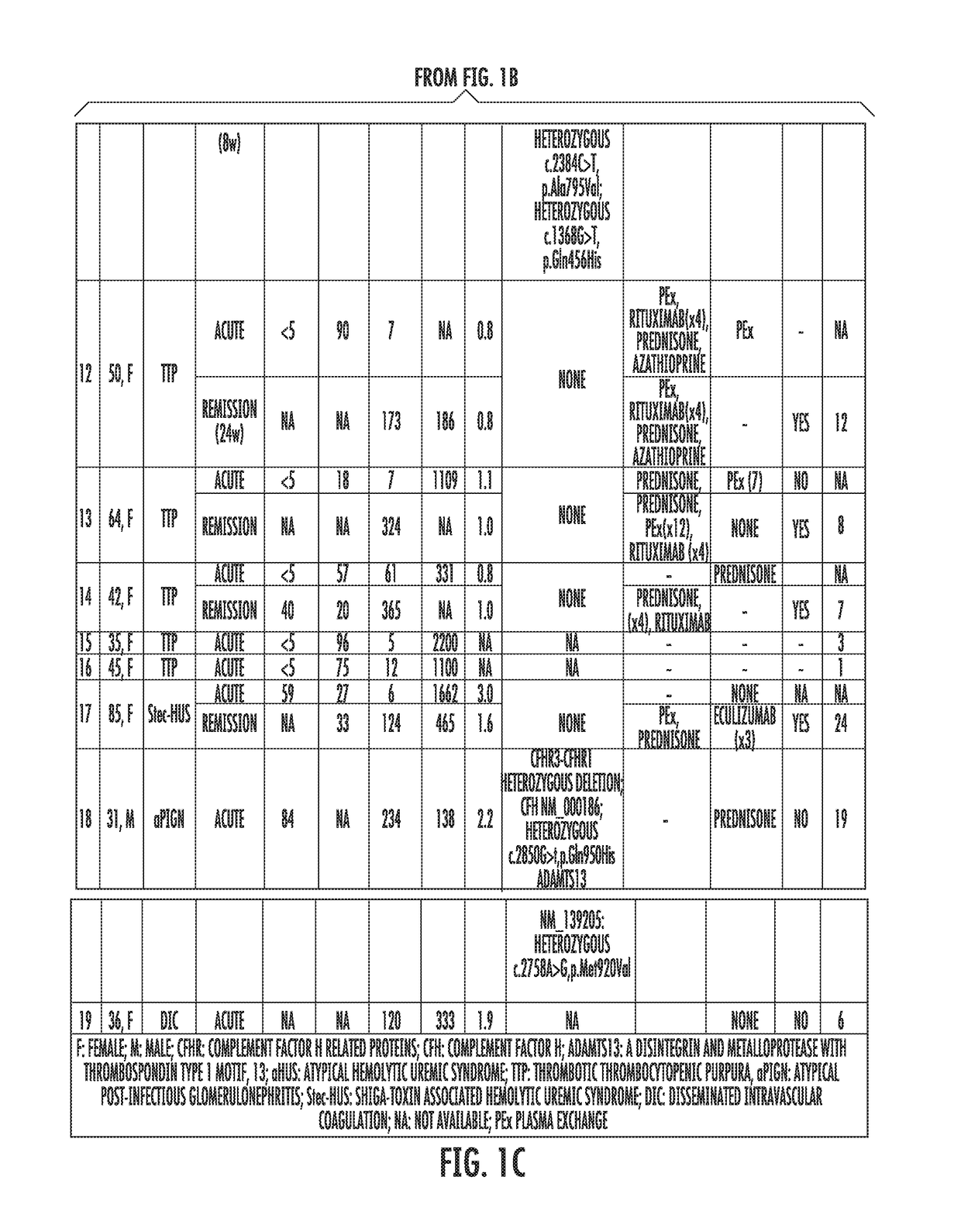

Assay to diagnose and treat disorders of the alternative pathway of complement activation

ActiveUS20180246082A1Increase activationSimple and rapidImmunoglobulins against animals/humansDisease diagnosisBlood serumViable cell

The present invention relates generally to the field of disorders of complement activation. More specifically, the present invention provides methods and compositions useful for diagnosing and treating atypical hemolytic uremic syndrome, antiphospholipid antibody syndrome and other disorders of the alternative pathway of complement activation. In one embodiment, a method comprises the steps of (a) incubating or contacting serum obtained from a patient suspected of having atypical hemolytic uremic syndrome (aHUS) with a glycosylphosphatidylinositol-anchored protein (GPI-AP) deficient cell line; and (b) performing a cell viability assay on the cells from step (a). In a specific embodiment, the method further comprises the step of diagnosing the patient as having aHUS based on a statistically significant increased difference of non-viable cells from the patient serum as compared to a control.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

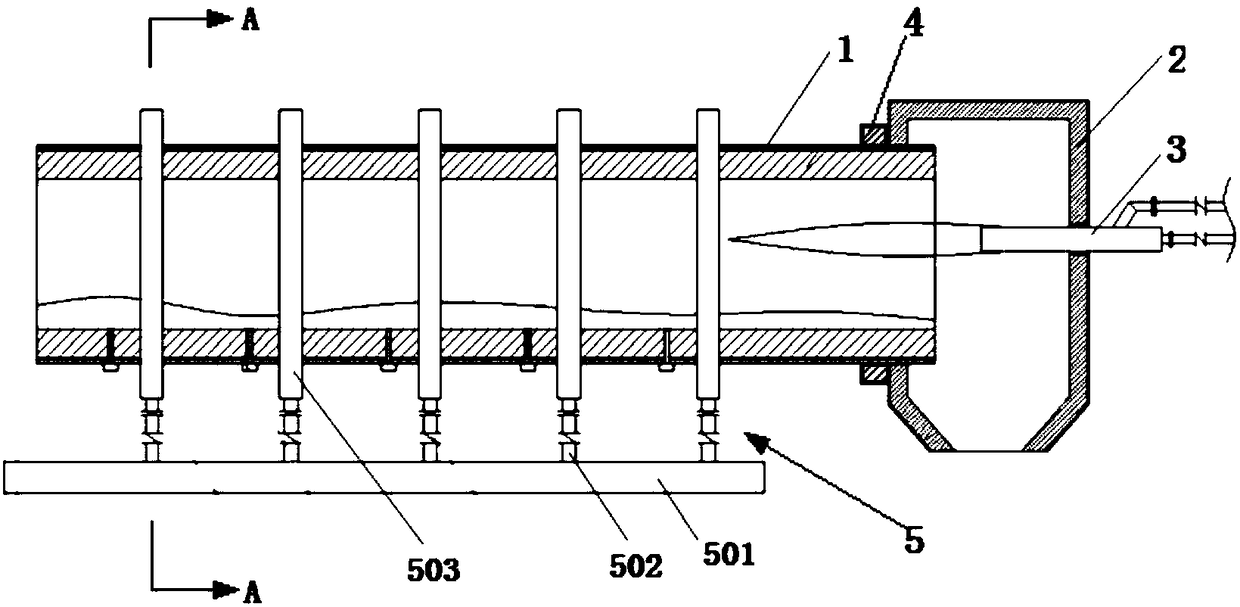

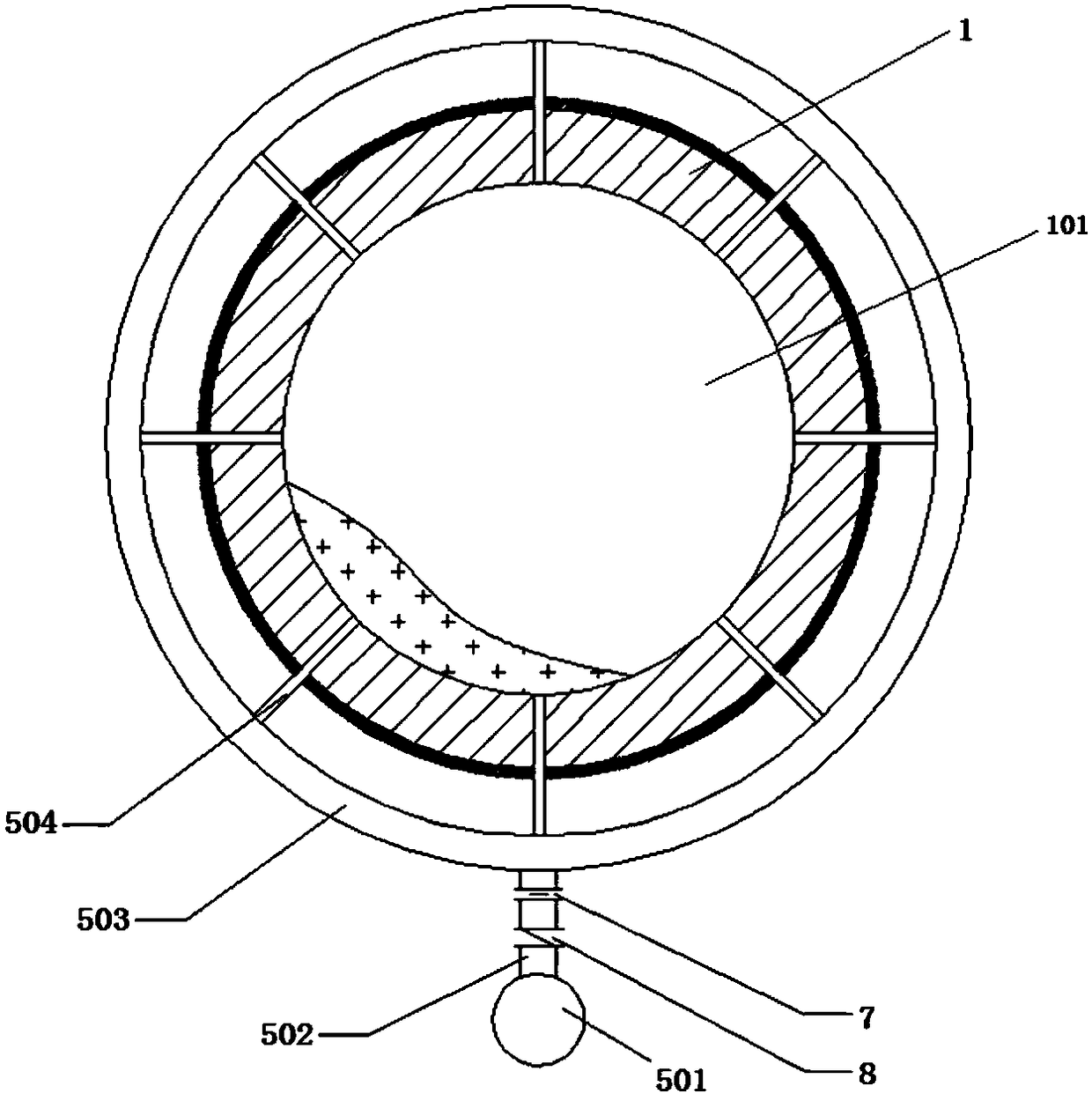

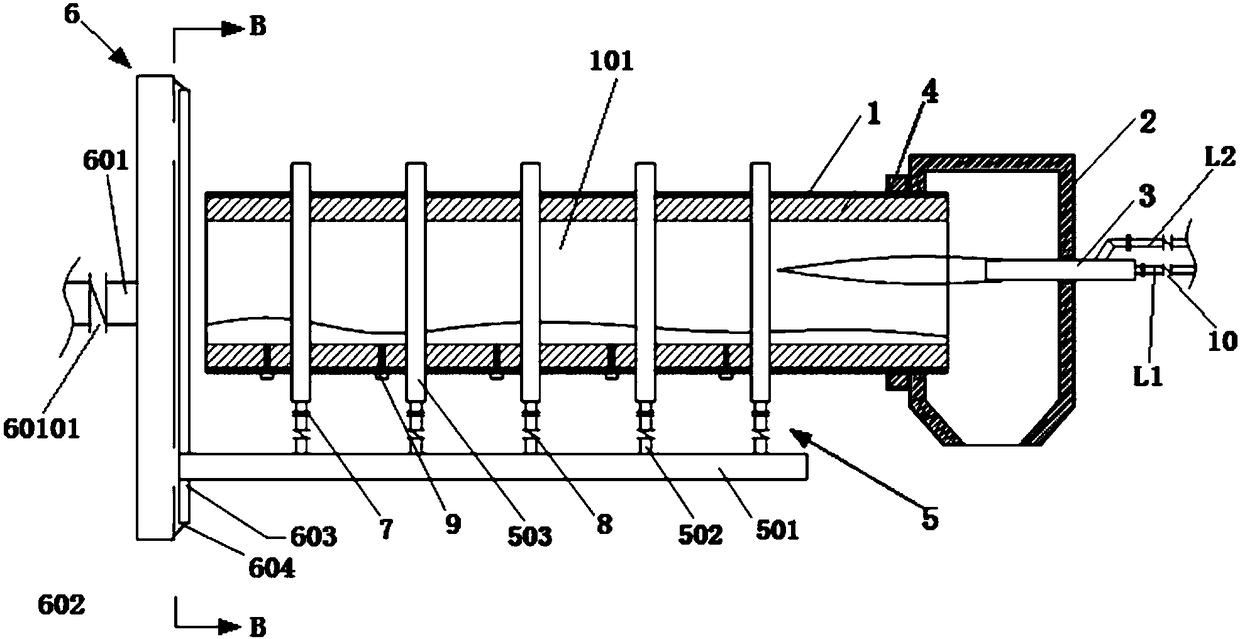

Annular multi-pipe embedded type cascade steam injection activation kiln device and control method and application thereof

PendingCN108120272AIncrease the number ofAccurate monitoring of kiln temperatureCarbon compoundsRotary drum furnacesEngineeringBiological activation

An annular multi-pipe embedded type cascade steam injection activation kiln device comprises a kiln body, a kiln head box, a burner, a drive device and a steam injection device. The tail end of the kiln body is connected with and communicates with the kiln head box. The burner is arranged on the side wall of the kiln head box. The drive device is connected with the kiln body and drives the kiln body to rotate. An activation chamber is arranged in the kiln body. The steam injection device comprises a steam conveying header pipe, a steam conveying branch pipe, a steam conveying ring and a steaminjection pipe. The steam conveying ring is arranged on the outer side of the kiln body in a surrounding mode. One end of the steam injection pipe penetrates through the kiln body to communicate withthe activation chamber. The other end of the steam injection pipe is connected with and communicates with the steam conveying ring. The steam conveying ring is connected with and communicates with thesteam conveying header pipe through the steam conveying branch pipe. According to the activation kiln device, steam injection inlets are formed in a kiln body, the number is increased substantially,and steam is injected in a segmental independent-control mode; and the contact specific surface area of materials in the kiln and steam is increased substantially, and thus the activation grade of products is improved effectively.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Wet grinding system for nonmetal mineral powder and grinding method thereof

The invention provides a wet grinding system for nonmetal mineral powder and a grinding method thereof. The wet grinding system for nonmetal mineral powder provided by the invention comprises a blade type stirring grinder, a continuous modifying machine and a drying machine. After the nonmetal mineral powder is prepared into first slurry, the first slurry is ground in the blade type stirring grinder and then enters into the drying machine. After the first slurry is dried in the drying machine, the first slurry enters into the continuous modifying machine so as to be modified. An obtained product has a fine grain size; the grain size of brucite can reach 8000 meshes; the grain size of barite can reach 10000 meshes; the grain size distribution is narrow; the cycling grinding is unnecessary during a production process; a plurality of grinding devices need not be serially connected; the energy consumption is low; and the excessive grinding phenomenon of the powder is avoided.

Owner:内蒙古超牌新材料股份有限公司

Alumina ceramic wafer treatment process

A treatment process for alumina ceramic sheets, the steps are as follows: (1) Distilled water cleaning: wash and dry the ceramic sheets in 100% pure water; (2) Ketone washing: place the cleaned ceramic sheets in 20‑30 % acetone and dried; (3) Alkaline cleaning: Soak the ketone-washed ceramic sheet in 90-100% sodium carbonate solution and dry; (4) Pickling: Dry the ceramic sheet in step (3) The ceramic sheet is placed in 8‑12% sulfuric acid solution for soaking and drying; the beneficial effects of the present invention are: high hardness, excellent wear resistance, light weight, and strong surface adsorption, which is the surface adsorption of untreated ceramic sheet The strength is 10‑20, and it is very strong and durable after being combined with glue and rubber.

Owner:解伟伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com