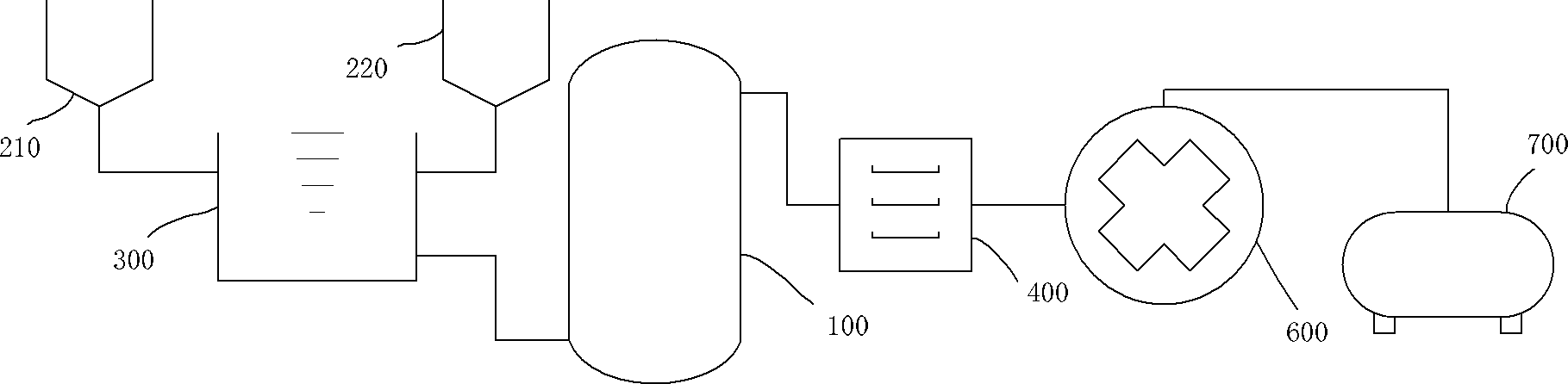

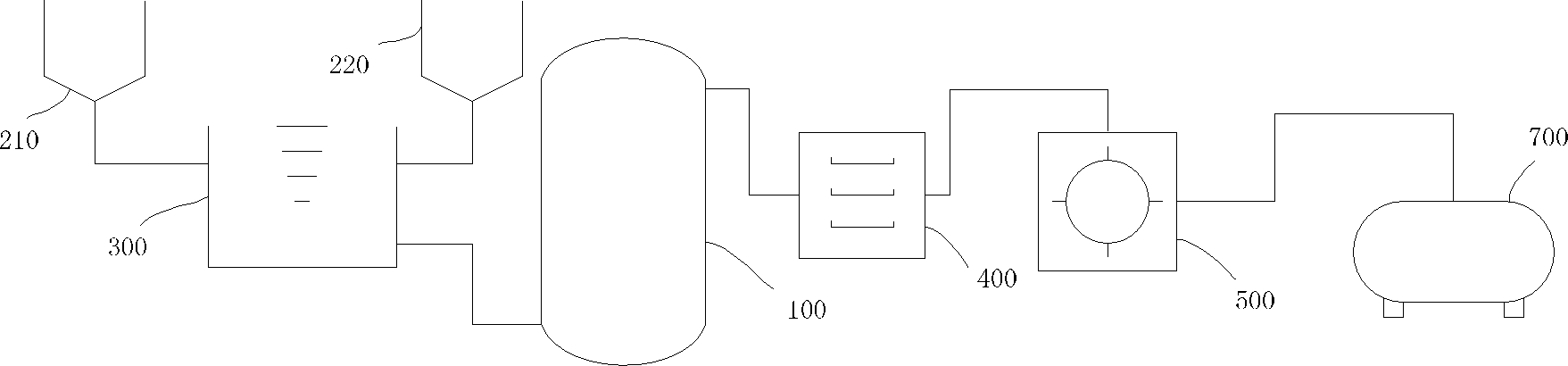

Wet grinding system for nonmetal mineral powder and grinding method thereof

A non-metallic mineral powder, wet grinding technology, applied in the field of mineral crushing, can solve the problems of complex operation, long production process, large particle size, etc., and achieve the effect of high activation degree, narrow particle size distribution and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

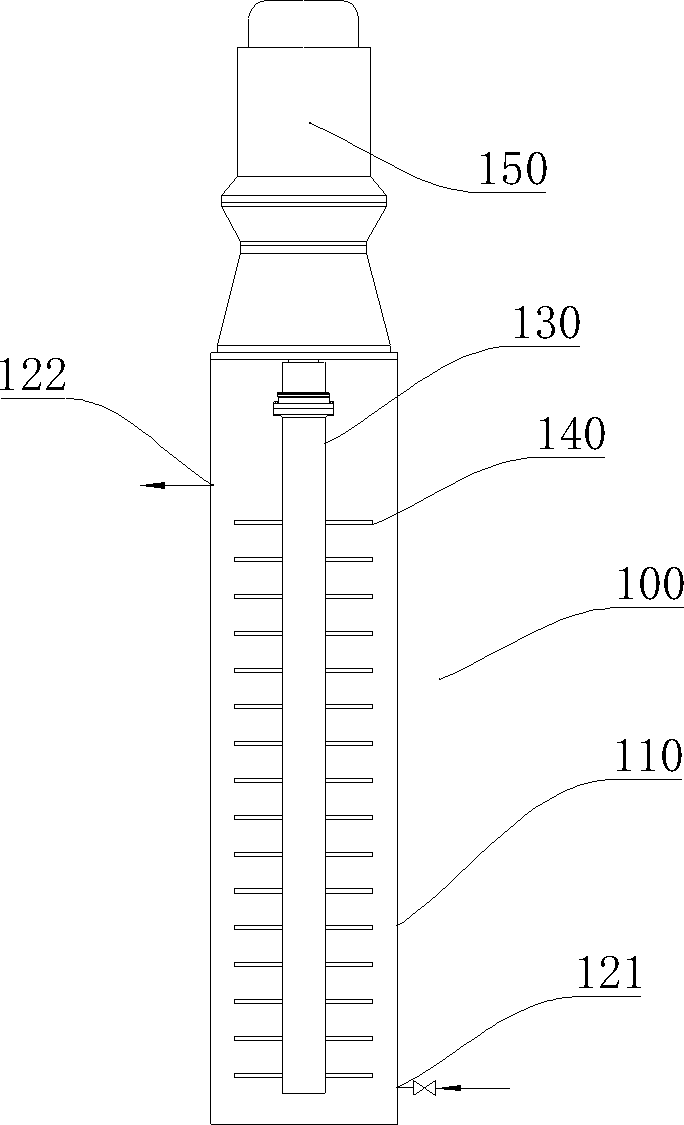

Method used

Image

Examples

Embodiment 1

[0054] Mix 5 tons of 325-mesh brucite, 5 tons of water and 40 kg of polyacrylate dispersant (9400), mix well, and pump it into a CYM-3000 blade-type stirring mill. The grinding medium uses ceramic beads of 3mm, 2mm and 1mm , The ratio of ceramic beads with a diameter of 3mm: 2mm: 1mm is 1:2:1, and the volume of the added grinding medium is 70% of the cylinder. The output is 900 kg per hour (calculated as dry powder), and the fineness has been tested to reach 7000 mesh. Filter with a plate and frame filter press, and the water content of the filter cake is 29.8%. Add the filter cake to the powerful dryer with a screw feeder, control the air inlet temperature to 320°C, the outlet to 180°C, and the moisture content of the dry powder to be 0.11%. The modifying agent is stearic acid, and the dosage is 1.5% of the mass of brucite. Put the dry powder from the hopper into the feed hopper of the continuous reformer SLG-300 for modification. Modification conditions: modification at 1...

Embodiment 2

[0056] Mix 7 tons of 200-mesh barite, 3 tons of water and 42 kg of sodium hexametaphosphate, mix well, and pump it into the CYM-3000 stirring mill. The grinding medium uses 2mm, 1mm and 0.5mm ceramic beads, and the ratio is 1:1: 1. The volume of the added grinding medium is 60% of the barrel. The output is 800 kg per hour (calculated as dry powder), and the fineness has been tested to reach 10,000 mesh, and more than 90% of which are less than 2 microns. Directly pump the slurry into the powerful dryer, control the air inlet temperature to 310°C, the outlet to 180°C, and the moisture content of the dry powder to be 0.19%. The modifying agent is aluminate, and the dosage is 0.3% of the mass of barite. Put the dry powder from the hopper into the feed hopper of the continuous reformer SLG-200D for modification. Modification conditions: modification at 120° C. for 5 minutes. The degree of activation after modification is 99%, without caking.

Embodiment 3

[0058] Mix 8 tons of 200-mesh barite, 2 tons of water and 42 kg of sodium hexametaphosphate, and pump them into the CYM-3000 stirring mill. The grinding medium is 10mm, 1mm and 0.1mm ceramic beads, and the ratio is 1:1: 2. The volume of the added grinding medium is 80% of the barrel. The output is 800 kg per hour (calculated as dry powder), and the fineness has been tested to reach 10,000 mesh, and more than 90% of which are less than 2 microns. Directly pump the slurry into the powerful dryer, control the air inlet temperature to 310°C, the outlet to 180°C, and the moisture content of the dry powder to be 0.19%. The modifying agent is titanate, and the dosage is 2.5% of the mass of barite. Put the dry powder from the hopper into the feed hopper of the continuous modification machine GMZ70 for modification. Modification conditions: modification at 100°C for 5 minutes. The degree of activation after modification is 97%, without caking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com