Patents

Literature

907results about How to "To avoid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

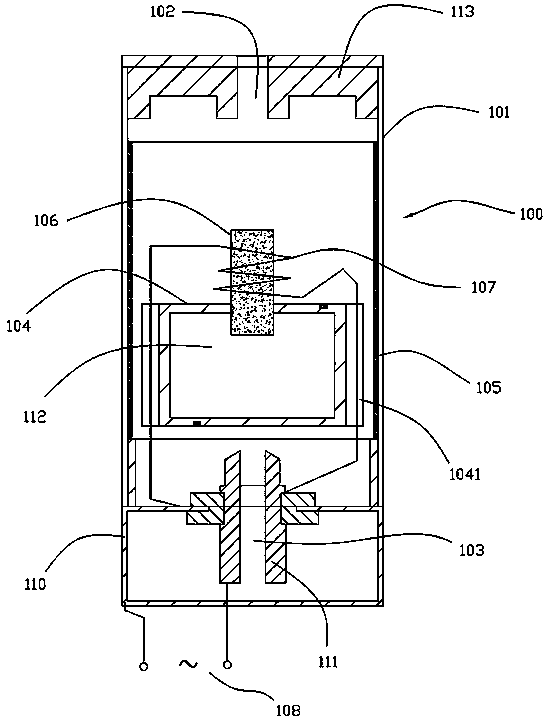

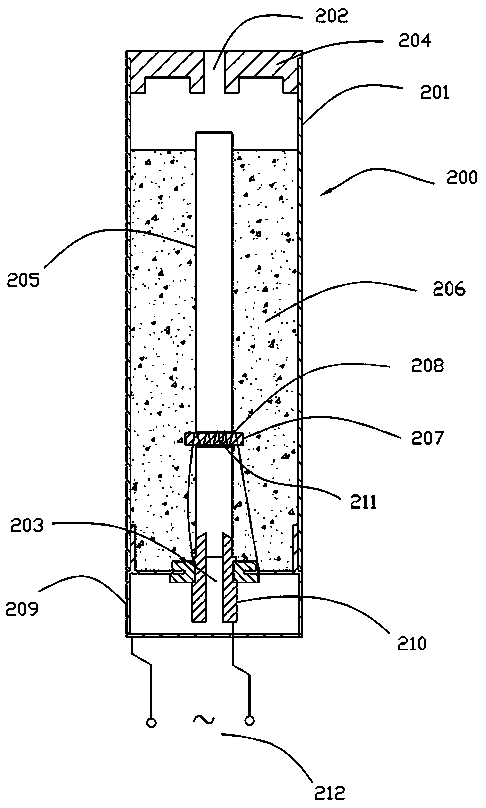

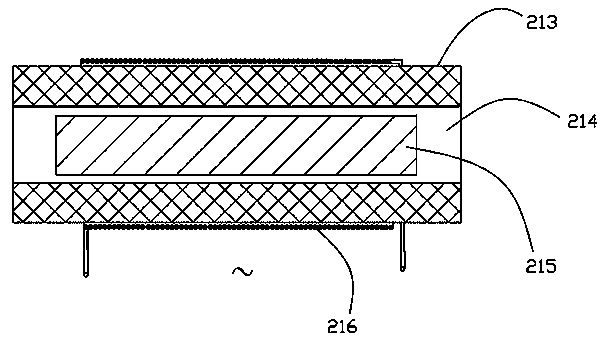

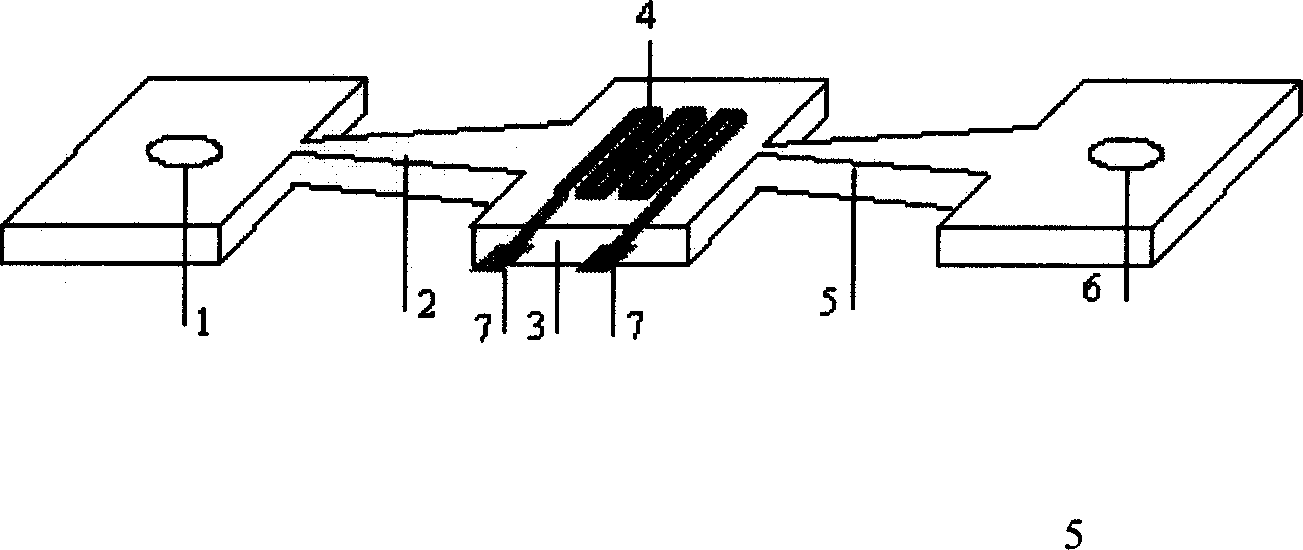

Smoke generator and electronic cigarette with same

InactiveCN103689812ASimple structureFully heatedTobacco devicesElectronic cigaretteAlternating current

The invention discloses a smoke generator and an electronic cigarette with the same. The smoke generator comprises a shell and a heating component. The shell is provided with a smoke inlet hole and a smoke outlet hole, and the heating component is arranged in the shell. The shell is further provided with an accommodating area used for storing smoke generating materials. The heating component comprises a metal component and an induction coil wound on the periphery of the metal component. Two ends of the induction coil are connected with an alternating-current power source. The heating component is used for directly heating the smoke generating materials in the accommodating area or permeating from the accommodating area to enable the smoke generating materials to generate smoke which is then exhausted from the smoke outlet hole. Compared with smoke generators with conventional atomizing modes, the smoke generator has the advantages that the smoke generating materials are atomized by a heating mode in which vortexes are generated through electromagnetic induction, so that the smoke generator is large in heating area, full in atomization and the like.

Owner:SHENZHEN FIRST UNION TECH CO LTD

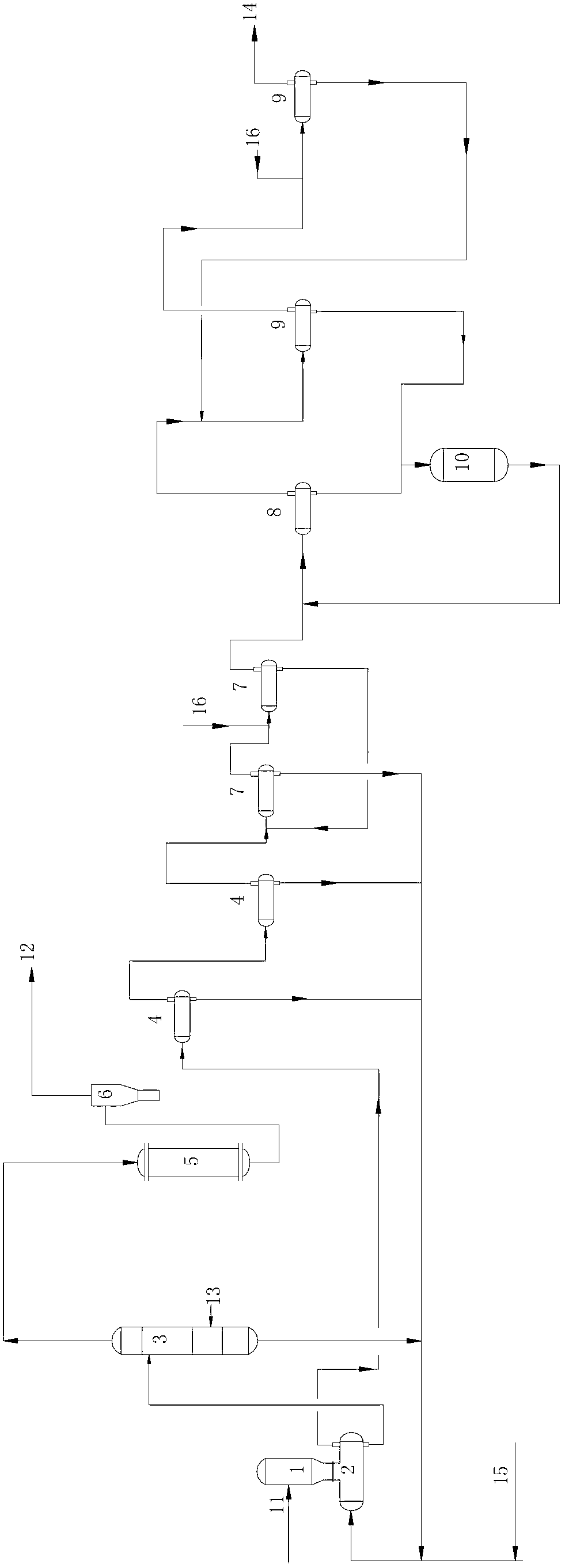

System for comprehensive utilization of three industrial wastes

InactiveCN101618292AAchieve energy saving and emission reductionReduce manufacturing costDispersed particle separationWater/sewage treatmentElectric powerToxic industrial waste

The invention provides a system for comprehensive utilization of three industrial wastes, mainly relating to the field of energy conservation and emission reduction, in particular to the comprehensive utilization of the three industrial wastes; to realize the objective of energy conservation and emission reduction required by the recycle economy, a system technology targeted at comprehensive utilization of the three industrial wastes of factories is adopted; in the invention, the reactor in the nuclear plant, the boiler in the coal-fired power plant and other types of supercritical boilers are utilized to provide a new cooling and turbine drive mode to solve the issue of industrial discharge of greenhouse gas and other polluting gases; in addition, collected emissions are utilized to produce nuclear fuel, compound chemical fertilizer or feedstuff and other chemical raw materials; moreover, to realize recycling of resources and sustainable utilization of energy, the original three wastes are innovatively applied to nuclear electric power generation. The system is characterized by comprising 10 major links and the beneficial effect thereof lies in utilizing new methods to realize energy conservation and emission reduction and production cost in the late stage of production can be reduced.

Owner:李元胜

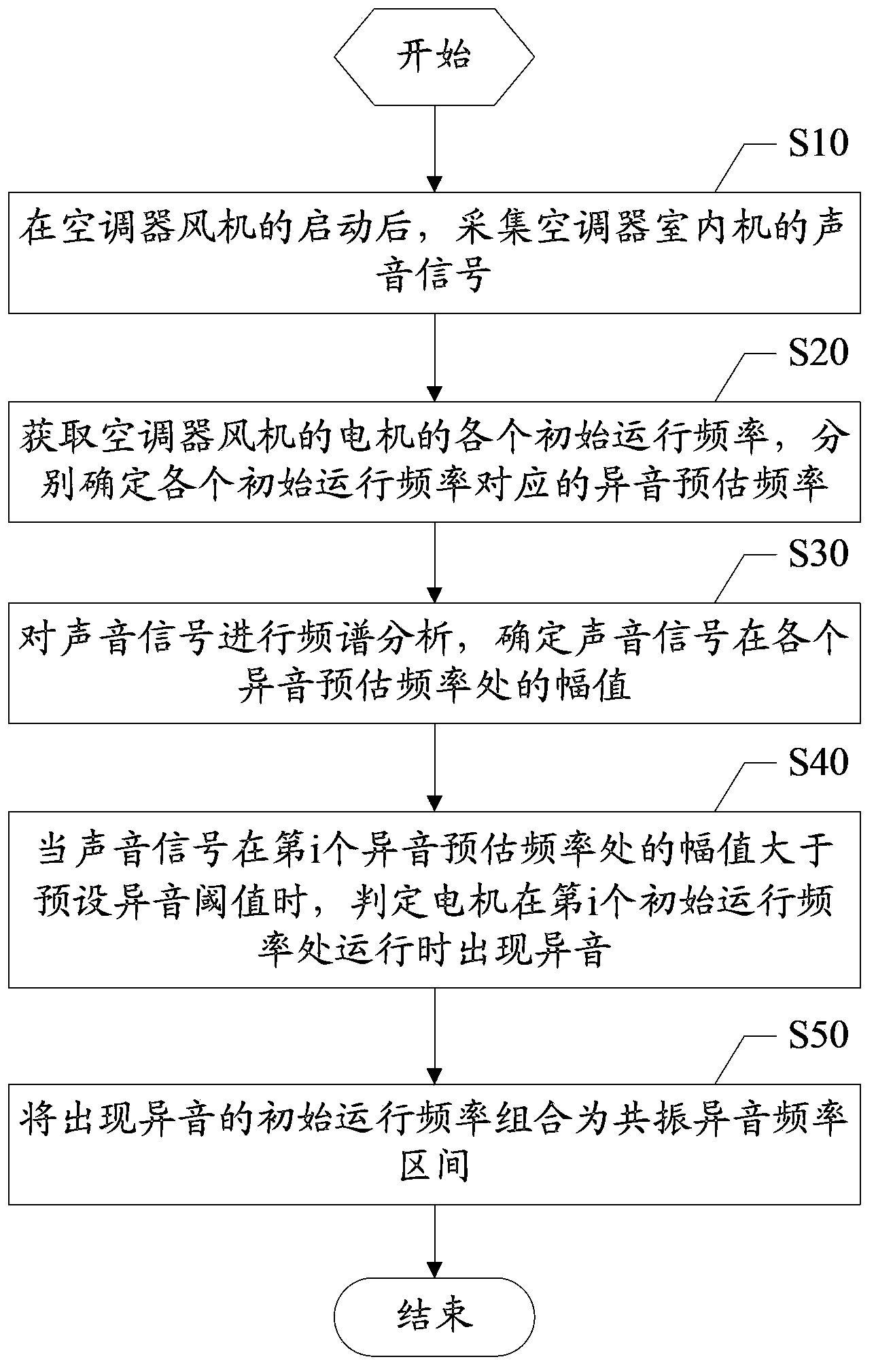

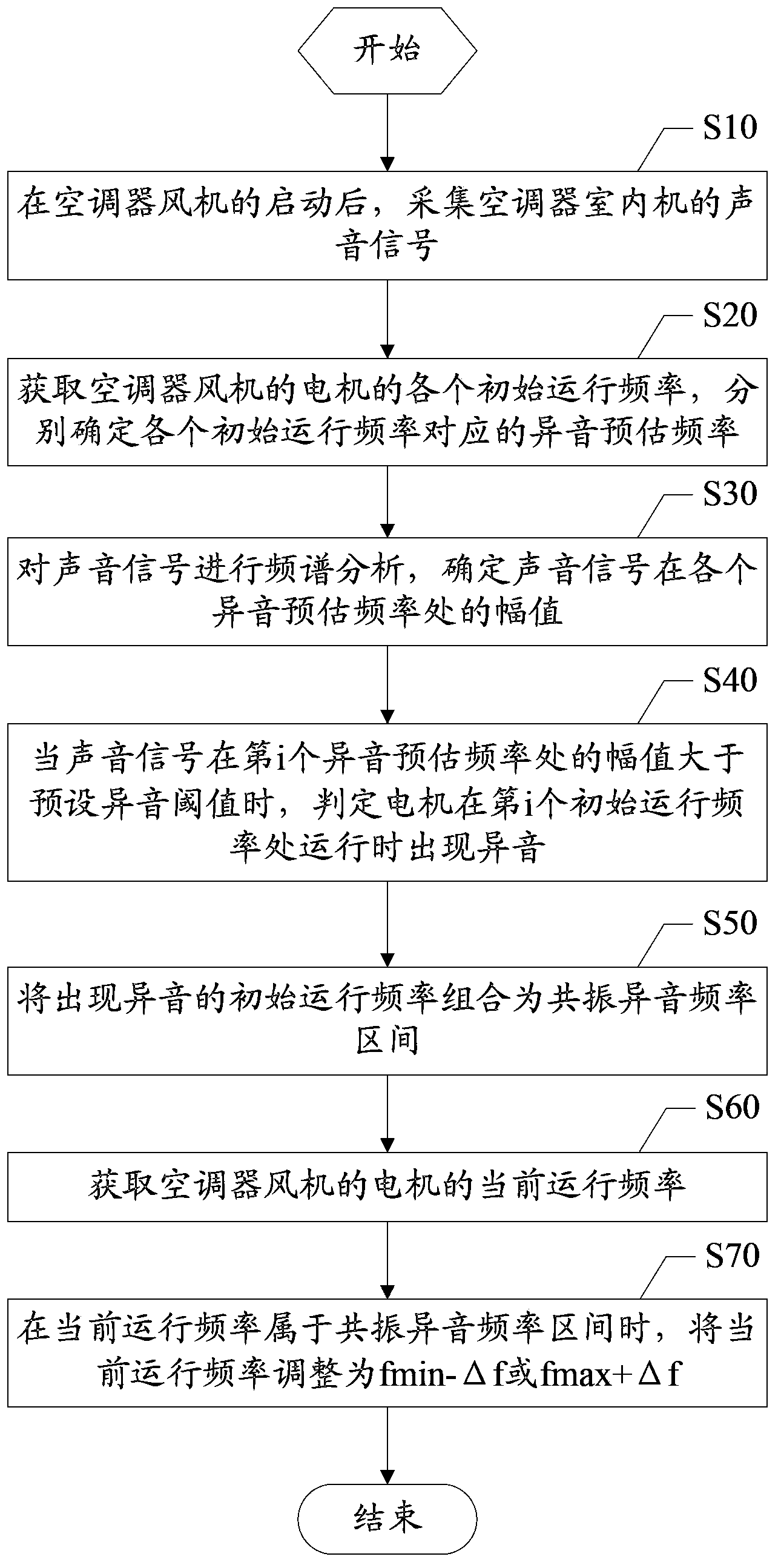

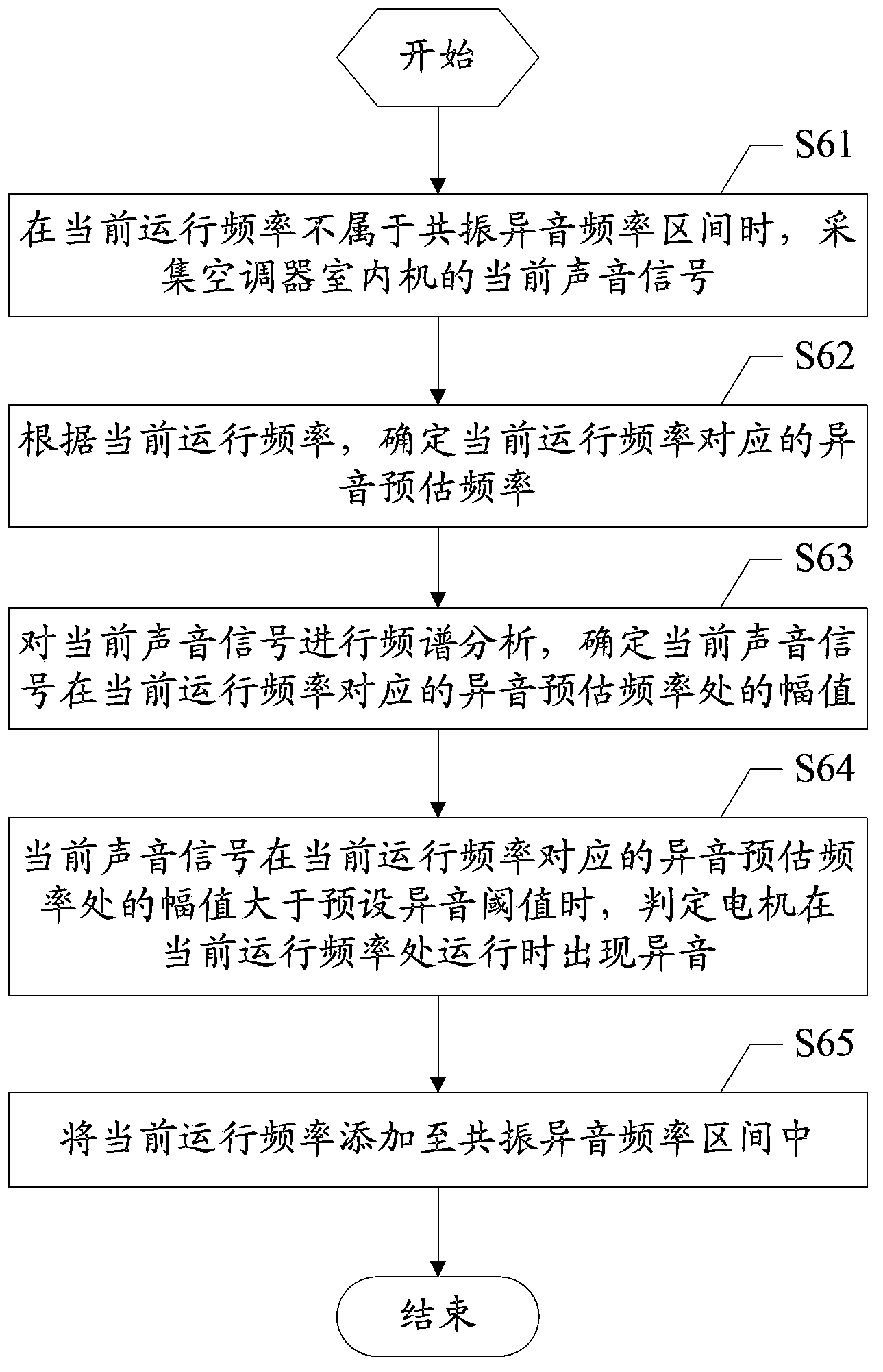

Method and device for adaptively adjusting frequency of conditioner motor and air conditioner

ActiveCN104344535AAvoid noiseTo avoidMechanical apparatusSpace heating and ventilation safety systemsSpectral analysisSound generation

The invention discloses a method and a device for adaptively adjusting frequency of a conditioner motor and an air conditioner. The method includes: acquiring an acoustic signal of a conditioner indoor unit; acquiring initial operating frequencies of a motor of a conditioner fan and determining each abnormal sound pre-estimated frequency; subjecting the acoustic signal to spectral analysis to determine an amplitude value of the acoustic signal under each abnormal sound pre-estimated frequency; if the amplitude value of the acoustic signal under the i-th abnormal sound pre-estimated frequency is greater than an abnormal sound preset threshold, determining that the motor produces abnormal sound when running under the i-th initial operating frequency; combining the initial operating frequencies where the abnormal sound occurs into a resonant abnormal sound frequency range. The method and the device have the advantages that according to the relevancy between abnormal sound generation frequencies and motor operating frequencies, the acoustic signal is subjected to spectral analysis through the motor operating frequencies, whether or not the abnormal sound occurs is judged, the resonant abnormal sound frequency range is set, and the indoor fan can constantly adaptively avoid the resonant abnormal sound frequencies during operating so that the abnormal sound is effectively avoided.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

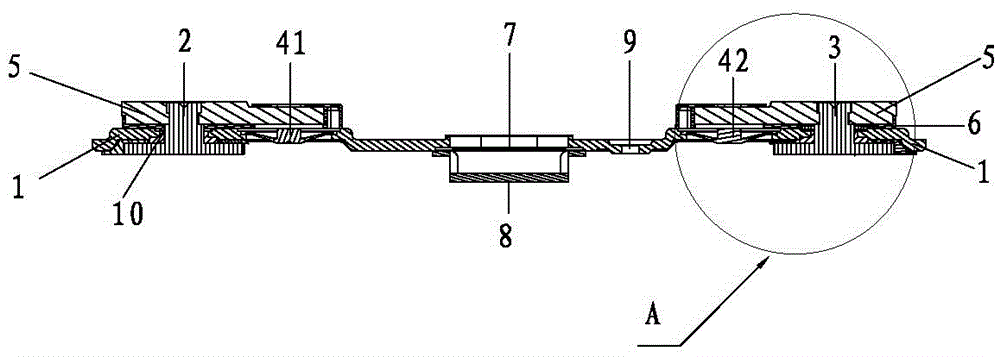

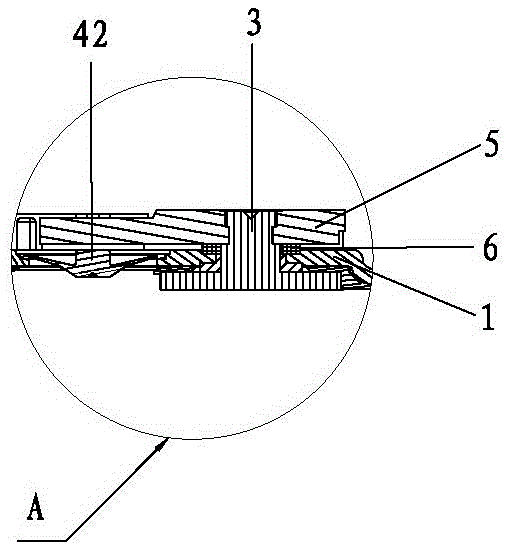

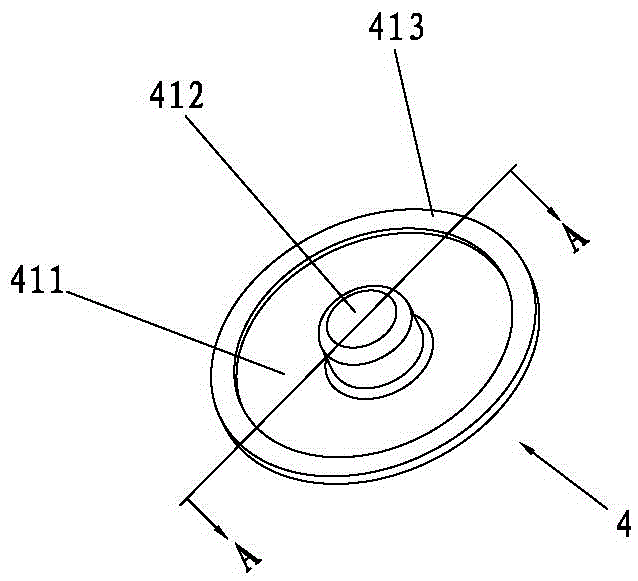

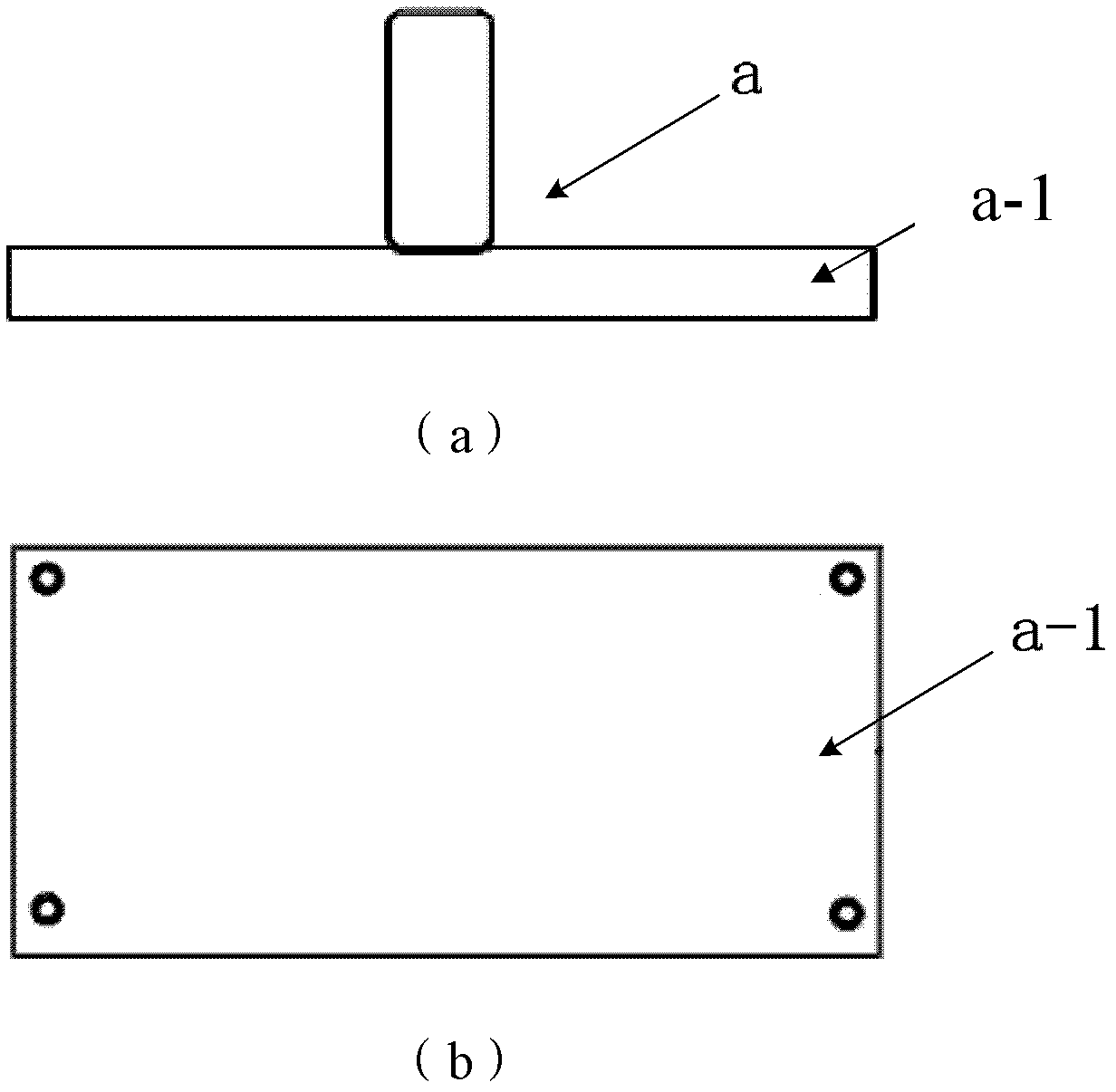

Power battery top cover and power battery using top cover

ActiveCN105932181AOptimized designGood security featuresCell lids/coversBatteriesPower batteryEngineering

The invention belongs to the technical field of power batteries, and especially relates to a power battery top cover and a power battery using the top cover. The power battery top cover comprises a top cover sheet, and a firs pole pillar, a second pole pillar, a pressure release valve, a liquid injection hole, pneumatic overturning sheets and a resistor block, the first pole pillar is in insulation connection with the top cover sheet, the second pole pillar is electrically connected with the top cover sheet through the resistor block, the pneumatic overturning sheets are electrically connected with the top cover sheet, the conductive block is arranged above the pneumatic overturning sheets, a baffle plate is arranged under the pressure release valve, the pneumatic overturning sheets comprise a first pneumatic overturning sheet and a second pneumatic overturning sheet, and the thickness of the first pneumatic overturning sheet is smaller than the thickness of the second pneumatic overturning sheet; and when the pressure in the power battery increases, the pneumatic overturning sheet and the second pneumatic overturning sheet sequentially move upward in order to electrically connect the first pole pillar with the second pole pillar. Compared with power battery top covers in the prior art, the power battery top cover disclosed in the invention makes the power battery have an excellent safety protection function in overcharging, nailing, short circuit and hot box test.

Owner:东莞永蓝电子科技有限公司

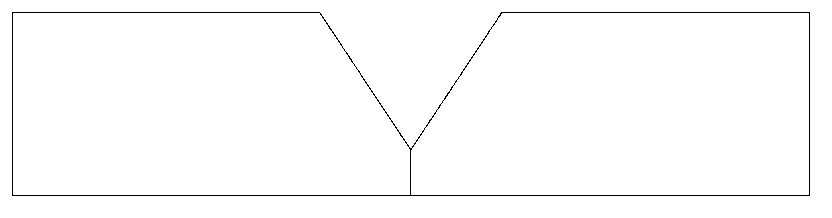

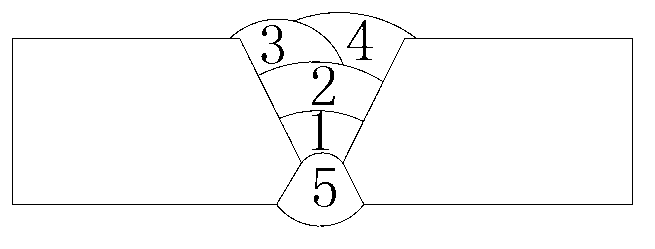

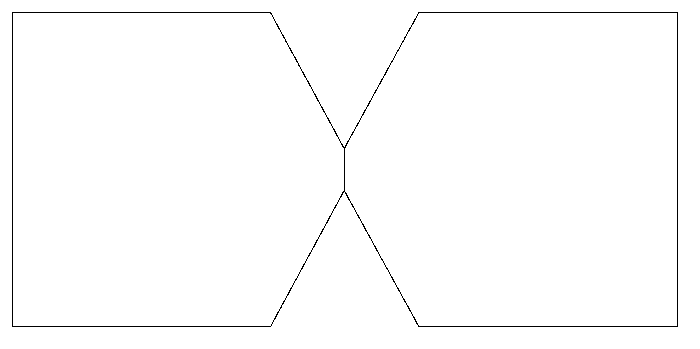

Method for welding Q500qE ultralow-carbon bainite steel for bridge

ActiveCN103286427ASolve welding process problemsAvoid cold cracksArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention provides a method for welding Q500qE ultralow-carbon bainite steel for a bridge. The method is excellent in joint mechanical performance and high in welding efficiency and specifically includes that aiming at specific chemical components, applicable technical conditions and different plate thicknesses of the Q500qE ultralow-carbon bainite steel for the bridge, preheating temperature before welding, groove types and welding process parameters are determined; a welding joint type adopts butt joint, penetration angle joint or ship position T-shaped angle joint; a welding method adopts submerged arc welding, CO2 gas shielded semiautomatic welding or shielded metal arc welding. By the welding method, the joint type and thickness specifications of a bridge structure are comprehensively covered, the technical scheme is simple, convenient and high in adaptivity, all implementing effects meet technical requirements of standards related to building of bridge steel and the bridge structure, and the method is of great significance in promoting upgrading of the bridge steel and development of large-span steel bridge building technology. The method can be applied to building of the bridge structure, can also be applied to welding of other ultrathin-carbon bainite steel and is high in adaptivity.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

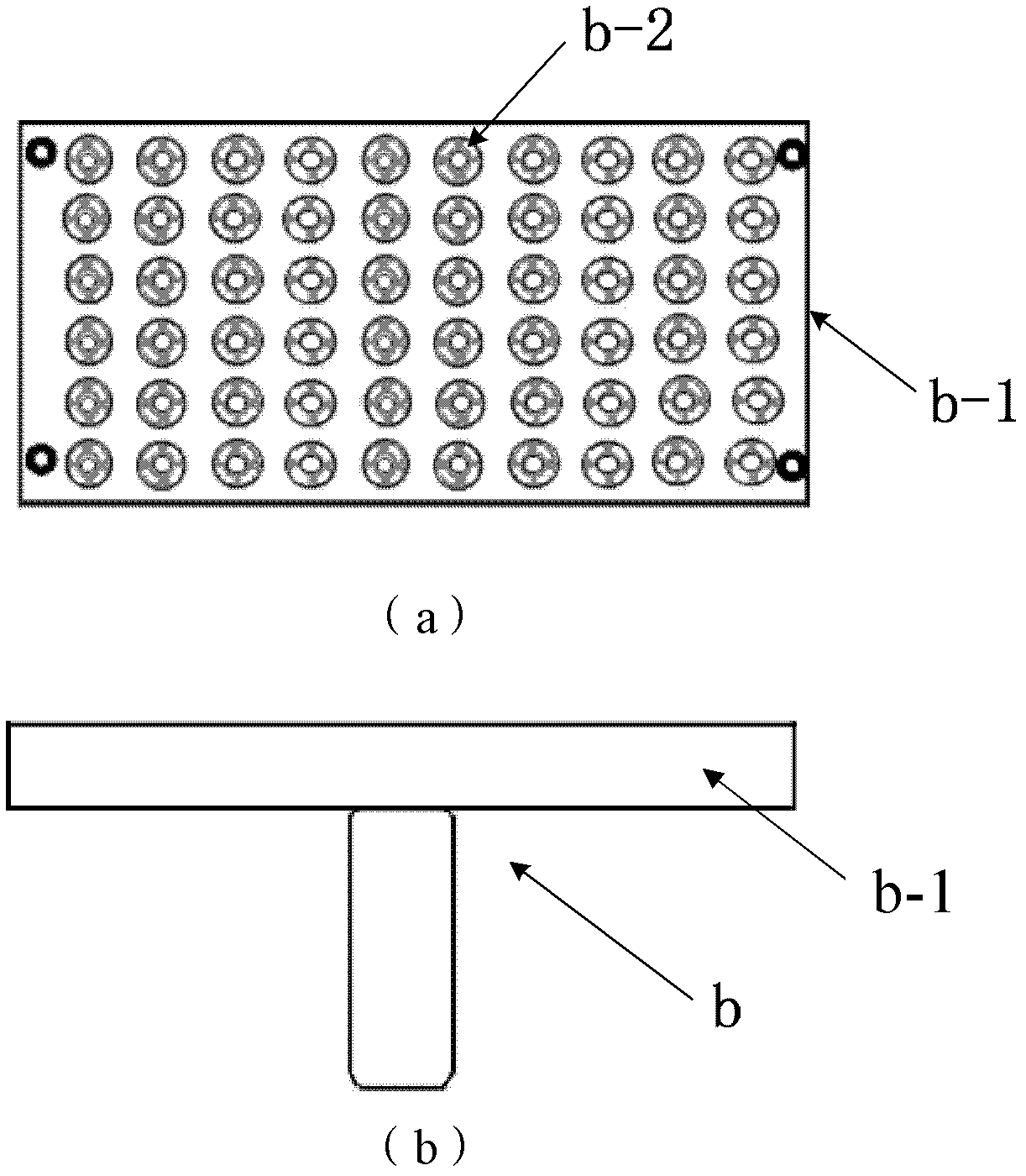

Minisize diffusion pump and preparation method thereof

InactiveCN1844681AReduce processing difficultyNo increase in processing difficultyMachines/enginesDiffusion pumpsMicrofluidicsPump chamber

The invention discloses a micro disperse pump which comprises a pump chamber, a one-way valve, a pump inlet, a pump outlet and a driving device inside the pump chamber; wherein, the one-way valve is between the pump chamber and the pump inlet, and between the pump chamber and the pump outlet; the one-way valve is a wedge disperse tube with different positive and passive fluxes; the fluid of pump chamber can be expanded and contracted to generate pressure difference, and according to the different pressures of positive and passive fluxes in the wedge disperse tube, to generate one-way continuous fluid transmission. The inventive micro disperse pump can drive fluid via adsorbing fluid or directly drive fluid. The production is based on silicon micro-mechanical processing technique and micro-mould technique, with simple process, lower cost, high reliability and the application for integrating other micro-fluid systems. It has wider application in the micro-fluid control analysis chip.

Owner:PEKING UNIV

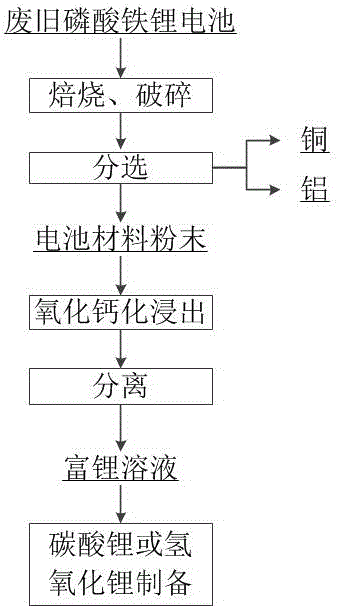

Method for recovering lithium in waste and old lithium iron phosphate batteries

ActiveCN106848472AHigh purityImprove recycling efficiencyWaste accumulators reclaimingBattery recyclingWater insolubleLithium hydroxide

The invention provides a method for efficiently recovering lithium in waste and old lithium iron phosphate batteries. The method comprises that waste and old lithium iron phosphate batteries are roasted and sorted to form lithium-containing positive pole powder, lithium-containing positive pole powder and a calcium-containing alkaline solution undergo a reaction under conditions of oxidation so that iron and phosphate radical are converted into a water-insoluble compound and lithium is converted into water soluble lithium hydroxide, and the reaction products are filtered so that a lithium hydroxide solution is obtained and can be used for further preparation of lithium hydroxide or lithium carbonate products. The method replaces the conventional wet acid leaching method in waste and old lithium iron phosphate battery recovery and is free of a strong acid so that production of a large amount of high-salt waste water is avoided. The method realizes selective leaching of lithium, prevents iron impurities from entering the leaching liquid from the source, can produce a high-purity lithium product, has simple processes, utilizes chemical agents having wide sources, has simple process conditions, can prepare a high-purity lithium product through a one-step method, greatly improves recovery efficiency of waste and old lithium iron phosphate batteries and has a good industrial application prospect.

Owner:SINO SCI PROCESS BEIJING SCI&TECH CO LTD

Method for synthesizing TS-2 molecular sieves

InactiveCN101993090AReduce generationTo avoidCrystalline aluminosilicate zeolitesMolecular sieveWater baths

The invention relates to a method for synthesizing TS-2 molecular sieves, in particular to a method for synthesizing the TS-2 molecular sieves under the condition of adding H2O2, which belongs to the technical field of chemical engineering. The method for synthesizing the TS-2 molecular sieves has the advantages of simple operation and high framework titanium content and can effectively avoid the formation of anatase TiO2. The method comprises the following steps of: placing tetraethoxysilane (TEOS) into a dripping tube, dripping the TEOS into a flask, and properly accelerating the stirring speed; adding tetrabutyl orthotitanate (TBOT) into anhydrous isopropyl alcohol (IPA); slowly dripping the mixed liquid into a three-neck flask under the condition of severe stirring; adding 10 percent (wt) of TBAOH template agents into the three-neck flask after the dripping is completed, and adding H2O2 according to a certain n(H2O2) / n(Ti) ratio to obtain light yellow solution; and carrying out heating and alcohol removal through water baths to obtain clear glue solution.

Owner:邓宇辰

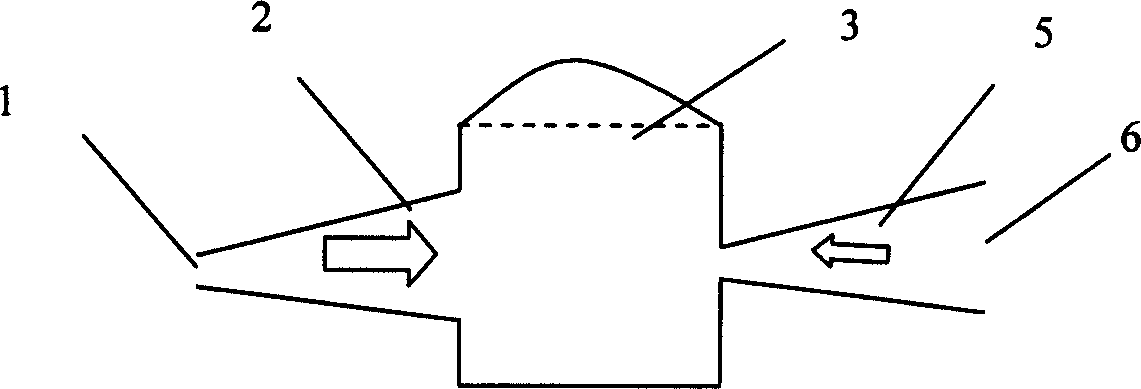

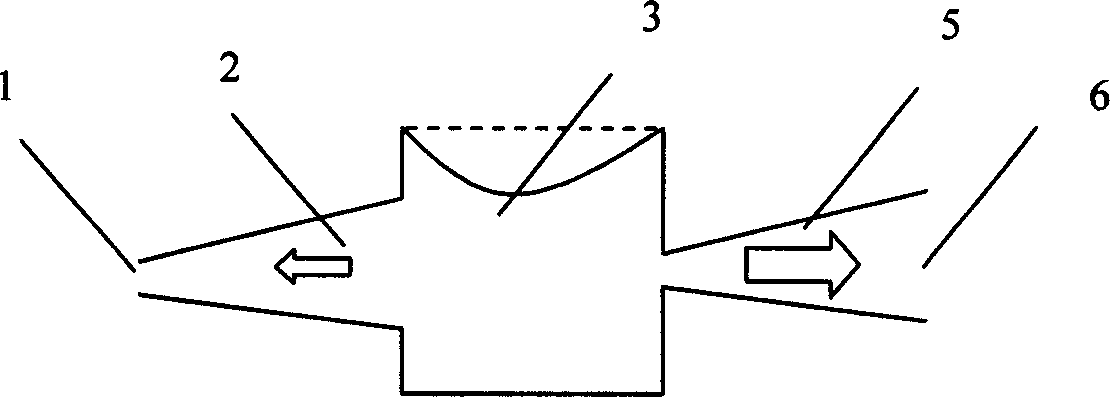

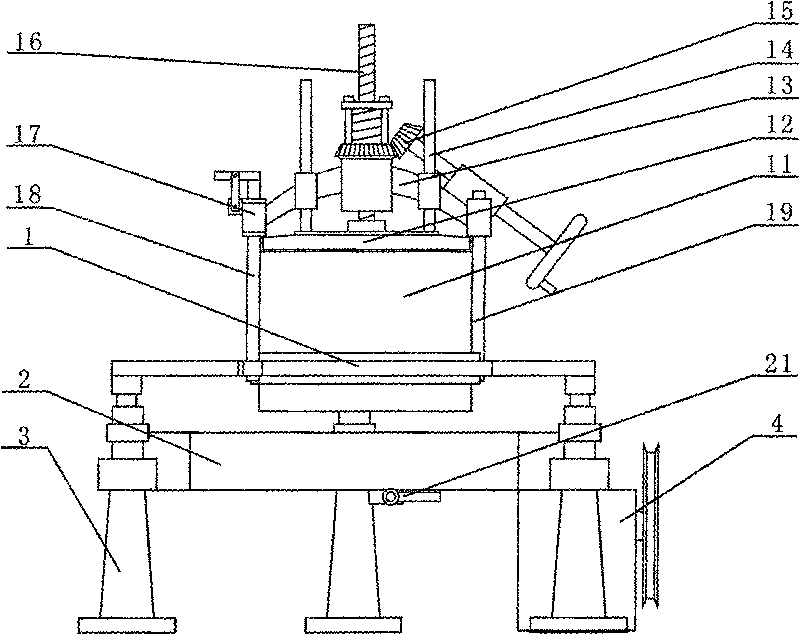

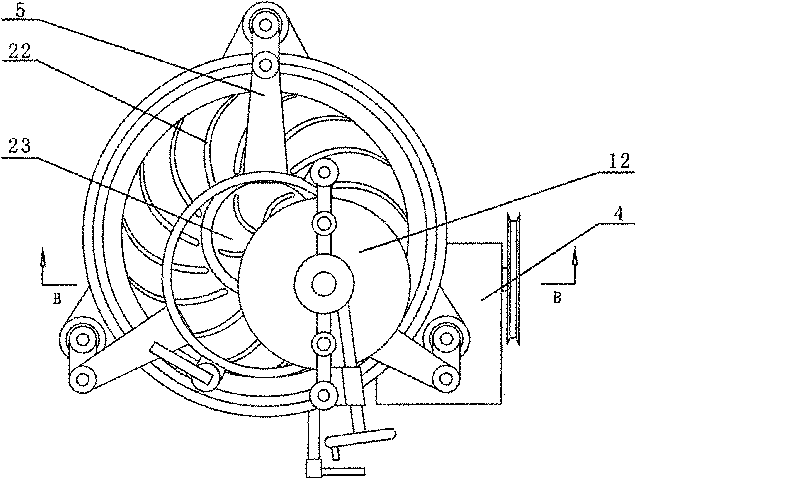

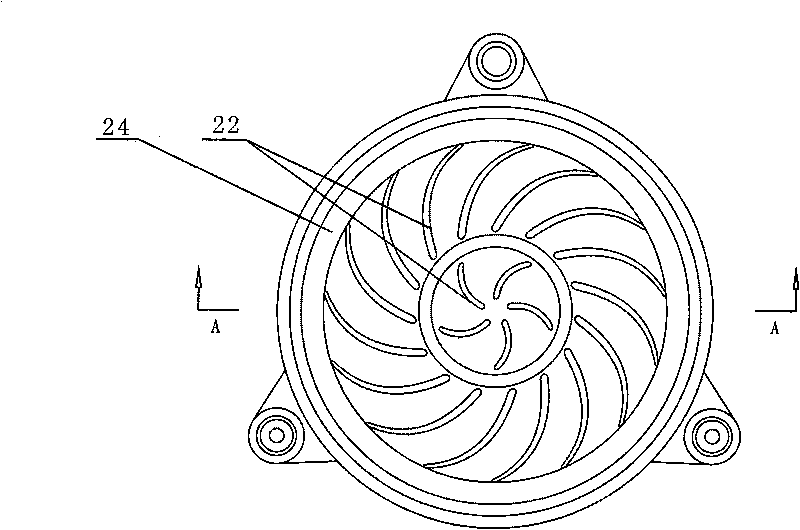

Novel tea knead entwist machine

The invention discloses a novel tea knead entwist machine and relates to tea processing machineries. The circular movement of the knead entwist device above the knead entwist plate can be realized by connecting the knead entwist device with a crank rocker mechanism; and the tailor-made knead entwist plate matches with the screw cover in the knead entwist device. The stripping tea rate of the tea is high, broken tea is little, and the broken tea generated in production can be separated from the mature tea automatically, thus improving tea grade and increasing production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

Lubricating agent for superfine copper wire drawing

The invention discloses a lubricating agent for superfine copper wire drawing. The lubricating agent comprises the following components in parts by mass: 5-25 parts of lubrication base oil, 10-30 parts of an emulsifying agent, 1-5 parts of a surface active agent, 1-10 parts of an antirust agent, 1-5 parts of an extreme pressure antiwear additive, 1-5 parts of a thickening agent, 5-25 parts of an alkali retention agent, 1-5 parts of a bactericide, 0.1 part of a defoaming agent and 30-50 parts of water. The lubricating agent for superfine copper wire drawing has good oxidation resisting, cooling, cleaning, lubricating, rust preventing, hard water resisting and copper soap dispersing properties, and is particularly suitable for superfine copper wire drawing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Aqueous double-component polyurethane varnish and preparation method of aqueous double-component polyurethane varnish

The invention discloses an aqueous double-component polyurethane varnish and a preparation method of the aqueous double-component polyurethane varnish. The raw material formula of the aqueous double-component polyurethane varnish is composed of a component 1 and a component 2, wherein the component 1 comprises the following components: 55-65% of hydroxy polyurethane dispersion, 15-18% of water, 0.2-0.5% of acetobutyryl cellulose flatting agent, 0.5-0.8% of flowing deformation auxiliary agent, 0.5-0.8% of nano silica particle, 0.1-0.3% of defoamer, 0.3-0.5% of defoaming agent, 0.1-0.3% of thickener, 0.4-0.6% of film-forming auxiliary agent, 0.2-0.5% of aqueous drier and 0.5-1.5% of teflon wax; and the component 2 comprises 15-20% of polyisocyanate and 1-3% of degassing solvent. The aqueousdouble-component polyurethane varnish has the characteristics of fast drying speed and good leveling property, is not easy to generate bubbles, is easy to store, and can endow a varnish film with high hardness and high anti-scratching property.

Owner:HUIZHOU CHANGRUNFA PAINT

Continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel

The invention discloses continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel. According to the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel, cracks are reduced by adopting low carbon amount and high viscosity, reducing thermal stress inside blank shells and increasing powder consumption amount. The alkalinity of the casting powder is 0.8-1.1, the cracks caused by uneven heat transmission are avoided; through the adoption of 8-12% of Na2O, 6-8% of F- and 3-4.5% of Li2O, weak coldness and even heat transmission of the upper portion in a crystallizer are achieved, inclusion absorbing effects are improved, and the cracks are reduced; through the adoption of 2-8% of MnO, lattice vibration and conduction heat transmission are weakened, and the crystallization properties of the casting powder and the casting blank quality are improved. Raw materials of the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel are easy to obtain, and production cost is low. Through field testing, the casting power is good in spreadability and good in air permeability and can be smelted stably and be free of caking, the consumption amount of the casting powder is around 0.3-0.42kg per ton of steel, the consumption cost is relatively low, and the qualified rate of the first grate casting blanks is improved significantly.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

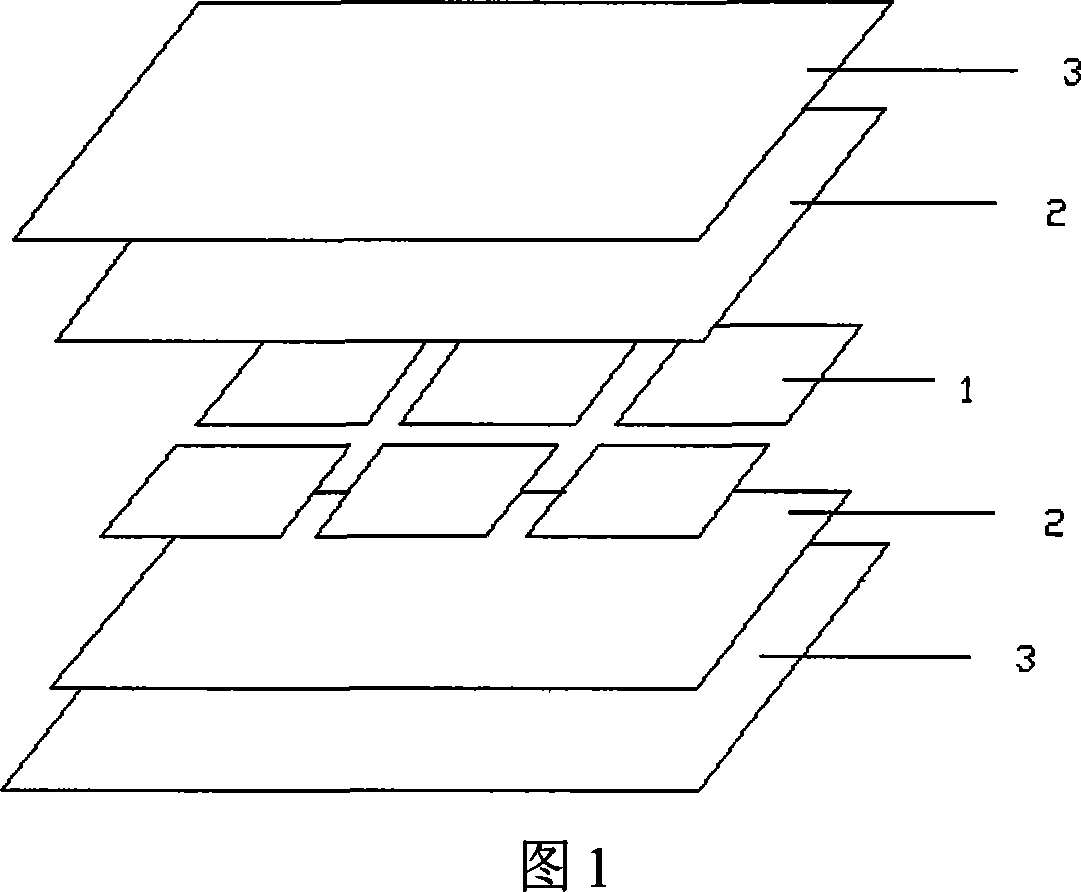

A package method for double-side silicon-glass solar cell assembly

InactiveCN101060146ATo avoidGood effectFinal product manufactureSemiconductor devicesCell layerSilicon solar cell

The related package method for double-face glass crystal silicon solar cell assembly comprises: from top to bottom, stacking a glass-EVA film-solar cell-EVA film-glass structure with the serial solar cell, glass, and EVA film; treating the five-layer structure with special macromolecular material; when heating the cell layer-press machine to 70Deg, putting the five-layer structure into the machine for pressing; setting the machine temperature as 125-145Deg for 15-25min; then, balancing the gas pressure of machine lower cavity with outer atmosphere, and taking out the product. This invention overcomes the damage to product.

Owner:SOUTH CHINA UNIV OF TECH

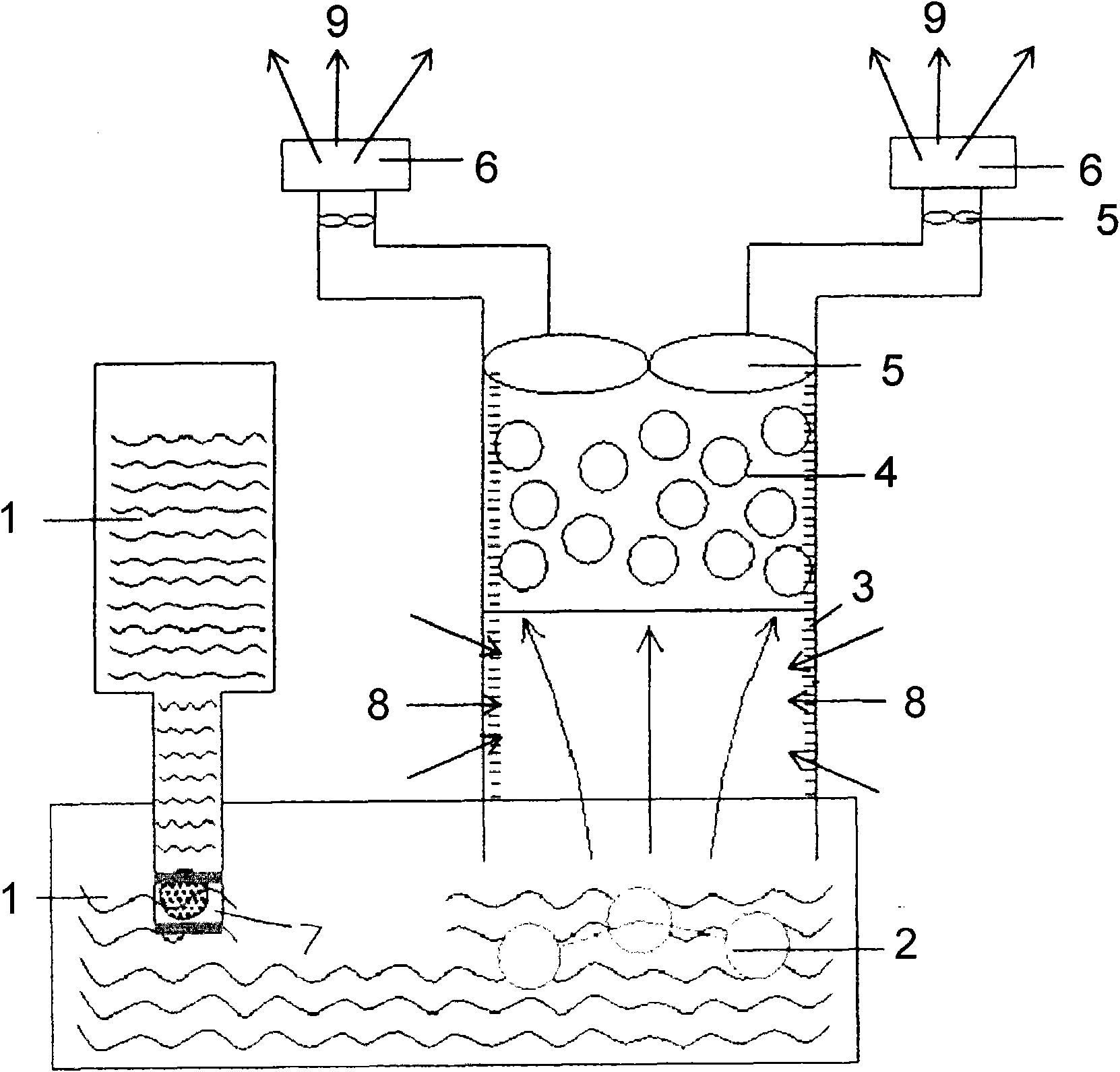

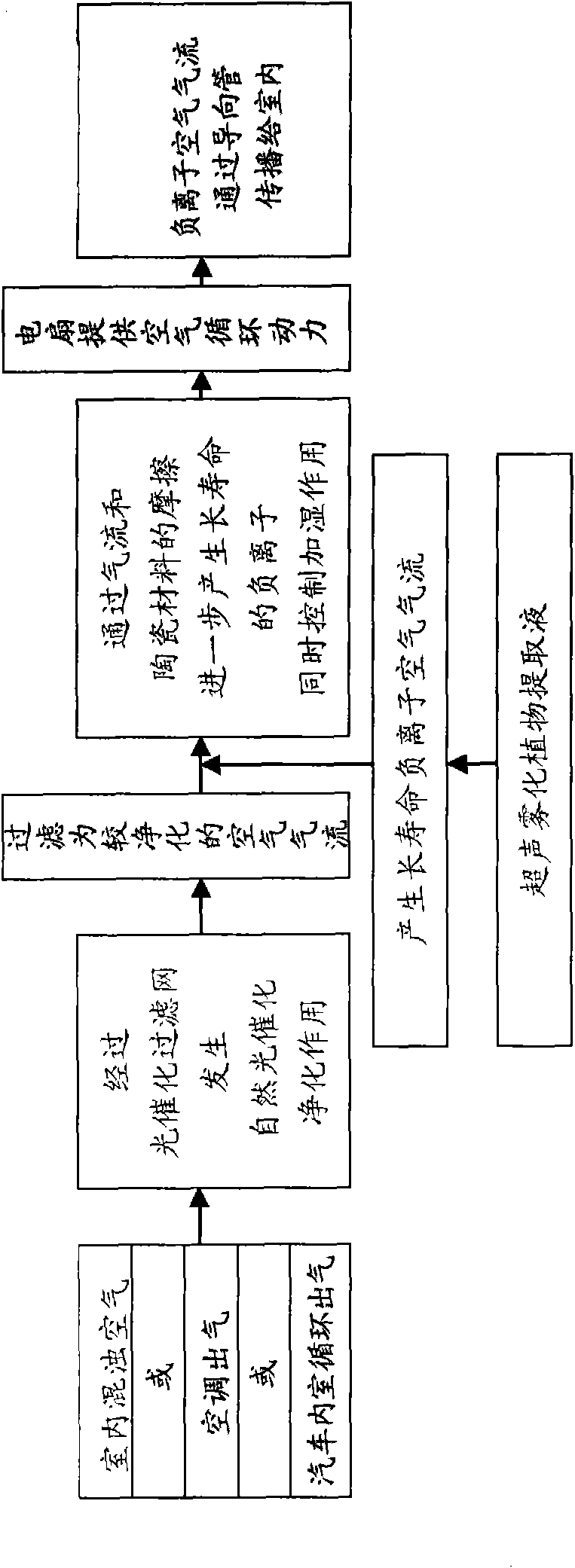

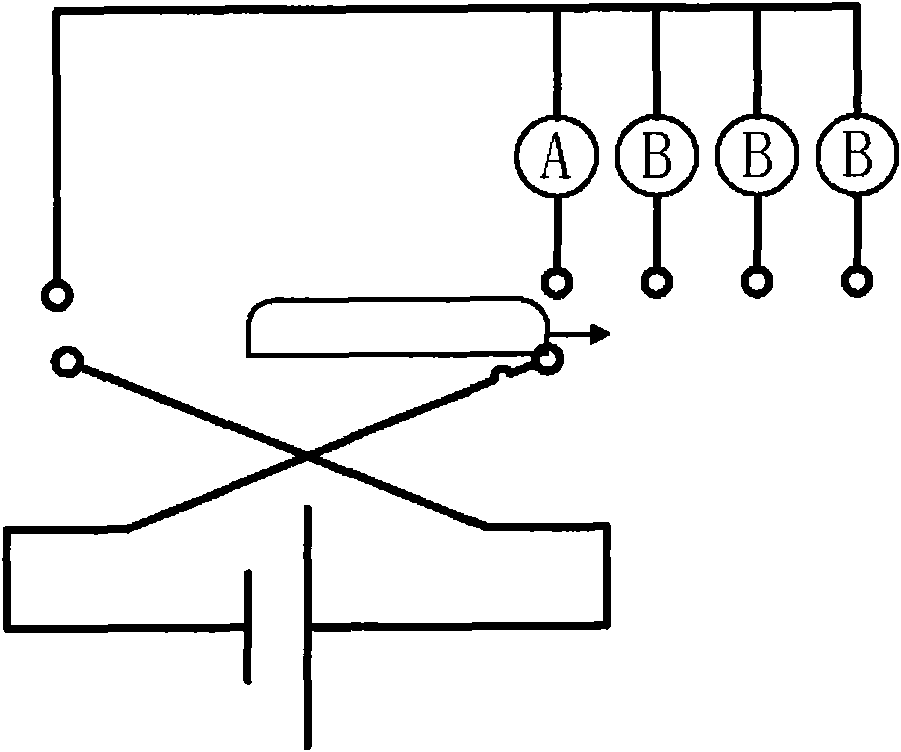

Negative ion generator and air purifier comprising same

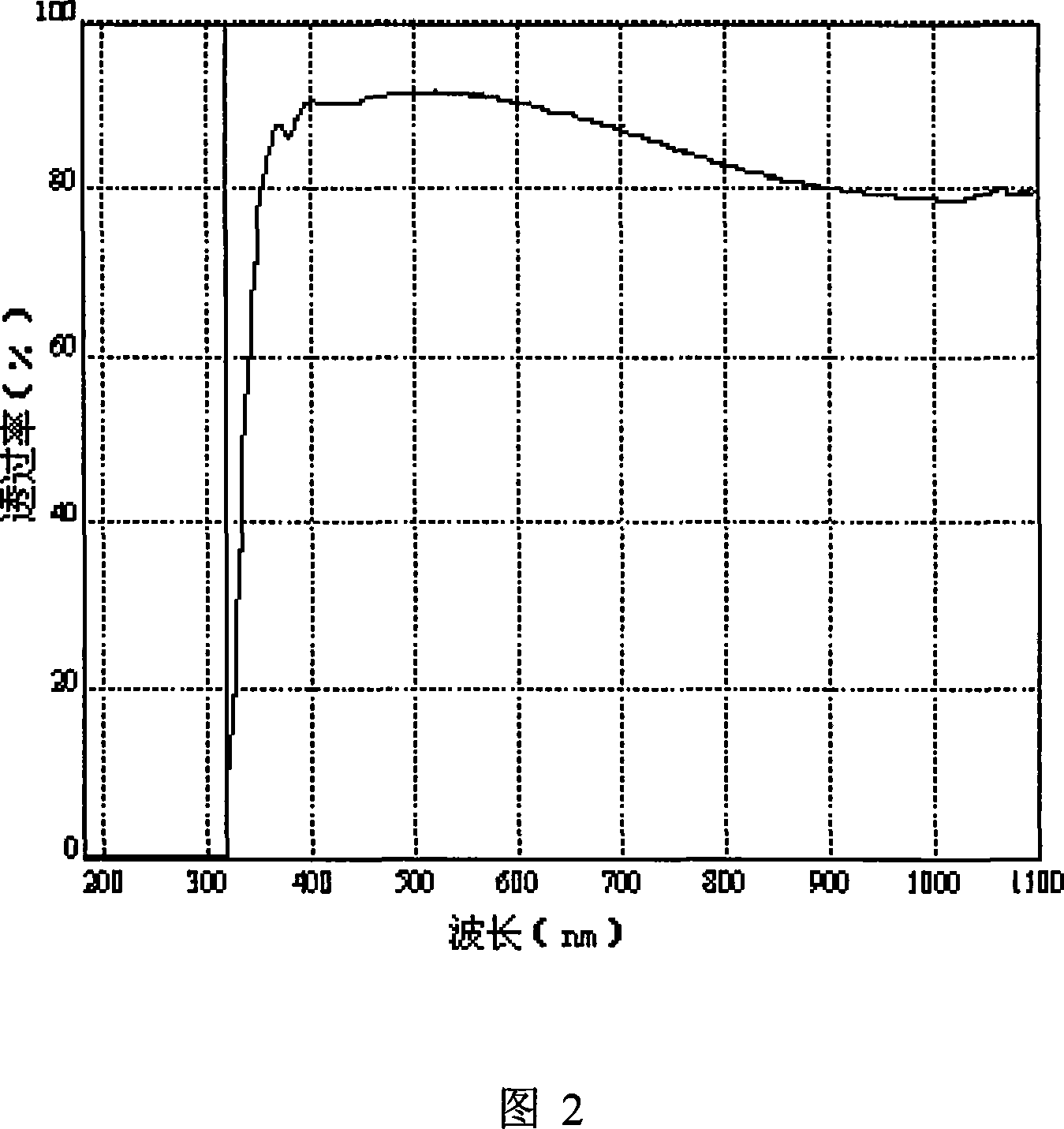

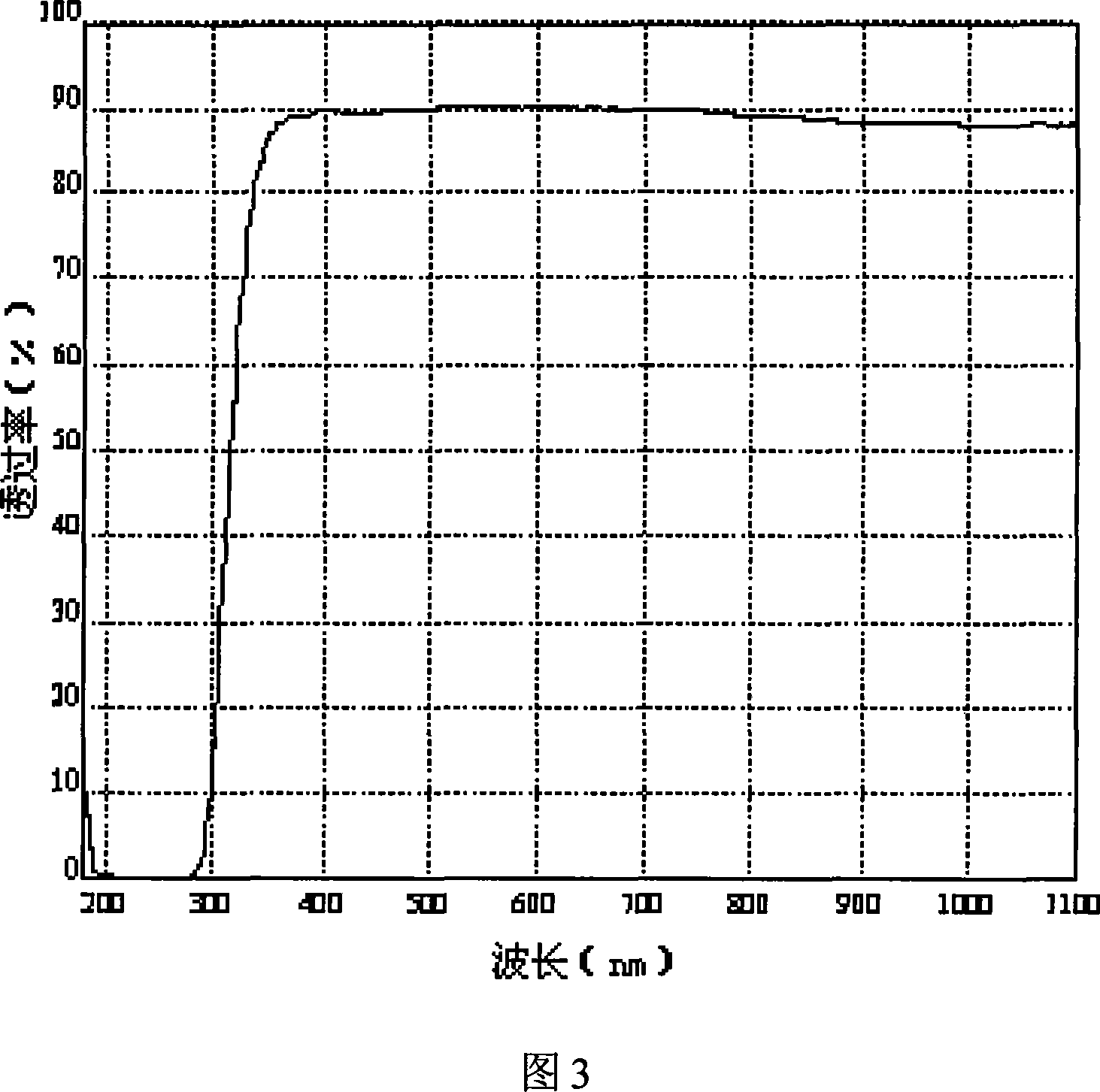

ActiveCN101826704AIncrease concentrationExtension of timeElectrical apparatusDeodrantsAir purifiersIon

The invention relates to a negative ion generator, comprising a liquid-storing device for storing liquid and an atomizing device for atomizing the liquid to generate a negative ion. The negative ion generator is characterized in that the liquid is plant extracting solution. The negative ion generator can realize zero ozone and no radiation and can prolong the negative ion life. The invention alsorelates to an air purifier comprising the negative ion generator.

Owner:HEBEI SINARAY NEW CONSTR MATERIALS CO LTD

Diaphragm attaching method and diaphragm attaching device

InactiveCN102649337ANot easy to produceTo avoidLaminationLamination apparatusEngineeringContact mode

The invention provides a diaphragm attaching method, which comprises the following steps of: A, unfolding a diaphragm flatly, and then conveying the diaphragm to a position opposite to a substrate; B, aligning the diaphragm and the substrate; and C, attaching the diaphragm onto the substrate in a surface contact mode. Correspondingly, the invention provides a diaphragm attaching device. According to the diaphragm attaching method and the diaphragm attaching device disclosed by the invention, high-precision attachment between the diaphragm made of flexible material and the substrate can be realized, and bubbles can not be produced easily in an attaching process.

Owner:BOE TECH GRP CO LTD +1

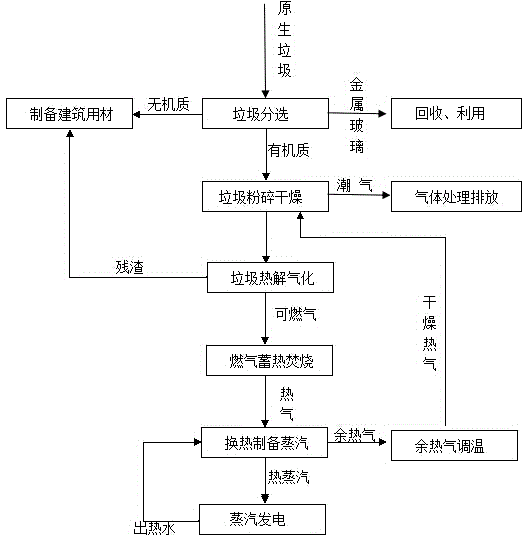

Power generation technique based on pyrolyzation and gasification of household refuse and incineration of fuel gas

InactiveCN105351941AHigh heat conversion rateImprove power generation efficiencySolid waste disposalIncinerator apparatusCombustible gasSteam power

The invention discloses a power generation technique based on pyrolyzation and gasification of household refuse and incineration of fuel gas. The power generation technique comprises the steps that the household refuse is sorted, pulverized and dried; then pyrolyzation and gasification are conducted on the household refuse, so that combustible gas is generated; the combustible gas is incinerated; steam is prepared from hot air obtained through incineration through heat exchange; and the steam is introduced into a steam power generator for power generation. According to the power generation technique based on pyrolyzation and gasification of the household refuse and incineration of the fuel gas, the heat energy conversion rate of pyrolyzation and gasification is higher, the power generation efficiency is greatly improved, and the cost caused by procedure increment can be counteracted by the increased economic benefits; the refuse is subjected to pyrolyzation and gasification under an oxygen-free or oxygen-deficient condition firstly after being dried instead of being directly incinerated, and thus the amount of generated dioxin is greatly reduced; the dioxin can be evenly decomposed by conducting heat-storage incineration of the generated combustible gas through secondary gas at the temperature over 850 DEG C. Tail gas is used for dying the refuse, and smoke emission hardly exists under the adsorption action of the pulverized refuse.

Owner:FUJIAN ZHENGREN ENVIRONMENTAL PROTECTION

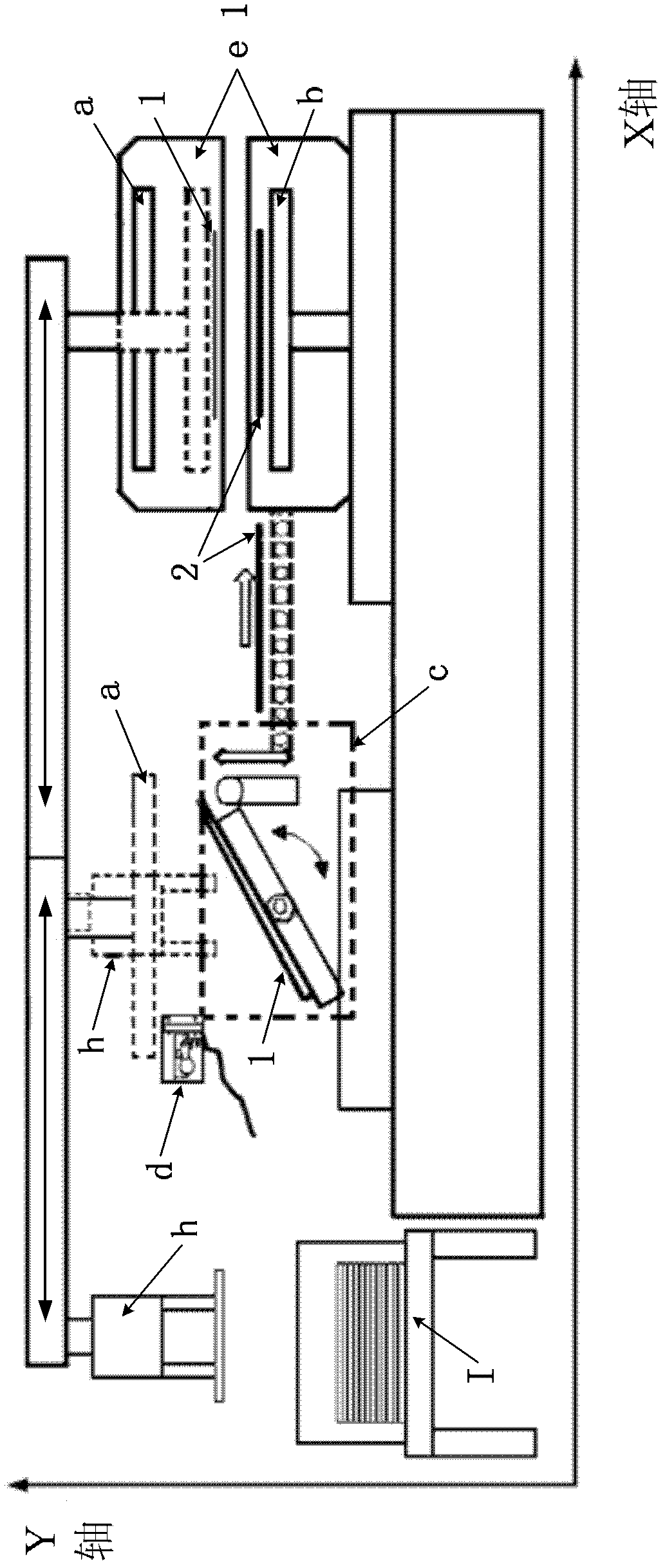

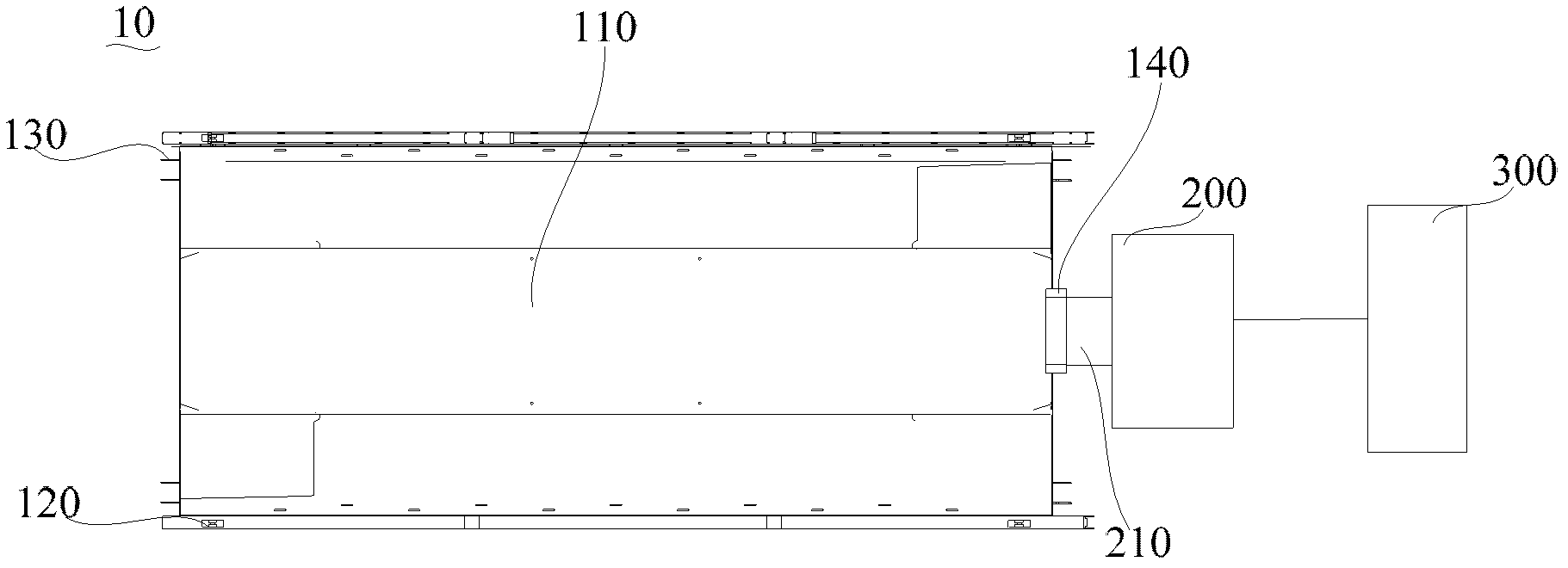

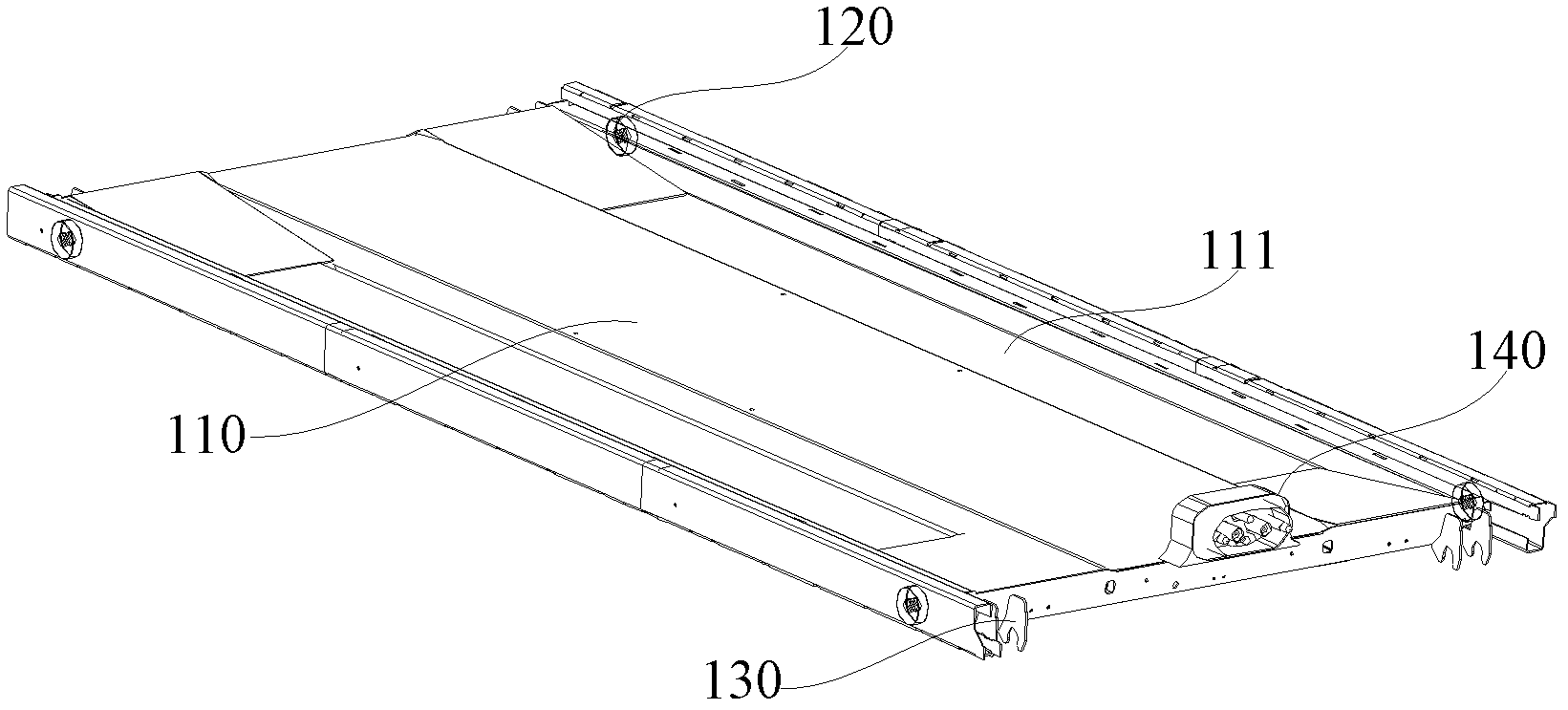

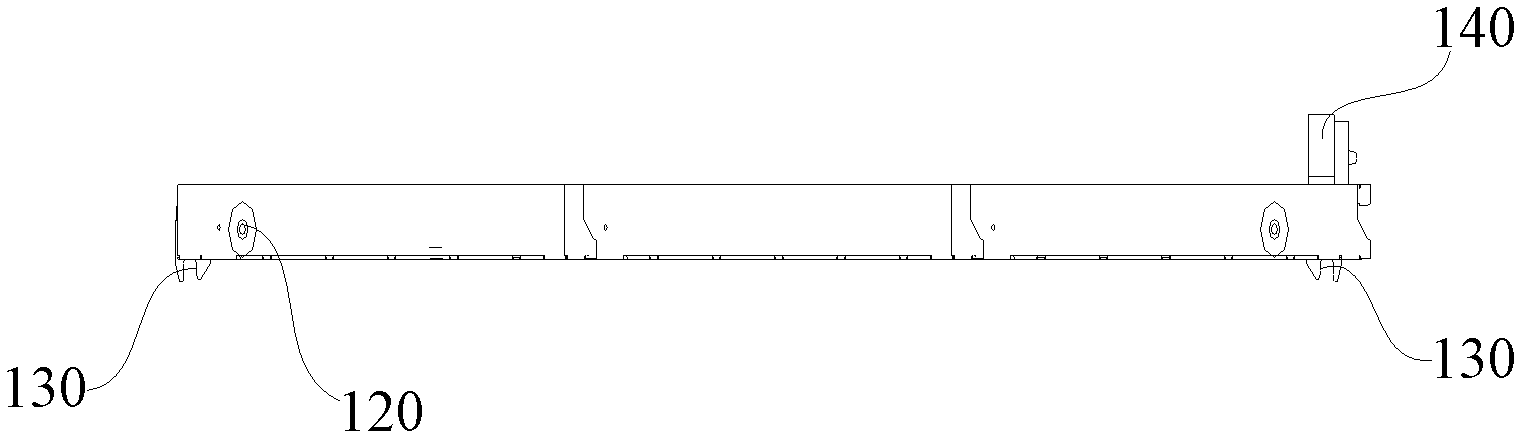

Charging system for garage

ActiveCN102611160AAffect the charging effectAvoid it happening againBatteries circuit arrangementsElectric powerElectricityParking space

A charging system for a garage is used for charging electric vehicles in a stereo garage and comprises a vehicle carrier plate, a charger and a control module, wherein the vehicle carrier plate is provided with a charging plug and a charging butt joint port, and the control module is used for controlling the transport process of the vehicle carrier plate and charging states of the charger. The charging plug is electrically connected with an electric vehicle, and the charger is in butt joint with the charging butt joint port through an output interface. When the vehicle carrier plate enters a parking space of the stereo garage and the output interface is in butt joint and communicated with the charging butt joint port, the control module controls the charger for charging. When the electric vehicle leaves the parking space of the stereo garage, the control module controls the charger to stop charging before the output interface and the charging butt joint port are separated or / and the charging plug is separated from the electric vehicle. The control modules prevents electrical sparkles generated during plugging and unplugging when the output interface and the charging plug are electrified from damaging the charging butt joint port, the output interface, the charging plug and the electric vehicle, and utilization safety factor of the charging system for the garage is increased.

Owner:SHENZHEN JINGZHI MACHINE

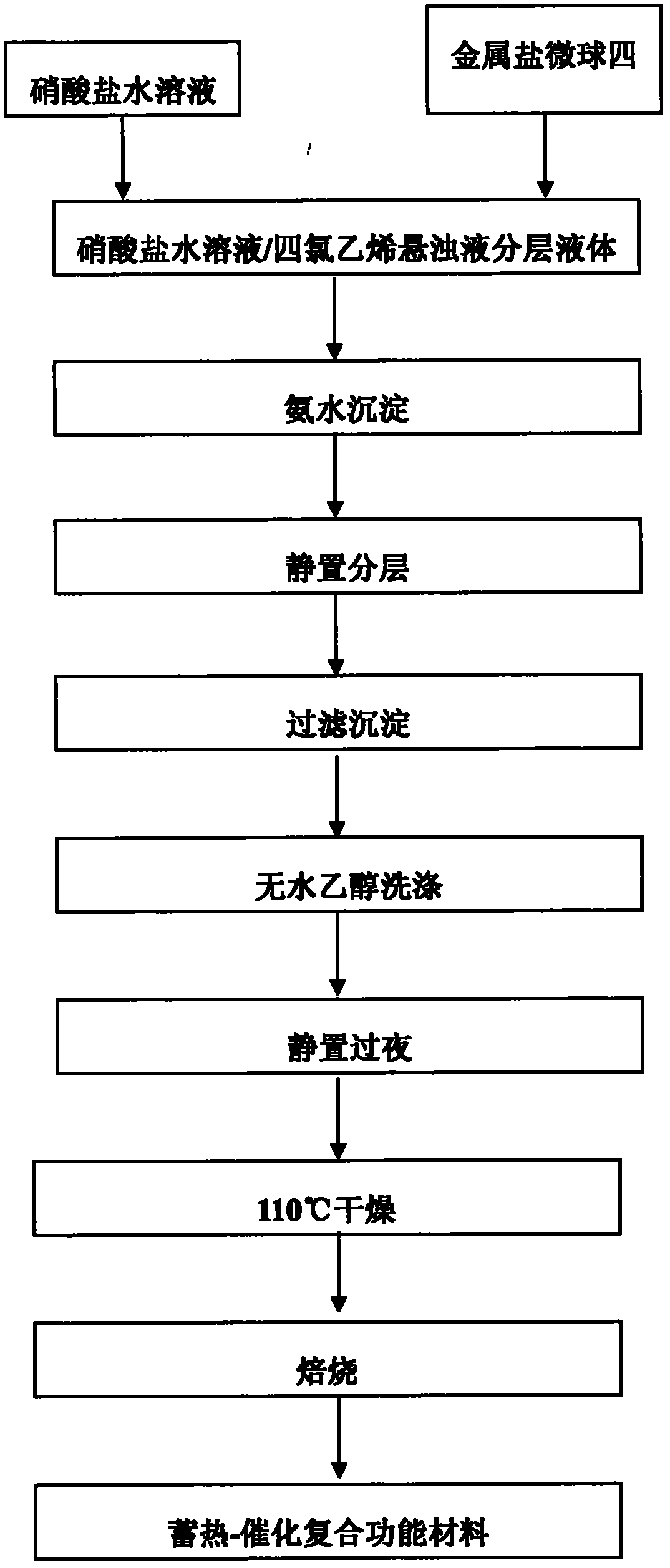

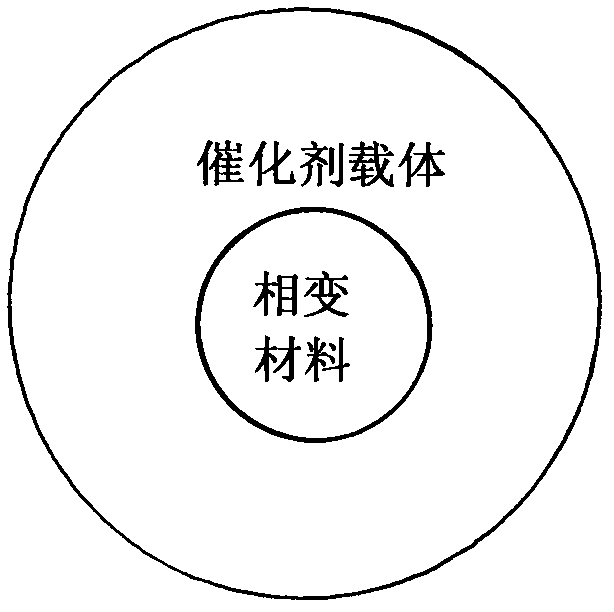

Heat-storing catalytic composite functional material and preparation method thereof

InactiveCN102166532ATo avoidStable temperatureCatalyst carriersHeat-exchange elementsInorganic materialsPhase-change material

The invention relates to a catalyst carrier with a heat-storing function and a preparation method thereof, belonging to the field of application catalysis. The heat-storing catalytic composite functional material is of a nuclear shell structure, wherein an inorganic material such as aluminum oxide, titanium oxide, magnesium oxide or zirconium oxide is used as a shell layer for tightly coating a metal salt used as a phase-change material, such as Na2CO3, K2CO3, Li2CO3, NaCl, KCl or LiCl or mixture thereof as a nuclear layer. The heat-storing catalytic composite material has the textural characteristics of a traditional catalyst carrier on pattern, specific area, crystallographic form and the like, and the phase-change material metal salt of the nuclear layer and the catalyst inorganic material of the shell layer are combined to form an enhanced body.

Owner:KUNMING UNIV OF SCI & TECH

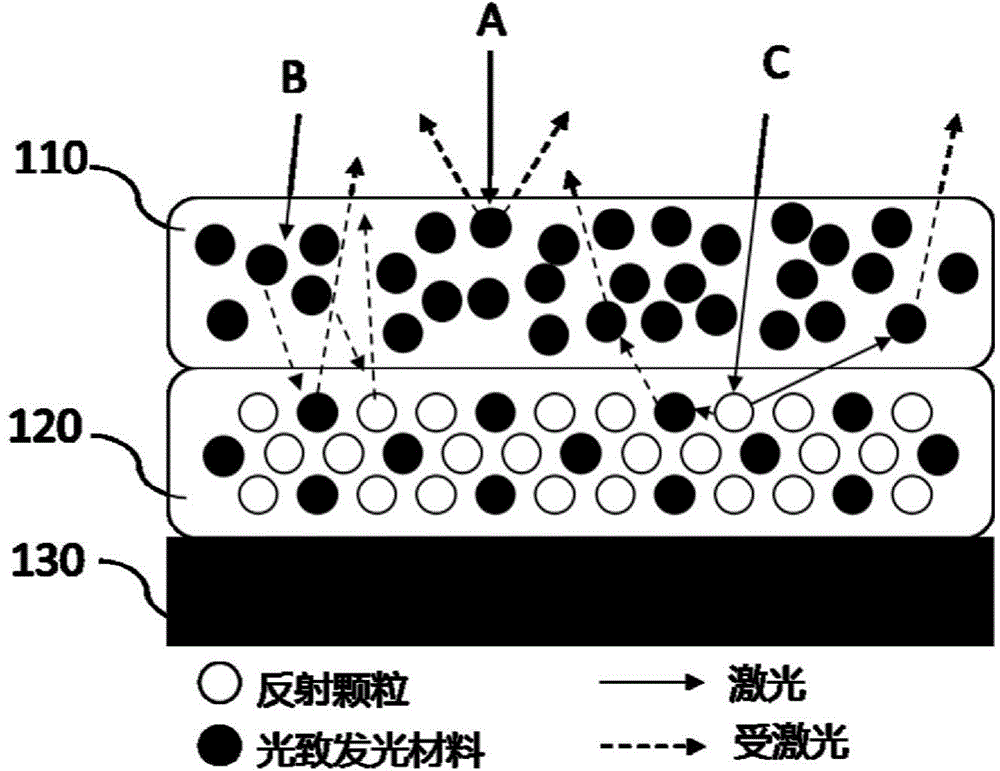

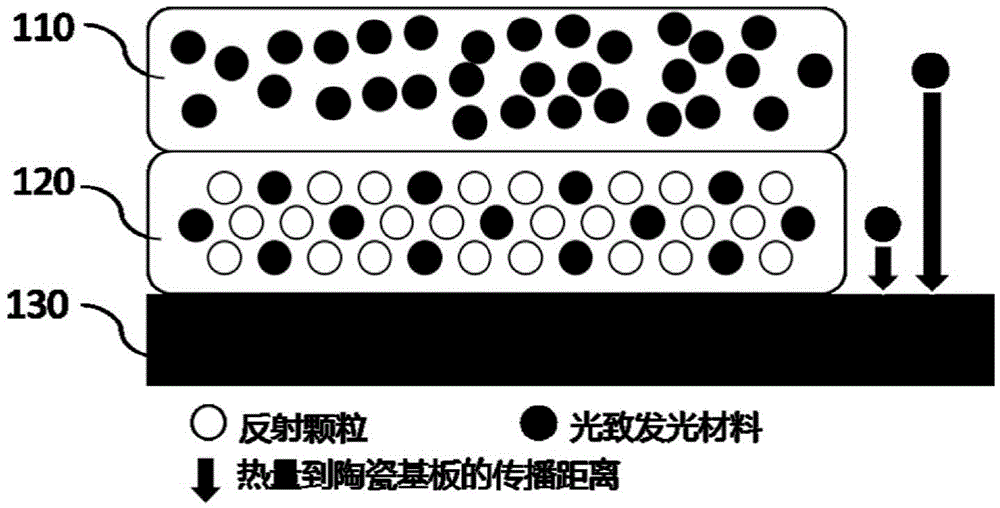

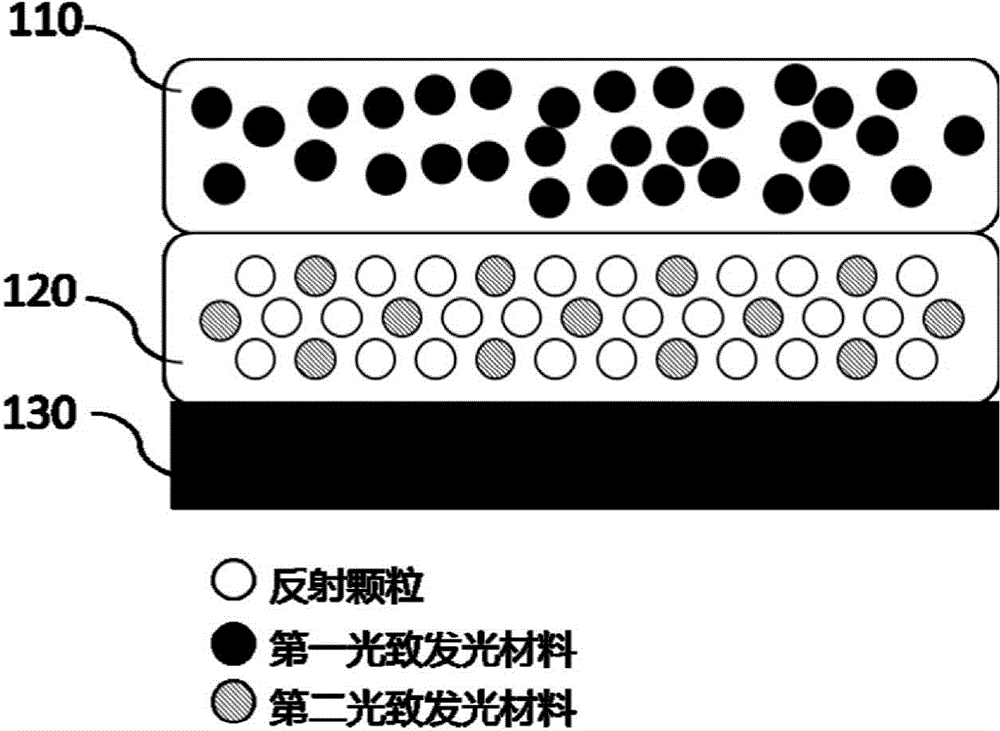

Wavelength conversion device, light emitting device and projecting device

InactiveCN106195925APreserve reflexesShorten the propagation distanceLaser output parameters controlSpectral modifiersPhotoluminescenceAdhesive

The invention relates to a wavelength conversion device, a light emitting device which comprises the wavelength conversion device and a projecting device comprising the wavelength conversion device. The wavelength conversion device comprises a light emitting layer and a reflecting layer which are arranged in a stacked manner. The light emitting layer comprises a first photoluminescence material and a first adhesive. The reflecting layer comprises a second photoluminescence material, a second adhesive and reflecting particles. Light emitted from the reflecting layer completely exits through the light emitting layer, and the light emitting layer and the reflecting layer are directly connected or connected through a sintering layer. On one hand, heat generated by the second photoluminescence material only needs to penetrate a part of the reflecting layer to be emitted, the heat spread distance is shortened, and meanwhile the reflecting capacity of the reflecting layer is retained; and on the other hand, the heat generated by the second photoluminescence material is reduced, the wavelength conversion device can work at a low temperature, and therefore the better light emitting efficiency is achieved.

Owner:APPOTRONICS CORP LTD

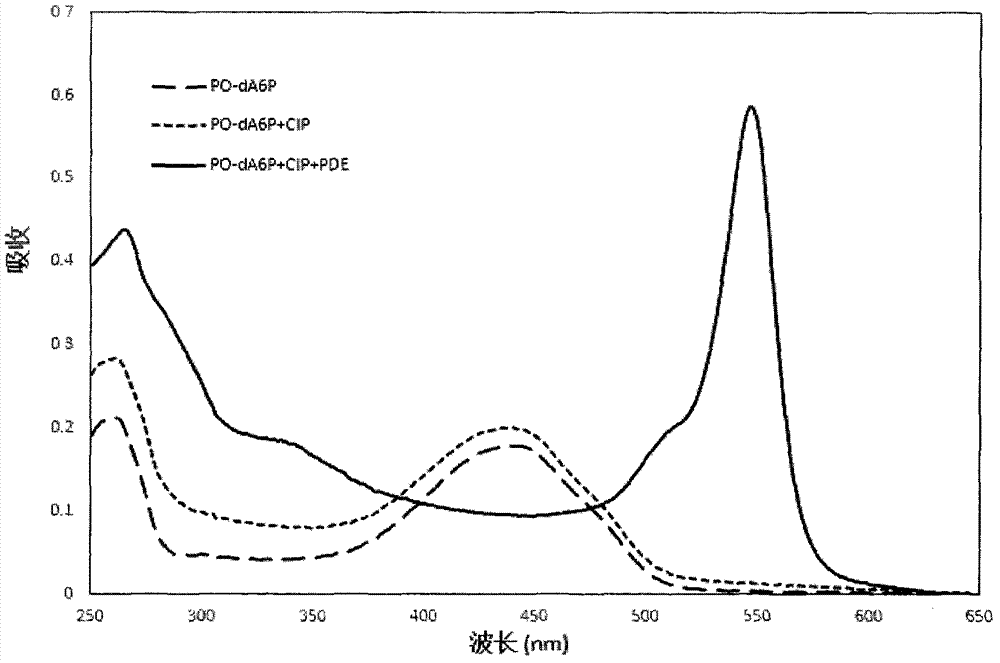

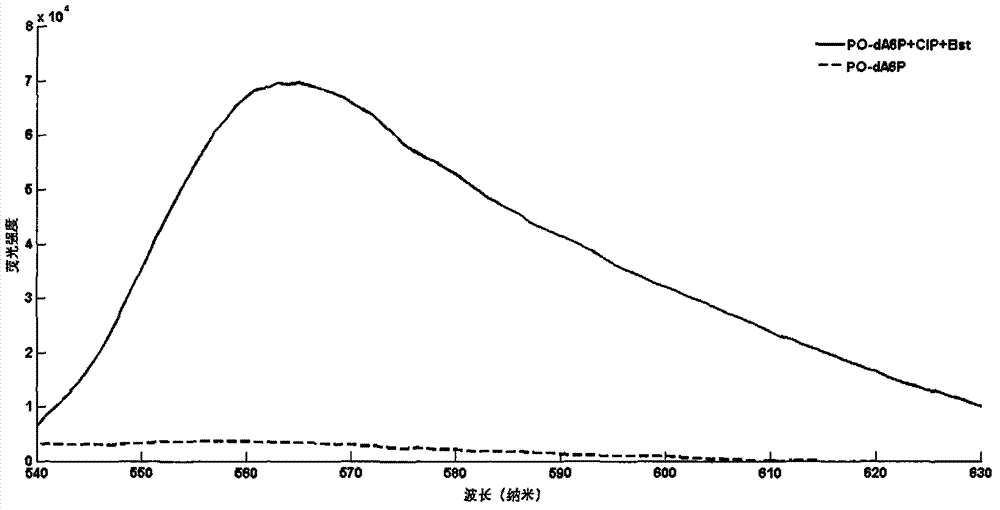

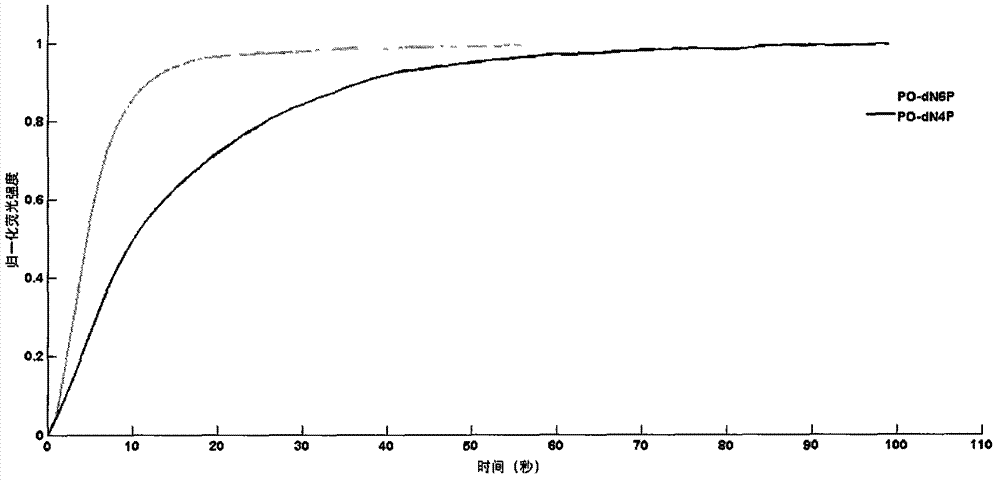

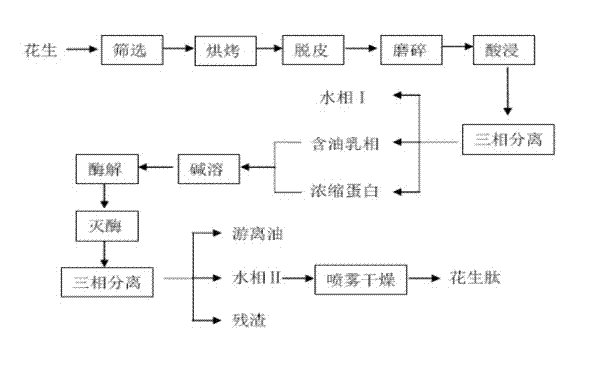

Novel polymerase substrate, fluorescence generable polyphosphoric acid end-labeled nucleotide, and its application

ActiveCN104844674ASimple methodAvoid by-productsSugar derivativesMicrobiological testing/measurementPhosphoric acidEnzyme

The invention relates to a 5'-phosphoric acid and fluorescence end-labeled nucleotide and provides a molecular structure and a synthetic method thereof. The 5'-phosphoric acid and fluorescence end-labeled nucleotide is better recognizable to DNA (deoxyribonucleic acid) polymerases; after recognized by the polymerases and correctly combined with the same, by the aid of alkaline phosphatase, the 5'-phosphoric acid and fluorescence end-labeled nucleotide allows a fluorescent signal to quickly change from closure to opening; thus the 5'-phosphoric acid and fluorescence end-labeled nucleotide can serve as the polymerase substrate applicable to the fields such as nucleic acid sequencing.

Owner:CYGNUS BIOSCI BEIJING CO LTD

Method of continuous concentrated acid hydrolysis of organochlorosilane

The invention relates to a method of continuous concentrated acid hydrolysis of organochlorosilane. The method comprises the following steps: step 1, the organochlorosilane is subject to hydrolysis reaction with a concentrated acid in a hydrolysis reactor to produce a hydrochloric acid with higher concentration, and a crude hydrolysate; step 2, after the liquid produced after hydrolysis reaction is separated through a preliminary separator, the concentrated acid enters a falling-film evaporator to generate HCL (hydrogen chloride) gas for production of methyl chloride through heat exchange; the concentrated acid at the tower bottom enters the hydrolysis reactor for cyclic use; the oil phase separated by the preliminary separator enters a primary phase separator and a secondary phase separator, the separated acid liquor returns to the hydrolysis reactor for cyclic use, and the oil phase enters the subsequent water washing procedure; and step 3, the two-stage series water-washing and the phase separation are carried out to the oil phase in the water washing procedure, then the recycle washing with a dilute alkali lye and the phase separation are carried out, and finally, the latest two-stage series water-washing and the phase separation are carried out; and the washed oil phase is a siloxane oligomer.

Owner:QINGDAO UNIV OF SCI & TECH

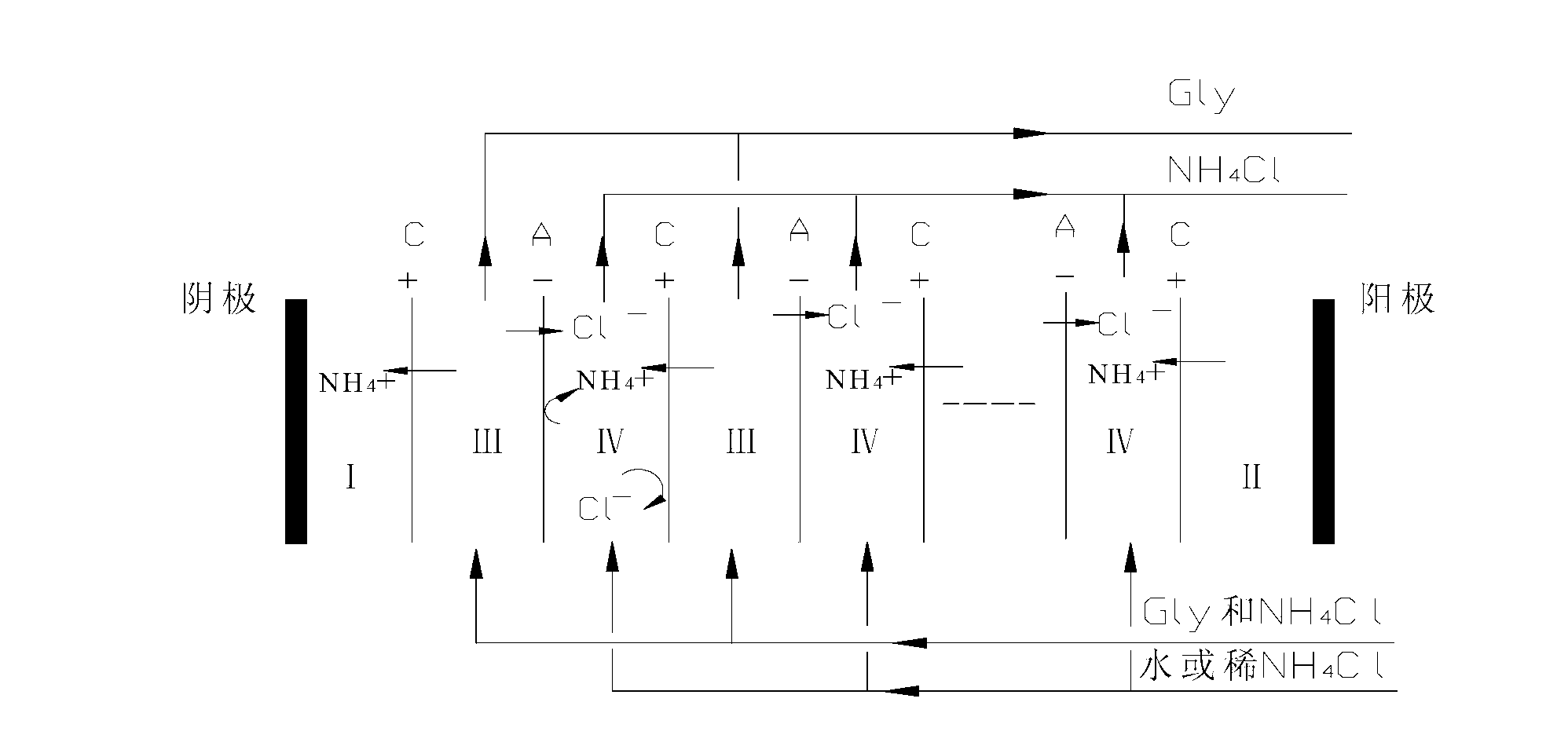

Cleaning production process of glycine

ActiveCN102838497ATo avoidNo three wastes pollutionOrganic compound preparationAmino-carboxyl compound preparationChemical reactionChloroacetic acids

The invention relates to a cleaning production process of glycine. According to the method, a mixed solution of glycine and ammonium chloride is produced on the basis of a chloroacetic acid ammonolysis method and glycine and ammonium chloride are separated by an electroosmosis method. The cleaning production process has the following advantages: 1, based on the traditional chloroacetic acid ammonolysis, the electroosmosis technology is carried out without chemical reaction or addition of any raw material, so the prepared product is good in quality and high in yield; 2, no byproduct is generated, no three wastes pollution is caused, the situation that a large quantity of wastewater rich in chlorine formaldehyde is generated in the traditional process can be avoided; and 3, diluted liquid and concentrated liquid can be recycled in the electroosmosis process, thereby saving the production cost of glycine.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

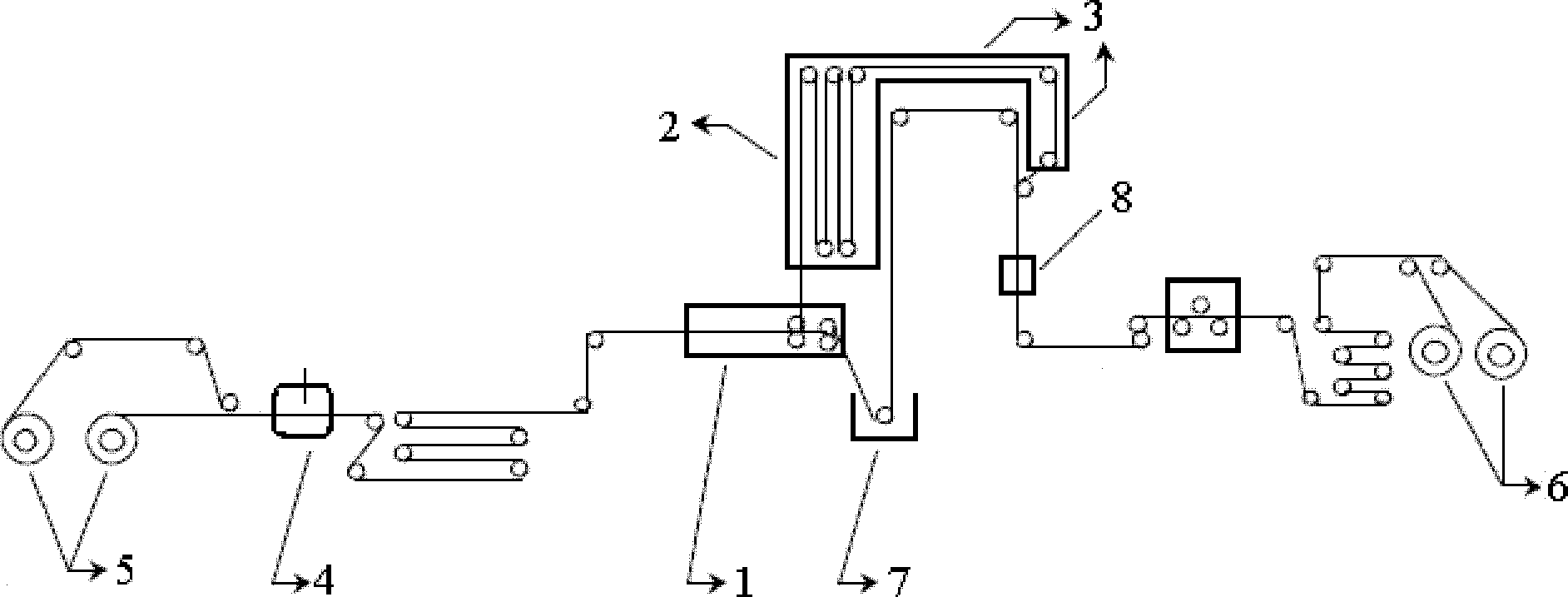

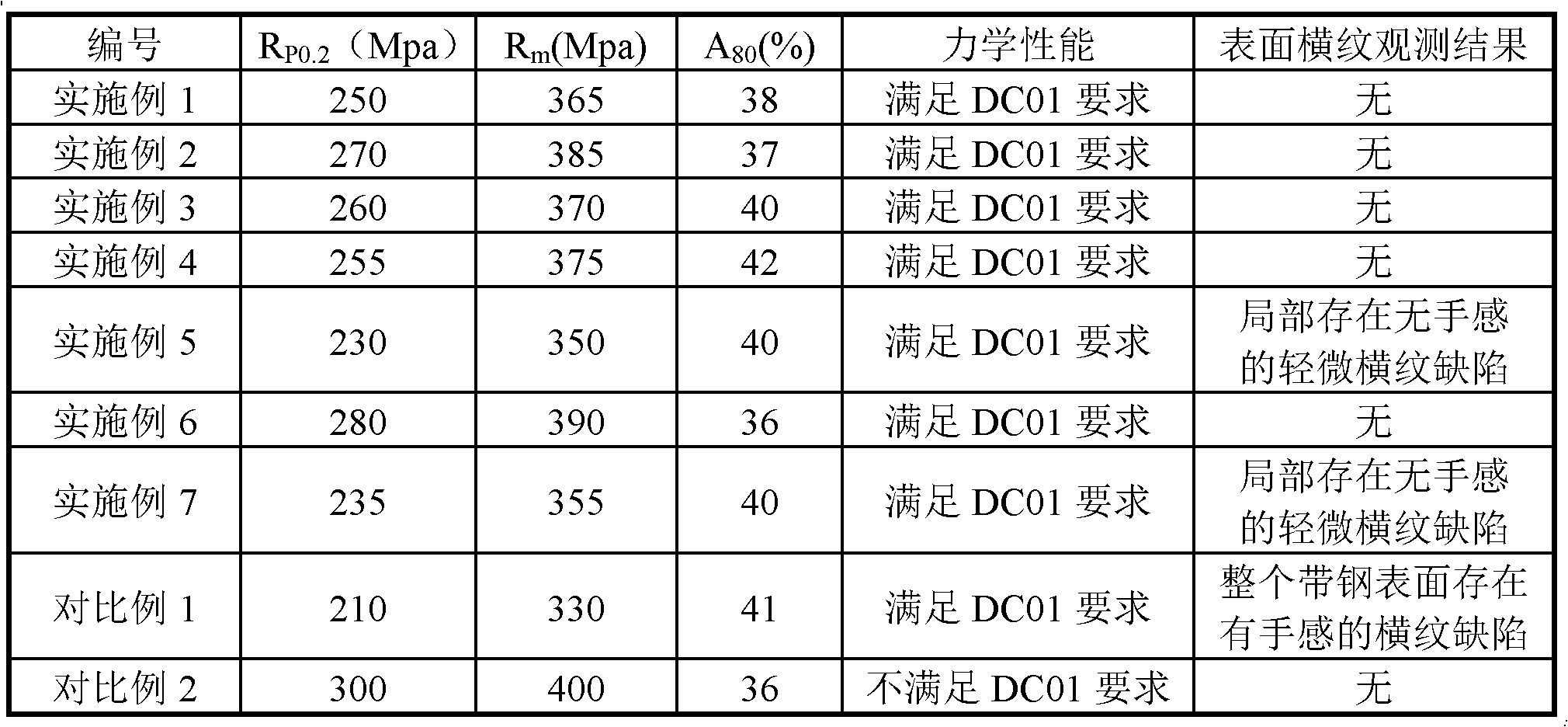

Production method of low carbon steel plate and low carbon steel plate

ActiveCN103103328AOvercome the defect of prone to produce horizontal stripesEasy to blockContinuous annealingCarbon steel

The invention provides a production method of a low carbon steel plate and the low carbon steel plate. The method comprises hot rolling, cold rolling and continuous annealing on a low carbon steel slab; the hot rolling comprises soaking, rough rolling and finishing rolling; the continuous annealing method comprises successive annealing treatment, aging treatment and secondary cooling treatment on low carbon steel subjected to cold rolling; and the low carbon steel subjected to hot finishing rolling is cooled to 670-720 DEG C with a cooling rate of 100-200 DEG C / s, and then cooled to 620-660 DEG C with a cooling rate of 10-20 DEG C / s for hot rolling batching. The low carbon steel obtained by the method provided by the invention has good mechanical properties, and can avoid cross striation generation.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Plasma reactor catalyst and its preparation method and use

ActiveCN101143335AReduce contentEfficient removalMolecular sieve catalystsDeodrantsActive componentReducing atmosphere

The invention provides a catalyst, which has the comprehensive functions of removing various volatile pollutants of different properties via the function of plasma and reducing the content of NOX, and the preparation method and the application. The catalyst is pure ZSM-5 zeolite or adopts industrial commercial grade ZSM-5 zeolite as the carrier to load one or more than one of active components such as copper, silver, gallium and cobalt, etc, and adopts the active component or components as discharge carrier (filling material) after molding to directly fill in the plasma reactor for operation. Compared with other filling medium or catalyst in the plasma reactor, the catalyst is not only capable of reducing the content of by-products such as NOX but also has brilliant capacities of removing various volatile pollutants. And compared with the method of reducing the by-product of NOX by adding reducing atmosphere into the plasma reactor, the invention of the catalyst is characterized in that the process is simple and no added device or given atmosphere is needed, which avoids the production of new pollutants.

Owner:FUZHOU UNIV

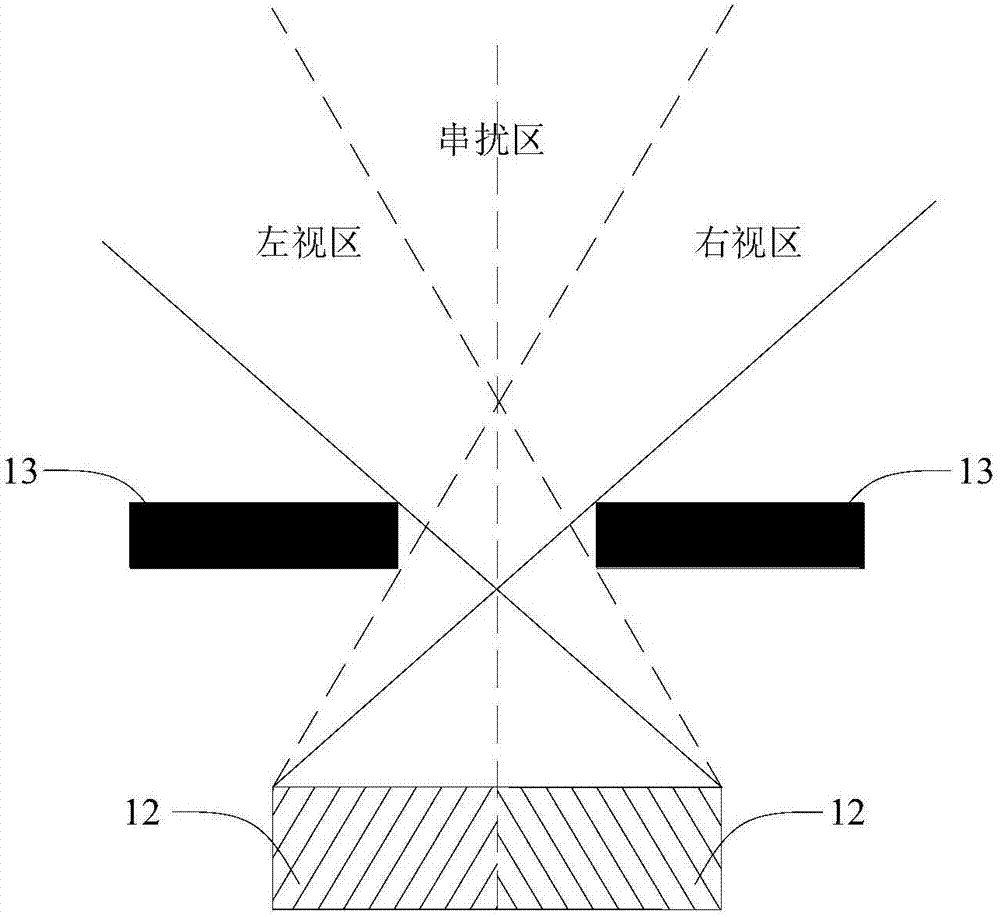

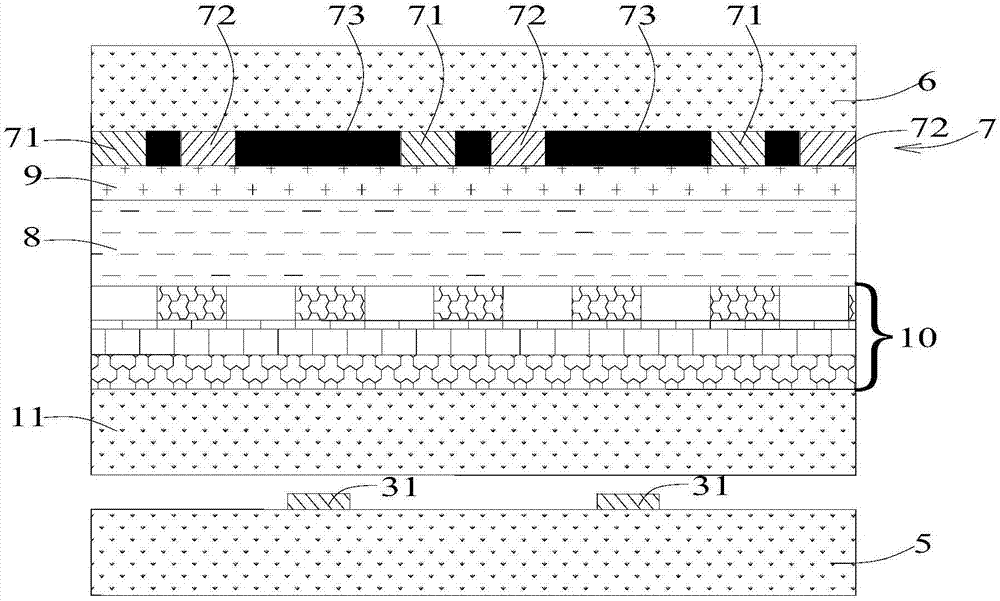

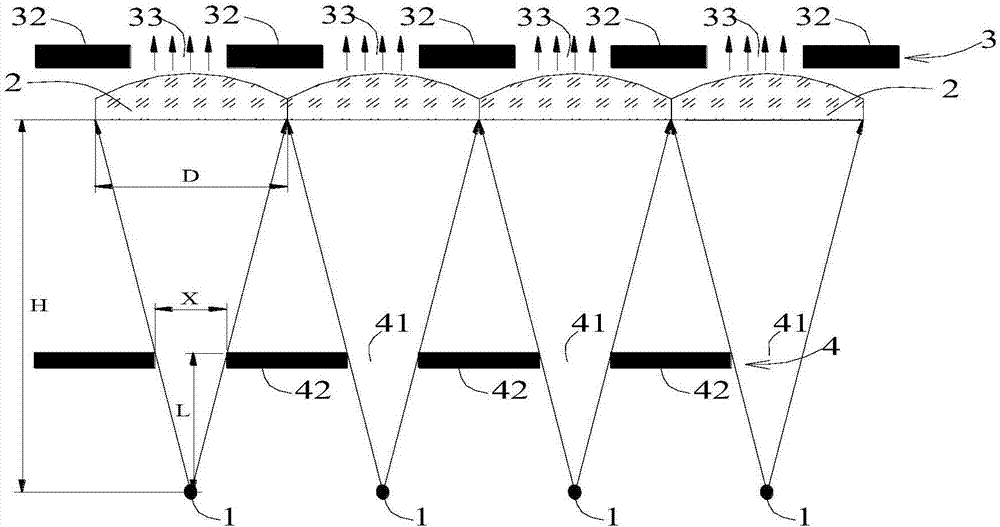

Double-vision display panel and display device

ActiveCN107490901ADiffraction effect is goodTo avoidSteroscopic systemsNon-linear opticsGratingDisplay device

The invention relates to the technical field of display and provides a double-vision display panel and a display device. The double-vision display panel comprises a backlight source, a liquid crystal grating, a color film layer and the like; the backlight source is used for providing collimating light; the liquid crystal grating is arranged in the light emitting direction of the backlight source; the color film layer is arranged on the side, away from the backlight source, of the liquid crystal grating, the color film layer comprises a plurality of first pixel areas and a plurality of second pixel areas, and shading areas are arranged between the first pixel areas and the second pixel areas which are adjacent to each other; the liquid crystal grating is used for diffracting the collimating light given out by the backlight source to the first pixel areas and / or the second pixel areas. Light rays which penetrate through the first pixel areas and the second pixel areas are generated through diffraction of the liquid crystal grating, therefore, the first pixel areas and the second pixel areas cannot be observed on a central area at the same time, and the generation of a central crosstalk area can be avoided.

Owner:BOE TECH GRP CO LTD

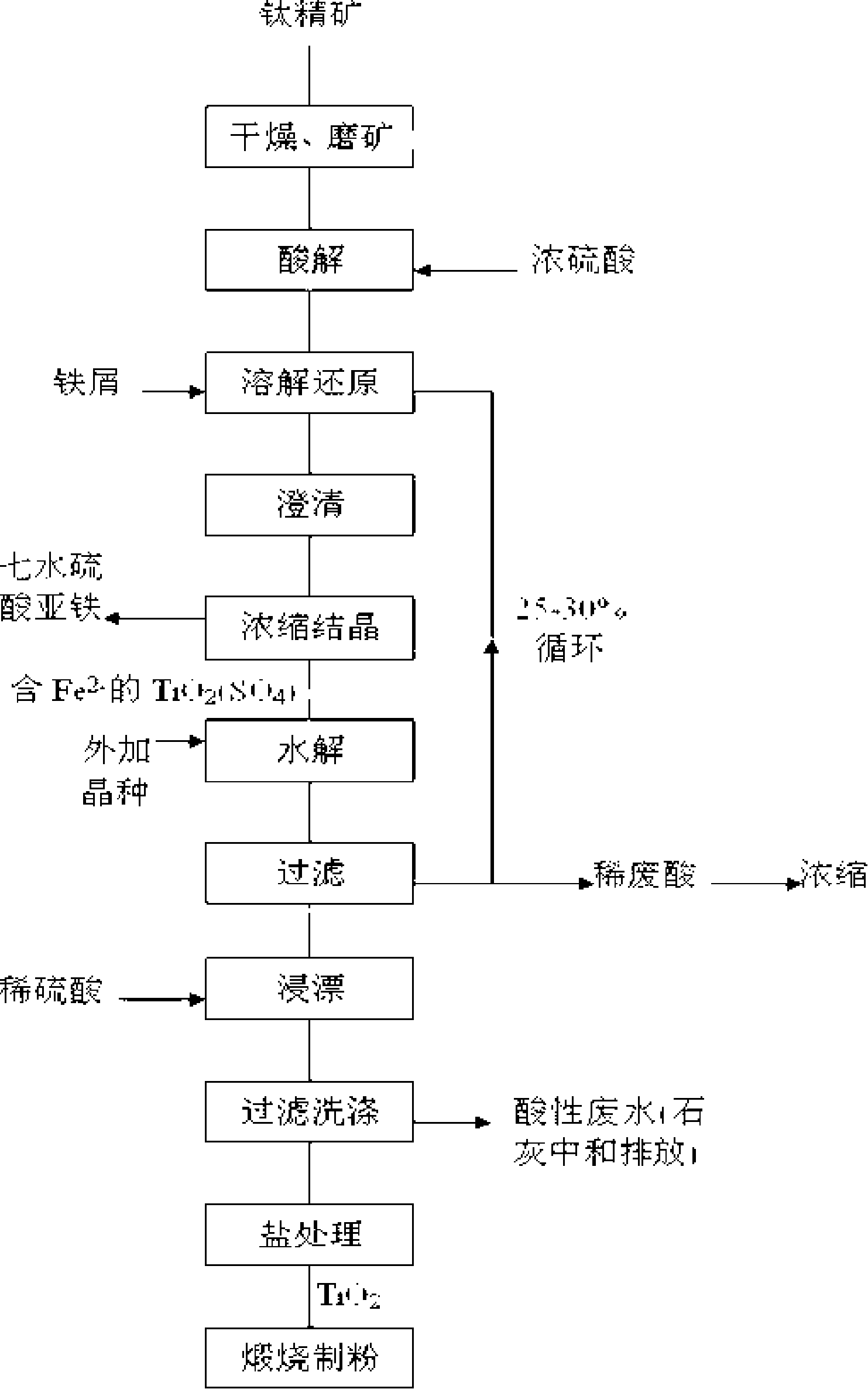

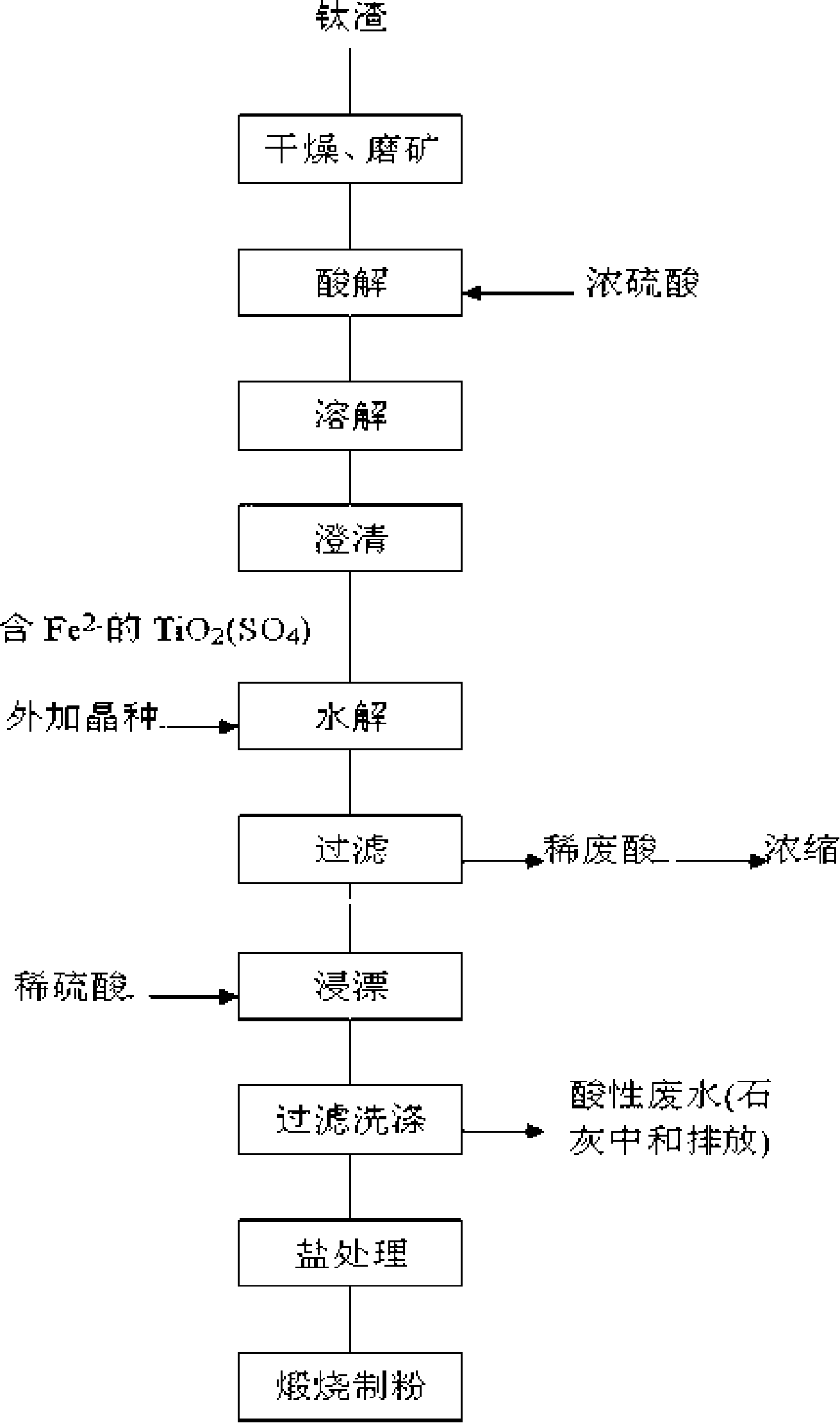

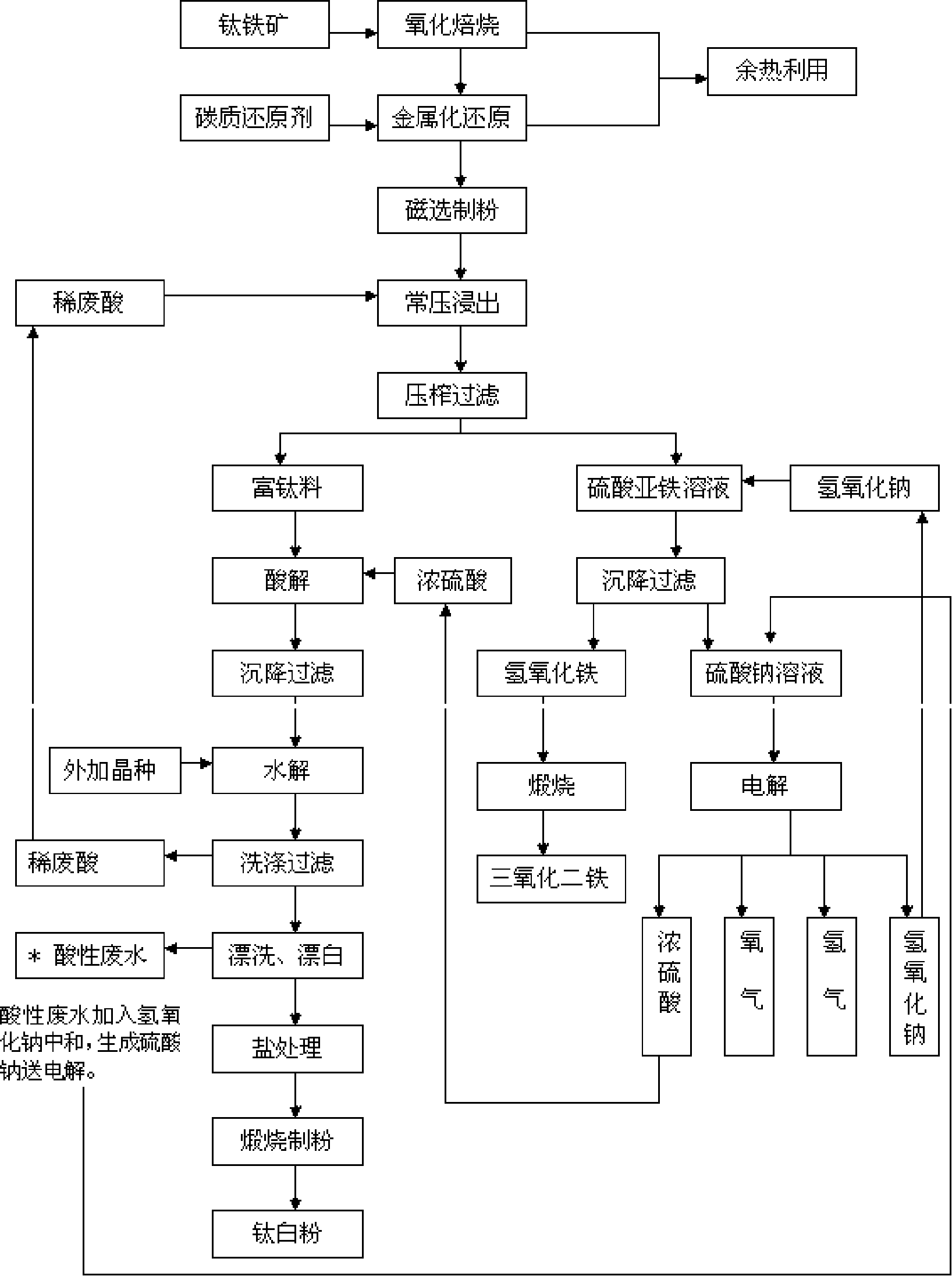

Method for producing gtitanium dioxide with sulphuric acid method

InactiveCN101172647ATo avoidRealize comprehensive utilizationTitanium dioxideChemistryWater treatment

The invention relates to a method for preparing titanium dioxide by a sulfuric acid method, belonging to the field of smelting. The method for preparing titanium dioxide by the sulfuric acid method of the present invention is characterized in that the acid waste water generated in the preparation process is neutralized by adding sodium hydroxide or potassium hydroxide, and the sulfate produced by neutralization is electrolyzed to generate concentrated sulfuric acid. This treatment method avoids the production of a large amount of gypsum. At the same time, the neutralized sulfate can be sold as a by-product, and the concentrated sulfuric acid generated by sulfate electrolysis can be applied again to the sulfuric acid method to prepare titanium dioxide. The problem of acid wastewater treatment and gypsum landfill has also realized the utilization of by-products. At the same time, electrolysis will also produce by-products such as hydrogen, oxygen, and hydroxide. Hydroxide can be used to neutralize acid wastewater. The method not only reduces the discharge of pollutants, but also realizes the recycling of waste water and achieves the purpose of energy saving and efficiency enhancement.

Owner:杨绍泉

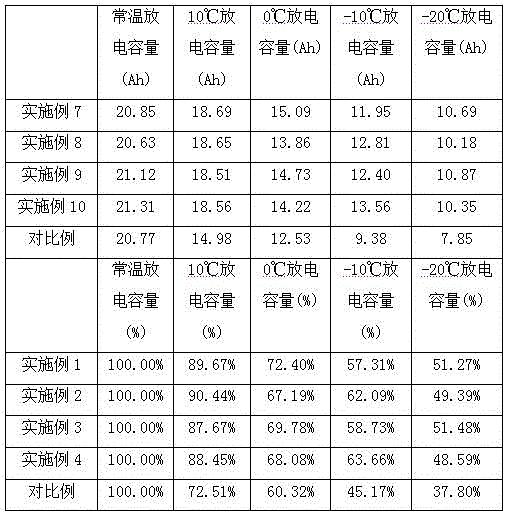

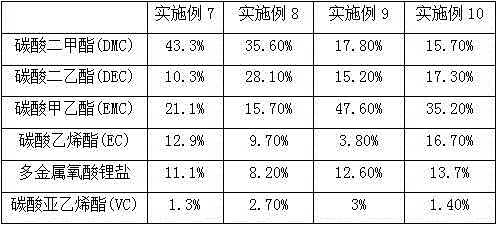

Low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries

InactiveCN102983362AIncrease migration rateGood low temperature characteristicsSecondary cellsElectrolytic agentPhosphomolybdic acid

The invention relates to a low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries, belonging to the technical field of low-temperature electrolytes for lithium batteries. The electrolyte comprises dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, ethylene carbonate, a film-forming additive and lithium polyoxometallate, wherein the lithium polyoxometallate refers to lithium phosphomolybdate Li3PMo12O40, lithium phosphotungstate Li3PW12O40, lithium silicotungstate Li4SiW12O40 or lithium silicomolybdenate Li4SiMo12O40. For solving the problems that in the prior art, the lithium ion transport of an electrolyte is blocked, slow in speed and low in efficiency and the electrolyte is poor in low-temperature performance, the invention provides a novel fluoride-free low-temperature electrolyte for LiFePO4 lithium-ion batteries; and by taking the non-fluoride lithium polyoxometallate with a three-dimensional skeleton structure as an electrolytic lithium salt and selectively adopting a low-viscosity carbonate solvent, through optimized proportioning, the migration rate of lithium ions is increased, and the low temperature properties of LiFePO4 batteries can be significantly improved.

Owner:中国东方电气集团有限公司

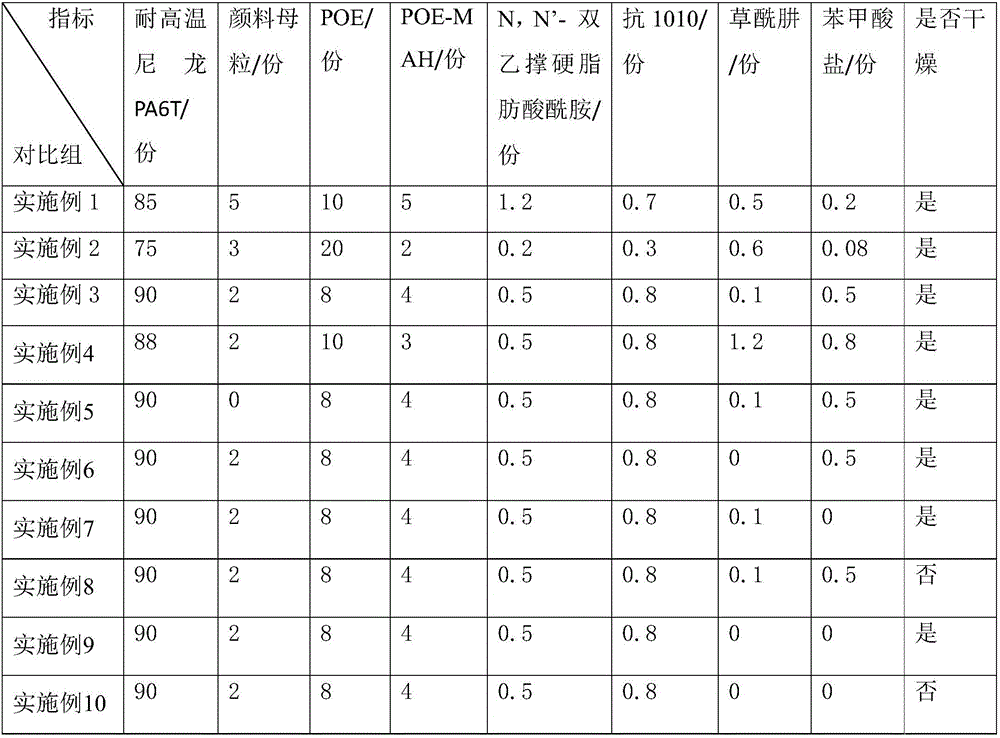

Spray-free high-tenacity high-temperature-resistant nylon PA6T composite material and preparing method thereof

The invention discloses a spray-free high-tenacity high-temperature-resistant nylon PA6T composite material .The composite material is mainly prepared from, by weight, 70-90 parts of high-temperature-resistant nylon PA6T, 1-5 parts of pigment master batch, 5-30 parts of flexibilizer, 1-5 parts of compatilizer, 0.3-1.2 parts of lubricant, 0.2-0.8 part of antioxidant, 0-1.2 parts of passivator and 0.1-1 part of a nucleating agent .The invention further discloses a preparing method of the composite material .The preparing method includes the steps of weighing all the raw materials, mixing, extruding, drafting, cooling, drying, pelletizing and the like .The composite material has the advantage of being free of spray, the process can be simplified greatly, and the composite material is more environmentally friendly.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +1

Smelting-casting technique of 6010 aluminum alloy

The invention relates to a 6010 aluminum alloy melting and casting process. This process effectively reduces the non-metallic slag content, hydrogen content and alkali metal content in the melt by controlling the melting temperature, refining in the melt furnace and on-line treatment, and ensures the uniformity of the alloy composition. The ingot casting machine controls the casting speed and water flow during the casting process, avoiding casting cracks and feather crystals, and improving the surface quality of the ingot.

Owner:GUANGXI UNIV

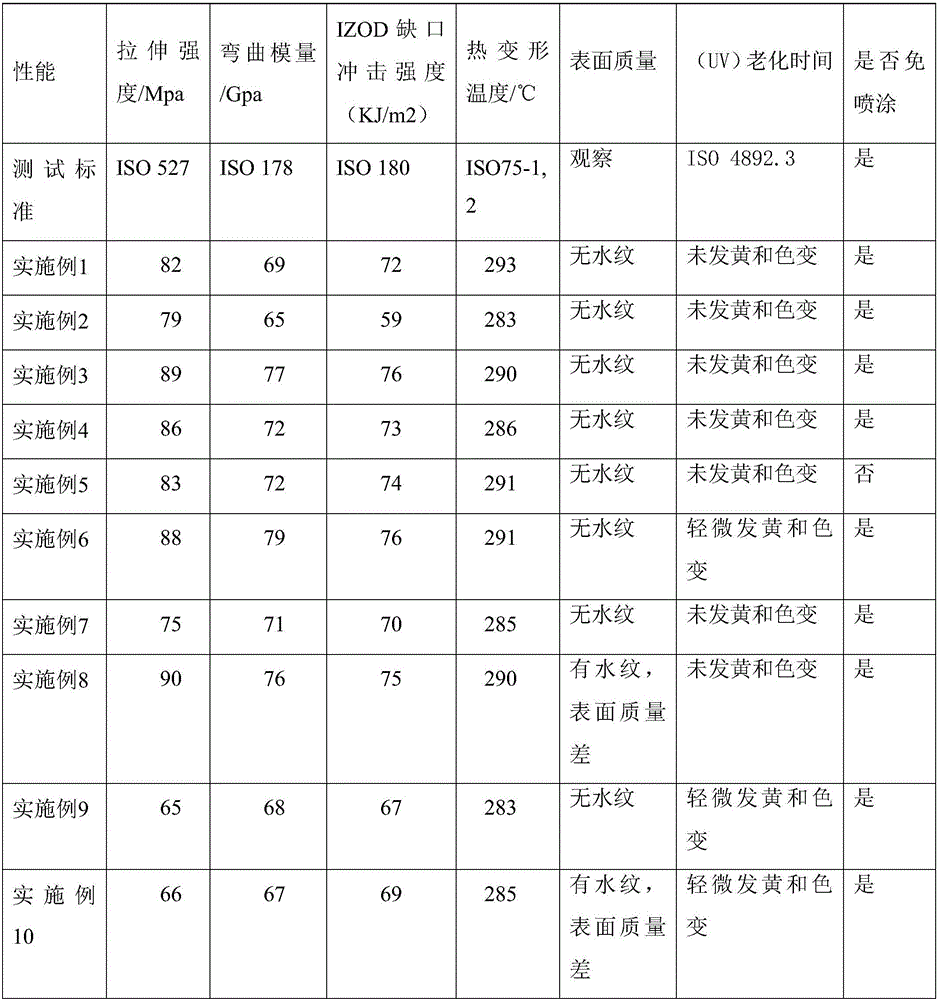

Method for synchronously preparing peanut oil and peanut peptides through aqueous enzymatic extraction

InactiveCN103113977AReduce pollutionAdd flavorFatty-oils/fats productionFermentationBiotechnologyEnzymatic hydrolysis

The invention provides a method for synchronously preparing peanut oil and peanut peptides through aqueous enzymatic extraction and belongs to the technical field of deep processing of agricultural products and comprehensive utilization of byproducts of the agricultural products, mainly solving the technical problems that protein products obtained according to a conventional technology for preparing oil from peanuts through aqueous enzymatic extraction have low purity and are imperfect in oil flavor and easy in generation of emulsion and the like. The method comprises the following steps of: baking peanut kernels, grinding, adding water so as to adjust acid for extraction, carrying out three phase centrifugation, combining oil bearing emulsion phase and protein concentrate, adjusting alkali, adding protease for enzymatic hydrolysis, carrying out high-temperature enzyme deactivation after the enzymatic hydrolysis is ended, and carrying out three phase centrifugation under a hot condition, thus directly obtaining the free oil and the peanut peptides. Peanuts are processed by adopting the method, so that the emulsion can be basically avoided, and the obtained oil has strong flavor and high quality; the peanut peptides have high purity (75% of protein content) and low relative molecular mass and can be used as a good functional additive to be widely applied to food processing.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com