Method of continuous concentrated acid hydrolysis of organochlorosilane

A hydrolysis technology of organochlorosilane and concentrated acid, which is applied in the direction of silicon organic compounds, can solve the problems of difficult control of hydrolyzate viscosity, achieve stable and controllable quality, reduce water consumption, and increase residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

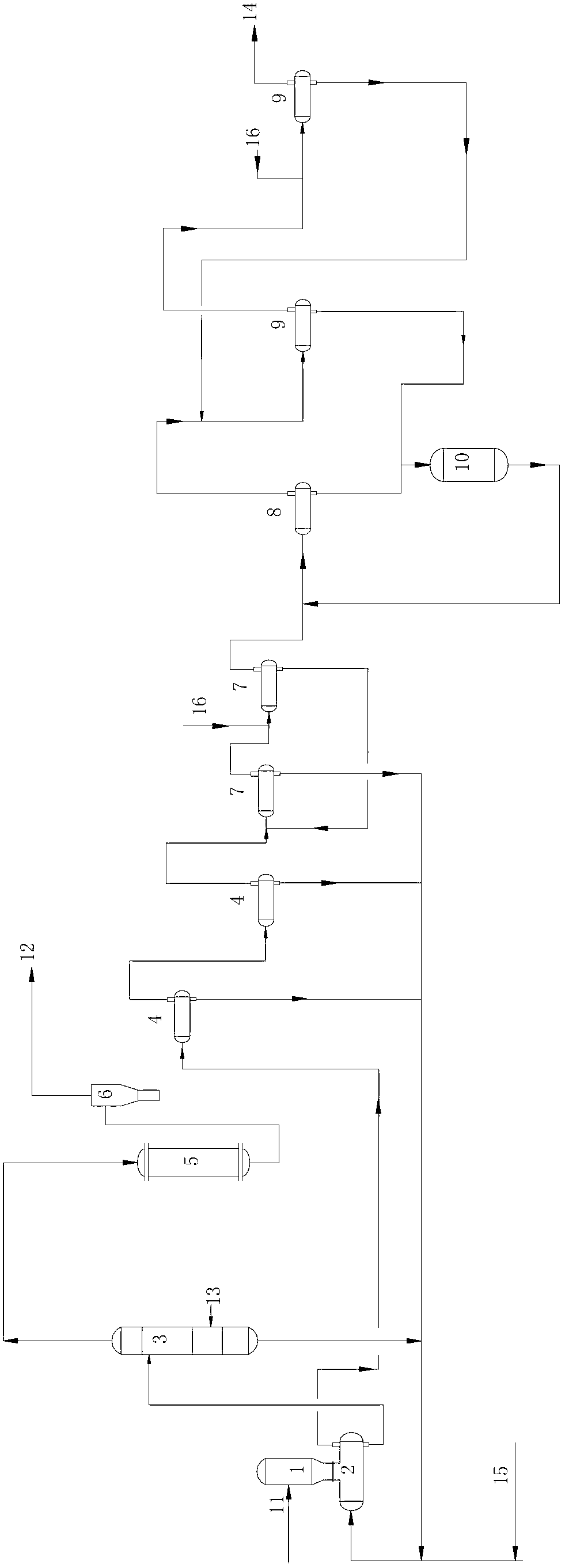

Image

Examples

Embodiment 1

[0033]Example 1: Dimethyldichlorosilane and concentrated acid enter the hydrolysis reactor 1 for hydrolysis reaction. The molar ratio of water to dimethyldichlorosilane in the reaction system is 5:1, and the water source comes from the hydrolyzed oligosiloxane In the water washing process, the concentrated acid is recycled between the hydrolysis reactor 1 and the falling film evaporator 3 . The reaction temperature is controlled at 30°C, the operating pressure is 0.4MPa, and the residence time is 60s. The volume ratio of water to oligosiloxane is 0.5:1, the operating temperature is 55°C, and the operating pressure is 0.1MPa for the first two stages of series washing. The volume ratio of dilute lye to oligosiloxane is 8:1 for alkali cleaning, the operating temperature is 55°C, and the operating pressure is 0.1MPa. The volume ratio of water to oligosiloxane is 1:1, the operating temperature is 70°C, and the operating pressure is 0.1MPa for the last two-stage series washing. Th...

Embodiment 2

[0034] Example 2: Dimethyldichlorosilane and concentrated acid enter the hydrolysis reactor for hydrolysis reaction, the molar ratio of water to dimethyldichlorosilane in the reaction system is 10:1, and the water source comes from the hydrolyzate oligosiloxane washing In the process, the concentrated acid is recycled between the hydrolysis reactor and the falling film evaporator. The reaction temperature is controlled at 20°C, the operating pressure is 0.3MPa, and the residence time is 90s. The volume ratio of water to oligosiloxane is 2:1, the operating temperature is 75°C, and the operating pressure is 0.2MPa for the first two stages of series washing. The volume ratio of dilute lye to oligosiloxane is 6:1 for alkali cleaning, the operating temperature is 65°C, and the operating pressure is 0.1MPa. The volume ratio of water to oligosiloxane is 1:1, the operating temperature is 60°C, and the operating pressure is 0.3MPa for the last two-stage series washing. The specificat...

Embodiment 3

[0035] Example 3: Dimethyldichlorosilane and concentrated acid enter the hydrolysis reactor for hydrolysis reaction, the molar ratio of water to dimethyldichlorosilane in the reaction system is 15:1, and the water source comes from the hydrolyzate oligosiloxane washing In the process, the concentrated acid is recycled between the hydrolysis reactor and the falling film evaporator. The reaction temperature is controlled at 40°C, the operating pressure is 0.2MPa, and the residence time is 1200s. The volume ratio of water to oligosiloxane is 3:1, the operating temperature is 60°C, and the operating pressure is 0.1MPa for the first two stages of series washing. The volume ratio of dilute lye to oligosiloxane is 4:1 for alkali cleaning, the operating temperature is 60°C, and the operating pressure is 0.2MPa. The volume ratio of water to oligosiloxane is 3:1 for the last two-stage series washing, the operating temperature is 70°C, and the operating pressure is 0.2MPa. The specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com