Spray-free high-tenacity high-temperature-resistant nylon PA6T composite material and preparing method thereof

A composite material, high temperature resistant technology, applied in the field of organic polymer compounds, can solve the problems of difficult to meet customer requirements for product diversification, restrict the promotion and application of high added value, and reduce spray-free high temperature resistant materials. Effects of aging and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

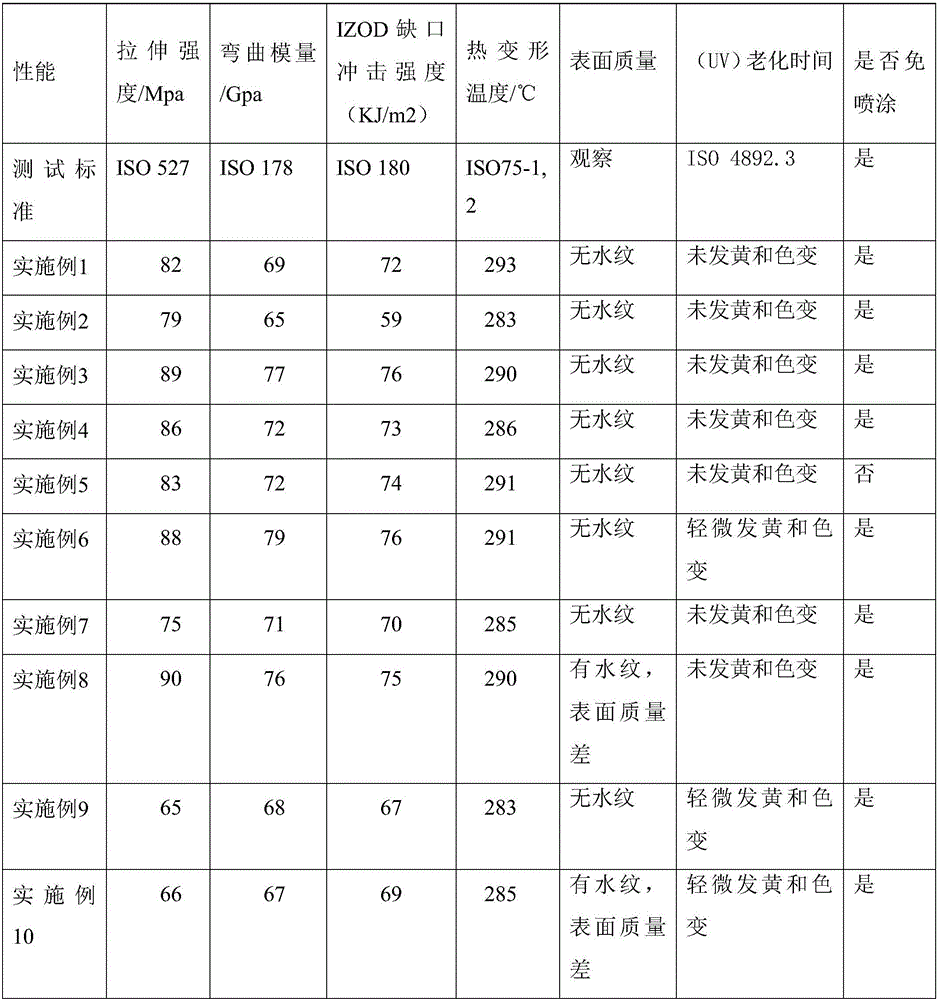

Examples

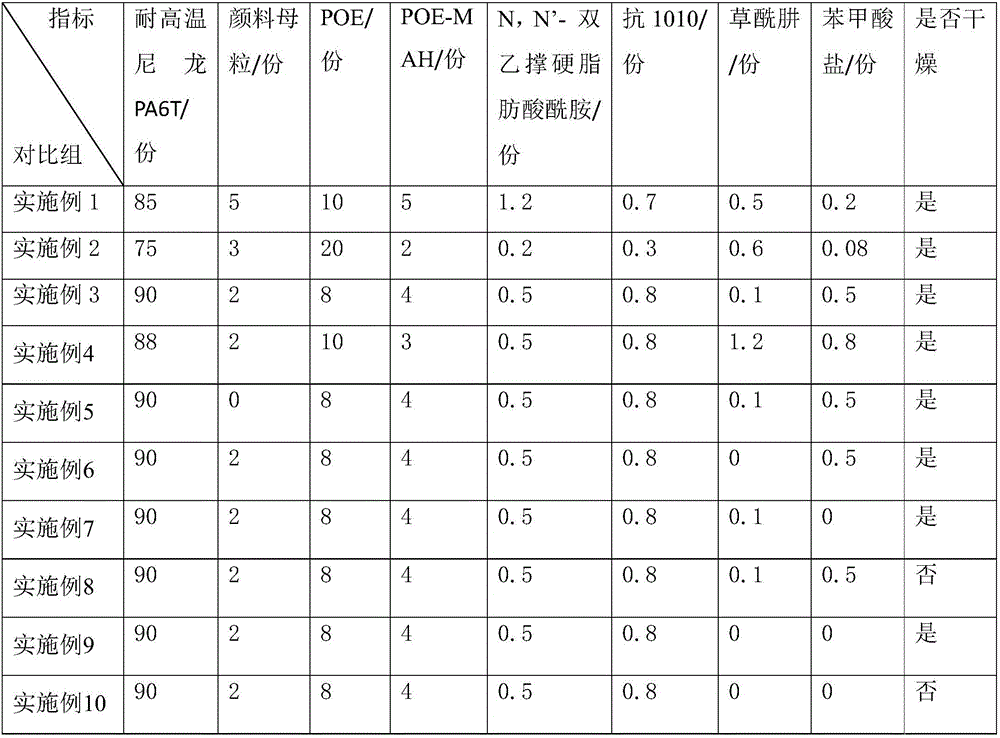

Embodiment 1

[0038] A spray-free high-toughness and high-temperature-resistant nylon PA6T composite material mainly includes the following raw materials in parts by weight: 85 parts of high-temperature-resistant nylon PA6T; 5 parts of pigment masterbatch; 10 parts of ethylene-octene copolymer (POE); ethylene-octene copolymer 5 parts of grafted maleic anhydride (POE-MAH); 1.2 parts of N, N'-diethylene stearic acid amide; tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid ] Pentaerythritol ester (anti-1010) 0.7 part; Oxalhydrazide 0.5 part; Benzoate 0.2 part.

[0039] The preparation method of the spray-free high toughness and high temperature resistant nylon PA6T composite material of the present embodiment is as follows:

[0040] A method for preparing a spray-free high-toughness and high-temperature-resistant nylon PA6T composite material, comprising the following steps:

[0041] Before the first step, dry the high-temperature-resistant nylon PA6T in a drying oven at a temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com