Patents

Literature

220results about How to "Renewable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental protection energy-saving diesel oil

The present invention is one kind of environment friendly energy-saving diesel oil and its compounding process, and belongs to the field of petroleum technology. The environment friendly energy-saving diesel oil is compounded with fatty methyl ester 5-50 wt%, base oil 10-60 wt%, GB diesel oil 5-50 wt%, cetane number improver 0.1-2 wt%, pour point depressant 0.1-2 wt%, viscosity regulator 1-10 wt%, deodorant 0.1-2 wt%, smoke-eliminating oil saver 0.1-2 wt%. The production process of the present invention is simple and low in cost, and the environment friendly energy-saving diesel oil has lowered consumption, high dynamic property, high stability, good low temperature starting performance and environment friendship.

Owner:姜彬

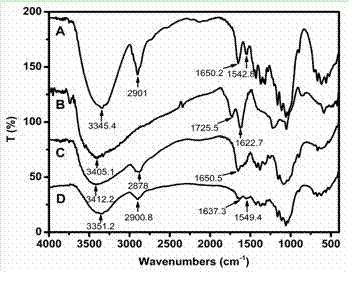

Amphoteric cellulose material and application thereof

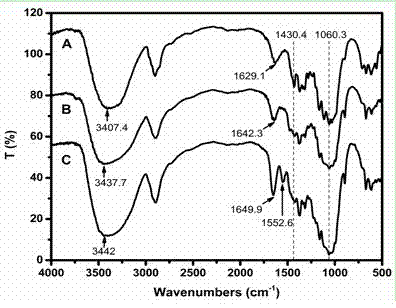

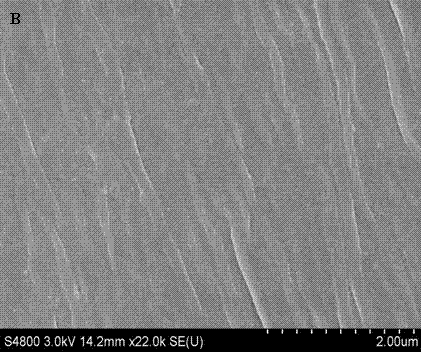

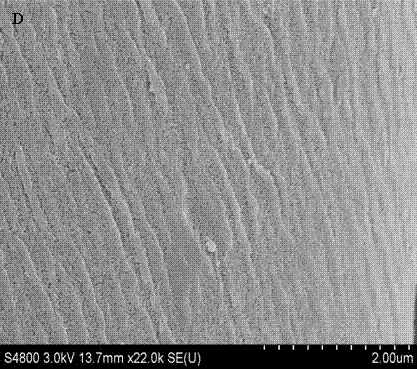

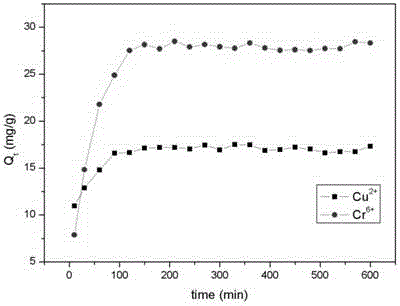

InactiveCN103497278ARenewableDegradableOther chemical processesWater/sewage treatment by sorptionCellulosePolymer science

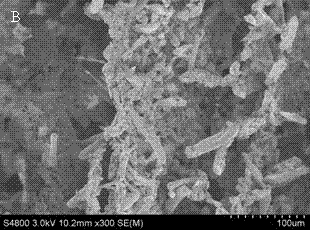

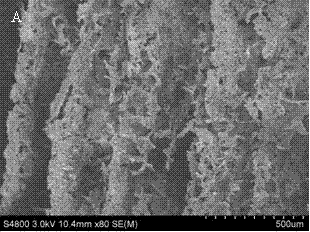

The invention discloses amphoteric cellulose material and application thereof. Cellulose is subjected to alkali pretreatment to obtain alkali cellulose and achieve hydroxyl activation; 3-chloro-2 hydroxypropyl trimethyl ammonium chloride is used as etherifying agent to perform quaternization modification on the alkali cellulose so as to obtain quaternized cellulose; ceric ammonium nitrate is used as initiator and monomer 2-acrylamide-2-methyl propane sulfonic acid to perform sulphonation on the quaternized cellulose. The prepared quaternized and sulfated cellulose has good hydrophilicity, high reaction activity, bulky macrostructure and porous microstructure, is capable of adsorbing negatively charged anion, negatively charged anionic compound, positively charged cation and positively charged compound in the same time, is high in adsorption capacity, is applicable to the fields such as treatment of heavy metal ion waste water and treatment of organic waste water, and can also serve as functional carriers of other materials.

Owner:SUZHOU UNIV

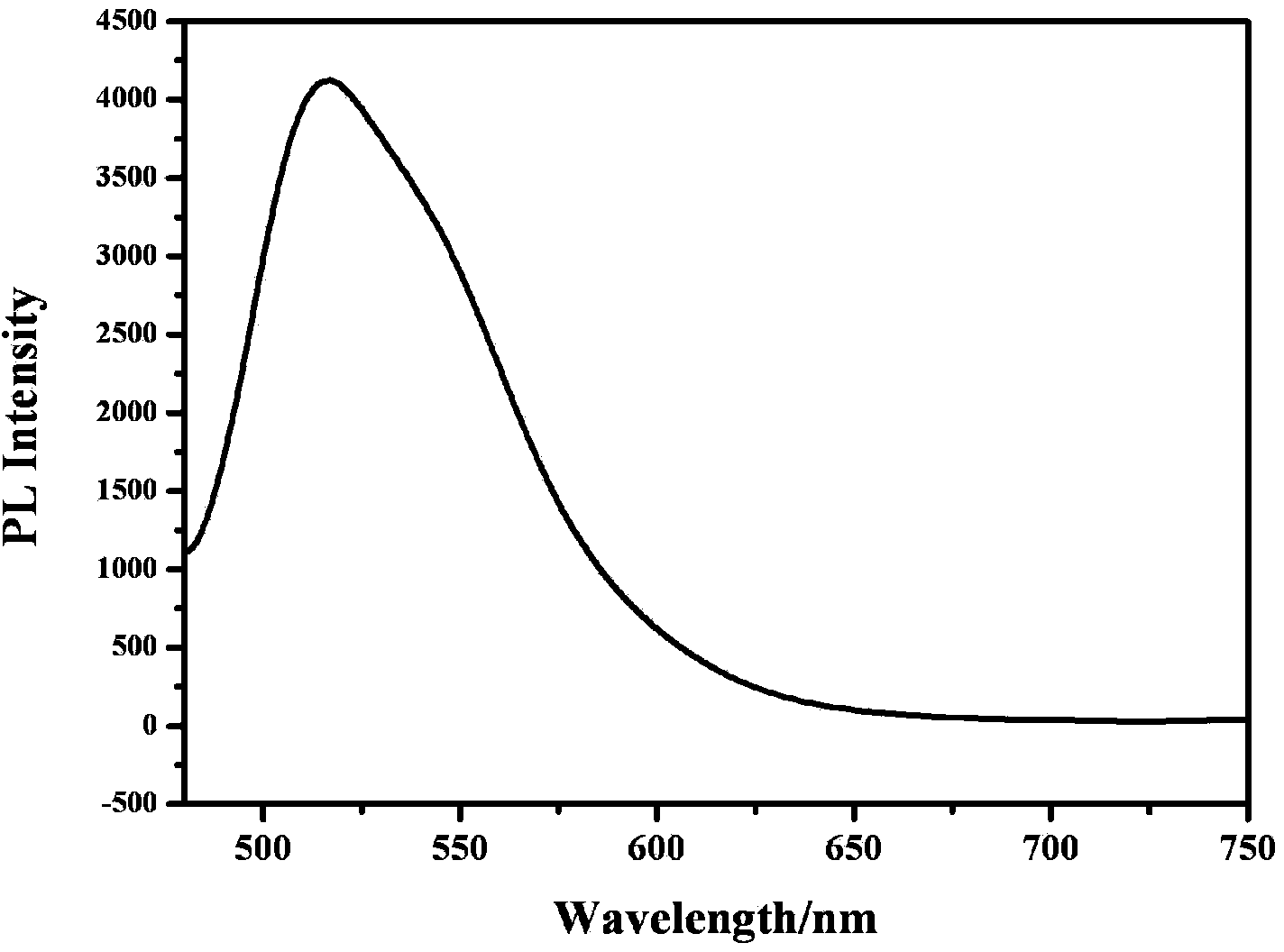

Carbon quantum dot magnetic and fluorescent difunctional nano material and preparation method thereof

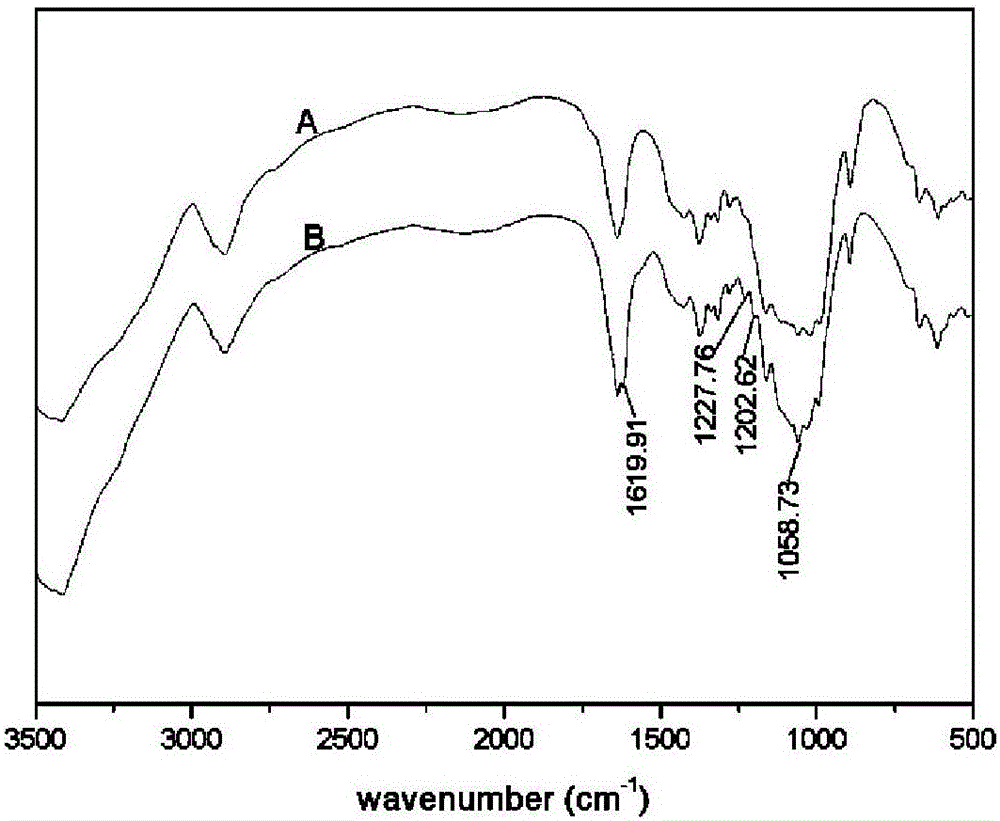

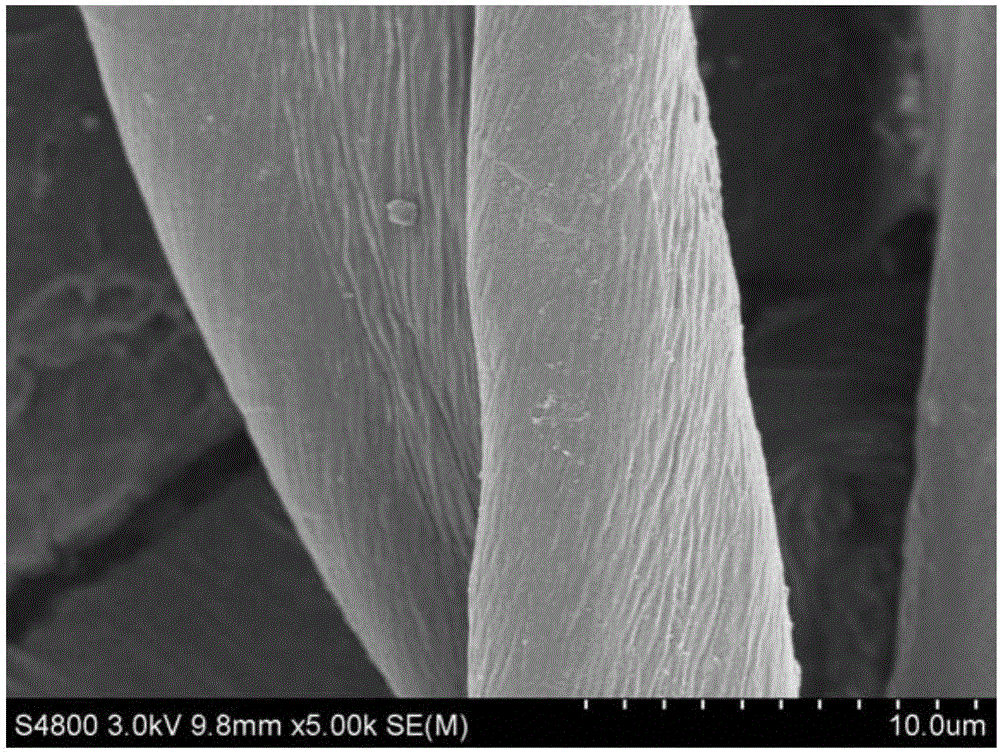

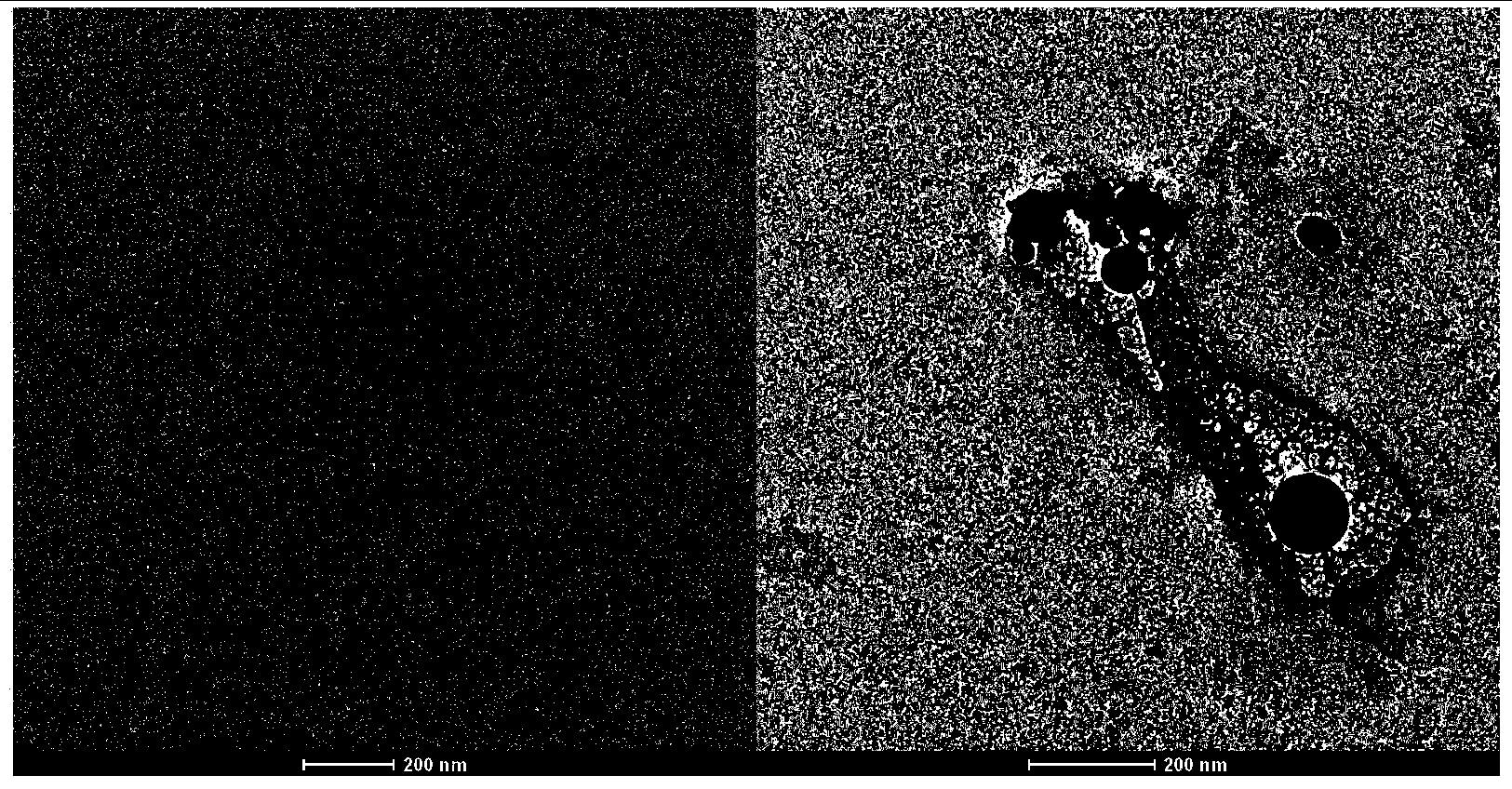

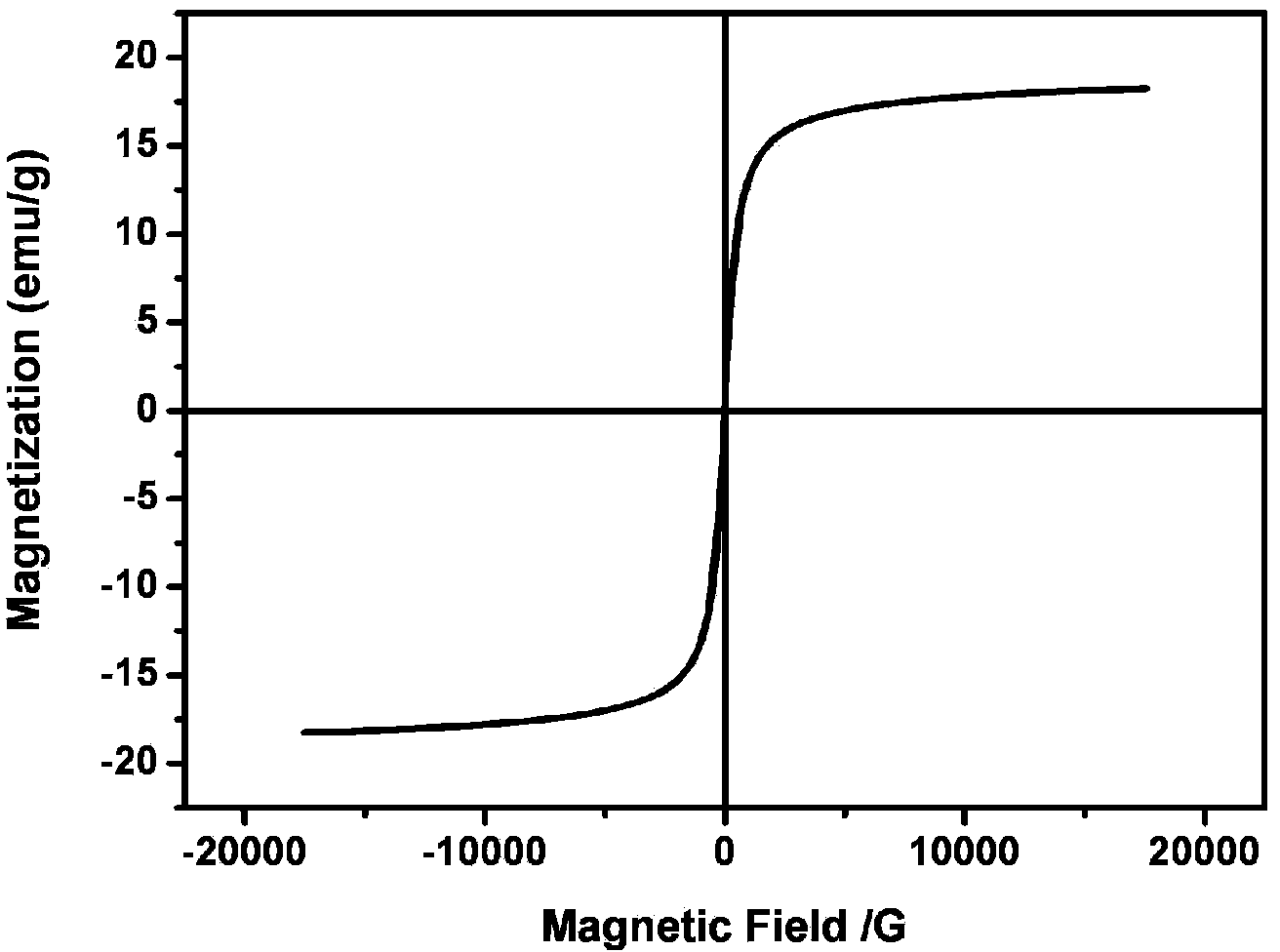

ActiveCN103525414AGood biocompatibilityImprove environmental safetyMaterial nanotechnologyNanomagnetismCelluloseBiocompatibility Testing

The invention relates to a multifunctional nano composite material in a core-shell structure, specifically relates to a carbon quantum dot magnetic and fluorescent difunctional nano material and a preparation method thereof, and belongs to the field of preparation of materials. The carbon quantum dot magnetic and fluorescent difunctional nano material which takes magnetic particles Fe3O4 as a core, chitosan and polyanionic cellulose as a shell material and carbon quantum dots as a fluorescent material is obtained by a self-assembling method layer by layer. The preparation method comprises the following steps: after synthesizing a magnetic fluid nano Fe3O4, preparing carbon quantum dots; then, preparing Fe3O4@CS / CDs; finally, preparing the carbon quantum dot magnetic and fluorescent difunctional nano material through the self-assembling method layer by layer. The carbon quantum dot magnetic and fluorescent difunctional nano material is good in biocompatibility and stability and adjustable in magnetism and fluorescence intensity.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Preparation method of modified cellulose heavy metal adsorbent

InactiveCN105013447AEfficient use ofRaw materials are cheap and easy to getOther chemical processesWater/sewage treatment by sorptionSorbentWastewater

The invention discloses a preparation method of a modified cellulose heavy metal adsorbent. The method includes the steps of: 1. preparation of alkalized cellulose; 2. preparation of oxidized cellulose; and 3. preparation of polyamino modified cellulose. The method specifically includes: firstly conducting alkali pretreatment on cellulose to obtain alkalized cellulose, then using sodium periodate as the oxidizing agent to carry out selective oxidation on the alkalized cellulose to obtain oxidized cellulose, then using glutaraldehyde as the cross-linking agent, and employing a polyamino compound to conduct amination modification on the oxidized cellulose, thus obtaining the modified cellulose heavy metal adsorbent. The method provided by the invention has the advantages of relatively mild preparation conditions, simple process, convenient operation, easy large scale, and good industrial popularization prospect. The product has strong heavy metal adsorption ability, and can be used for heavy metal ion wastewater, organic wastewater treatment and other fields.

Owner:NANTONG UNIVERSITY

Magnetic fluorescent difunctional nano material based on natural polymer and preparation method thereof

ActiveCN103525405AGood biocompatibility and degradabilityExtensive sources of raw materialsMaterial nanotechnologyNanomagnetismCelluloseCarbon quantum dots

The invention relates to a multifunctional nano composite material of a core-shell structure and in particular relates to a carbon quantum dot magnetic fluorescent difunctional nano material and a preparation method thereof. Magnetic particle Fe3O is taken as a core, chitosan and polyanionic-based cellulose are taken as shell material, a carbon quantum dot is taken as a fluorescent material, and the carbon quantum dot magnetic fluorescent difunctional nano material is obtained by adopting a layer-by-layer self-assembly method; the carbon quantum dot is coated by adopting a natural polymer material, so that no free carbon quantum dot is formed, and stability is improved; magnetic property and fluorescence strength can be regulated and controlled by virtue of number of layers of the shell material and the addition amount of the carbon quantum dot; the obtained magnetic fluorescent difunctional nano material has a broad application prospect in the biological medicine fields of cell marking and absorption, bioimaging, medicine detection and disease diagnosis, medicine carrying and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method based on amphoteric cellulose composite material

InactiveCN103480344AImprove adsorption capacityReasonable useOther chemical processesCellulosePolymer science

The invention discloses a preparation method based on an amphoteric cellulose composite material. Cellulose is used as a raw material to obtain amphoteric quaternary ammonium-sulfated cellulose, then the amphoteric quaternary ammonium-sulfated cellulose is used as a carrier of oxidized grapheme and chitosan, the amphoteric quaternary ammonium-sulfated cellulose, the oxidized grapheme and the chitosan can be powerfully combined under the actions of the covalent bond, the electrostatic attraction, the hydrogen bond and the like, and then is subjected to freeze-drying to obtain the amphoteric quaternary ammonium-sulfated cellulose, the oxidized grapheme and the chitosan ternary composited material. The composite material has the renewability, the degradability, green and environment-friendly effect and high-efficiency adsorbability, the condition is mild and easy to realize in the preparation process, and the cellulose can be reasonably and effectively utilized, therefore, the preparation method has good economic and social benefits.

Owner:SUZHOU UNIV

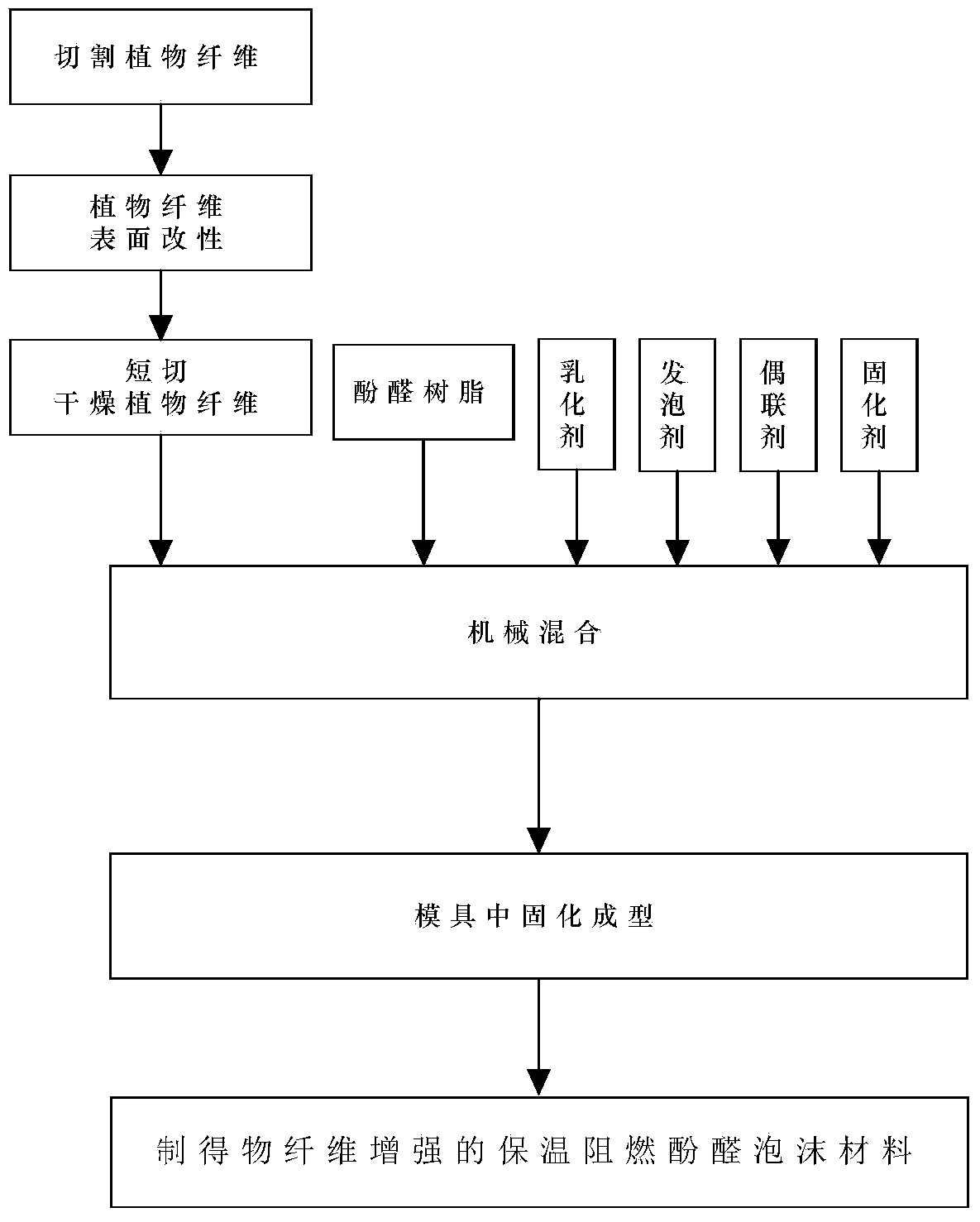

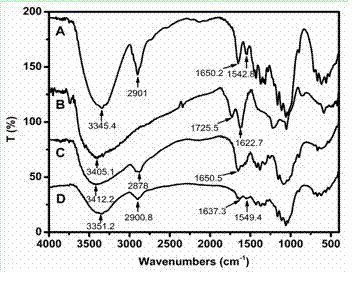

Plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and preparing method thereof

The invention discloses a plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and a preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material. The plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material is formed by adding plant fibers which have different lengths and are of a hollow structure into phenolic resin. The preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material comprises the steps that the dried plant fibers, obtaining through cutting, with the different lengths are mechanically mixed with the phenolic resin, an emulsifying agent, a coupling agent, a foaming agent and a curing agent, the mixture is cured and foamed for 30 min to 120 min at the curing temperature ranging from 45 DEG C to 80 DEG C, and then the plant fiber reinforcing type phenolic foam material used for internal walls and external walls of buildings is obtained after demolding. According to the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and the preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material, phenolic foam is reinforced through the environment-friendly and renewable natural plant fibers, the heat-preservation property and the inflaming-retarding property of the material are good, and the production cost of the phenolic foam material is greatly reduced due to the fact that the plant fibers are cheap and easy to obtain.

Owner:BEIHANG UNIV

Amphoteric-cellulose-based composite material and application thereof

InactiveCN103497476ALarge specific surface areaImprove adsorption performanceOther chemical processesWater contaminantsComposite materialCellulose

The invention discloses an amphoteric-cellulose-based composite material and application thereof. Quaternary ammonium-sulfonic acid cellulose serves as a carrier, grapheme oxide and chitosan are loaded in a blending manner, binding force among the three is utilized, and a quaternary ammonium-sulfonic acid cellulose / grapheme oxide / chitosan composite porous material is obtained through freeze drying. The quaternary ammonium-sulfonic acid cellulose / grapheme oxide / chitosan composite porous material comprises, by weight, 5-8 parts of quaternary ammonium-sulfonic acid cellulose, 0.5-3 parts of grapheme oxide and 0.5-3 parts of chitosan, is safe, non-poisonous and good in biocompatibility and degradability, has an orderly three-dimensional porous structure, good mechanical strength and efficient adsorption capability, can be used for water absorption and oil removal and processing of heavy metal ion waste water and organic waste water, and hopefully serves as a filtering material such as an air purification material and a medical adsorption material for use.

Owner:SUZHOU UNIV

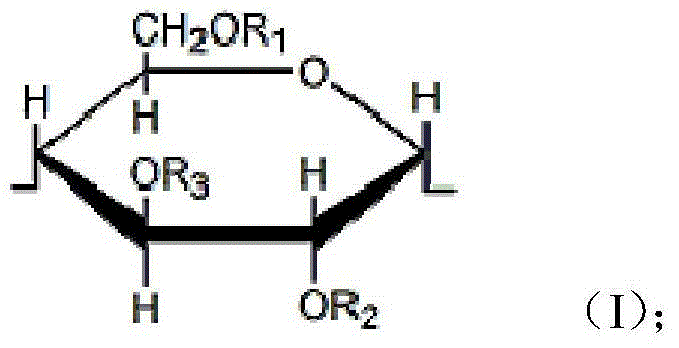

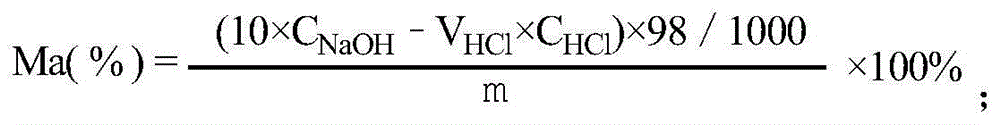

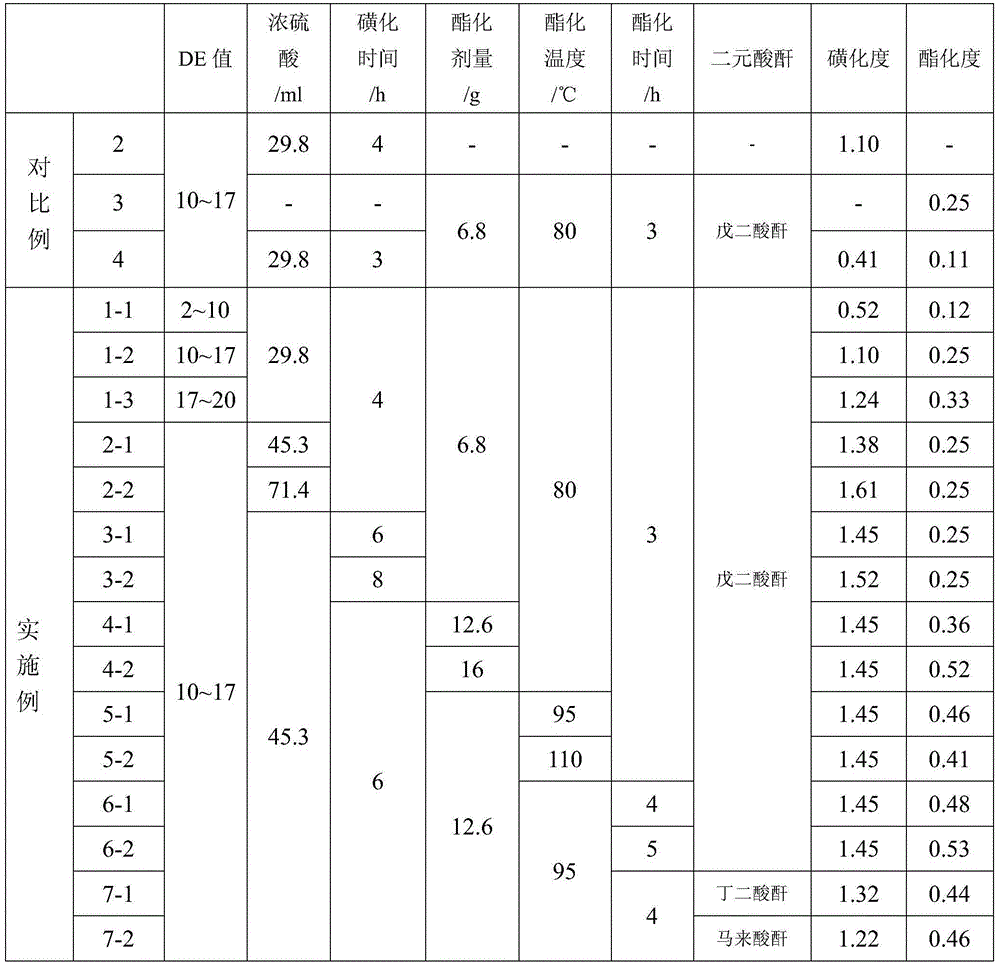

Dual-modified maltodextrin high efficiency water reducing agent and preparation method thereof

The invention provides a dual-modified maltodextrin high efficiency water reducing agent. The structural formula is disclosed as Formula I, wherein R1, R2 and R3 are respectively and independently sulfonate, mono dicarboxylate or hydrogen, and at least comprise one sulfonate (SO<3->) and one mono dicarboxylate. The invention also provides a preparation method of the water reducing agent. The preparation method comprises the following steps: diluting concentrated sulfuric acid with an organic solvent, carrying out sulfonation on maltodextrin at low temperature, carrying out esterification reaction on the sulfonation product by using dibasic acid anhydride, finally, dissolving the product in water, and adding an alkali for neutralization. The dual-modified maltodextrin high efficiency water reducing agent has the advantages of high water solubility and better water reducing performance than most naphthalene high efficiency water reducing agents at present, can be used as a cement water reducing agent, and has the characteristics of recoverability, no environmental pollution and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS

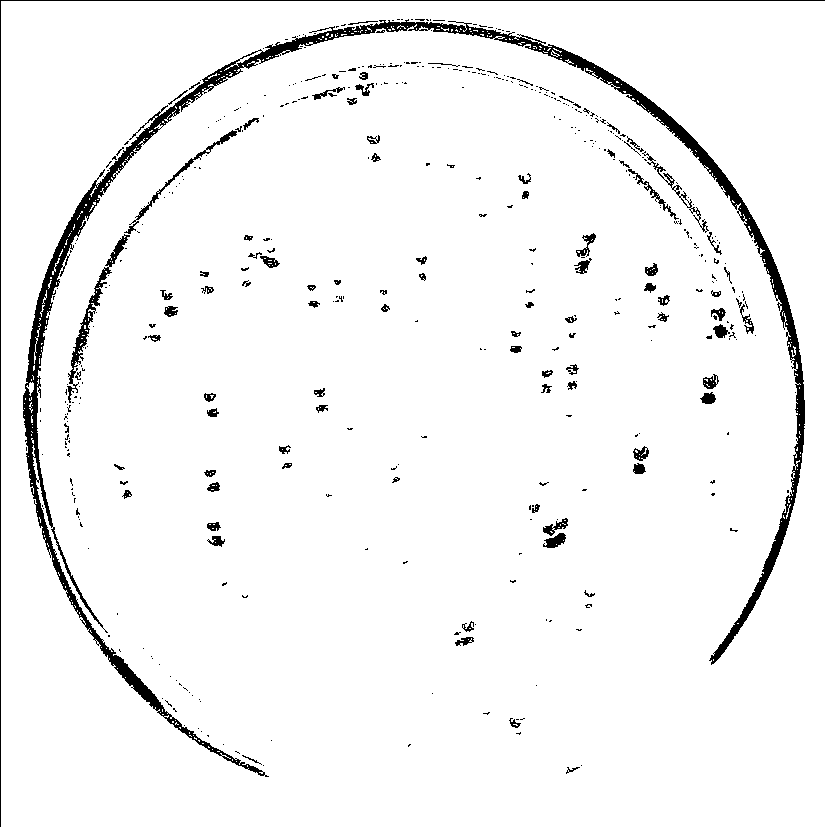

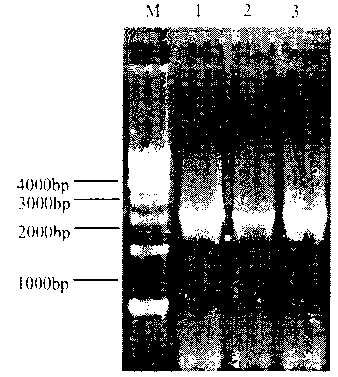

Rhodotorula glutinis oil genetic engineering strain and construction method and application thereof

ActiveCN102796675AImprove the lubrication effectImprove securityFungiMicroorganism based processesBiotechnologyLipid formation

The invention relates to a rhodotorula glutinis oil genetic engineering strain and a construction method and an application thereof. The construction method of the genetic engineering strain is mainly as follows: utilizing rDNA (recombinant deoxyribonucleic acid) of rhodotorula glutinis as a target sequence for homologous integration, using strong promoter genes PGK1 of saccharomyces cerevisiae and malate dehydrogenase genes ME of chaetomium cochloides to construct an expression vector to be introduced into rhodotorula glutinis, and enabling ME genes to obtain high-efficient expression in a rhodotorula glutinis body, wherein the content of lipid in a transformant is improved by 2.5 times in comparison with a wild strain. According to the construction method disclosed by the invention, key enzyme genes and a strong promoter for anabolism of the lipid are introduced on the basis that the anabolism of microbial oil is known, so that the lipid metabolism is regulated and controlled, and the yield of oil is improved. The genetic engineering strain can be applied to production of the microbial oil and development of functional oil related products, such as medicaments, health care products and the like.

Owner:广州溯原生物科技股份有限公司

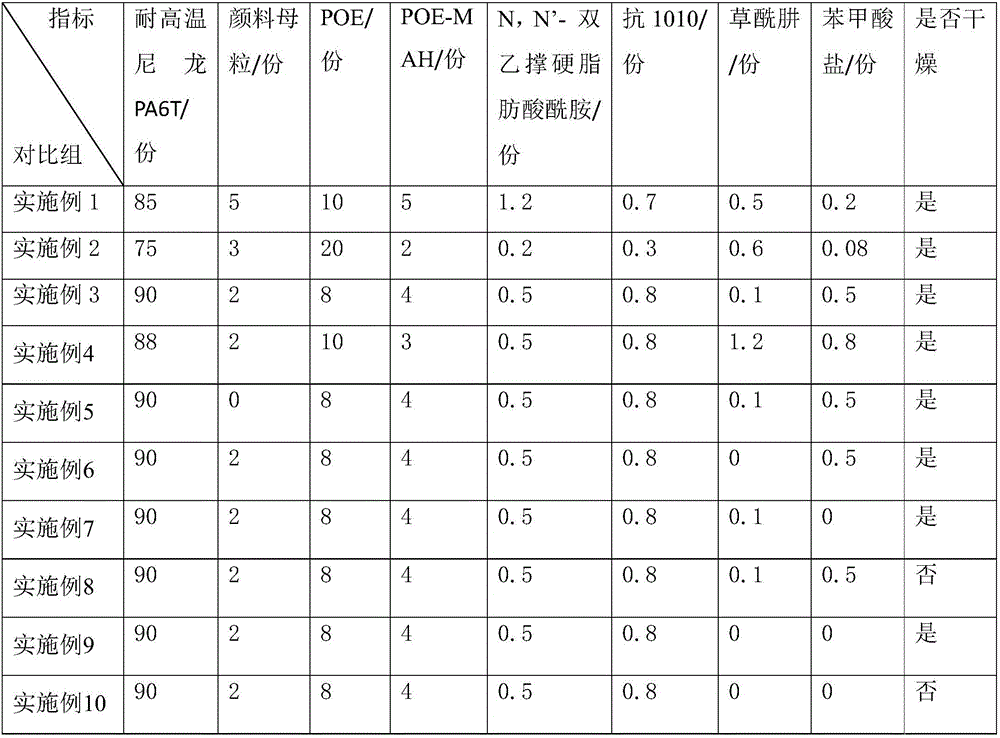

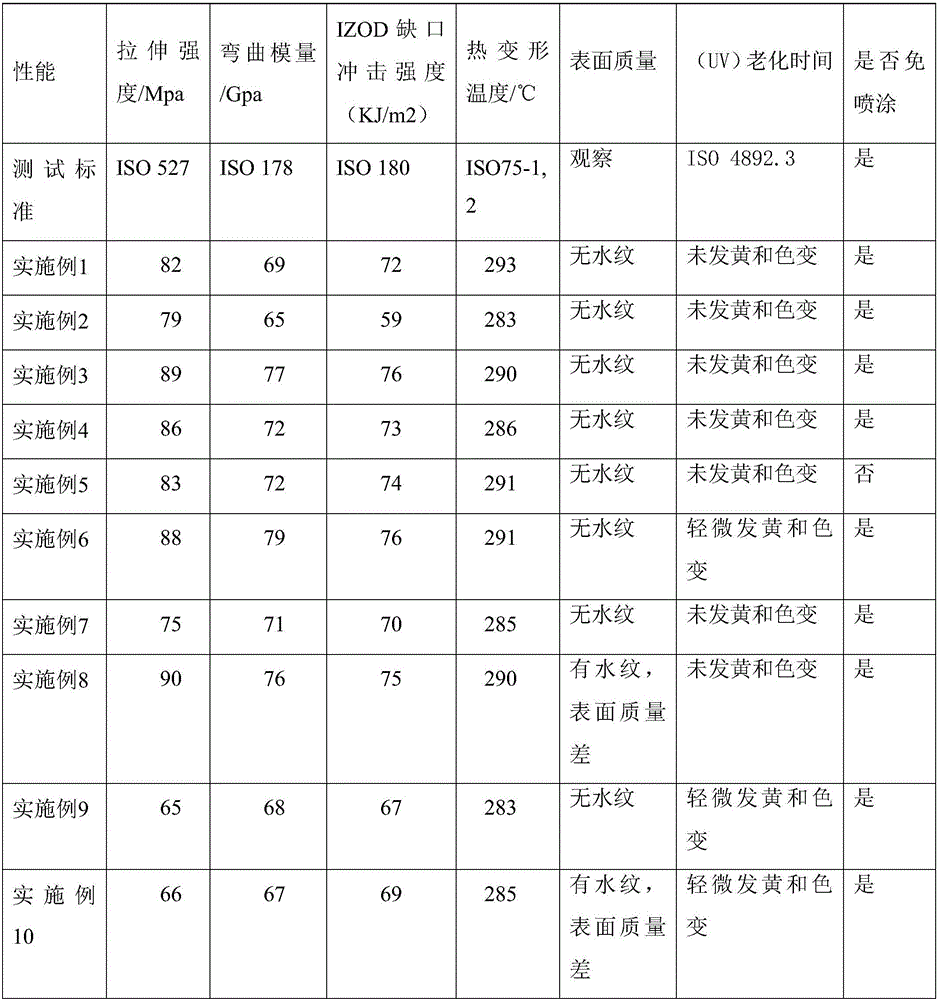

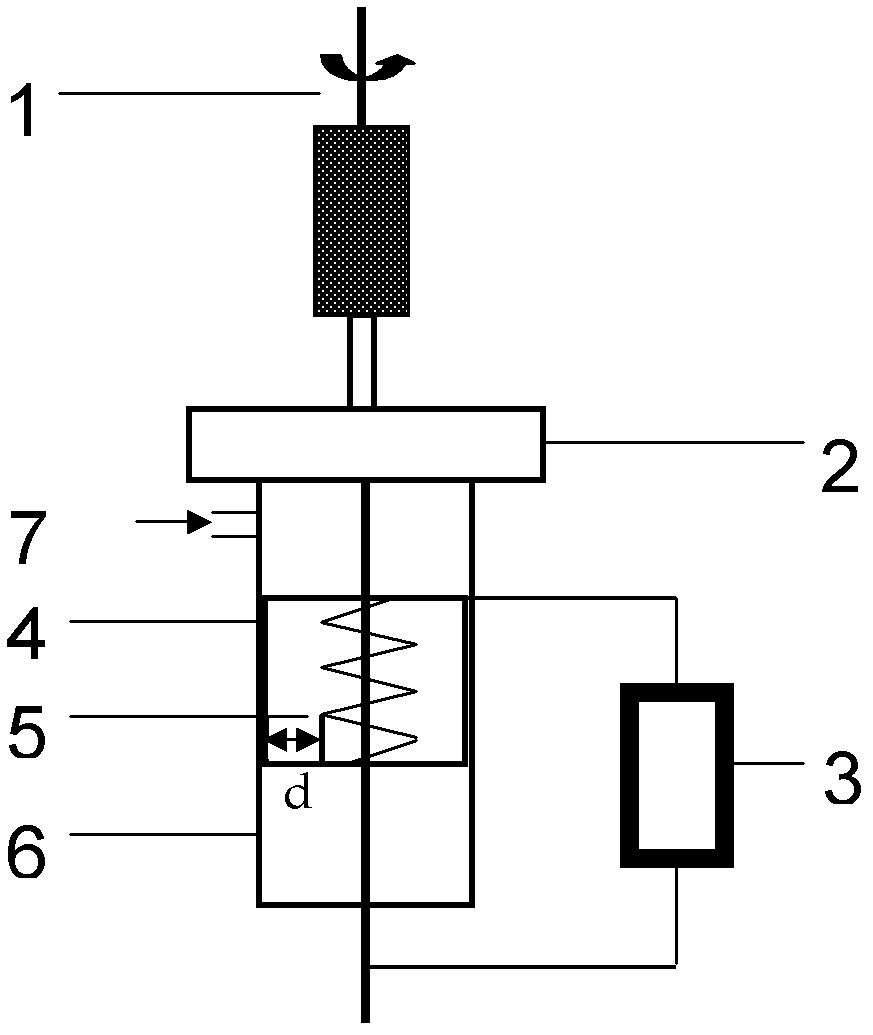

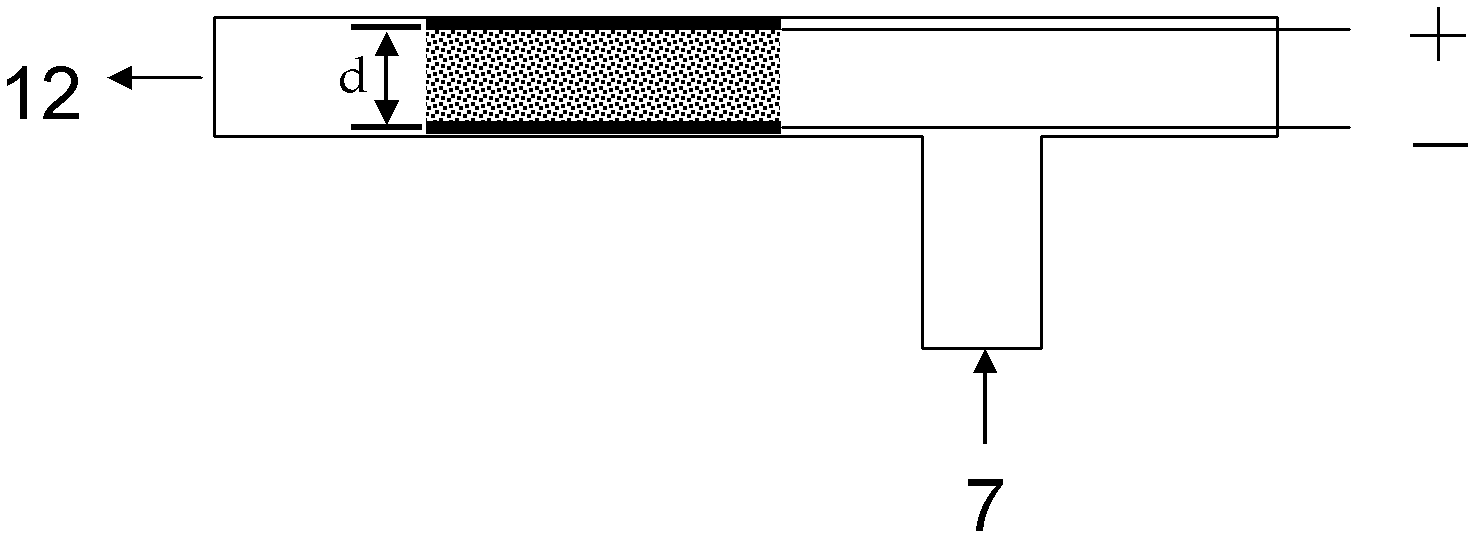

Spray-free high-tenacity high-temperature-resistant nylon PA6T composite material and preparing method thereof

The invention discloses a spray-free high-tenacity high-temperature-resistant nylon PA6T composite material .The composite material is mainly prepared from, by weight, 70-90 parts of high-temperature-resistant nylon PA6T, 1-5 parts of pigment master batch, 5-30 parts of flexibilizer, 1-5 parts of compatilizer, 0.3-1.2 parts of lubricant, 0.2-0.8 part of antioxidant, 0-1.2 parts of passivator and 0.1-1 part of a nucleating agent .The invention further discloses a preparing method of the composite material .The preparing method includes the steps of weighing all the raw materials, mixing, extruding, drafting, cooling, drying, pelletizing and the like .The composite material has the advantage of being free of spray, the process can be simplified greatly, and the composite material is more environmentally friendly.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +1

Ethanol conversion method

InactiveCN102424646AHigh selectivityNo pollution in the processHydrogenOrganic compound preparationRadio frequencyCorona discharge

Belonging to the chemical field of plasma synthesis, the invention relates to a method for direct preparation of polyols and higher alcohols from ethanol. The method is characterized by: choosing dielectric barrier discharge, corona discharge, pulsed corona discharge, glow discharge, radio frequency discharge, gliding arc discharge or microwave plasma and other discharge methods to perform selective activation to ethanol molecules, then setting the residence time of a reaction mixture in a reaction zone, the discharge reaction temperature, the discharge reaction pressure, and the mole ratio between a carrier gas and ethanol, conversing the selectively activated ethanol into target products. The method of the invention adopts ethanol as the raw material for preparing polyols and higher alcohols, while ethanol has various sources and renewability. The method provided in the invention belongs to a one-step synthesis technology, and has the advantages of no need for catalyst, no environmental pollution, as well as high selectivity.

Owner:DALIAN UNIV OF TECH

Preparation method for titanium alloy-hydroxyapatite salt biological ceramic porous material

PendingCN108950305ATake full advantage of performanceOvercome the performance mismatchAdditive manufacturing apparatusTransportation and packagingBiological propertyBone tissue

The invention discloses a preparation method for a titanium alloy-hydroxyapatite salt biological ceramic porous material. The preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material has the characteristics that the 3D printing technology is applied, and by means of the manner that the proportion value of hydroxyapatite salt powder to titanium alloy matrix powder of all fusion covering layers is dynamically adjusted, the titanium alloy-hydroxyapatite salt biological ceramic porous material with titanium alloy being a central layer and titanium alloy-hydroxyapatite salt being a transition layer is prepared. According to the preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material, because the performance advantages of various materials are sufficiently utilized and the internal stress is further reduced, excellent mechanical and biological properties are exhibited, therefore, the preparation method for the titanium alloy-hydroxyapatite salt biological ceramic porous material is suitable for the field of bone tissue replacing or implant repairing.

Owner:SHANDONG JIANZHU UNIV

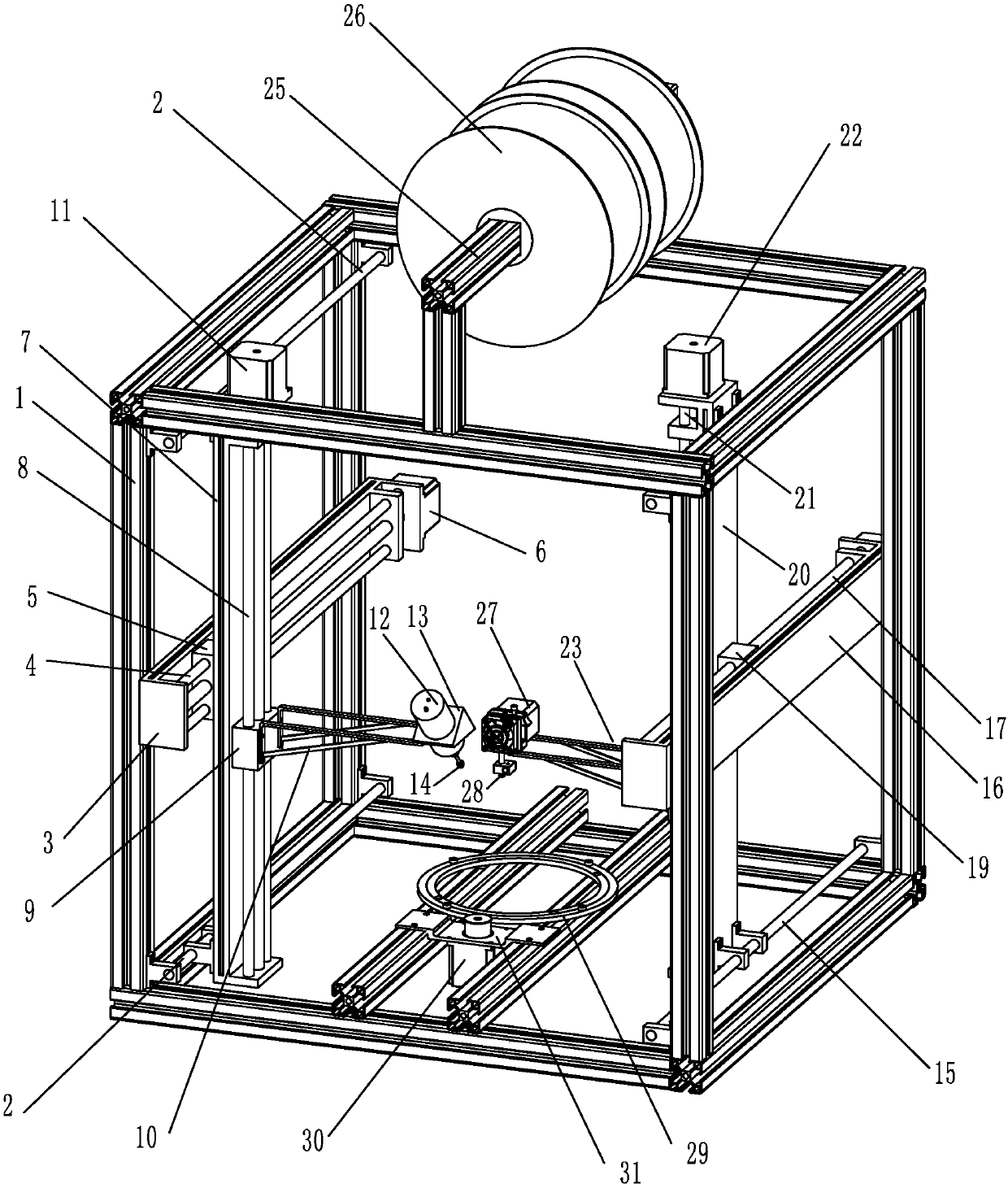

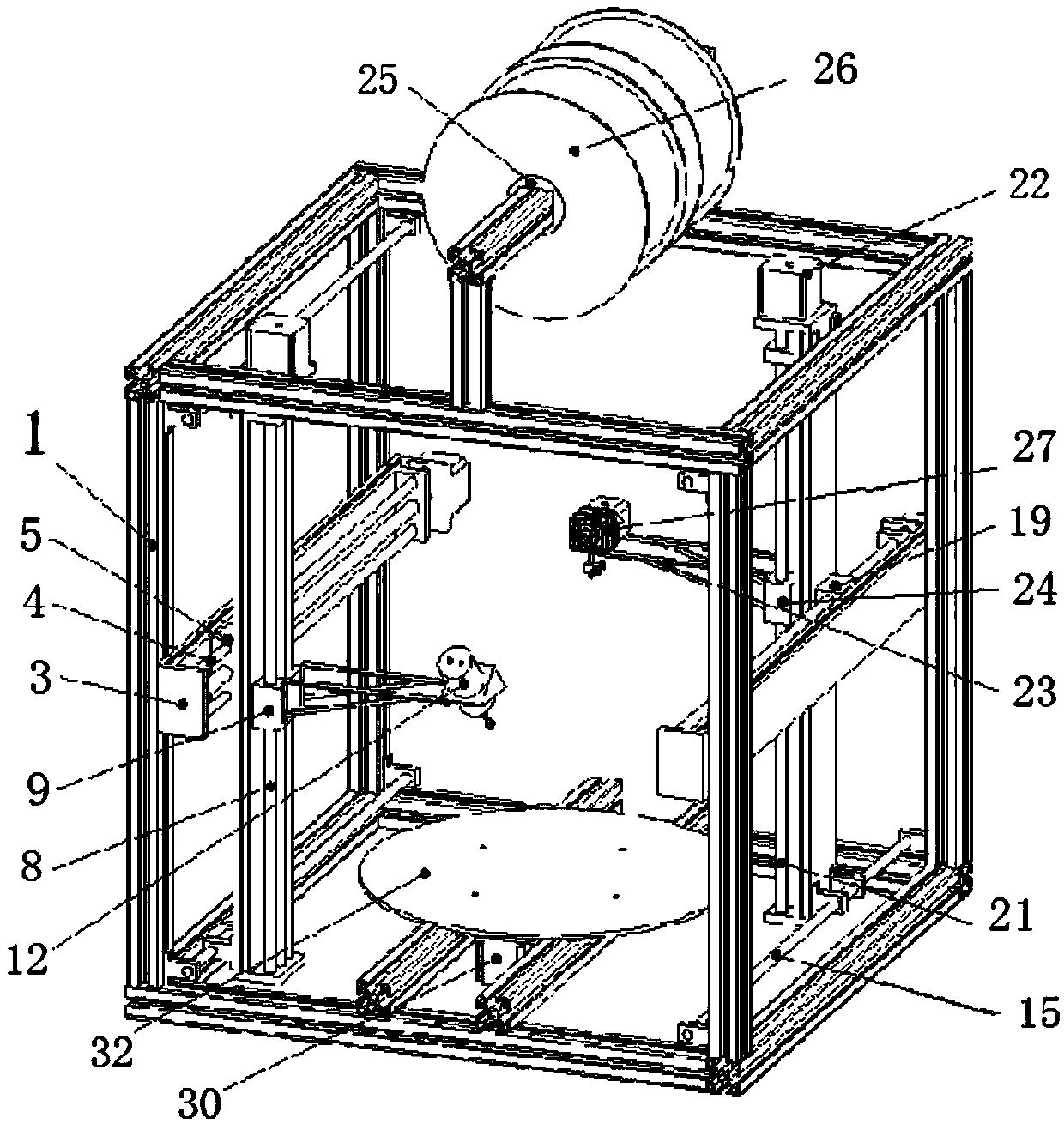

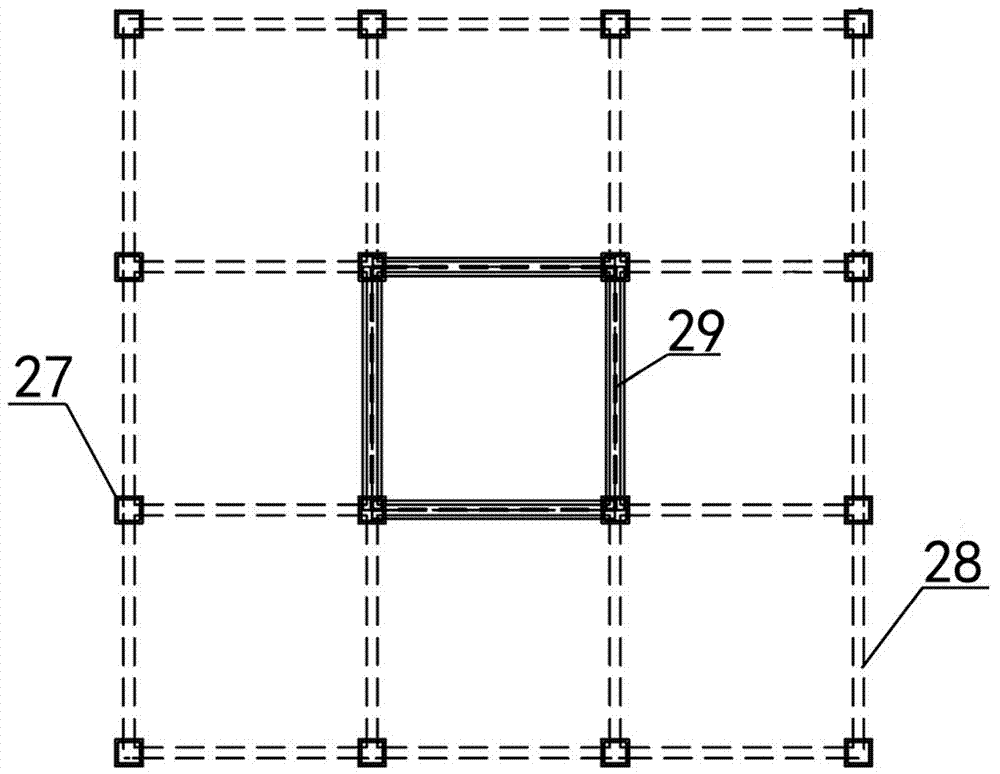

Table top material increasing and decreasing wood-plastic composite 3D printer with abrasive machining function

PendingCN107672162AImprove flexibilityShorten the timeEdge grinding machinesAdditive manufacturing apparatusWear particleSurface roughness

The invention discloses a table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function, and relates to table top material increasing and decreasing wood-plastic composite 3D printers. In order to solve the problem that the shape accuracy, dimensional accuracy, surface quality and the like of parts are both limited by the single-layer printingthickness and plane printing accuracy in an existing 3D printing layer-by-layer stacking manufacturing mode, the table top material increasing and decreasing wood-plastic composite 3D printer comprises a rectangular frame (1) and further comprises a material decreasing assembly, a material increasing assembly and a material increasing and decreasing working platform. The material increasing and decreasing working platform is installed at the lower end of the rectangular frame (1) in a rotating mode. The material decreasing assembly and the material increasing assembly are installed on the rectangular frame (1). According to the table top material increasing and decreasing wood-plastic composite 3D printer, the wood-plastic composite is used as a manufacturing raw material to be stacked layer by layer, so that the material increase manufacturing technology is implemented; and a grinding wheel serves as a cutter in abrasive machining, and grinding wheel abrasive particles serve as cutting blades so that the size and shape accuracy and surface roughness needs required can be met. The table top material increasing and decreasing wood-plastic composite 3D printer with the abrasive machining function is used for wood-plastic composite extrusion printing.

Owner:NORTHEAST FORESTRY UNIVERSITY

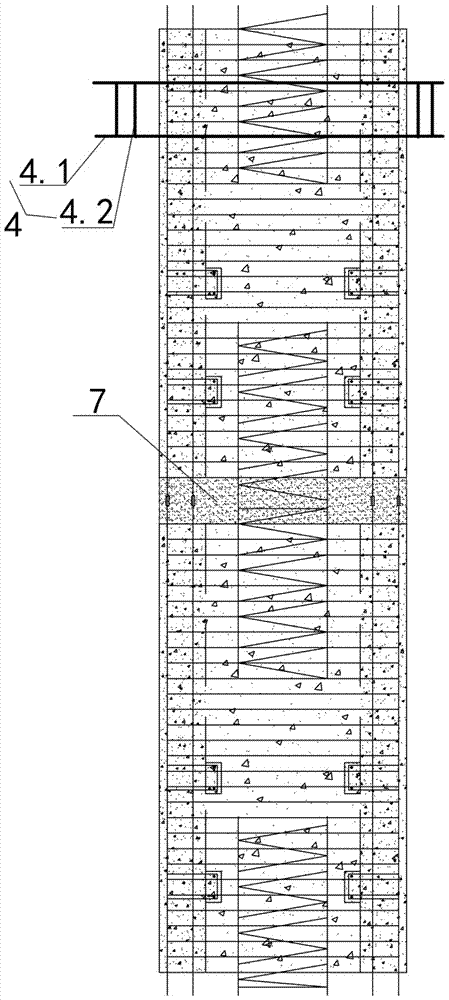

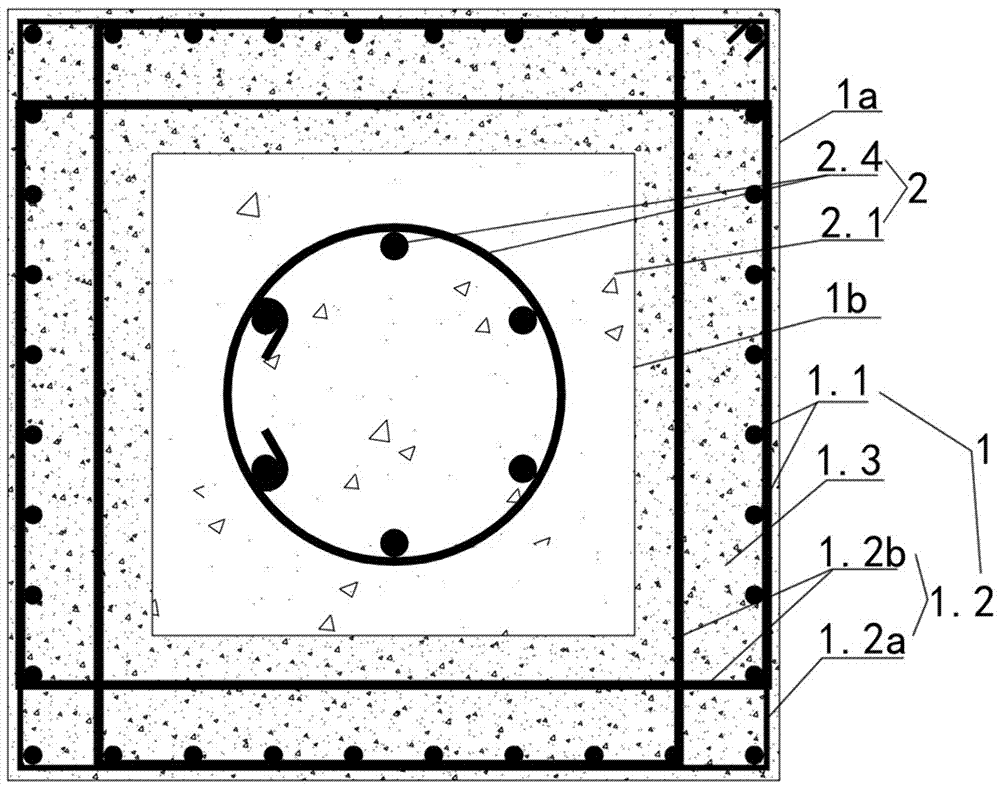

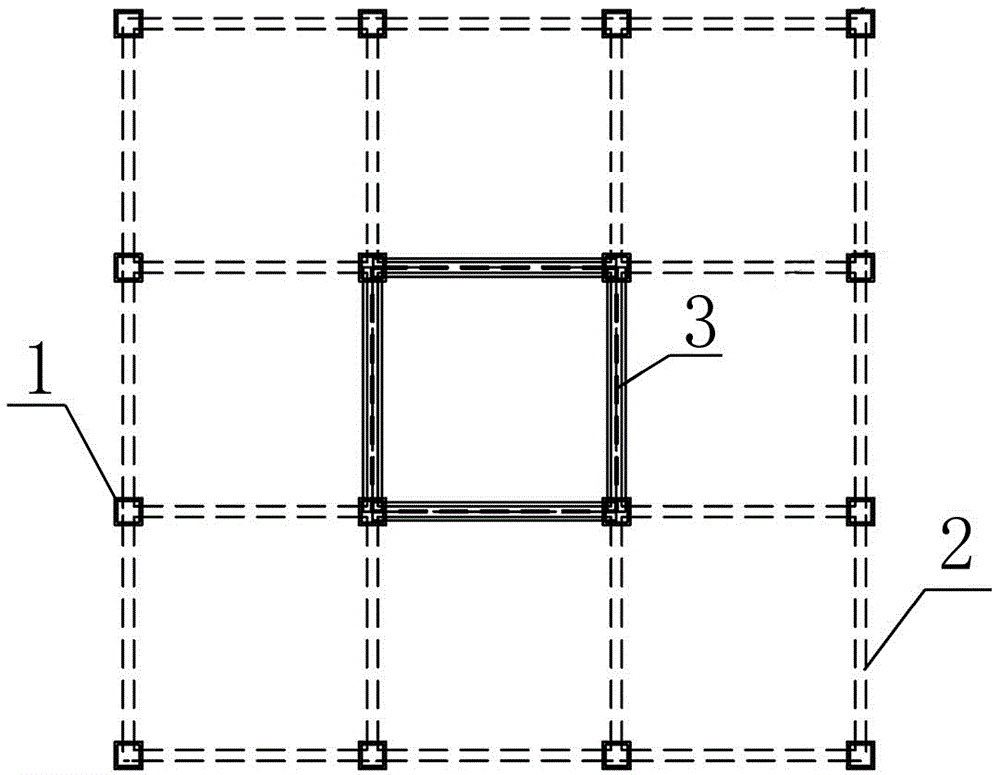

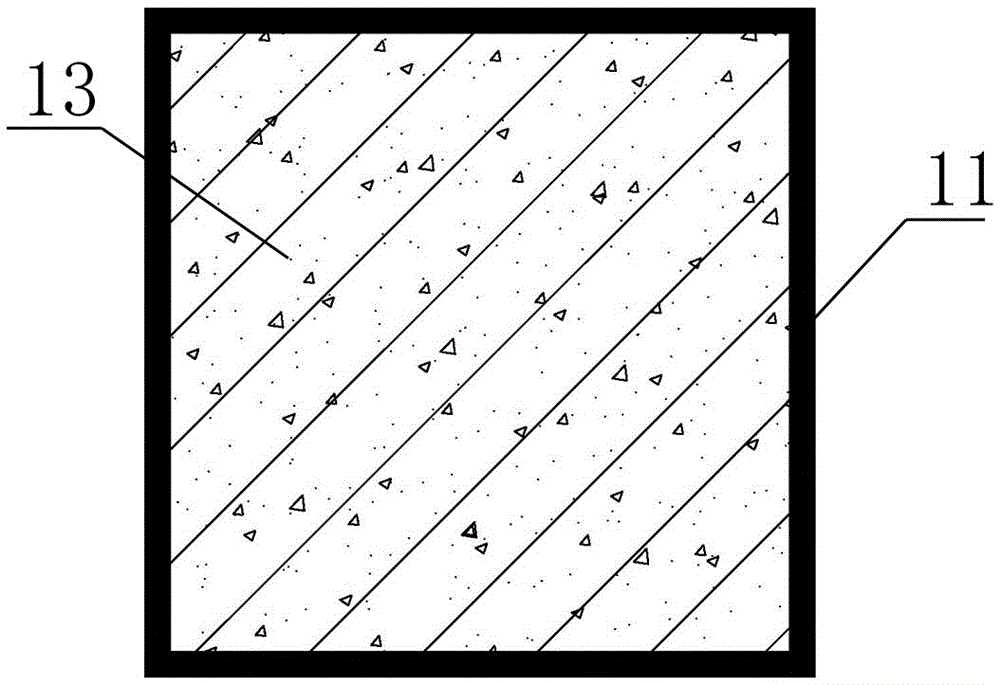

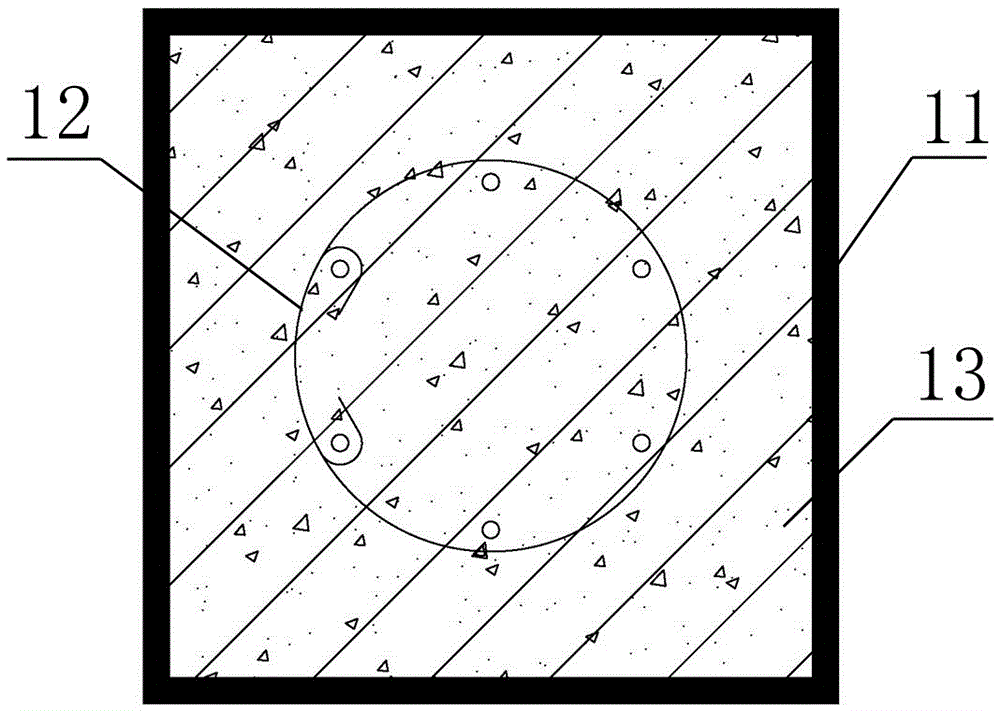

Overlapped prefabricated reinforced concrete structural system and construction method thereof

ActiveCN107060067ANot easy to collapseImprove seismic performanceConstruction materialStrutsFloor slabReinforced concrete

The invention discloses an overlapped prefabricated reinforced concrete structural system and a construction method thereof. The structural system comprises a frame structural system which is composed by connecting a foundation, a structural column, a structural beam and a floor. The structural column adopts an overlapped tubular column or an overlapped core tubular column, the structural beam adopts a prefabricated overlapped reinforced concrete beam or a prefabricated variable-stiffness mixed composite beam, and a shearing wall board can be additionally arranged and is a reinforcement-enhanced reinforced concrete prefabricated shearing wall, or a strip-type steel plate reinforced concrete prefabricated shearing wall or a bolt-free integral-type steel plate reinforced concrete prefabricated shearing wall. According to the structural system, the bearing capacity is high, the cross section is small, the effective net area is increased, the fire-proof property is good, the structural shock-resisting property is greatly promoted, the construction period is shortened, the construction quality is improved, and industrialized construction is facilitated.

Owner:姚攀峰

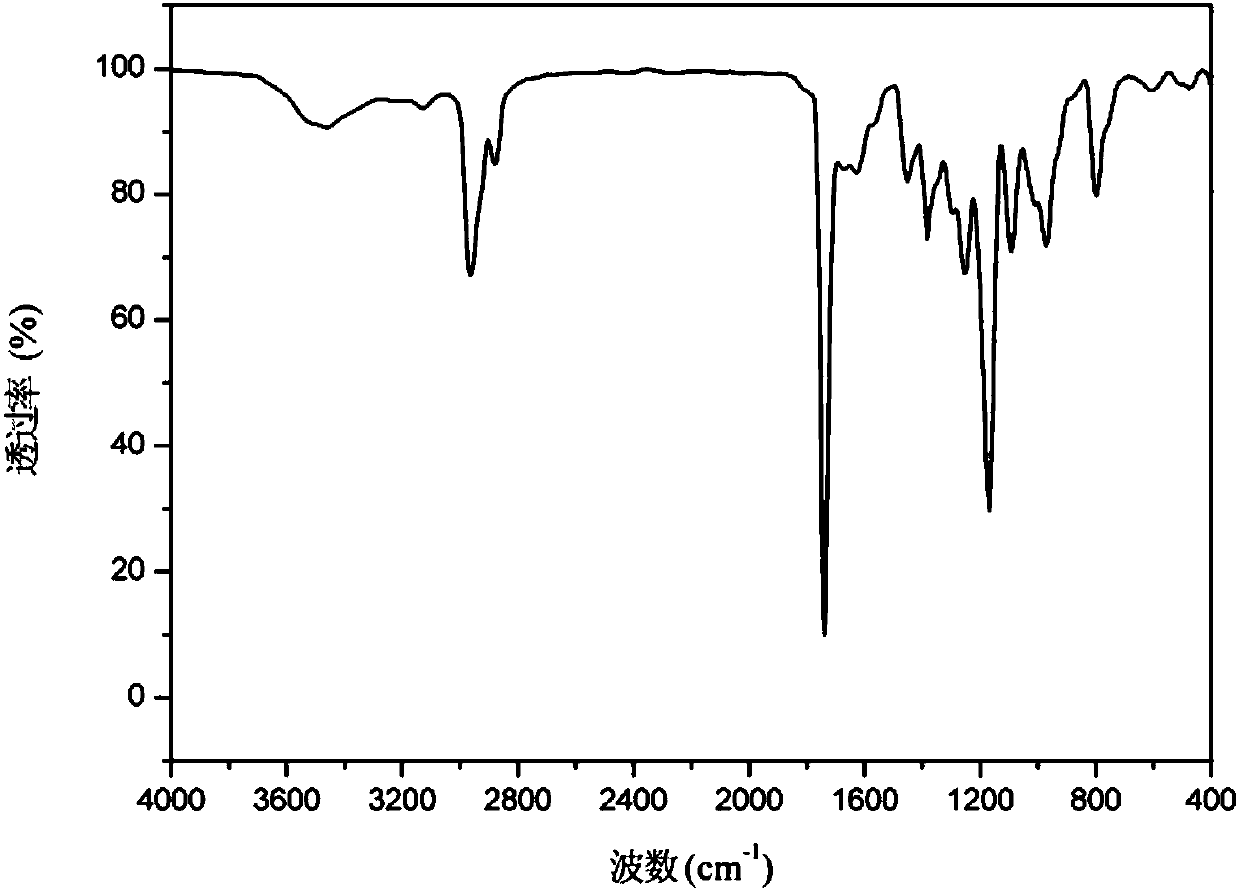

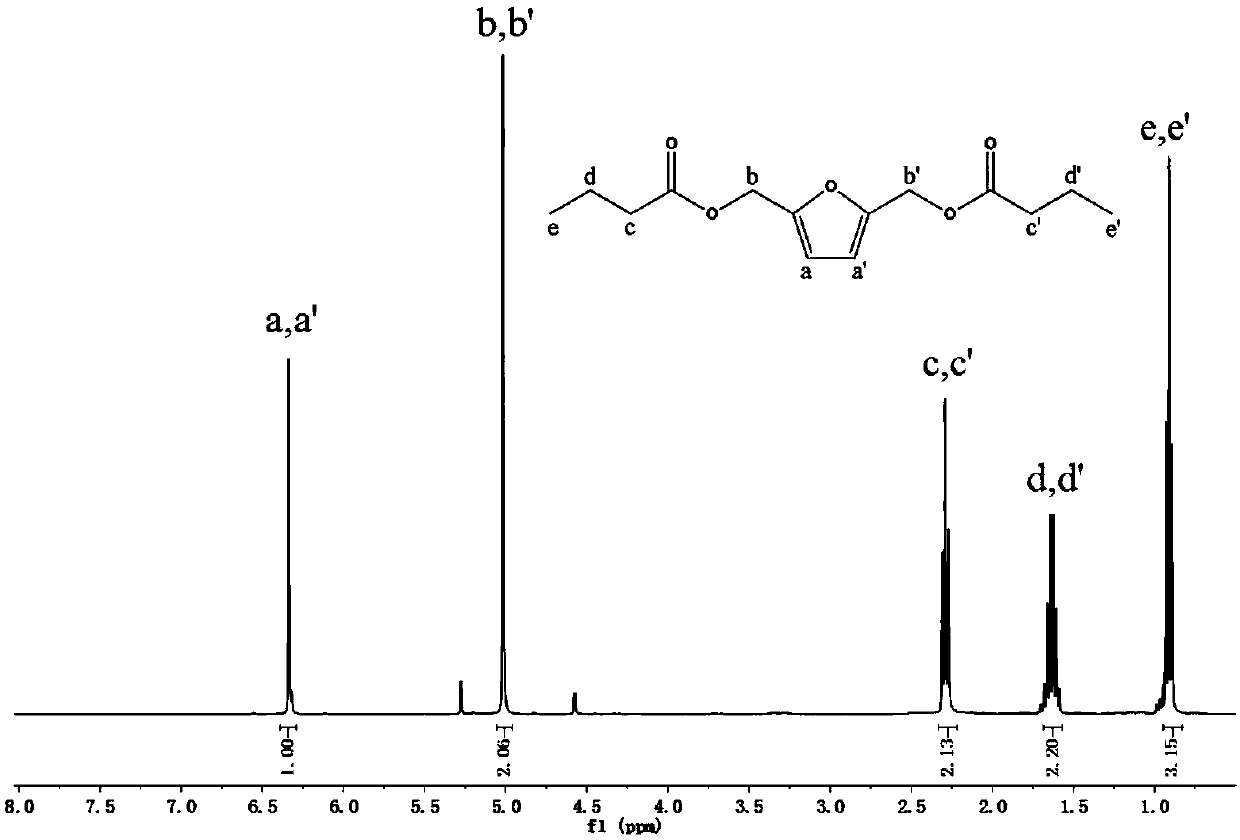

2,5-furandimethanol diester plasticizer and preparation method thereof

InactiveCN107686470AImprove plasticizing effectGood compatibilityOrganic chemistryPlasticizerPetrochemical

The invention discloses a 2,5-furandimethanol diester plasticizer, which is as shown in the formula (I), and discloses a preparation method of the 2,5-furandimethanol diester plasticizer. The preparation method comprises the following steps of, under the protection of an inert gas, carrying out esterification reaction on 2,5-furandimethanol and monocarboxylic acid under the joint action of a catalyst and a water carrying agent, and carrying out post treatment on a reaction product to obtain the 2,5-furandimethanol diester plasticizer. The plasticizer has the characteristics of no toxicity, environmental friendliness and the like, is used as a plastic plasticizer and has the advantage that a raw material can be regenerated; the dependency on a petrochemical resource when a plasticizer is prepared is greatly decreased, and meanwhile, the environmental pollution problem brought by a conventional petroleum-based plasticizer is solved at the same time. The formula (I) is shown in the description.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

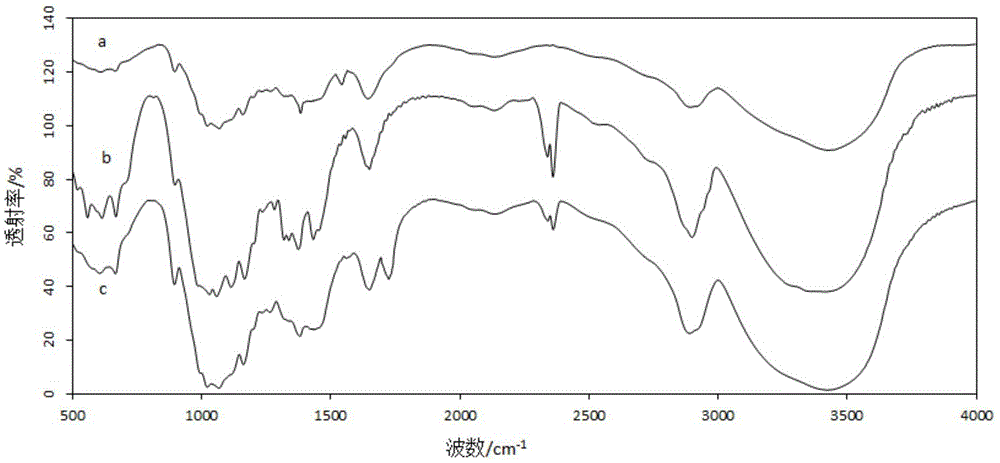

Method for preparing composite fibers in ionic liquid medium

ActiveCN105544004ASimple preparation processResponse to environmental protectionConjugated cellulose/protein artificial filamentsVegetal fibresFiberFreeze-drying

The invention discloses a method for preparing composite fibers in an ionic liquid medium. The method comprises the following steps: (1) oxidating cellulose into carboxyl cellulose in an oxidation system prepared from ionic liquid, nitric acid and NaNO2, and preparing a carboxyl cellulose solution; (2) subjecting silkworm cocoons to soda boiling, degumming, LiBr dissolving, dialysis and vacuum freeze drying so as to obtain silk fibroin, and then, preparing a silk fibroin solution in ionic liquid; (3) grafting the carboxyl cellulose to the silk fibroin in ionic liquid, thereby obtaining the composite fibers. According to the method, the ionic liquid serves as a solvent, cellulosic materials and the silkworm cocoons serve as raw materials, the chemical principle of amidation reaction is adopted, the preparation process is simple, the reaction is green, environment-friendly and pollution-free, the ionic liquid solvent can be recovered and reused through rotary-evaporation drying, and the recovery rate reaches 98%. The reaction system only needs an isothermal reaction of 1 to 2 hours, the percentage of grafting of the cellulosic materials reaches 21% to the maximum, and the composite fibers are excellent in mechanical properties, crinkle resistance, wear resistance and hygroscopic property and are degradable and reproducible.

Owner:JIANGSU UNIV OF SCI & TECH

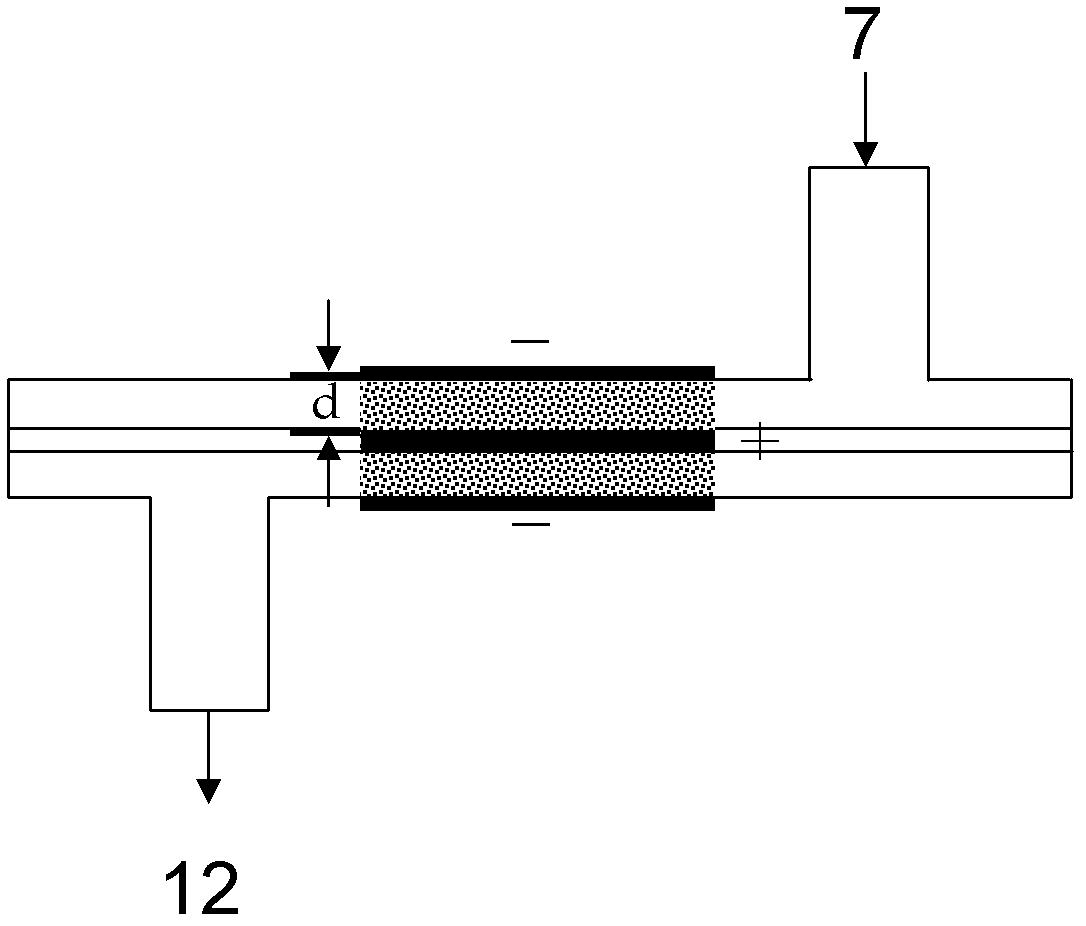

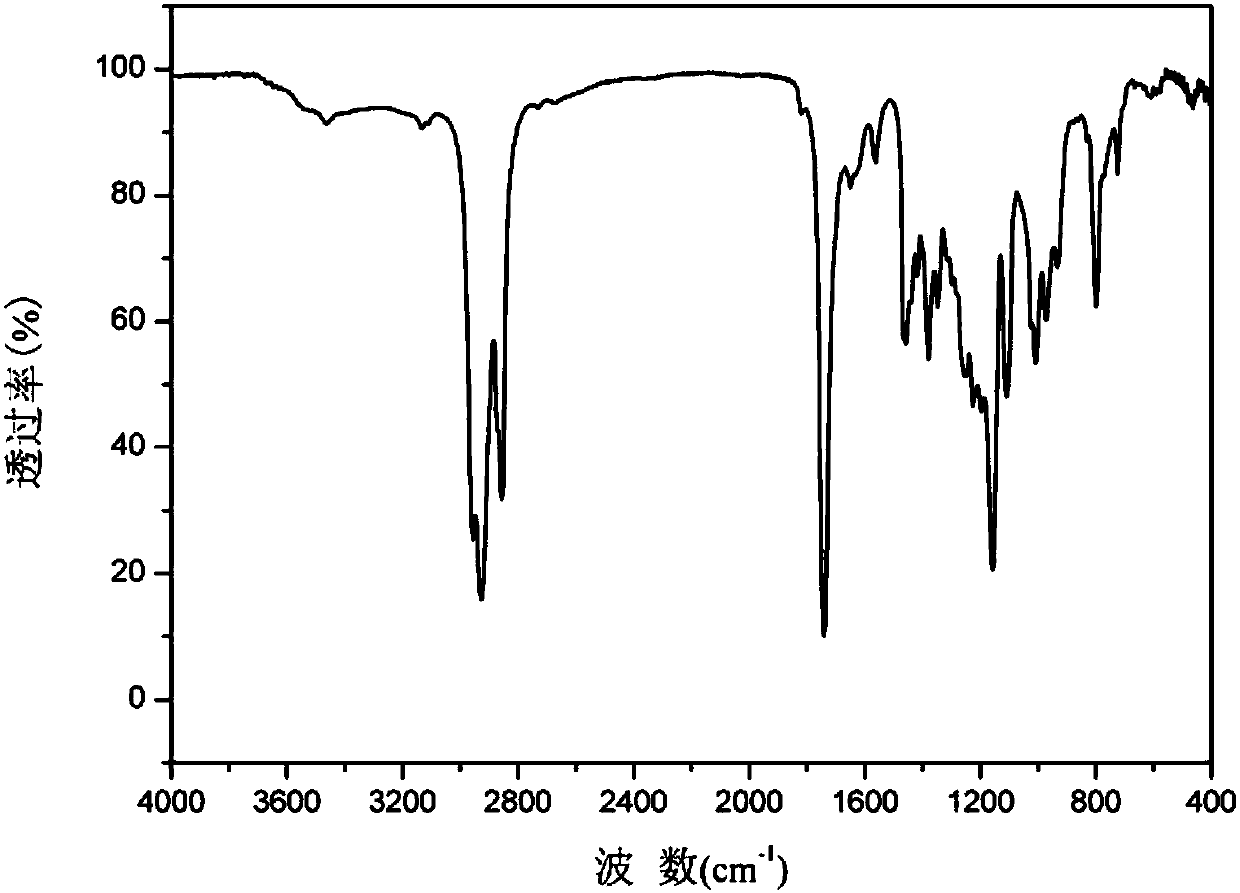

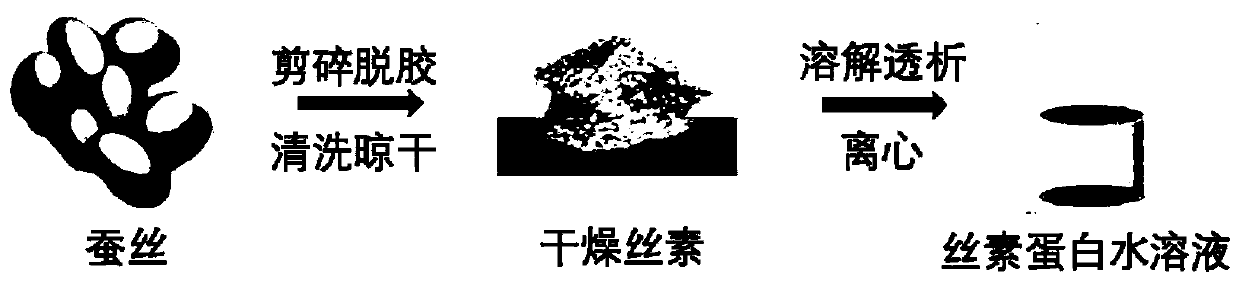

Preparation method of biocompatible silk fibroin film for flexible magnetoelectric device substrate

A preparation method of a biocompatible silk fibroin film for a flexible magnetoelectric device substrate comprises the following steps: 1, preparing a pure aqueous silk fibroin solution from naturalsilk, used as a substrate making material; 2, cleaning a rigid substrate; 3, coating the clean rigid substrate with the aqueous silk fibroin solution; 4, carrying out natural air drying, convection air drying or drying on the solution-coated rigid substrate; and 5, stripping the silk fibroin film from the surface of the rigid substrate after the water is completely evaporated in order to form theindependently supported biocompatible flexible silk fibroin film. The method using the natural silk as the raw material for preparing the flexible magnetoelectric device substrate has a simple and rapid preparation process and a high success rate, and can provide a substrate for health monitoring flexible magnetoelectric devices having great application values.

Owner:XI AN JIAOTONG UNIV

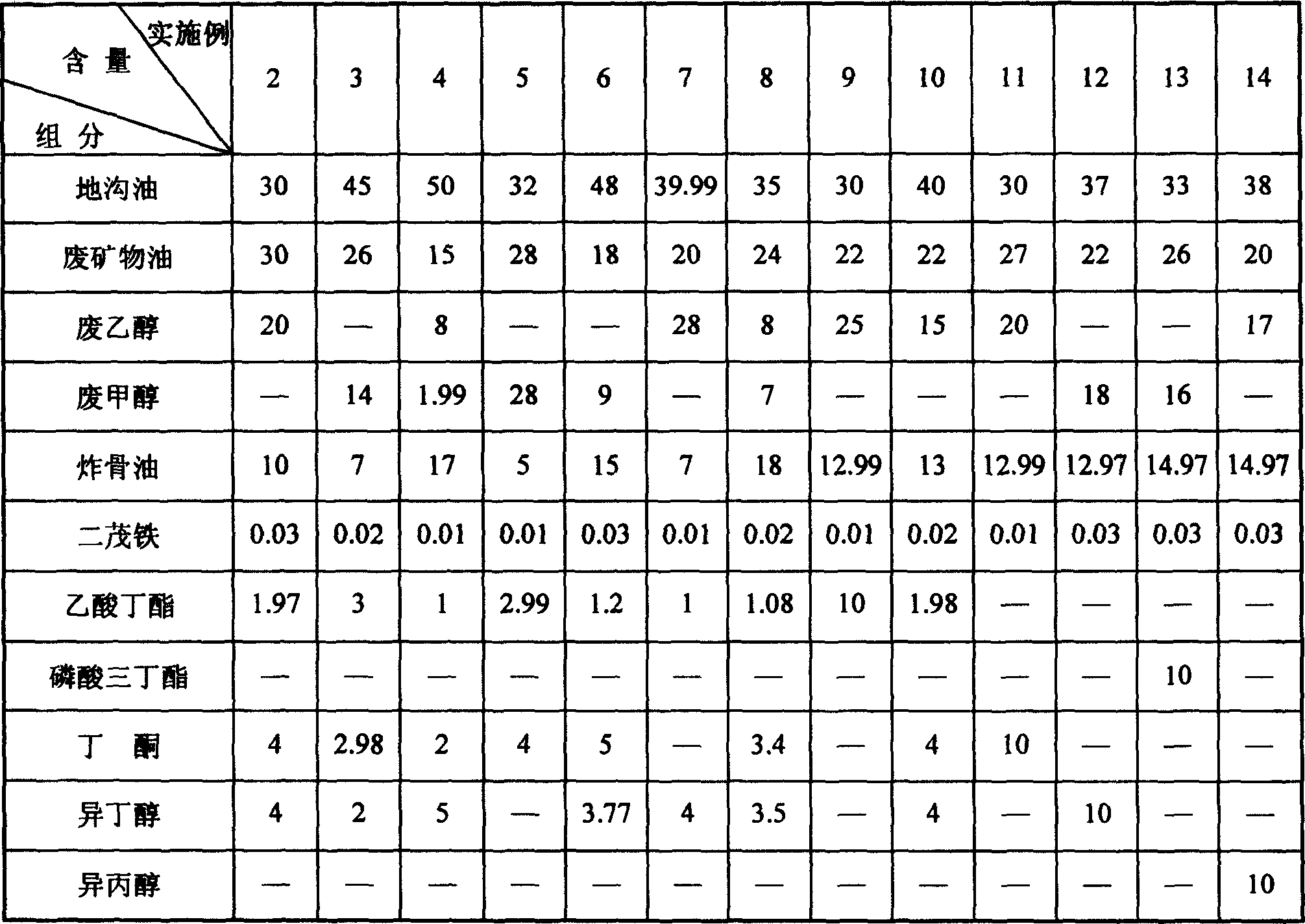

Fuel composition for stove

The invention relates to a furnace use fuel composition, which comprises (by weight percent), trench oil 30-50%, waste mineral oil 15-33%, waste ethanol and / or waste methanol 10-28%, ferrocene 0.01-0.03%, addition agent 5-10%, wherein the addition agent is selected from butanone, lower alcohol or their composition. The invention can provide an industrial or domestic furnace fuel with uniform mixing, ideal thickness, high calorific value, and lower contamination.

Owner:王福成

Manioca biological fuel mixture

InactiveCN1594512AEmission reductionReduce in quantityBiofuelsLiquid carbonaceous fuelsAlcoholJatropha

Owner:四川长江科技有限公司 +1

Method for improving cellulose enzymatic hydrolysis and saccharification yield

The invention belongs to the field of lignocellulose enzymatic hydrolysis, and discloses a method for improving cellulose enzymatic hydrolysis and saccharification yield by using a mixture of lignin sulfonate and straight-chain alcohol as an enzymatic hydrolysis auxiliary agent. The method comprises the specific steps that: cellulose is dispersed in a buffering solution; the mixture of lignin sulfonate and straight-chain alcohol is added; 5-20 FPU / g of cellulase calculated according to glucan content in cellulose is added; a reaction is allowed for 48-96h under a temperature of 45-60 DEG C, such that a saccharide compound hydrolysate is obtained. According to the invention, through the addition of the mixture of lignin sulfonate and straight-chain alcohol, cellulose enzymatic hydrolysis and saccharification yield can be improved by 15.1-24.6%.

Owner:SOUTH CHINA UNIV OF TECH

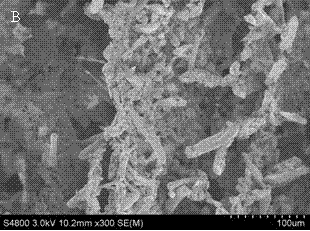

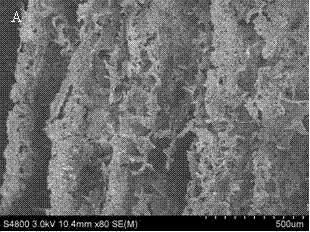

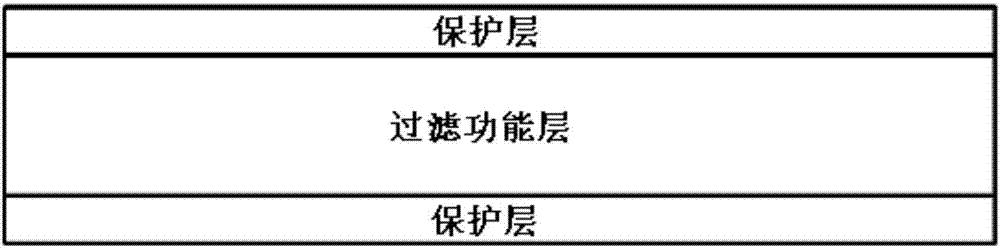

Composite structure filter felt and its preparation method and application

ActiveCN107224783ARenewableImprove filtration efficiencyGas treatmentDispersed particle filtrationElectrospinningFiltration

The invention belongs to the technical field of filter materials and discloses a composite structure filter felt and its preparation method and application. The composite structure filter felt is composed of a filtering function layer and protective layers coating the upper and lower surfaces of the filtering functional layer. The filtering function layer is prepared from a regenerated fiber layer containing 3D crimped structural fibers and an electrospinning nano-fiber layer through compounding. The composite structure filter felt has a fluffy filtering material skeleton structure of renewable micrometer fibers containing 3D crimped structural fibers and utilizes secondary electrospinning nanofibers attached to the micrometer fibers so that a high fiber specific surface area is obtained. The filter felt has the advantages of high filtration efficiency, low resistance and environmental friendliness.

Owner:SOUTH CHINA UNIV OF TECH +1

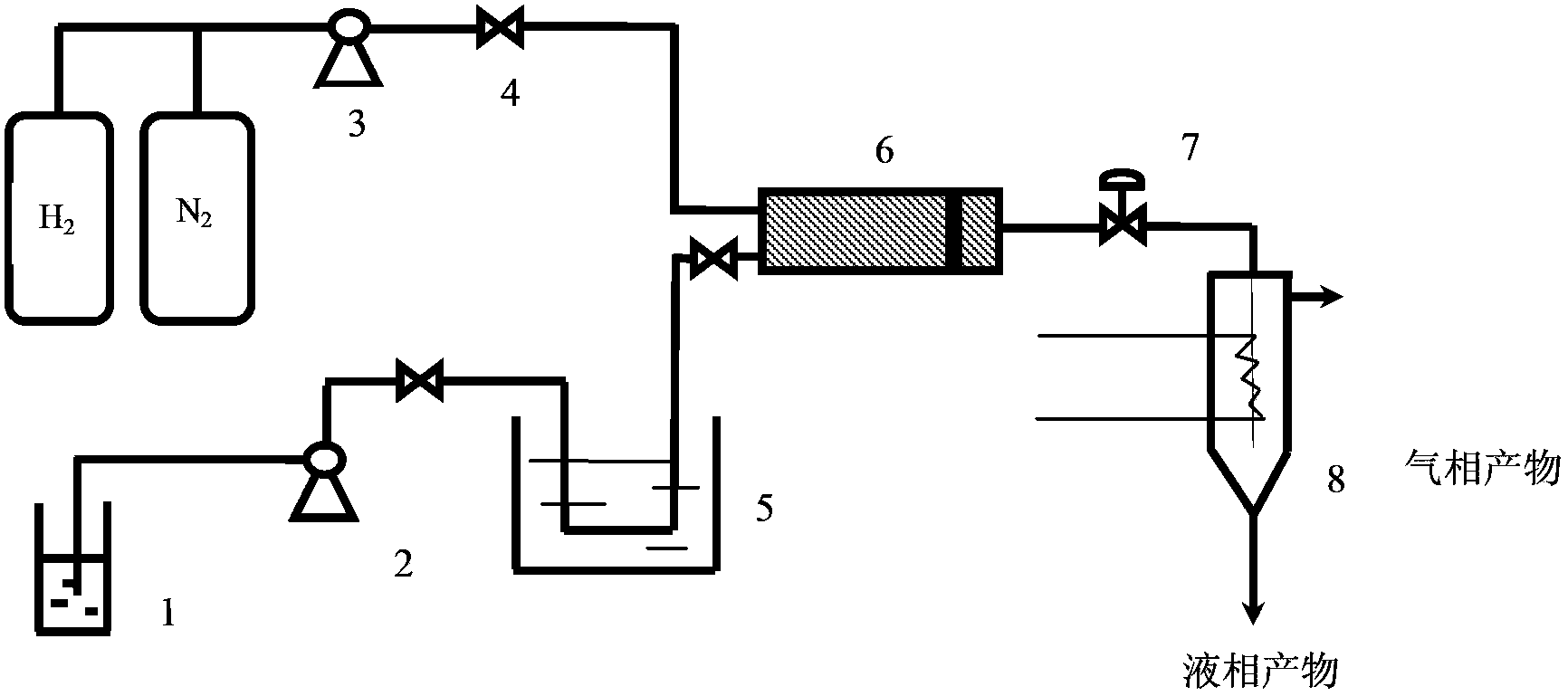

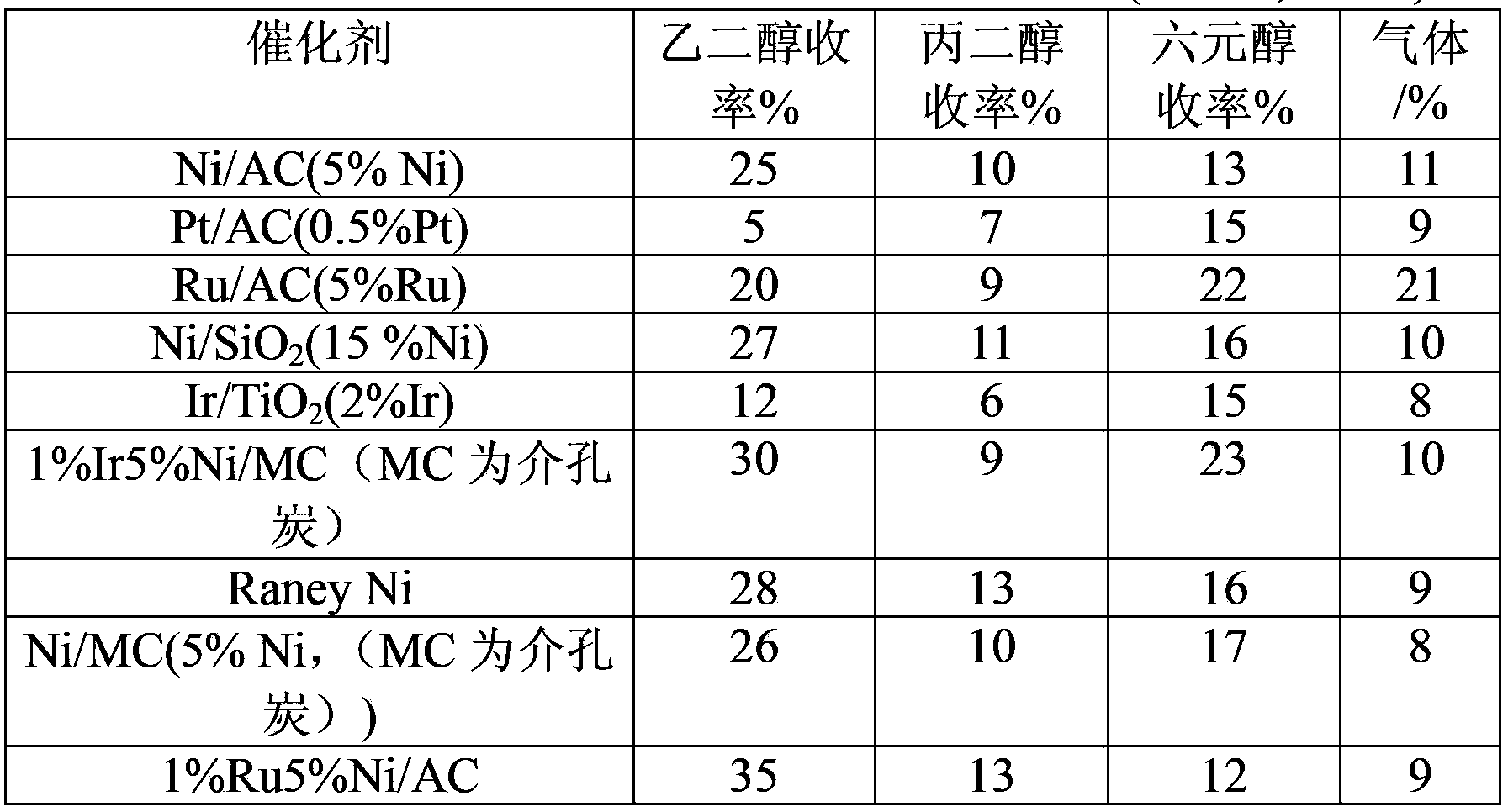

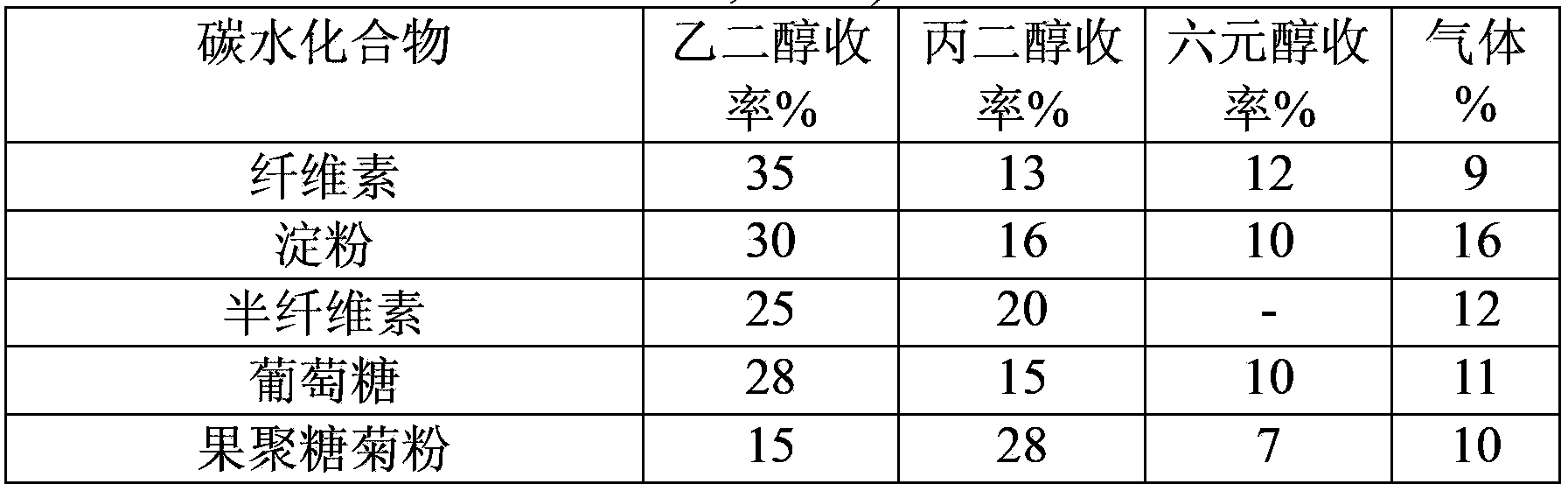

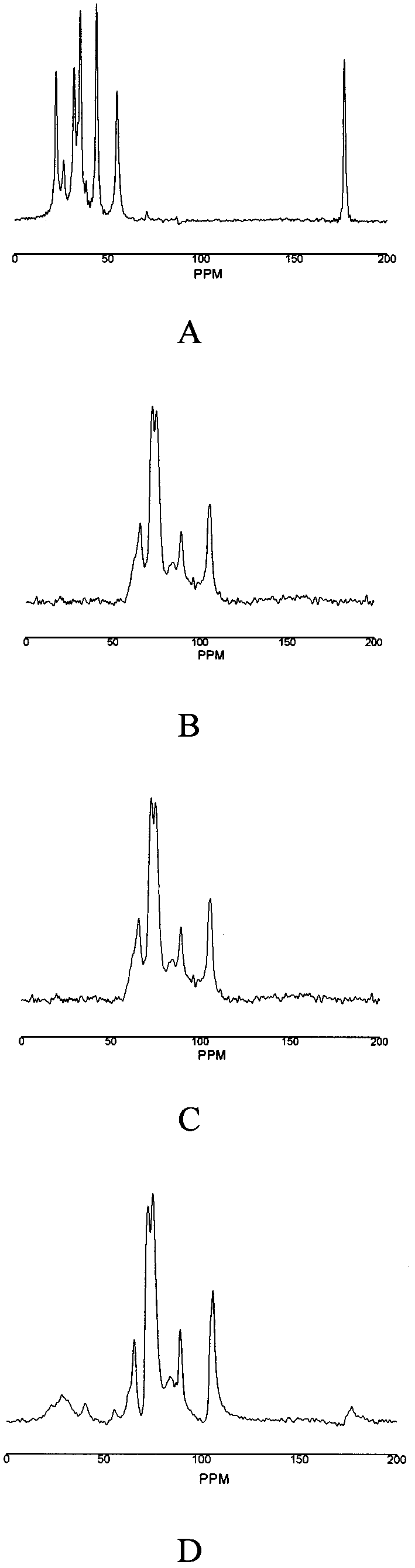

Method of preparing small molecule polyol from carbohydrate under near-critical or supercritical conditions

ActiveCN103420787ARenewableMeet the requirements of sustainable developmentOrganic compound preparationHydroxy compound preparationXyloseIridium

The method provides a method of preparing small molecule polyol such as glycol and propylene glycol from Cn(H2O)m compounds such as straw, paper pulp, waste paper, cellulose, starch, semi-cellulose, cane sugar, glucose, fructose, fructosan, xylose, and soluble xylo oligosaccharide under the near-critical or supercritical conditions. In the method, carbohydrate is taken as the raw material, the 8, 9 and 10 groups of transition metals, namely iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium, and platinum, are taken as the catalytic active components, one-step catalytic conversion process is carried out under the near-critical and supercritical water conditions: temperature of 300 to 450 DEG C, hydrogen pressure of 1 to 10 MPa, and total pressure of 10 to 35 MPa, and high efficient, high selective, and high yield preparation of small molecule polyol such as glycol and propylene glycol is achieved. The reaction provided by the invention has the prominent advantages of recyclable raw material and high atom economy, and the preparation of the catalyst has the advantages of simple and easy process and low cost. Furthermore, compared to other technologies, which prepare polyol from biomass, the method has the advantages of simple reaction process, high space time yield, and convenience for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

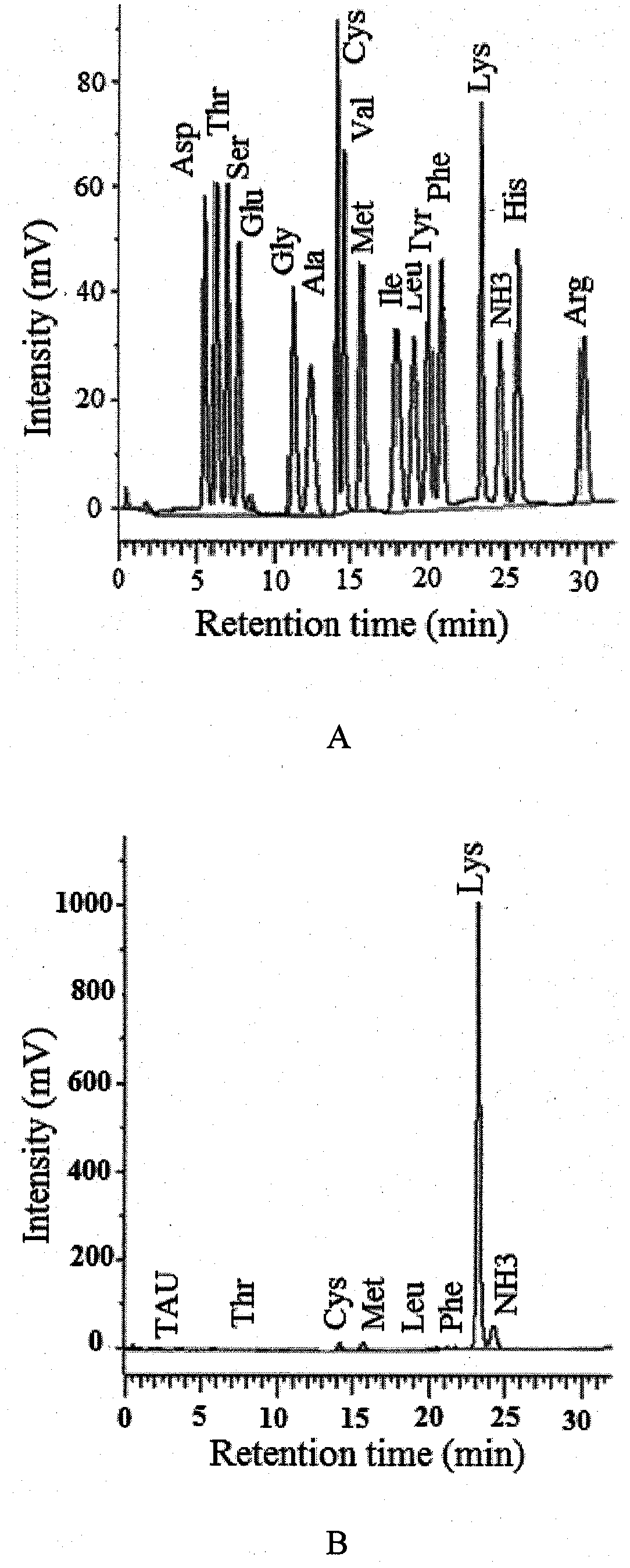

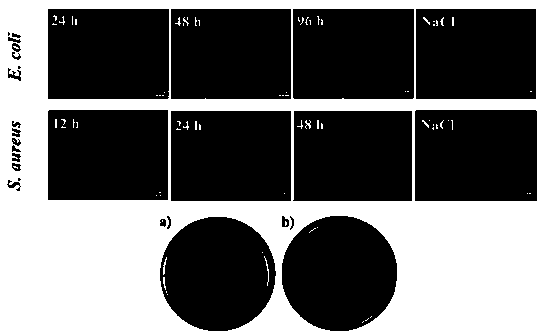

Preparation method of cellulose-based antibacterial material dialdehyde cellulose-lysine

The invention relates to a novel cellulose-based antibacterial material, which is mainly produced via the steps of: controlling reaction temperature, time, pH value and oxidization ratio of dialdehydecellulose in order to perform a reaction to the dialdehyde cellulose and lysine, and when the reaction is finished, performing centrifugal separation and drying and grinding the product. The antibacterial material has excellent antibacterial activity, and can reach 30 mg / ml in minimum inhibitory concentration (MIC) against Gram negative bacteria, such as Escherichia coli, and 7.5 mg / ml in MIC against Gram positive bacteria, such as staphylococcus aureus, with penicillin as a positive control and an LB liquid culture medium as a negative control; under special conditions, the antibacterial material can completely growth of bacteria. The antibacterial material has simple process and is free of toxic and side effect. The raw material, cellulose, has abundant sources and is environment friendly. The invention supplies a new idea for researching and developing novel antibacterial materials.

Owner:江苏灵源沂岸科技股份有限公司

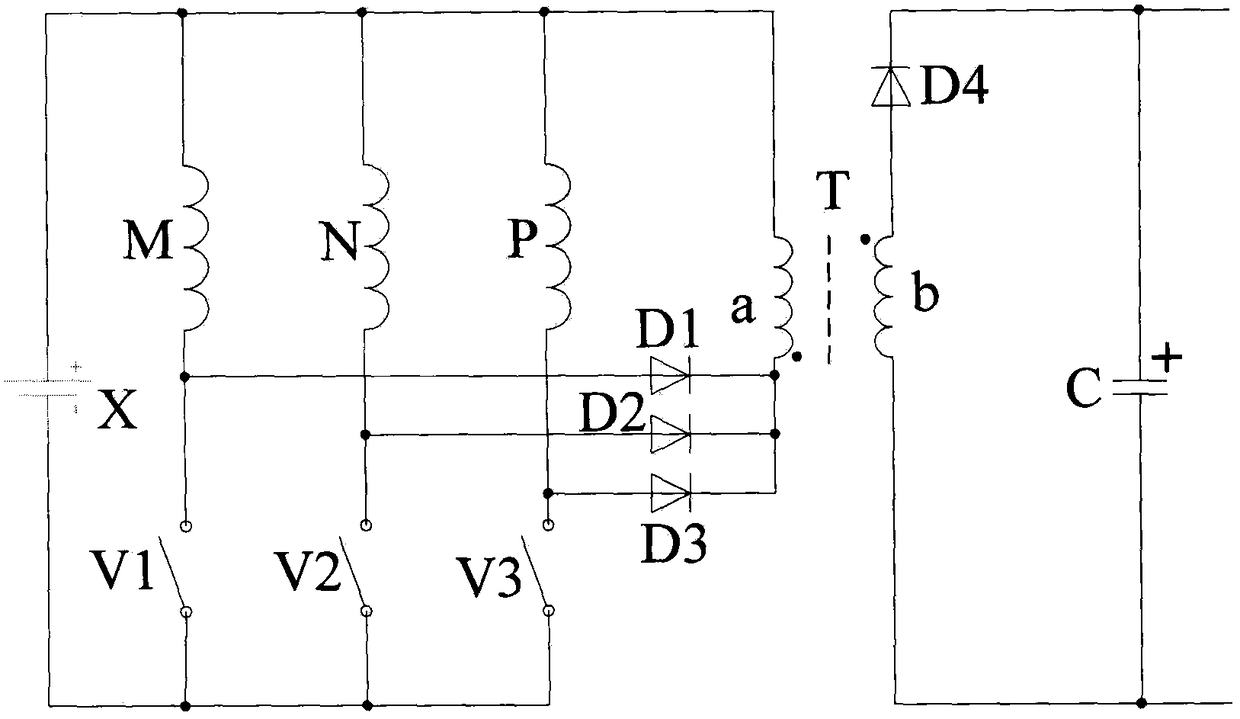

Single power converter system of separately-excited high-gain switch reluctance machine

InactiveCN108448972ASimple structureImprove reliabilityGenerator control by field variationTransformerEngineering

The invention relates to a single power converter system of a separately-excited high-gain switch reluctance machine. Each phase winding is provided with a switch tube and a diode, and the single power converter system is simple in structure and is convenient to control; with the introduction of a transformer, the function of high voltage gain and isolation are helped to be achieved; and except that working condition running of a power generation at two stages of excitation and power generation is simply completed by the power converter, the same control mode can be used as working condition control running of a motor, and the single power converter system is applicable to occasions of various small-power switch reluctance machines / motors.

Owner:CHINA JILIANG UNIV

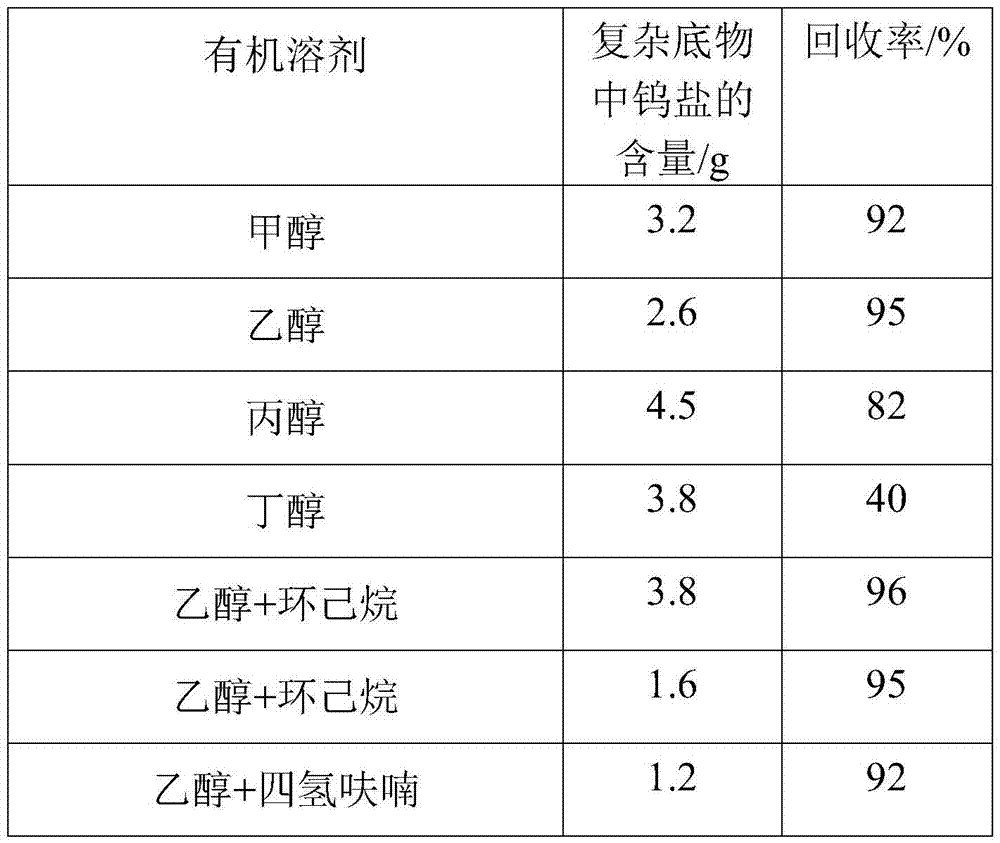

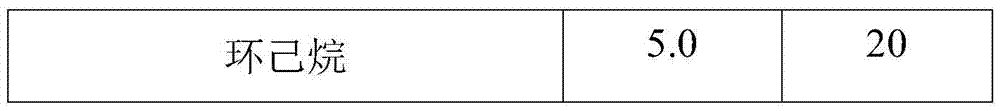

Method of recovering tungsten-based catalyst from complex reaction substrate

ActiveCN106868305ASimple recycling processConvenient and economicalProcess efficiency improvementTungsten compoundsIsopropylene glycolPropylene glycol

In reaction for preparing low-carbon alcohol through catalytic conversion of a carbohydrate compound, a tungsten-based catalyst may be wholly or partly dissolved in a reaction substrate, and is difficult to recover, and the cost of the catalyst is increased. The invention provides a method of recovering the tungsten-based catalyst from a complex reaction substrate. The method is characterized in that the complex reaction substrate is a rectification residual product after the catalytic conversion of the carbohydrate compound, after reaction products are subjected to rectification for separation of glycol and propylene glycol, a kettle bottom residual product is obtained, a boiling point of the kettle bottom residual product is greater than or equal to 200 degrees, and the kettle bottom residual product contains tungsten salt; and through adding an organic solvent to the kettle bottom residual product, the tungsten salt is dissolved out and recovered, fusel having a high boiling point is obtained, and a mass recovery rate of the tungsten salt is greater than or equal to 90%. According to the method, a catalyst recovery process is simple, the catalyst recovery efficiency is high, and the cyclic activity of the tungsten-based catalyst is excellent. In addition, the overall process facilitates operation and industrialized production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

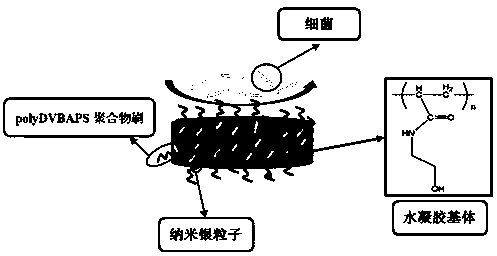

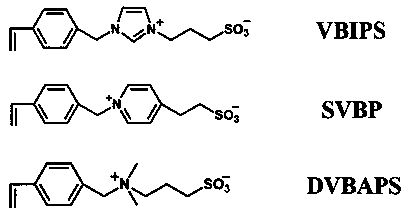

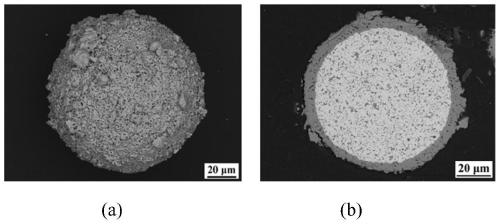

Preparation method of novel hydrogel with low bacterial adhesion and sterilization and regenerable functions

The invention discloses a preparation method of novel renewable hydrogel with low bacterial adhesion and sterilization and regenerable functions and belongs to the technical field of hydrogel preparation. The preparation method specifically comprises steps as follows: 1) a UV polymerization reaction; 2) an esterification reaction; 3) an ATRP reaction; 4) a sliver-supporting reaction. The preparation method is simple and feasible, a polymerization method guarantees the effectiveness and controllability of the length of a functional polymer brush, and the long-time antibacterial effect is realized through slow release of silver ions. The product has a remarkable inhibition effect on escherichia coli and staphylococcus aureus; compared with an antibacterial product containing single components in the prior art, the product has greatly improved antibacterial efficiency. Besides, through the environmental responsibility of the functional polymer brush, shrinkage and extension of the polymerbrush due to the outside environment are changed, desorption of dead bacteria is further driven, and the regenerable antibacterial property of the hydrogel is realized.

Owner:ZHEJIANG UNIV OF TECH

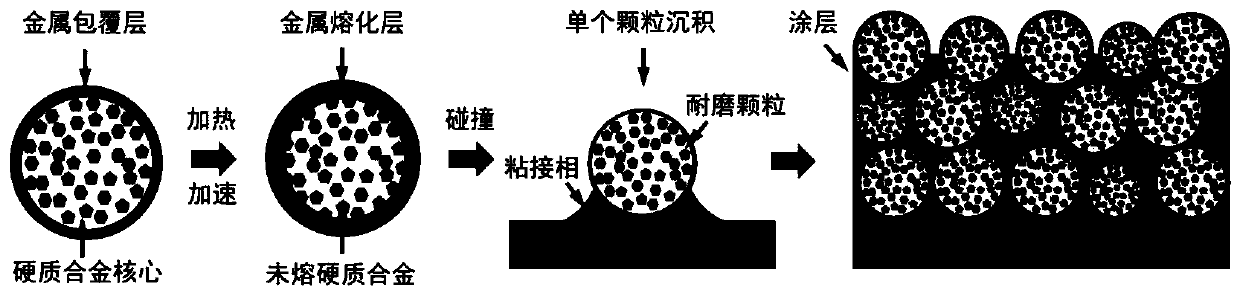

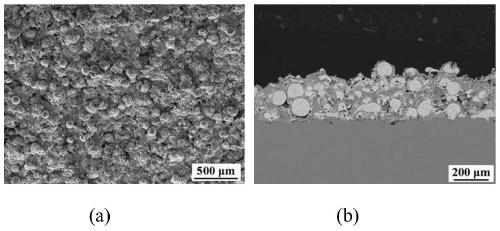

High-roughness reproducible high-friction coefficient wear-resistant coating and preparing method thereof

ActiveCN110434327AImprove performanceIncrease roughnessMolten spray coatingTransportation and packagingWear resistantMetal substrate

The invention discloses a high-roughness reproducible high-friction coefficient wear-resistant coating and a preparing method thereof. 1) metal is used as a coating material, metal ceramic particles are used as a coated material, and the metal ceramic particles are coated with the metal to prepare a spraying powder raw material, wherein the metal as the coating material is the same as the metal used for the metal ceramic particles as the coated material or is similar with the metal used for the metal ceramic particles as the coated material in thermophysical characteristic; and 2) a heat spraying method is adopted to heat the spraying powder raw material prepared in the step 1) until the state that the metal as the coating material is completely melted or nearly completely melted is obtained, semi-molten particles with cores of the metal ceramic particles of the coated material not melted are formed, and the semi-molten particles collide a metal substrate to be sprayed and deposited onthe surface of the metal substrate to form a metal ceramic coating, namely the high-roughness reproducible high-friction coefficient wear-resistant coating. A new method is provided for preparing thehigh-performance long-life high-roughness reproducible metal-based wear-resistant coating.

Owner:XI AN JIAOTONG UNIV

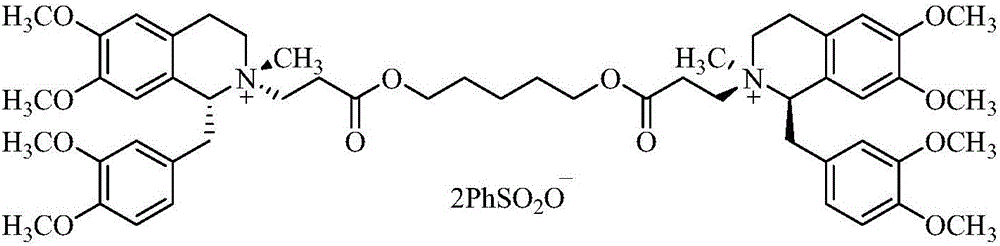

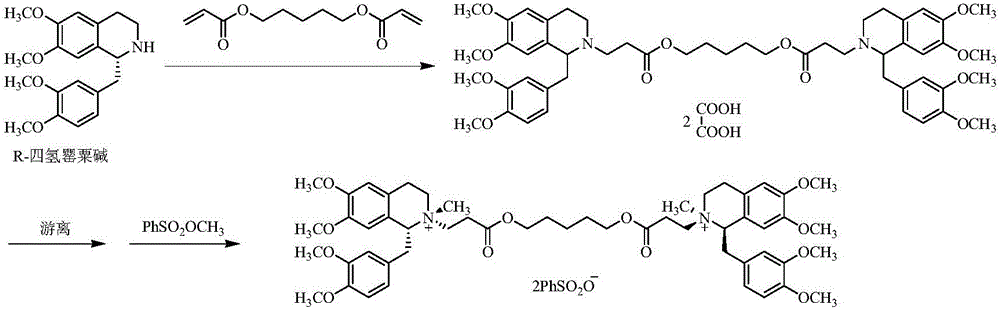

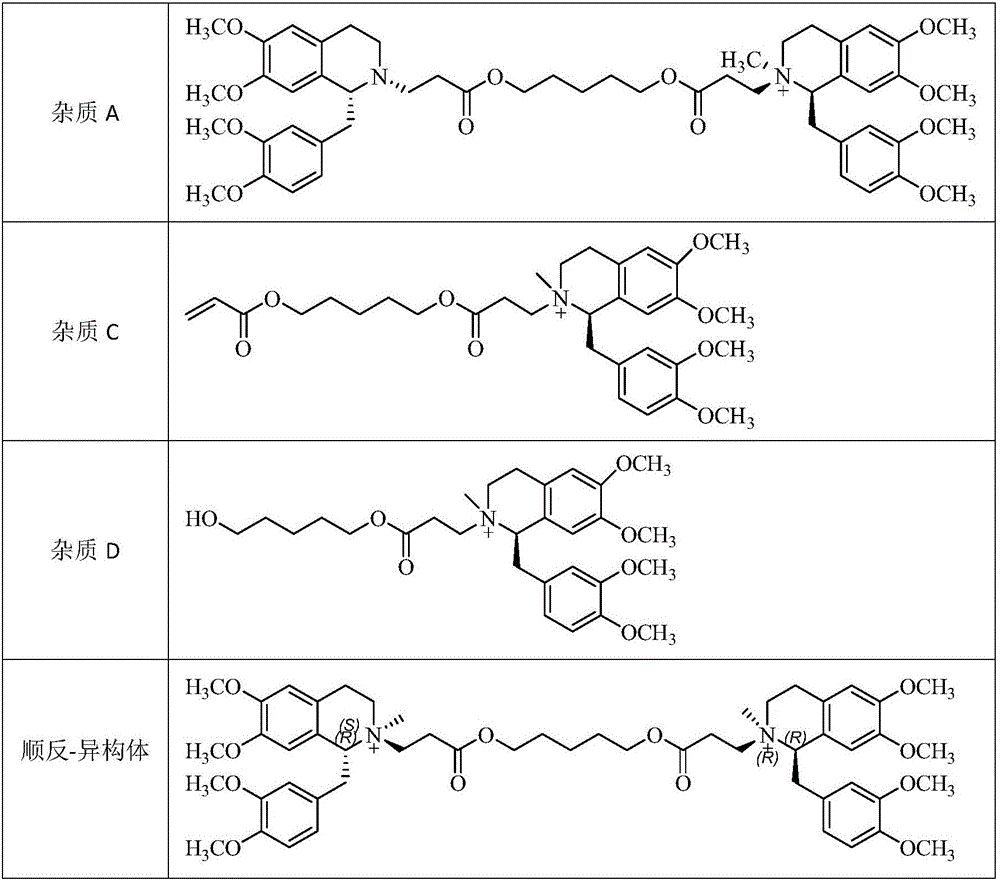

Method for purifying cisatracuriumbesylate

The invention relates to a method for purifying cisatracuriumbesylate. Specifically, the purification method is by using macroporous resin as a filler, eluting impurities by an eluent, then eluting a sample, and collecting an eluate. The samples elution employs a gradient elution method, can effectively separate cis-csi isomers and cis-trans isomer in the sample; at the same time, the method is conducive to the removal of residual methyl benzenesulfonate in the sample, and can effectively obtain the cisatracuriumbesylate product, significantly reduce the residual amount of toxic solvent in the cisatracuriumbesylate product, and significantly improve the medication safety and also reduce the cost of production.

Owner:JIANGSU HENGRUI MEDICINE CO LTD +1

Hybrid industrialized architectural structural system and construction method thereof

InactiveCN106223461ANot easy to collapseImprove seismic performanceWallsGirdersReinforced concrete columnVariable stiffness

The invention discloses a hybrid industrialized architectural structural system and a construction method thereof. The hybrid industrialized architectural structural system comprises a structural system, wherein the structural system is formed by connecting structural columns, structural beams, shear walls and floors; the structural columns are steel columns or concrete filled steel tube columns or steel tube reinforced concrete columns; at least one of the structural beams is a prefabricated variable-stiffness hybrid combination beam; at least one of the shear beams is a prefabricated shear wall; the prefabricated shear wall is connected into a frame structure formed by being enclosed by the structural columns and the prefabricated variable-stiffness hybrid combination beam; the prefabricated variable-stiffness hybrid combination beam comprises a steel skeleton and reinforced concrete blocks arranged on two sides of a web plate of the steel skeleton. By using the hybrid industrialized architectural structural system and the construction method thereof, the technical problems that a conventional cast-in-place concrete structure is poor in shock resistance performance and long in construction time and a conventional steel structure is poor in fire resistance are solved.

Owner:姚攀峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com