Preparation method of novel hydrogel with low bacterial adhesion and sterilization and regenerable functions

A technology of bacterial adhesion and hydrogel, which is applied in the field of preparation of new hydrogels, can solve the problems of high cost and poor antibacterial effect, achieve effective controllable length, improve antibacterial efficiency, and achieve renewable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

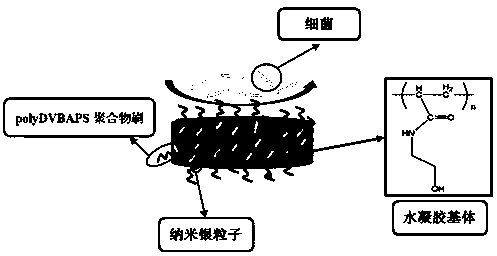

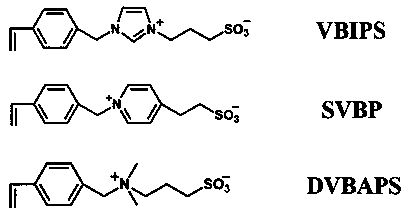

[0027] Example 1: Take a 50 mL beaker, add 1 g HEAA, 0.040 g AIBA, and 0.75 g deionized water in sequence, and after stirring until fully dissolved, transfer the solution to a spare mold, and use a wavelength of 365 nm UV irradiation for 60min to obtain the hydrogel matrix. Take 2 g of the above UV-synthesized hydrogel, add 1.50 g of EDCI, 1.10 g of DMAP, 10 mL of water, and 1.30 g of 3-bromopropionic acid, and stir at room temperature for 24 h to obtain an esterification-treated hydrogel matrix. Take 2 g of the esterified hydrogel (ATRP initiator) after the above treatment, add 0.50 g DVBAPS, 1.25 mL TFE, 2 mL ultrapure water, 6.5 μL Me 6 TREN, 10 mg CuBr, after multiple vacuum pumping-N 2 After cycling, the system was reacted at 25 °C for 24 h. Finally, the above-mentioned grafted hydrogel was placed in AgNO at a concentration of 0.01 mol / L 3 solution, soaked for 24 h, and irradiated with UV light for 30 min to obtain the functional hydrogel, as figure 2 shown.

Embodiment 2

[0028] Example 2: Take a 50 mL beaker, add 1.1 g HEMA, 0.11 g 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, and 0.78 g ultrapure water to it successively, and wait After stirring until fully dissolved, the solution was transferred to a spare mold and irradiated with UV light with a wavelength of 365 nm for 30 min to obtain a hydrogel matrix. Take 2 g of the above UV-synthesized hydrogel, add 1 g of 3-chloropropionic acid, 1.32 g of DCC, 0.68 g of HOBT, and 8 mL of water, and stir at room temperature for 24 h to obtain an esterification-treated hydrogel matrix. Take 2 g of the above esterified hydrogel (ATRP initiator), add 0.50 g of SVBP, 1.8 mL of LTFE, 1 mL of ultrapure water, 6.2 μL of Me 6 TREN, 8 mg CuCl, after multiple vacuum pumping-N 2 After cycling, the system was reacted at 25 °C for 24 h. Finally, the above-mentioned grafted hydrogel was placed in AgNO with a concentration of 0.001 mol / L 3 solution, soaked for 18 h, and irradiated with UV light for 30 min...

Embodiment 3

[0029]Example 3: Take a 50 mL beaker, add 1.3 g HEMA, 0.032 g 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, and 0.73 g deionized water to it successively, and wait After stirring until fully dissolved, the solution was transferred to a spare mold, and irradiated with UV light with a wavelength of 365 nm for 120 min to obtain a hydrogel matrix. Take 2 g of the above-mentioned UV-synthesized hydrogel, add 1.21 g of 3-bromopropionic acid, 1.32 g of EDCI, 1.04 g of DMAP, and 9 mL of water, and stir at room temperature for 12 h to obtain an esterification-treated hydrogel matrix. Take 2 g of the above esterified hydrogel (ATRP initiator), add 0.50 g VBIPS, 1.34 mL TFE, 2.5 mL ultrapure water, 9 mg CuBr, 5.8 μL Me 6 TREN, after multiple vacuum pumping - through N 2 After cycling, the system was reacted at 25 °C for 36 h. Finally, the above-mentioned grafted hydrogel was placed in AgNO at a concentration of 0.05 mol / L 3 solution, soaked for 6 h, and irradiated with UV ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com