Blend, blend film and preparation method thereof, and applications of blend film in supercapacitors

A blending and blending technology, applied in the direction of hybrid capacitor separators, etc., can solve problems such as the decline of mechanical properties, and achieve the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Preparation of methyl polyarylether sulfone (PAES-Me):

[0039]

[0040] 2-methylhydroquinone (HQ-Me), 4,4’-dichlorodiphenylsulfone (DCDPS) and potassium carbonate (K 2 CO 3) into a 250ml three-neck flask according to the molar ratio of 1:1:1, and nitrogen gas was introduced. Measure 100ml of sulfolane (TMS) and 50ml of toluene solution, pour it into a three-necked flask, use a spherical condenser and a water separator to build an experimental device, and install a stirring device. Adjust the temperature of the system to 150°C for three and a half hours, and use toluene to take out the water in the system; then raise the temperature and maintain it at 180°C to make 2-methylhydroquinone (HQ-Me) and 4, 4'-dichlorodiphenyl sulfone (DCDPS) fully polymerized. Observe the viscosity of the system. After about three and a half hours, the viscosity of the system remains stable, and the material starts to be discharged. During the discharging process, the product was po...

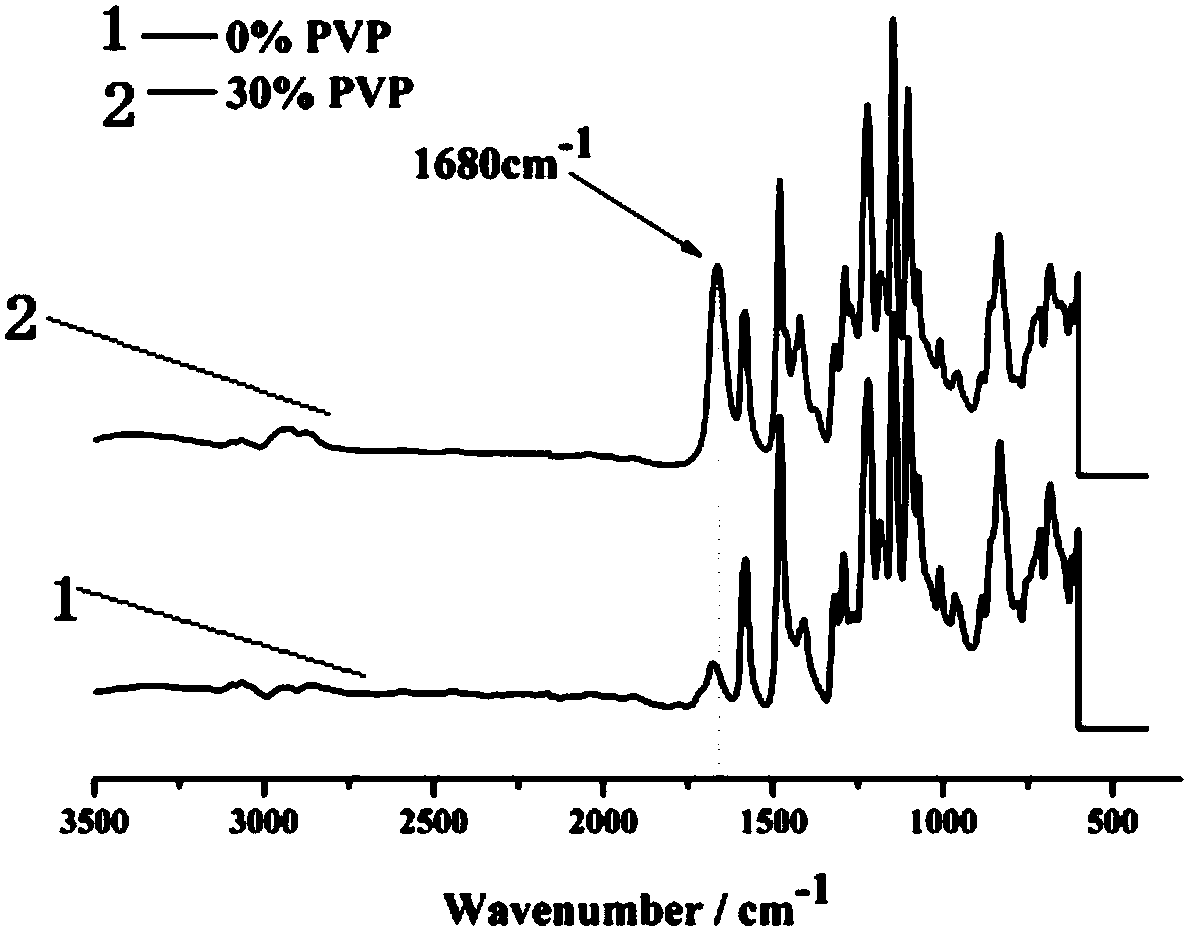

Embodiment 2

[0050] 1) Preparation of methyl polyarylethersulfone (PAES-Me)

[0051] 2-methylhydroquinone (HQ-Me), 4,4’-dichlorodiphenylsulfone (DCDPS) and potassium carbonate (K 2 CO 3 ) into a 250ml three-neck flask according to the molar ratio of 1:1:1, and nitrogen gas was introduced. Measure 100ml of sulfolane (TMS) and 50ml of toluene solution, pour it into a three-necked flask, use a spherical condenser and a water separator to build an experimental device, and install a stirring device. Adjust the temperature of the system to 150°C for three and a half hours, and use toluene to take out the water in the system; then raise the temperature and maintain it at 180°C to make 2-methylhydroquinone (HQ-Me) and 4, 4'-dichlorodiphenyl sulfone (DCDPS) fully polymerized. Observe the viscosity of the system. After about three and a half hours, the viscosity of the system remains stable, and the material starts to be discharged. During the discharging process, the product was poured into a b...

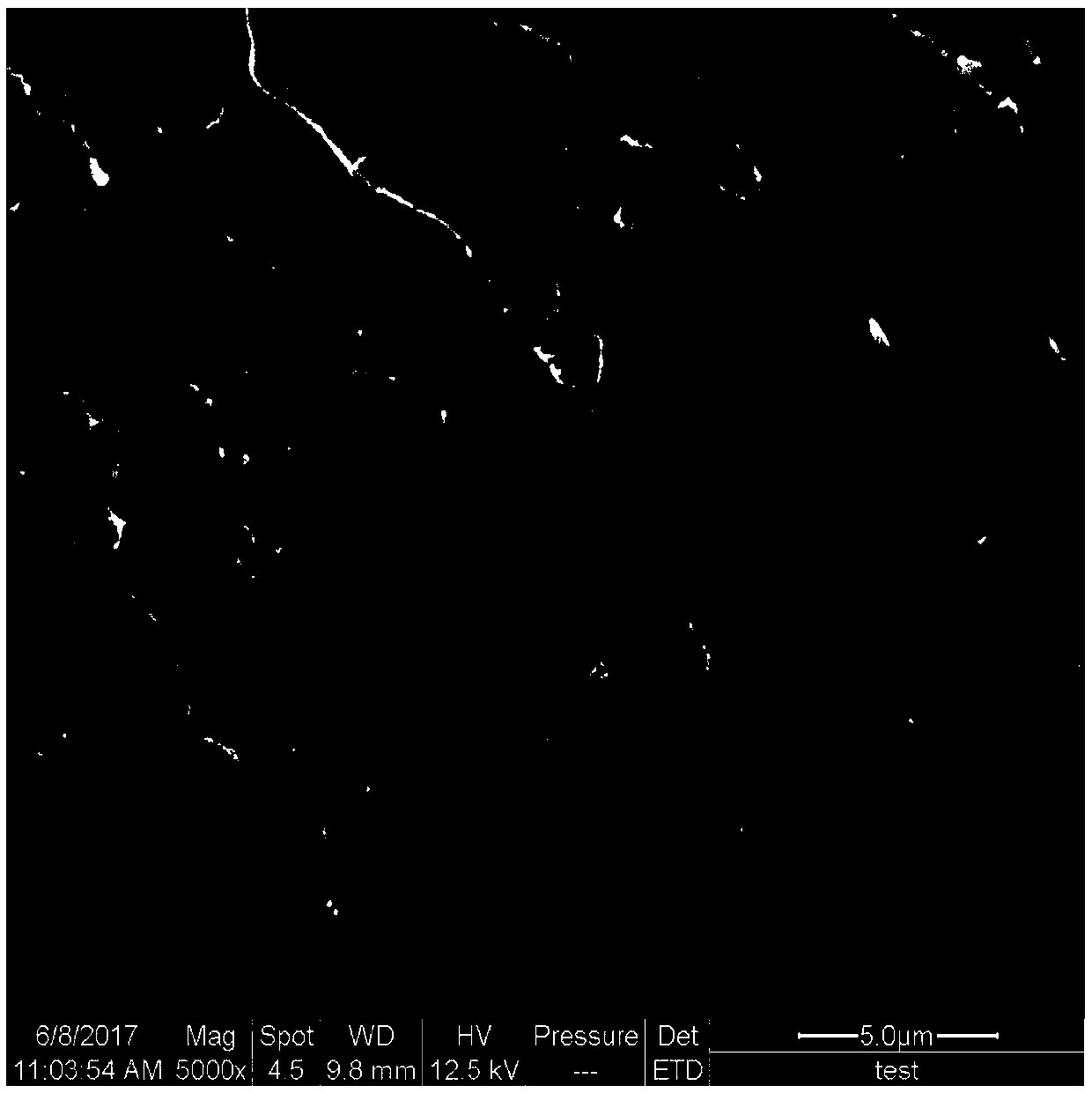

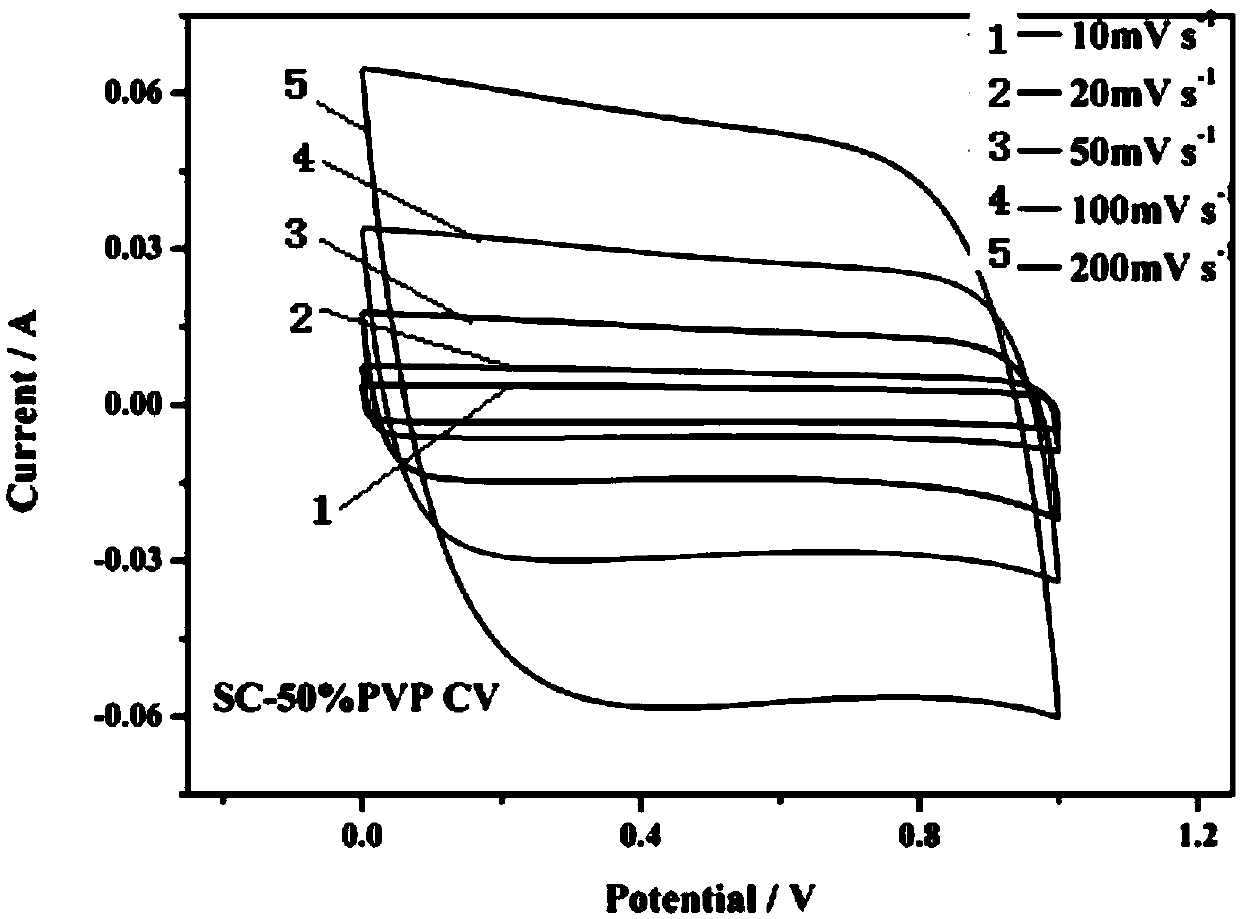

Embodiment 3

[0057] 1) Preparation of methyl polyarylethersulfone (PAES-Me)

[0058] 2-methylhydroquinone (HQ-Me), 4,4'-dichlorodiphenyl sulfone (DCDPS) and potassium carbonate (K2CO3) were packed into a 250ml three-necked flask according to the molar ratio of 1:1:1, Nitrogen was introduced. Measure 100ml of sulfolane (TMS) and 50ml of toluene solution, pour it into a three-necked flask, use a spherical condenser and a water separator to build an experimental device, and install a stirring device. Adjust the temperature of the system to 150°C for three and a half hours, and use toluene to take out the water in the system; then raise the temperature and maintain it at 180°C to make 2-methylhydroquinone (HQ-Me) and 4, 4'-dichlorodiphenyl sulfone (DCDPS) fully polymerized. Observe the viscosity of the system. After about three and a half hours, the viscosity of the system remains stable, and the material starts to be discharged. During the discharging process, the product was poured into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com