A kind of phenolic-based renewable polymer material and its preparation method and regeneration application

A polymer material and phenolic-based technology, which is applied in the field of phenolic-based renewable polymer materials and their preparation, can solve the problems of difficult to meet the application requirements of polyurethane, poor heat resistance and mechanical properties of materials, and material application limitations, etc., to achieve large The effect of degree of freedom, low cost and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a phenolic-based renewable polymer material according to an embodiment of the present invention. The phenolic-based renewable polymer material is formed by the reaction of a thermoplastic phenolic resin and an aromatic polyisocyanate compound, and can be formed by "solid crushing-molding" " process or "tertiary amine aprotic solvent dissolution-precipitation" process to realize its regeneration, and the preparation steps specifically include:

[0044] Step 1: Take 100 parts of thermoplastic phenolic resin and 40 to 1000 parts of organic solvent according to the number of parts by mass, put them in a reaction kettle with a reflux device, stir them to mix them evenly, and obtain a phenolic resin solution, that is, a solution A;

[0045] The second step: for solution A, according to the molar ratio of phenolic hydroxyl group and isocyanate group (10-1): 1, the aromatic polyisocyanate compound is dissolved in an organic solvent to obtain a polyisocyan...

Embodiment 1

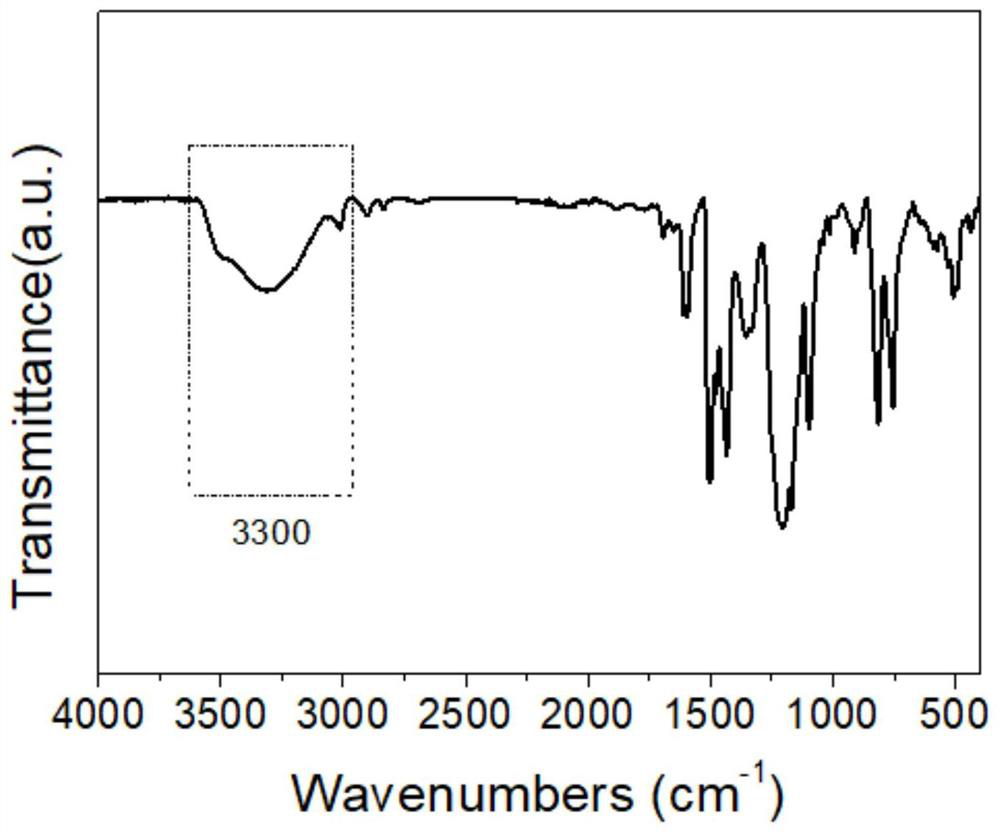

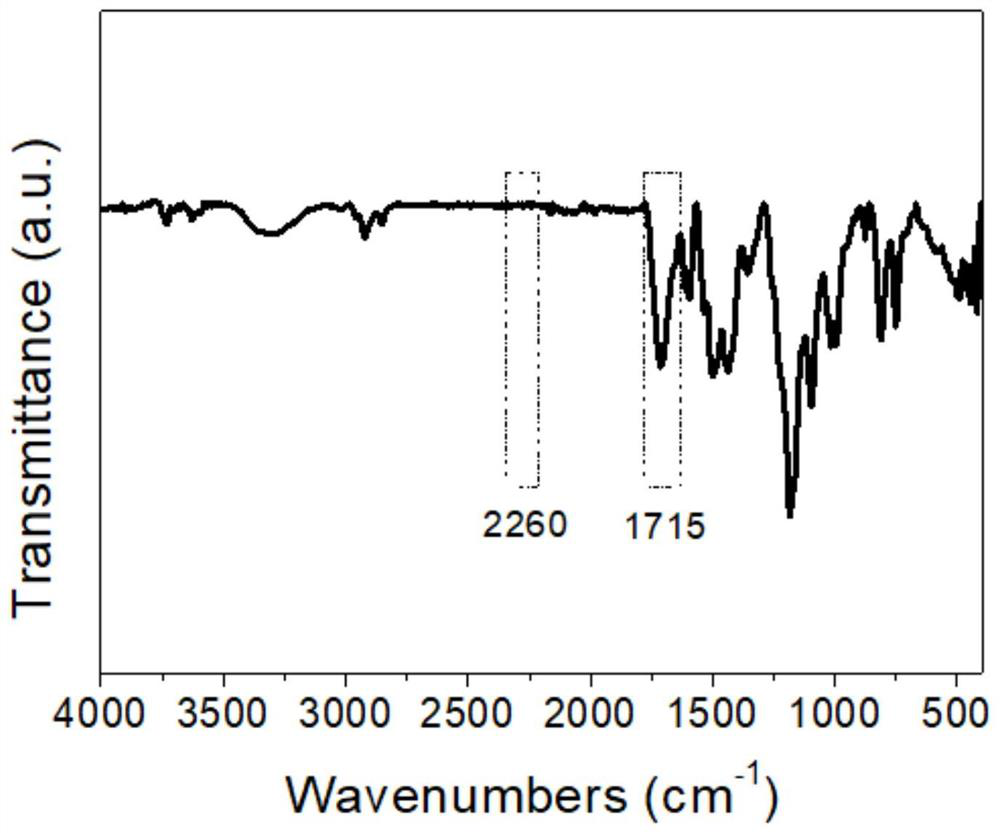

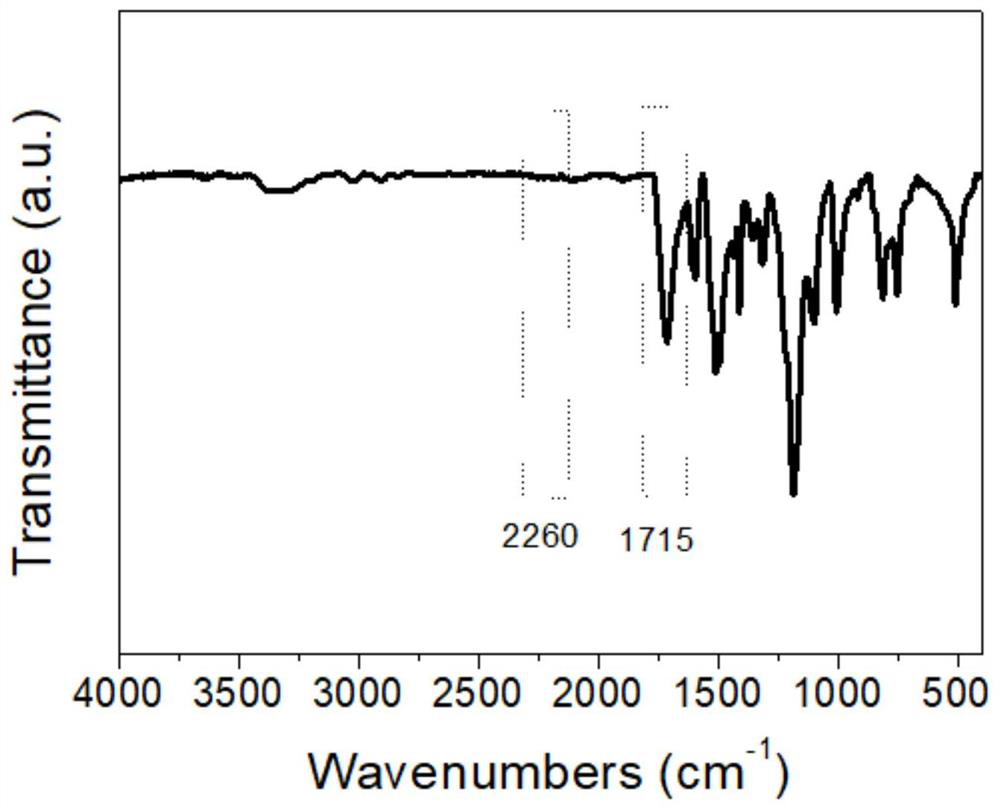

[0066] see figure 1 , in the embodiment of the present invention, the preparation of TDNR2.0: According to the number of parts by mass, add 100 parts of random phenolic resin 8063# and 200 parts of acetone into the reactor with reflux device, stir and mix evenly to obtain phenolic resin Resin solution (solution A); add 41 parts of 2,4-TDI and 41 parts of acetone into a flask with reflux, stir and mix well to obtain solution B; mix solution A and solution B, and stir at room temperature Uniform, when the resin is gelled, move it into a vacuum oven (vacuum degree is 0.01MPa), remove the solvent at 40°C, and obtain a cross-linked polymer material, which is marked as TDNR2.0.

[0067] TDNR2.0 is regenerated through the process of "solid crushing-molding molding": crush TDNR2.0 into powder with a pulverizer, evenly spread the TDNR2.0 powder in the cavity of the metal mold, and mold it at 180°C / 4MPa for 1 hour , to obtain a transparent resin block.

[0068] TDNR2.0 is regenerated ...

Embodiment 2

[0080] In the embodiment of the present invention, the preparation of MDNR2.0: according to the number of parts by mass, add 100 parts of high ortho phenolic resin 3490# and 60 parts of N,N-dimethylformamide into a reaction kettle with a reflux device , stirred and mixed uniformly to obtain a phenolic resin solution (solution A); 59 parts of 4,4'-diphenylmethane diisocyanate and 17.7 parts of N,N-dimethylformamide were added to a flask with reflux , stirred and mixed evenly to obtain solution B; mixed solution A and solution B, stirred evenly at 50°C, moved into a vacuum oven (vacuum degree of 0.01MPa) after the resin gelled, and removed the solvent at 80°C to obtain cross-linked Linked polymer materials, denoted as MDNR2.0.

[0081] The obtained MDNR2.0 has a glass transition temperature of 148° C., a tensile strength of 57 MPa, and a modulus of 1.6 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com