Uninsulated superconducting magnet

A superconducting magnet without insulation technology, applied in the superconducting field, can solve the problems of too strong conductivity, no inter-turn resistance, and unfavorable charging and excitation of superconducting magnets, so as to improve low temperature stability, improve temperature stability, and effectively Conducive to the effects of charging excitation and quench protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

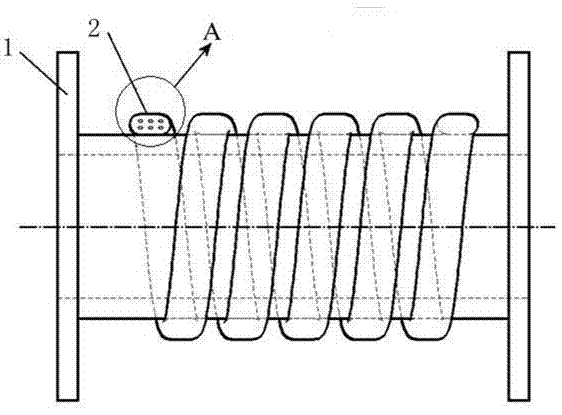

Embodiment 1

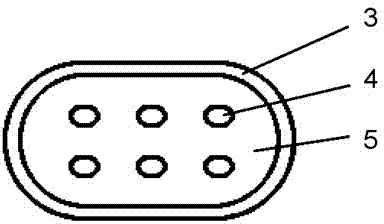

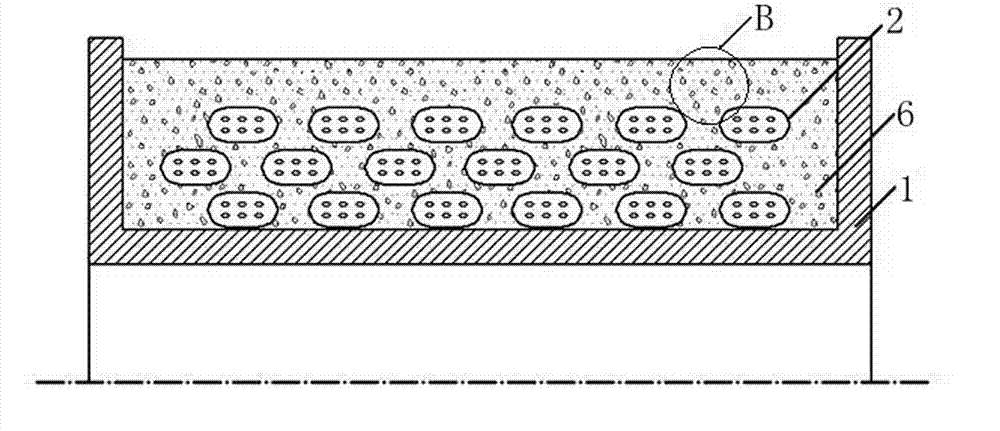

[0042] Wind the superconducting wire on the coil frame, and at the same time spread the surface-activated micron or nano-sized alumina powder in the form of dry powder or wet powder between the turns of the coil, and wind the superconducting wire in a vacuum chamber of 1-100Pa The completed superconducting coil is immersed in the metal tin liquid at 150-300°C, then remove the vacuum, rely on atmospheric pressure, or apply a pressure of 0.1-10MPa at the same time, so that the metal tin liquid is immersed in the inter-turn of the superconducting coil, and the metal is cooled. get a structure like Figure 5 The shown non-insulated superconducting magnets are filled with 1%-99% of aluminum oxide-based heat-conducting materials and 0.1%-99% of metal tin-based materials with both solidification and electrical conductivity by volume percentage. , the amount of pure inorganic curing material is 0%.

[0043] The surface-activated micron or nano-scale alumina powder refers to the use o...

Embodiment 2

[0050] First, micron or nanometer aluminum nitride powder is wetted in tin chloride liquid and air-dried to make a powder with surface activity. The surface of the powder particles is coated with a thin metallic silver conductive layer by electrochemical method to form a conductive layer. The volume ratio of the conductive fine powder is 1%-50%. Since the conductive metal material is only attached to a thin layer on the outer surface of the aluminum nitride powder particle, the larger the aluminum nitride powder particle is, the smaller the relative volumetric gravity of the surface metal is. , the volume ratio of the conductive material in the filling material between turns of the final coil is 0.1%-1%, and the rest is epoxy resin curing material, accounting for about 50%-99% by volume.

[0051] While winding the superconducting coil on the coil frame, apply conductive micropowder between the superconducting coils, put the wound magnet into a vacuum container, control the vacu...

Embodiment 3

[0057] Mix silicon carbide powder with water or shellac into a paste, soak the glass fiber braided paste with silicon carbide thermal conductivity and metal lead conductive powder, wind the glass fiber flat tape with powder attached and the superconductive flat tape side by side to make Superconducting single-cake or double-cake coils, put the wound magnet into a vacuum container, control the vacuum degree at 1-10Pa, use high temperature heating to melt the metal lead of the glass fiber braid, and fuse with the silicon carbide heat-conducting powder Together, inter-turn interlayers with high electrical resistance are formed, resulting in non-insulated superconducting magnets.

[0058] Only a small amount of conductive and thermally conductive materials are impregnated in the thin glass fiber braid, which helps to form a lower turn-to-turn resistance. Usually, the thickness of the glass fiber conductive tape is smaller than that of the superconducting tape. Glass fiber is an at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com