Preparation method of quantum dot film

A quantum dot film and quantum dot technology, applied in the field of quantum dots, can solve problems such as inability to achieve quantum dot cross-linking, and achieve the effects of excellent electrical conductivity and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

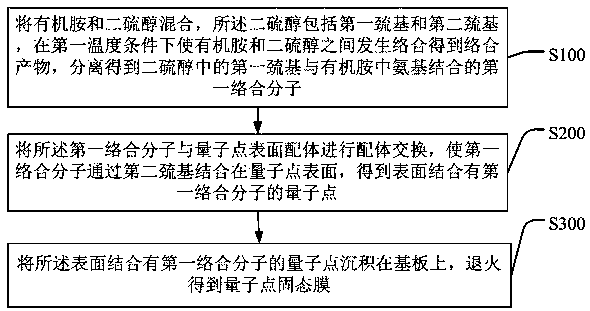

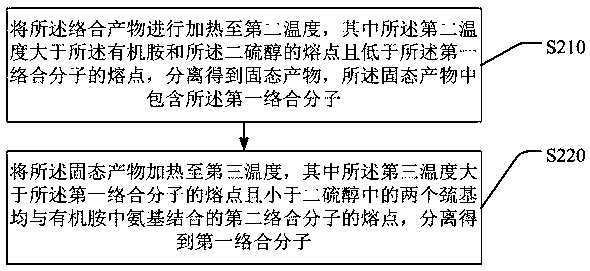

Method used

Image

Examples

Embodiment 1

[0037] Taking CdSe / ZnS oil-soluble quantum dots, ethanedithiol, and octylamine as examples to prepare quantum dot films:

[0038] 1) Preparation of complex molecules: Take 100mmol of ethanedithiol and 150mmol of octylamine, mix and stir at room temperature for a certain period of time, use a separatory funnel to separate excess ethanedithiol and octylamine at room temperature, and then The temperature of the separated solution was raised to 40° C., and separated again using a separatory funnel to obtain a complex molecule of ethanedithiol and octylamine containing only one mercapto group;

[0039] 2) Preparation of quantum dots with complex molecules on the surface: Take 100 mg of CdSe / ZnS quantum dot solution and disperse it into 10 ml of toluene solution, and then take 5 mmol of complex molecules of ethanedithiol and octylamine containing only one mercapto group Adding to the quantum dot mixed solution, stirring at room temperature for 30 minutes to fully exchange, to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com