Plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and preparing method thereof

A technology of phenolic foam material and plant fiber, which is applied in the field of preparation of plant fiber reinforced phenolic foam material and thermal insulation and flame retardant phenolic foam material, can solve the problems of polluting the environment and wasting resources, and achieves simple preparation method and short foaming time , good thermal insulation and flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

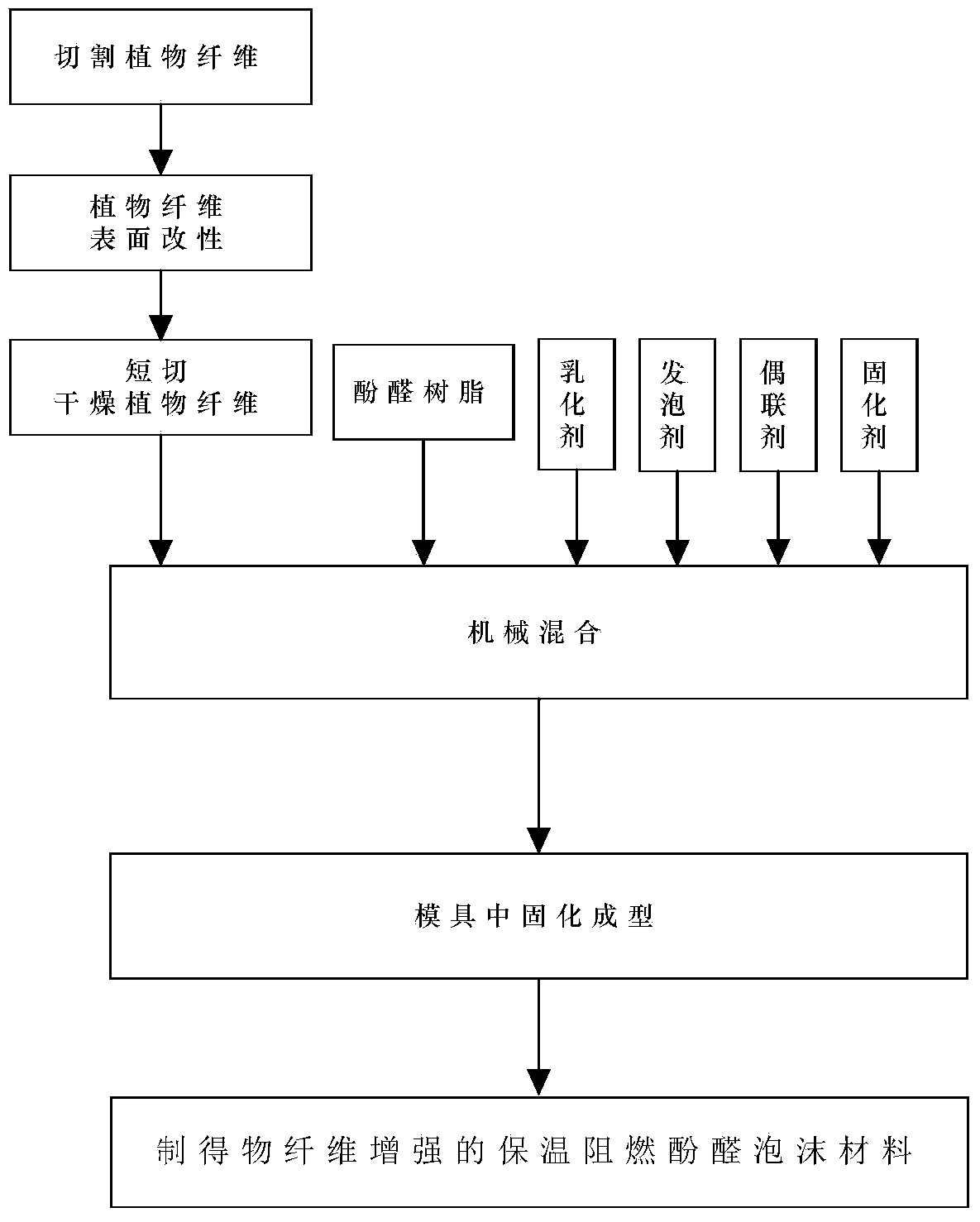

Method used

Image

Examples

Embodiment 1

[0060] Example 1 Production of Corn Stalk Fiber Reinforced Phenolic Foam Composite Material

[0061] Step 1: Pretreatment of Corn Stalks

[0062] Step 101: first put the corn stalks with a water content lower than 10% into a corer separator to remove the core layer inside the stalk (the main component of the corn stalk core layer is lignin, which is an unnecessary substance in the present invention), and then Cut into the first chopped fibers with a length of less than or equal to 1mm in a cutting machine; then, place the first chopped fibers in a 10% NaOH aqueous solution at a temperature of 22° C., at a stirring speed of 60 rpm After soaking for 60 minutes under the condition of 1 / min, take it out, wash it repeatedly with deionized water to neutrality, and obtain the A pretreated plant fiber; finally, place the A pretreated plant fiber at a temperature of 30° C. and the mass percentage concentration is 50%. In the flame retardant aqueous solution, after soaking for 75 minut...

Embodiment 2

[0088] Example 2 Manufacture of long wheat straw fiber reinforced phenolic foam composite material

[0089] Step 1: Pretreatment of long straw fibers

[0090] Step 101: First, cut the long wheat straw fibers with a moisture content of less than 5% into first chopped fibers with a length of less than or equal to 1mm with a cutting machine; In the NaOH aqueous solution with a concentration of 20%, after soaking for 40 minutes at a stirring speed of 55 rpm, take it out, wash it repeatedly with deionized water to neutrality, and obtain A pretreated plant fiber; finally, A pretreated Plant fibers are placed in a diammonium phosphate aqueous solution with a mass percentage concentration of 65% at a temperature of 25°C, soaked for 40 minutes at a mechanical stirring speed of 55 rpm, then taken out, and placed in an oven at a temperature of 60°C Drying and processing for 180 minutes to obtain A ready-to-use chopped plant fibers;

[0091] Step 102: First, cut the long wheat straw fib...

Embodiment 3

[0107] Example 3 Making the phenolic foam composite material reinforced by Ulagrass fiber

[0108] Ulagrass is one of the only two plants in the world's plant kingdom that can resist fungal erosion and parasitic ability for life, which is a natural attribute that ordinary animal and plant products do not have. Ulagrass has an excellent ability to absorb and not be eroded, it can absorb moisture, and automatically adjust and maintain the degree of humidity. Applying this plant fiber to the development of phenolic foam, the mechanical properties, thermal insulation performance and weather resistance of phenolic foam are expected to be improved.

[0109] Step 1: Pretreatment of Ulagrass

[0110] Step 101: first cut the Ulagrass fiber with a moisture content of less than 5% into first chopped fibers with a length less than or equal to 1 mm by cutting machine; then place the first chopped fibers at a temperature of 20° C. In a 5% NaOH aqueous solution, after soaking for 90 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com