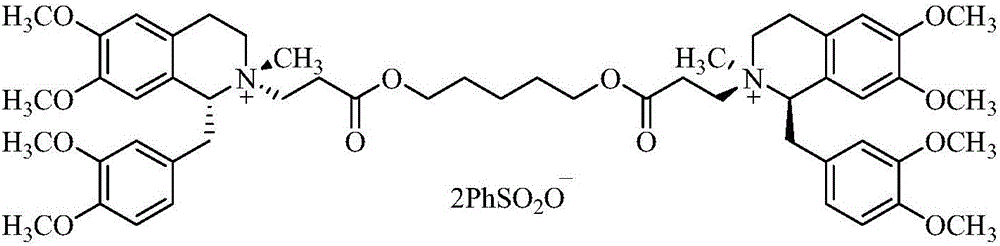

Method for purifying cisatracuriumbesylate

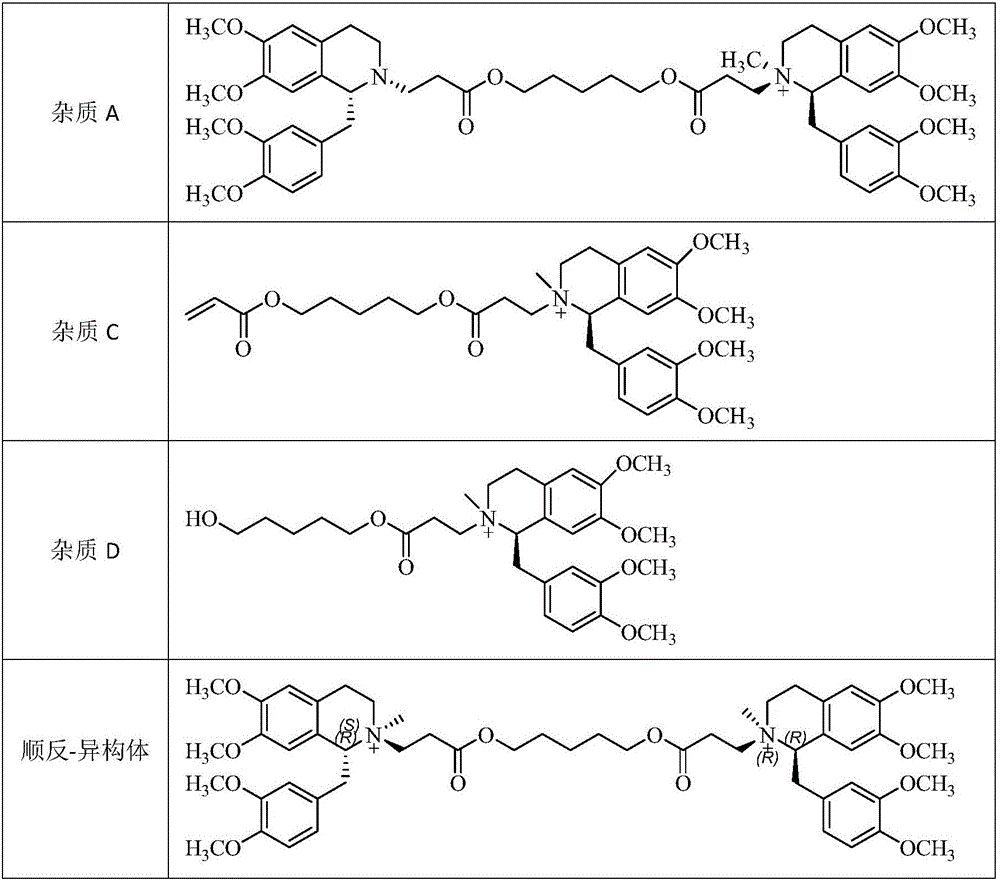

A technology of cistracurium besylate and a purification method, which is applied in the purification field of cistracurium besylate, can solve the problems of high cost, low production capacity, complicated technological process, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

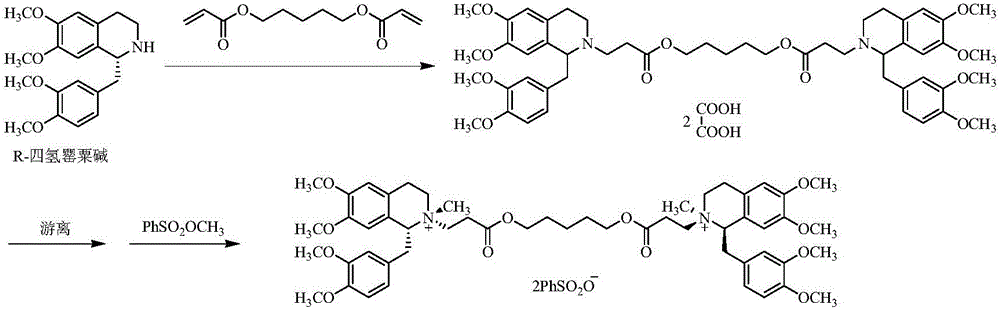

[0038] Embodiment 1: the preparation of citracurium besylate crude product (with reference to WO92 / 00965)

[0039] a) Preparation of Condensate Oxalate (3)

[0040]

[0041] (R)‐1,2,3,4‐tetrahydropapaverine N‐acetylleucine salt (2,180g, 98.6%, 0.348mol) was dissolved in 2700ml of water and treated with ammonia water to adjust the pH value to 9‐10. After the precipitate was filtered with suction, toluene (900ml×3) was added, the combined toluene layer was washed with deionized water (900ml×3), dried over anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure to obtain oil 3 (123.6g). (R)‐1,2,3,4‐tetrahydropapaverine was reacted with 1,5‐pentamethylene diacrylate (33g, 0.156mol) and toluene (180ml) at 80°C for 48 hours. The reaction solution was concentrated to obtain 3 as a yellow oil. The product was dissolved in ethanol (360ml) and treated with oxalic acid (37.5g, 0.417mol) in ethanol (360ml) to give a white precipitate as the condensate oxalate...

Embodiment 2

[0044] Embodiment 2: DiaionHP20ss resin purifies citracurium besylate

[0045] Use DiaionHP20ss type macroporous adsorption resin 150g to pack chromatography column (effective column height 50cm, inner diameter 6cm), wash a moment with eluent, the composition of this eluent is deionized water: benzenesulfonic acid (500ml: 1g), column Cool with ice water and keep the column temperature below 5°C. Dissolve 10g of cistracurium benzenesulfonate crude product with pre-cooled eluent and put it on the column, and carry out gradient elution after half an hour of elution, and gradually add 1‐6% isopropanol for gradient elution during the elution process, until When the product component appears, continue to elute with eluent (deionized water: isopropanol: benzenesulfonic acid (100m: 6ml: 1g), and start to collect the component solution containing citracurium benzenesulfonate at the same time, and combine the components containing After all the components of cistracurium benzenesulfona...

Embodiment 3

[0046] Embodiment 3: DiaionHP20 resin purifies citracurium benzenesulfonate

[0047] Use HP20 type macroporous resin 150g to pack chromatography column (effective column height 50cm, internal diameter 6cm), wash a moment with eluent, the composition of eluent is deionized water: benzenesulfonic acid (500ml: 1g), the column passes through Cool with ice water and keep the column temperature below 5°C. Dissolve 10g of cistracurium benzenesulfonate crude product with pre-cooled eluent and put it on the column, and carry out gradient elution after half an hour of elution, and gradually add 1‐6% isopropanol for gradient elution during the elution process, until When product component occurs, continue eluting with eluent (deionized water: isopropanol: benzenesulfonic acid (100ml: 6ml), begin to collect the component solution that contains citracurium benzenesulfonate simultaneously, add two after merging Extract with methyl chloride, wash with water to remove excess benzenesulfonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com