Hybrid industrialized architectural structural system and construction method thereof

A technology of building structure and construction method, applied in building components, building structure, truss structure, etc., can solve the problems of long construction time, poor fire resistance, poor seismic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

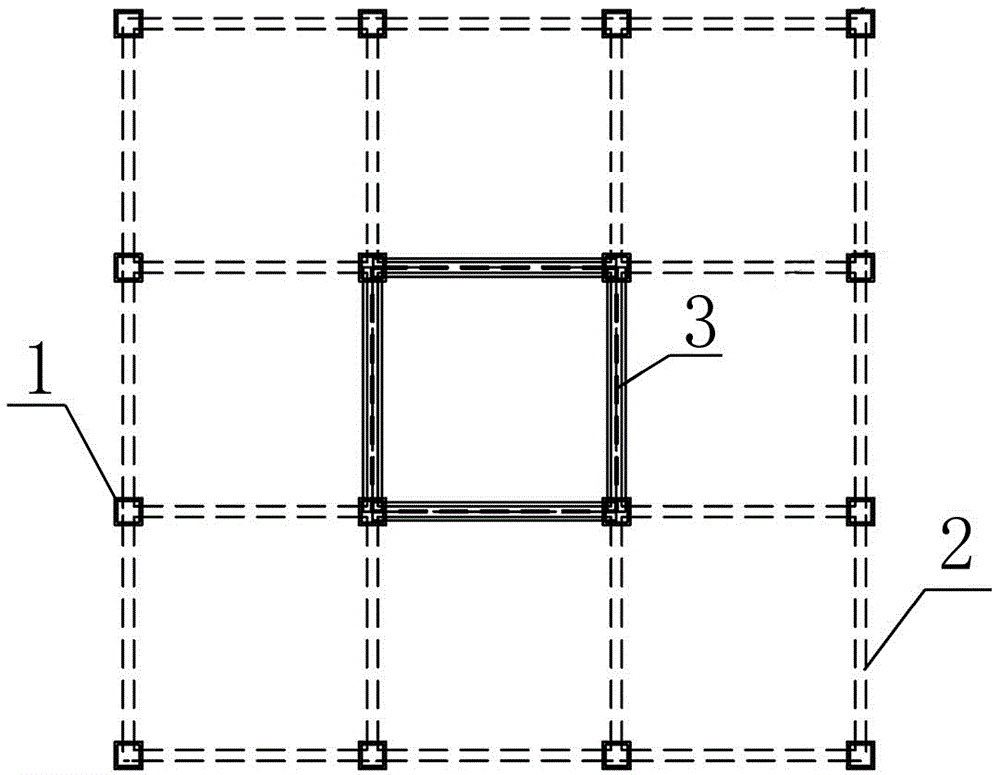

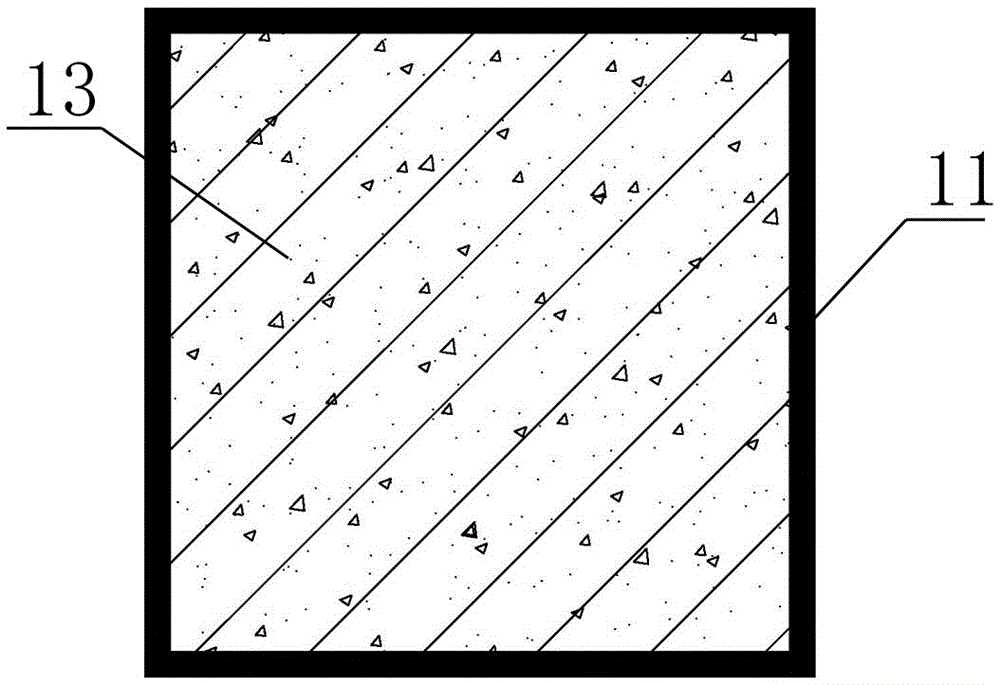

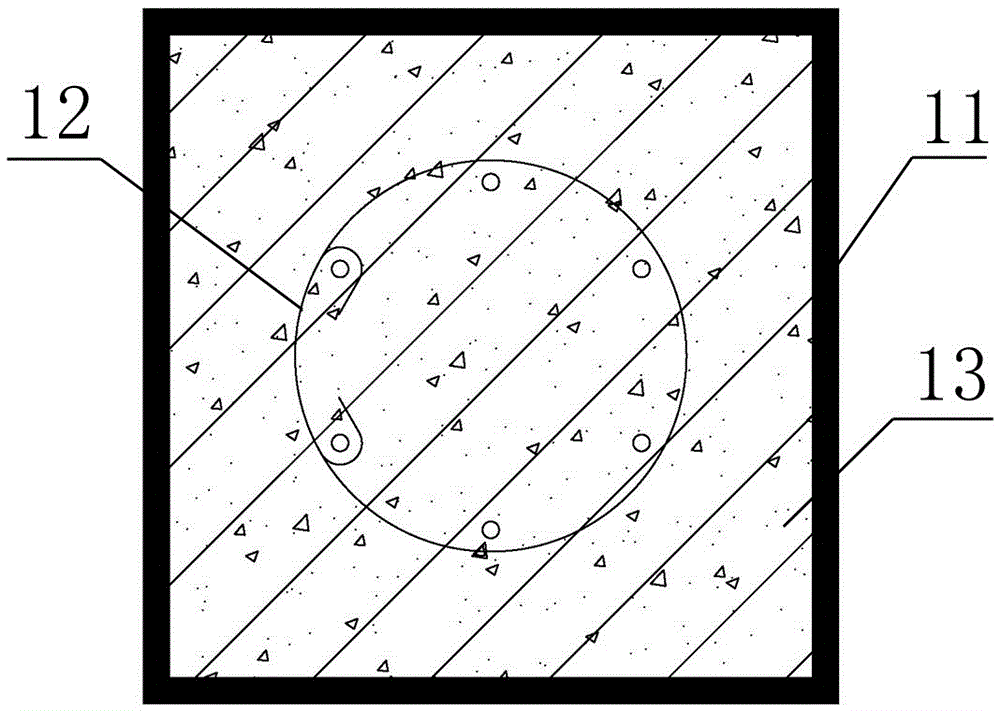

[0095] This hybrid industrial building structure system includes a structural system composed of structural columns 1, structural beams, shear walls and floor slabs 4 connected, the structural column 1 is a steel column or a steel tube concrete column or a steel tube reinforced concrete column; the structure At least one of the beams is a prefabricated variable stiffness composite beam 2; at least one of the shear walls is a prefabricated shear wall 3; the prefabricated shear wall 3 is connected to the structural column 1 and the prefabricated variable stiffness composite beam In the frame structure enclosed by beams 2; the prefabricated variable stiffness hybrid composite beam 2 includes a steel skeleton 21 and reinforced concrete blocks 22 arranged on both sides of the web of the steel skeleton 21; the steel skeleton includes upper, The lower flange plate and the web plate connected between the upper and lower flange plates near the middle of the flange plate; the reinforced ...

Embodiment 2

[0118] This hybrid industrial building structure system includes a structural system composed of structural columns 1, structural beams, shear walls and floor slabs 4 connected, the structural column 1 is a steel column or a steel tube concrete column or a steel tube reinforced concrete column; the structure At least one of the beams is a prefabricated variable stiffness composite beam 2; at least one of the shear walls is a prefabricated shear wall 3; the prefabricated shear wall 3 is connected to the structural column 1 and the prefabricated variable stiffness composite beam In the frame structure enclosed by beams 2; the prefabricated variable stiffness hybrid composite beam 2 includes a steel skeleton 21 and reinforced concrete blocks 22 arranged on both sides of the web of the steel skeleton 21; the steel skeleton includes upper, The lower flange plate and the web plate connected between the upper and lower flange plates near the middle of the flange plate; the reinforced ...

Embodiment 3

[0142]This hybrid industrial building structure system includes a structural system composed of structural columns 1, structural beams, shear walls and floor slabs 4 connected, the structural column 1 is a steel column or a steel tube concrete column or a steel tube reinforced concrete column; the structure At least one of the beams is a prefabricated variable stiffness composite beam 2; at least one of the shear walls is a prefabricated shear wall 3; the prefabricated shear wall 3 is connected to the structural column 1 and the prefabricated variable stiffness composite beam In the frame structure enclosed by beams 2; the prefabricated variable stiffness hybrid composite beam 2 includes a steel skeleton 21 and reinforced concrete blocks 22 arranged on both sides of the web of the steel skeleton 21; the steel skeleton includes upper, The lower flange plate and the web plate connected between the upper and lower flange plates near the middle of the flange plate; the reinforced c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com