Positive electrode material, positive electrode comprising same, and electrochemical device comprising positive electrode material

A positive electrode material and coating technology, applied in electrochemical generators, positive electrodes, inorganic chemistry, etc., can solve the problems of easily broken particles, limited application, high bulk density, etc., to reduce side reactions and achieve excellent structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation method of cathode material

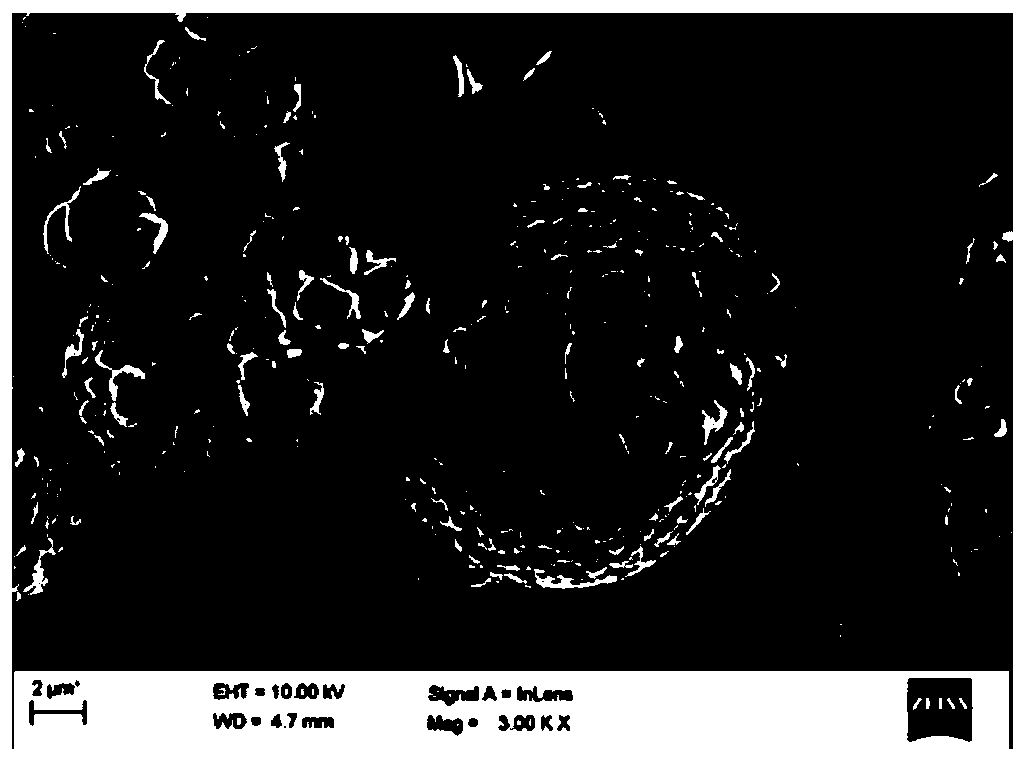

[0056] According to some embodiments of the present application, the cathode material may be prepared by forming first particles, forming second particles, and uniformly mixing the first particles and the second particles.

[0057] Forming the first particle: mix the first precursor, lithium (Li) source, and the first doping element according to the stoichiometric ratio of the first lithium-containing transition metal oxide and dry them. The calcining is carried out once for about 14h to about 18h to form the first particles composed of the third particles.

[0058] Forming the second particle: mix the second precursor, lithium source, and the second doping element uniformly according to the stoichiometric ratio of the second lithium-containing transition metal oxide and dry it once at about 820°C to about 880°C after drying. Calcining for about 14 hours to about 18 hours to form second particles consisting of fourth particles. ...

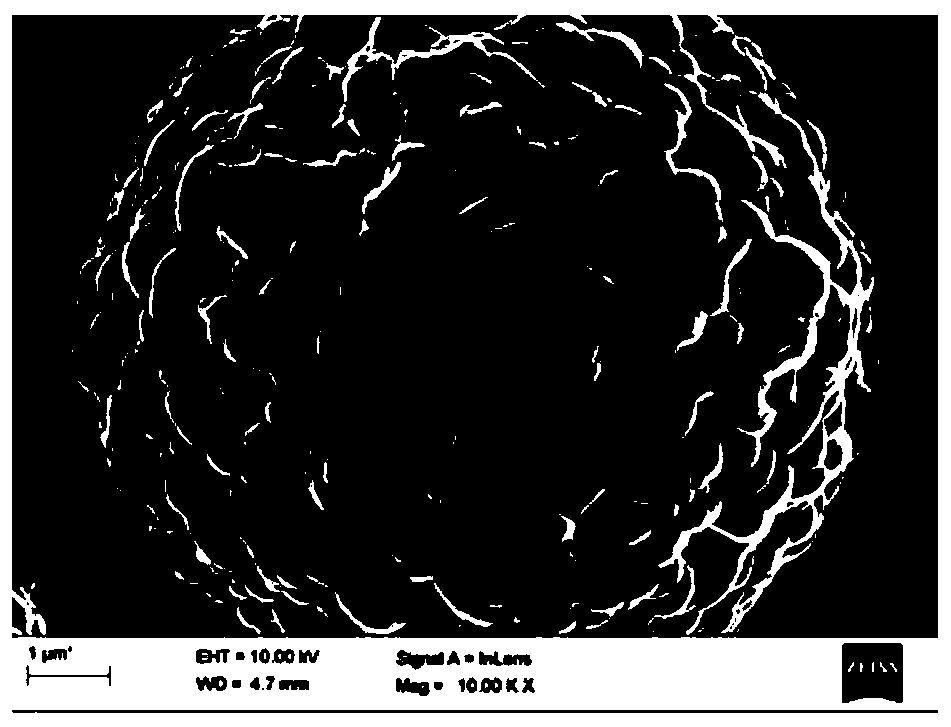

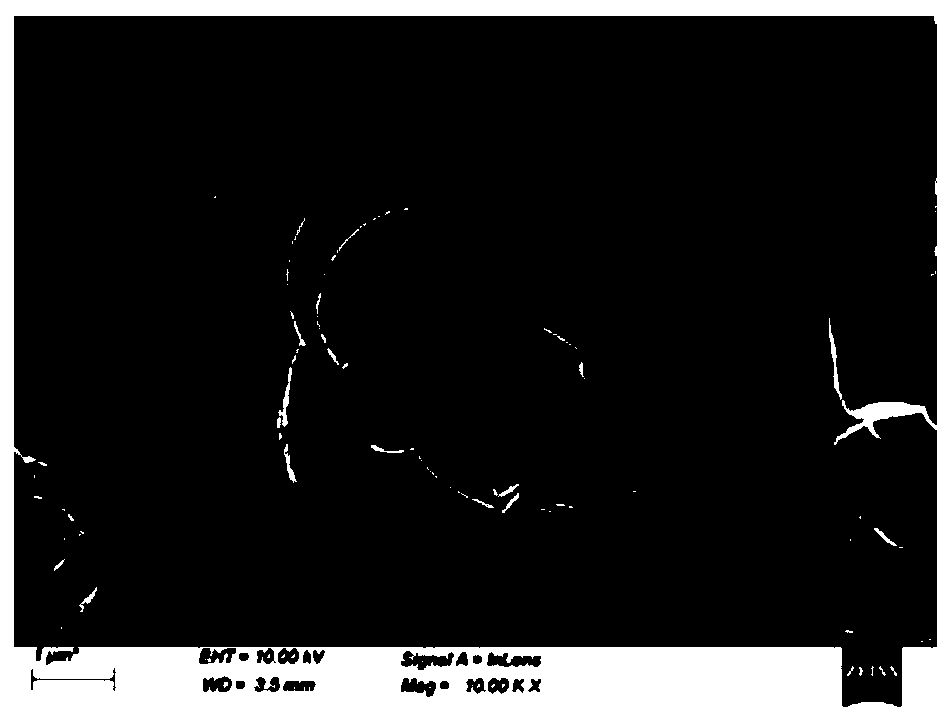

Embodiment 1

[0087] According to LiNi 0.84 co 0.08 mn 0.05 Mg 0.03 o 2 (First transition metal oxide) stoichiometric ratio Prepare the first NCM precursor, lithium hydroxide (LiOH) and nano-magnesium oxide (MgO) with a Dv50 of 9 μm, and mix them uniformly and dry them, and after drying, heat them at 800 °C Calcination was carried out once for 16 hours at the same time to obtain the first particles (Dv50 of 11.5 μm) composed of the third particles (Dv50 of 0.6 μm). Then, the first particles were mixed with aluminum hydroxide (Al(OH) 3 ) after being evenly mixed, pre-coated at 600° C. for 6 hours by secondary calcination, and the molar percentage of aluminum was 0.3%; then the first particle after pre-coating was mixed with boric acid (H 3 BO 3 ) mixed evenly, and sintered at 400° C. for 4 hours to carry out boron coating, the mole percentage of boron is 0.3%, and finally the coated first particle is obtained.

[0088] According to LiNi 0.85 co 0.08 mn 0.05 Mg 0.02 o 2 (The stoic...

Embodiment 2- Embodiment 4

[0096] The preparation method of Example 2-Example 4 is the same as that of Example 1, except that the mass ratio of the first particle to the second particle is different, and the specific mass ratio is shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com