Patents

Literature

69results about How to "Thin and uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoshells and Discrete Polymer-Coated Nanoshells, Methods For Making and Using Same

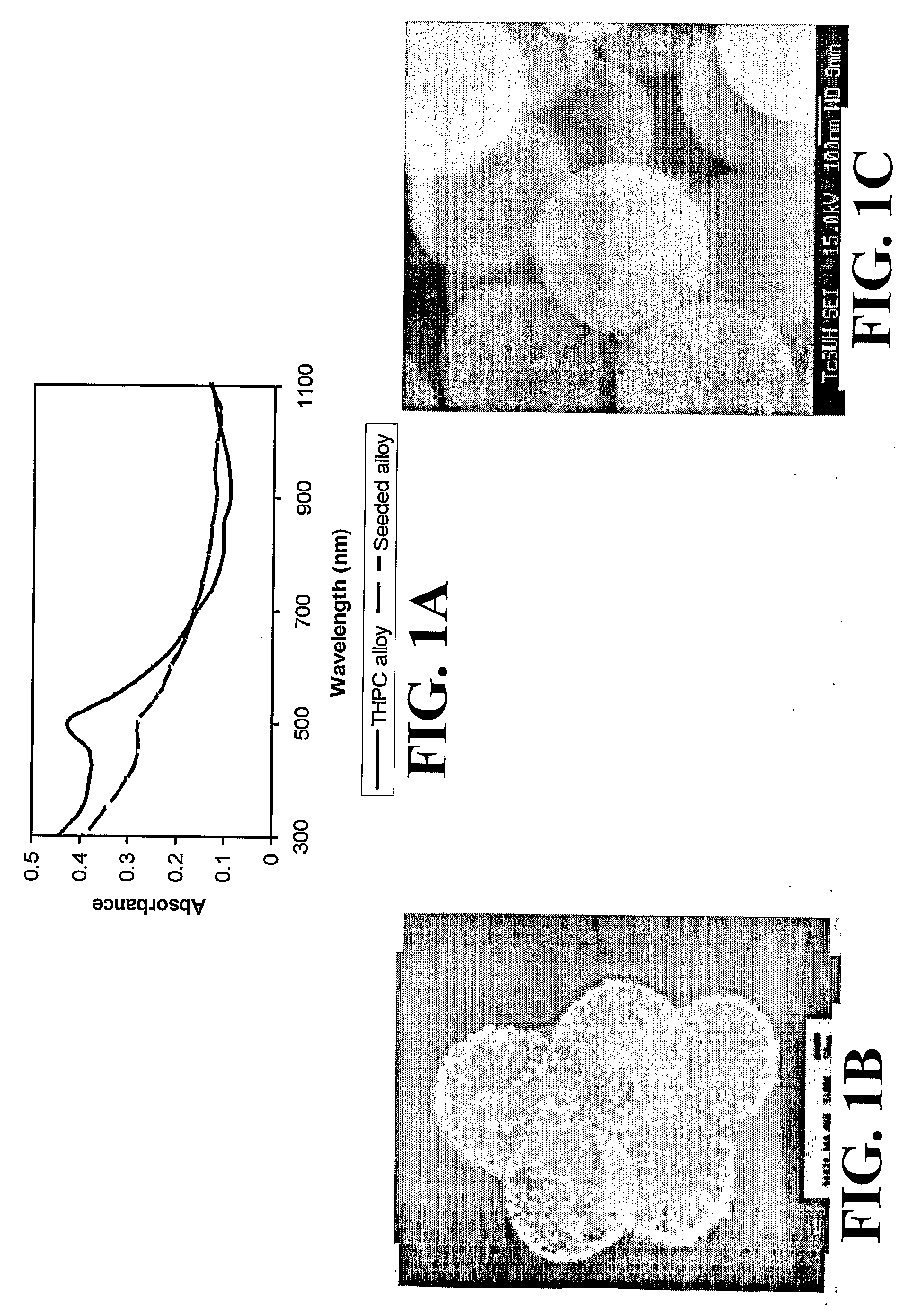

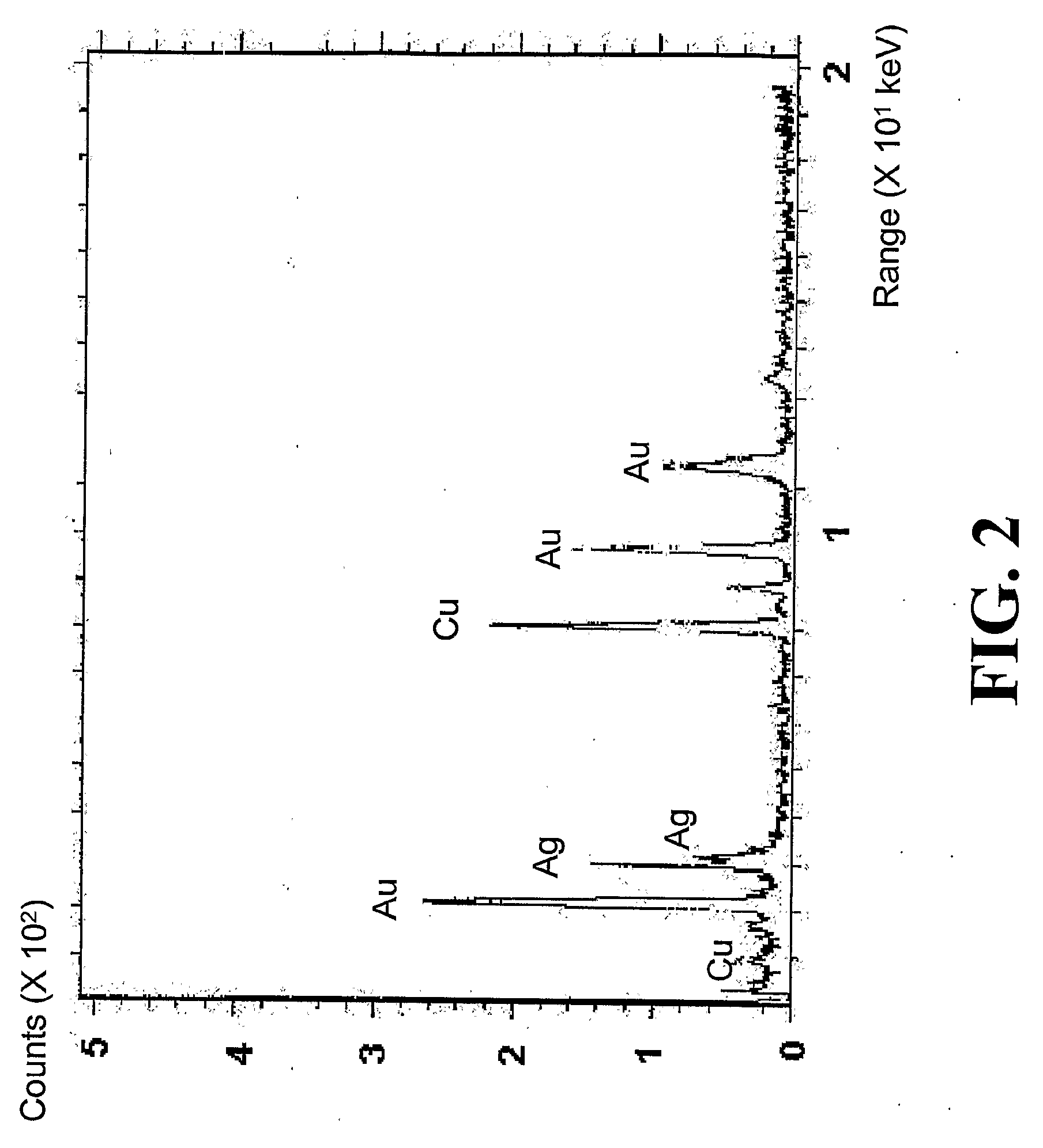

InactiveUS20080241262A1Increasing kill efficacySimilar and improved opticalPowder deliveryMaterial nanotechnologyOxideElectromagnetic radiation

Nano-structures are disclosed that are ideally suited for microelectronics, medical treatment, drug-delivery systems, targeted thermal absorption media, or other similar applications, where the nano-particles include metal oxide nano-particles and metallic nano-particles including a metallic nano-shell or metallic nano-rods deposited on the surface of the nano-particles or nano-shell nano-particles including metallic nano-rods deposited on the surface of the nano-particles and where the nano-structures have a plasmon resonance. For in vivo medical applications, the plasmon resonance is tuned to a tissue-transparent frequency range. Hydrogel-coated nanostructures are also disclosed, which are capable of transitioning between a non-collapsed hydrogel and a collapsed hydrogel via thermal activation induced by electromagnetic irradiation.

Owner:UNIV HOUSTON SYST

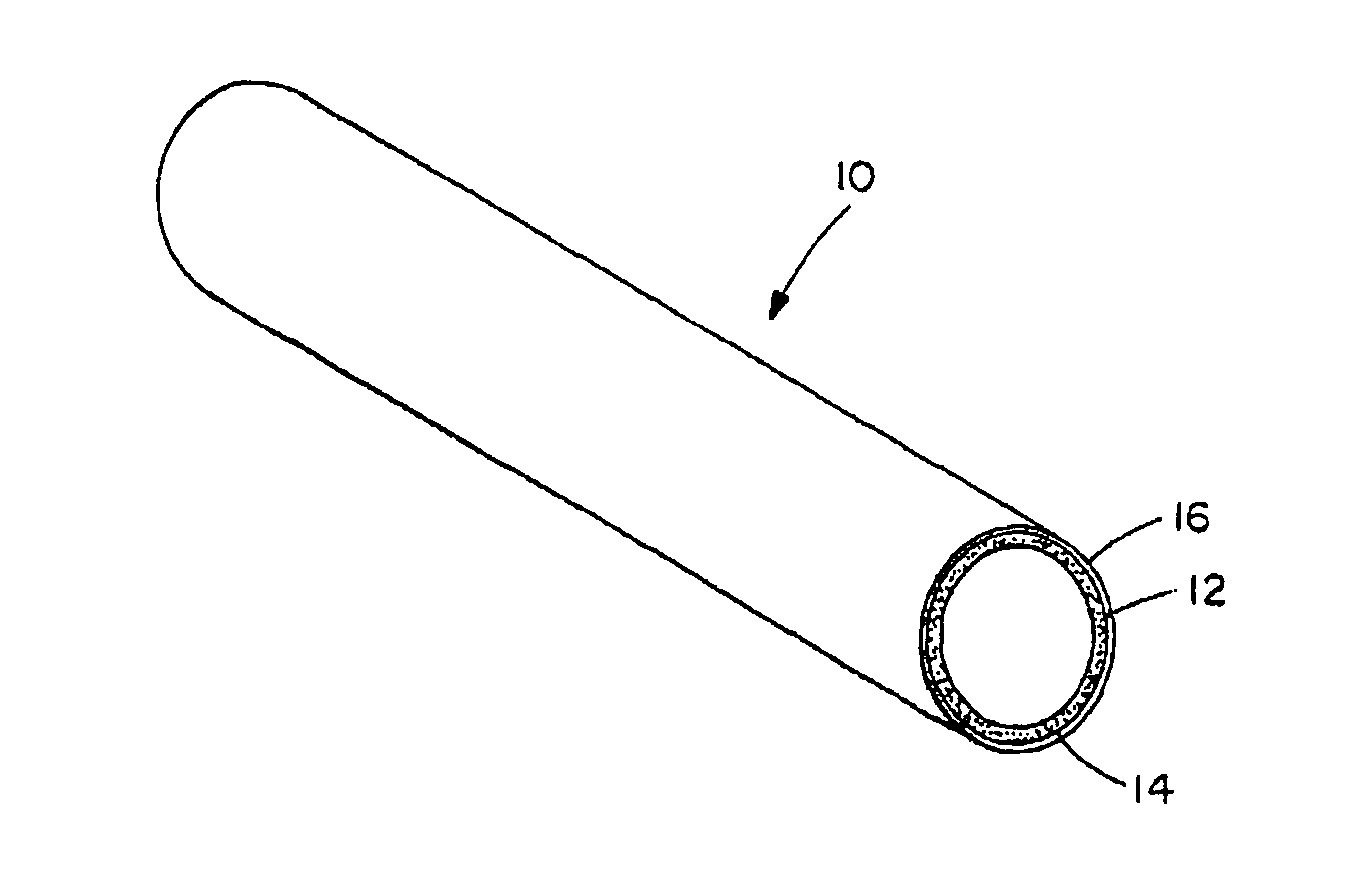

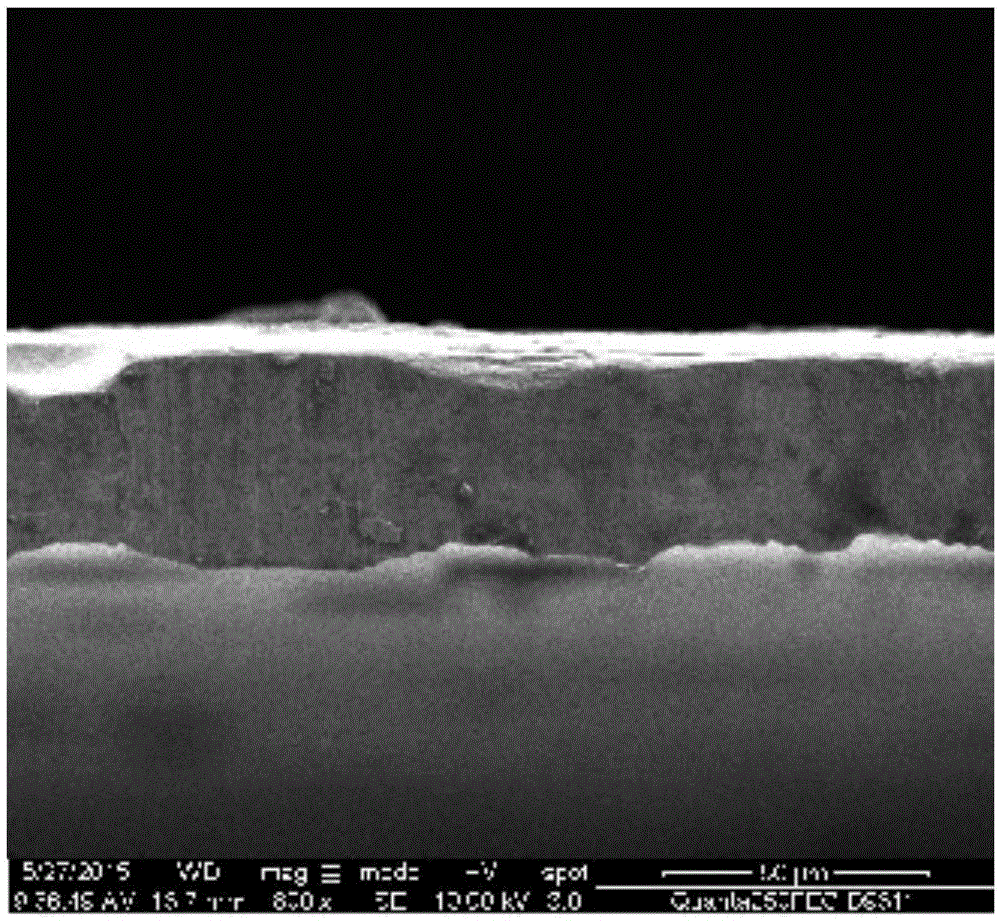

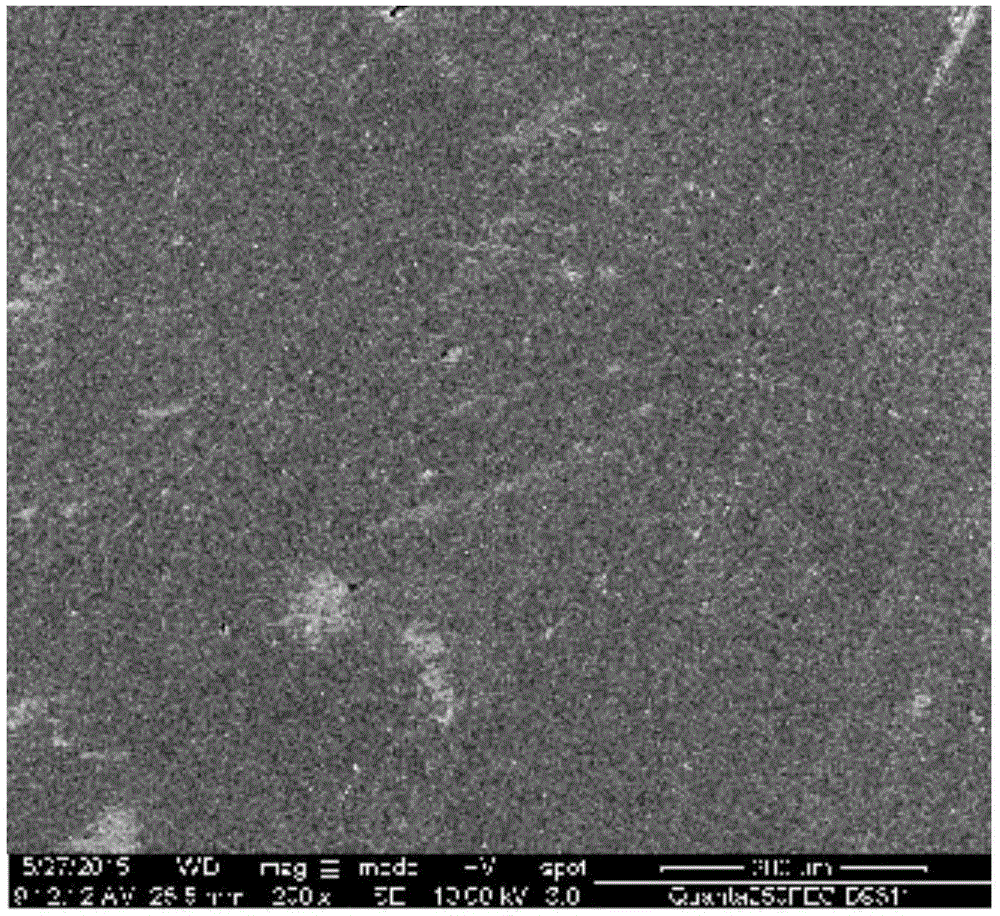

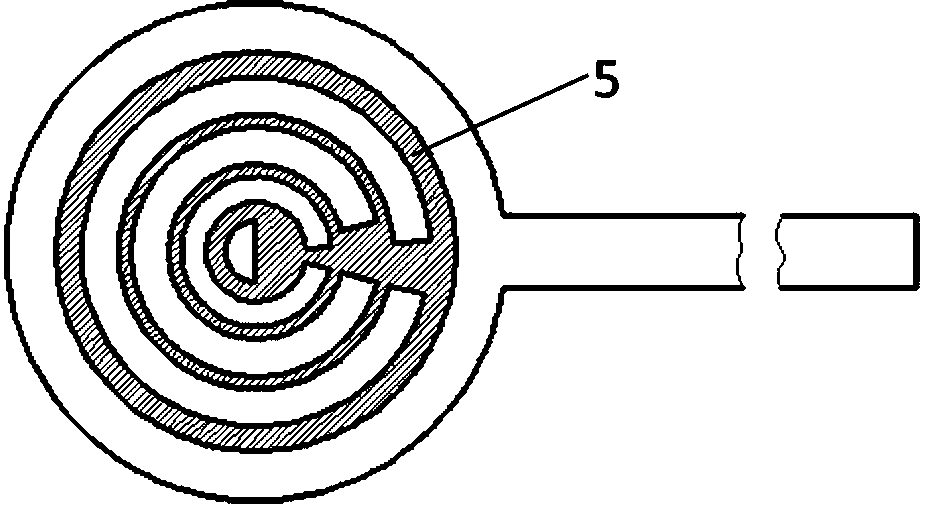

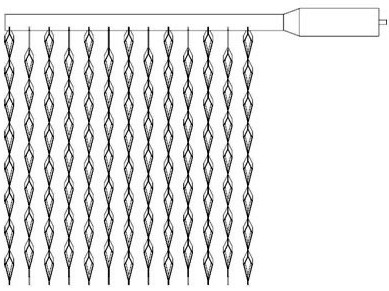

Method for fabricating composite gas separation modules

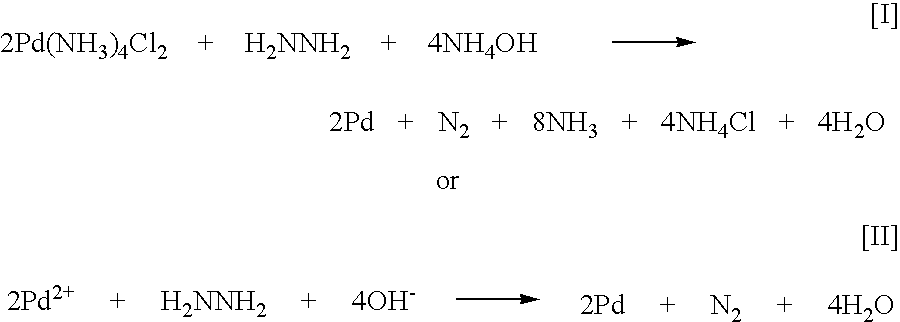

InactiveUS7390536B2Thin and uniformUniform depositionMolten spray coatingVacuum evaporation coatingPorous substrateHydrogen

The present invention relates to a method for fabricating a composite gas separation module and to gas separation modules formed by the method. In one embodiment, the method for fabricating a composite gas separation module includes depositing a first material on a porous substrate, thereby forming a coated substrate. The coated substrate is abraded, thereby forming a polished substrate. A second material is then deposited on the polished substrate. The first material, the second material, or both the first material and the second material can include a gas-selective material such as a hydrogen-selective metal, e.g., palladium, or an alloy thereof. In one embodiment, the method includes the step of forming a dense gas-selective membrane over the porous substrate. The present invention also relates to a method for selectively separating hydrogen gas from a hydrogen gas-containing gaseous stream.

Owner:WORESTER POLYTECHNIC INST

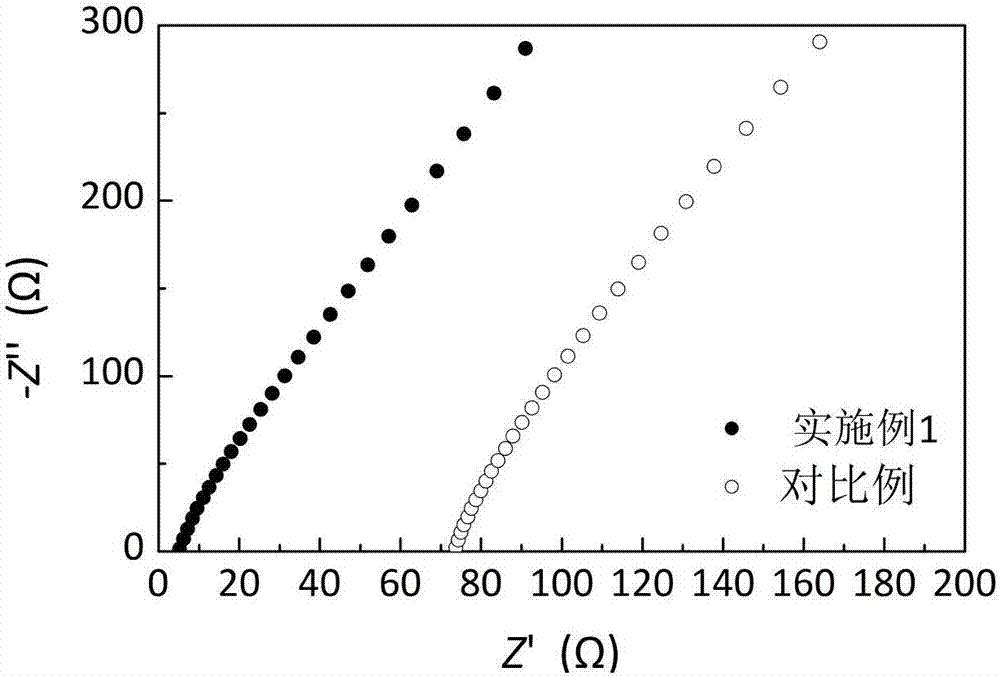

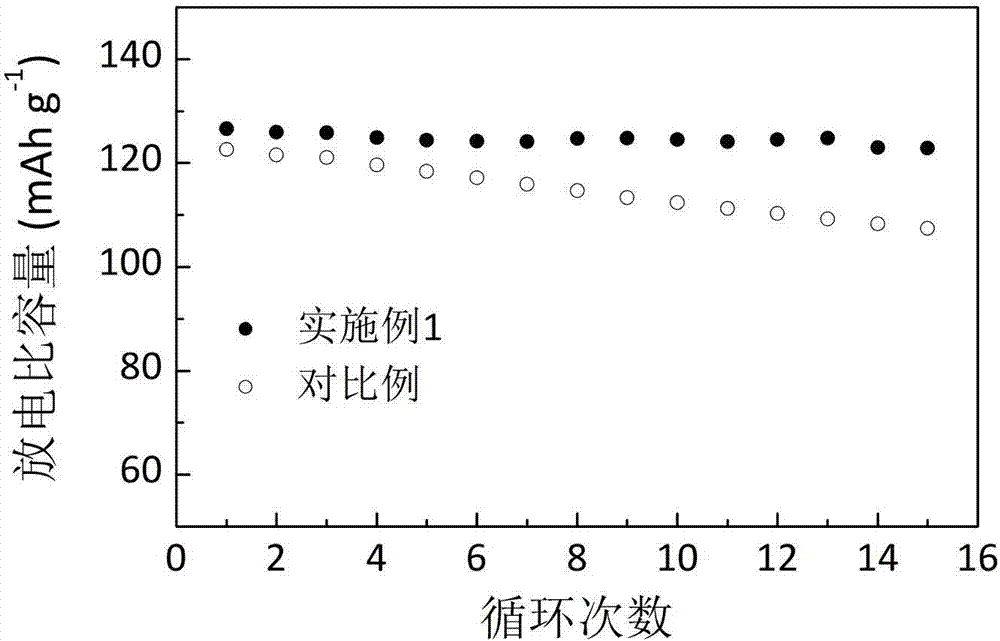

Preparation method of sulfide solid electrolyte material

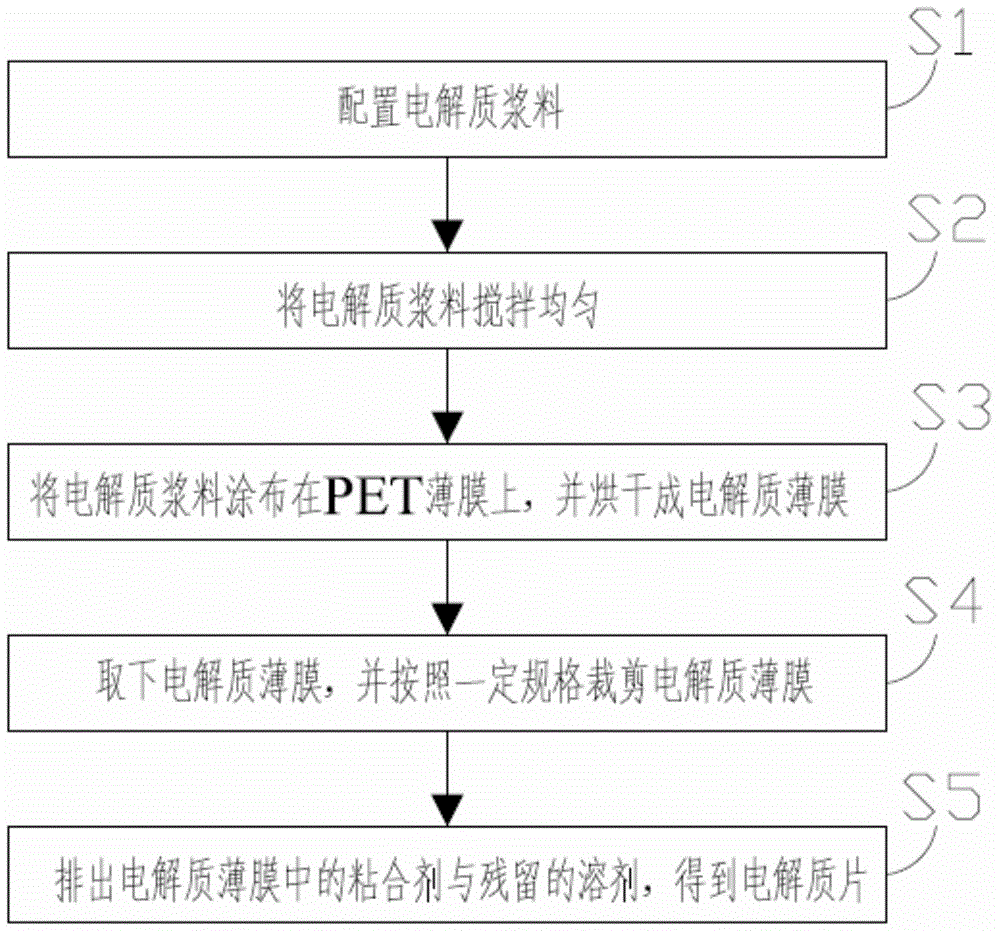

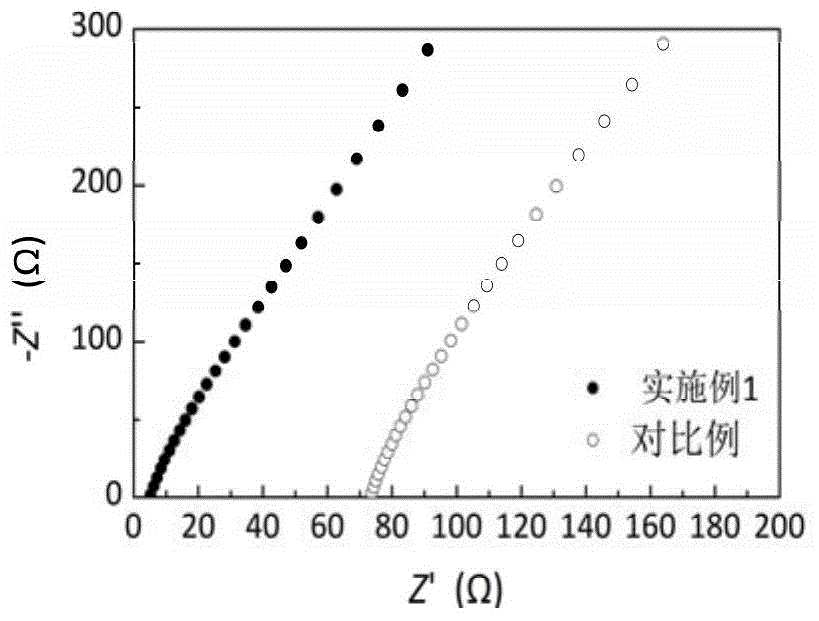

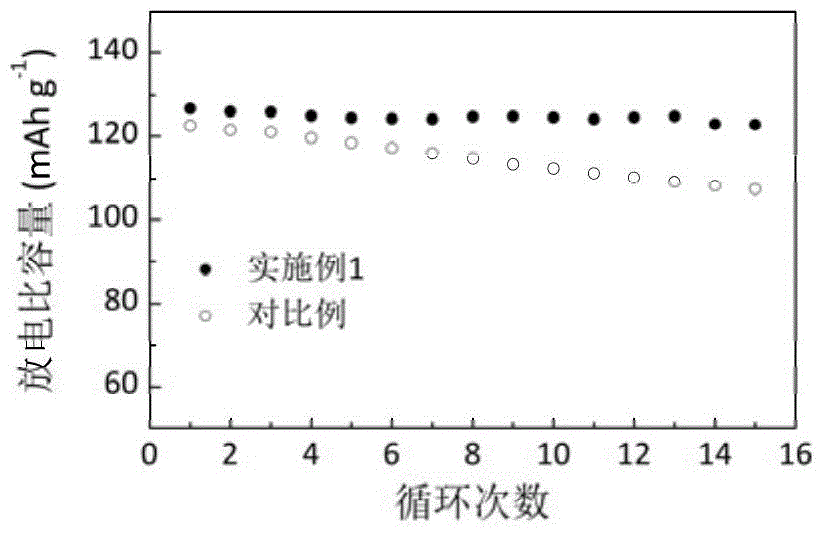

InactiveCN105870497AUniform thicknessThin and uniformNon-metal conductorsSecondary cellsAll solid stateElectrolysis

The invention provides a preparation method of a sulfide solid electrolyte material. The preparation method comprises the following steps: sulfide lithium ion conductor electrolyte powder, an adhesive and a solvent are mixed, and electrolyte slurry is obtained; the electrolyte slurry is uniformly stirred and dispersed, and uniform electrolyte slurry is obtained; the uniform electrolyte slurry is uniformly coated on a PET film, the electrolyte slurry which is coated on the PET film is dried at a set drying temperature, in order to evaporate the solvent part, and an electrolyte film is obtained; the electrolyte film is taken from the PET film, and the electrolyte film is cut according to a certain specification; the adhesive and the residual solvent in the cut electrolyte film are discharged, and a compact sulfide lithium ion conductor electrolyte sheet is obtained. The preparation method of the sulfide solid electrolyte material can effectively solve the problem that when an electrolyte sheet is prepared according to the prior preparation method of the all solid state electrolyte sheet, the electrolyte sheet which is thicker influences electrical performance of an all solid state battery.

Owner:新余赣锋新能源产业投资合伙企业(有限合伙)

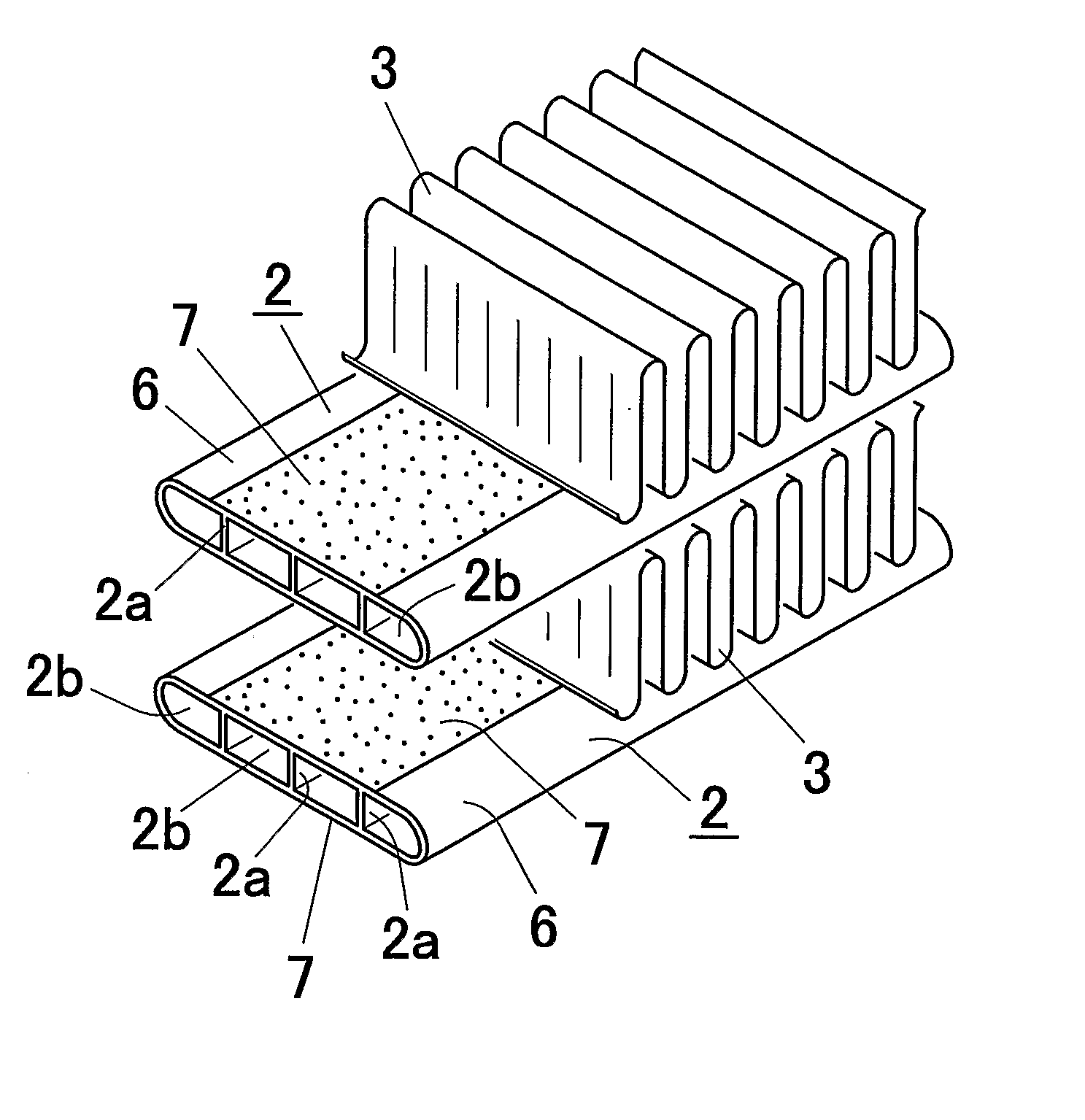

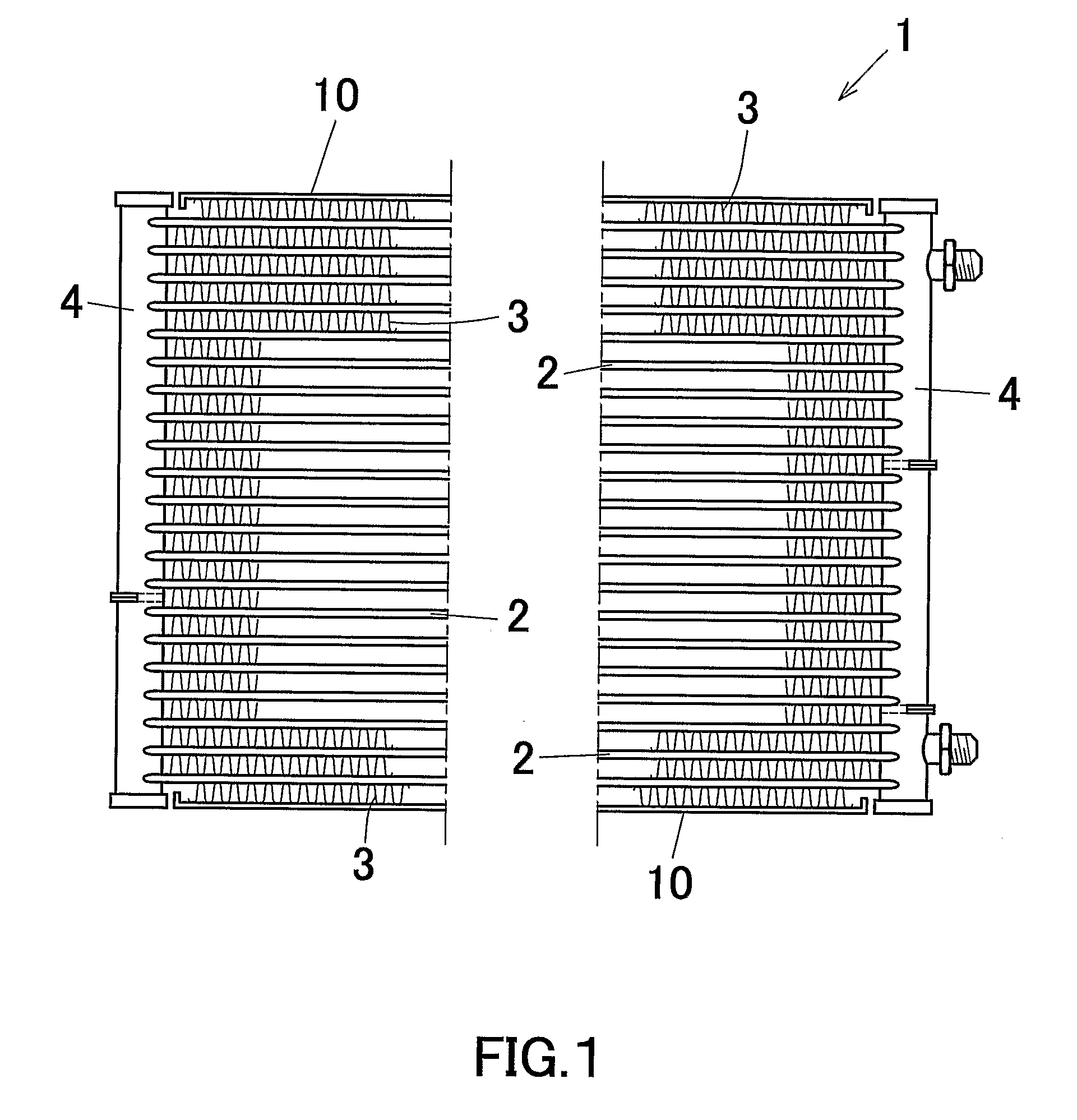

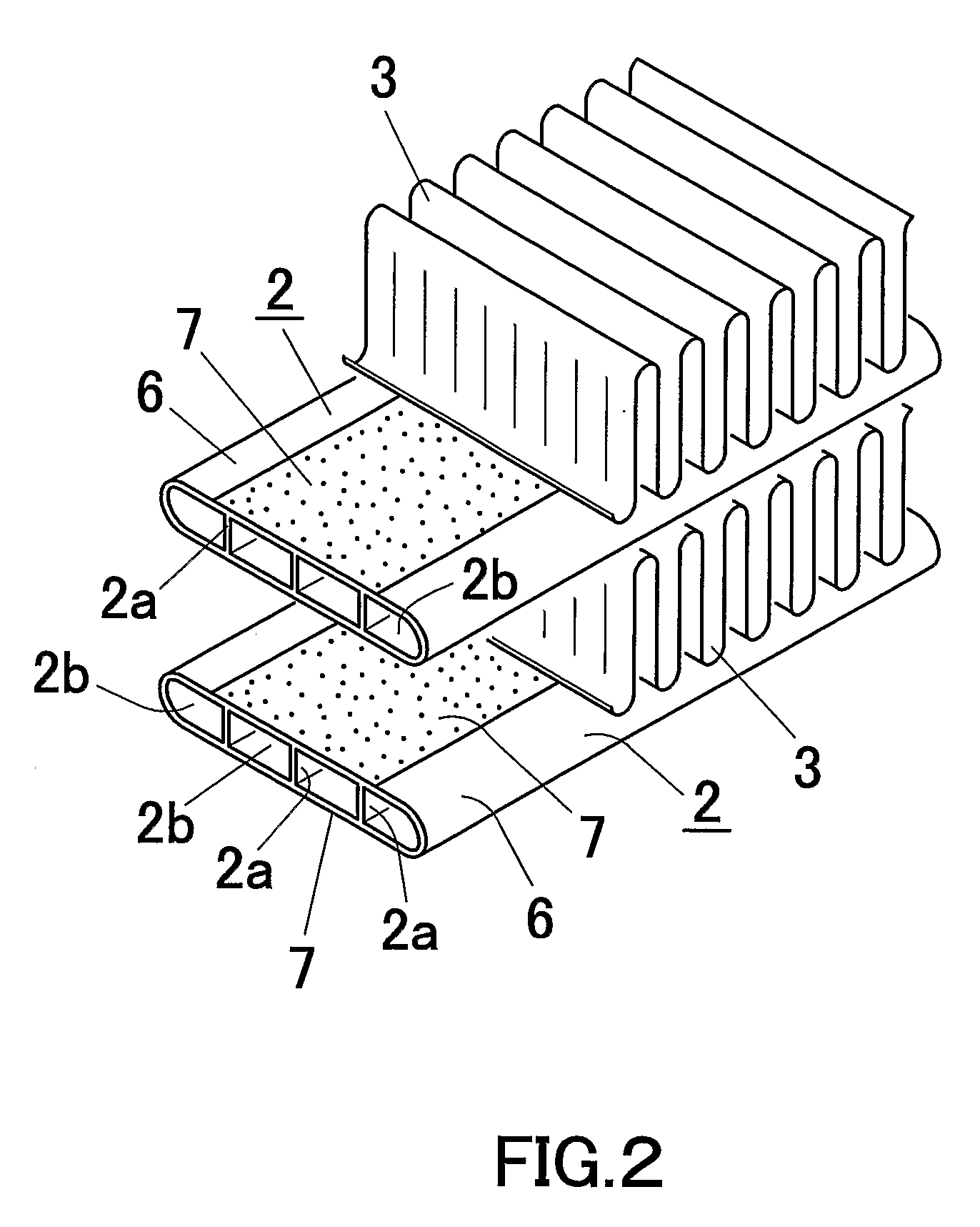

Heat Exchanger And Method For Manufacturing The Same

InactiveUS20070251091A1Improve corrosion resistanceThin and uniformSoldering apparatusStationary conduit assembliesAlloyZinc

A method for manufacturing a heat exchanger according to the present invention includes the steps of forming a thermally sprayed layer on a surface of an aluminum tube core by thermally spraying Al—Si series alloy brazing material onto the surface of the aluminum tube core to obtain a tube 2, applying flux composite containing non-corrosive flux showing zinc substitution reaction onto a surface of the tube 2, combining the tube 2 with the fin 3, and brazing the tube 2 and the fin 3 in an combined state.

Owner:SHOWA DENKO KK

Preparation method for garnet type solid electrolyte material

The invention relates to a preparation method for a garnet type solid electrolyte material. The preparation method comprises the following steps: mixing garnet type electrolyte powder, a binder and solvent so as to obtain electrolyte slurry; coating a PET film with the obtained electrolyte slurry and carrying out drying at a set drying temperature to partially evaporate the solvent so as to obtain an electrolyte film; peeling the electrolyte film from the PET film and cutting the electrolyte film according to a certain specification; and discharging the binder and the residual solvent in the cut electrolyte film so as to obtain a compact garnet type lithium-ion conductor electrolyte sheet. The preparation method provided by the invention can effectively overcome the problem that an electrolyte sheet prepared by using a conventional all-solid electrolyte sheet preparation method has large thickness and poses influence to the electrical performance of an all-solid-state battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

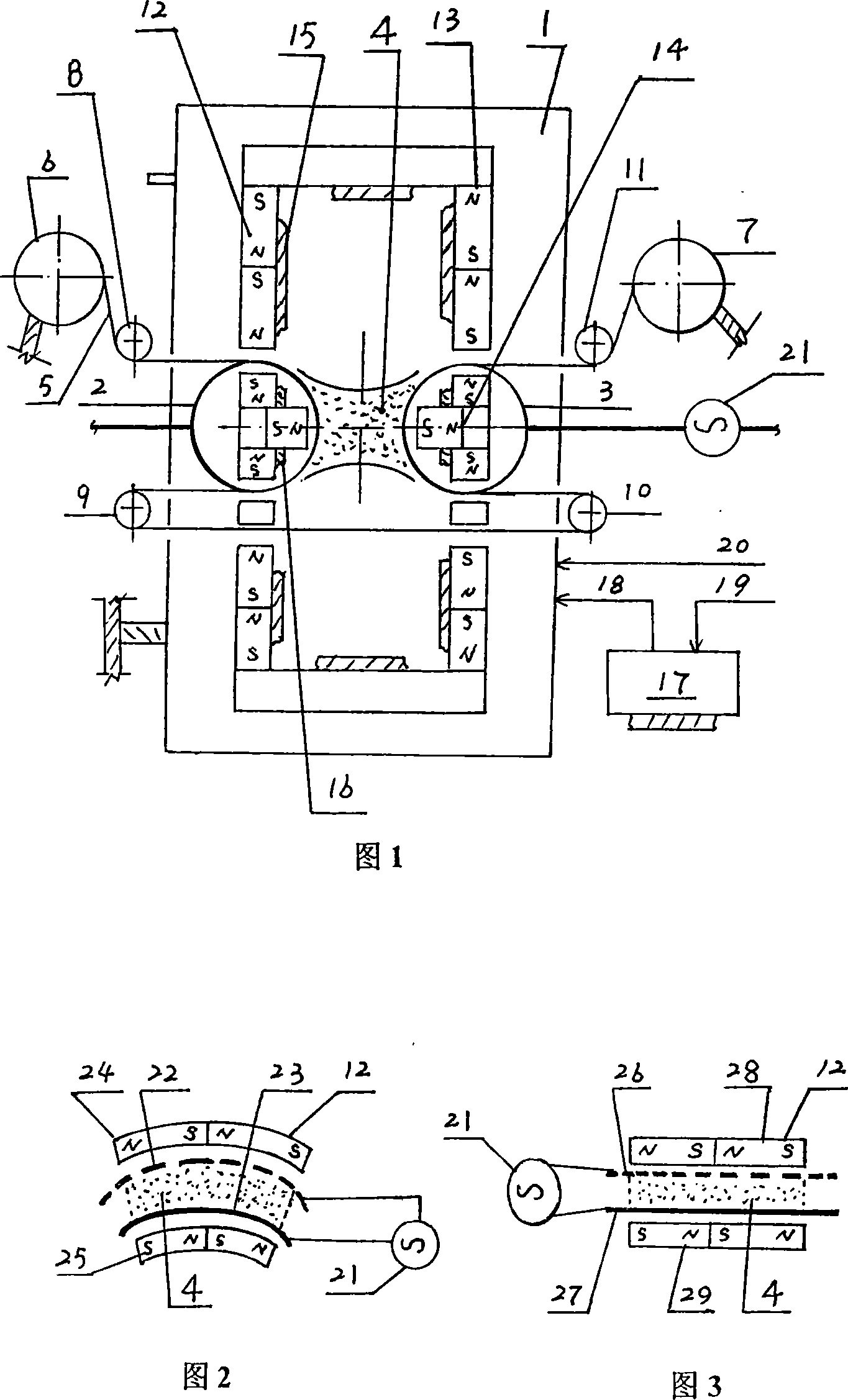

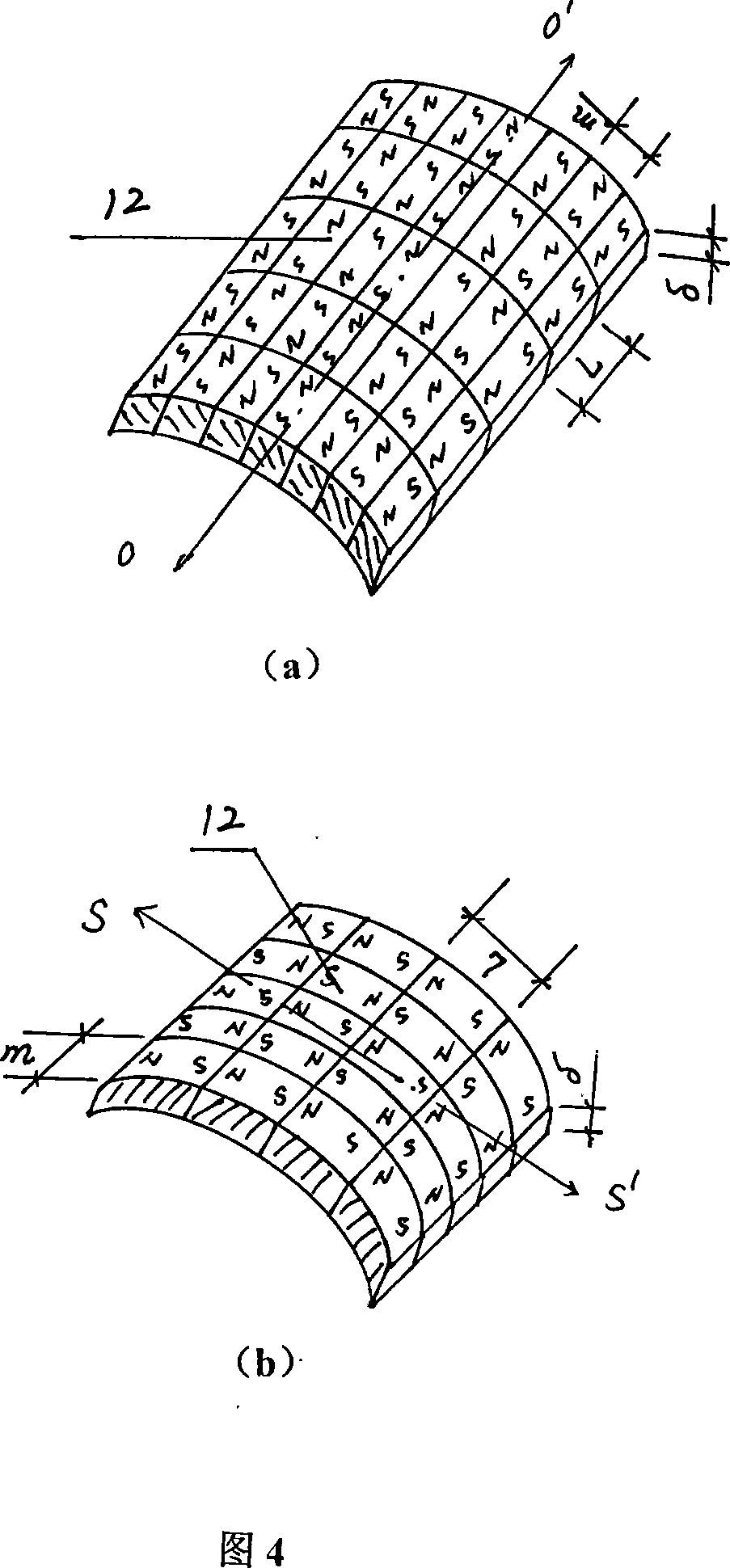

Nano thin film with separation and protection function and manufacturing method thereof

InactiveCN101126148AImprove corrosion resistanceImprove continuityVacuum evaporation coatingSputtering coatingWater vaporVolumetric Mass Density

The invention relates to a nano film with the function of obstructing and protection and the manufacturing method belonging to the technical field of protective film and manufacturing method, aiming at improving the performance of protective film; with the plasma device which is provided with a magnetic field strengthening device, the plasma chemical vapor deposition and the gas of organic silicone chemistry as the working gas, the nano film is manufactured on the parent metal surface by depositing and converging with a thickness of 1 to 1000nm, a transmission rate of oxygen less than 50ml / cm2 / 24h and a transmission rate of water vapor less than 10g / m2 / 24h. The magnetic field strengthening device is magnet assembly(12) made of permanent magnets, consisting of an outside and inside magnet assembly(13),(14) which are respectively corresponding to a left and a right roll electrode(2),(3), and the magnetic field strengthening device can increase the density of the plasma in the plasma area; the nano film has high density, great obstructing performance, uneasy breaking-off and corrosion resistance, being widely applicable as the protective layer for food, drug package and functional apparatus; the manufacturing method is suitable for the production line of continuous coiling based on the parent metal.

Owner:BEIJING BEIYIN EAST ORIENT NEW MATERIALS TECH

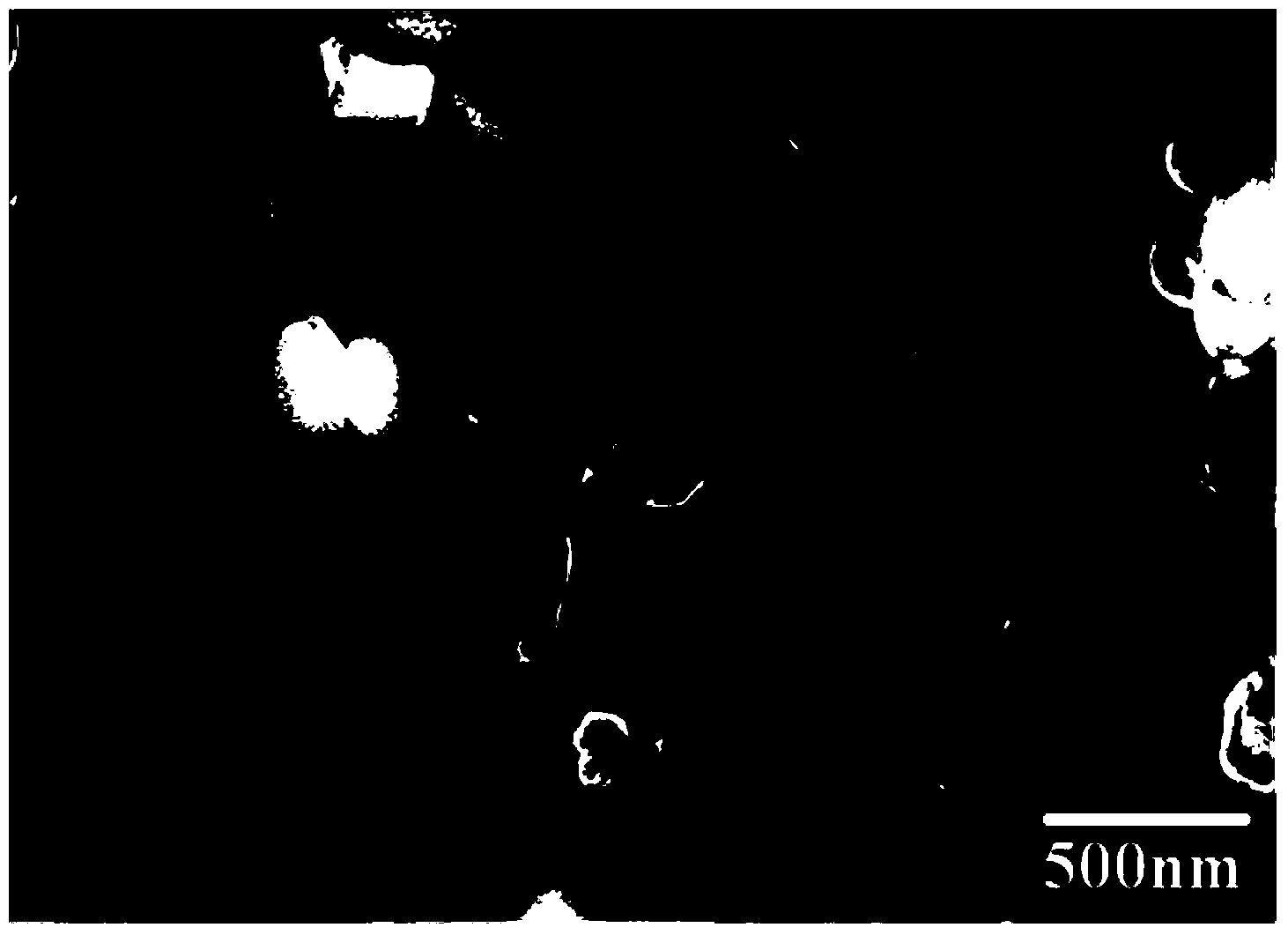

Electrochemical method for preparing hydroxylapatite granule thin coating on metallo-implantation surface

InactiveCN101358370AImprove clinical successThin and uniformElectrolytic inorganic material coatingProsthesisApatiteHydroxylapatite

The invention discloses an electrochemical method for preparing a hydroxylapatite particle thin coating on the surface of a metal implant, which comprises the following steps: electrolyte is put into a container equipped with a constant temperature heating system and heated to be 30 DEG C to 95 DEG C, and then the temperature is kept; platinum is taken as the anode and evenly distributed around the container, and the metal implant is taken as the cathode, put in the middle of the container and totally soaked in the electrolyte; DC voltage of 2V to 4V is added between the anode and the cathode, the surface of the metal implant has cathode reduction reaction, the pH value is increased and the supersaturation degree of the hydroxylapatite is also increased, so as to crystalize on the surface of titanium; after 0.5h to 5h of deposition, a layer of hydroxylapatite particle thin coating which can be excellently adhered to the matrix metal is formed on the surface of the implant. The hydroxylapatite particle thin coating prepared by the method is thin and even, is not easy to fall off during the operation process, can guide the bone tissue to quickly grow to the surface after being implanted into the bone tissue, so as to greatly improve the clinical success rate of the implant.

Owner:ZHEJIANG UNIV

Composite graphene electrode material and solid-phase catalysis preparation method thereof

The invention discloses a composite graphene electrode material. The material comprises an electrode material body and is characterized in that a graphene coating structure grows on the surface of the electrode material body in situ. The graphene coating structure is composed of a graphene close coating layer which is located on an electrode active material surface and a peripheral graphene conductive network and can improve the electrical conductivity of particles of the electrode material and the conductive connection among the particles. The invention also discloses a solid-phase catalysis preparation method for the composite graphene electrode material. The method comprises the steps of 1) mixing electrode materials, organic carbon source and catalyst precursors fully and uniformly as per the ratio of 200:(1-5):(5-30); 2) performing heat treatment on the mixture obtained through Step 1) in reducing atmosphere at 400-1000DEG C for 1-24 hours; 3) naturally cooling the mixture to the room temperature, performing porphyrizing and sieving, and finally obtaining the composite graphene electrode material. The method has the advantages of being low in cost and easy to implement and popularize.

Owner:SUZHOU UNIV

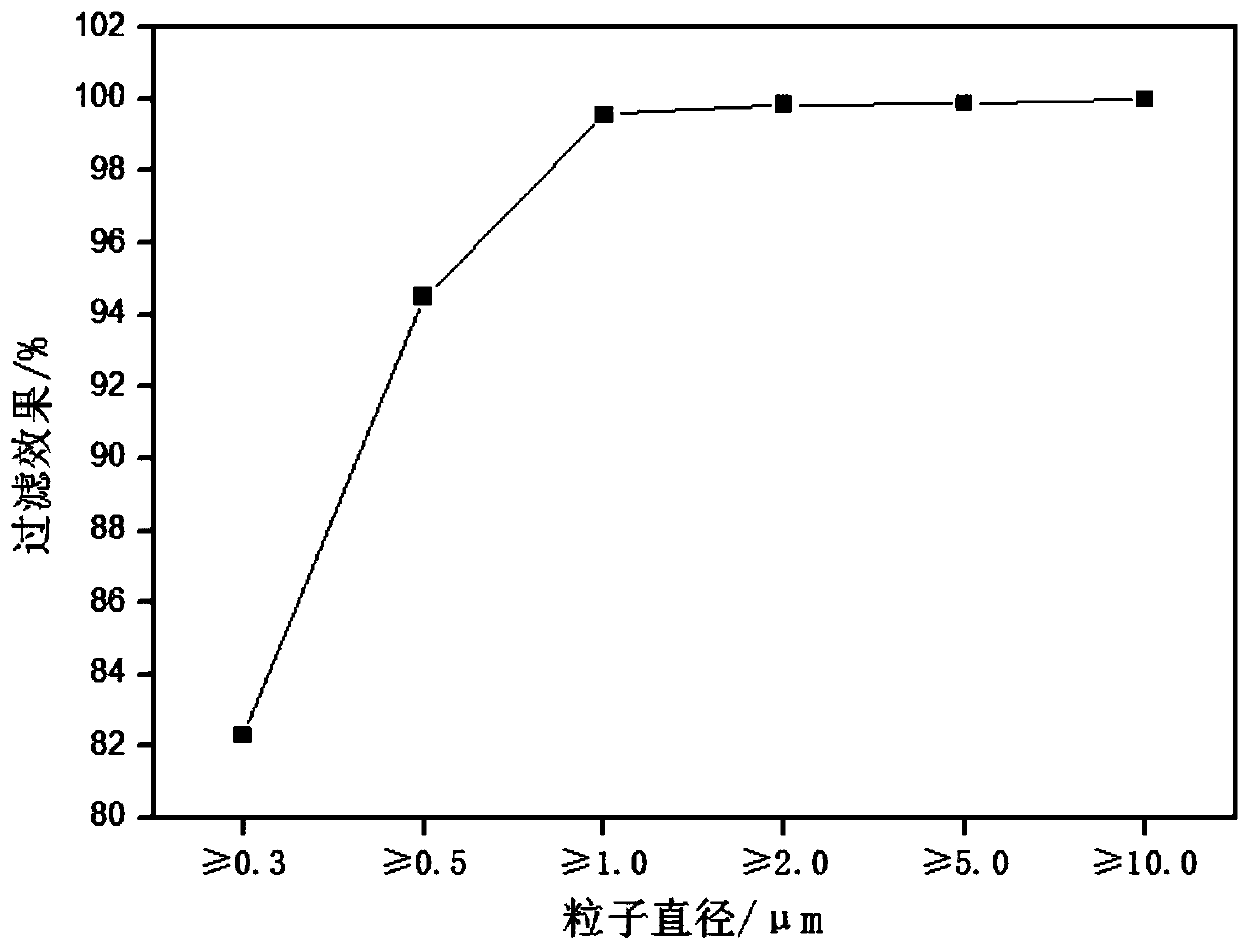

Preparation method of cotton bast fiber and chitosan composite nonwoven fabric for filtering

ActiveCN107604739AAvoid damageEasy to separatePulp beating methodsReinforcing agents additionHigh volume manufacturingElectrospinning

The invention discloses a preparation method of cotton bast fiber and chitosan composite nonwoven fabric for filtering, and belongs to the technical field of fiber materials. Cotton bast is separatedthrough steam flash-explosion pretreatment, formation is conducted by a papermaking method, and chitosan is added to enhance the mechanical property and the filtering efficiency. The preparation method is simple, convenient and environment-friendly in process flow and adapts to industrialized production. The nonwoven fabric adopts lignin-enriched cotton bast fiber and chitosan as raw materials, sothat the nonwoven fabric has high antibacterial property. The cotton bast and the chitosan are biology-based materials and can be degraded in the natural environment after use, so that environmentalburden is reduced and the problem that the electrostatic spinning method is difficult in industrialized and mass production is solved.

Owner:JIANGNAN UNIV

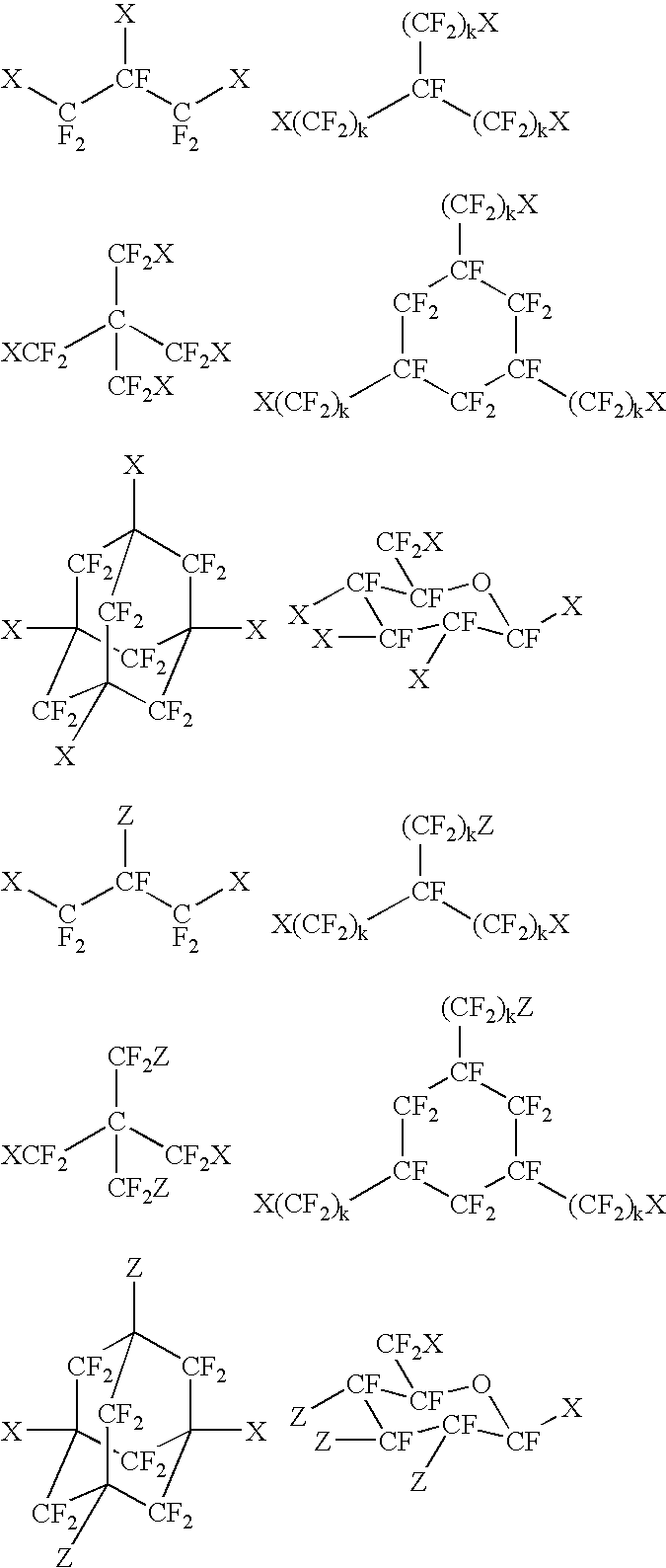

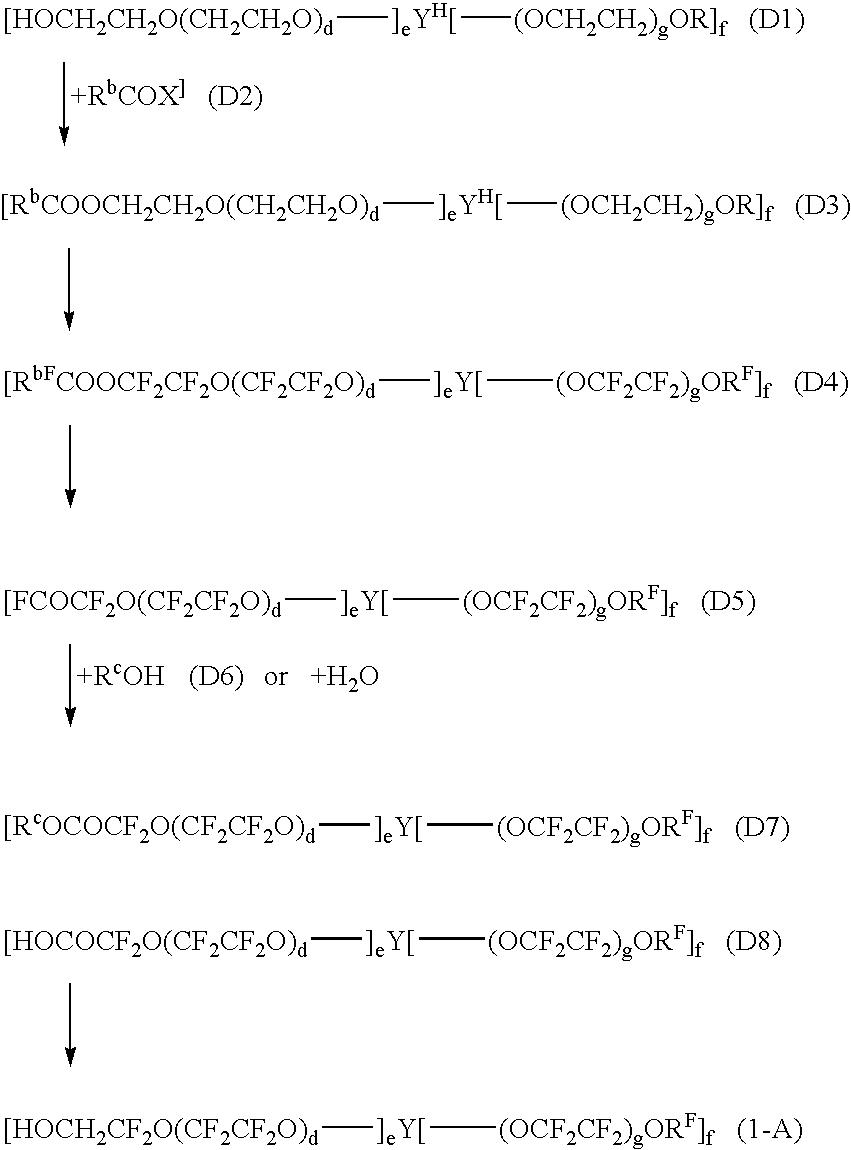

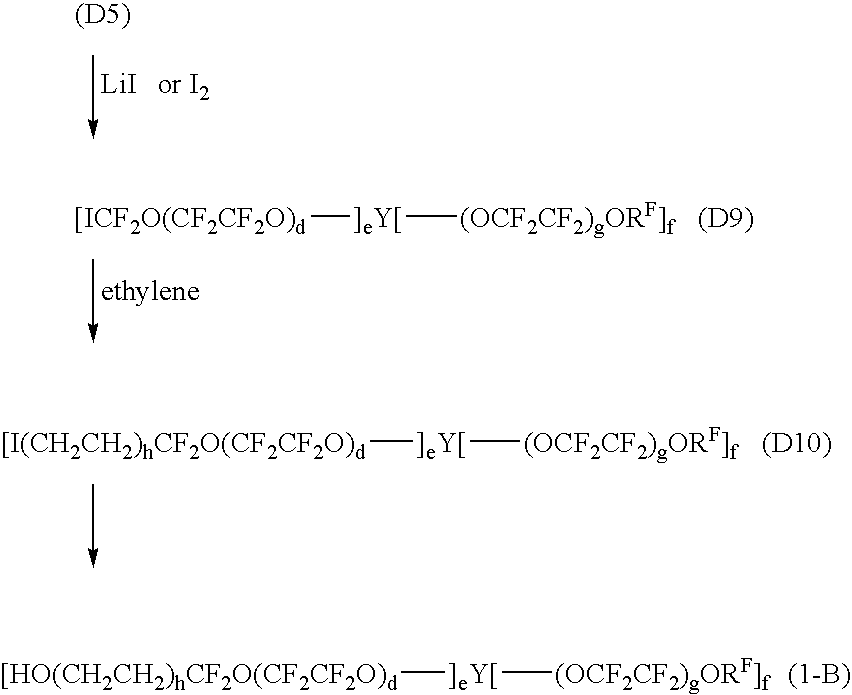

Lubricant solution for magnetic recording media, containing fluorinated polyether compound as lubricant

InactiveUS20070116990A1Low vapor pressureLow viscosityOrganic chemistryOrganic compound preparationOzone layerSolvent

To present a lubricant solution for magnetic recording media, which comprises a lubricant excellent in chemical stability and capable of imparting excellent lubricity, and a solvent having a suitable dissolving power for the lubricant and being excellent in drying properties and not influential over the ozone layer. A lubricant solution comprising a lubricant and a fluorinated alkyl ether. For example, as the lubricant, a compound of the formula (HO—CH2—CF2(OCF2CF2)dO—)3Y wherein Y is a trivalent perfluorohydrocarbon group, is used, and as the fluorinated alkyl ether, 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether is used.

Owner:ASAHI GLASS CO LTD

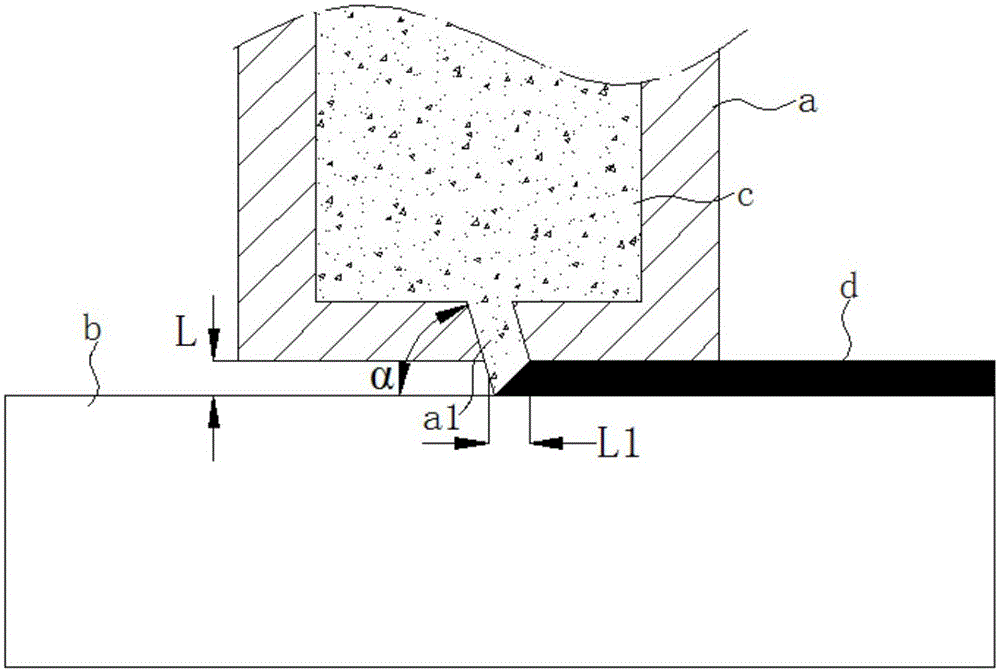

Preparing method of ultrathin amorphous alloy strip

The invention relates to a preparing method of an ultrathin amorphous alloy strip. Molten steel obliquely sprays the surface of a cooling body, and the spraying direction of the molten steel is opposite to the rotating direction of the cooling body. Meanwhile, the distance between the lower end face of a nozzle and the cooling body is reduced, and therefore the scraping pressing and correcting functions on molten steel laminar flow from the lower end face of the nozzle are improved, and the prepared amorphous alloy strip is thin and even. Meanwhile, the smoothness and density of the free surface of the amorphous alloy strip are improved. The acute angle formed between a nozzle runner and the surface of the cooling body is set in the range of 15-85 degrees, the transverse disturbance of the amorphous alloy strip to the laminar flow molten liquid is small in cooperation with the scraping pressing and correcting functions of the lower end face of the nozzle, and therefore the surface stress of the strip is reduced, and the transverse radian of the strip is reduced; and the quality and the finished product performance of the amorphous alloy strip are improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

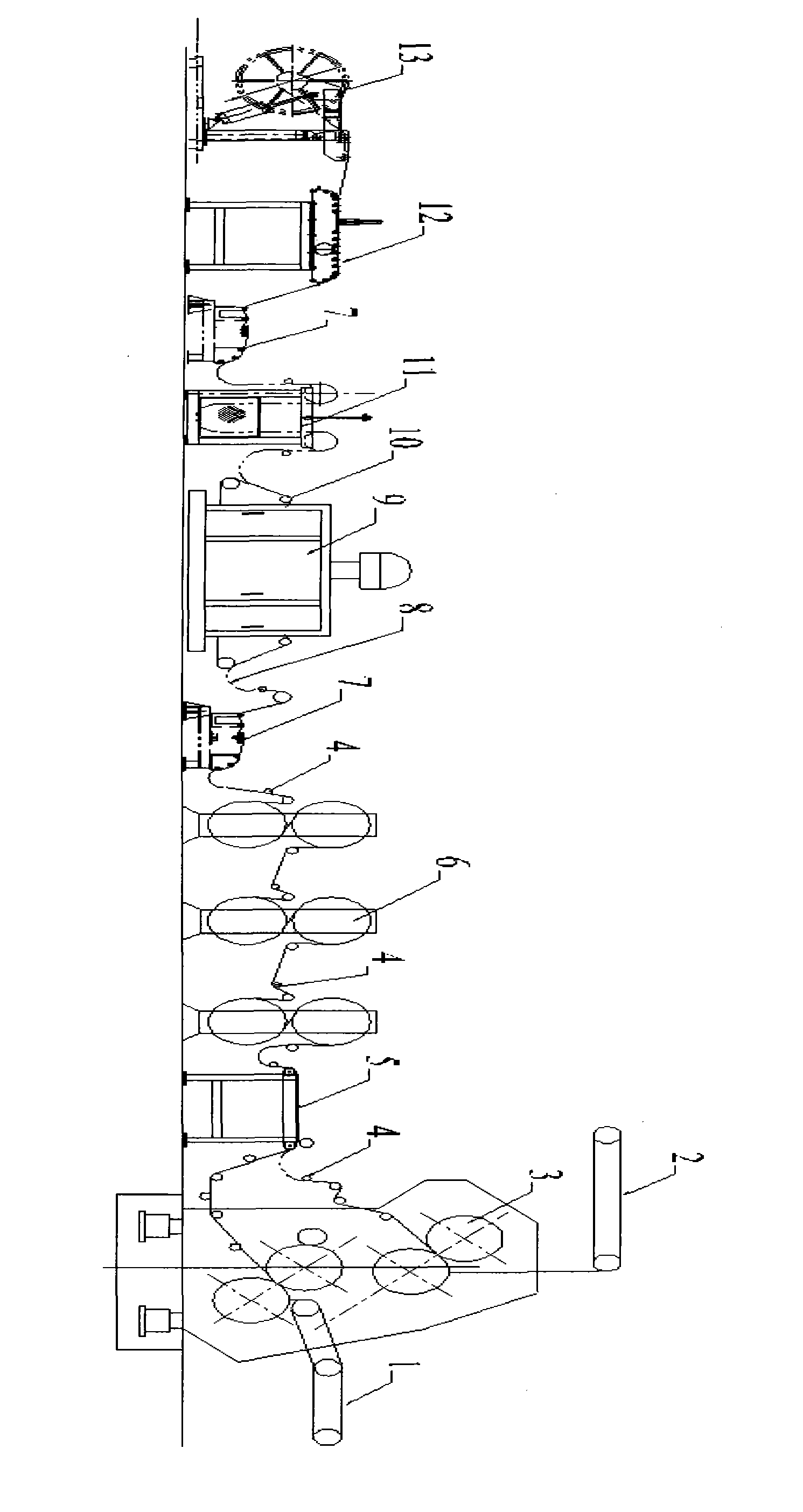

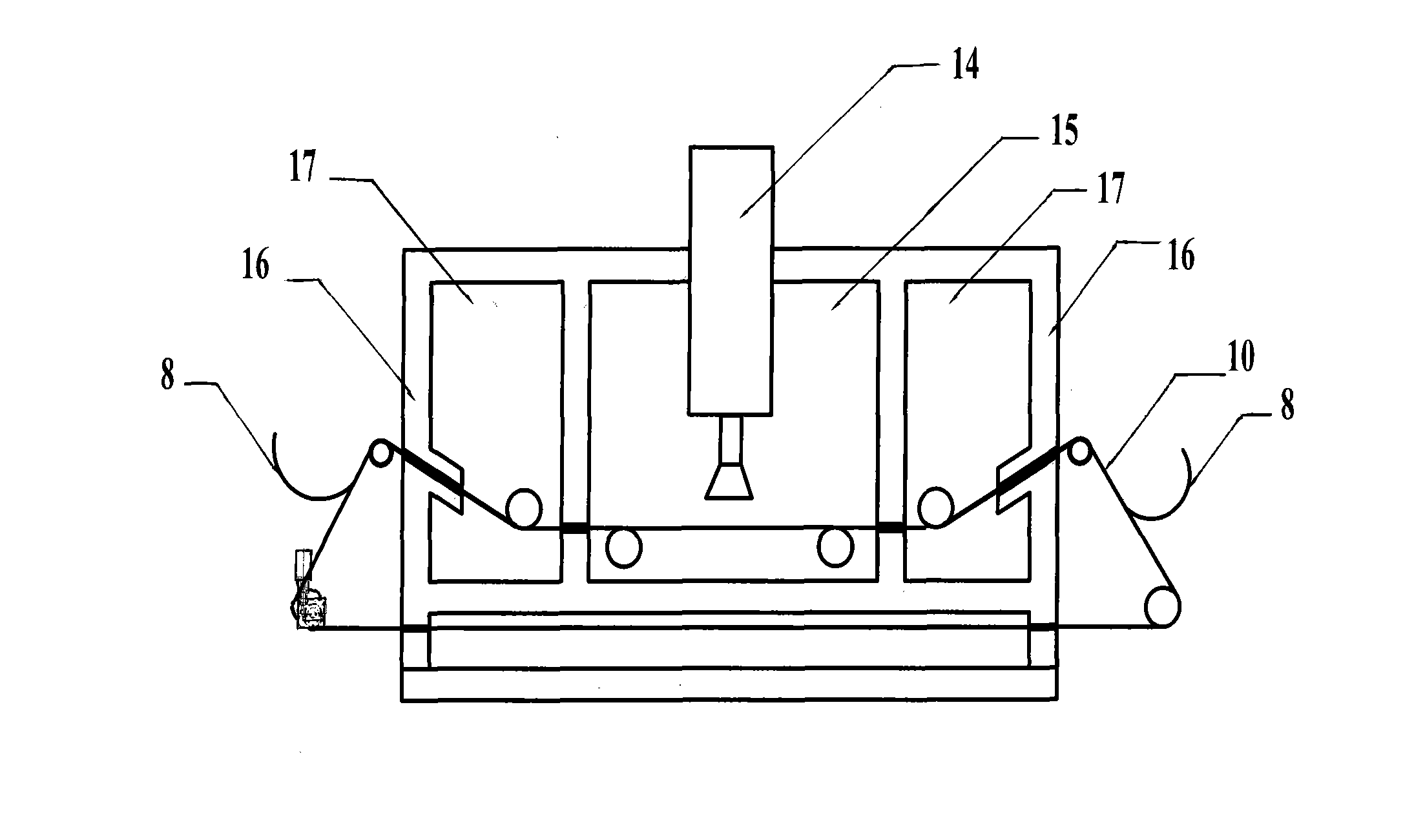

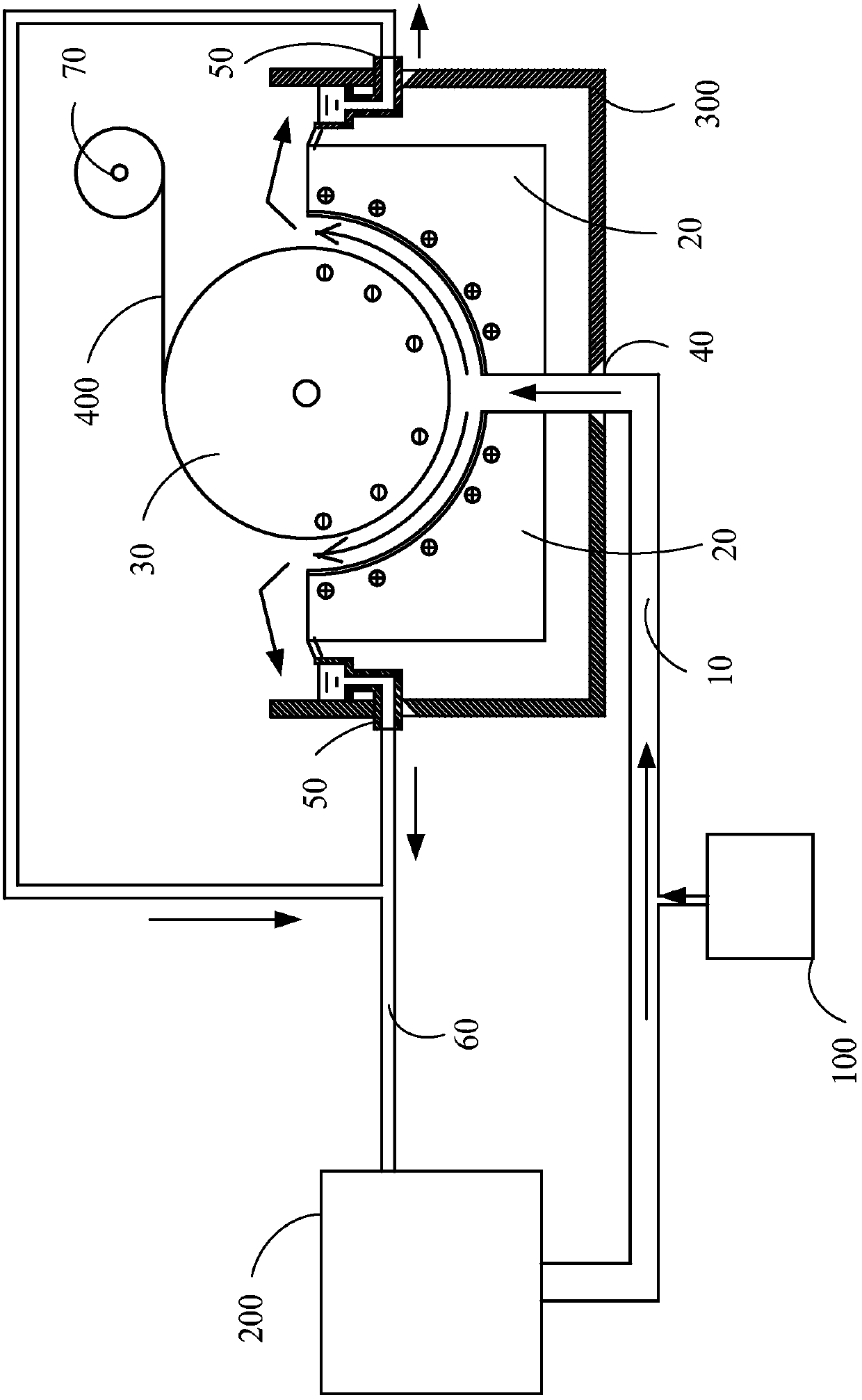

Device assembly for manufacturing radial tire inner liner component

The invention discloses a device assembly for manufacturing a radial tire inner liner component. The device assembly consists of a main rubber supply device, a secondary rubber supply device, a four-roll calender, a floating roll speed regulating device, an attached conveying device, a cooling device, an automatic deviation correction device, a self-shield radiation device, a rubber sheet storage device, another automatic deviation correction device, a slicing device and a double coiling device, wherein raw rubber is fed into the four-roll calender through the main rubber supply device and the secondary rubber supply device to form an inner liner component rubber sheet through calendering; the inner liner component rubber sheet enters a beam transition device in the self-shield radiation device through the attached conveying device, the cooling device and the automatic deviation correction device; the rubber sheet is irradiated through high-energy electron ray emitted by an electron accelerator; the irradiated rubber sheet gets out of transition cabins to enter the rubber sheet storage device to be tidied, is adjusted through the automatic deviation correction device, enters the slicing device to be cut and is coiled by the double coiling device for later use. The device assembly has the advantages of self-shielding function, easiness and convenience in operation, safety, convenience, stability in operation, high production efficiency, low operation cost, capability of being seamlessly connected with an inner liner calendering production line and suitability for being used in an automatic production line.

Owner:BEIJING RADIATION APPL RES CENT

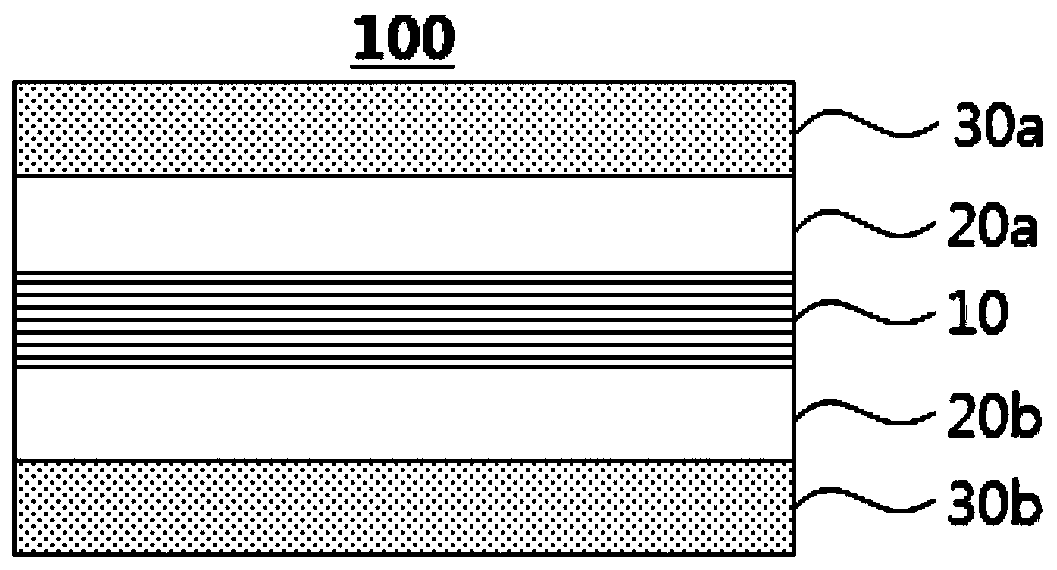

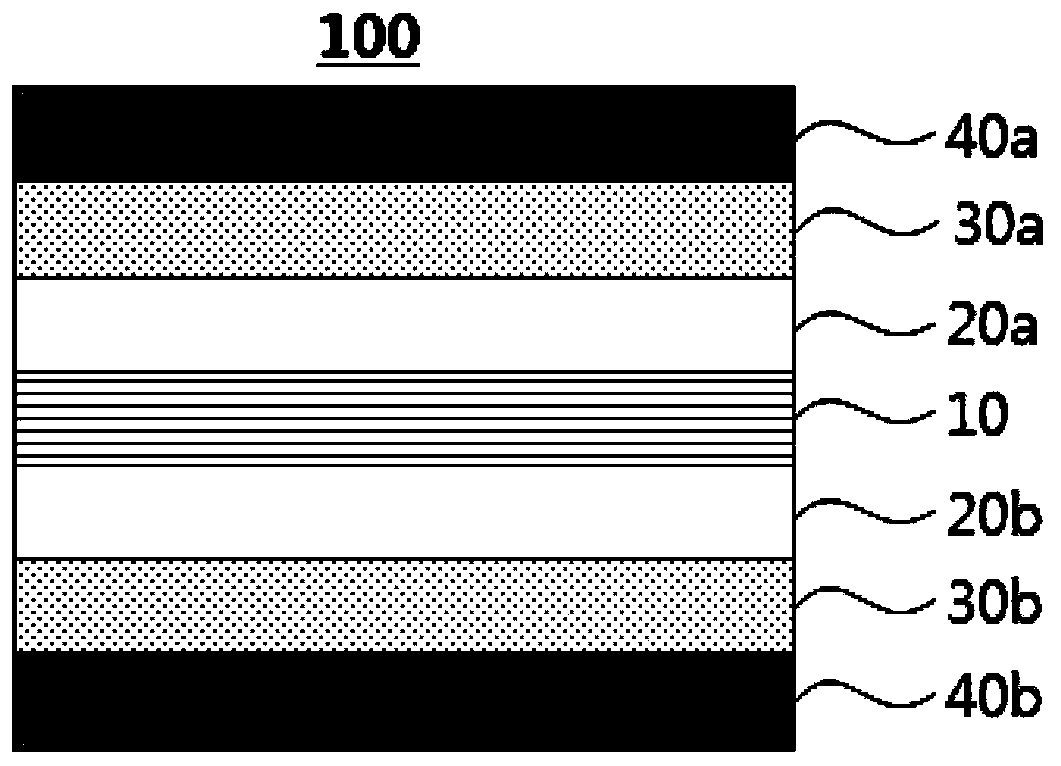

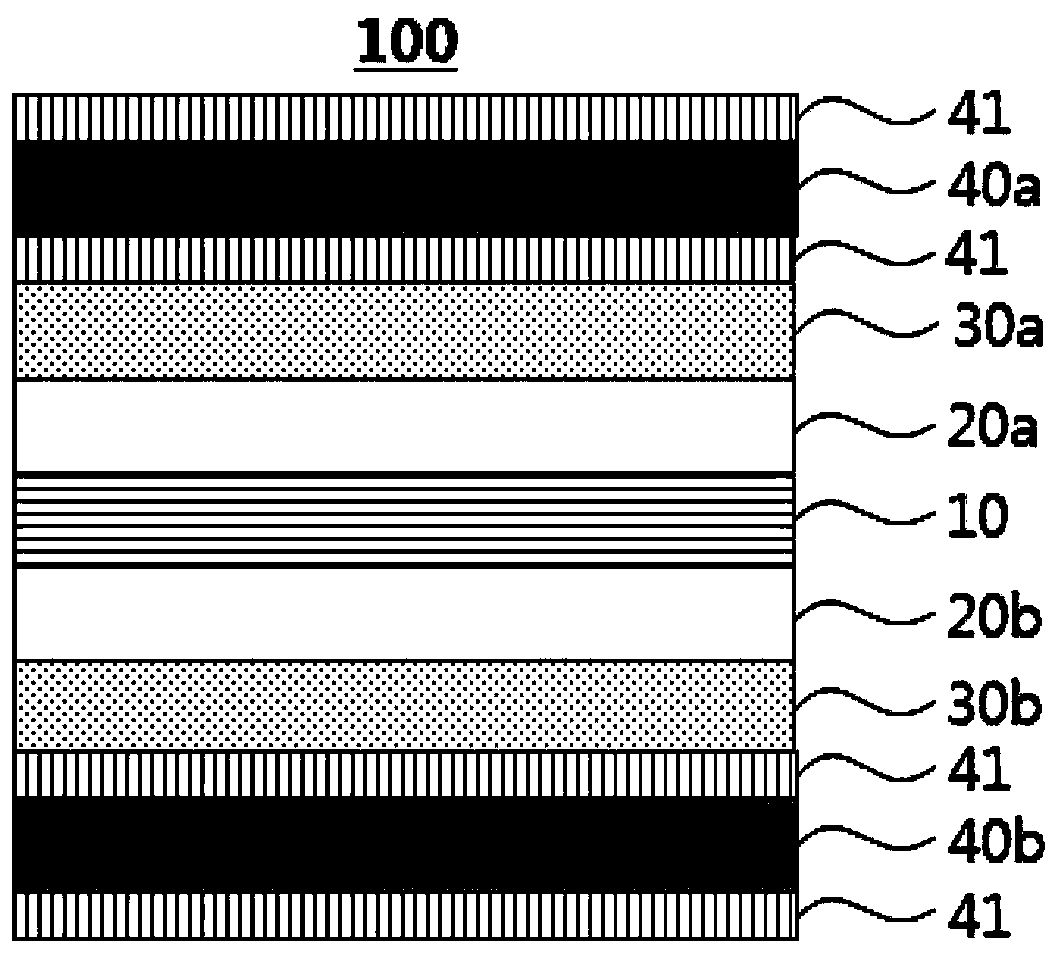

Lithium electrode and lithium secondary battery comprising same

ActiveCN111201645AInhibit deteriorationThin and uniformElectrode carriers/collectorsLi-accumulatorsLithium metalPhysical chemistry

The present invention relates to a lithium electrode and a lithium secondary battery comprising the same. More particularly, the present invention is capable of manufacturing a lithium electrode having a thin and uniform thickness by: firstly forming a protective layer capable of protecting a lithium metal on a substrate while manufacturing a lithium electrode; depositing the lithium metal on theprotective layer; and then transferring the deposited lithium metal layer to at least one surface of a current collector, and thereby the energy density of a lithium secondary battery using a lithiumelectrode manufactured as above may be improved.

Owner:LG ENERGY SOLUTION LTD

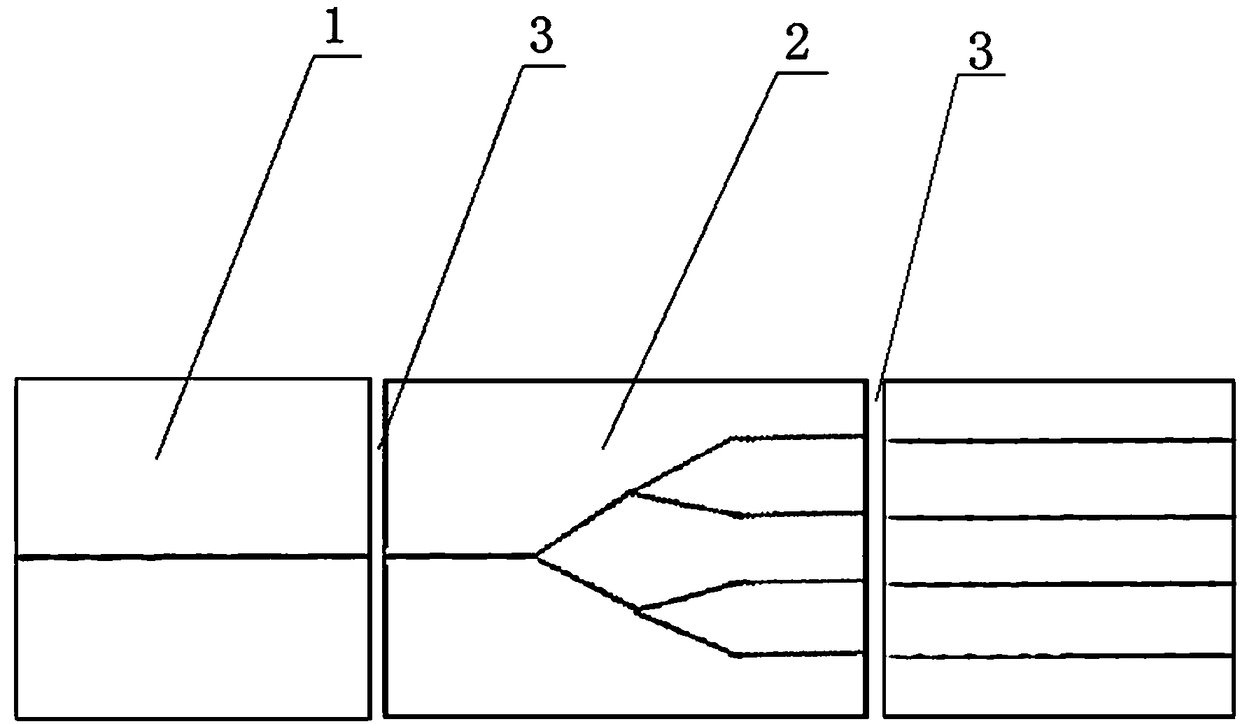

Coupling method for planar waveguide chip and fiber array

InactiveCN109031532AThin and uniformReduced loss variationCoupling light guidesUltrasound attenuationOptical power meter

The invention discloses a coupling method for a planar waveguide chip and a fiber array. The coupling method comprises the following steps: S1, placing a single fiber and a PLC chip on a six-dimensional adjusting frame; S2, adjusting the six-dimensional adjusting frame to align a fiber core of the planar waveguide chip with a main waveguide at an input end of the PLC chip, and completing aligned light transmission of a 1CH / 2CH fiber array and a display waveguide chip through a red light derived image; S3, adjusting the six-dimensional adjusting frame to make an output end of the PLC chip parallel to an 8-degree end face of the fiber array until no gap exists between display contact surfaces of a horizontal CCD and a vertical CCD, and adjusting the product attenuation value of an optical power meter to lowest; and S4, gluing left and right 8-degree end faces of the planar optical waveguide chip, the fiber array and the PLC chip, so that glue on a dispensing surface can flow evenly to the 8-degree end faces. The coupling method has the advantage that the thickness of a coupling adhesive layer can be controlled within 10 microns, and the 8-degree end faces are evenly coated.

Owner:SICHUAN TIANYI COMHEART TELECOM

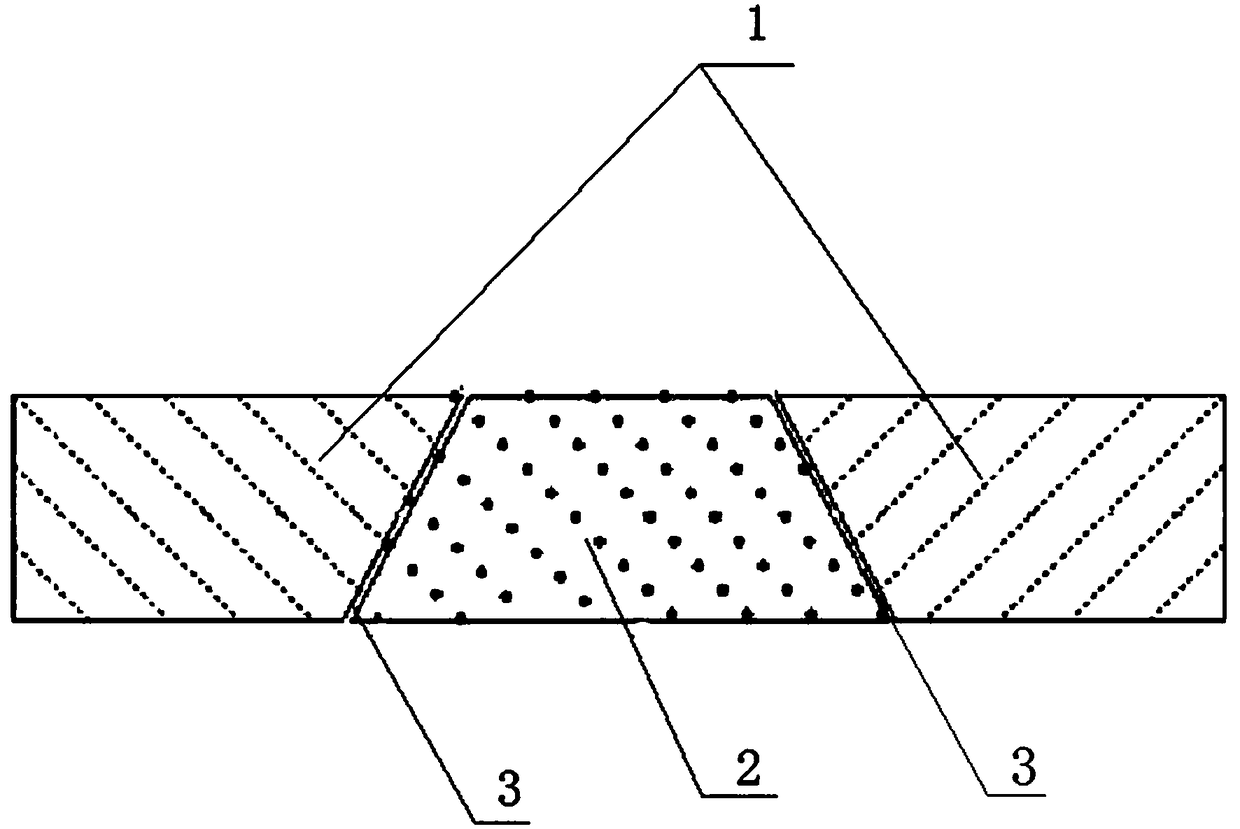

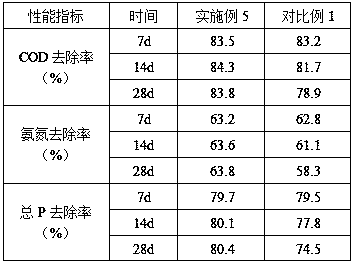

Suspended filler ball for treating sewage by biofilm method and preparation method thereof

InactiveCN111484120AHigh specific surface areaIncrease roughnessTreatment with microorganism supports/carriersCalcium silicateFiber

The invention relates to the field of sewage treatment, and provides a suspended filler ball for treating sewage by a biofilm method and a preparation method thereof. The method comprises the following steps: cutting loofah sponge into small sections, firstly immersing the loofah sponge into a nano calcium silicate dispersion solution for deposition and adsorption, then immersing the loofah spongeinto a sodium alginate solution for cross-linking film formation, and finally loading the loofah sponge into hollow filler balls, thereby preparing the suspended filler balls for biofilm process sewage treatment. Compared with a traditional method, the surfaces of the loofah sponge fiber yarns are loaded with the calcium silicate nanoparticles, so that the specific surface area of the loofah sponge is increased, the sodium alginate and Ca<2+> of the nanoparticles are crosslinked to form a film, and the calcium silicate nanoparticles can be effectively prevented from being agglomerated or falling off. When the filler ball prepared by the invention is used for sewage treatment, a good sewage purification effect can be kept after long-time use.

Owner:成都其其小数科技有限公司

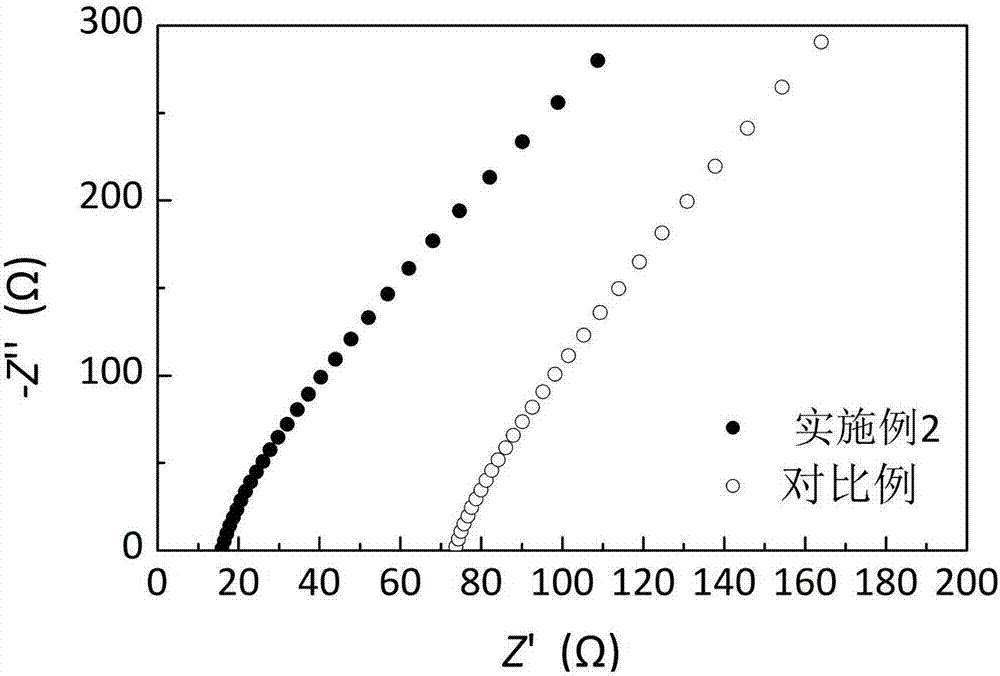

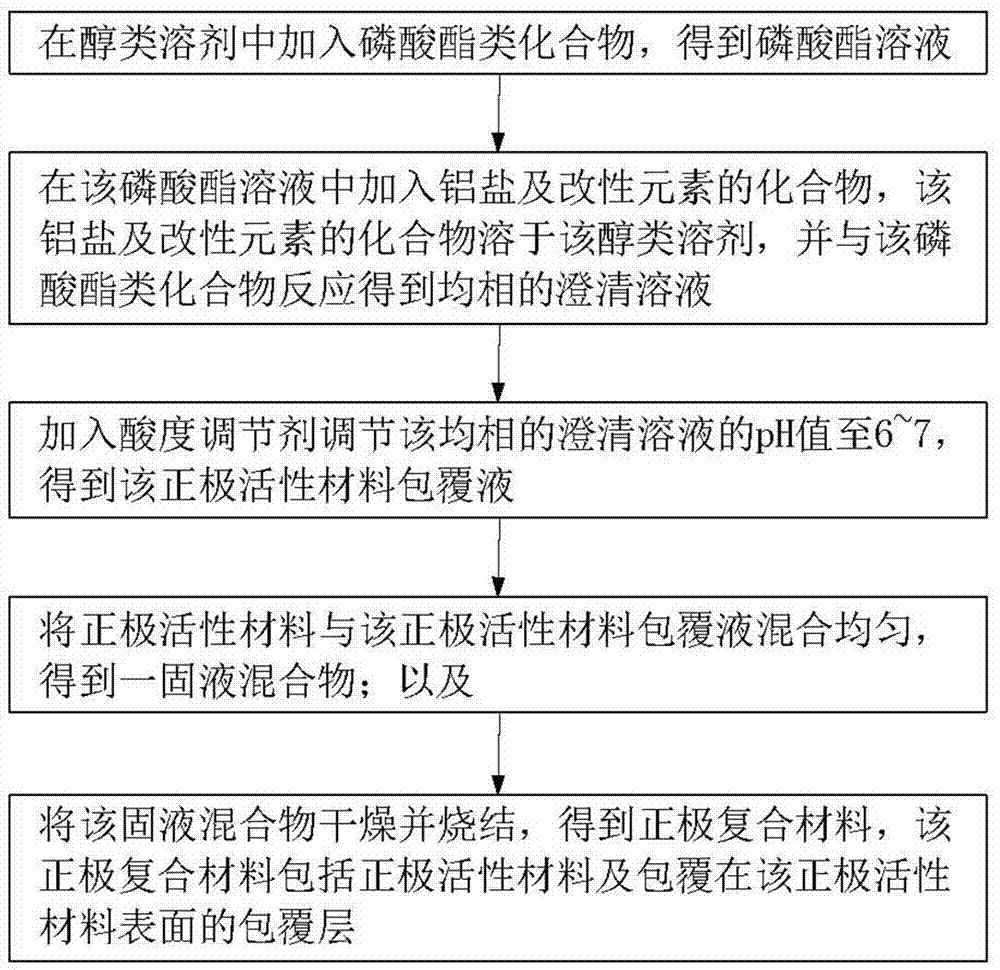

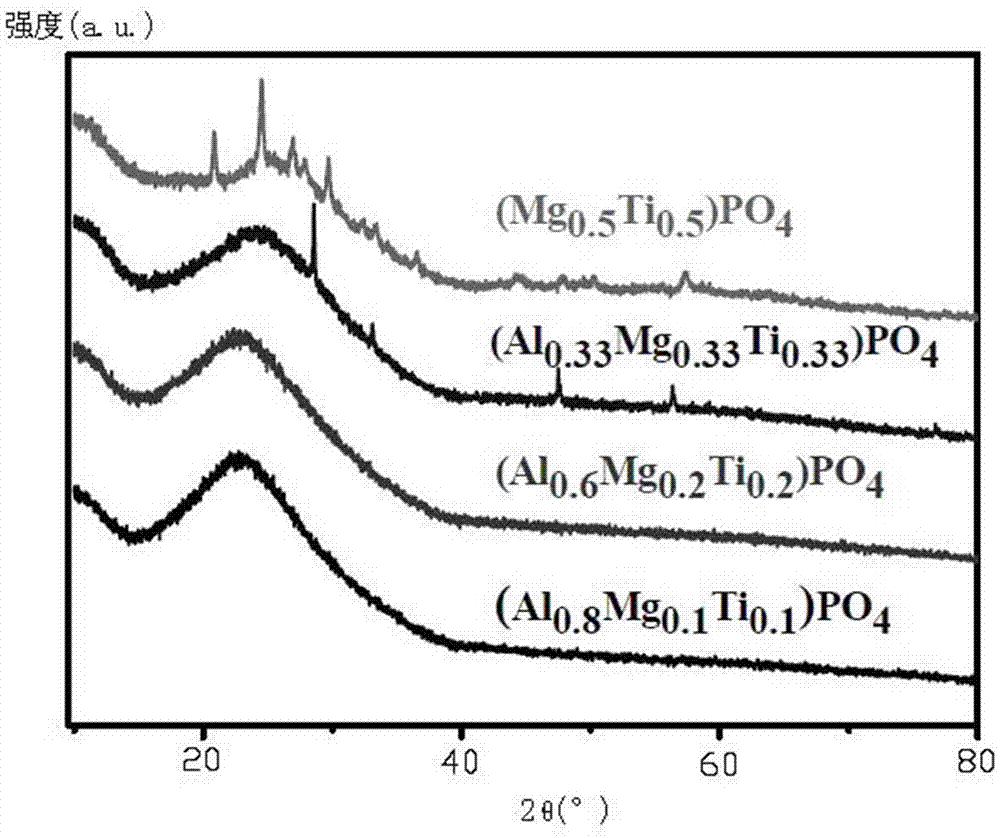

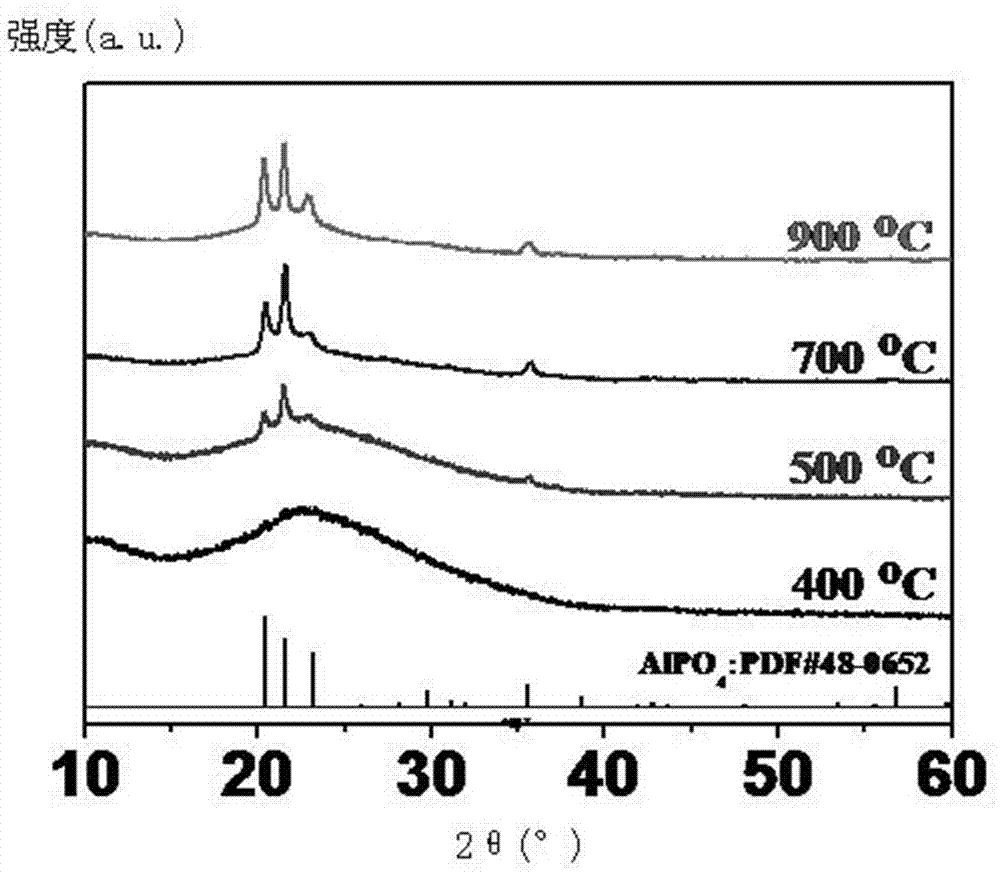

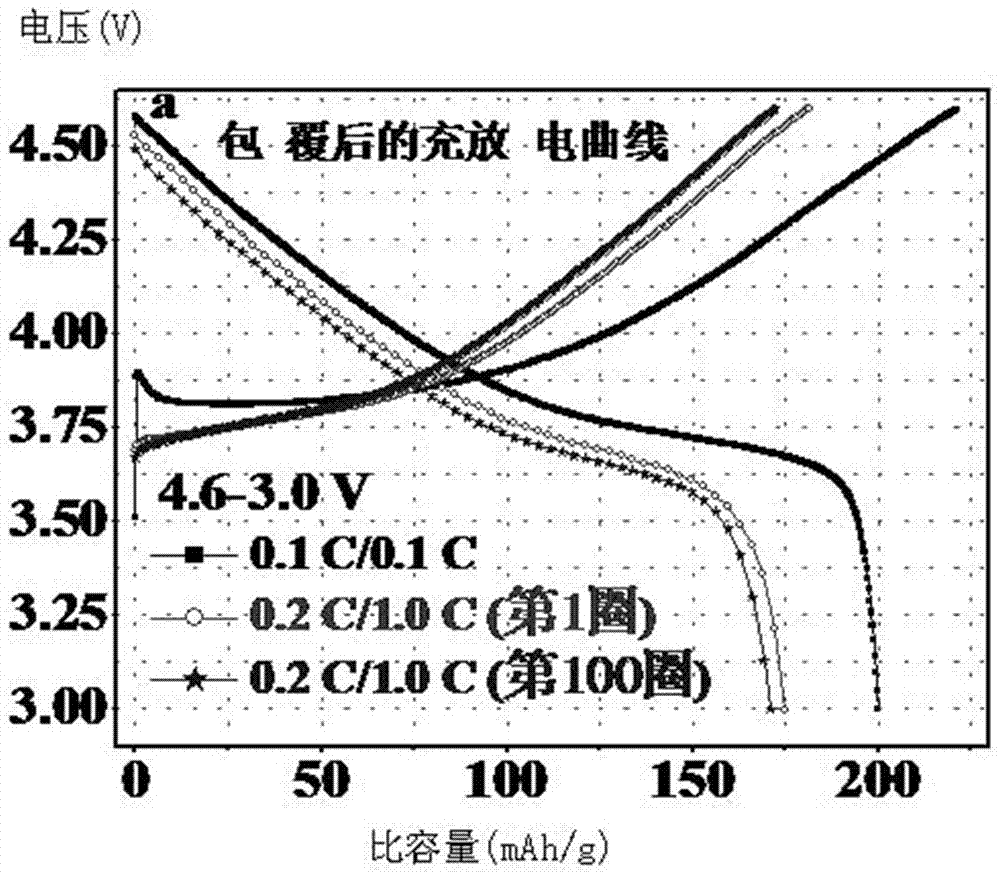

Positive electrode active material coating liquid and preparation method therefor and positive electrode active material coating method

ActiveCN106960958AThin and uniformInhibit side effectsElectrode thermal treatmentSecondary cellsSolventPhosphate

The invention relates to a positive electrode active material coating liquid. The positive electrode active material coating liquid comprises a solvent and a phosphate-coated precursor which can be dissolved in the solvent, wherein the solvent at least comprises an alcohols solvent; the phosphate-coated precursor is subjected to heat treatment to generate phosphate Al<m>M<n>PO<4>, wherein M is one or more of alkaline-earth metal elements or transitional group metal elements with valence state of k; m is greater than or equal to 0 and less than 1; n is greater than 0 and less than or equal to 1; and 3m+kn is equal to 3. The invention also relates to the positive electrode active material coating liquid and a positive electrode active material coating method.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

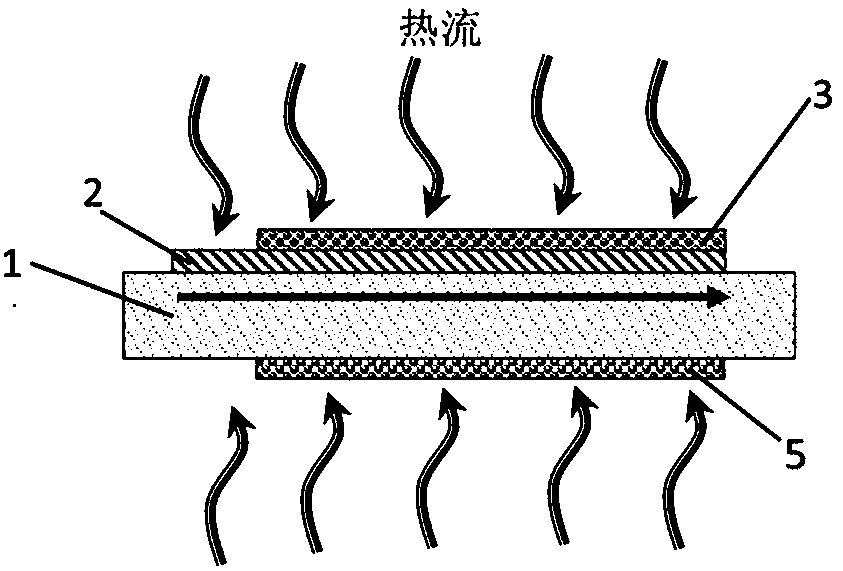

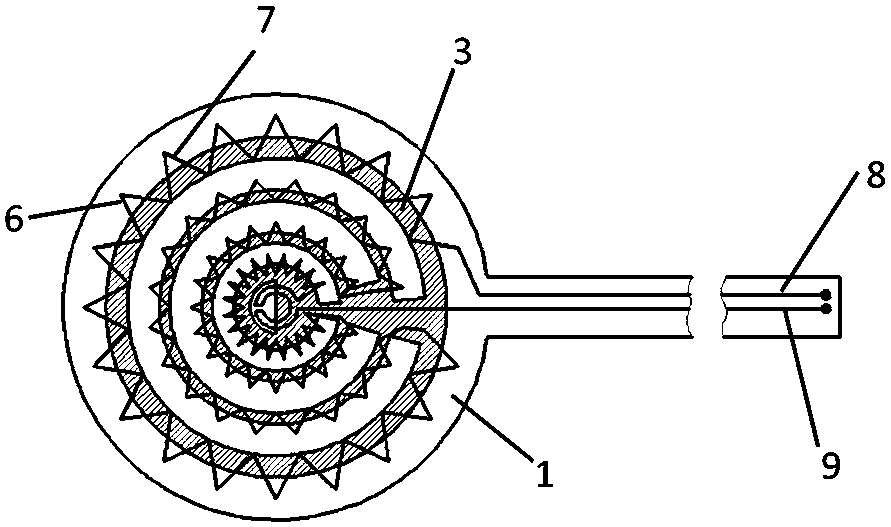

Film sensor for measurement of heat flow in high temperature environment and manufacturing method thereof

The present invention provides a film sensor for measurement of a heat flow in a high temperature environment and a manufacturing method thereof, belonging to the technical field of film sensors. Theobjective of the invention is to provide a film sensor capable of improving the sensitivity of the heat flow sensor, performing stable work in a high temperature environment and achieving stable reading of thermoelectric force signals with a simple process. The technical scheme employed to solve the technical problem is that: the sensor comprises a micron ceramic substrate, a thermopile, an uppertemperature gradient isolation layer, a lower temperature gradient isolation layer, a positive extraction electrode and a negative extraction electrode, the positive extraction electrode and the negative extraction electrode are printed on an extraction electrode substrate, the thermopile is printed on a thermopile substrate, the thermopile comprises multiple pairs of positive and negative thermocouples which are connected end to end and circularly connected in series in a surrounding mode. The present invention further provides a manufacturing method of the sensor. The film sensor for measurement of the heat flow in the high temperature environment and the manufacturing method thereof are widely applied to the field of temperature gradient measurement.

Owner:ZHONGBEI UNIV

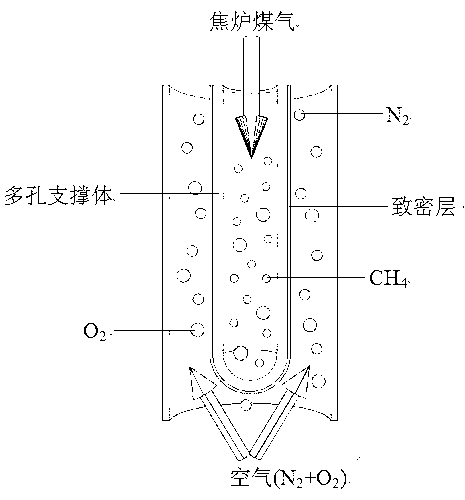

Preparation method of tubular asymmetric oxygen-permeable membrane

InactiveCN103253982AHighlight substantiveUniform adhesionCeramicwareMaterial technologyMechanical strength

The invention relates to a preparation method of a tubular asymmetric oxygen-permeable membrane, belonging to the technical field of functional ceramic materials. By selecting the pore forming agent and controlling the bisque firing temperature, the invention implements bisque firing of a porous support under the condition of undecomposed pore forming agent, effectively prevents the compact layer slurry from entering the inside of the pores of the support in the dipping process, and enables the precursor obtained by bisque firing to have higher mechanical strength. The asymmetric bifacial dipping method is utilized to successfully attach the uniform-thickness thin compact layer to the outer wall of the tubular precursor, thereby lowering the possibility of damage of the precursor due to overhigh pressure in the dipping process, and having favorable effect on preparing complex-shape great-dimension tubular compact layers.

Owner:SHANGHAI UNIV

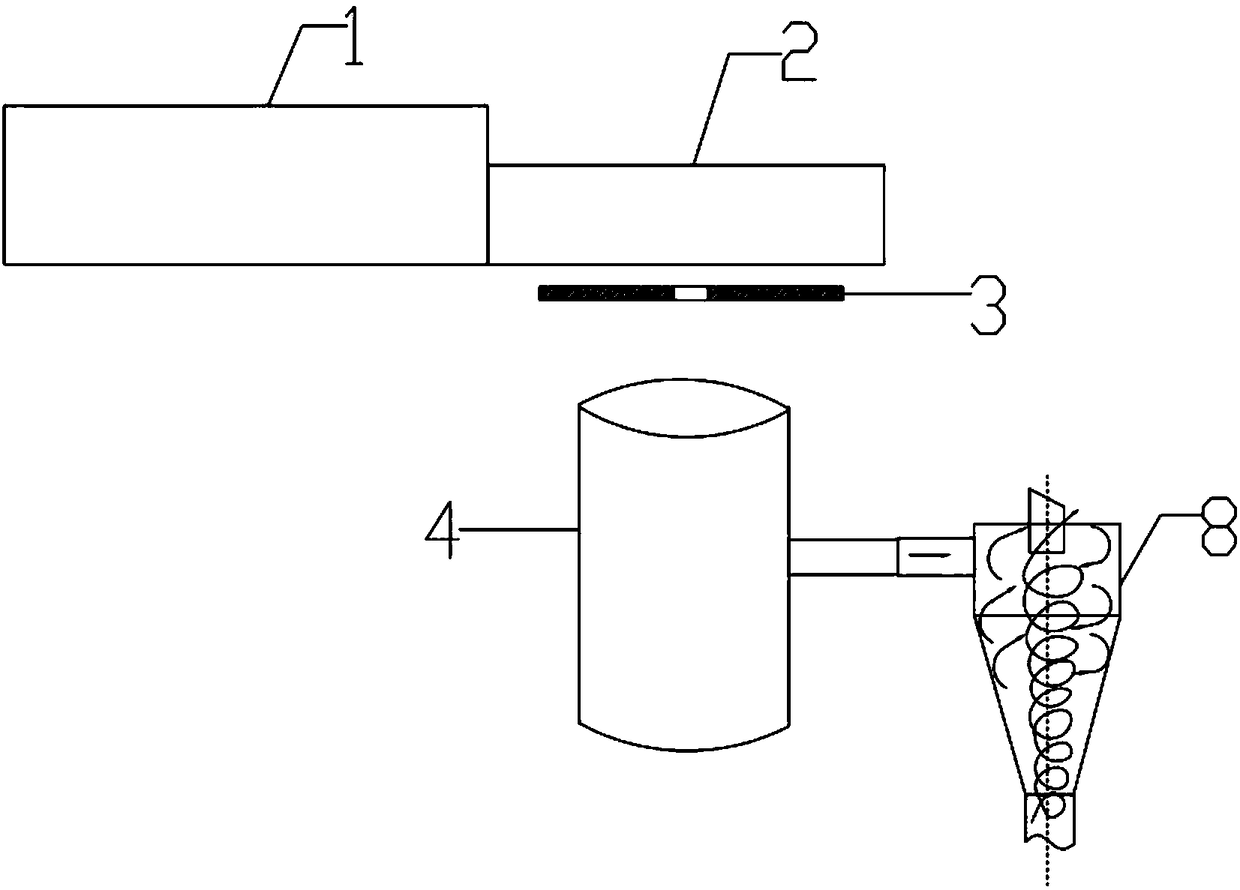

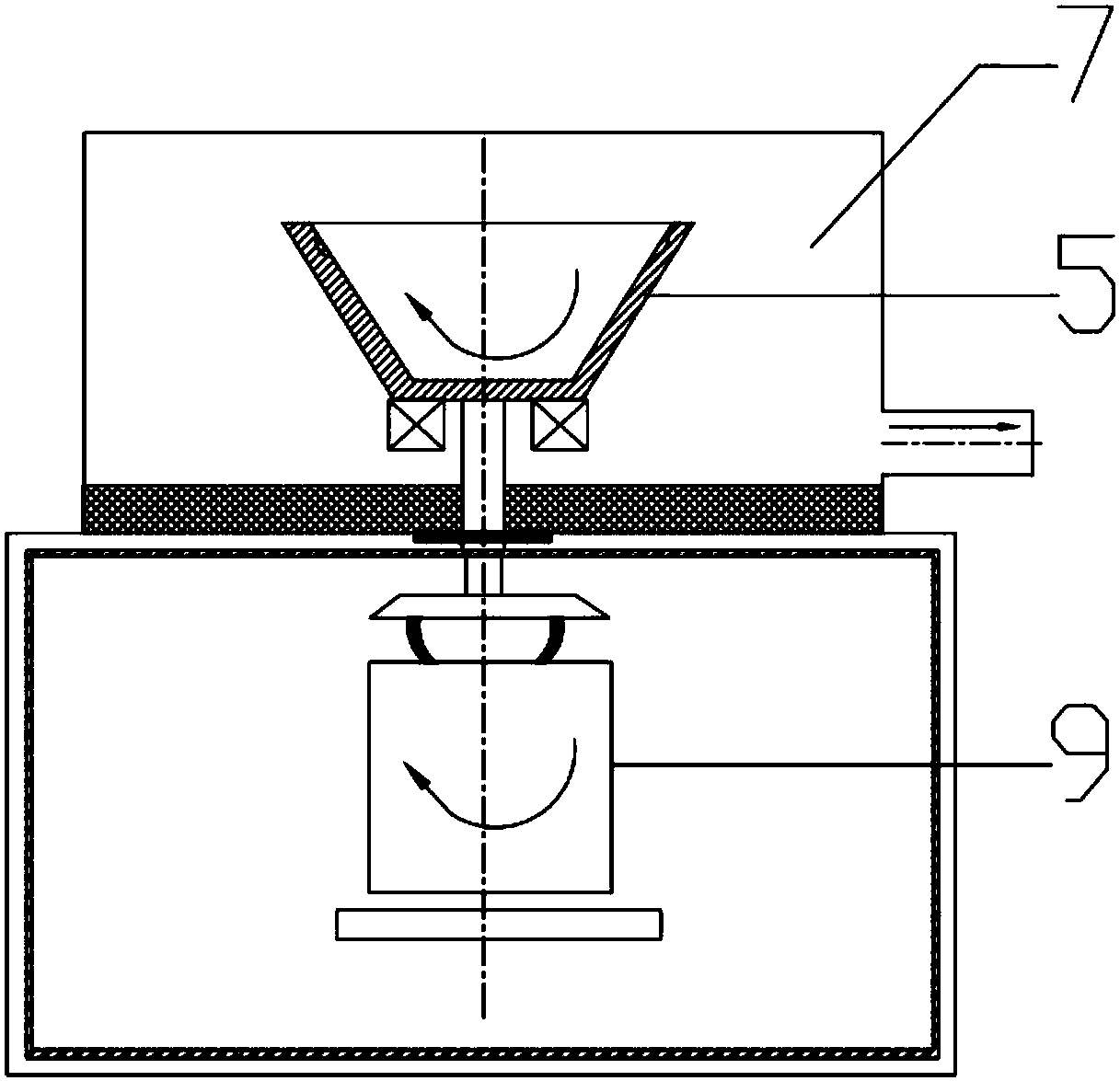

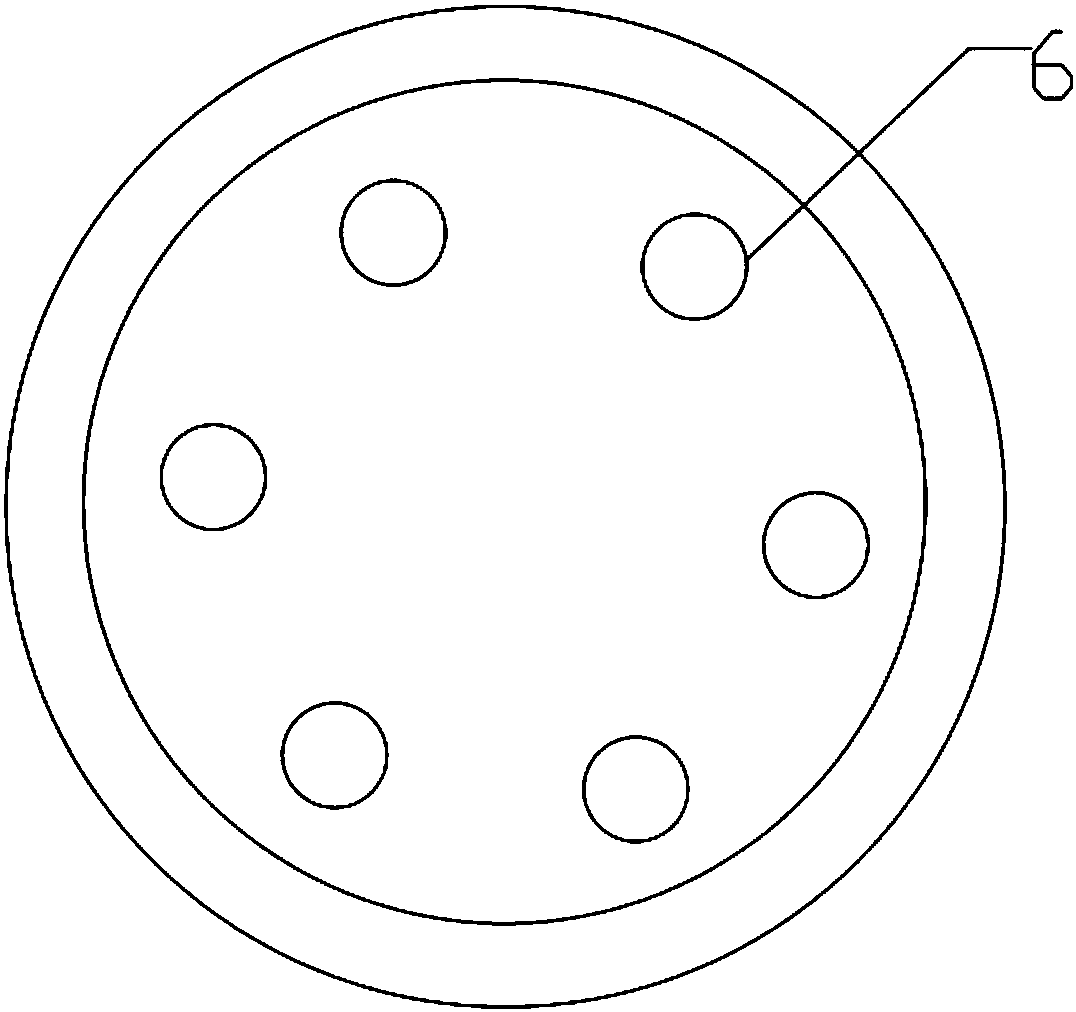

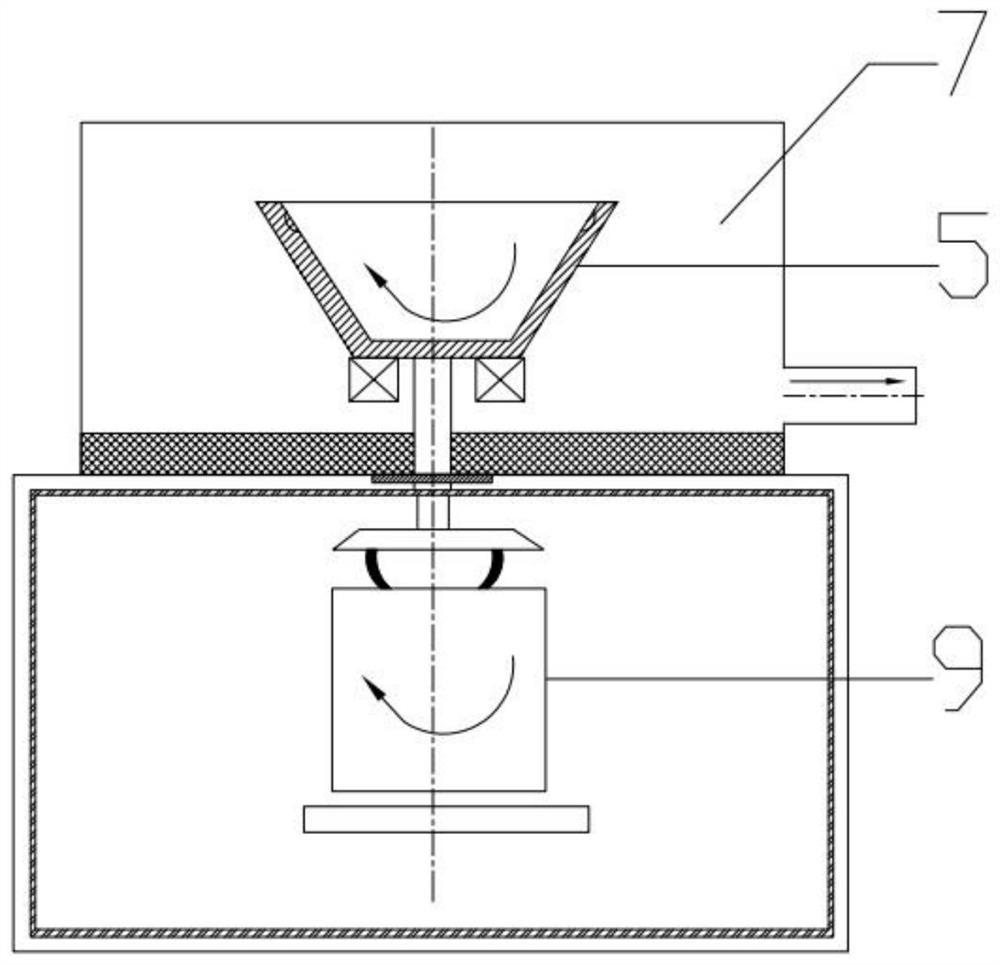

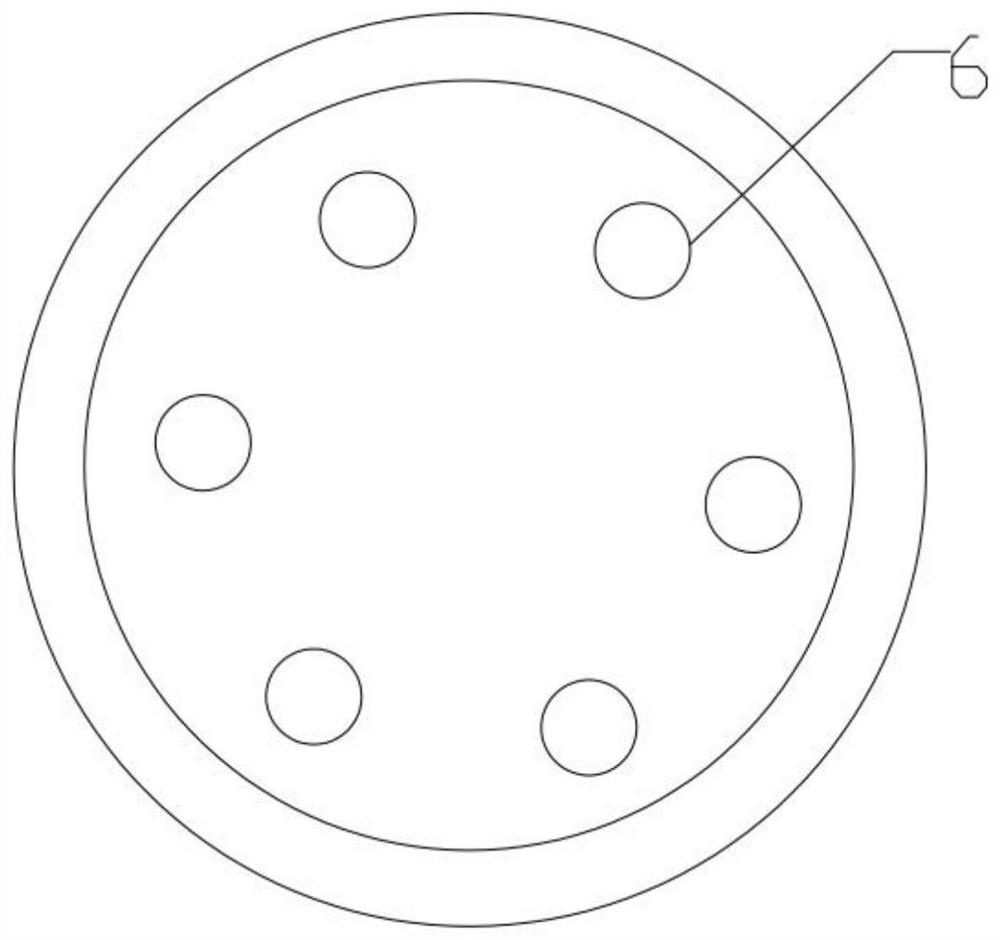

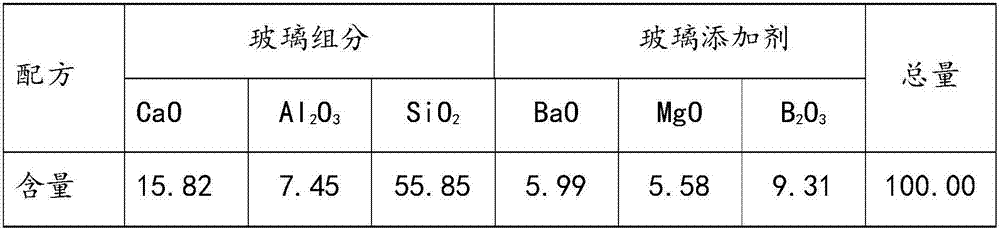

Device and method for producing scaly material from mineral melt

The invention relates to a device and a method for producing a scaly material from a mineral melt. The device comprises a furnace and a feeder, a discharge port of the furnace is communicated with a feed port of the feeder, a high temperature resistant alloy plate is arranged under a discharge port of the feeder, the center of the high temperature resistant alloy plate is provided with a through hole, a scale forming device is arranged below the high temperature resistant alloy plate, a discharge port of the scale forming device is communicated with a feed port of a cyclone separator, the scale forming device comprises a scale collecting chamber, a funnel-shaped rotating dispersing disc, and a motor driving the rotating dispersing disc to rotate, the rotating dispersing disc is arranged inside the scale collecting chamber, the top surface of the scale collecting chamber above the rotating dispersing disc is provided with an opening fitting in the position of the through hole in the center of the high temperature resistant alloy plate, and the inner upper end portion of the rotating dispersing disc is provided with a plurality of gas injection holes uniformly distributed in a ring shape.

Owner:烟台华正科信新材科技有限公司

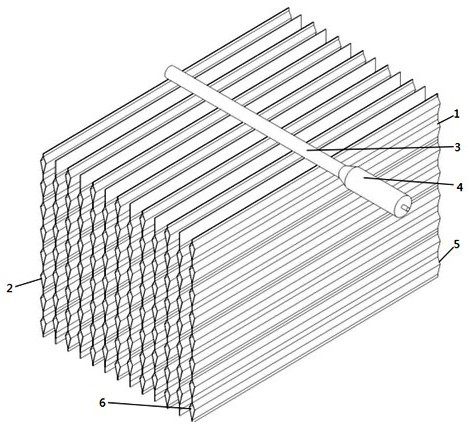

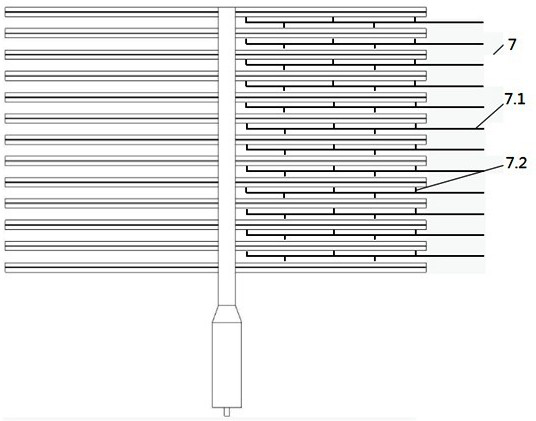

Horizontal shell-and-plate falling film anti-scale evaporator and application method thereof

PendingCN113916029AThin and uniformIncrease heat transfer areaCorrosion preventionVibration cleaningVibration amplitudeEngineering

The invention provides a horizontal shell-and-plate falling film anti-scale evaporator and an application method thereof. A heat transfer plate bundle of the horizontal shell-and-plate falling film anti-scale evaporator comprises multiple heat transfer plates which are parallel to one another and vertically arranged side by side to form the heat transfer plate bundle, and ultrasonic vibration transfer rods are arranged on the heat transfer plate bundle; and the ultrasonic vibration transfer rods are perpendicular to the heat transfer plate bundle, one end of each ultrasonic vibration transfer rod is connected with an ultrasonic transducer, wherein multiple communicated rhombic cavities are formed in the two sides of each heat transfer plate, and the rhombic cavities between the adjacent heat transfer plates are arranged in an up-and-down staggered mode. The rhombic cavity at the bottom of one side of each heat transfer plate is a steam inlet, and the rhombic cavity at the bottom of the other side of each heat transfer plate is a condensed water outlet. According to the horizontal shell-and-plate falling film anti-scale evaporator and the application method thereof, the evaporation efficiency is effectively improved by adopting the special-shaped rhombic cavities with large upper parts and small lower parts, and the heat transfer plates always keep high-frequency low-amplitude fluctuation in the operation process by combining scraper blades with the ultrasonic vibration transfer rods, so that the online scale prevention and removal capability is realized. The evaporator and the application method thereof are wide in application range and simple and stable in structure.

Owner:上海兴全电力技术有限公司

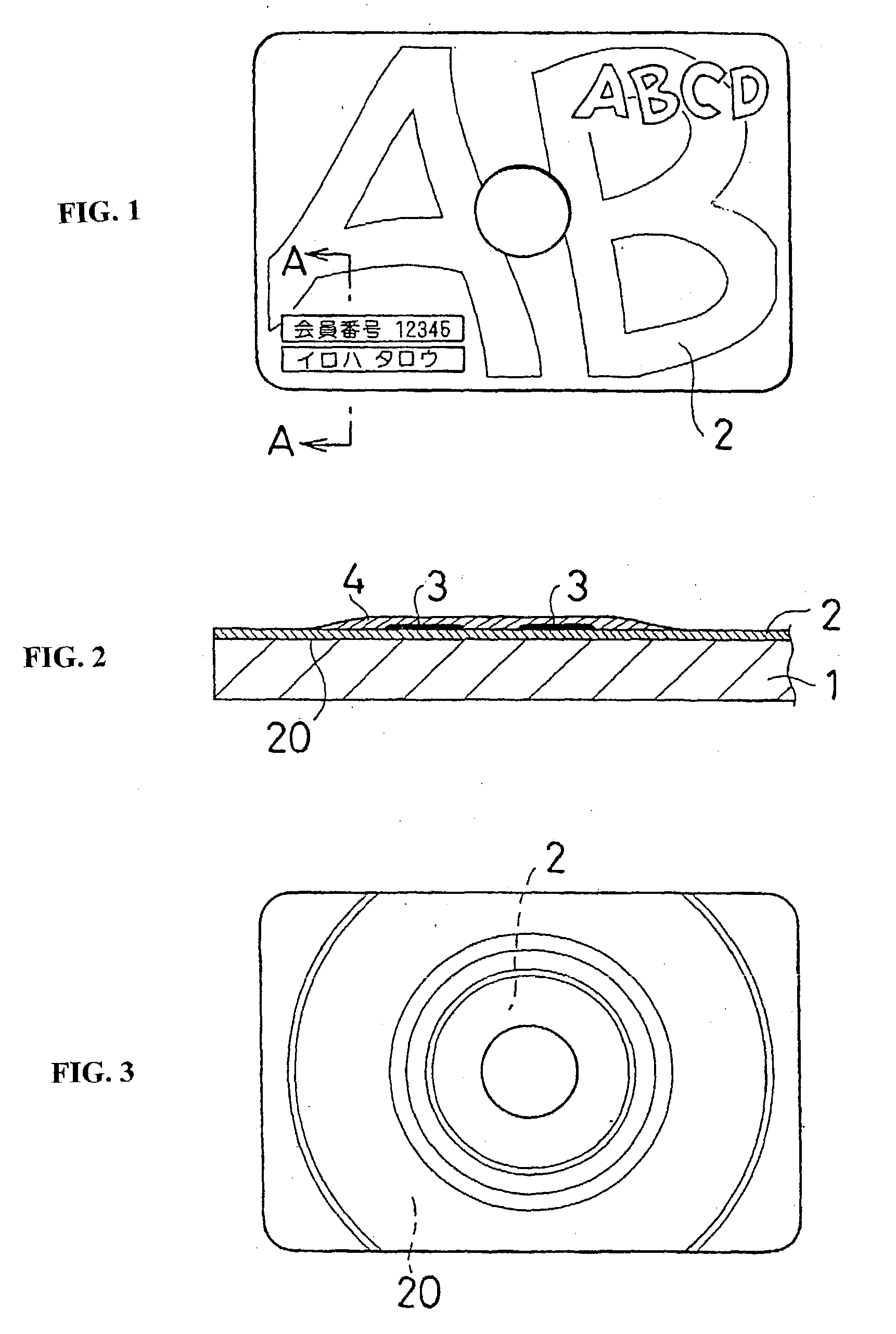

Protective agent for printed matter and protection layer forming method

InactiveUS20030152754A1Improve distributionEnhance layeringLayered productsDecorative surface effectsPolymer scienceOrganic solvent

A protective agent for protecting a print formed on a printing object comprises a high-volatile organic solvent as a dispersion medium and non-water family high polymer emulsion liquid including synthetic resin particles as a dispersoid. This protective agent is sprayed onto a print formed on a printing object by a spray method and then dried. For example, an oil-based first print layer 2 is formed on a surface of an information record member 1, an oil-based second print layer 3 is formed on at least a part of the upper surface of the first print layer 2, and the aforementioned protective agent is applied on the upper surface of the second print layer 3 and dried to form a protective layer 4. Thus, the print will not disappeared even if a hands touches or water is adhered, and no bad influence will be given to the substrate material since the protective agent is excellent in quick-drying property.

Owner:ORIENT INSTR COMP CO LTD

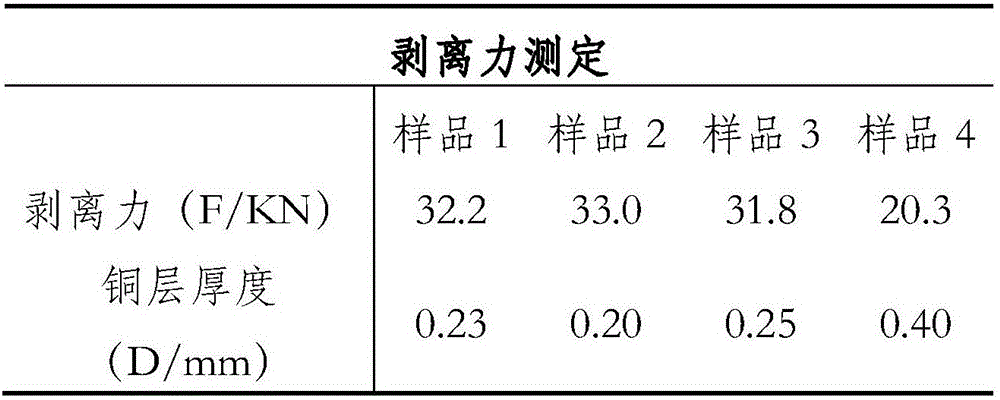

Preparation method of molten-copper-aluminum melt alloy bus

ActiveCN106683794AThin and uniformIncrease section sizeApparatus for heat treatmentConductive materialRare-earth elementHigh energy

The invention provides a preparation method of a molten-copper-aluminum melt alloy bus. The preparation method includes: removing an oxide layer on the surface of an aluminum bar and oxide on the inner wall of a copper tube, and preheating the copper tube; melting the aluminum bar, feeding inert gas, adding rare-earth elements, and performing high-energy ultrasonic treatment; melting the aluminum bar, adding intermediate alloy, fast cooling, preparing semi-solid slurry, and performing heat preservation; placing the preheated copper tube into the female die cavity of a hydraulic machine, quantitatively pouring the semi-solid rare-earth molten-aluminum slurry into the female die cavity, using the hydraulic machine to perform fast extrusion forming through the female die cavity, and performing heat preservation; performing multi-pass continuous rolling, and cooling in the air. The preparation method has the advantages that the mechanical performance of the prepared molten-copper-aluminum melt alloy bus can stably shows excellent combining and tensile properties as compared with that of similar products on the market; the prepared molten-copper-aluminum melt alloy bus is excellent in conductivity, and the measured conductivity of the prepared molten-copper-aluminum melt alloy bus is stably higher than that of the similar products; the preparation method is energy-saving, environmentally friendly and promising in industrial application prospect.

Owner:美嘉科技(镇江)有限公司

Method for forming sn-ag-cu three-element alloy thin film on base

A method of forming an Sn-Ag-Cu ternary alloy thin-film of the present invention forms the ternary alloy thin-film by electroplating. A plating bath contains an Sn compound, an Ag compound, a Cu compound, an inorganic chelating agent and an organic chelating agent. The inorganic chelating agent is one of a polymerized phosphate-based chelating agent and a chelating agent represented by a chemical formula (I): MF X (X-Y)- ... (I) where M is an arbitrary metal, X is an arbitrary natural number and Y is an oxidation number of M. The organic chelating agent is one of porphyrins, dipivaloylmethane, phthalocyanines and a compound represented by a chemical formula (II): R-(CH 2 CH 2 O) n -A ... (II) where R is an alkyl group having a carbon number of 8 to 30, A is CH 2 COONa or CH 2 SO 4 Na and n is a natural number.

Owner:FCM CO LTD

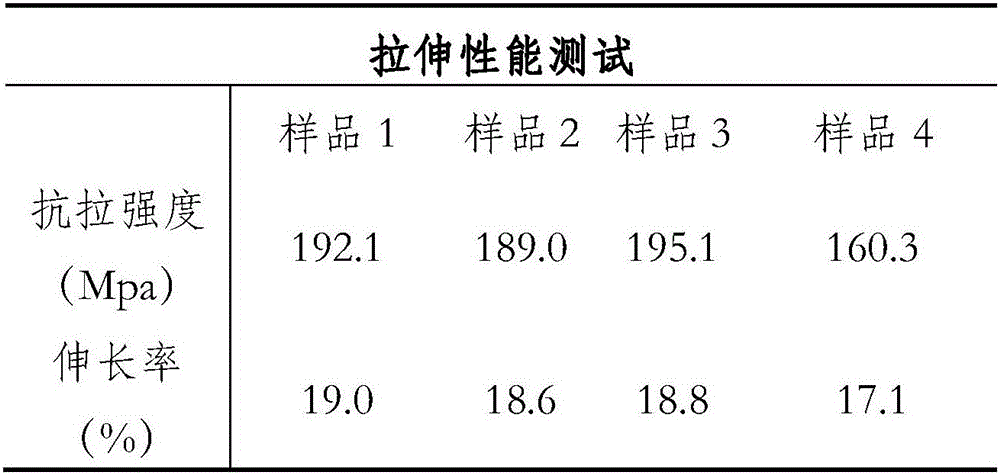

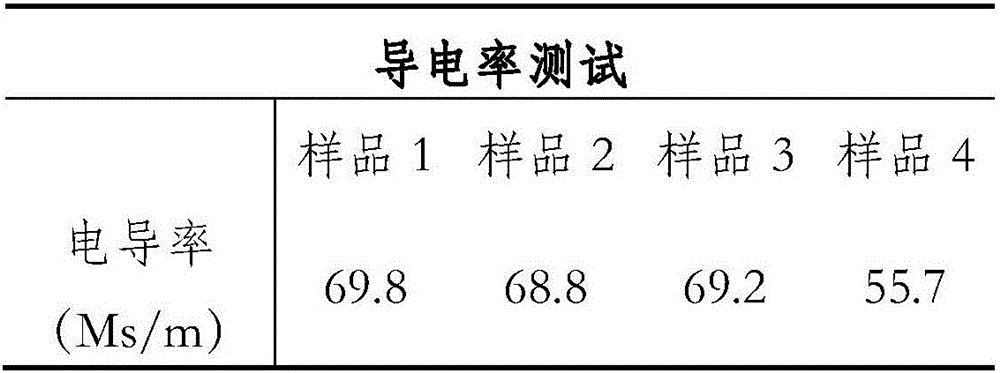

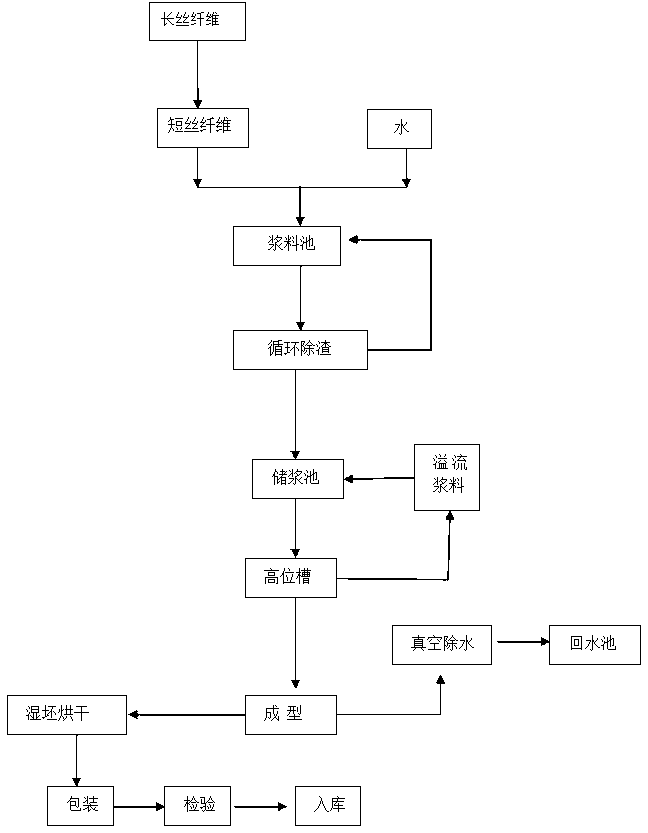

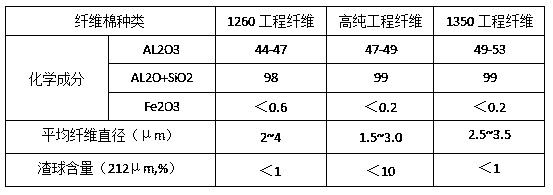

Preparation method of fire-resistant engineering fiber

InactiveCN109763369AGood dispersionThin and uniformDryer sectionSevering to form staple fibresFiberSlag

The invention provides a preparation method of a fire-resistant engineering fiber. The preparation method includes the following steps of (1) short cutting; (2) dispersing; (3) circulation slag removing; (4) molding; and (5) drying. The preparation method of the fire-resistant engineering fiber has the advantages that 1, circulation slag removing is conducted through a slag separator, produced products have the low shot content, and the content of 212 [mu]m shots can reach 1% or below; 2, the fire-resistant fiber subjected to wet slag removal has good dispersibility, and product performance isstable; and 3, the thickness of a fiber wet billet is low and uniform by adopting long mesh molding, in this way, the drying time of hot air is reduced by 30% compared with traditional technologies,and the production efficiency is improved.

Owner:湖北烁砺新材料科技有限公司

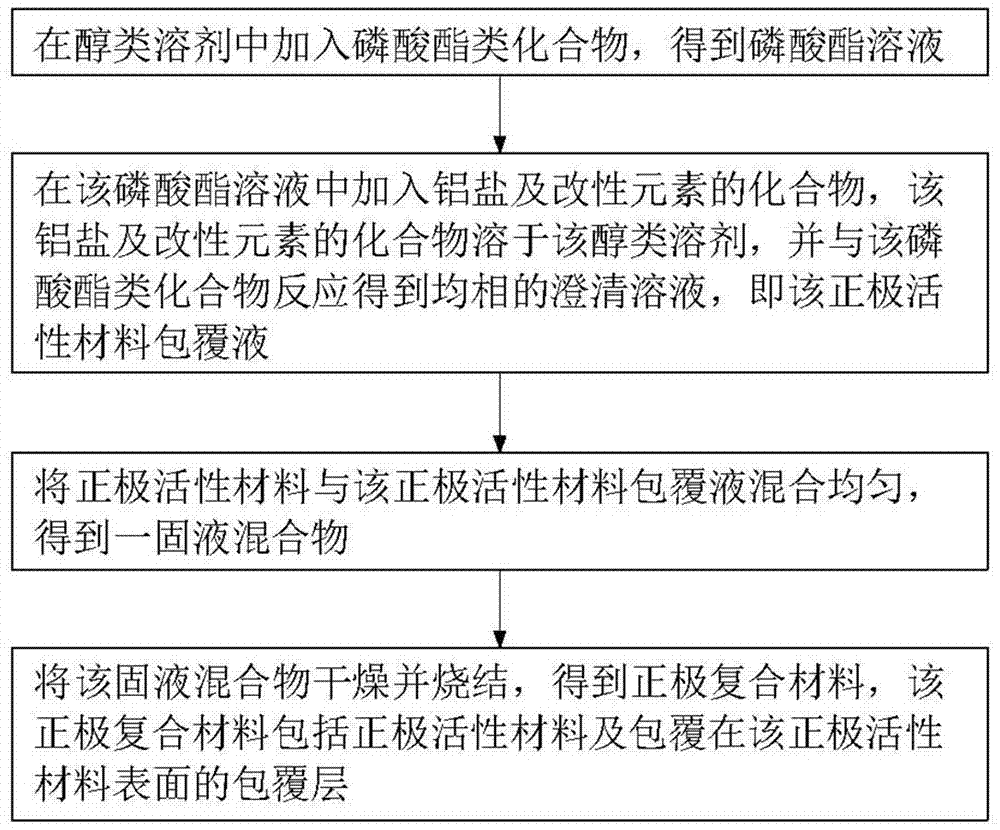

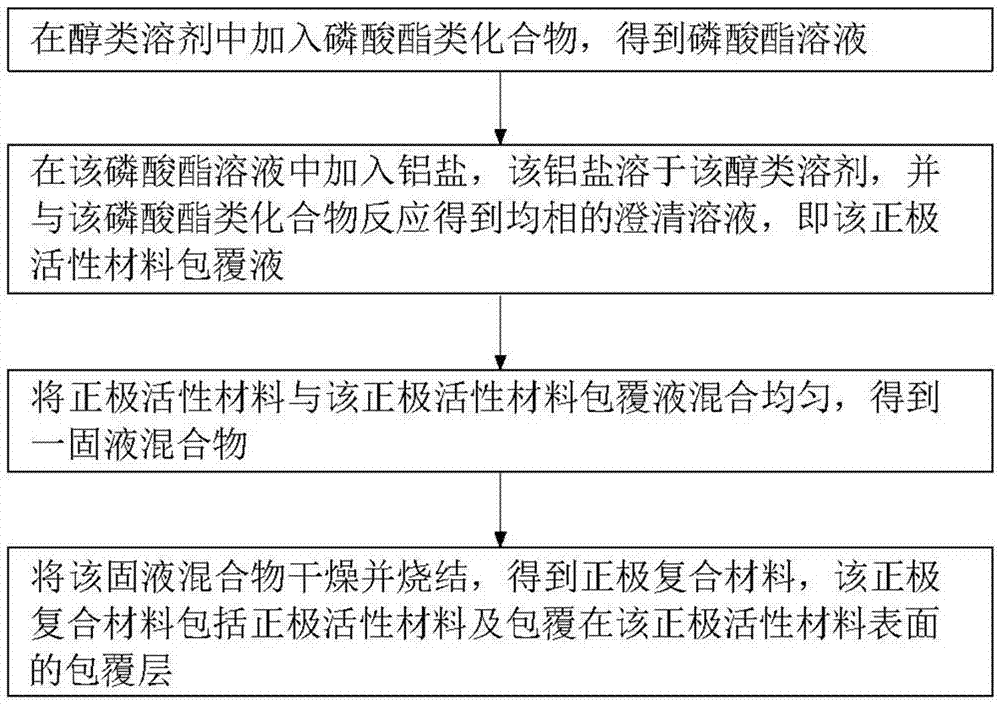

Positive pole active material cladding liquid, preparation method thereof, and cladding method for positive pole active material

ActiveCN106898734AThe overall thickness is thinThin and uniformConductive materialSecondary cellsAlcoholPhosphate

The invention relates to a preparation method of a positive pole active material cladding liquid. The preparation method includes the steps of: 1) adding a phosphate compound to an alcohol solvent to prepare a phosphate solution; 2) adding an aluminum salt to the phosphate solution, wherein the aluminum salt is soluble in the alcohol solvent and can be reacted with the phosphate compound to obtain a homo-phase clear solution. The invention also relates to the positive pole active material cladding liquid and a cladding method for a positive pole active material.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

Apparatus and method for producing scaly material from mineral melt

The invention relates to a device and method for producing scaly materials from mineral melts, comprising a furnace and a feeder, the outlet of the furnace communicates with the inlet of the feeder, and the outlet of the feeder A high-temperature-resistant alloy plate is provided below the feed port, and a through hole is provided in the center of the high-temperature-resistant alloy plate. A scale forming device is provided below the high-temperature-resistant alloy plate. The discharge port of the scale forming device is connected to the inlet of the cyclone separator. The feed port is connected, and the scale forming device includes a scale collection bin, a funnel-shaped rotating dispersing disc and a motor that drives the rotating dispersing disc to rotate, and the rotating dispersing disc is arranged inside the scale collecting bin, above the rotating dispersing disc The top surface of the scale collection bin is provided with an opening matching the position of the through hole in the center of the high-temperature-resistant alloy plate, and the inner upper end of the rotating dispersing disc is provided with a number of circular and evenly distributed air injection holes.

Owner:烟台华正科信新材科技有限公司

Terminal having surface layer , and part and product having the same

ActiveCN1638198AThin and uniformImprove solderabilityContact materialsCoupling contact membersSurface layerElectroplating

The present invention provides a terminal in which a surface layer composed of Sn-Ag-Cu ternary alloy is formed on the entirety or part of a conductive base through electroplating. The characteristic is that the Sn-Ag-Cu ternary alloy is composed of Sn It is composed of a ratio of 70 to 99.8% by mass, 0.1 to 15% by mass of Ag, and 0.1 to 15% by mass of Cu. Its melting point is 210 to 230°C, and compared with when the surface layer is formed only of Sn, the Finer granular crystalline state.

Owner:FCM CO LTD

A preparation method of ultra-thin double-sided optoelectronic copper foil and the prepared copper foil

ActiveCN106086945BThin and uniformThe roughness of the rough surface is moderate and uniformElectroforming processesElectrochemical responseElectrolysis

The invention relates to a preparation method of an ultra-thin double-sided photoelectronic copper foil and the prepared copper foil. The method comprises the following steps of: adding alkylphenol polyoxyethylene ether sodium sulfonate, 1,3-thiazolidine-2-one and collagen in deionized water and dissolving to obtain an additive solution for ultra-thin copper foil production; under the condition of a copper sulphate electrolyte at a temperature of 20-90 DEG C, adding 5.0-10.0L of the additive solution in per cubic metre of the electrolyte per hour, uniformly stirring and then enabling the electrolyte to enter an electrolytic bath; and electrolysing the electrolyte in the electrolytic bath under an electrolytic current density of 2000-6000A / m<2>, and carrying out an electrochemical reaction to generate the ultra-thin double-sided photoelectronic copper foil. The ultra-thin double-sided photoelectronic copper foil manufactured by the process disclosed by the invention has the following performance: the thickness is small and uniform, the roughness of a rough surface is moderate and uniform, the two sides of the copper foil are smooth and bright, the surface tension of the copper foil is high, the adhesion force of lithium-ion negative electrode active materials can be effectively increased, the electric capacity and charge-discharge times of a battery are increased, and the service life of the battery is prolonged.

Owner:ANHUI TONGGUAN COPPER FOIL +1

Preparation method of 99.6 percent of Al2O3 ceramic substrate for thin film integrated circuit

ActiveCN106986665AHigh softening pointFlat surfaceSemiconductor/solid-state device manufacturingIntegrated circuitMaterials science

The invention provides a preparation method of a 99.6% Al2O3 ceramic substrate for a thin film integrated circuit. Through the preparation method of the 99.6% Al2O3 ceramic substrate for the thin film integrated circuit, provided by the invention, the surface roughness of the substrate can be reduced, so that the smoothness and the flatness are improved, therefore, the precision and the reliability of the thin film integrated circuit are improved, and the practical value is important. Meanwhile, the preparation method of the 99.6% Al2O3 ceramic substrate for the thin film integrated circuit, provided by the invention, has the advantages of being small in surface roughness, good in flatness, good in smoothness, specular in surface and the like.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

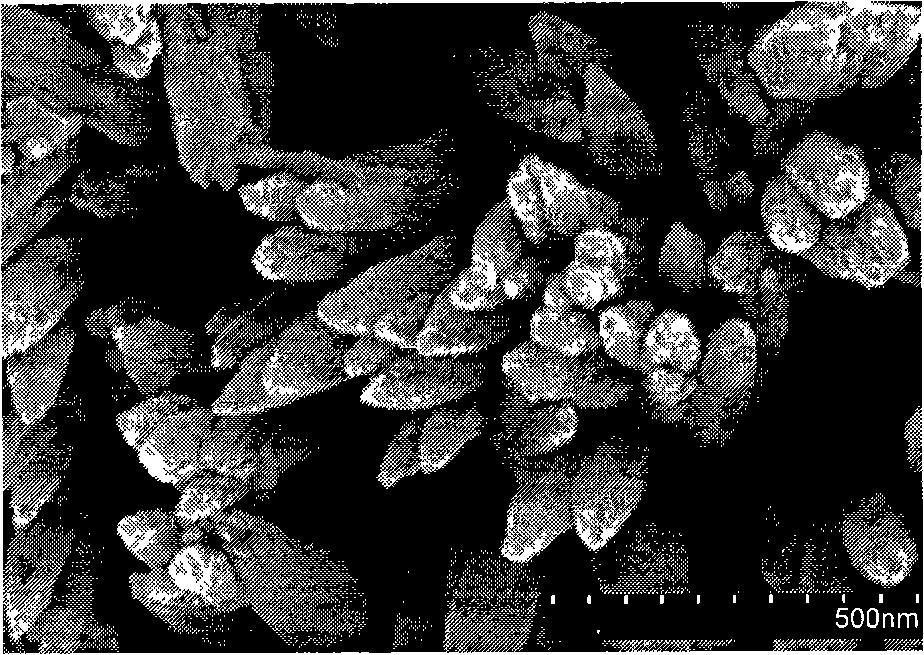

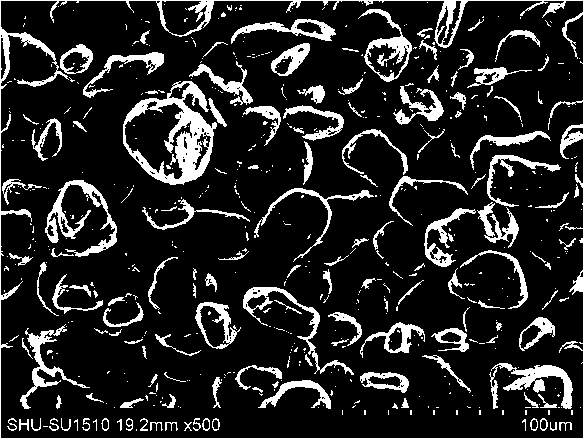

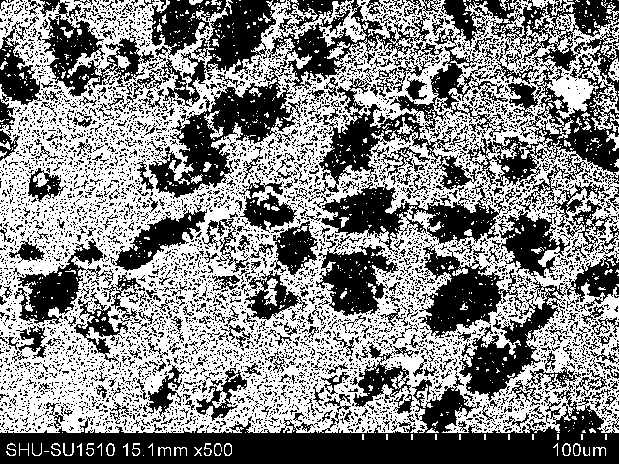

Preparation method of gypsum scanning electron microscope sample

PendingCN108680591AUniform thicknessUniform sizeMaterial analysis using wave/particle radiationGypsumElectrically conductive

Belonging to the technical field of preparation of scanning electron microscope samples, the invention relates to a preparation method of a gypsum scanning electron microscope sample. The preparationmethod comprises the steps of: 1) blending water and a gypsum powder raw material into a homogeneous slurry; 2) pouring the well blended slurry of step 1) into a mold, scraping the slurry flat, makingthe slurry surface flush with the upper mouth margin of a die, and then conducting drying, molding, demoulding, curing and drying to obtain a gypsum test block; 3) pasting a conductive adhesive tapeto a sample table, and then pasting the gypsum test block of step 2) on the conductive adhesive tape; and 4) using inert gas to purge the upper surface of the sample table pasted with the gypsum testblock of step 3), then conducting spray coating of a conductive metal. The gypsum sample prepared by the method provided by the invention has small size, is regular, thin and uniform, and has a smoothsurface, and the microcrystalline morphology is not destroyed, and the microcrystalline morphology photograph obtained by the gypsum sample under a scanning electron microscope is free of false and fuzzy phenomena. At the same time, the preparation method provided by the invention has the advantages of simple operation, rapid sample preparation and high efficiency.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com