A preparation method of ultra-thin double-sided optoelectronic copper foil and the prepared copper foil

An optoelectronic and electrolytic copper foil technology, applied in electroforming, electrolytic process, etc., can solve the problems of unstable production process control, uneven thickness of copper foil, low yield, etc., and achieves smoothness and bright, uniform thickness, surface high tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

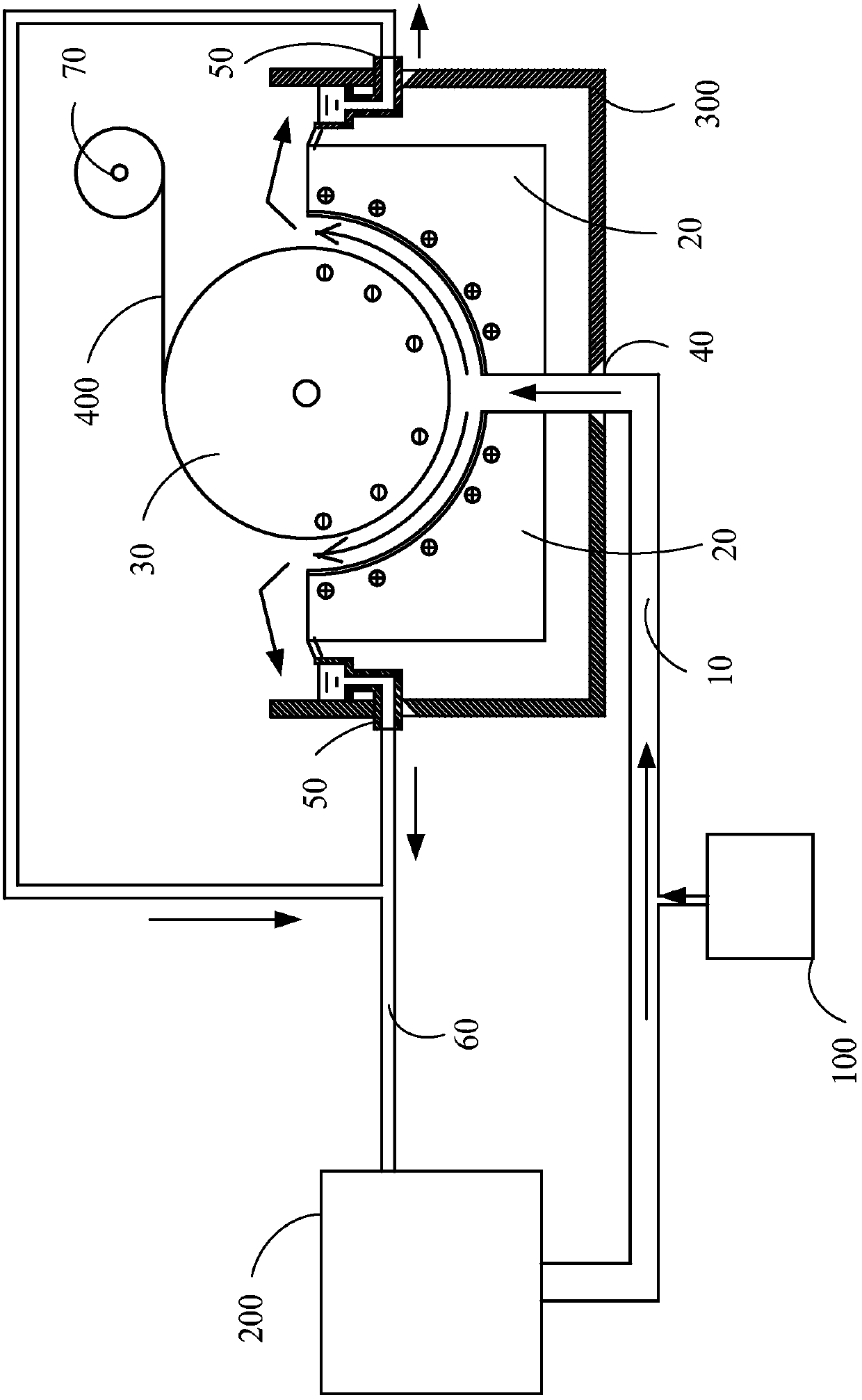

[0029] see figure 1 , The preparation of the ultra-thin double-sided optoelectronic copper foil provided by the first embodiment of the present invention, that is, the manufacturing method of the 6 μm ultra-thin double-sided optoelectronic copper foil, comprises the following steps.

[0030] Inject the prepared additive into the electrolyzer liquid inlet pipe through the metering pump at 7.5L / h, fully mix with the electrolyte in the electrolyte preparation system during the fluid transportation process, and then enter the electrolyzer;

[0031] The flow rate of the electrolyte is 40-60m 3 / h, after the additive solution is mixed with the electrolyte and enters the electrolytic cell, at 4000~5000A / m 2 Electrolyzed for 60 seconds under the current density of the electrolytic solution, under the action of the electric field, the anions move to the anode, and the cations move to the cathode roller of the electrolytic cell, and electrochemical deposition is performed on the surfac...

Embodiment 2

[0037] Referring to the production method of Example 1, the copper foil product was prepared. The temperature of the electrolyte was 50-55° C., and the concentrations of the components were as follows: copper ion concentration 85 g / L, sulfuric acid concentration 170 g / L, and chloride ion concentration 0.03 g / L , the electrolyte flow rate is 40-60m 3 / h, the additive flow rate is 7.0L / h, and the formula of additive solution is: 2.0g / L alkylphenol polyoxyethylene ether sulfonate sodium (octylphenol polyoxyethylene ether sodium sulfonate), 2.0g / L 1,3-Tetrahydrothiazol-2-one, 1.5g / L collagen.

[0038] The rough surface of the lithium battery copper foil prepared in this example is mirror-like like the smooth surface, and the surface is smooth and wrinkle-free. After testing, the crystallization of the copper foil grains is a fine layered structure, and the thickness of the copper foil is 5.9-7.1um. The surface roughness Rz of the rough surface is 1.56um, and the tensile strength ...

Embodiment 3

[0040] Referring to the production method of Example 1, the copper foil product was prepared. The temperature of the electrolyte was 50-55°C, and the concentration of each material component was: copper ion concentration 75g / L, sulfuric acid concentration 165g / L, chloride ion concentration 0.03g / L , the electrolyte flow rate is 40-60m 3 / h, the flow rate of the additive is 8.0L / h, and the formula of the additive solution is: 1.0g / L alkylphenol polyoxyethylene sodium sulfonate (sodium nonylphenol polyoxyethylene ether sulfonate), 1.0g / L 1 , 3-tetrahydrothiazol-2-one, 0.5g / L collagen.

[0041] The rough surface of the ultra-thin double-sided optoelectronic copper foil prepared in this example is mirror-like like the smooth surface, and the surface is smooth and wrinkle-free. After testing, the crystallization of the copper foil grains is a fine layered structure, and the thickness of the copper foil is 5.9 ~7.1um, rough surface roughness Rz is 1.43um, tensile strength is 45.6Kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wettability | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com