Coupling method for planar waveguide chip and fiber array

An optical fiber array and planar waveguide technology, which is applied in the field of optical guide communication, can solve the problems of large shrinkage of the adhesive layer, not particularly obvious changes in IL, and large fluctuation range of IL parameters, and achieves uniform thickness, thin thickness and stable optical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

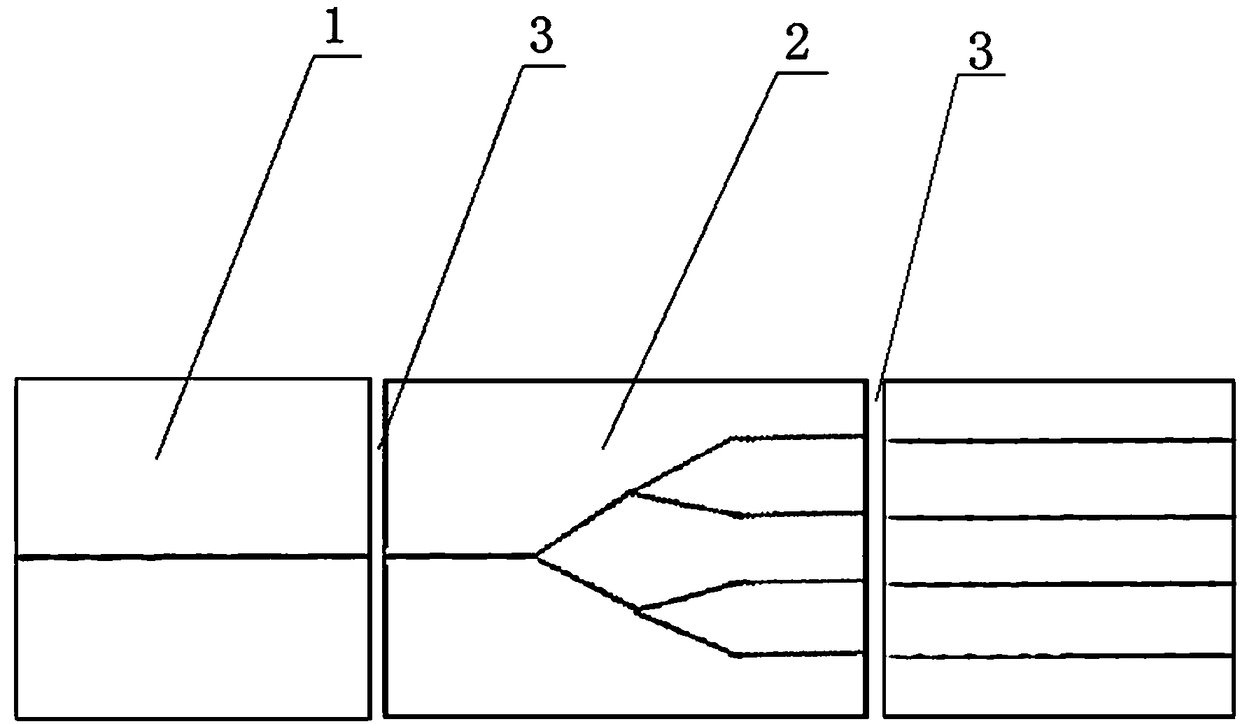

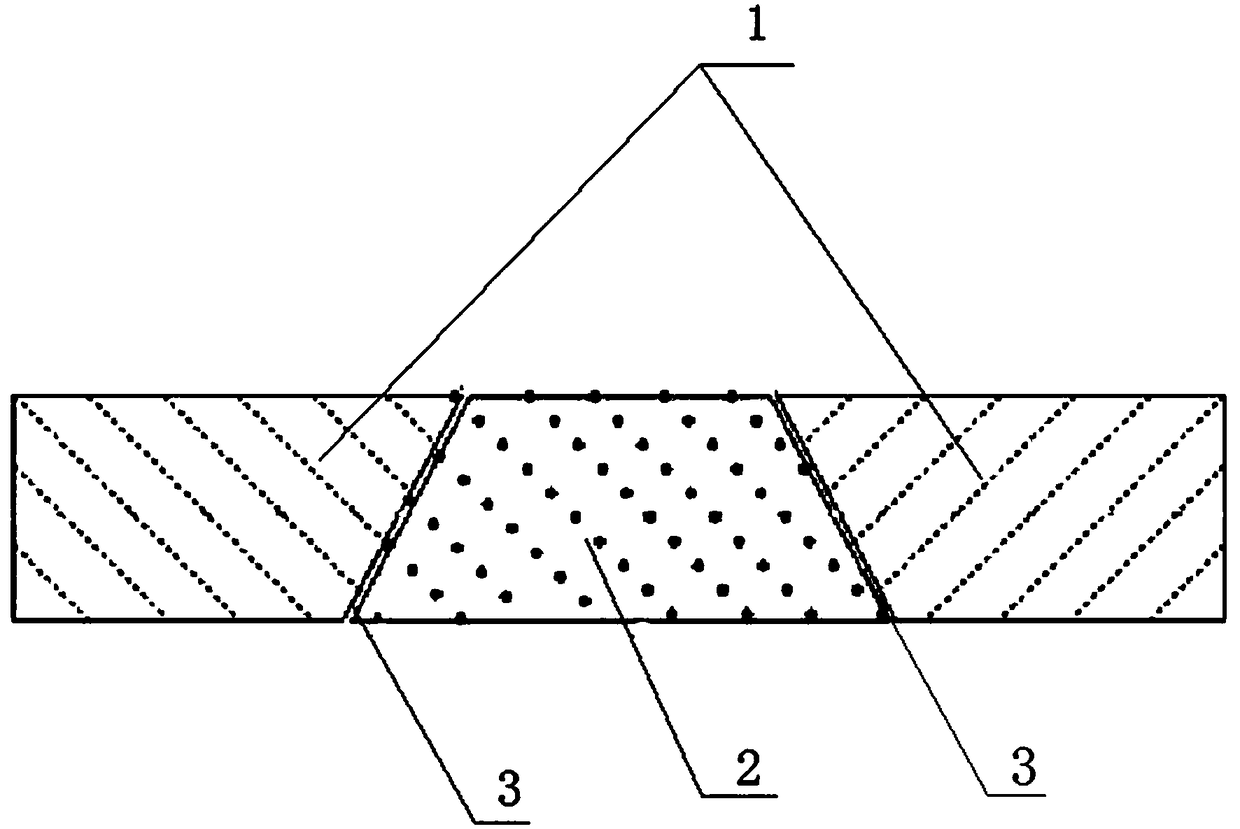

[0019] Such as Figure 1~2 As shown, a coupling method of a planar waveguide chip and an optical fiber array comprises the following steps:

[0020] S1. Clean the surface of the planar optical waveguide chip and the PLC chip, and then place the single fiber and the PLC chip on the six-dimensional adjustment frame, so that the 8° end face of the PLC chip is facing the light-transmitting surface of the FA;

[0021] S2. Adjust the six-dimensional adjustment frame to align the fiber core of the planar optical waveguide chip with the main waveguide of the input end of the PLC chip, and directly connect more than two light sources to the light source of the 2-point N optical splitter, and each station has a light source belt There are red light and wavelength light sources, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com