Suspended filler ball for treating sewage by biofilm method and preparation method thereof

A technology of suspended filler and biofilm method, which is applied in biological water/sewage treatment, granular microbial carrier treatment, chemical instruments and methods, etc. It can solve the problem that nanoparticles are easy to agglomerate or fall off, the specific surface area of loofah is reduced, and the purification effect is difficult. Guarantee and other issues, to achieve the effect of improving specific surface area and roughness, preventing specific surface area reduction, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

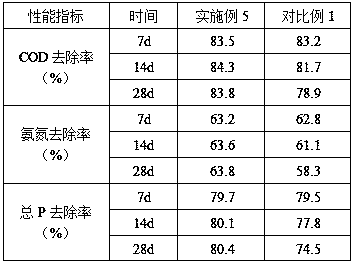

Examples

Embodiment 1

[0028] (1) Disperse calcium silicate nanoparticles and calcium stearate in deionized water to obtain dispersion A; the mass ratio of calcium silicate nanoparticles, calcium stearate and deionized water is 6:0.2:100;

[0029] (2) Add sodium alginate and monoglyceride into deionized water, stir and dissolve at 70°C to obtain solution B; the mass ratio of sodium alginate, monoglyceride and deionized water is 0.5:0.02:100;

[0030] (3) Cut the loofah into small pieces of 2cm, clean it, and dry it under vacuum at 80°C for 2 hours, then immerse the loofah in the dispersion A, stir at 1200rpm for 30min, stop stirring, and then use a frequency of 25kHz and a power density of 0.5 W / cm 2 Ultrasonic treatment 2h, filter, obtain the loofah of depositing and adsorbing calcium silicate nanoparticles;

[0031] (4) Immerse the loofah on which calcium silicate nanoparticles are deposited and adsorbed in solution B, using a frequency of 25kHz and a power density of 0.5W / cm 2 Ultrasonic treatm...

Embodiment 2

[0034] (1) Disperse calcium silicate nanoparticles and calcium stearate in deionized water to obtain dispersion A; the mass ratio of calcium silicate nanoparticles, calcium stearate and deionized water is 5:0.4:100;

[0035] (2) Add sodium alginate and monoglyceride into deionized water, stir and dissolve at 70°C to obtain solution B; the mass ratio of sodium alginate, monoglyceride and deionized water is 0.4:0.03:100;

[0036] (3) Cut the loofah into small pieces of 2cm, clean it, and dry it under vacuum at 80°C for 2 hours, then immerse the loofah in the dispersion A, stir at 1200rpm for 30min, stop stirring, and then use a frequency of 25kHz and a power density of 0.5 W / cm 2 Ultrasonic treatment 2h, filter, obtain the loofah of depositing and adsorbing calcium silicate nanoparticles;

[0037] (4) Immerse the loofah on which calcium silicate nanoparticles are deposited and adsorbed in solution B, using a frequency of 25kHz and a power density of 0.5W / cm 2Ultrasonic treatme...

Embodiment 3

[0040] (1) Disperse calcium silicate nanoparticles and calcium stearate in deionized water to obtain dispersion A; the mass ratio of calcium silicate nanoparticles, calcium stearate and deionized water is 6:0.2:100;

[0041] (2) Add sodium alginate and monoglyceride into deionized water, stir and dissolve at 70°C to obtain solution B; the mass ratio of sodium alginate, monoglyceride and deionized water is 0.3:0.04:100;

[0042] (3) Cut the loofah into small pieces of 2cm, clean it, and dry it under vacuum at 80°C for 2 hours, then immerse the loofah in the dispersion A, stir at 1100rpm for 50min, stop stirring, and then use a frequency of 25kHz and a power density of 0.5 W / cm 2 Ultrasonic treatment 3h, filtration, obtains the loofah of depositing and adsorbing calcium silicate nanoparticles;

[0043] (4) Immerse the loofah on which calcium silicate nanoparticles are deposited and adsorbed in solution B, using a frequency of 25kHz and a power density of 0.5W / cm 2 Ultrasonic t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com