Composite graphene electrode material and solid-phase catalysis preparation method thereof

A graphene composite and electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of inability to achieve complete and uniform coating of LiFePO4, unsatisfactory combination of electrode materials and graphene, and difficulty in complete coating of graphene, etc. problems, to achieve excellent electrochemical performance, good batch stability, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

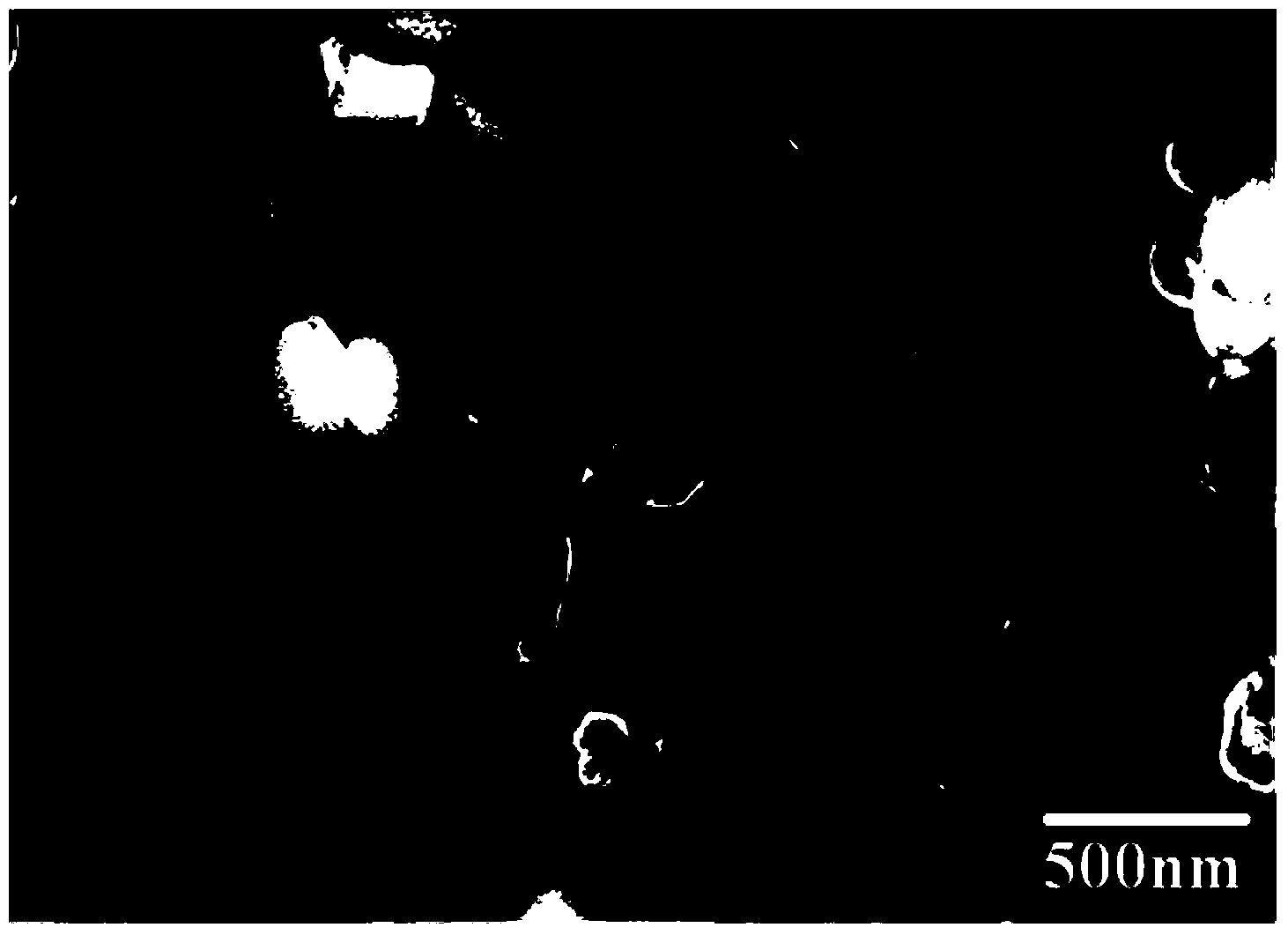

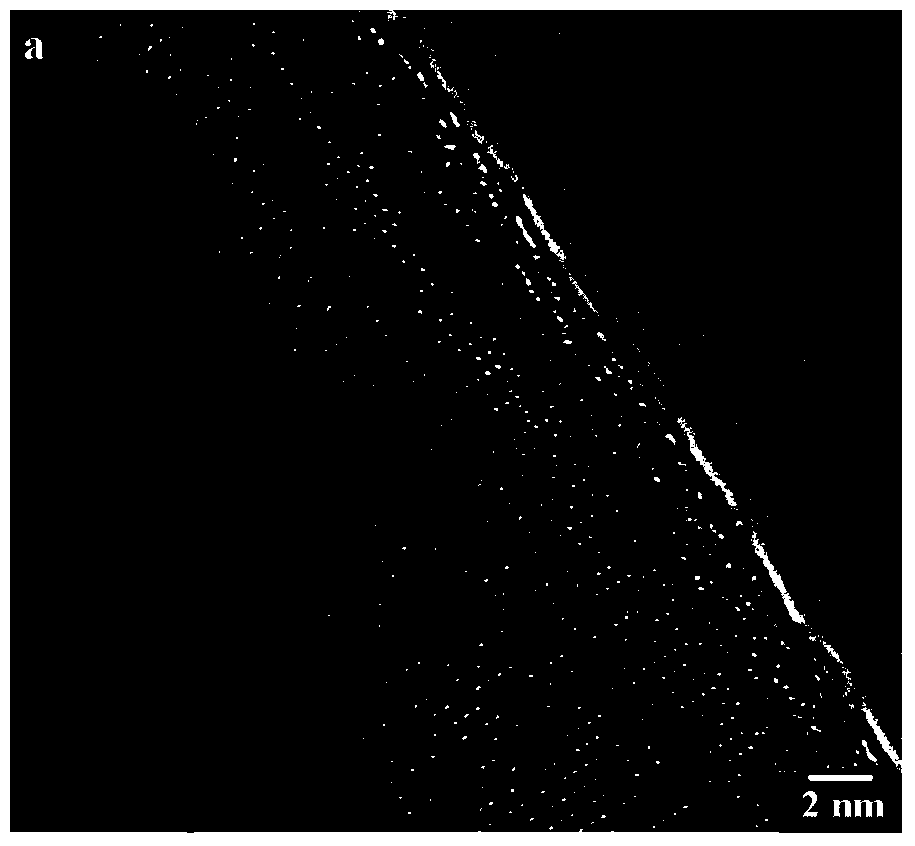

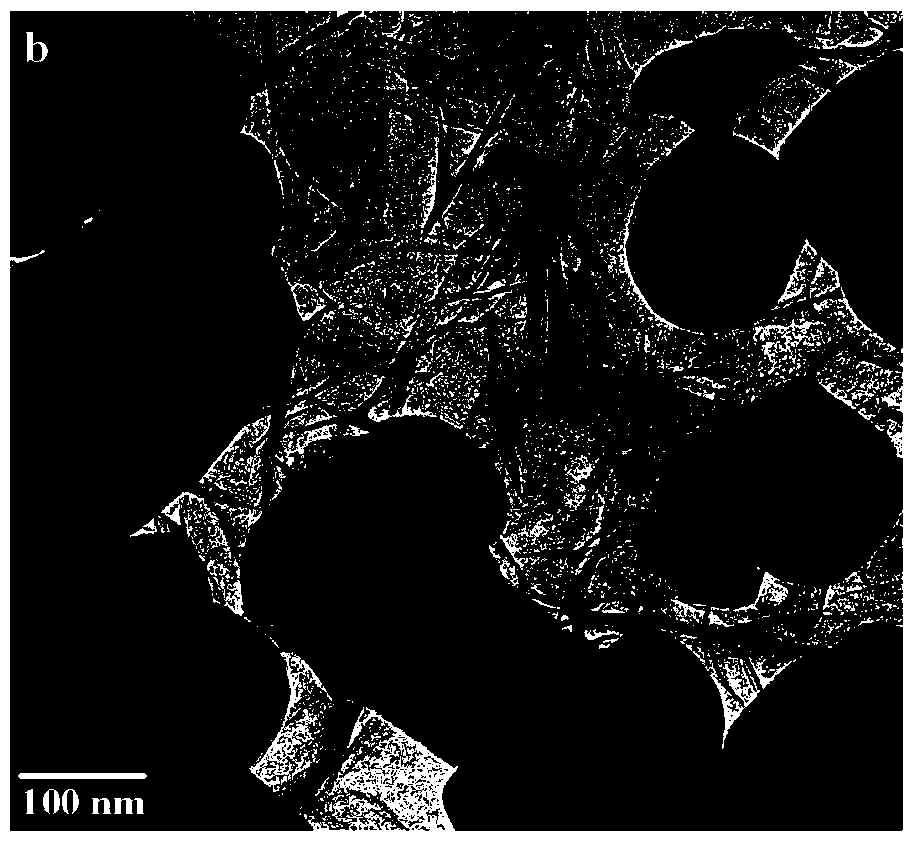

[0038] LiFePO with olivine structure 4 (Li-ion battery electrode material), glucose (organic carbon source), FeSO 4 (Catalyst precursor) was thoroughly mixed according to the ratio of 200:1:15, and then in Ar / H 2 (95:5) In a reducing atmosphere composed of an inert mixed gas, heat treatment at a reaction temperature of 700°C in a closed tube furnace for 10 hours, then naturally cool to room temperature, grind finely, and sieve to obtain LiFePO 4 / Graphene composite electrode material (as anode material). combine Figure 1 ~ Figure 3 As shown, it can be known that LiFePO 4 The graphene tight coating layer of the electrode active material outer layer of the graphene composite electrode material is uniform and thin, with a thickness of 2.5nm, and the graphene conductive network will LiFePO 4 The effective connection between the particles of the middle electrode active material makes LiFePO 4 The electrochemical performance of the / graphene composite electrode material is sig...

Embodiment 2

[0040] LiFePO with olivine structure 4 (electrode material for lithium-ion batteries), sucrose (organic carbon source), NiSO 4 (Catalyst precursor) was thoroughly mixed according to the ratio of 200:1:15, and then in Ar / H 2 (95:5) In a reducing atmosphere composed of an inert mixed gas, heat treatment at a reaction temperature of 750°C in a closed tube furnace for 10 hours, then naturally cool to room temperature, grind finely, and sieve to obtain LiFePO 4 / Graphene composite electrode material (as anode material).

Embodiment 3

[0042] LiFePO with olivine structure 4 (electrode material for lithium-ion batteries), glucose (organic carbon source), CoCl 2 (Catalyst precursor) was thoroughly mixed according to the ratio of 200:2:20, and then in Ar / H 2 (95:5) In a reducing atmosphere composed of an inert mixed gas, heat treatment in a closed tube furnace at a reaction temperature of 700°C for 8 hours, then naturally cool to room temperature, grind finely, and sieve to obtain LiFePO 4 / Graphene composite electrode material (as anode material).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com