Pyrolysis preparation method of two-dimensional nano-sheet-layer lithium ion battery negative electrode material

A lithium-ion battery and carbon nanosheet technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of complex preparation process, unsuitability for mass production, and high cost of synthetic materials, and achieves low preparation cost and no capacity. Attenuation, high degree of graphitization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

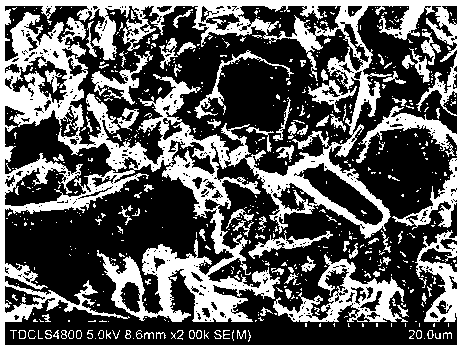

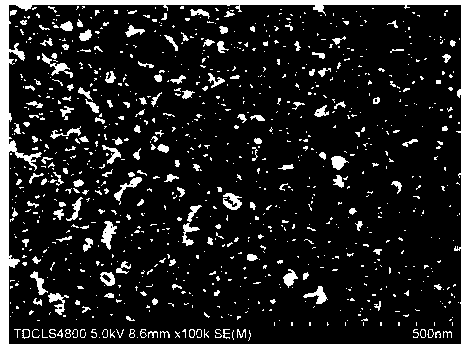

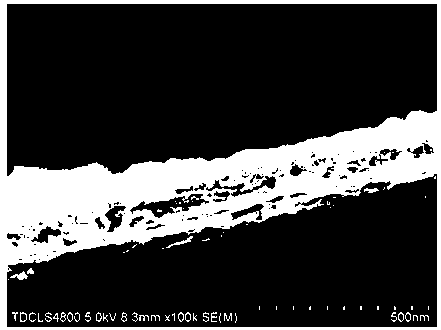

[0024] Weigh 5 g of glucose, 3.366 g of ferric nitrate and 48.213 g of sodium chloride and add them into 175 mL of deionized water to prepare a mixed solution. Put the mixed solution into a Φ80 petri dish and place it in a vacuum drying oven with the open mouth, and dry it in vacuum at 80°C. After the water is completely evaporated, a uniform solid mixture is obtained. The solid mixture was pulverized and passed through a 100-mesh sieve to obtain a precursor powder. Take 4 g of precursor powder and spread evenly on the bottom of the corundum ark, place the ark in the constant temperature zone of the tube furnace, and flow Ar gas at a flow rate of 200 mL / min for 40 min to remove the air in the tube, and then start heating. The temperature was raised to 300 °C for 1 h at a heating rate of 5 °C / min, and then heated to 700 °C for 2 h at a heating rate of 5 °C / min. After the heat preservation is over, the sample is cooled to room temperature with the furnace, taken out, and ground...

Embodiment 2

[0027]Weigh 5 g of glucose, 3.366 g of ferric nitrate and 48.213 g of sodium chloride and add them into 175 mL of deionized water to prepare a mixed solution. Put the mixed solution into a Φ80 petri dish and place it in a vacuum drying oven with the open mouth, and dry it in vacuum at 80°C. After the water is completely evaporated, a uniform solid mixture is obtained. The solid mixture was pulverized and passed through a 100-mesh sieve to obtain a precursor powder. Take 10 g of precursor powder and spread evenly on the bottom of the corundum ark, place the ark in the constant temperature zone of the tube furnace, and flow Ar gas at a flow rate of 200 mL / min for 40 min to remove the air in the tube, and then start heating. The temperature was raised to 300 °C for 1 h at a heating rate of 5 °C / min, and then heated to 700 °C for 2 h at a heating rate of 5 °C / min. After the heat preservation is over, the sample is cooled to room temperature with the furnace, taken out, and ground...

Embodiment 3

[0029] Weigh 5 g of glucose, 3.366 g of ferric nitrate and 48.213 g of sodium chloride and add them into 175 mL of deionized water to prepare a mixed solution. Put the mixed solution into a Φ80 petri dish and place it in a vacuum drying oven with the open mouth, and dry it in vacuum at 80°C. After the water is completely evaporated, a uniform solid mixture is obtained. The solid mixture was pulverized and passed through a 100-mesh sieve to obtain a precursor powder. Take 4 g of precursor powder and spread evenly on the bottom of the corundum ark, place the ark in the constant temperature zone of the tube furnace, and flow Ar gas at a flow rate of 200 mL / min for 40 min to remove the air in the tube, and then start heating. The temperature was raised to 300 °C for 1 h at a heating rate of 5 °C / min, and then heated to 800 °C for 2 h at a heating rate of 5 °C / min. After the heat preservation is over, the sample is cooled to room temperature with the furnace, taken out, and ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com