Patents

Literature

56results about How to "Continuous mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrolysis preparation method of two-dimensional nano-sheet-layer lithium ion battery negative electrode material

InactiveCN103227327AReduce manufacturing costHigh degree of graphitizationCell electrodesPhysical chemistryGraphite

The invention discloses a pyrolysis preparation method of a two-dimensional nano-sheet-layer lithium ion battery negative electrode material. The method comprises the steps that: a mixed solution comprising glucose, ferric nitrate and sodium chloride is prepared by using deionized water; the solution is dried and grinded into powder; the powder is added into a tubular furnace and is heated, and is cooled with the furnace; the powder is fetched and finely grinded, such that gray-black powder is obtained; the gray-black powder is dispersed into deionized water, such that a suspension liquid is obtained; pump-filtration and washing are carried out, such that black powder is obtained; the black powder is dispersed in hydrochloric acid; and water-bath heating, refluxing, pump-filtration, and washing are carried out, such that the two-dimensional nano-sheet-layer lithium ion battery negative electrode material is obtained. According to the method, the raw materials are cheap and are easy to obtain; a preparation cost is low; a process is simple and feasible; and continuous large-scale production can be carried out. The obtained material has high graphitization degree, large specific surface area, and substantial mesoporous characteristics. As the lithium ion battery negative electrode material, the material has good circulation performance, good rate performance, good stability, and wide application prospect.

Owner:TIANJIN UNIV

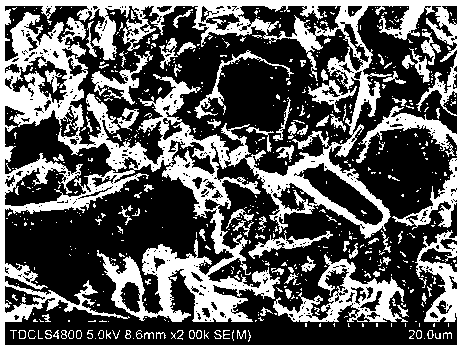

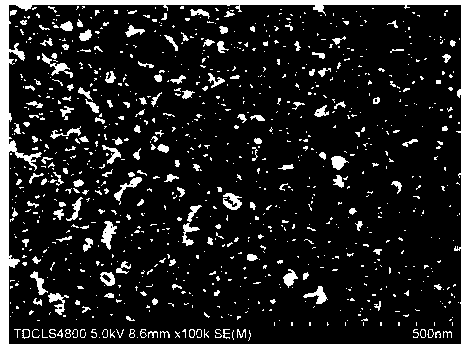

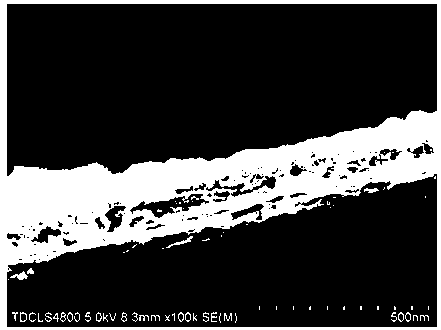

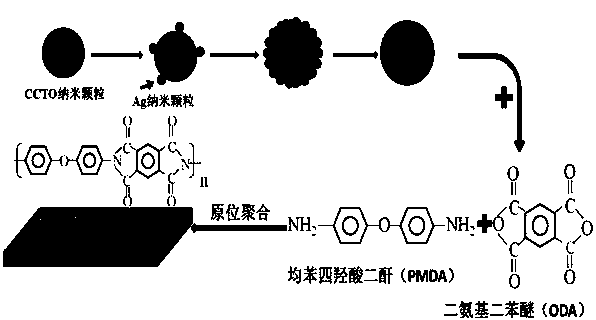

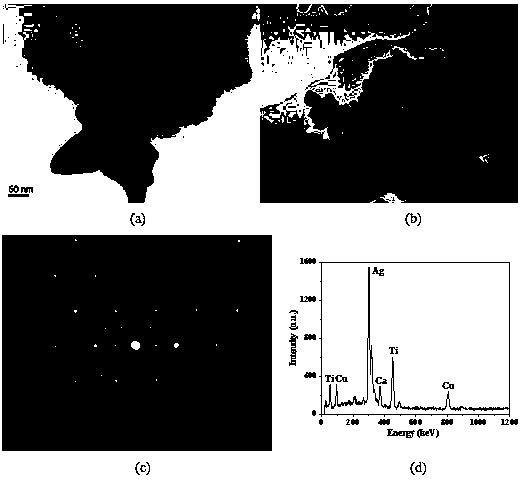

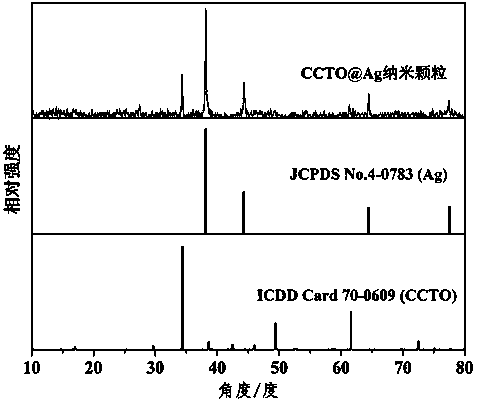

Preparation method of polyimide/copper calcium titanate coated silver nanoparticle composite material

InactiveCN103755958APromote recombinationImprove electric field distributionIn situ polymerizationHigh energy

The invention discloses a preparation method of polyimide / CCTO@Ag nanoparticle composite material with high dielectric and low loss. According to the method, polyimide is used as matrix, the prepared CCTO@Ag nanoparticles are ultrasonically dispersed in absolute ethyl alcohol, then is blended with polyimide monomer in solvent, then in situ polymerization reaction is carried out on the monomer at room temperature to simultaneously realize copolymerization of polyimide and intercalation recombination with the CCTO@Ag nanoparticles, obtained stock solution is subjected to gradient annealing according to a coating method to finally obtain the polyimide / CCTO@Ag nanoparticle composite film. Compared with pure polyimide, the polyimide / CCTO@Ag nanoparticle composite material prepared according to the preparation method has the dielectric constant (103) increased by 30 times, also has low dielectric loss (0.006) and can be widely applied in fields of high energy storage capacitors, artificial organs, high speed integrated circuits, and the like.

Owner:WUHAN UNIV

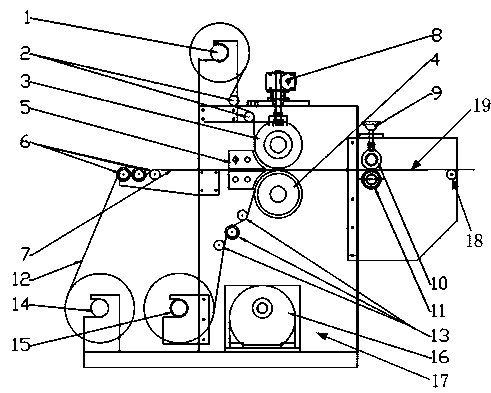

Production method of thin steel strip hot galvanizing

ActiveCN102776460AStrong corrosion resistanceGood machinabilityHot-dipping/immersion processesCorrosionAir drying

The invention relates to a production method of thin steel strip hot galvanizing. The production method comprises the following steps of uncoiling, welding, chemical desorption, electrolysis, cleaning, air drying, annealing, galvanizing, air cooling, straightening, chemical coating and coiling. A steel strip subjected to galvanizing has good corrosion resistance and better machining performance, the plating layer is firm and uniform, the color is bright, the service life is long, the environment pollution is avoided, and the continuous large-scale production can be realized.

Owner:江苏大力神科技股份有限公司

High-efficiency fireproof heat insulating material and preparation method thereof

The invention relates to a fireproof heat insulating material with a nano-pore structure. The high-efficiency fireproof heat insulating material comprises the following components in proportion by weight: 50-70 parts of nano-SiO2, 25-40 parts of lyosol, 5-10 parts of structural stabilizer and 5-20 parts of opacifier. The preparation method of the high-efficiency fireproof heat insulating material comprises the following steps: preparing the lyosol by utilizing tetraethoxysilane(TEOS) and hydrochloric acid; adding the nano-SiO2, the structural stabilizer and the opacifier to the lyosol to obtain gel; soaking in ethanol to obtain SiO2 alcogel; and obtaining the high-efficiency fireproof heat insulating material by supercritical drying. The fireproof heat insulating material of the invention has uniform and stable nano-pore structure distribution, is not affected by whether water is absorbed or not, still has the stable nano-pore structure when being used in a high-temperature environment of more than 1000 DEG C, has low production cost, can realize continuous large-scale production, and simultaneously does not have asbestos and organic matters, which are harmful to the human health, during the production process.

Owner:无锡市明江保温材料有限公司

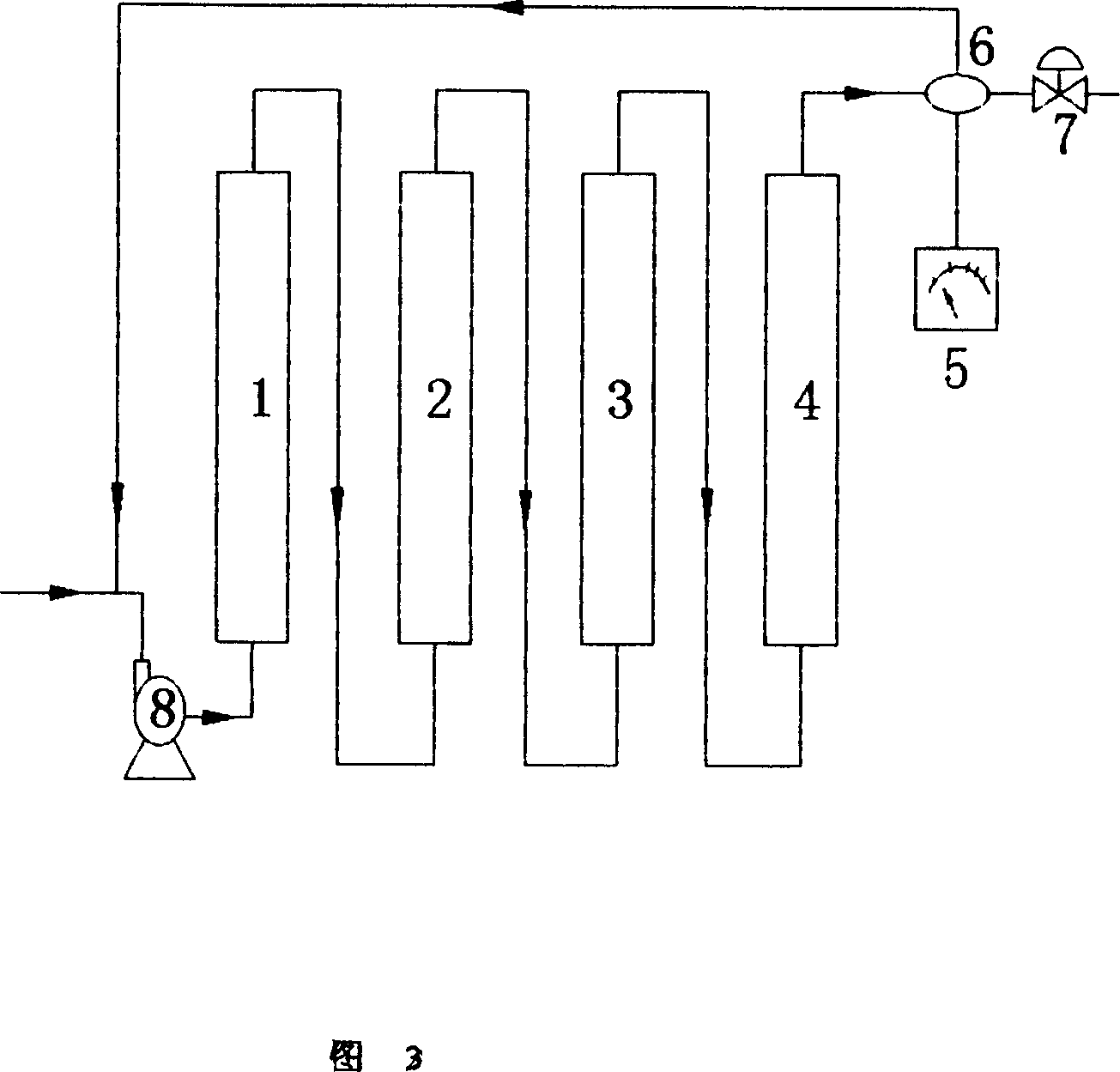

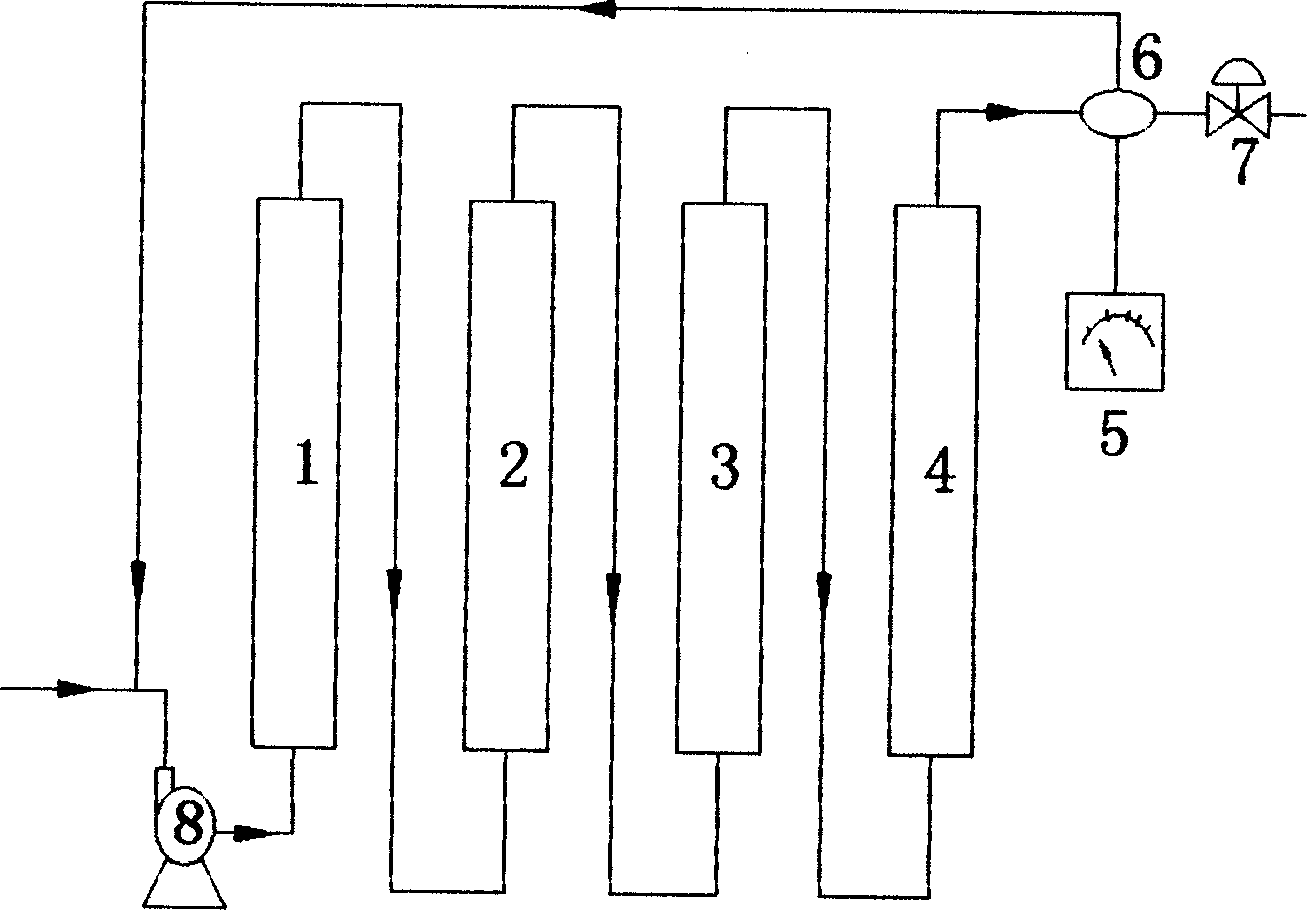

CVD diamond film continuous preparation system

InactiveCN101008082AContinuous mass productionAchieve replacementChemical vapor deposition coatingContinuous useMaterials science

The invention discloses a CVD diamond membrane continuous preparing system, comprising settling deceive, transition device and loading device. It realizes continuous preparation by changing substrate on condition of constant working condition in settling cavity. It guarantees no breakage for carbonized filament, greatly reduces filament consumption, dramatically increases preparing efficiency for diamond membrane and reduces production cost.

Owner:海安常科技术转移中心有限公司

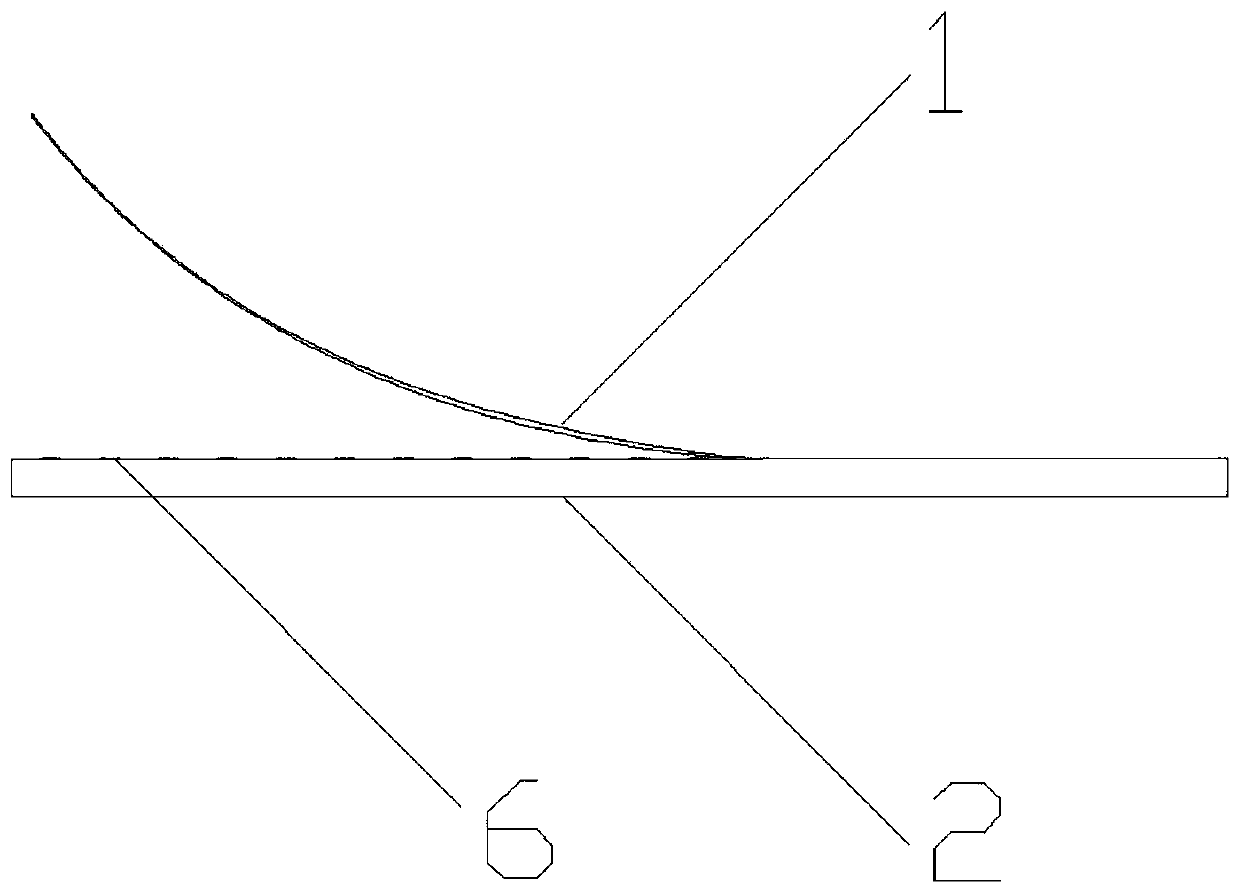

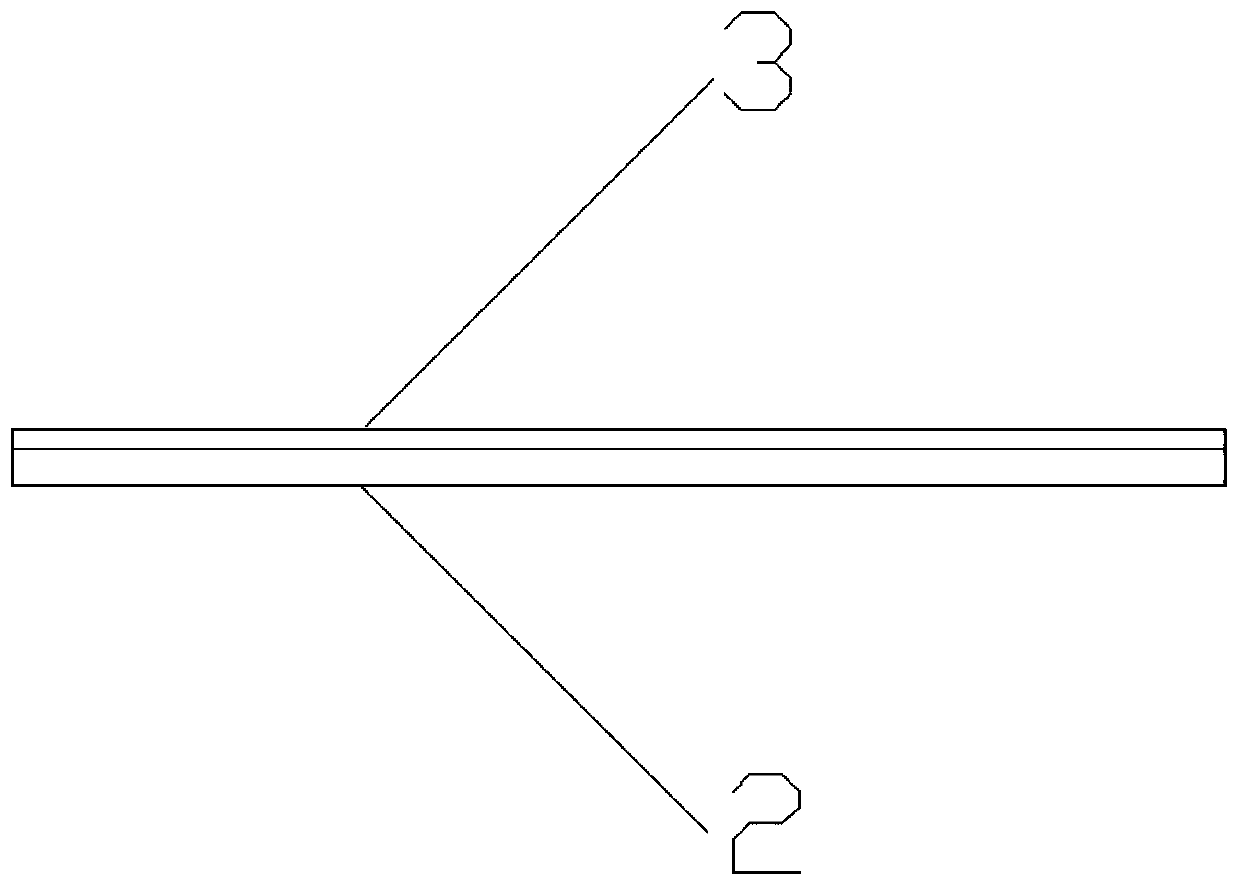

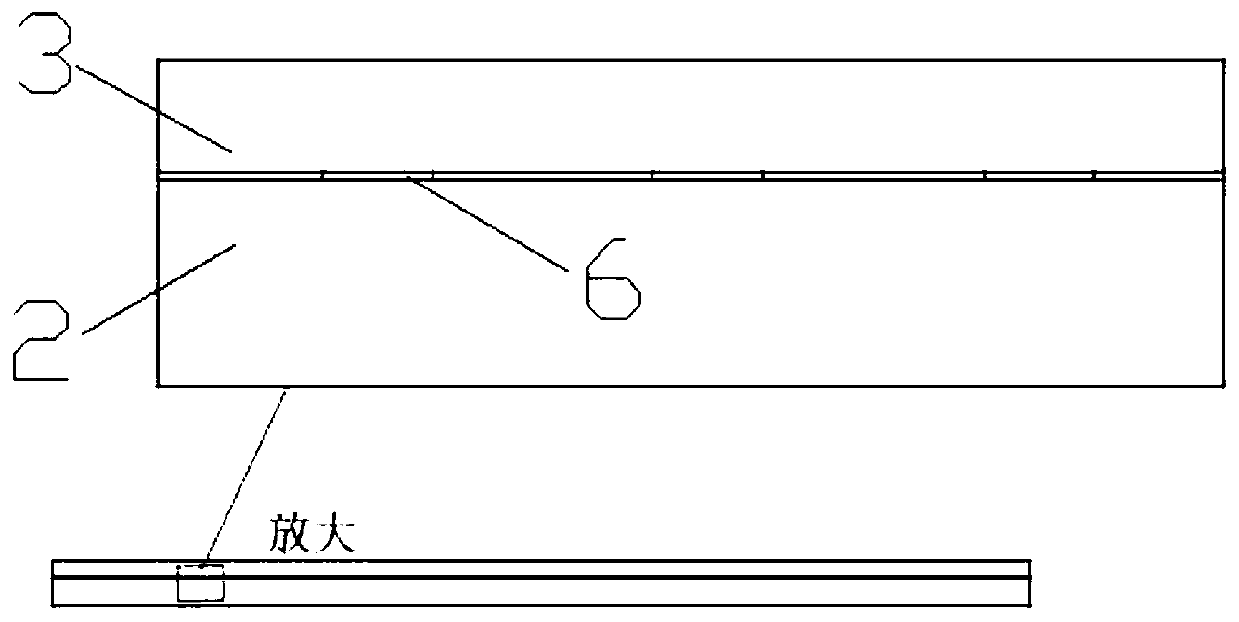

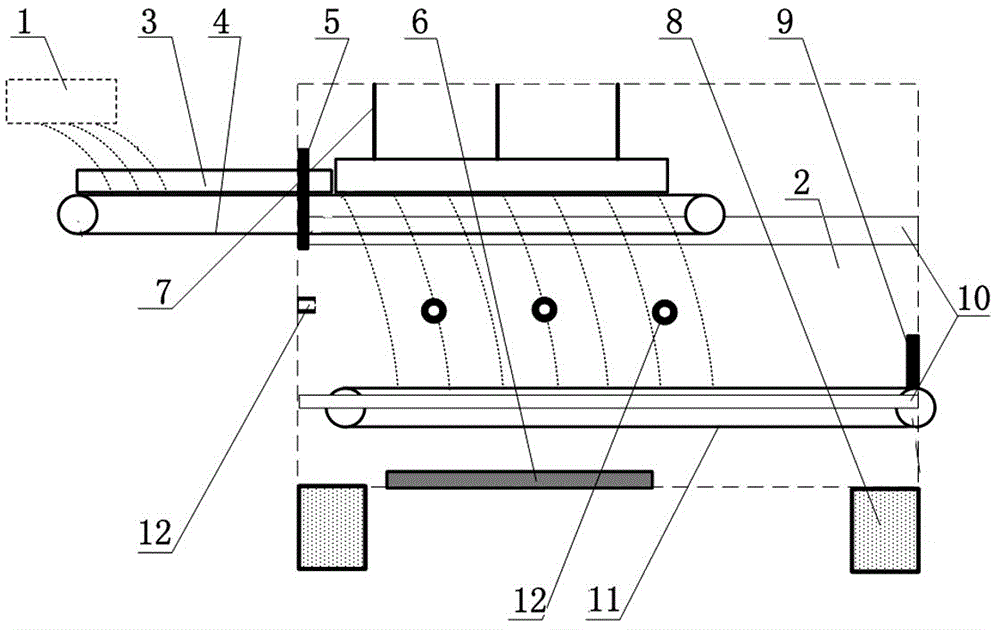

Device and method for continuously and rapidly preparing graphene thin film on copper foil

InactiveCN108516537AContinuous preparationContinuous mass productionGrapheneCopper foilCollection system

The invention discloses a method and a device for continuously and rapidly preparing a graphene thin film on a copper foil. The device for continuously and rapidly preparing the graphene thin film onthe copper foil mainly comprises a laser generation system and a graphene thin film collection system. High-power pulse laser is irradiated to a graphite suspension solution, so that high-temperatureand high-pressure plasmas are instantly generated on the surface of a target material; the plasmas cannot be freely dispersed due to a restraining action of liquid at the periphery; continuous gas-state carbon is formed on the surface of the target material along self-adjustment heat conduction of a reaction region, and a feather tract range of the plasmas is continuously enlarged; the plasmas aredirectionally and locally expanded and emitted and are deposited on a substrate to form the graphene thin film. According to the technical scheme disclosed by the invention, the preparation efficiency of the graphene thin film can be improved.

Owner:JIANGSU UNIV

Non-heat-treated self-strengthening aluminum and magnesium alloy and preparation technology thereof

The invention discloses a non-heat-treated self-strengthening aluminum and magnesium alloy and a preparation technology thereof. The preparation technology comprises technological steps as follows: firstly, melting pure aluminum, heating the pure aluminum to the temperature of 680 DEG C, adding pure magnesium ingots, performing heat preservation after the pure magnesium ingots are molten, adding intermediate alloys AL-Si and AL-Mn into an alloy liquid heated to the temperature of 740-760 DEG C, and performing heat preservation at the temperature of 740 DEG C after the alloys are molten; secondly, heating the alloy liquid to the temperature of 780 DEG C, adding misch metal, removing surface scums after the misch metal is molten, stirring the alloy liquid, heating the alloy liquid to the temperature of 770-780 DEG C, performing the heat preservation and leaving the alloy liquid to stand for 30 min; finally, cooling the alloy liquid to the temperature of 750 DEG C for refining, removing slag and gas after refining is performed for 15 min, and finishing casting production. According to the non-heat-treated self-strengthening aluminum and magnesium alloy and the preparation technology thereof, the misch metal and the elements including Mn and Mg in a strict mole fraction ratio are adopted for refining dendritic crystal composition of Mn and Mg in the aluminum alloy material, and one aluminum and magnesium alloy with high heat resistance, high elongation percentage and excellent deformability is obtained.

Owner:FENGYANG L S NET FORMING CO LTD +1

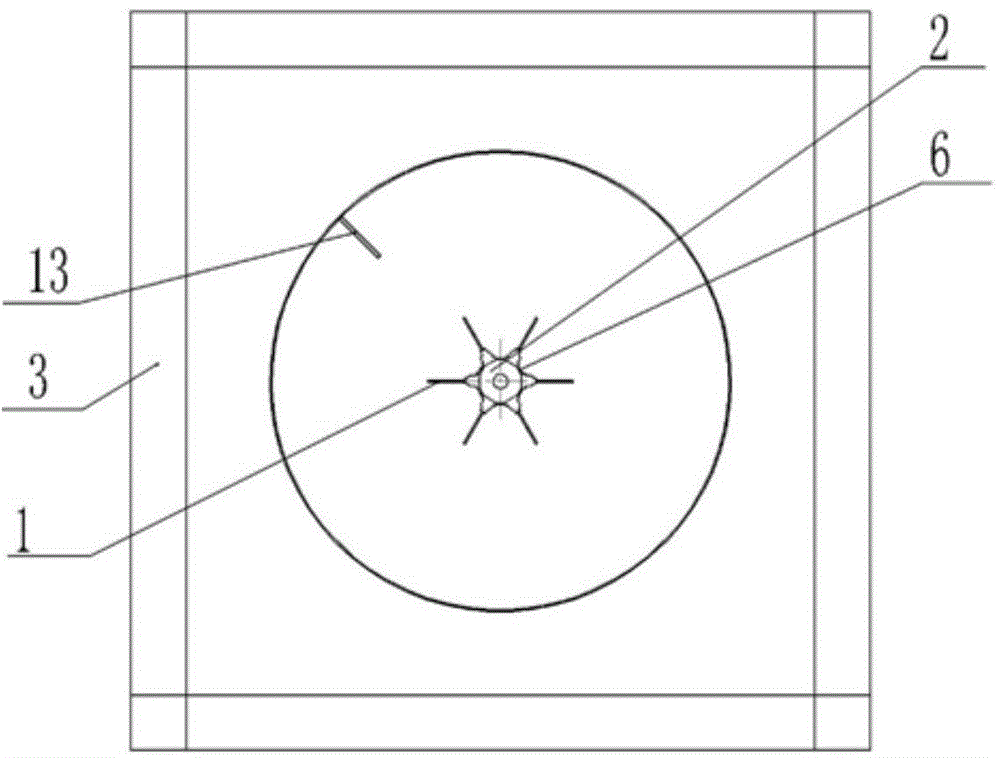

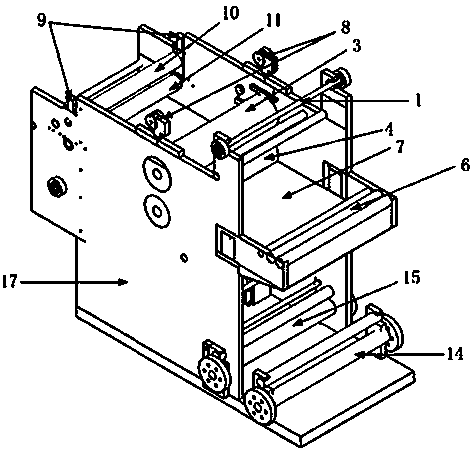

Full-automatic efficient cutting machine for bus bar

PendingCN108274241APrevent slippingAvoid offsetOther manufacturing equipments/toolsEngineeringMechanical engineering

A full-automatic efficient cutting machine for a bus bar is characterized in that the full-automatic efficient cutting machine comprises a square cutting machine shell; a controller support is arranged on the top of the cutting machine shell; one end of the controller support is fixed to the top of the cutting machine shell, and a controller is fixed to the bottom of the other end of the controller support and is a PLC; and an operation room is arranged on the upper portion of the cutting machine shell, and a discharging assembly, a deburring mechanism, a straightening mechanism, a compressionfeeding mechanism, a cutting mechanism and a traction mechanism are sequentially arranged on a bottom plate of the operation room from left to right. Using of manual work is avoided, labor force is liberated, the time and labor are saved in operation, and the requirement of enterprises for large-scale mechanical production is met conveniently.

Owner:苏州市中辰昊科技有限公司

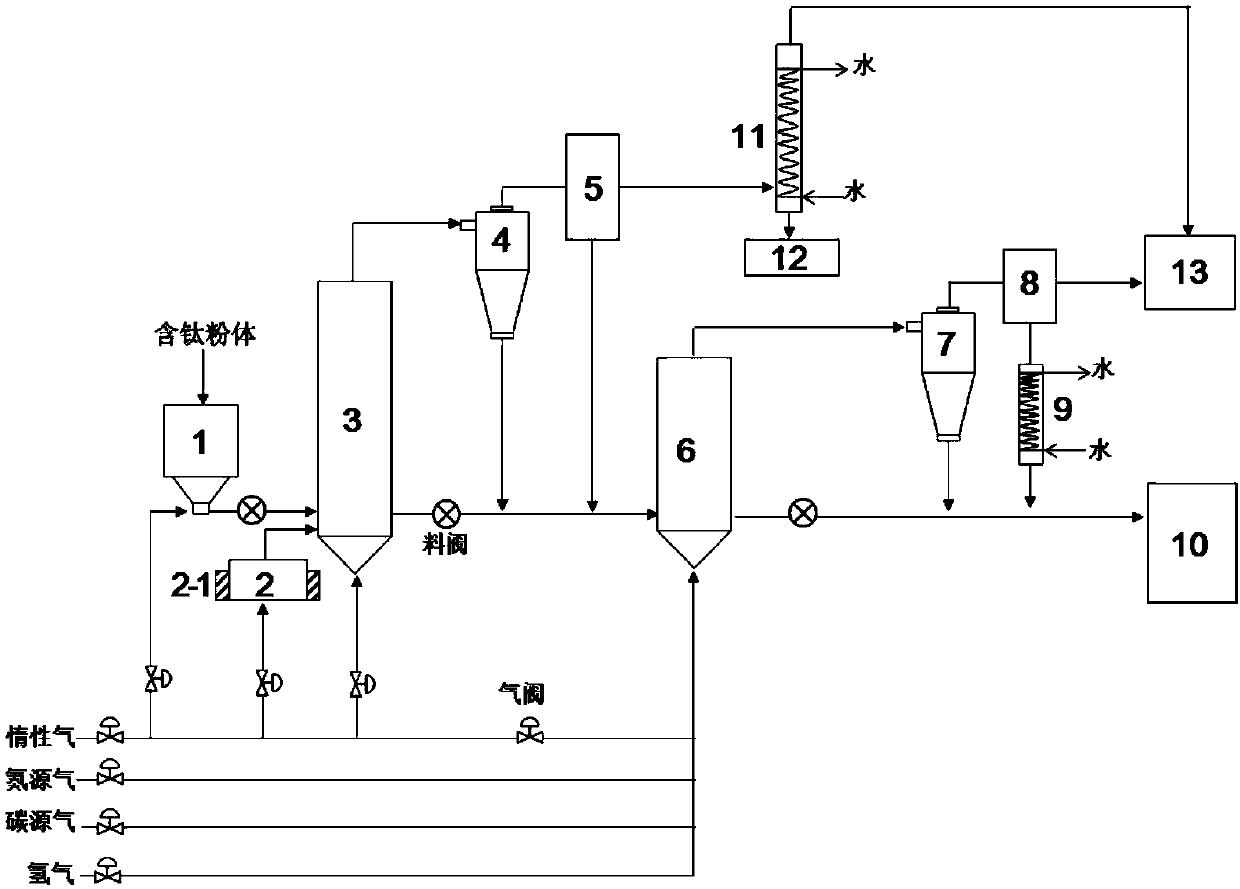

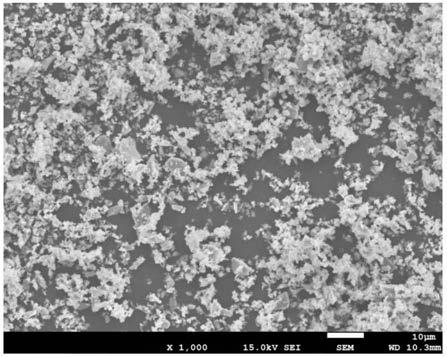

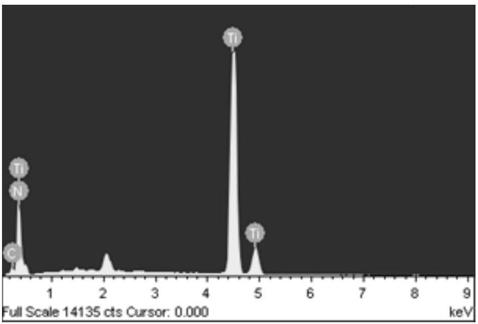

Preparation system and preparation method of TiN, TiC and TiCN powder

ActiveCN110155966AAchieve recyclingLow preparation temperatureTitanium carbideNitrogen and non-metal compoundsCarbonizationMaterials science

The invention discloses a preparation system and preparation method of TiN, TiC and TiCN powder. Coarse titanium-containing powder is transported to a powder synthesis fluidized bed after pretreatmentin a pre-reaction fluidized bed, and then is directly nitrided or (and) carbonized into fine the TiN, TiC and TiCN powder in the atmosphere of a nitrogen source and a carbon source. According to theinvention, the synthesis temperature of the TiN, TiC and TiCN powder is reduced, the processes of multiple crushing, repeated nitridation or (and) carbonization in the traditional direct nitridation or (and) carbonization process are overcome, the powder preparation efficiency is improved, the problem of low nitridation or (and) carbonization efficiency of a TiCl4 titanium source in the traditional process is solved, the utilization rate of the raw material is improved, the process flow is simple, continuous batch production of the TiN, TiC and TiCN powder can be realized, and the method is suitable for large-scale industrial production, and has good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

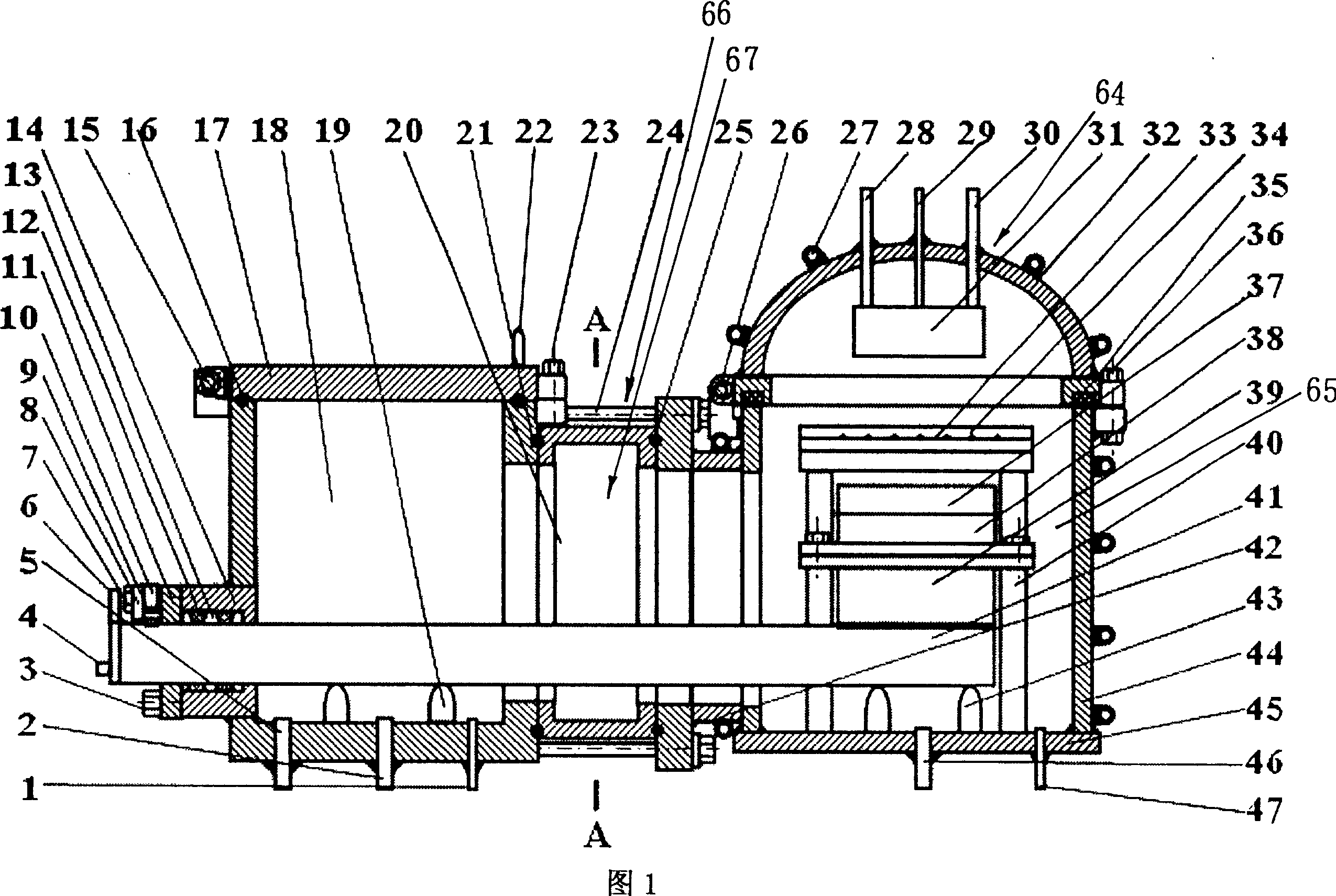

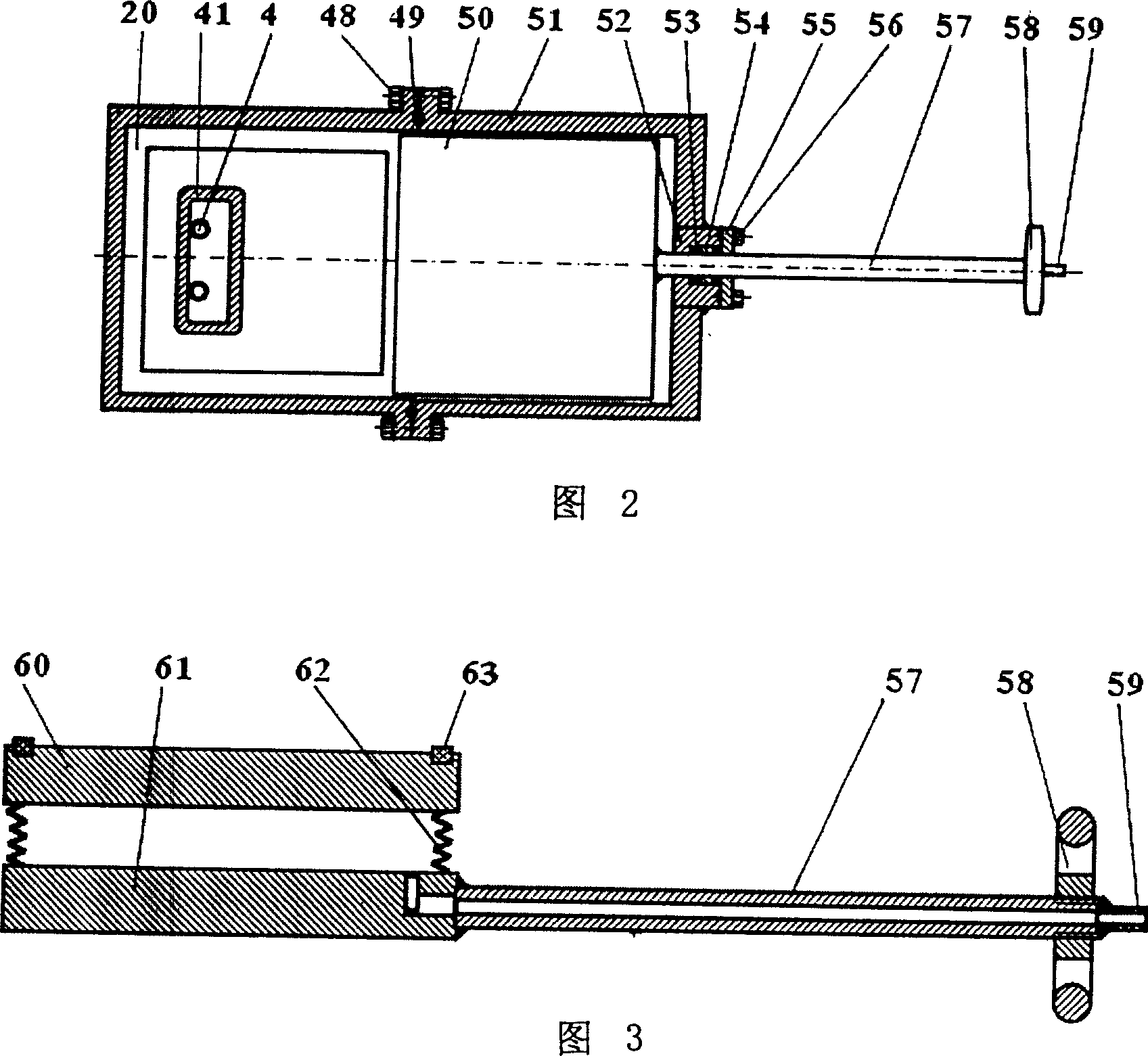

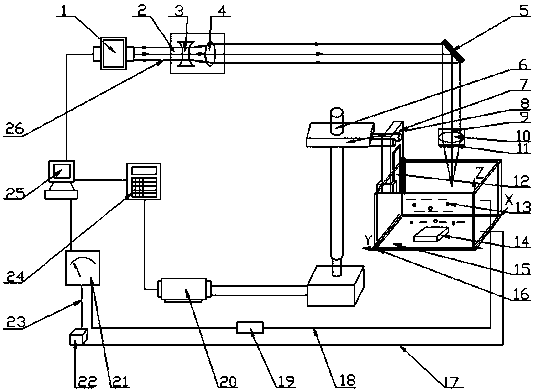

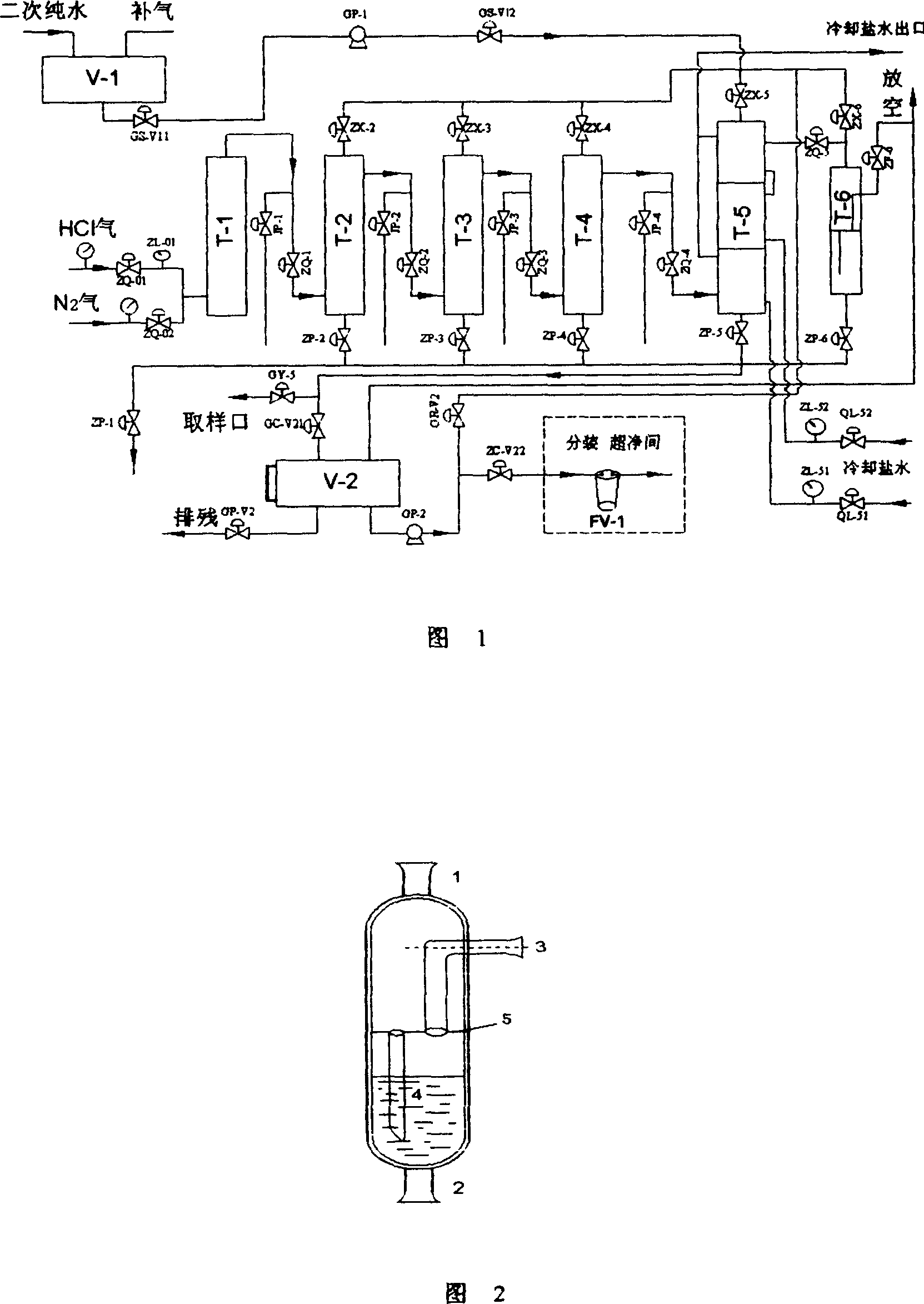

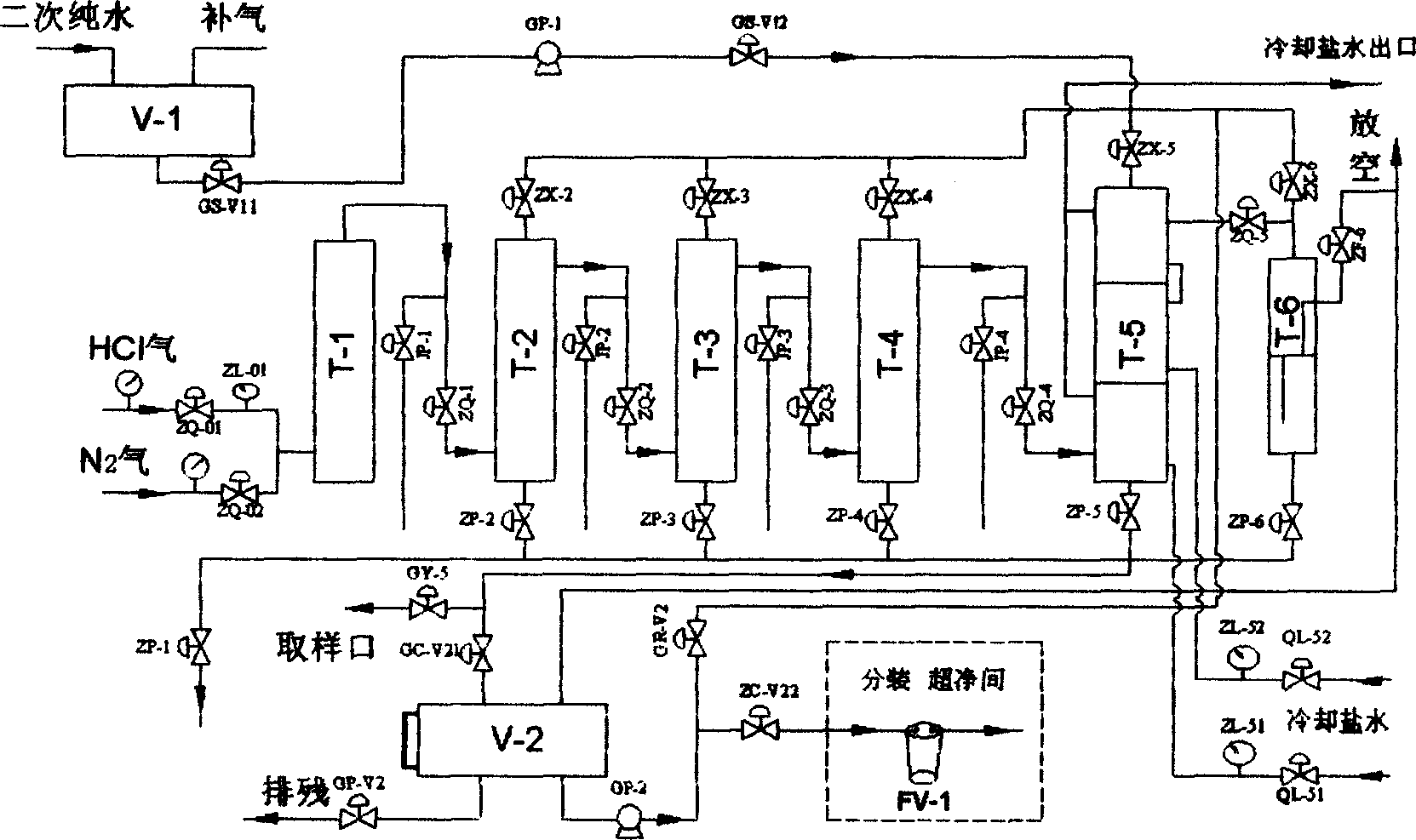

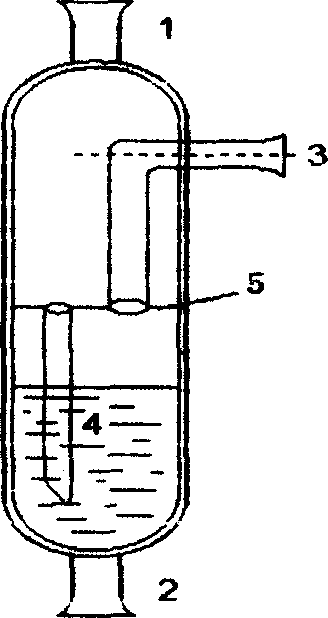

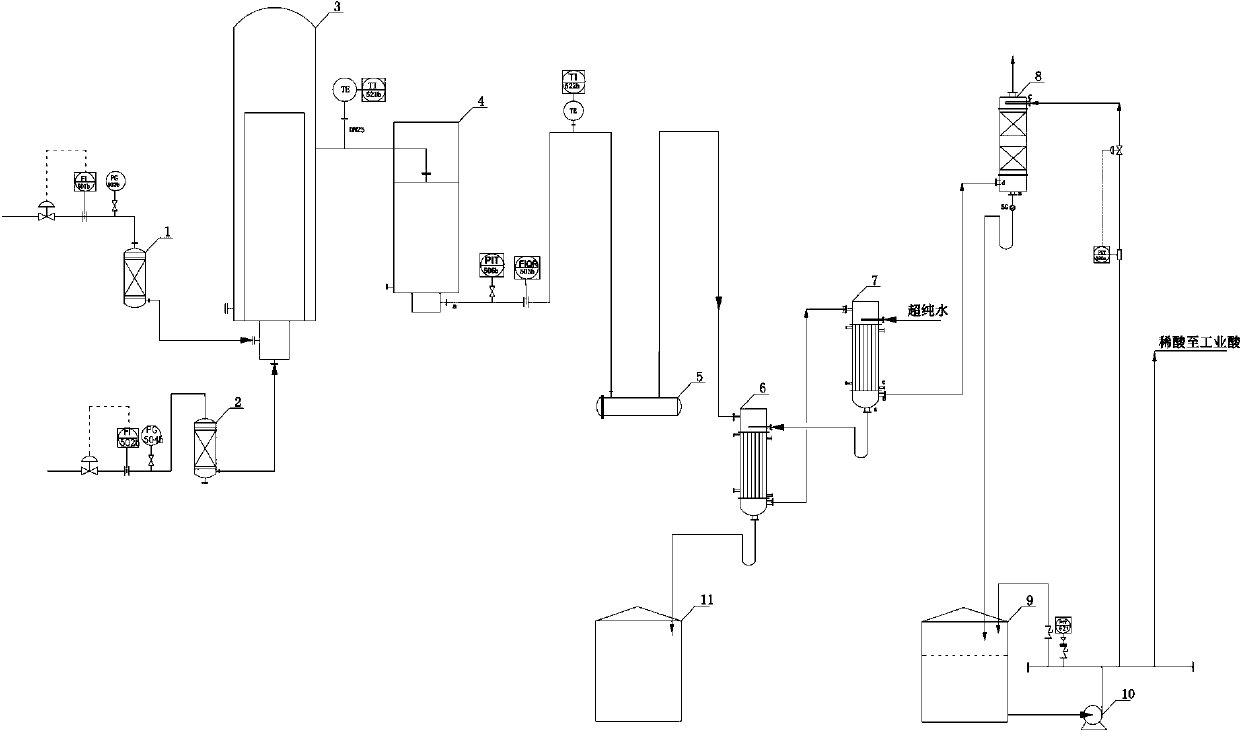

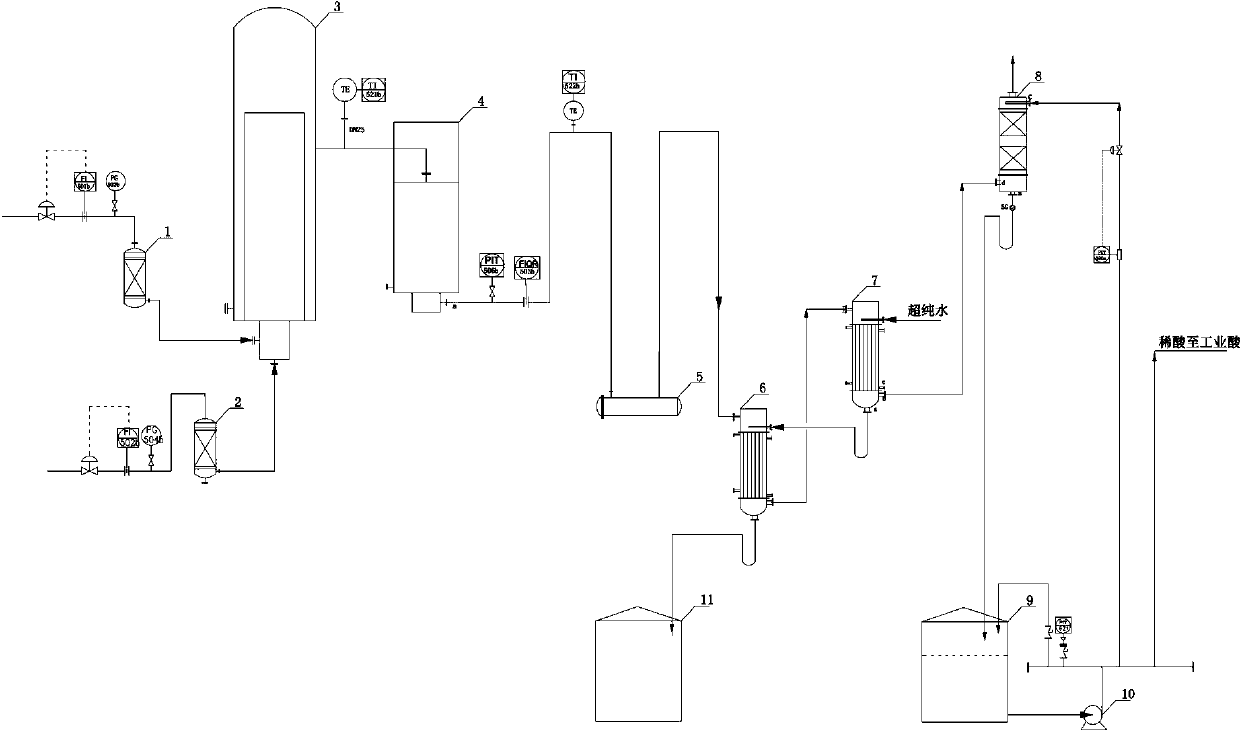

Apparatus and process of producing electronics level high purity hydrochloric acid

InactiveCN1326766CContinuous mass productionNo pollution in the processChlorine/hydrogen-chloride purificationEngineeringHydrogen chloride

The present invention relates to gas absorbing process of producing high purity hydrochloric acid and corresponding production apparatus. By means of the method and apparatus of the present invention, high purity hydrochloric acid as one kind of electronic chemical may be produced directly. The present invention solves the difficult problem of purifying hydrogen chloride gas and realizes the large scale production of high purity hydrochloric acid via gas absorbing process. The product has metal impurity and anion contents meeting the requirement as MOS grade, BV-III grade product standard for VLSI production.

Owner:BEIJING INST OF CHEM REAGENTS

Apparatus and process of producing electronics level high purity hydrochloric acid

InactiveCN1608975AContinuous mass productionNo pollution in the processChlorine/hydrogen-chloride purificationMetal impuritiesHydrogen chloride

The present invention relates to gas absorbing process of producing high purity hydrochloric acid and corresponding production apparatus. By means of the method and apparatus of the present invention, high purity hydrochloric acid as one kind of electronic chemical may be produced directly. The present invention solves the difficult problem of purifying hydrogen chloride gas and realizes the large scale production of high purity hydrochloric acid via gas absorbing process. The product has metal impurity and anion contents meeting the requirement as MOS grade, BV-III grade product standard for VLSI production.

Owner:BEIJING INST OF CHEM REAGENTS

Non-heat-treated self-strengthening aluminum-silicon alloy and its preparation process

A preparation process of a non-heat-treated self-strengthening aluminum-silicon alloy comprises the following process steps: firstly adding a pure magnesium ingot and intermediate alloys AL-Si, AL-Mn, AL-Cu and AL-Ti into an aluminum solution having a temperature of 740-760ºC, fusing the above materials, and retaining the alloy solution for 30 minutes at 740ºC; heating the alloy solution to 780ºC, adding mixed rare earths into the alloy solution, removing surface scum after the fusion of the mixed rare earths, stirring the solution for 3-6 minutes, heating the alloy solution to 770-780ºC, and keeping the temperature and allowing the alloy solution to rest for 30 minutes; and cooling the alloy solution to 750ºC, refining for 15 minutes, removing slag and degassing, and finally completing a casting production.

Owner:FENGYANG L S NET FORMING CO LTD +1

Method for preparing metal composite sheet strip through electroplating deposition and rolling

ActiveCN111014293AImprove clippingHigh bonding strengthMetal rolling arrangementsShear stressMetal sheet

The invention belongs to the technical field of metal composite sheet strips, and particularly relates to a method for preparing a metal composite sheet strip through electroplating deposition and rolling. The method comprises the following steps of 1, surface treatment, 2, laminating, 3, electroplating deposition, 4, blank manufacturing, 5, rolling, 6, thermal treatment, and 7, finishing. Electroplating deposition is combined with a traditional rolling process, a to-be-compounded surface of a metal sheet strip base material is deposited with a clad layer, one part of the deposited clad layeron the surface of the base material generates a hooking effect and a riveting effect with base material metals, the other part of the clad layer and an contact interface between the base material metals generate diffusion, the clad layer generating the hooking effect and the riveting effect with the base material metals prompts the coplastic deformation of the special-shaped metal sheet strips andthe clad layer under the action of a rolling force, the action area of the shearing force of the surfaces of the metals is remarkably increased, the numerical value is increased, the shearing actionof the metals is enhanced, the fracture of the interface between the metals is accelerated, the metallurgical welding is prompted, and the comprehensive mechanical performance is further improved through the combination with the post heat treatment.

Owner:TAIYUAN UNIV OF TECH

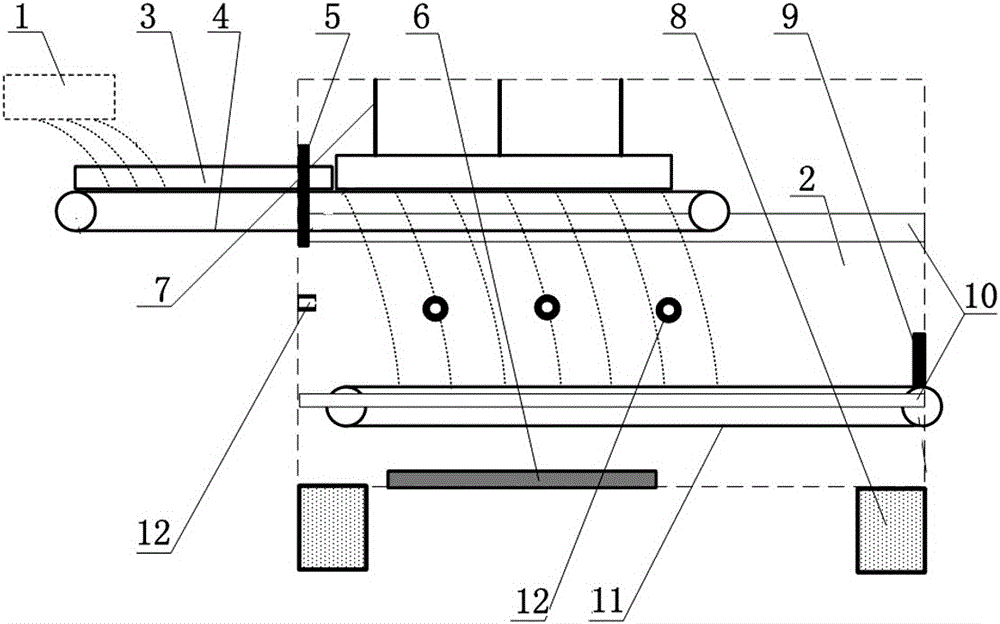

Closed tobacco-leaf front-back-face material adding device

InactiveCN104983055AReduce breakage rateControl the feeding processTobacco preparationEngineeringLiquid injection

The invention discloses a closed tobacco-leaf front-back-face material adding device. The closed tobacco-leaf front-back-face material adding device is characterized by comprising a leaf feeding system, a flow dividing system, a tobacco leaf inlet, an atomizing chamber, an atomizing chamber sealing plate, a liquid injection nozzle and a leaf outlet conveying belt. The closed tobacco-leaf front-back-face material adding device has the advantages that the structure is simple, the material adding evenness is high, the tobacco leaf breaking rate is low, the adding accuracy and the adding stability are good, and continuous large-scale production can be achieved; as materials are added to the front face and the back face of tobacco leaf flow in a closed mode, the tobacco material adding process can be more fine and more evenly controlled, and the tobacco material adding effect can be effectively improved.

Owner:KUNMING UNIV OF SCI & TECH

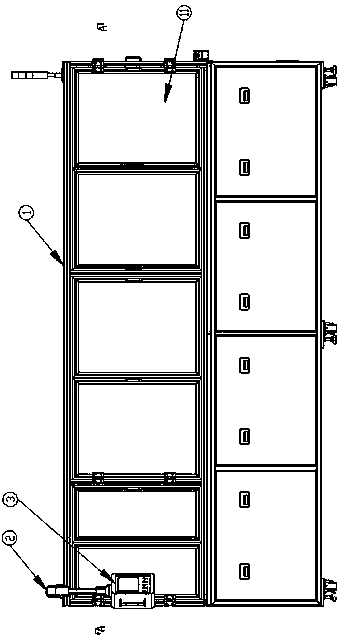

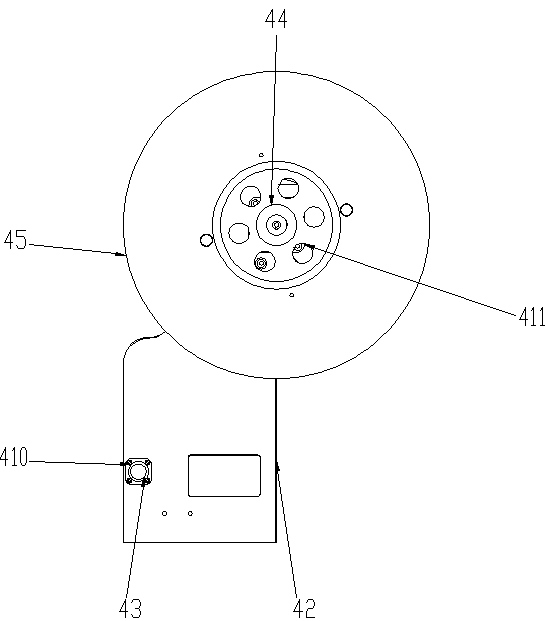

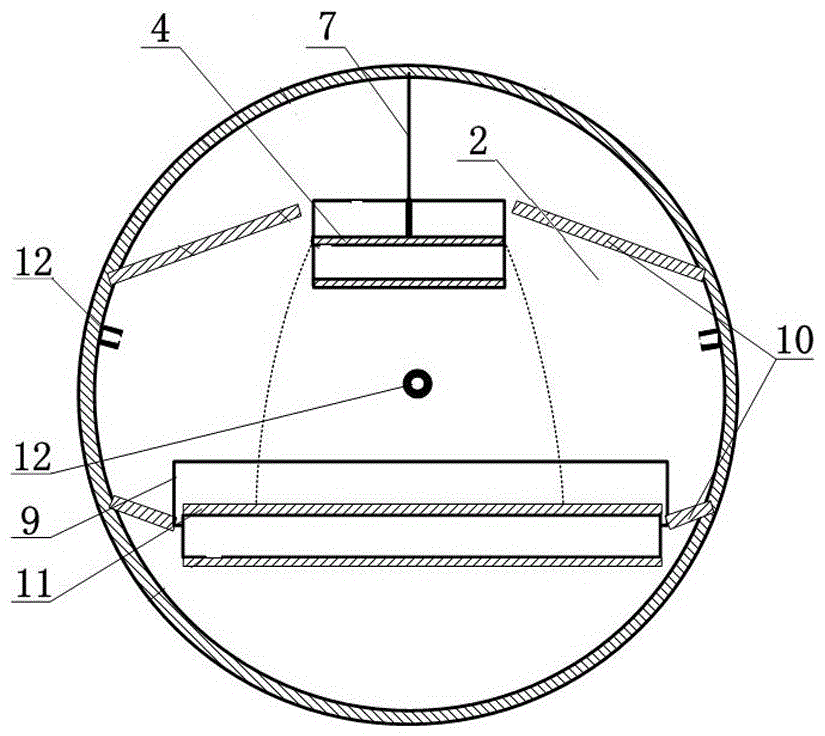

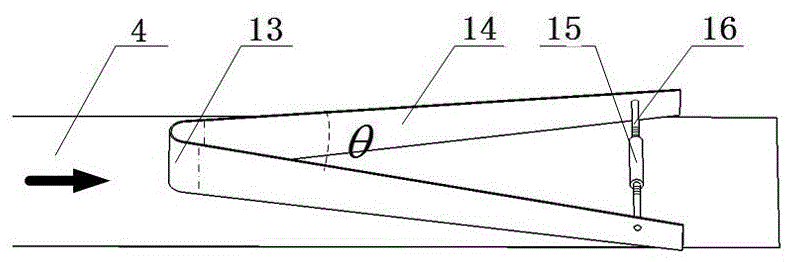

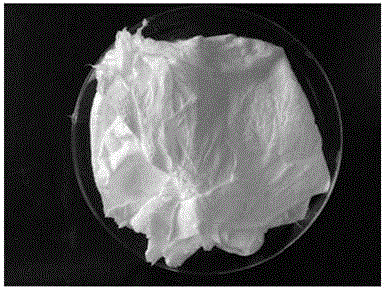

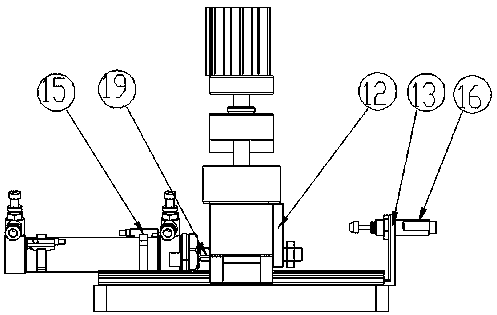

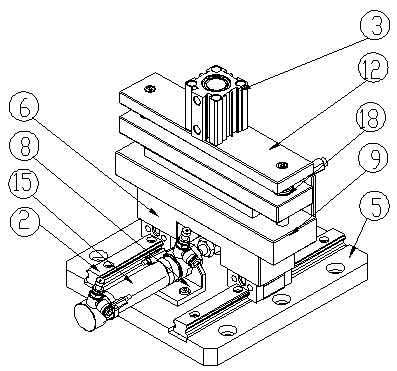

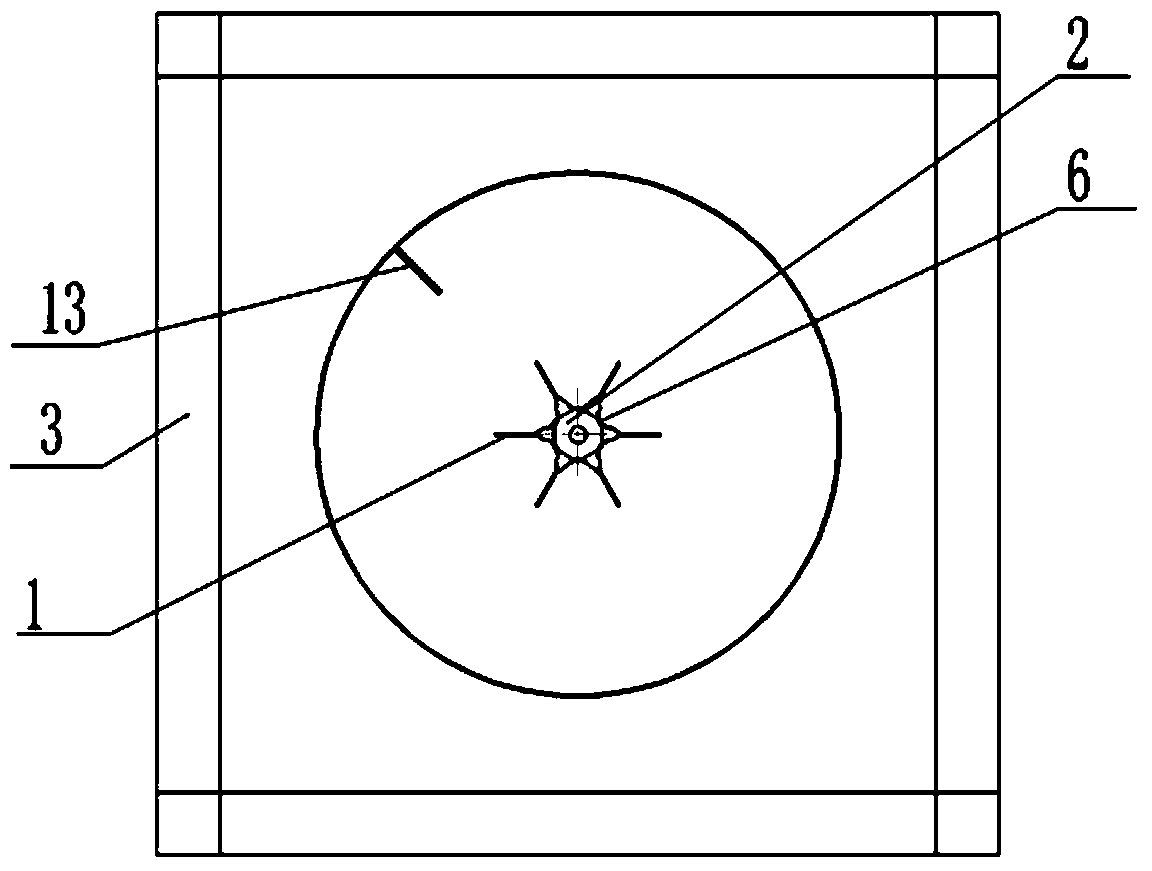

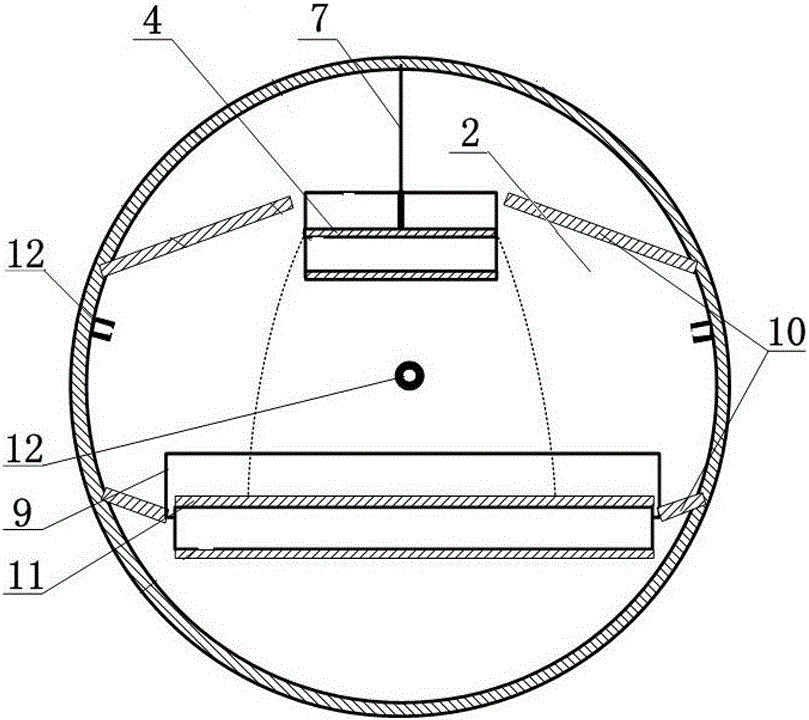

Efficient cage-shaped needle-type-nozzle electrostatic spinning device and application thereof in preparation of inorganic material nanofiber

ActiveCN106149066AEfficient mass productionContinuous mass productionMaterial nanotechnologyFilament/thread formingFiberElectrospinning

The invention discloses an efficient cage-shaped needle-type-nozzle electrostatic spinning device which comprises a nozzle set array integration component, a direct-current high-voltage power source, a receiving part and a driving part. An annular multi-nozzle set array is designed, and a nozzle set and the receiving part are arranged respectively in an internally-externally concentric mode; annular designing of the nozzle set effectively weakens repelling between electrified jet flows of adjacent nozzles, and efficiency of each needle in the nozzle set is close to an extreme value of spinning efficiency of a single needle-type nozzle. The invention further discloses application of the device in preparation of inorganic material nanofiber.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Adhesive composition for coating of glass slide and single-surface coating technology

ActiveCN108641634AImprove mechanical propertiesHigh tensile strengthMacromolecular adhesive additivesCoatingsAdhesivePolyvinyl alcohol

The invention relates to an adhesive composition for coating of a glass slide and a single-surface coating technology. The adhesive composition is prepared from the following components according to amass / volume ratio: a component 1 and a component 2, wherein the component 1 is prepared from 0.05 to 0.3% of film forming agent (polyvinyl alcohol), 0.02 to 0.25% of adhesive (carboxymethylcellulose), and the balance of water; the component 2 is prepared from 0.2 to 1mg / 100ml of cationic swelling agent (polylysine), and the balance of water. The single-surface coating technology comprises the following steps of cleaning the glass slide by ultrasonic waves in an alkaline solution, drying, spraying and coating the component 1 to the front surface according to the amount of 20 to 50mu l per piece, drying at the temperature of 35 to 55 DEG C, cooling to room temperature, spraying and coating the component 2 to the same surface according to the amount of 10 to 30mu l per piece, drying at the temperature of 35 to 55 DEG C, and packaging under the vacuum condition. The adhesive composition has the advantages that the effects of high adhesivity, uniform distribution and high definition of cells or tissues on the glass slide are realized; the continuous, automatic, stable, uniform and batch type single-surface zonal spraying and coating technology is realized. The prepared pathology slidecan resist the repeated washing and soaking by various alcohols and reagents, be suitable for the wall attaching, single-layer distribution and no falling of the cells, the tissues and the like, and can reach the effects of clear background and no impurity.

Owner:HANGZHOU YIGUOREN BIOTECH CO LTD

Method for mechanically plating zinc on surface of steel piece

InactiveCN108048825AImprove oxidation resistanceImprove corrosion resistanceLiquid/solution decomposition chemical coatingZincWear resistance

The invention discloses a method for mechanically plating zinc on a surface of a steel piece. The method comprises the following operation steps that 1, the surface of the prepared steel piece is cleaned, then the steel piece is added into a mechanical zinc plating roller and is added with an activating solution, and a rotating cylinder is started to process the mixture for 5-7 minutes; and 2, a zinc plating solution is continuously added into the mechanical zinc plating roller, and the rotating cylinder is starting to process the mixture for 25-30 minutes to obtain a finished product. The method for mechanically plating zinc on the surface of the steel piece has the advantages of being is stable in process and can realize continuous large-scale production; the prepared steel piece has excellent oxidation resistance and corrosion resistance, the adhesive force of a film layer of the steel piece is relatively high, the surface film layer is uniformly distributed, and excellent wear resistance of the the film layer is achieved; the obtained piece has no hydrogen embrittlement phenomenon; and therefore the quality of the steel piece is greatly improved.

Owner:刘珍

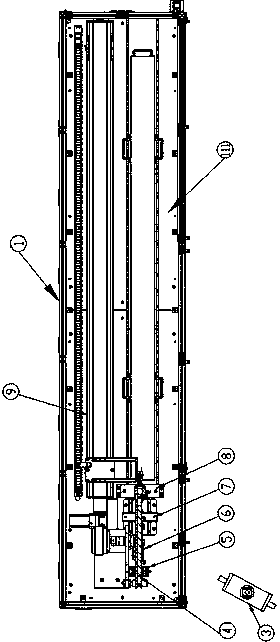

Compression feeding mechanism of busbar high-efficiency cutting machine

InactiveCN108521061AImprove mass production efficiencyAvoid Manual HandlingContact member manufacturingBusbarEngineering

Provided is a compression feeding mechanism of a busbar high-efficiency cutting machine. The compression feeding mechanism is characterized in that the compression feeding mechanism comprises a feeding base plate, a feeding cylinder, a feeding cylinder installation support, a linear guide rail, a feeding workbench, a buffer and a buffer installation support. Mechanized production is realized, themanual operation is avoided, the efficiency is high, and the effect is good; continuous mass production can be realized, and the efficiency of mass production of enterprises is greatly improved; and two cylinders are adopted for mutual cooperation, rapid feeding is realized after press fit, busbars can be transmitted to a cutting mechanism through multiple times of reciprocation, the accuracy is high, and the rate is high.

Owner:镇江市创富东日科技有限公司

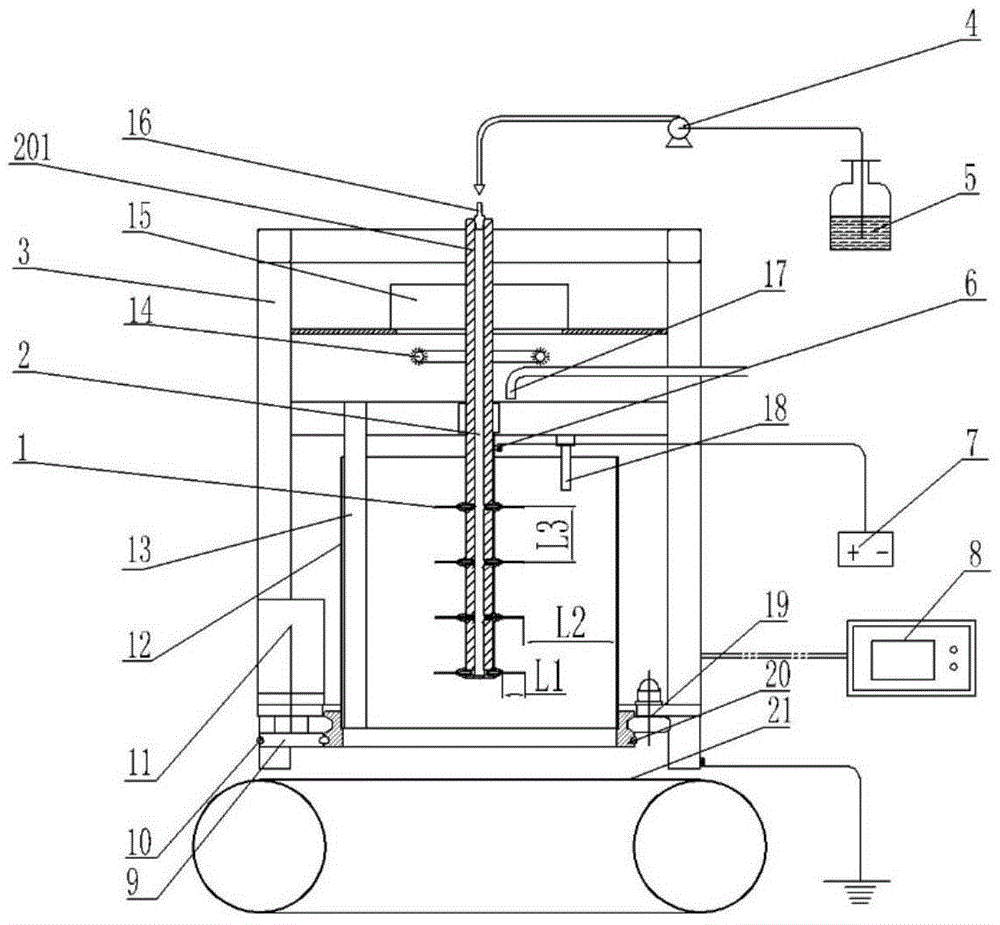

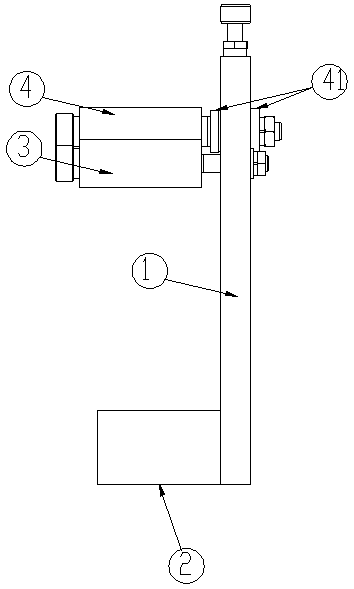

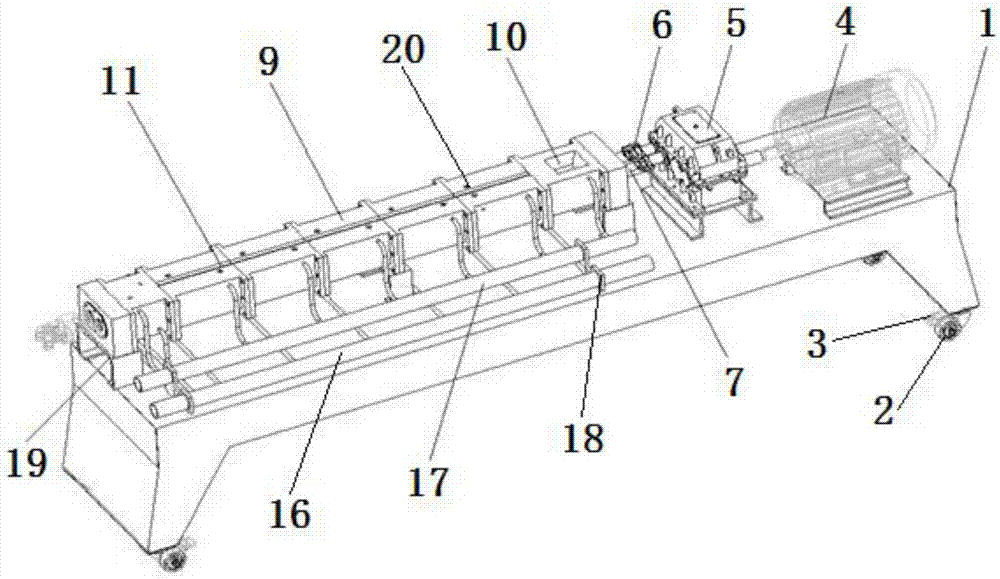

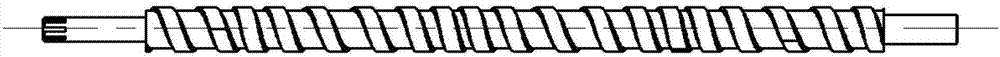

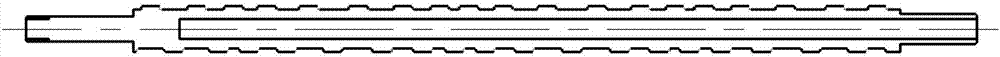

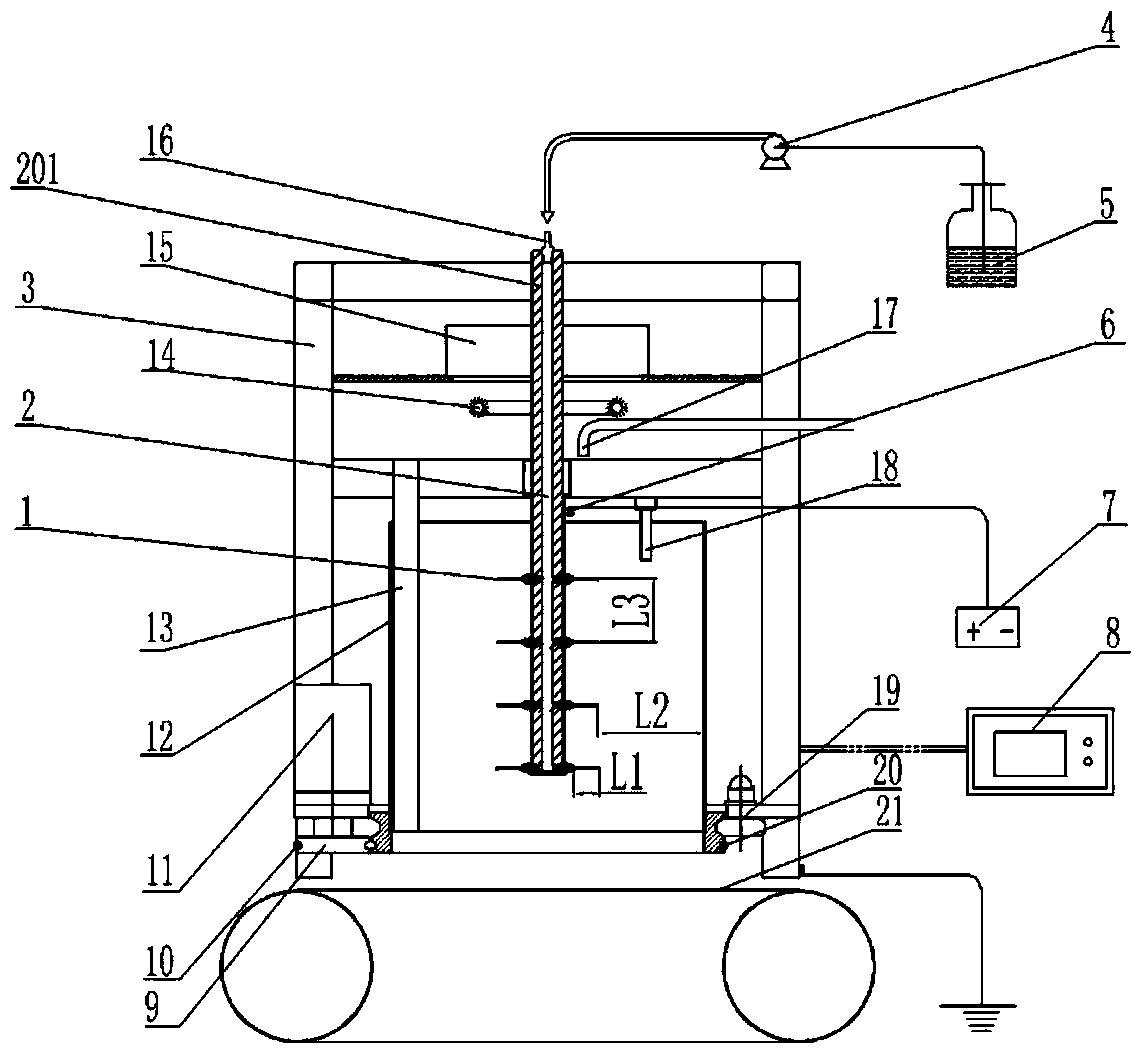

Dual-screw non-closed water removal device used for gunpowder continuous processing

PendingCN107289736AGuaranteed performanceEnsure safetyDrying solid materials without heatHeating arrangementGunpowderElectric machinery

The invention belongs to the technical field of gunpowder processing auxiliary equipment, and relates to a dual-screw non-closed water removal device used for gunpowder continuous processing. A main structure comprises a base, universal wheels, a foot brake piece, a motor, a reducer casing, a coupler, a dual-screw assembly, a core shaft, a machine barrel, a gunpowder inlet, a rotary air leakage roller, a scraping knife, a draining hole, a filter net, a hot water hole, a first hot water supply pipe, a second hot water supply pipe, a gunpowder outlet and an exhaust hole; water-containing gunpowder is subject to extrusion water removal to the maximum degree, water in the water-containing gunpowder is removed to the maximum degree, water can be effectively extruded, the damage or the dangerous condition of the gunpowder performance caused by continuous and excessive extrusion of the water-containing gunpowder can be avoided, the dual-screw assembly can be arranged to have different draw ratios according to the different water removal requirements, extrusion water removal of the water-containing gunpowder to the maximum degree can be achieved, the water removal rate of the water-containing gunpowder can be improved, the structure is simple, and the device is energy-saving, environment-friendly, friendly in use environment and easy to use and popularize.

Owner:QINGDAO UNIV OF SCI & TECH

Method and device for preparing reagent hydrochloric acid

The invention discloses a method and a device for preparing a reagent hydrochloric acid. The method comprises the following steps: chlorine and hydrogen are sent into a graphite synthesis furnace, synthesized hydrogen chloride gas is sent into a hydrogen chloride cooler and is cooled, the cooled hydrogen chloride gas enters an I-stage falling film absorption tower, and is absorbed by dilute hydrochloric acid, from an II-stage falling film absorption tower, in the I-stage falling film absorption tower to form reagent grade hydrochloric acid, the hydrogen chloride gas discharged from the I-stagefalling film absorption tower enters the II-stage falling film absorption tower, and is absorbed by ultrapure water in the II-stage falling film absorption tower to form dilute hydrochloric acid, andthe hydrogen chloride gas discharged from the II-stage falling film absorption tower enters a tail gas absorption tower, and is absorbed by the pure water in the tail gas absorption tower to form dilute hydrochloric acid for cycle use. The method has the advantages of simple production process, low investment, small occupied area, high production efficiency, high utilization rate of raw materials, high product quality, low energy consumption, low production cost, no discharge of wastewater or waste gas, convenience in maintenance and control, simplicity in operation, and realization of continuous and stable large-scale production.

Owner:华融化学(成都)有限公司

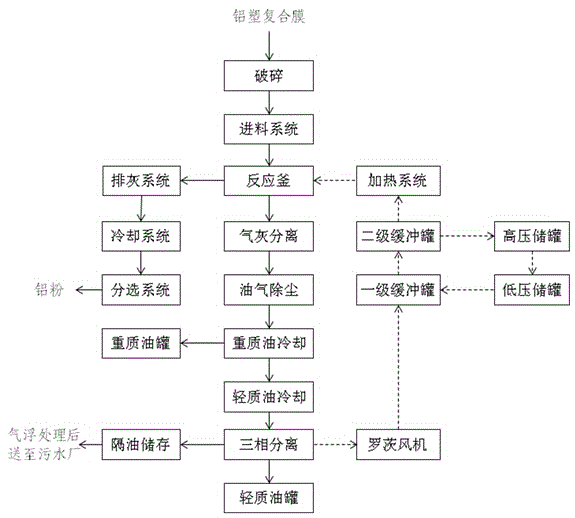

Method for recovering and using aluminum-plastic composite film

InactiveCN104532003ASolve pollutionImprove heat transfer performanceLiquid hydrocarbon mixture productionProcess efficiency improvementComposite filmCombustible gas

The invention discloses a method for recovering and using an aluminum-plastic composite film, which comprises the following steps: 1)crushing waste and old aluminum-plastic composite films, introducing in a bunker by a conveying system; 2)introducing the crushed waste and old aluminum-plastic composite films through a charging system into a reaction vessel for pyrolysis, wherein the reaction temperature is 350-500 DEG C; and 3)dedusting on oil gas and separating the oil gas, removing carbon black in the oil gas to respectively obtain heavy oil, light oil and combustible gas; cooling the crude aluminium powder in the reaction vessel through an ash-discharging system, and separating by a sorting system to obtain aluminium powder. The method is carried out under anoxic condition, aluminium foil can be recovered, plastic can be reduced to oil gas, the heat transfer effect is good, processing amount is large, no secondary pollution is generated, continuous large-scale production can be realized, and a brand new technology is created. The method has wide economic meaning and social meaning.

Owner:HANGZHOU DIANZI UNIV

Continuous pickling method for hot-rolled dual-phase steel

The invention relates to a pickling method for hot-rolled dual-phase steel and belongs to the field of metallurgy. The invention provides a continuous pickling method for hot-rolled dual-phase steel. The steps include: uncoiling of hot-rolled raw materials, laser welding, phosphorus breaking in a tension and straightening unit, turbulent flow pickling, rinsing and online leveling, wherein turbulent flow pickling Single-acid environment pickling is used in the process. The pickling temperature is 55-85°C. Pickling is carried out in at least three stages, and the pickling conditions of each stage are controlled as follows: During the first pickling process, the Fe2+ concentration in the pickling tank is ≤ 150g / l, the concentration of the single acid is 50~120g / l; during the second pickling process, the Fe2+ concentration in the pickling tank is ≤120g / l, and the concentration of the single acid is 60~160g / l; third During the pickling process, the Fe2+ concentration in the pickling tank is ≤80g / l, and the concentration of the single acid is 80-200g / l. The process steps are simple and easy to implement, the acid liquid can be recycled and regenerated, and has certain environmental protection. It also has the characteristics of continuous large-scale production, high pickling efficiency, and low pickling cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Hollow floor mandrel filling body and manufacturing method thereof

The invention belongs to the building domain, and relates to a hollow floor mandrel filling body and a manufacturing method thereof. The hollow floor mandrel filling body is at least prepared from, by mas s, 60-80 parts of mountain flour type material, 10-30 parts of fiber material, 8-12 parts of starch, 0.5-1.5 parts of release agent, and 25-45 parts of water. The hollow floor mandrel filling body adopts the high-temperature foaming principle of starch, and the finished product is light in weight, low in cost, big in flexibility, and more environment-friendly; moreover, the filling body can be industrially produced on a large batch; the manufactured mandrel filling body has smooth outer wall and porous inner part; thus the material dosage is reduced, the product weight is lightened, the product performance cost is greatly improved; moreover, the product can be shaped by compression molding in one time or separately; the filling body is assembled and shaped on site in use.

Owner:熊文彬

A high-efficiency cage-shaped needle nozzle electrospinning device and its application in the preparation of inorganic material nanofibers

ActiveCN106149066BEfficient mass productionContinuous mass productionMaterial nanotechnologyFilament/thread formingFiberElectrospinning

The invention discloses an efficient cage-shaped needle-type-nozzle electrostatic spinning device which comprises a nozzle set array integration component, a direct-current high-voltage power source, a receiving part and a driving part. An annular multi-nozzle set array is designed, and a nozzle set and the receiving part are arranged respectively in an internally-externally concentric mode; annular designing of the nozzle set effectively weakens repelling between electrified jet flows of adjacent nozzles, and efficiency of each needle in the nozzle set is close to an extreme value of spinning efficiency of a single needle-type nozzle. The invention further discloses application of the device in preparation of inorganic material nanofiber.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A doped photovoltaic thin film material

ActiveCN106024935BExcellent semiconductor propertiesLow costFinal product manufacturePhotovoltaic energy generationSolar cellSilicon dioxide

The invention discloses a doping type photovoltaic thin film material. A carbon-doped silicon dioxide layer and a defect-free doping type grapheme layer are sequentially arranged on an n type Si substrate, and the doping type photovoltaic thin film material with photovoltaic and photoconduction effects is formed. The prepared photovoltaic thin film material has good semiconductor properties, is low in cost, can be continuously produced on a large scale, and is used for numerous fields of solar cells and the like.

Owner:SHAOXING UNIVERSITY

Production method of thin steel strip hot galvanizing

ActiveCN102776460BImprove corrosion resistanceImprove machinabilityHot-dipping/immersion processesElectrolysisDesorption

The invention relates to a production method of thin steel strip hot galvanizing. The production method comprises the following steps of uncoiling, welding, chemical desorption, electrolysis, cleaning, air drying, annealing, galvanizing, air cooling, straightening, chemical coating and coiling. A steel strip subjected to galvanizing has good corrosion resistance and better machining performance, the plating layer is firm and uniform, the color is bright, the service life is long, the environment pollution is avoided, and the continuous large-scale production can be realized.

Owner:江苏大力神科技股份有限公司

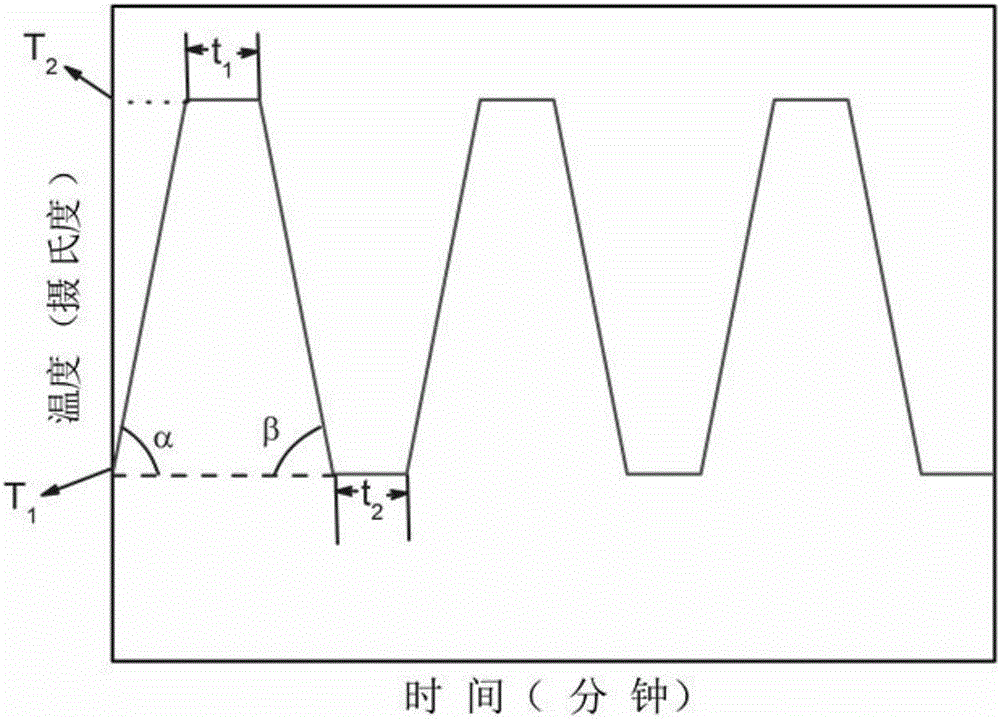

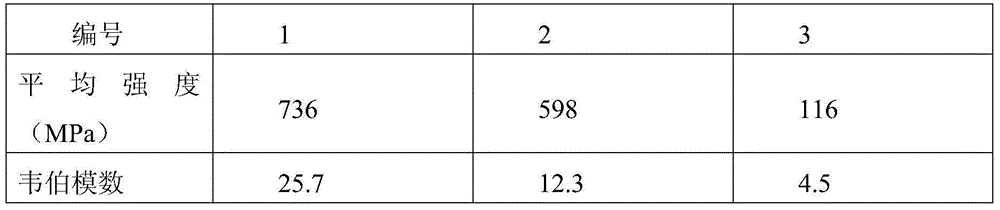

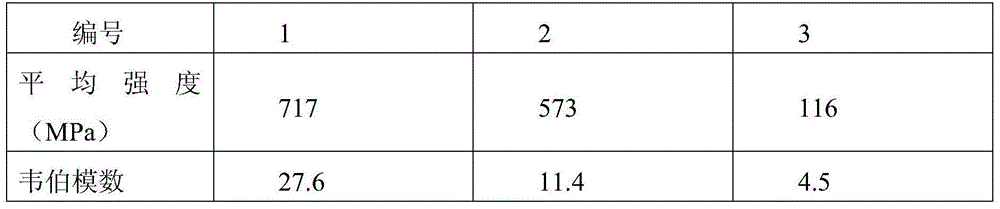

A Method for Reducing Strength Dispersion of Chemically Strengthened Glass by Temperature Modulation

ActiveCN103588388BLittle dispersion of strengthIncreased strength dispersionGlass tempering apparatusDispersitySurface stress

The invention relates to a method for reducing the chemically strengthened glass strength dispersity, and particularly relates to the method for reducing the chemically strengthened glass strength dispersity through temperature modulation. The invention provides the method of reducing the chemically strengthened glass strength dispersity through the temperature modulation. According to the method, periodicity control of the temperature rising / reducing speed and the heat-preservation temperature is carried out during a chemical strengthening process, so as to reach the purpose of changing the chemically strengthened glass internal potassium ion concentration distribution and the glass surface stress distribution, and thus the glass strength dispersity is reduced. The chemically strengthened glass manufactured by the method not only has the strength greatly increased (about 8-10 times that of annealed glass), but also has the strength dispersity greatly decreased (the Webber modulus is 2 times that of ordinary chemically strengthened glass). The method has the advantages of simple process, easy operation and good process repeatability, and can realize the continuous, stable and batch production.

Owner:BAIMTEC MATERIAL CO LTD

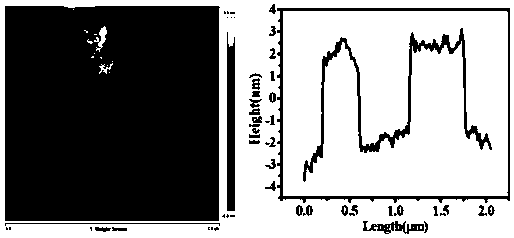

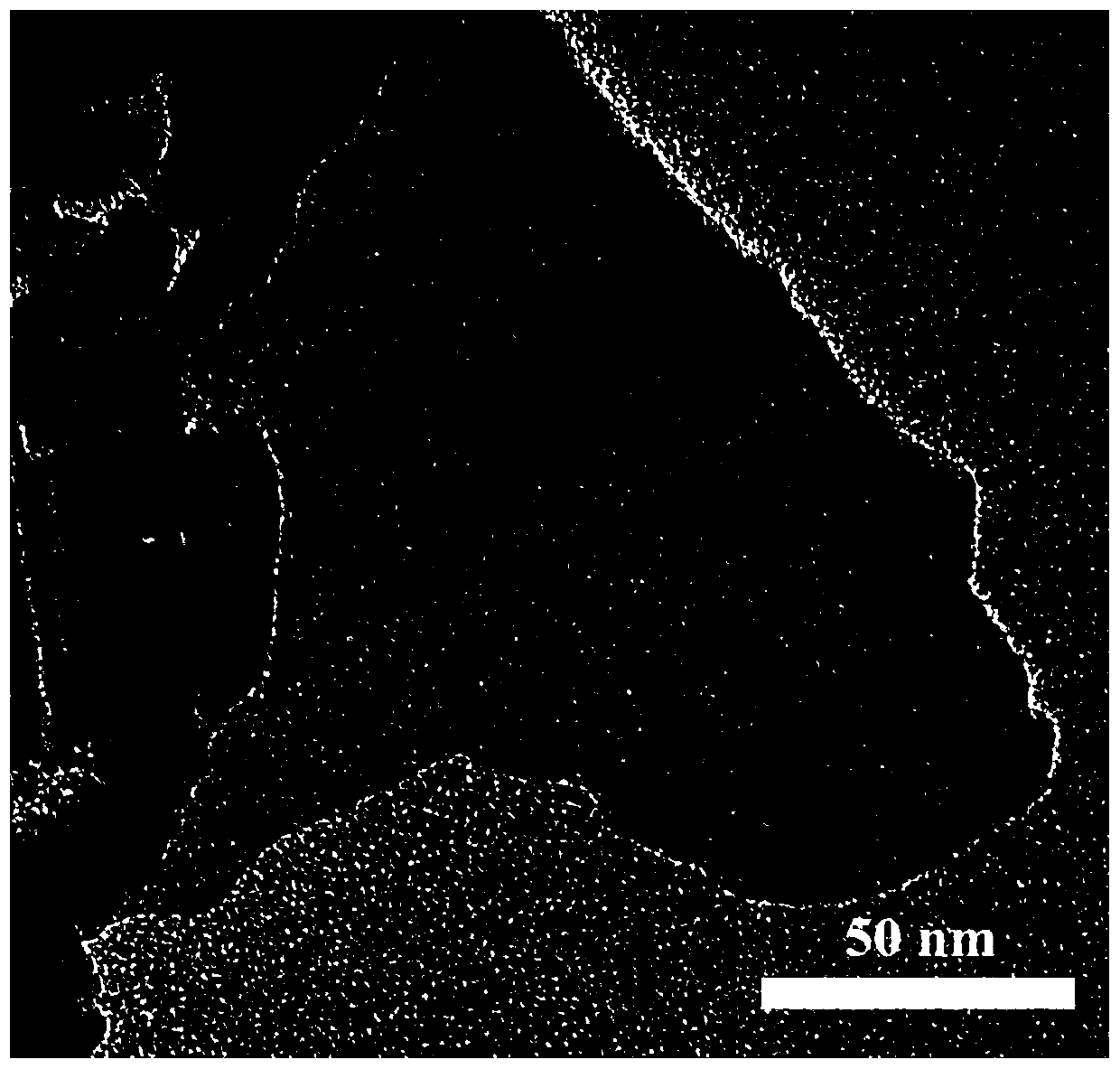

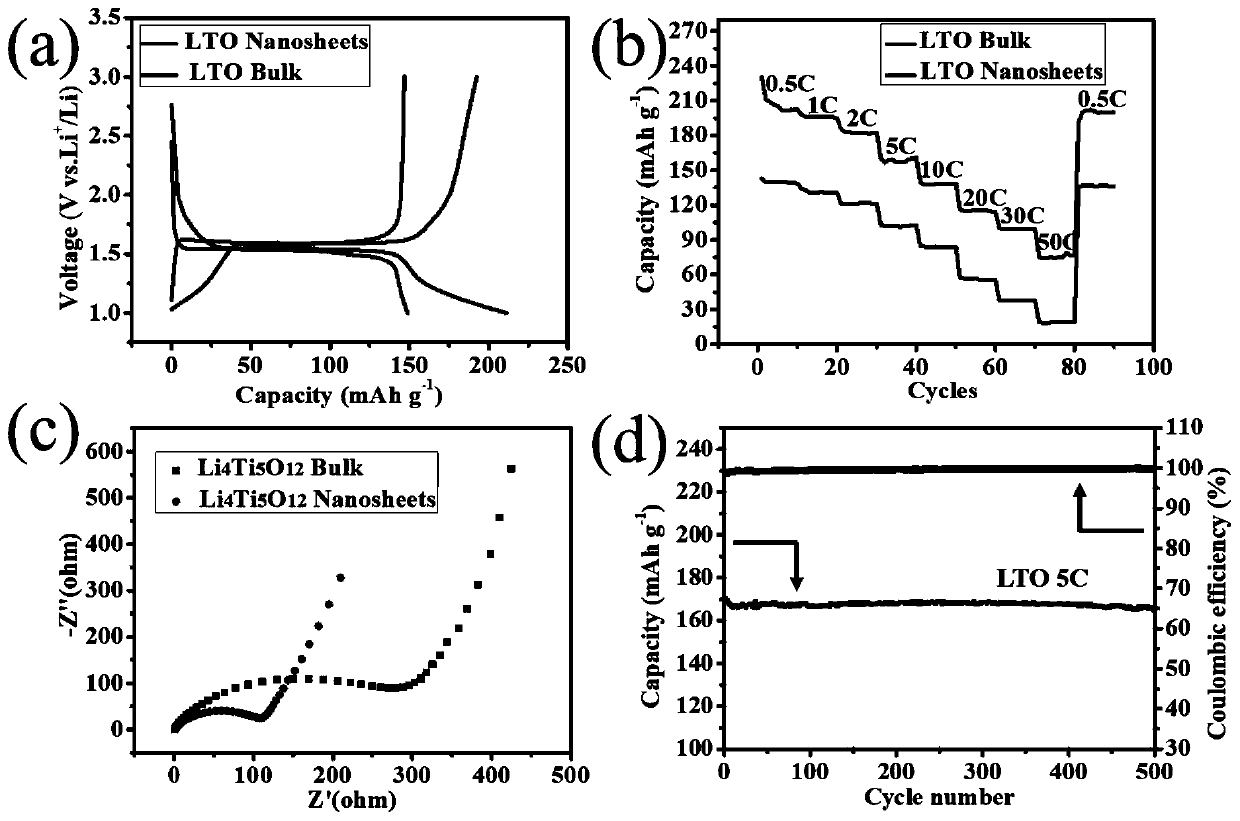

Method for preparing spinel type Li4Ti5O12 ultrathin nano-sheets

InactiveCN110844934APromote circulationExcellent rate performanceAlkali titanatesCell electrodesAir atmosphereMethylamines

The invention discloses a method for preparing spinel type Li4Ti5O12 ultrathin nano-sheets. The method comprises: 1, preparing an original layered Na2Ti3O7 material by adopting a sol-gel method; 2, dispersing Na2Ti3O7 in an HCl solution, and stirring for enough time, so that Na<+> is completely exchanged by H <+> to obtain H2Ti3O7; 3, putting the H2Ti3O7 into a methylamine aqueous solution, and carrying out a hydrothermal reaction on the mixed solution to obtain a methylamine intercalation compound (MA / Ti3O7); 4, dispersing the MA / Ti3O7 in water, stripping the MA / Ti3O7 into nano-sheets by utilizing shearing force provided by an ultrasonic means, centrifuging the mixed solution to remove the unstripped precipitate, taking the supernatant, and drying to obtain MA / Ti3O7 nano-sheets; 5, dispersing the MA / Ti3O7 nano-sheets in a LiOH aqueous solution, and carrying out a hydrothermal reaction to obtain Li2Ti3O7 nano-sheet; and 6, carrying out heat treatment on the Li2Ti3O7 nano-sheets prepared in the step 5 in an air atmosphere to finally obtain the Li4Ti5O12 nano-sheets. According to the invention, with the method, the problems that the capacity of Li4Ti5O12 g is low and high-rate circulation is not facilitated can be effectively solved.

Owner:西安越遴新材料研究院有限公司

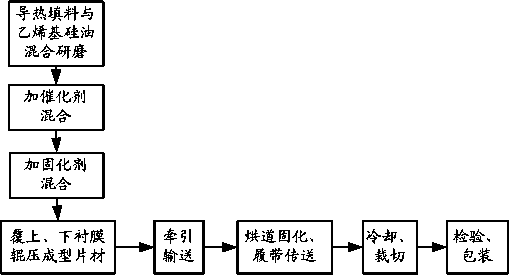

Method for continuously forming organosilicon heat-conducting patch

The invention discloses a method for continuously forming an organosilicon heat-conducting patch. The method sequentially comprises the following steps: preparing organosilicon heat-conducting composition slurry; coating the prepared slurry on an upper lining film and a lower lining film, simultaneously rolling and forming a patch, and dragging and conveying the patch forwards; and conveying the patch to a flat continuous track of a drying channel, continuously conveying the patch forwards, and simultaneously heating and curing the patch in the drying channel. According to the forming method disclosed by the invention, the organosilicon heat-conducting composition is continuously formed into the patch with the required dimension and uniform thickness, and the continuous large-scale production is realized.

Owner:SHENZHEN ANPIN SILICONE MATERIAL

A closed tobacco leaf front and back feeding equipment

InactiveCN104983055BReduce breakage rateControl the feeding processTobacco preparationEngineeringLiquid injection

The invention discloses a closed tobacco-leaf front-back-face material adding device. The closed tobacco-leaf front-back-face material adding device is characterized by comprising a leaf feeding system, a flow dividing system, a tobacco leaf inlet, an atomizing chamber, an atomizing chamber sealing plate, a liquid injection nozzle and a leaf outlet conveying belt. The closed tobacco-leaf front-back-face material adding device has the advantages that the structure is simple, the material adding evenness is high, the tobacco leaf breaking rate is low, the adding accuracy and the adding stability are good, and continuous large-scale production can be achieved; as materials are added to the front face and the back face of tobacco leaf flow in a closed mode, the tobacco material adding process can be more fine and more evenly controlled, and the tobacco material adding effect can be effectively improved.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com