Method for preparing metal composite sheet strip through electroplating deposition and rolling

A technology of metal composite plates and metal strips, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as uncontinuous production, low bonding strength, and poor plate shape, so as to improve comprehensive mechanical properties, The effect of good quality and numerical increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 一种电镀沉积辅助轧制金属复合板带的方法,包括以下步骤:

[0038] 1)表面处理:选取TA1钛板、6061铝板,钛板尺寸为厚0.5mm×宽50mm×长120mm作为基板2,铝板尺寸为厚0.3mm×宽50mm×长120mm作为复板3,用打磨机清理TA1钛板和6061铝板表面,直至见到金属基体;

[0039] 2)覆膜:首先,利用抛光机对所述基材带复合面进行抛光,表面粗糙度达Ra0.6,接下来,对抛光后的待复合面进行覆膜,所述膜为表面带有通孔的聚酯复合薄膜,通孔直径为63um,全部通孔面积所占整张膜面积的比例为:

[0040]

[0041] 其中,λ为通孔面积占覆膜面积的比例,l b 为所述基材的长边的长度,w b 为所述基材的短边的长度,d c 为聚酯薄膜上通孔的直径大小;

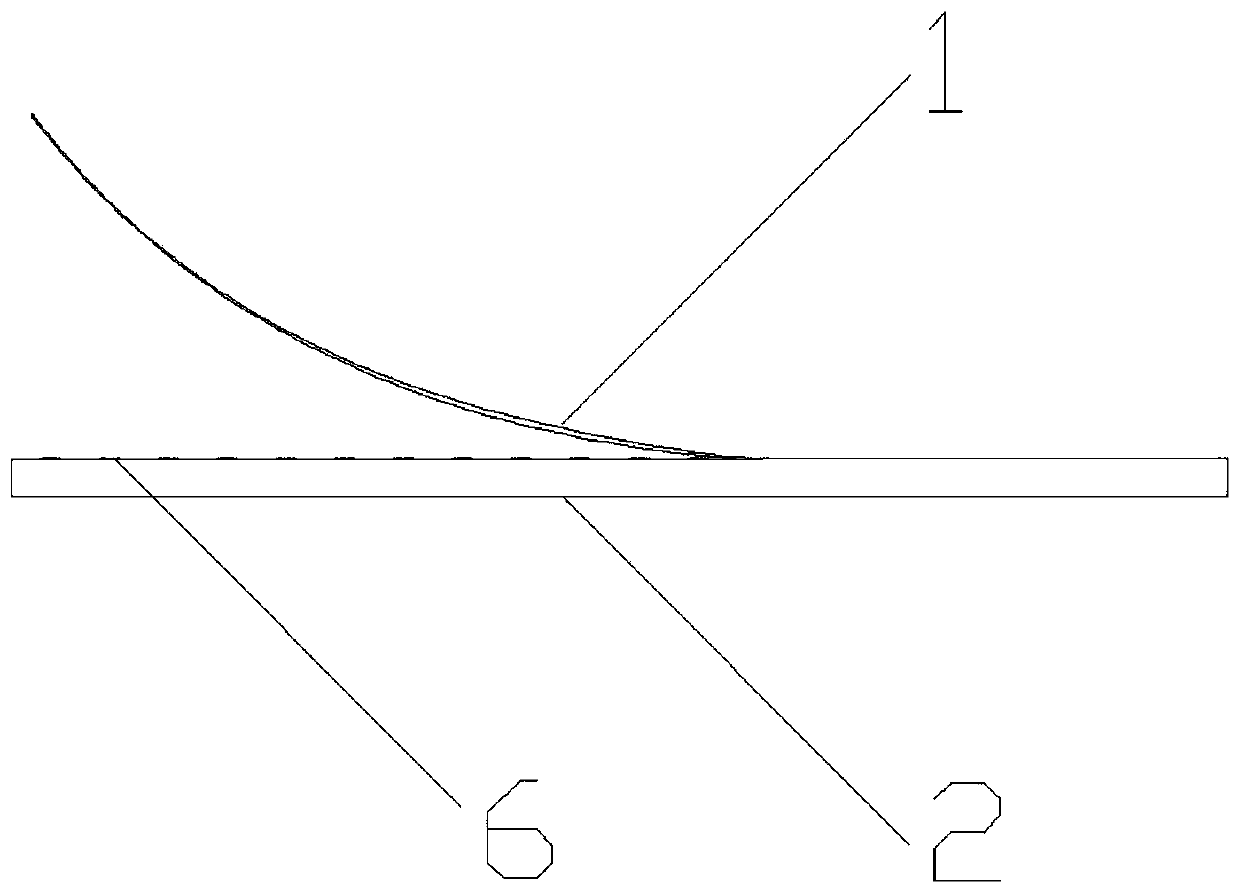

[0042] 3)电镀沉积:首先,对已覆膜的基材用有机溶剂和碱性溶液清洗表面,接下来,用去离子水清洗表面,电镀溶液由铬酐(250g / L)、浓硫酸H 2 SO 4 (2.5g / L)组成,镀液流速为3.6L / min,两极间距为48mm,温度为55℃,电流密度为50A / dm 2, the pulse frequency is 10kHz, the pulse duty ratio is a square wave pulse current of 85%, and the thickness of the coating is 48um. After electroplating, the coating substrate is cleaned and dehydrogenated, and finally removed along the corners of the substrate in step 2) coating, such as figure 1 shown;

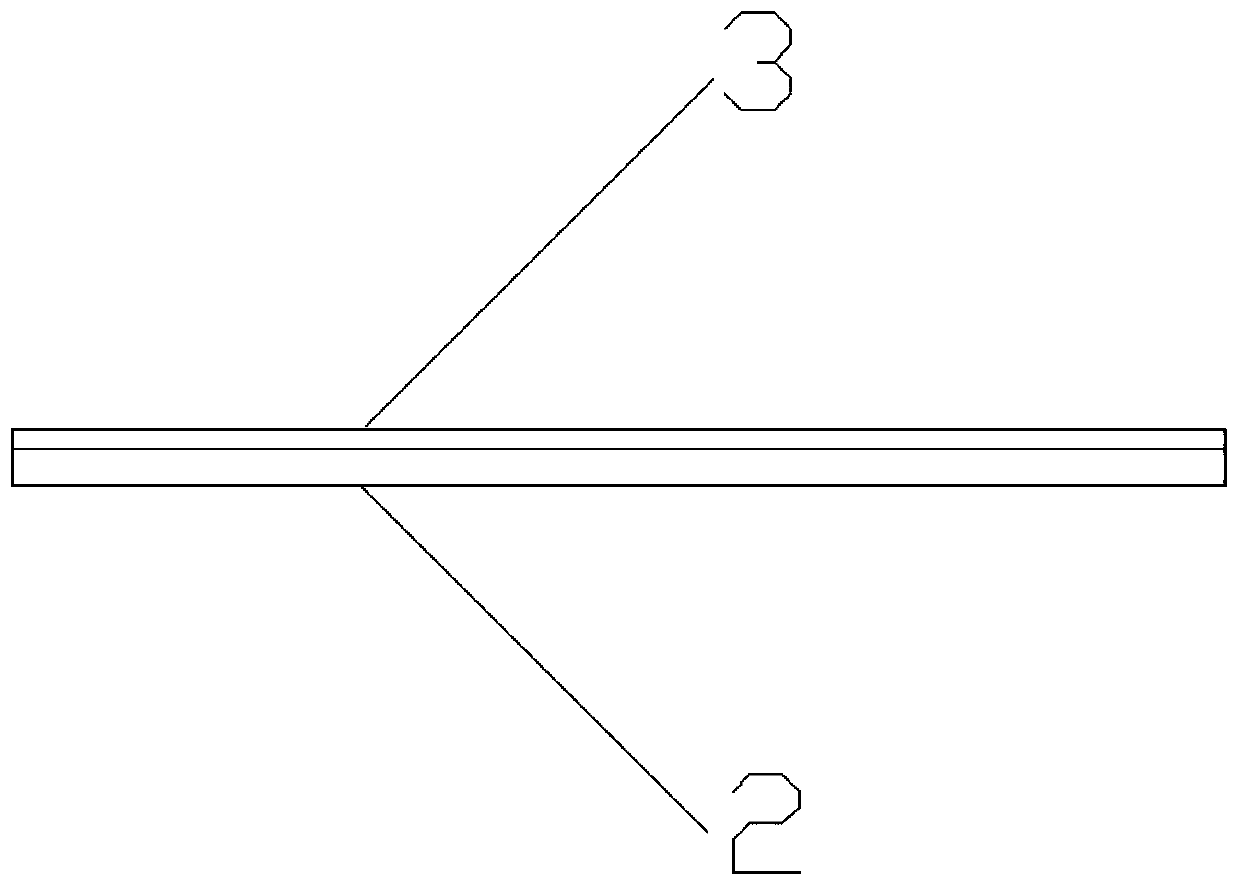

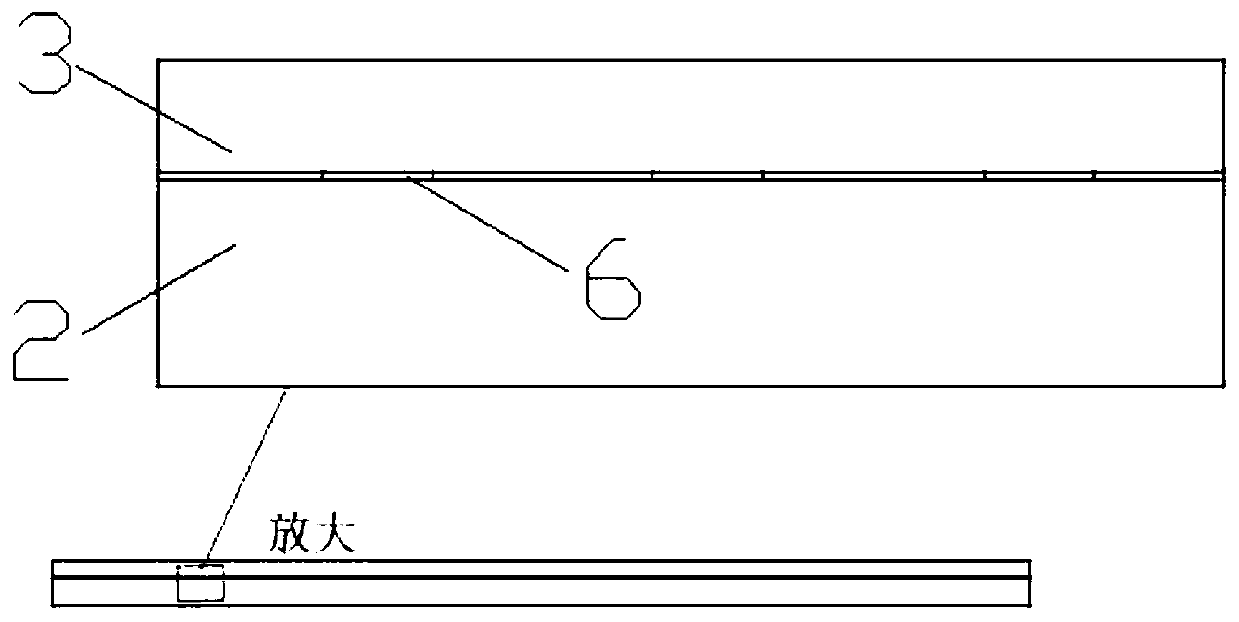

[0043] 4) Blank making: such as figure 2 , 3 As shown, the polished surface of the TA1 titanium plate and the 6061 aluminum plate are stacked and buckled, and then sent to...

Embodiment 2

[0048] A method for electroplating deposition-assisted rolling metal composite strips, comprising the following steps:

[0049] 1) Surface treatment: such as figure 1 , 2 As shown, select TA1 titanium plate and SUS304 stainless steel plate, the size of the stainless steel plate is 0.8 mm thick × 40 mm wide × 100 mm long, as the substrate 2; the titanium plate is 0.5 mm thick × 40 mm wide × 100 mm long, as the doubler plate 3, use The grinding machine cleans the surface of TA1 titanium plate and SUS304 stainless steel plate until the metal matrix is seen;

[0050] 2) Coating: First, use a polishing machine to polish the compound surface of the base material with a surface roughness of Ra0.3, and then coat the polished surface to be compounded. The through-hole polyester composite film has a through-hole diameter of 110um, and the ratio of the total through-hole area to the entire film area is:

[0051]

[0052] Among them, λ is the ratio of the via area to the film area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com