Patents

Literature

399 results about "Shearing (manufacturing)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shearing, also known as die cutting, is a process which cuts stock without the formation of chips or the use of burning or melting. Strictly speaking, if the cutting blades are straight the process is called shearing; if the cutting blades are curved then they are shearing-type operations. The most commonly sheared materials are in the form of sheet metal or plates, however rods can also be sheared. Shearing-type operations include: blanking, piercing, roll slitting, and trimming. It is used in metalworking and also with paper and plastics.

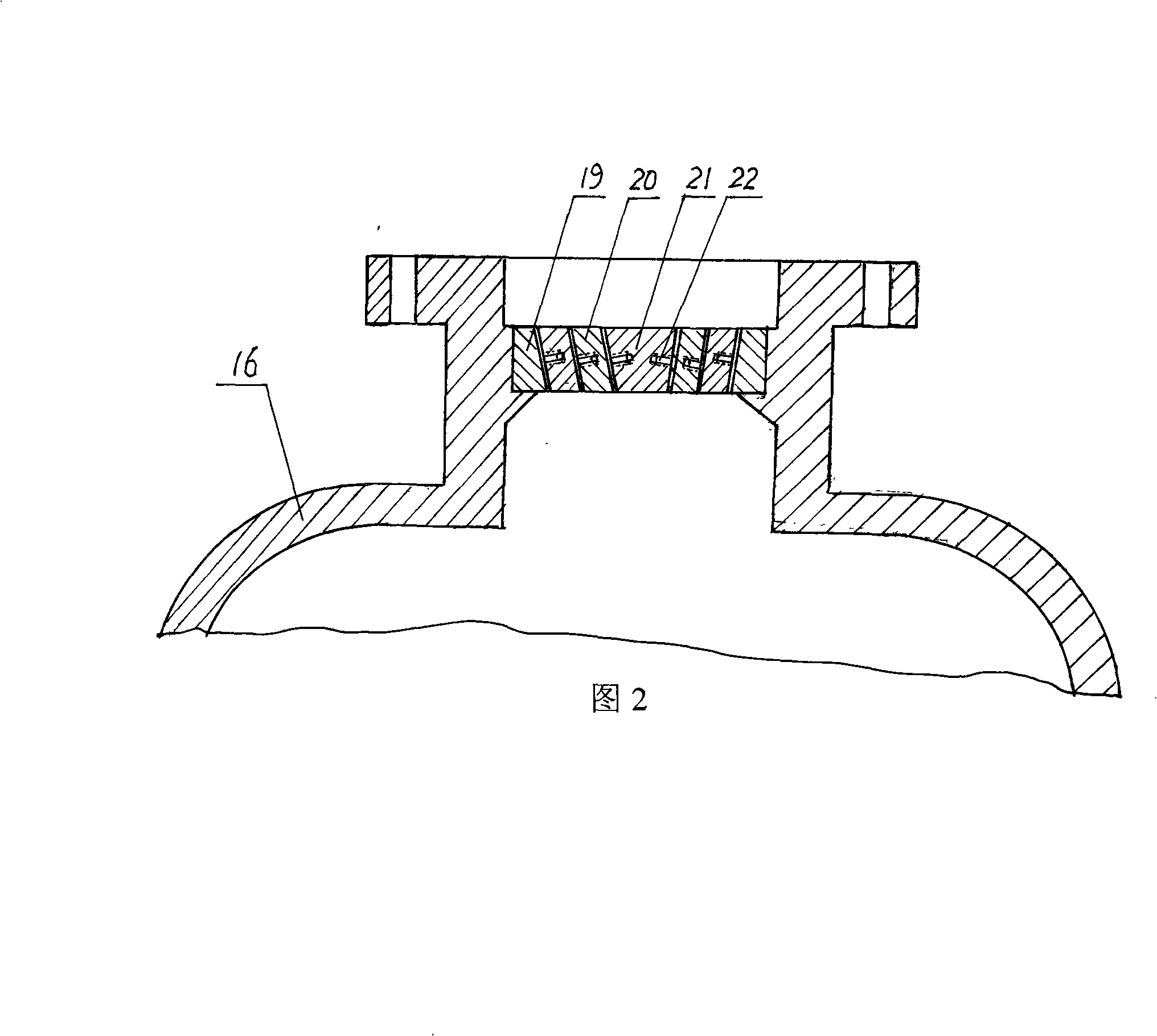

Method for manufacturing amorphous alloy stator iron core for motor

InactiveCN102738976AShort production processProduction energy saving and environmental protectionManufacturing stator/rotor bodiesApplying solid insulationStatorAlloy

The invention, which belongs to the magnetic circuit component field of the motor, more particularly relates to a method for preparing a high-performance stator iron of an amorphous alloy, wherein the stator iron is used for a motor. The method comprises the following steps: carrying out lateral shearing on an amorphous strip to obtain a plurality of amorphous slices with the same shape; carrying out stacking, compaction and clamping on the amorphous slices, carrying out cutting wholly, and then carrying out mechanical fastening along a stator shaft; and carrying out whole annealing processing on a complete amorphous alloy iron core. According to the method, the mechanical fastening is used to replace adhesion fixing among the amorphous slices to solve problems that interlaminar fracture occurs frequently with utilization of the interlaminar adhesion method and the iron core performance is reduced due to the existence of the adhesion stress, thereby further substantially improving the performance of the stator iron core of the amorphous alloy.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

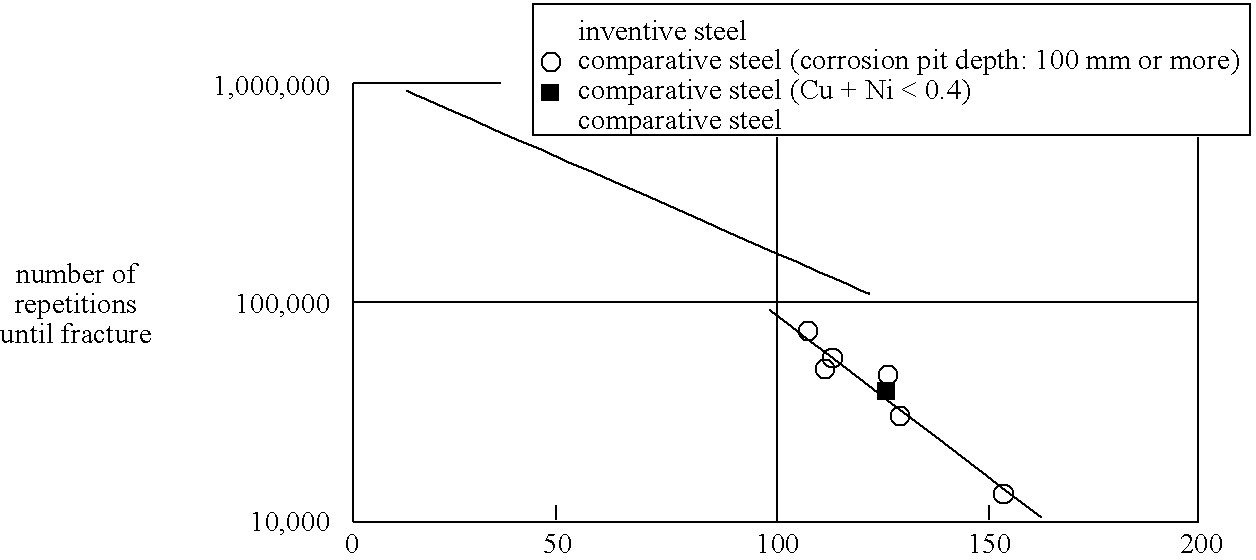

High Strength Spring Steel, High Strength Springs and Manufacturing Method Thereof

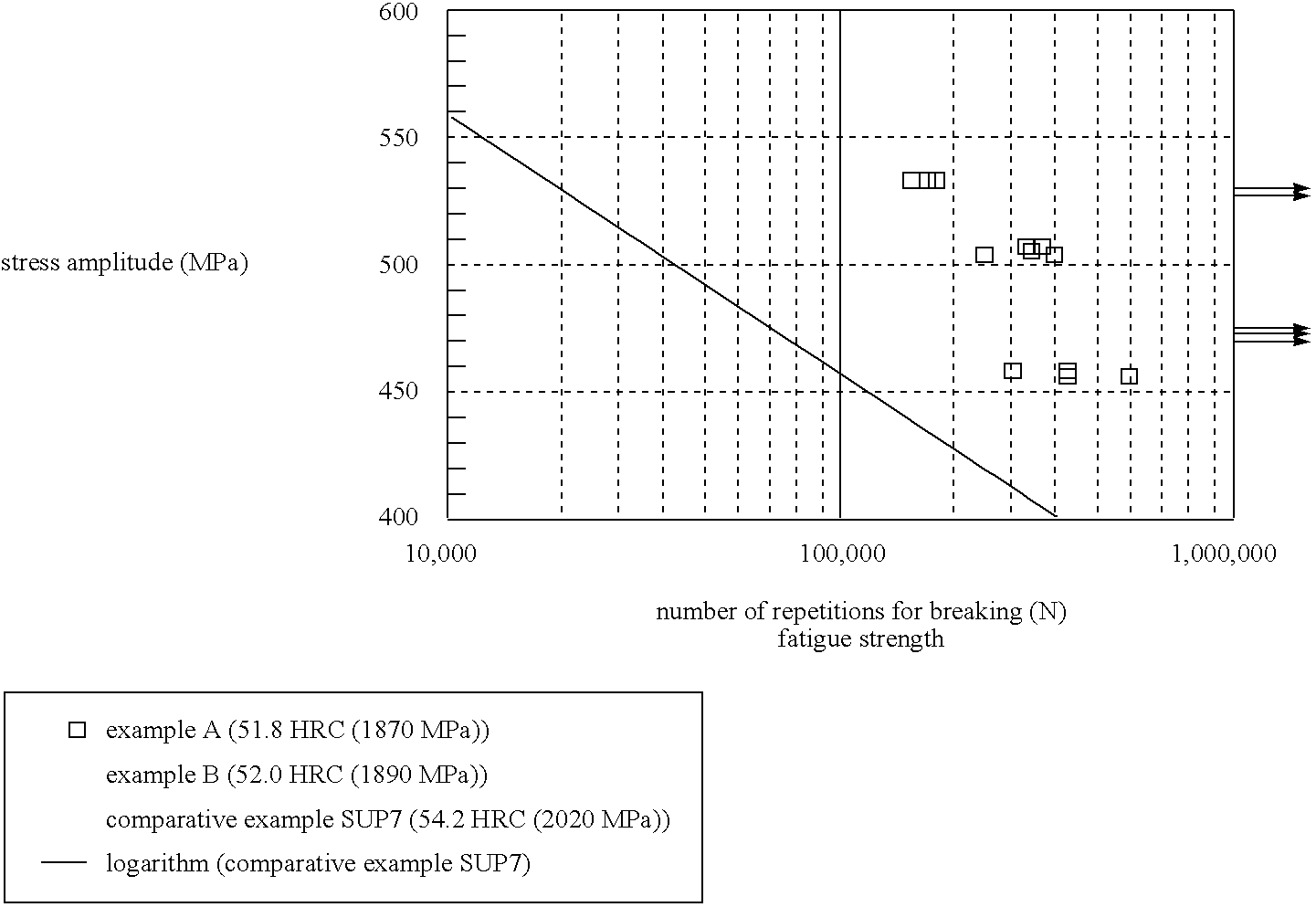

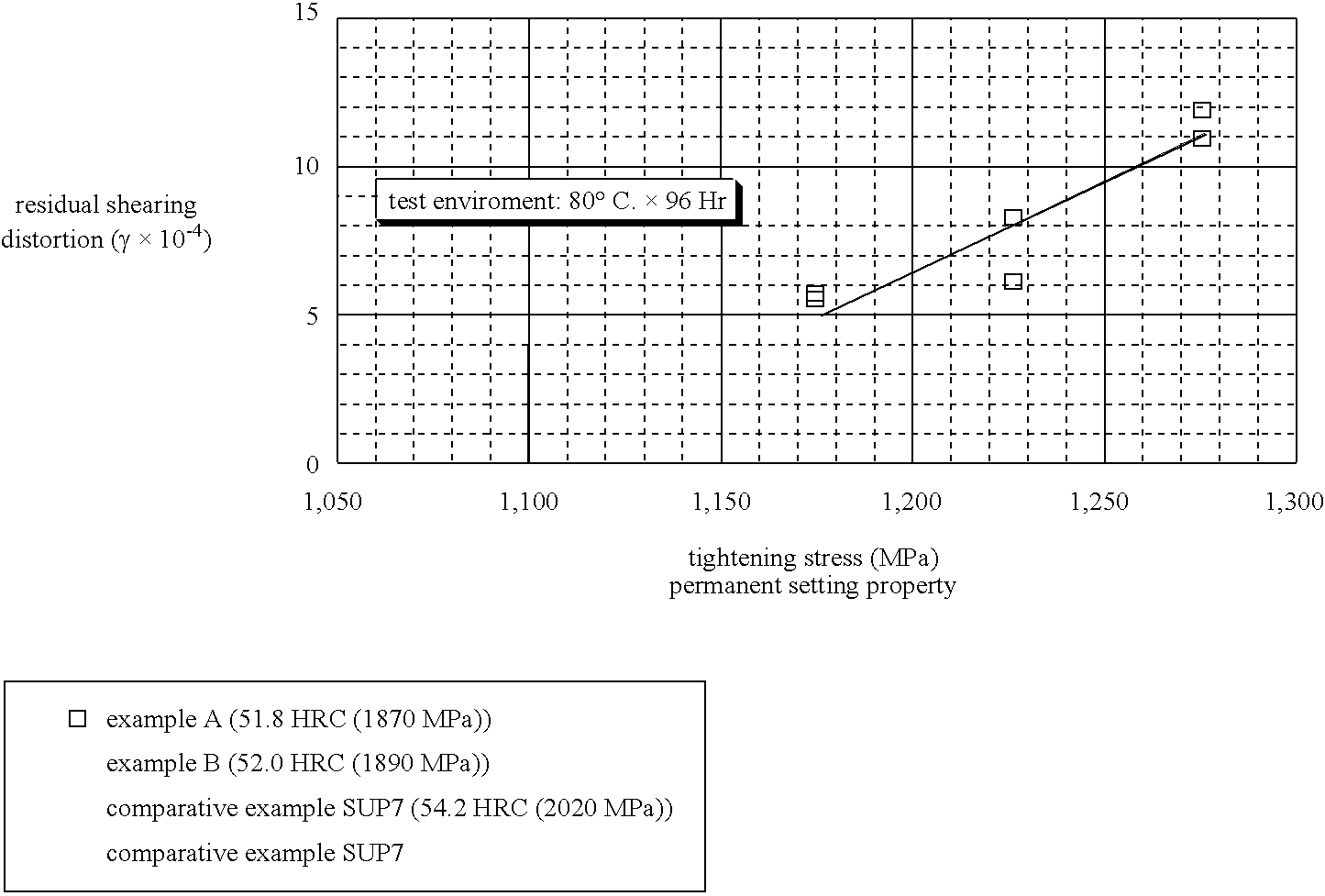

InactiveUS20070256765A1Large compressive residual stressSufficient compressive residual stressSpringsFurnace typesHigh intensitySpring steel

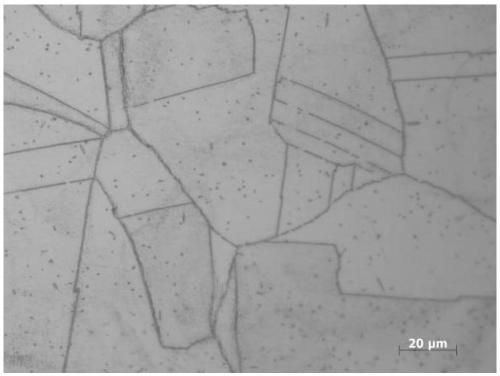

A high strength spring steel of this invention is characterized in containing, in percent of mass, of C: 0.36-0.48%; Si: 1.80-2.80%; Mn: 0.20-1.40%; P: 0.015% or less; S: 0.010% or less; Cu: 0.10-0.50%; Ni: 0.10-2.00%; Cr: 0.05-1.20%; s-Al: 0.005-0.040%; N: 0.002-0.012%; O: 0.002% or less, while the remainder is constituted of Fe and inevitable impurities and the quantity of inclusions of 10 μm or larger in diameter per field of vision of 100 mm2 is 10 or less. A manufacturing method of high strength spring of this invention is characterized in that the high strength spring steel which is tempered to HRC52 or higher is formed into a spring shape by hot forming or cold forming and warm shot peening is carried out so as to produce a high strength spring of 1176 MPa or higher in maximum shearing stress.

Owner:NHK SPRING CO LTD

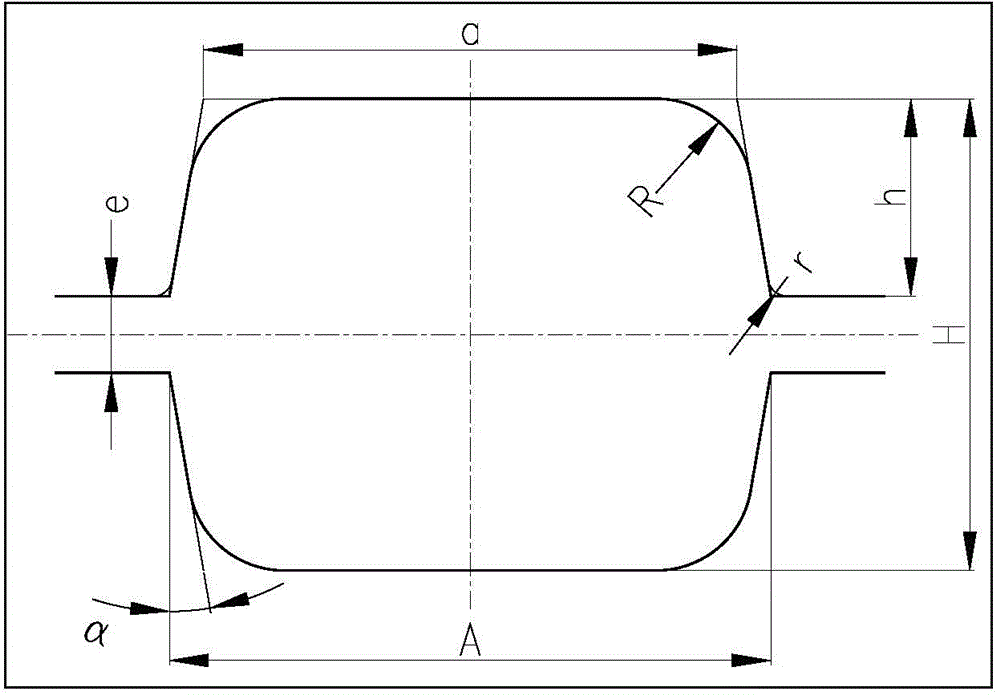

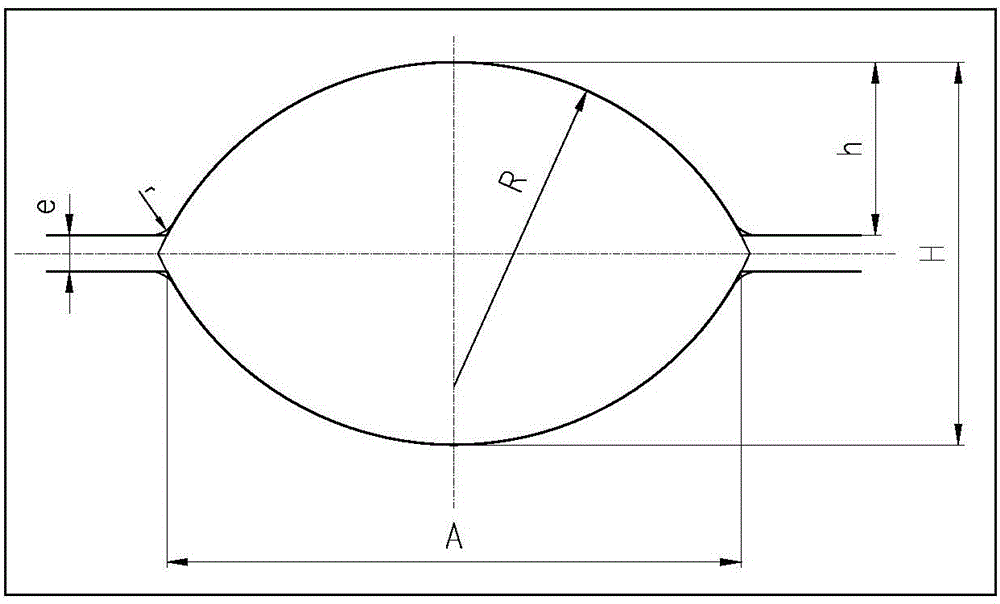

Production method of aluminum-aluminum composite inflation type pipeline board

The invention provides a method for manufacturing an Al-Al composite inflation-typed pipeline plate, comprising the steps as follows: a. blanking and punching; b. cleaning and drying; c. printing; d. heating; e. hot rolling; f. cold rolling; g. cleaning; h. annealing; i. inflating; j. marking, shearing and punching; k. welding connecting pipe; l. whole detecting, etc. The composite aluminium pipeline plate processed by the method can increase or reduce the proportion of the internal chamber and the heat exchanging surface in extremely large range, and freely changes the geometrical shape, diameter and volume of the pipeline. The component is completely a whole and has high heat transfer rate and extremely small temperature difference of the medium and the heat exchanging surface. Compared with the traditional heat exchanger, the Al-Al composite inflation-typed pipeline plate has the supreme characteristic that the working pressure endurance value is large and generally keeps at 30kgf / cm<2> for long-term operation. The Al-Al composite inflation-typed pipeline plate has wide application and can be used in internal-heat type or external-heat type and is an extremely good exhaust-reducing and energy-saving product.

Owner:奚啸谷

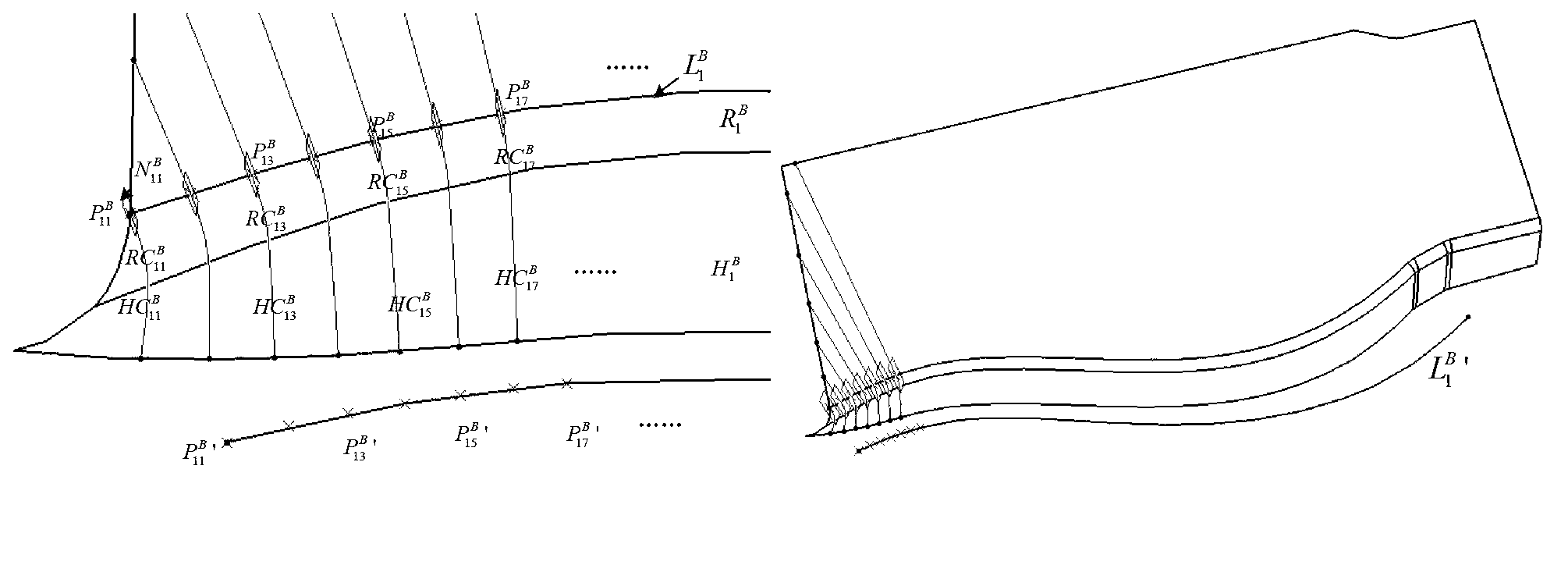

Unfolding method for complex flange of frame rib sheet metal part

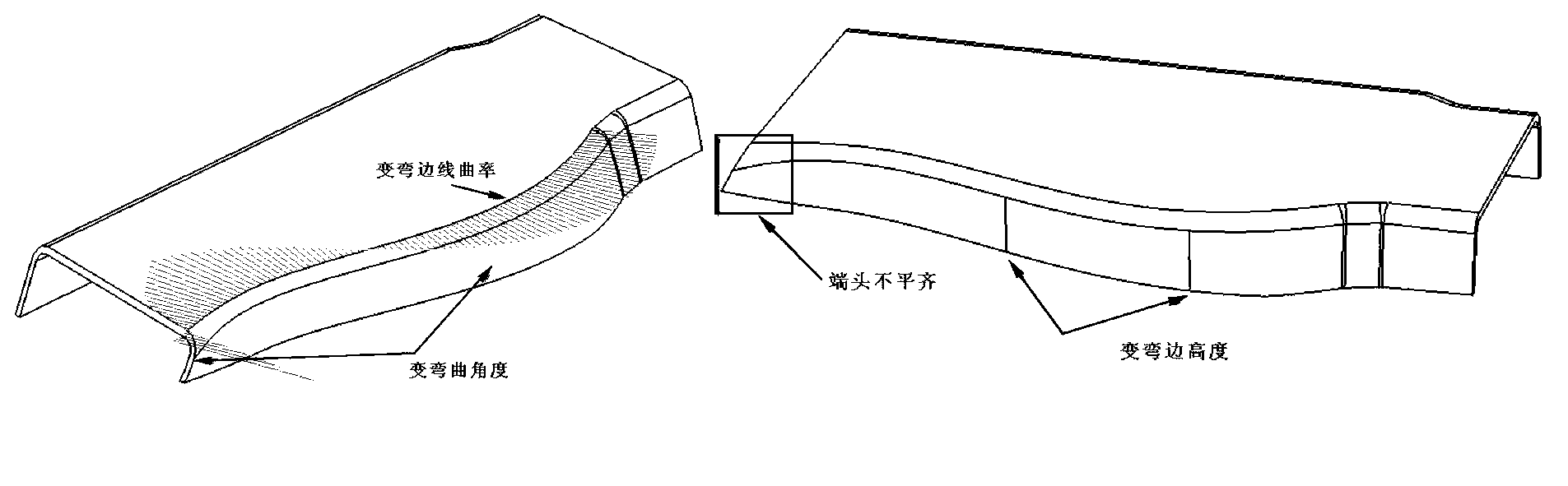

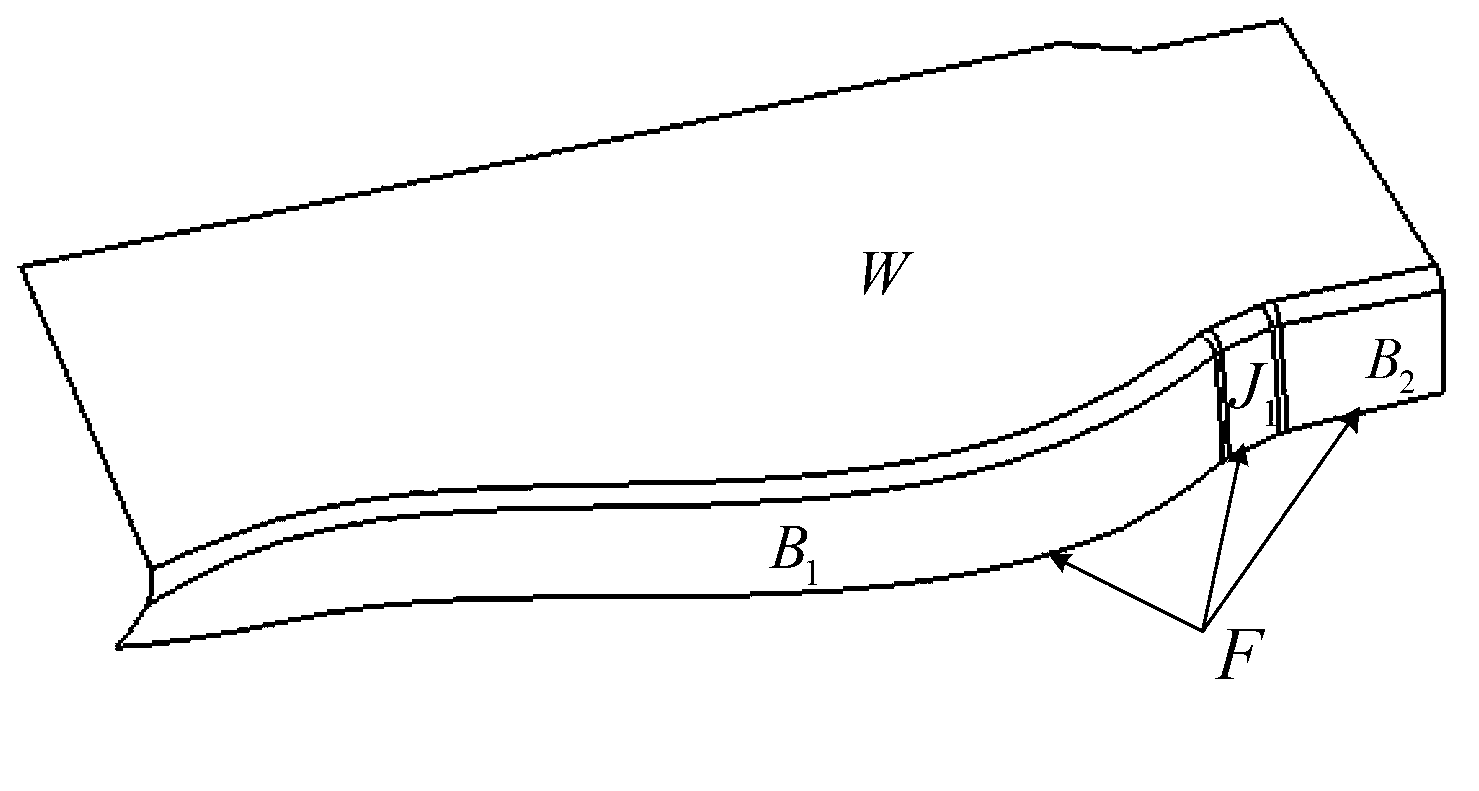

ActiveCN103008497ASolve unrolled puzzlesAircraft componentsStructural engineeringDigital manufacturing

The invention relates to an unfolding method for a complex flange of a frame rib sheet metal part and belongs to the technical field of aircraft manufacturing. A digital manufacturing technology is adopted for dividing the flange of the frame rib sheet metal part into a bent area and a sunken area, respectively unfolding and then jointing and shearing, so that an unfolded outline of the flange is obtained. The unfolding problem of the frame rib sheet metal part with the complex flange is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

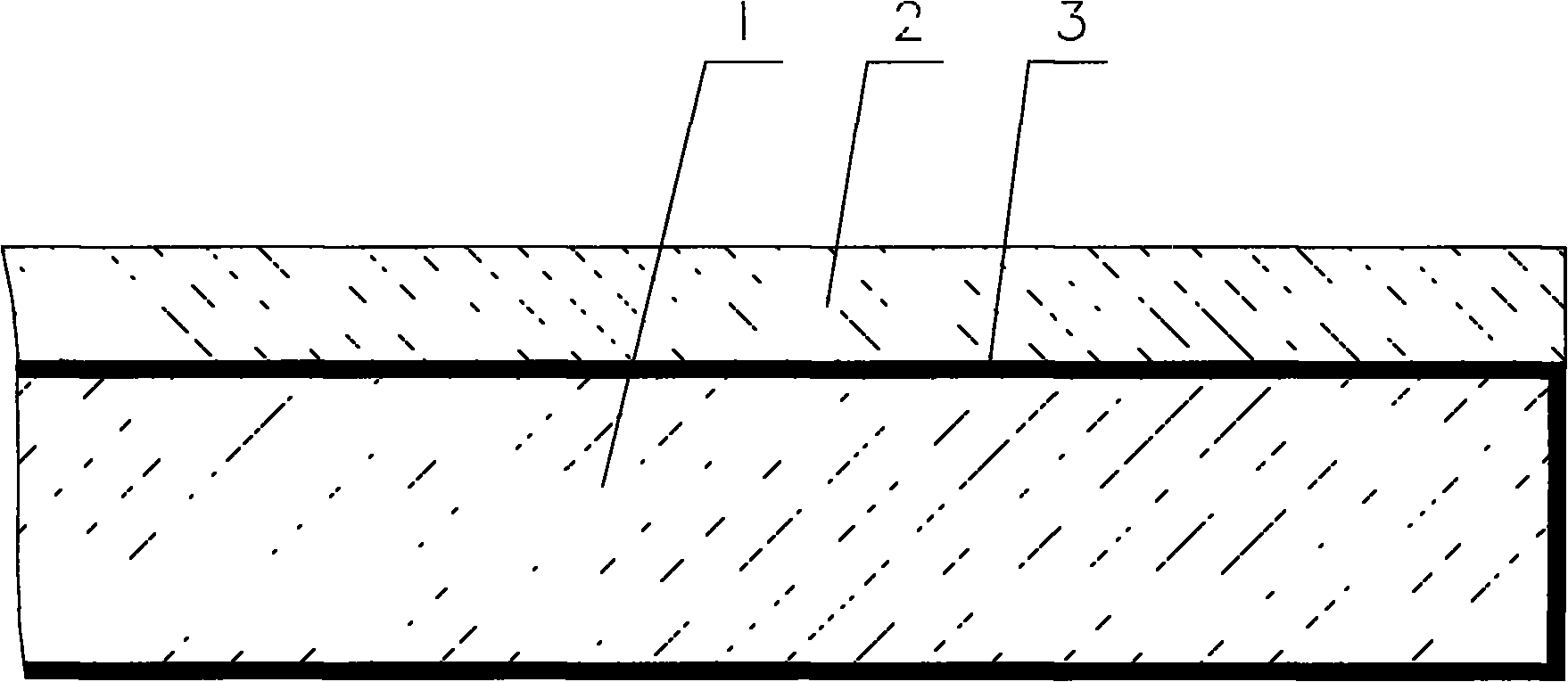

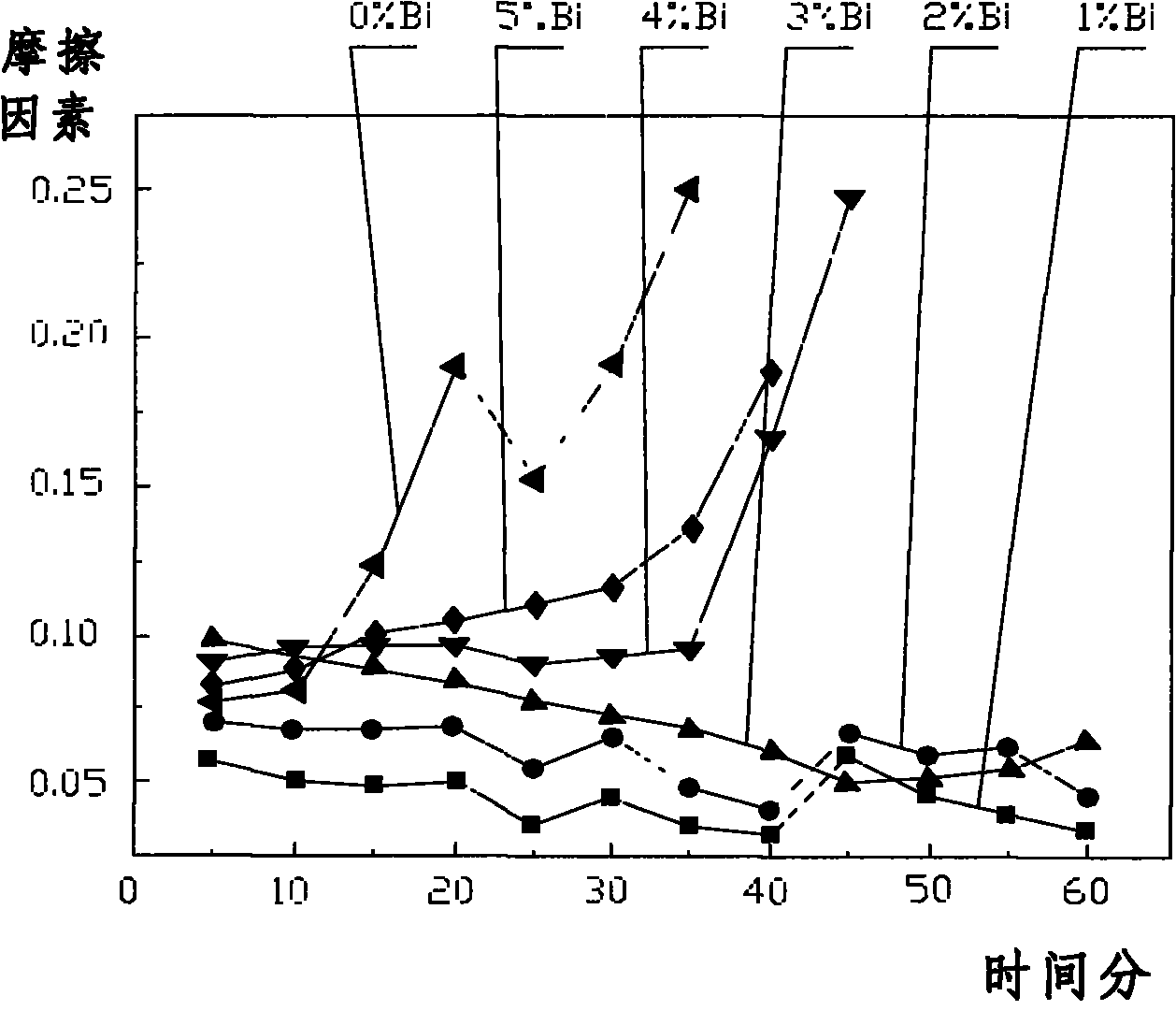

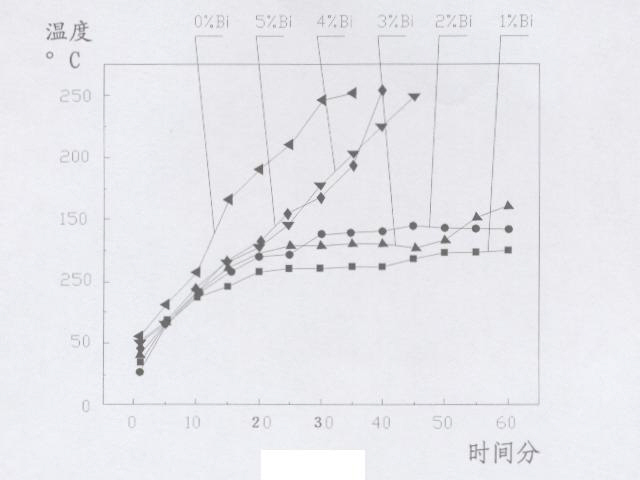

High-performance environmentally-friendly copper-bismuth dual-metal bearing material and manufacturing method thereof

The invention discloses a high-performance environmentally-friendly copper-bismuth dual-metal bearing material and a manufacturing method thereof and aims to provide a high-performance environmentally-friendly copper-bismuth dual-metal bearing material without containing lead which is harmful to a human body and a manufacturing method thereof. The high-performance environmentally-friendly copper-bismuth dual-metal bearing material is prepared by sintering a steel plate and a copper-based alloy wear-resisting layer and is characterized in that the copper-based alloy wear-resisting layer comprises the following components in percentage by weight: 1%-3% of bismuth, 5%-11% of tin and the balance of copper. The manufacturing method comprises the steps of: shearing and blanking of the steel plate, inspecting, powder spreading, primary sintering, rolling, secondary sintering, rerolling, and finally obtaining the finished plate product of the high-performance environmentally-friendly copper-bismuth dual-metal bearing material. As the bismuth is used for replacing lead in the copper-based alloy, the high-performance environmentally-friendly copper-bismuth dual-metal bearing material does not contain lead, is non-hazardous to the human body, does not pollute the environment and is an environmentally-friendly copper-based-steel dual-metal bearing material. Simultaneously, when the content of bismuth is 1.0-3.0wt%, the best frictional wear resistance of the high-performance environmentally-friendly copper-based-steel dual-metal bearing material is achieved; in addition, as the density of bismuth is less than that of lead, the manufactured bearing material is lighter than that containing lead.

Owner:HEFEI UNIV OF TECH +1

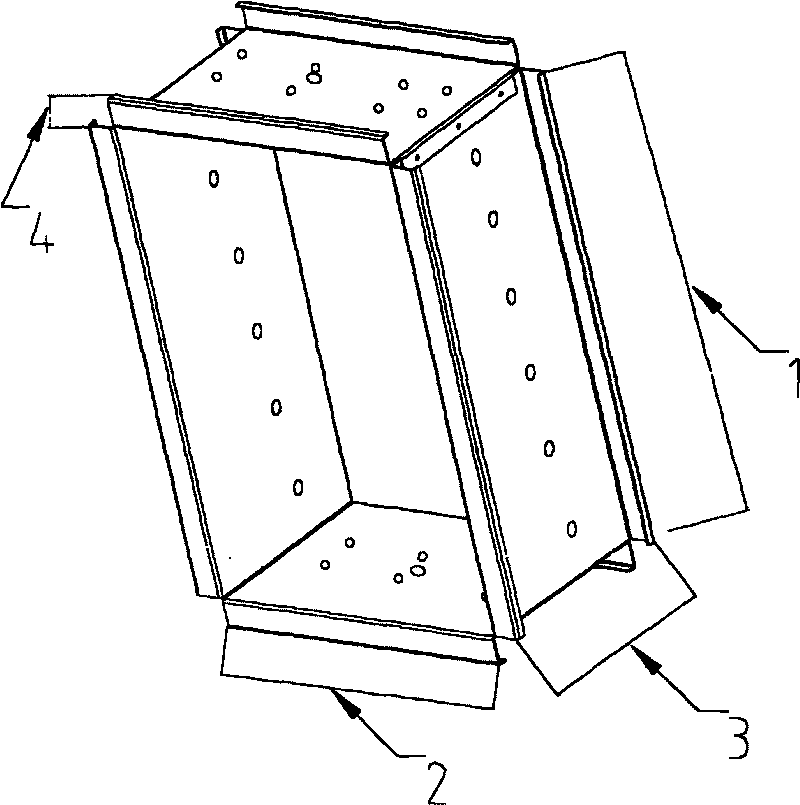

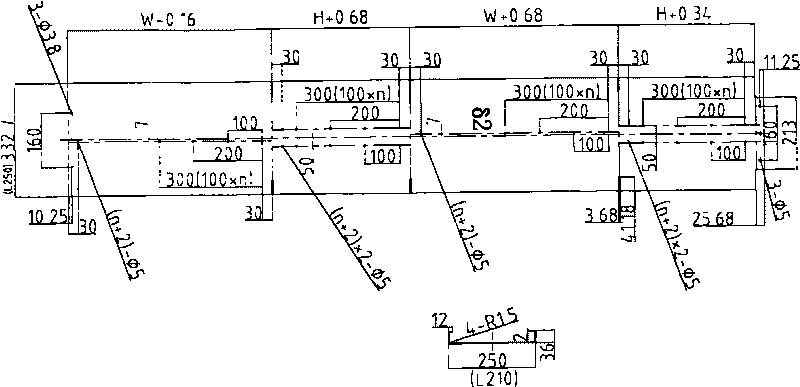

Manufacturing method of integrated square fire-resisting damper valve buckle body molding and rolling forming device thereof

The invention provides a manufacturing method of integrated square fire-resisting damper valve buckle body molding, comprising the following process steps: carrying out blanking on a complete board with a plate shearing machine according to the ordered size of the valve body and cutting into a rectangular panel veneer; carrying out working procedure processing like corner cutting, notching, punching and the like on the panel veneer with a press tool; performing bending operation of the flange edge at the two sides of the panel veneer with a bending machine; carrying out molding operation on the square frame body with a valve body molding device; and finally adopting welding or riveting operation at the seam position to finish the processing of the valve body frame body in the end. The invention has the following advantages: the method only needs shearing the board once, and the manufacturing can be completed through press working; compared with the current board-shearing and tailor welding four times, the method in the invention leaves out a plurality of working hours and reduces the disadvantages of size deformation; the total processing time of the frame body can be saved by 59.5%, thus the cost of the valve body is substantially lowered; the integrated board is under press working with almost no deformation; and welding is only carried out on the joint at one side, and the generated air leakage rate of the weld porosity is reduced to 25% of the original air leakage rate.

Owner:大荣空调设备(南京)有限公司

Manufacturing method of aluminum foil used for 1060 alloy cable

ActiveCN102899594AMeet the parameter requirementsSimple preparation processMetal/alloy conductorsCable/conductor manufactureAlloyAluminum foil

The invention relates to a manufacturing method of aluminum foil used for a 1060 alloy cable. The manufacturing method sequentially comprises the following steps: a. smelting; b. roll casting, controlling the thickness to be 6.8-7.0mm; c. cold rolling and cogging, rolling the thickness to be 3.0-4.0mm; d. intermediate annealing at 500-550 DEG C, and lasting for 20-24h; e. roughing, roughing the thickness to be 0.5mm for longitudinal edge shearing; f. finish rolling, after 2-3 passes, rolling to obtain a finished product with the thickness of 0.18-0.2mm; and g. finished product annealing, adopting a gradient differential temperature annealing method for a low-temperature purging period at 200-220 DEG C with the heat preservation time of 2-4h, an intermediate-temperature oil removal period at 240-260 DEG C with the heat preservation time of 8-10h, and a high-temperature yellow spot removal and mechanical property stabilizing period at 380-400 DEG C with the heat preservation time of 8-10h. The manufacturing method is simple in manufacturing process and low in cost, and can enable the elongation to be greater than or equal to 23% simultaneously when obtaining low tensile strength and completely meet the parameter requirements for the aluminum foil used for high-quality cables.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Method for manufacturing titanium and titanium alloy bars by means of hot continuous rolling

ActiveCN104148382AMeet the small batchMeet the characteristicsMetal rolling arrangementsStructure propertyTitanium

The invention relates to a method for manufacturing titanium and titanium alloy bars by means of hot continuous rolling, and belongs to the technical field of plastic machining for metal. The method is applicable to manufacturing the titanium and titanium alloy bars on the traditional hot continuous rolling unit for steel. The method for manufacturing the titanium and titanium alloy bars by means of hot continuous rolling includes controlling heating cycles, blooming temperatures, rolling speeds and hole patterns; performing shearing, cooling and bundling processes; primarily heating and discharging titanium and titanium alloy square billets out of furnaces; then rolling the titanium and titanium alloy square billets to obtain the bars with the sizes ranging from phi16mm to phi100mm. The method for manufacturing the titanium and titanium alloy bars by means of hot continuous rolling has the advantage that titanium and titanium alloy bar products which are good in surface quality and roundness and uniform in structure property can be quickly and efficiently manufactured on the traditional hot continuous rolling unit for the steel by the aid of the method.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cu-P based amorphous brazing filler metal and method for manufacturing the same

InactiveCN101367159AFlat surfaceImprove toughnessWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention relates to the technical field of the brazing of amorphous filler metal, copper and copper alloy, and relates to Cu-P based amorphous filler metal and a preparation method thereof. The Cu-P based amorphous filler metal comprises the following compositions with the content in percentage by mass: 7.0 to 8.0 percent of P, 14.0 percent of Ni, 5.0 percent of Sn, 0.02 to 0.06 percent of Zr, 0.2 percent of Si, and the balance being Cu. The preparation of the Cu-P based amorphous filler metal adopts a fast solidification technology, and the prepared filler metal has bright and clean surface, smooth two sides, and good toughness. The melting temperature range of the filler metal is between 590 and 635 DEG C, and the temperature of the brazing is between 650 and 685 DEG C. The filler metal is applicable to the brazing of the copper and the copper alloy, and applicable brazing techniques comprise flame brazing, furnace brazing, gas-shielded brazing, salt bath brazing and the like. When the filler metal is adopted to perform the flame brazing to red copper, the wettability of the filler metal is apparently better than that of filler metals which has the same compositions and are prepared by the prior melting technology, and the shearing strength of a brazed joint is larger than 92MPa, so the filler metal has good application prospect.

Owner:JIANGSU UNIV OF SCI & TECH

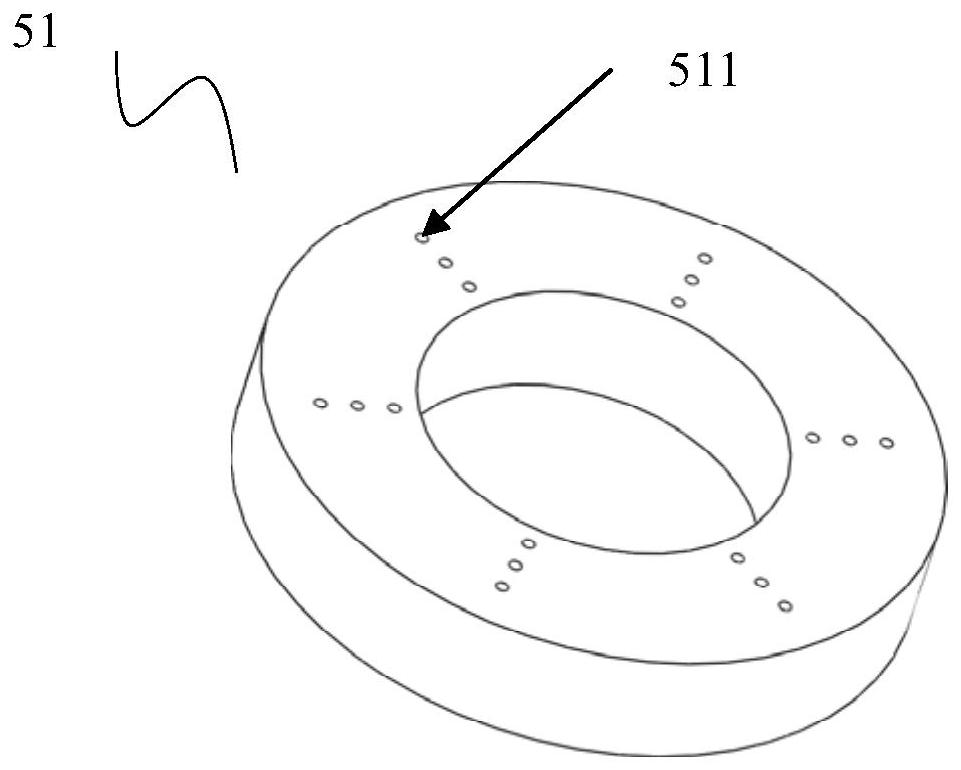

Method for manufacturing high-precision longitudinal shearing strip splitting tool blade

ActiveCN103707024AUniform hardnessHardness uniformity is smallFurnace typesHeat treatment furnacesAviationHardness

The invention discloses a method for manufacturing a high-precision longitudinal shearing strip splitting tool blade, and belongs to the technical field of tool machining. The method for manufacturing the high-precision longitudinal shearing strip splitting tool blade comprises the steps of (1) preparation of raw materials of the longitudinal shearing strip splitting tool blade; (2) annealing treatment on a forged blank; (3) rough machining on the forged blank; (4) heat treatment on the longitudinal shearing strip splitting tool blade, wherein the heat treatment on the longitudinal shearing strip splitting tool blade comprises the steps of annealing, quenching in a nitrate furnace and tempering in the nitrate furnace; (5) finish machining on the longitudinal shearing strip splitting tool blade, wherein the finish machining on the longitudinal shearing strip splitting tool blade comprises the steps of first time accurate grinding, second time accurate grinding and third time accurate grinding on a grinding machine. The flatness of the longitudinal shearing strip splitting tool blade manufactured and obtained through the method can reach 0.001mm, the thickness tolerance can reach + / -0.001mm, the hardness evenness of the whole longitudinal shearing strip splitting tool blade is smaller than 1HRC, and meanwhile the longitudinal shearing strip splitting tool blade has excellent high-wearing features and strong shock resistance performance, and meets the demands for splitting and cutting high-precision space flight and aviation plates for airplanes and the like.

Owner:ANHUI RISHENG MACHINERY MFG

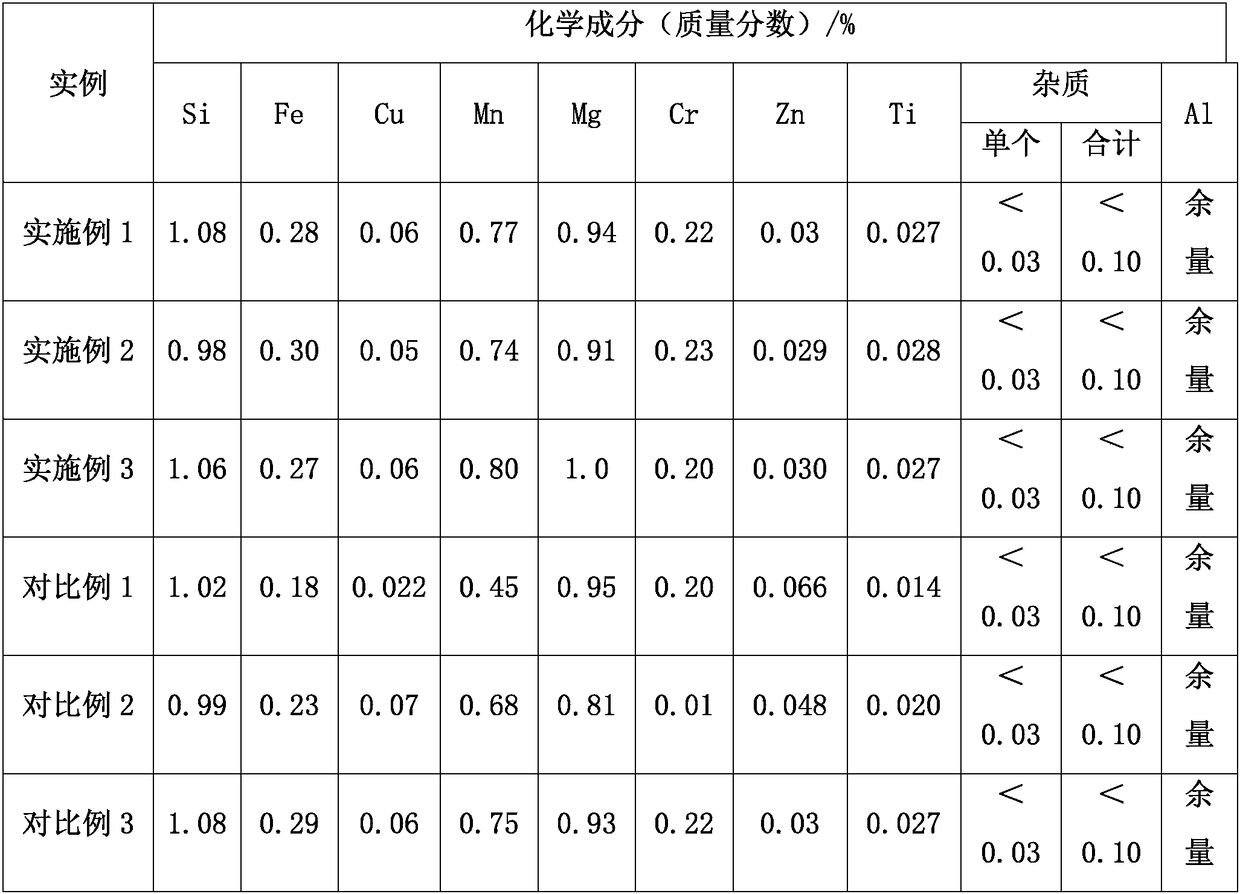

6082G aluminum alloy plate for rail transit and machining technology thereof

The invention belongs to the technical field of aluminum alloy machining and manufacturing, and relates to a 6082G aluminum alloy plate for rail transit and a machining technology thereof. The 6082G aluminum alloy plate is prepared from the following elemental components in percentage by weight: 0.9-1.2% of Si, 0.20-0.40% of Fe, less than or equal to 0.1% of Cu, 0.6-0.9% of Mn, 0.9-1.1% of Mg, 0.15-0.25% of Cr, less than or equal to 0.1% of Zn, 0.01-0.03% of Ti, less than or equal to 0.03% of single impurity, less than or equal to 0.10% of total impurity and the balance of Al. The machining technology includes the steps of batching, smelting casting, sawing and surface milling, homogenization heat treatment, hot rolling, shearing, solid solution treatment, stretching, aging, sawing and packaging. By strictly controlling the content of Fe, Mn, Cr in the machining process, the effect of inhibiting grain growth after welding is achieved through homogenization and solid solution treatment,a 6082G alloy with qualified cross-welding tensile properties for the rail transit is obtained, the mechanical properties of cross-welding tensioning of a vehicle body are improved, and the 6082G aluminum alloy plate can be widely applied to rail transit structural members.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

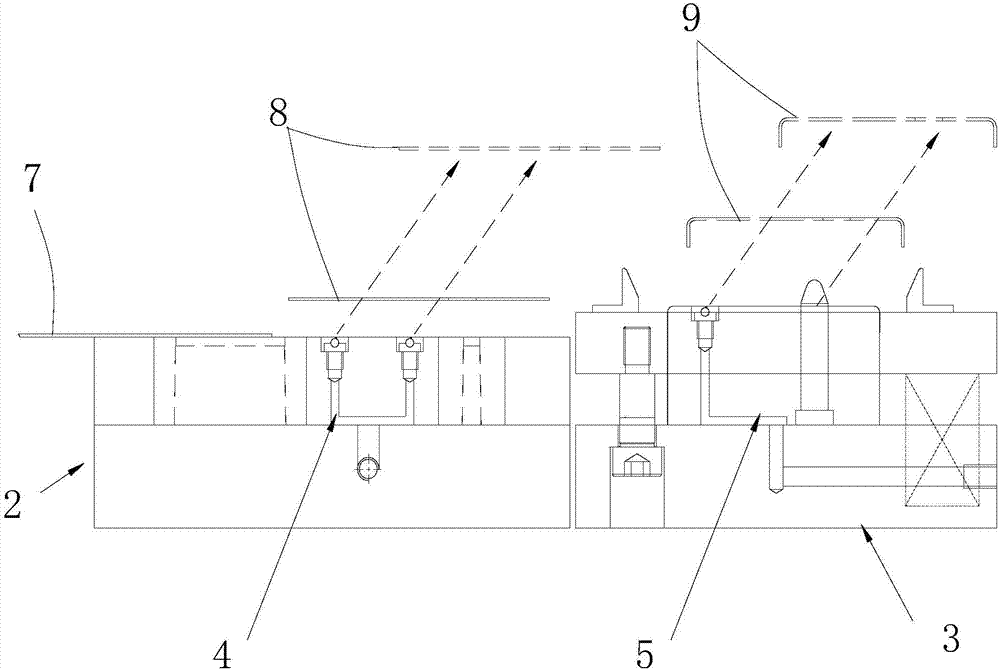

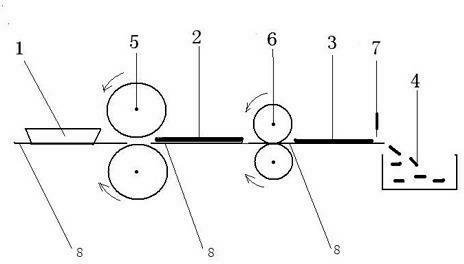

Method for continuously manufacturing stamping products and punch using same

ActiveCN104841760AGuaranteed work efficiencyReduce widthMetal-working feeding devicesStripping-off devicesPunch pressEngineering

The invention relates to the technical field of stamping dies, and discloses a method for continuously manufacturing stamping products and a punch using the same. The method for continuously manufacturing stamping products comprises steps of feeding belt material into a shearing apparatus through a feeding apparatus, punching the belt material through the shearing apparatus, blowing sheet material generated by the punching process into a shaping apparatus in an inclined way through a blowing device disposed in the shearing apparatus to stamp and shape. The punch comprises a stamping seat and a pedestal, the punch is provided with the shearing apparatus used for punching, a shaping apparatus used for stamping and an air source. The blowing device used for blowing sheet material punched by the shearing apparatus into a shaping apparatus is disposed in the shearing apparatus, the blowing device is connected with the air source, the air going direction of the blowing device is inclined to bottoms of sheet material. According to the method for continuously manufacturing stamping products and the punch using the same, the width of belt material can be reduced, material can be prevented from being waste, and the cost can be saved.

Owner:SHENZHEN JINZHOU PRECISION TECH

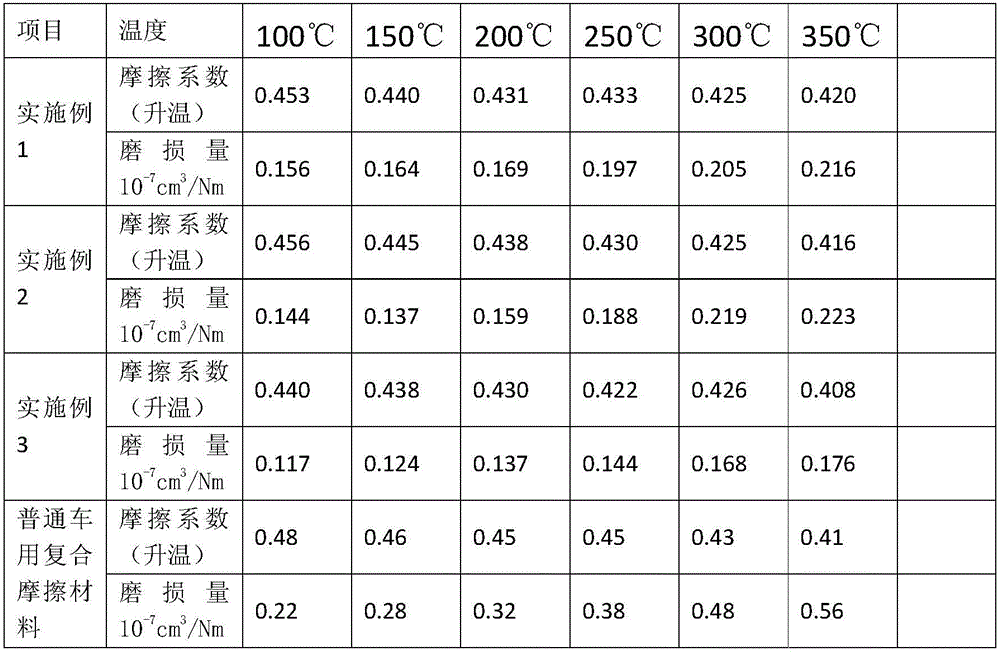

Automotive iron-based powder metallurgy composite frictional material and manufacturing method thereof

The invention discloses an automotive iron-based powder metallurgy composite frictional material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that an iron-based powder metallurgy friction material is obtained; secondly, the iron-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the iron-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is preserved at the temperature of 150-180 DEG C, cooled to the room temperature and then discharged from the furnace. The automotive iron-based powder metallurgy composite frictional material remains the stable friction coefficient and good abrasive resistance of the conventional powder metallurgy friction material, service life of the friction material is prolonged and its high-temperature stability is also improved.

Owner:SOUTH CHINA UNIV OF TECH

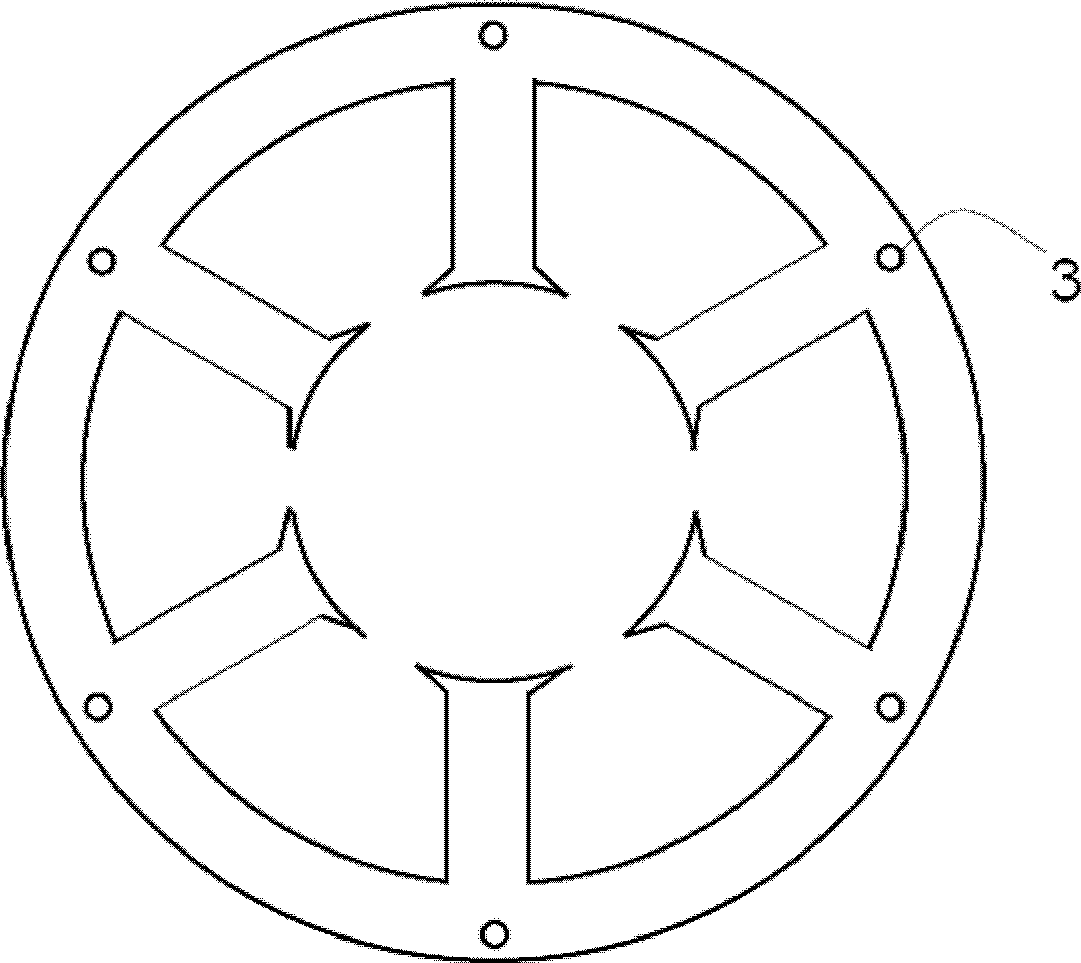

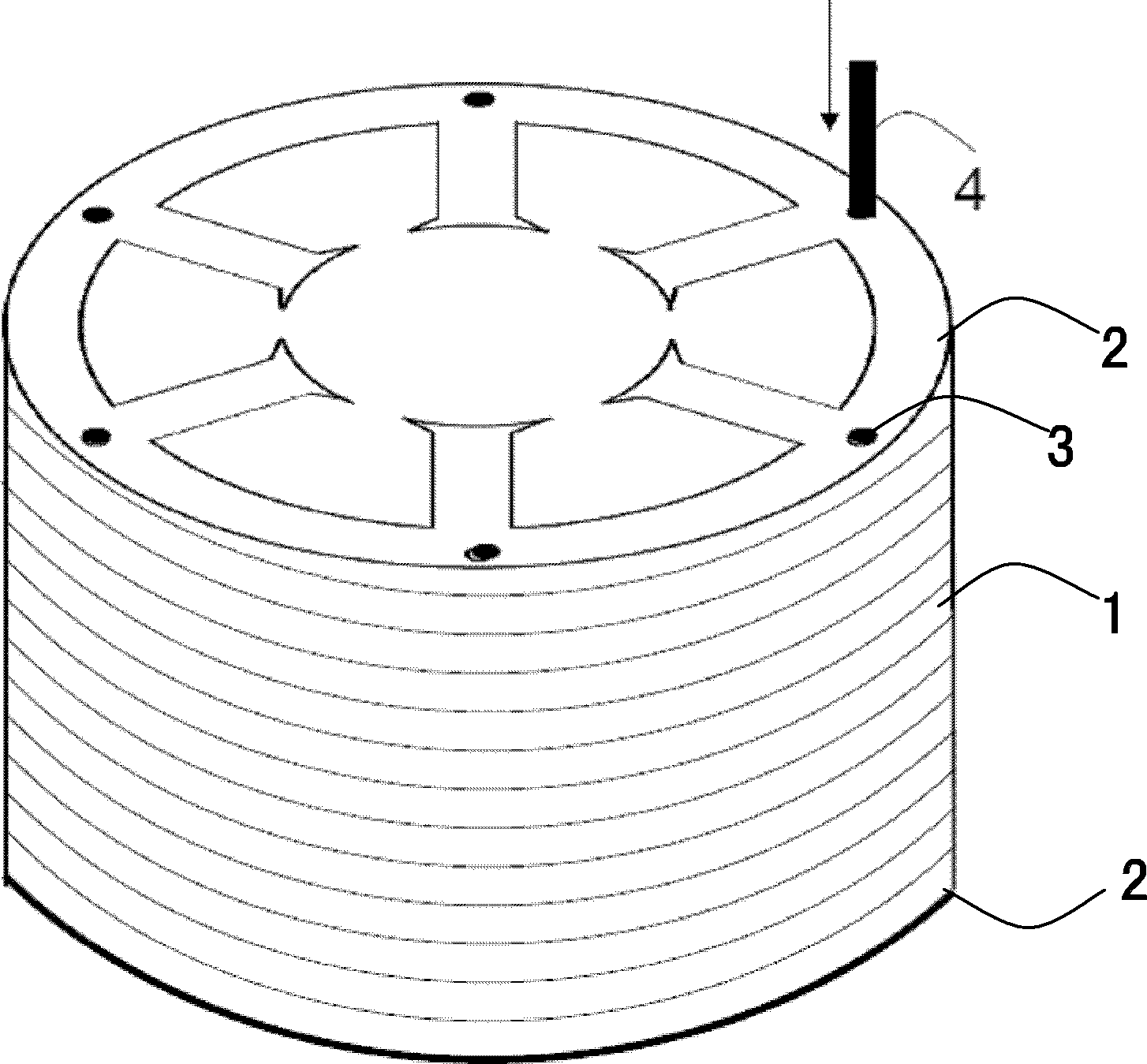

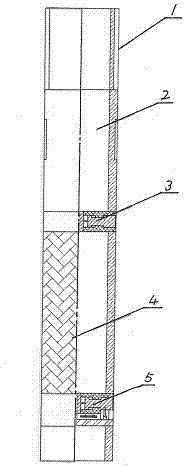

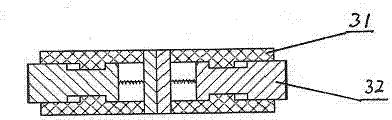

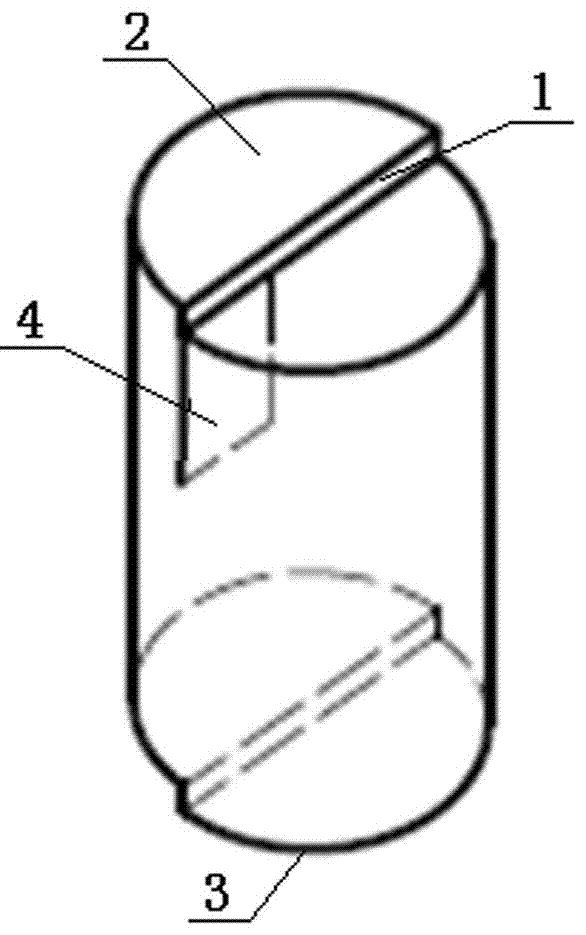

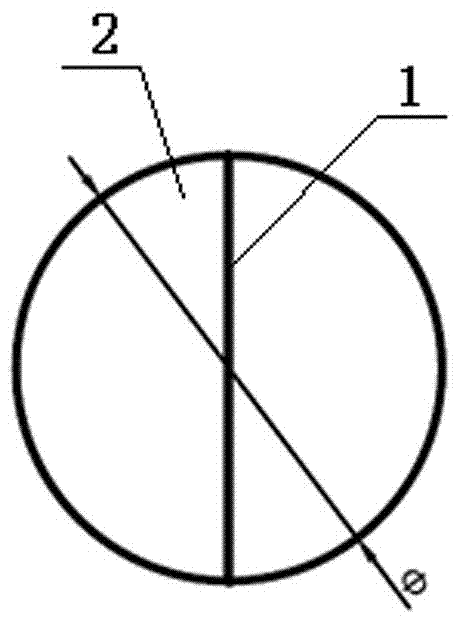

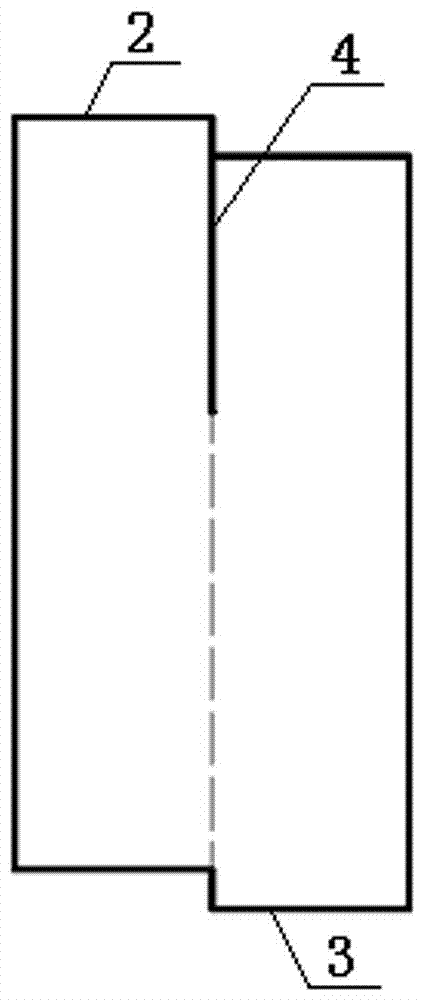

Rock mass drilling and shearing elastic modulus instrument

ActiveCN103115829ASave test costReliable reflectionMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesShear elastic modulusClassical mechanics

The invention relates to a rock mass drilling and shearing elastic modulus instrument which mainly comprises a stopper rod port (1), a sleeve rod (2), an upper disc knife (3), a rubber bag (4) and a lower disc knife (5); and the whole structure of the rock mass drilling and shearing elastic modulus instrument is shaped like a long cylinder body. A hole wall rock mass shear test is carried out on different drilling positions under different positive stresses, and a destructive curve can be drawn by a rock mass shear destruction test structure under the different positive stresses, so that rock mass shearing-resistant mild parameters can be confirmed. The rock mass drilling and shearing elastic modulus instrument is simple in structure, low in manufacturing cost, easy to use and simple and easy to maintain and repair.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

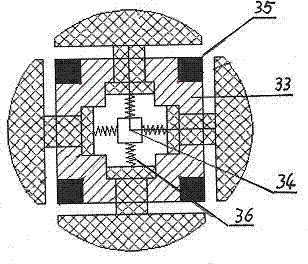

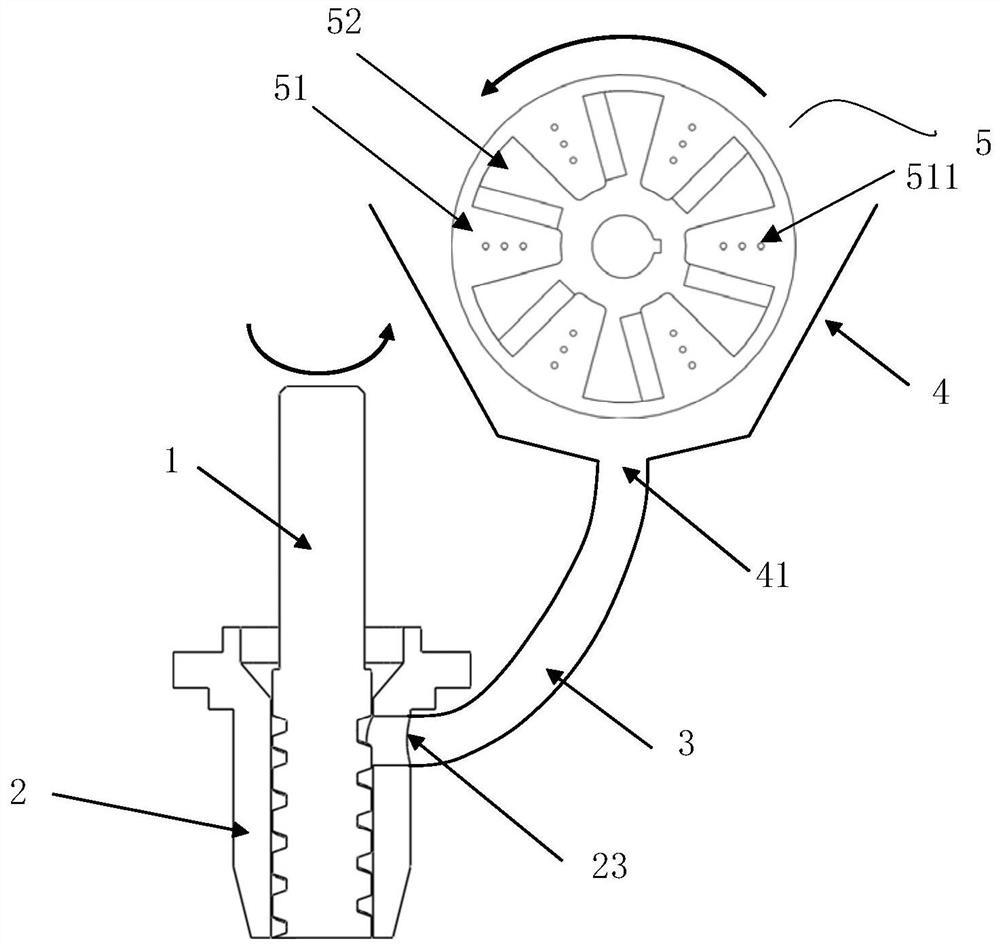

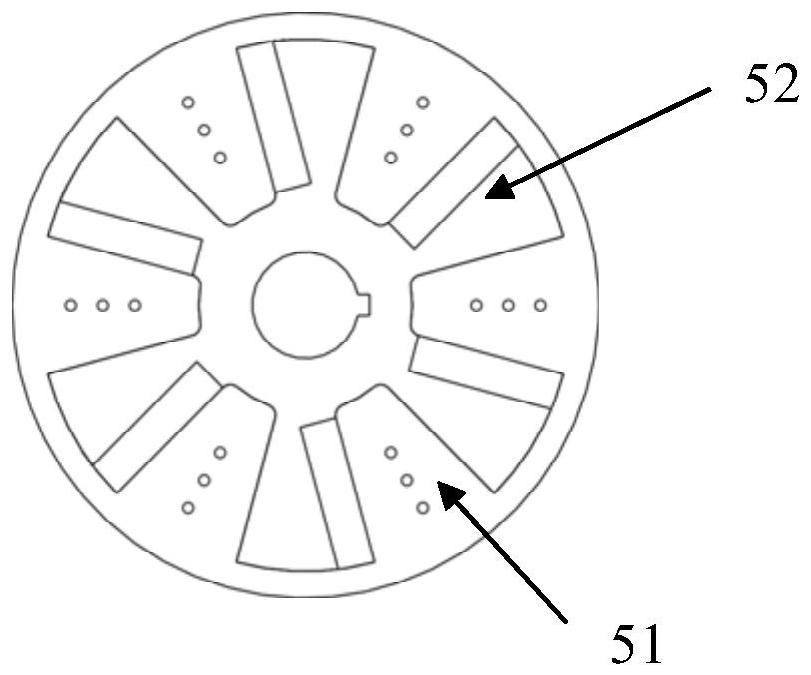

Particle type friction stir additive manufacturing device and method

ActiveCN113118612ANot easy to throw outLess impuritiesAdditive manufacturing apparatusIncreasing energy efficiencyMechanical engineeringAdditive layer manufacturing

The invention provides a particle type friction stir additive manufacturing device and method. The particle type friction stir additive manufacturing device comprises a wire shearing mechanism, the wire shearing mechanism comprises a base and a shearing part with a cutting edge, a wire guide hole is formed in the base, and a wire can pass through the wire guide hole. The particle type friction stir additive manufacturing device is characterized in that the shearing part is in close contact with the base, the shearing part rotates with the geometric center of the base as the axis, so that the cutting edge intermittently cuts the wire sent out from the wire guide hole. According to the particle type friction stir additive manufacturing device, additive particles of different diameters, different lengths and different materials can be obtained at the same time, friction stir additive manufacturing of gradient composite materials is achieved, and it can be guaranteed that the additive particles are continuously and stably provided; and meanwhile, operation is easy, and multi-layer additive manufacturing can be achieved under the condition that an additive device does not need to be adjusted.

Owner:安徽万宇机械设备科技有限公司

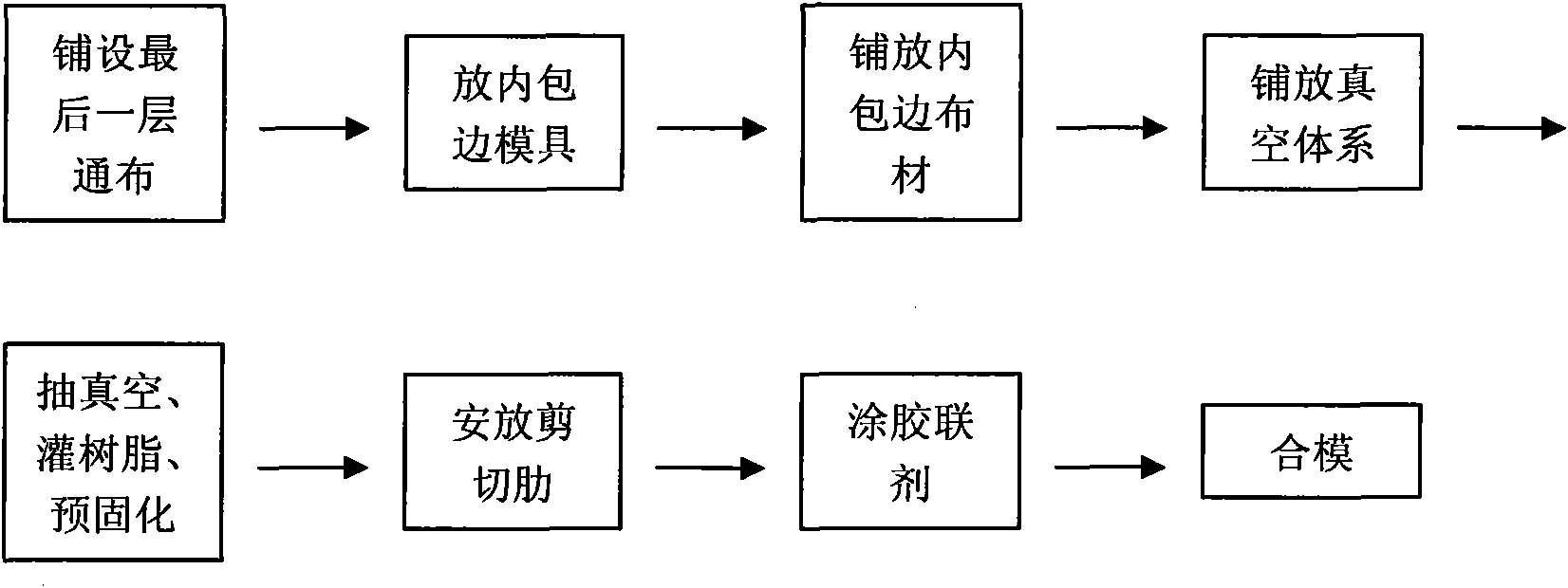

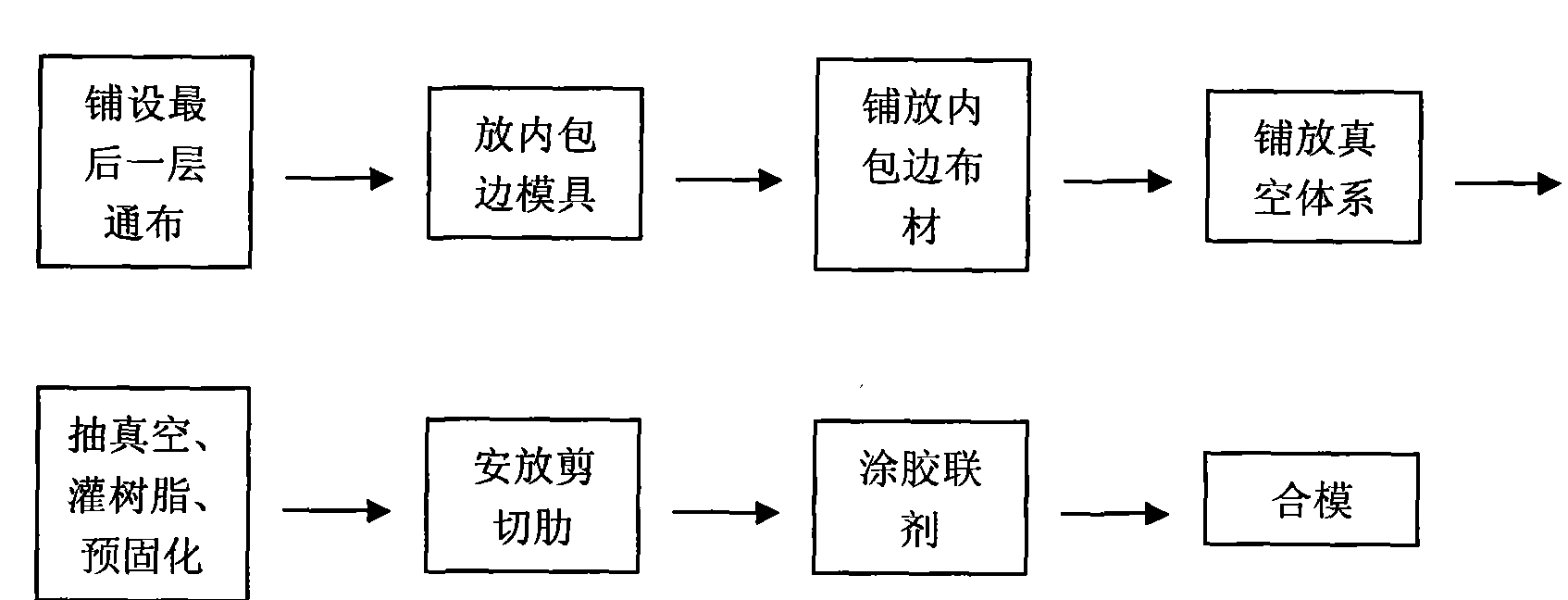

Glue shearing and mold clamping integrated forming process

InactiveCN102029721AImprove performance and stabilityImprove stabilityShearing (manufacturing)Materials science

The invention discloses a glue shearing and mold clamping integrated forming process, which comprises the following steps of (1) after a reinforcing material, a core material, a main beam cap and the like are completely paved, placing an inner wrapped edge mold on the rear part of the front edge of a lower mold; (2) paving an inner wrapped edge cloth material in the inner wrapped edge mold; (3) paving a vacuum system; (4) evacuating, pouring resin and pre-curing; (5) after curing is finished, placing a shearing rib in the lower mold; (6) coating a cross-linking agent on one exposed side of the shearing rib; and (7) clamping the mold, and pasting the rest inner wrapped edge close to the root part. The invention overcomes the defects of the manual inner wrapped edge pasting process and shearing rib positioning in the prior art, and provides the glue shearing and mold clamping integrated forming process for manufacturing the inner wrapped edge by adopting vacuum pouring and positioning the shearing rib.

Owner:KUNSHAN XINMENG ENERGY TECH CO LTD

Manufacturing and test method of rock compression shearing test specimen containing intermittent joints at high temperature

PendingCN107884288AVersatileCost-effectiveMaterial strength using steady shearing forcesComputed tomographyAcoustic emission

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Lead ingot pelletizing method and pelletizing assembly line thereof

The invention discloses a lead ingot pelletizing method and a pelletizing assembly line thereof. The pelletizing method comprises the following steps of: step 1, washing the surface of a pure lead ingot in advance, and carrying out wind-heat surface drying treatment after washing; step 2, manufacturing a lead board by using the cleaned and dried lead ingot through pressing and rolling equipment; step 3, cutting the lead board into a plurality of lead strips through roller shearing equipment; and step 4, cutting each lead strip into a plurality of lead grains through shearing equipment. According to the lead ingot pelletizing technique provided by the invention, a lead ingot melting process is eliminated, so that not only can the pollution of lead smoke to an environment be avoided, and the environment friendless is greatly improved, but also the effects on the aspects of energy conversation and emission reduction, consumption reduction and the like are very outstanding.

Owner:TIANNENG GRP JIANGSU TECH

Method and apparatus for lubricating grease continuous saponification

The invention discloses a method and a device for realizing continuous saponification of lubricating grease. The method comprises the following steps that: lubricating grease and a soap chemical raw material are added in a raw material blending tank with a stirrer; when the mixture is stirred evenly, the material flow inside the tank is pumped into a heat exchange bend pipe of a bent pipe-type heat exchange tank provided with high-temperature heat-conducting oil by a heating oil stove, so as to carry out heat exchange with the heat-conducting oil; then, lubricating grease undergoing heated saponification is pumped into a soap chill tank so as to carry out chilling, and is fed into a lubricating grease shearing tank with a stirrer after being sheared by a needle-type shear; after in-tank stirring, colloid milling and needle-type shear shearing, the lubricating grease is fed into a vacuum degassing device; and lubricating grease thin oil film is degassed under vacuum condition through a thin oil film generator of a degassing tank and then filling of product can be carried out. The method has easily controlled manufacturing temperature, evenly mixed raw materials, high utilization rate of raw materials and complete saponification; moreover, the method can realize continuous production and has high production safety, less energy consumption and high product quality.

Owner:XINJIANG FUKE OIL PROD CO LTD

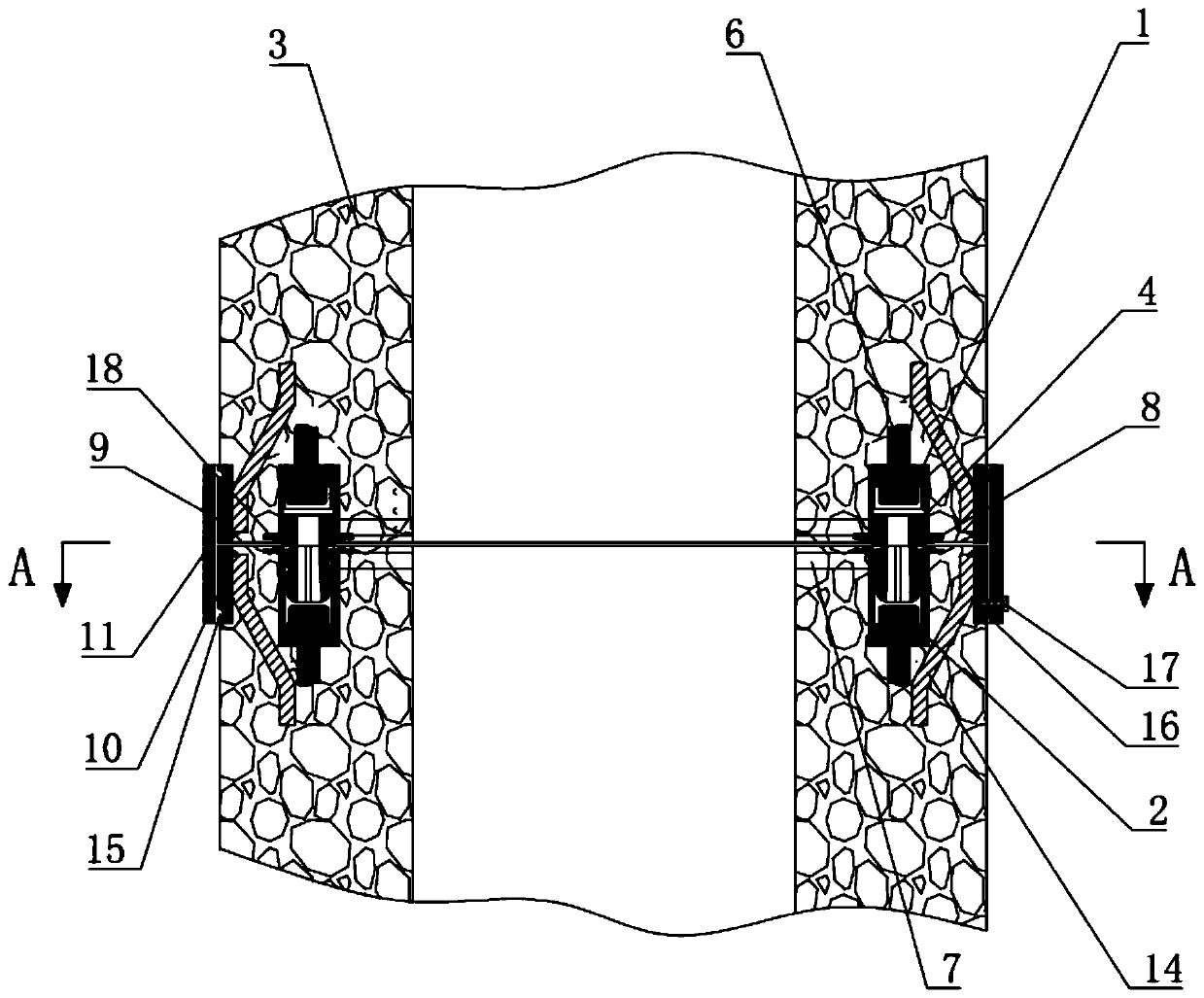

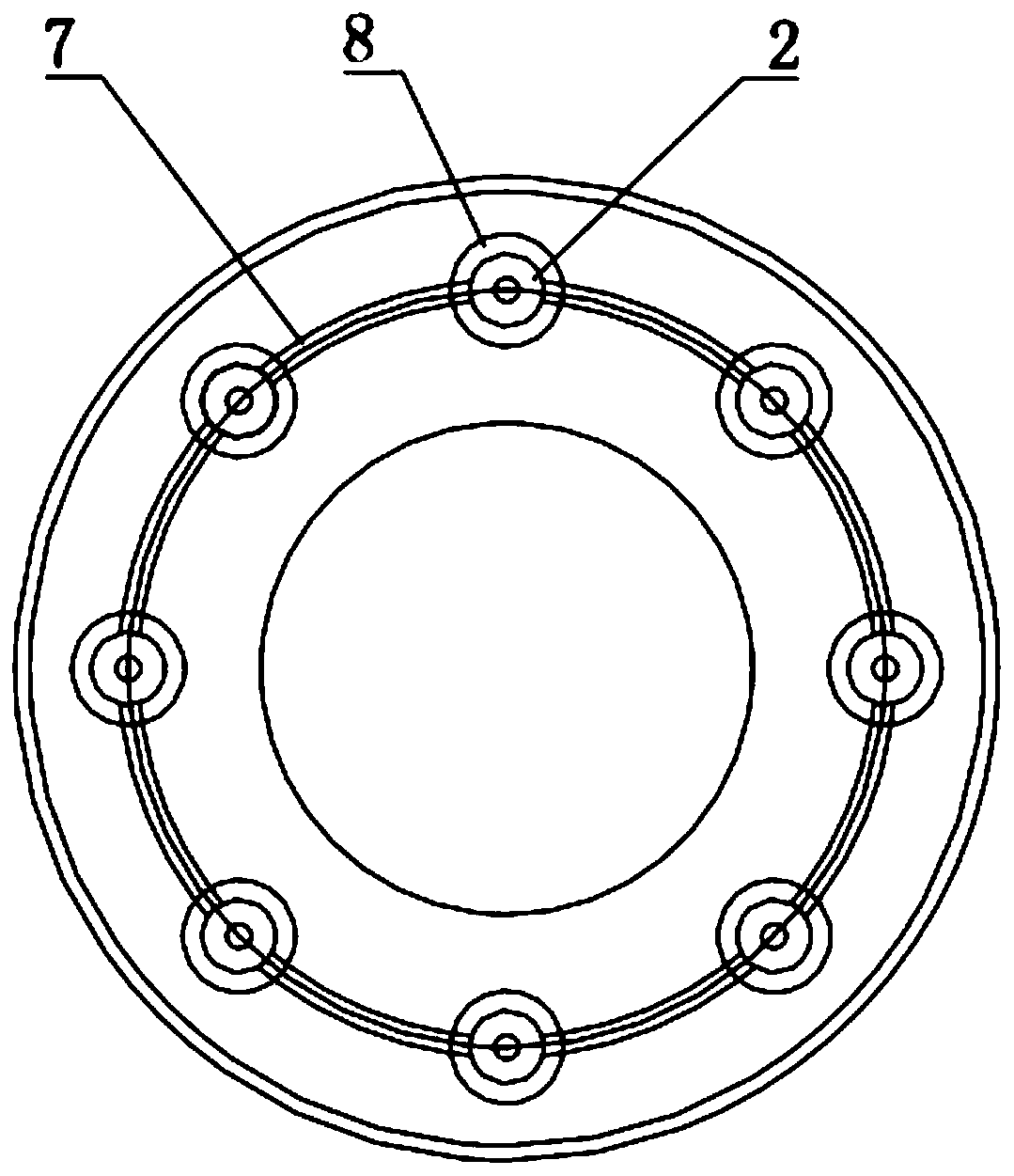

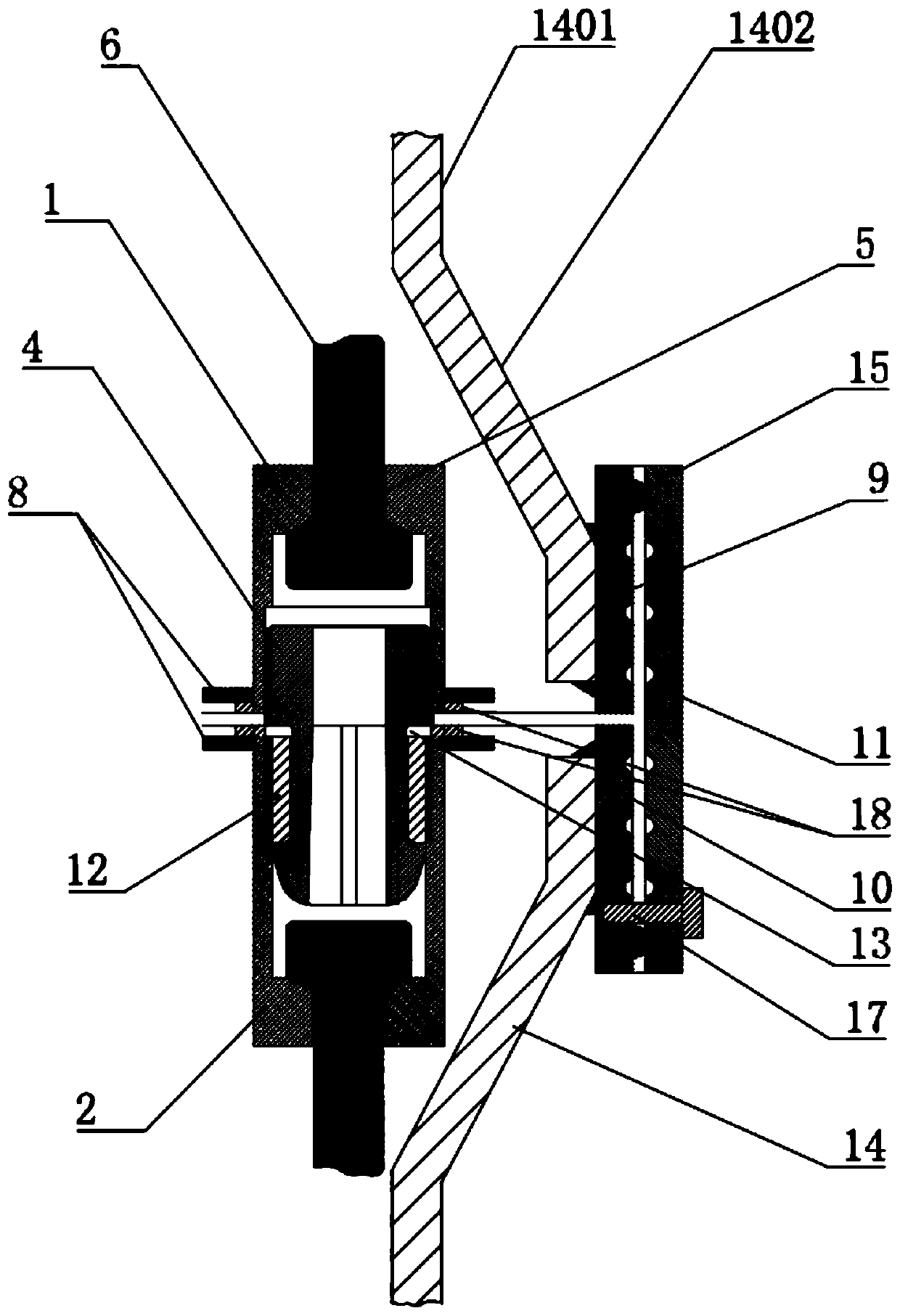

Mechanical connecting device of concrete precast pile and manufacturing method

PendingCN111058440AImprove connection qualityFirmly connectedBulkheads/pilesPre stressArchitectural engineering

The invention relates to a mechanical connecting device of a concrete precast pile and a manufacturing method. The mechanical connecting device comprises an axial pile body connecting unit, wherein the axial pile body connecting unit comprises a plurality of groups of first sleeve nuts and second sleeve nuts, and the first sleeve nuts and the second sleeve nuts are matched with each other; each group of first sleeve nuts and second sleeve nuts are correspondingly connected with the axial end surfaces of two pile bodies; the first sleeve nuts and the second sleeve nuts are connected with each other through connecting inserting rods; counter bores are correspondingly formed in one of the sides, which are inserted into the pile bodies, of the first sleeve nuts and the second sleeve nuts; andthe positions of the counter bores are matched with that of an upset head of prestressed steel bars. According to the mechanical connecting device, an auxiliary hoop grouting connecting mode is adopted, and bending-resistant, tensile and shearing-resistant stress loads at a pile end joint are uniformly distributed to a radial pile body connecting unit, so that the phenomenon that the pile joint cracks due to insufficient shearing-resistant, bending-resistant and shearing-resistant load capacity of the pile head mechanical connecting device is avoided, and the connecting quality and effect at the joint of the concrete precast pile are greatly improved.

Owner:NANJING JULI INTELLIGENT MFG TECH INST CO LTD +1

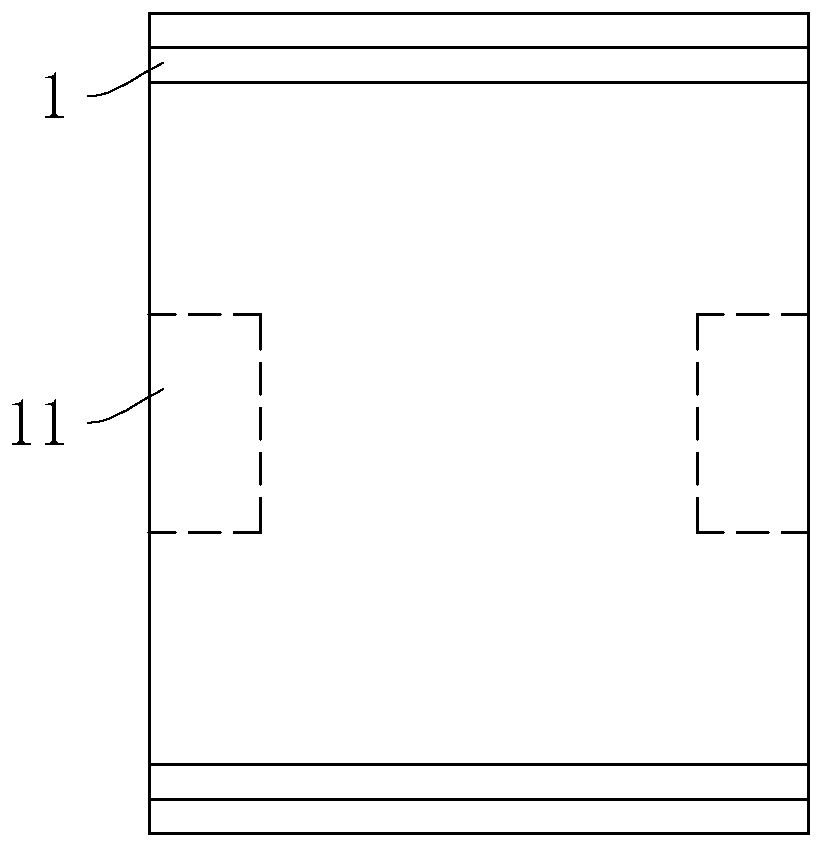

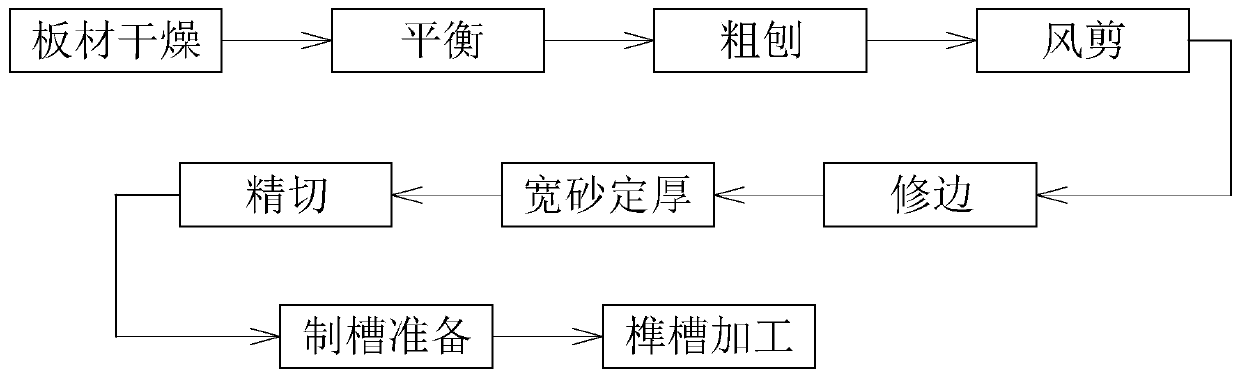

Processing technology of boards for solid wood furniture

ActiveCN111070364ARealize environmentally friendly preparationKeep the environment hygienicWood working apparatusSolid woodPolishing

The invention relates to a processing technology of boards for solid wood furniture. The technology comprises the following steps of first, board drying, wherein drying treatment is carried out on theboards while the moisture content of the boards is controlled to range from 12.5% to 15.5%; second, balancing, wherein the dried boards stand for 3 days to 7 days; third, rough planing, wherein thickness unification is carried out on the boards obtained in the second step to form raw log boards; fourth, wind shearing, wherein each raw log board is adjusted to be 10 millimeters to 20 millimeters longer than the actually needed length; fifth, trimming, wherein raw edges and burrs on the surfaces of the raw log boards are removed; sixth, wide sanding and thickness unification, wherein rough sanding and polishing sanding are carried out on the raw log boards as required to form flat boards; seventh, accurate cutting, wherein width determination and width determination are carried out on the flat boards; eighth, groove making preparation, wherein a preset mortise processing equipment is started up; and ninth, mortise processing, wherein the mortise processing equipment is used to process the flat boards obtained in the seventh step to form mortises, and generated saw dust are collected. The processing technology of the boards for solid wood furniture has the advantages that the environment health can be guaranteed, and environment-friendly manufacturing is benefited.

Owner:苏州鼎和家具有限公司

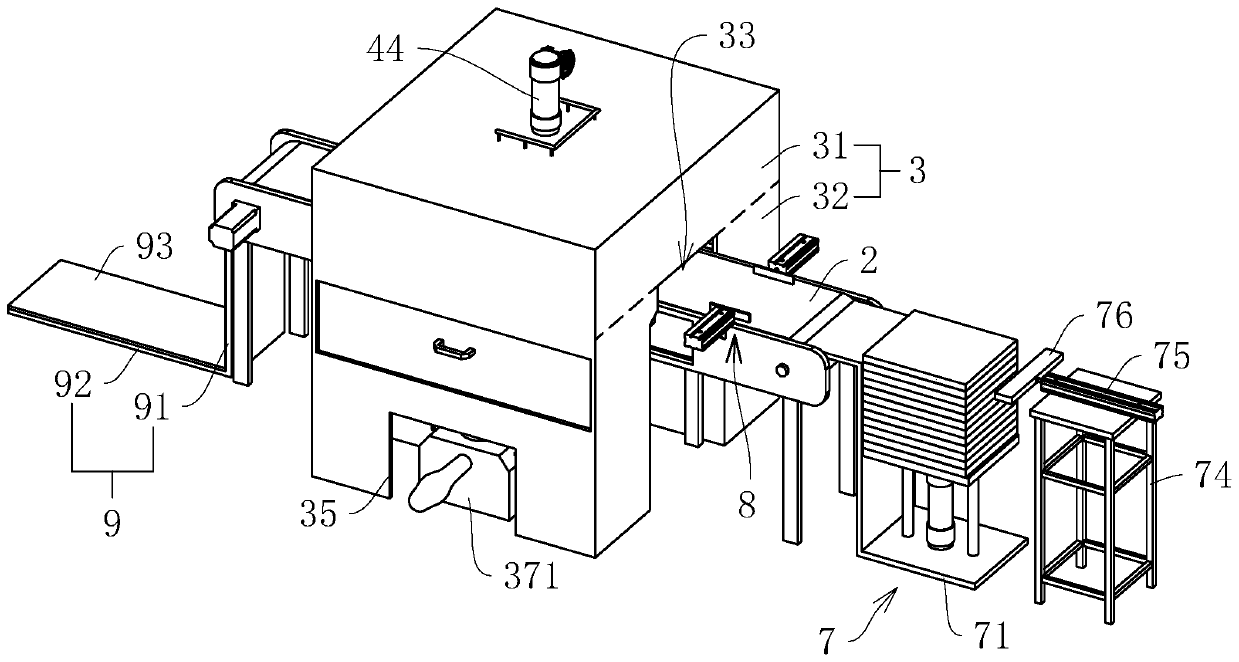

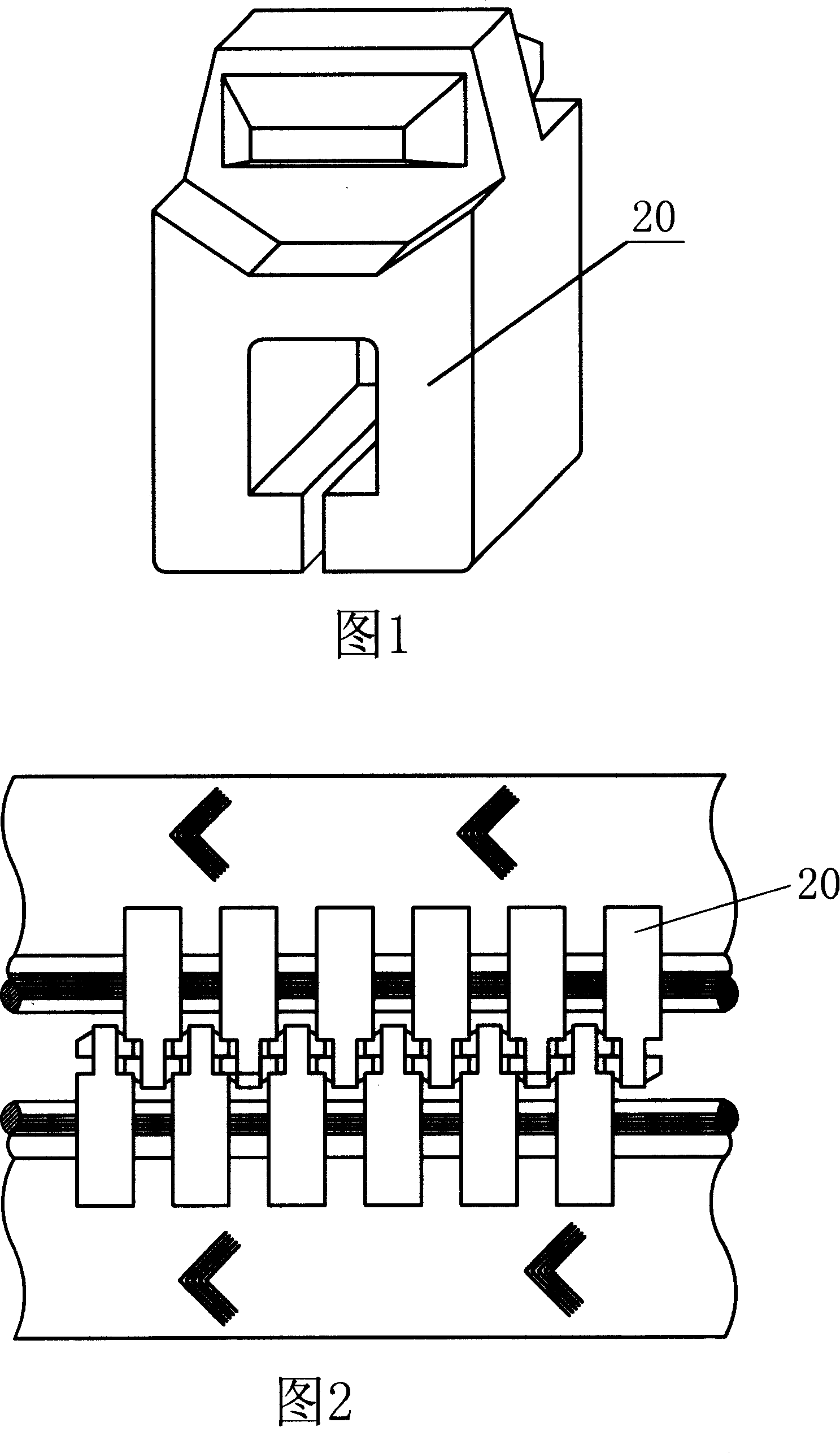

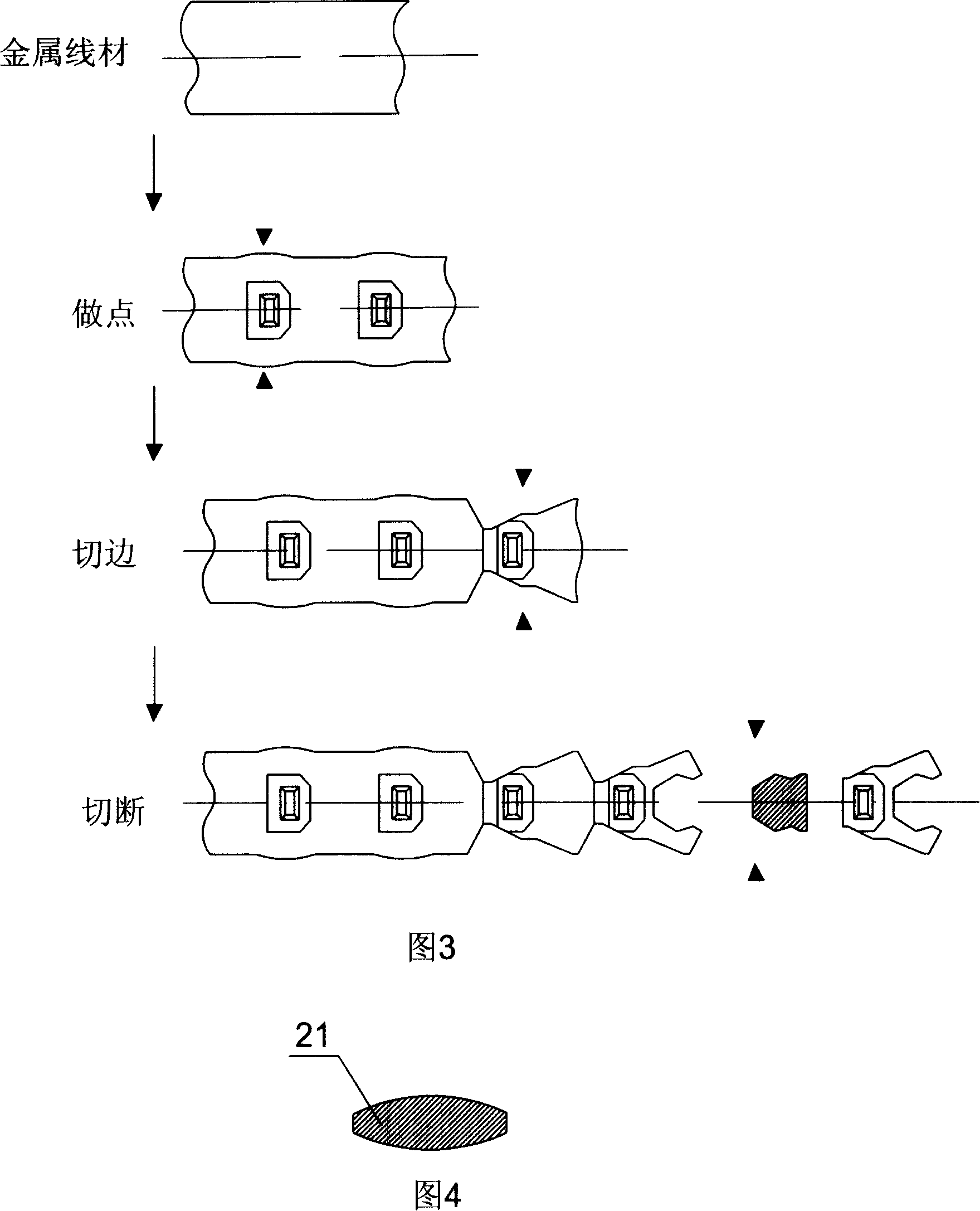

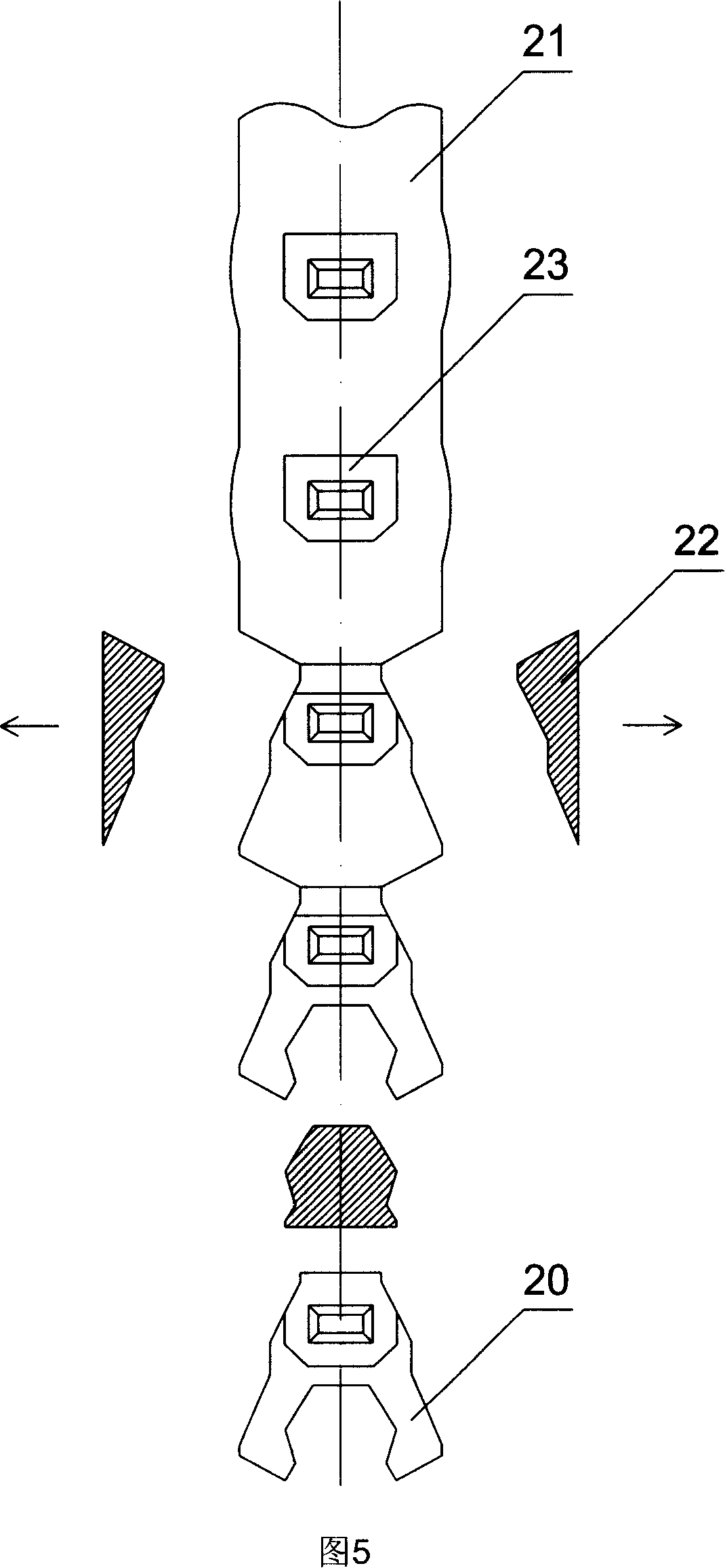

Technology for manufacturing bidirectional metal zip fastener

InactiveCN101147947ATo satisfy the market's needsHigh strengthShaping toolsSlide fastenersWire rodPunching

The present invention relates to the field of zipper technology, in the concrete, it relates to a manufacture process of bidirectional metal zipper. Said manufacture process is implemented by utilizing a set of precisely-combined metal shearing and cold-punching die equipment on one machine. On said die equipment a point-making took, an edge-cutting tool and a cutting-off tool are mounted. Said invention utilizes said die equipment to make the metal elliptical wire material with specific specification undergo the processes of cold-punching extruding, normal-temperature forming in the model, positioning directional blanking and stepped processing treatment to obtain specific form. The adoption of said technological process only can use one machine to implement procedures for manufacturing single zipper and obtain zipper blank, then the cloth strip with zipper teeth can be fed into a traditional polishing machine to make high-speed polishing treatment, finally the cloth strip with zipper teeth is undergone the process of electroplating treatment, so that the zipper finished product can be obtained.

Owner:东莞大兴拉链厂有限公司

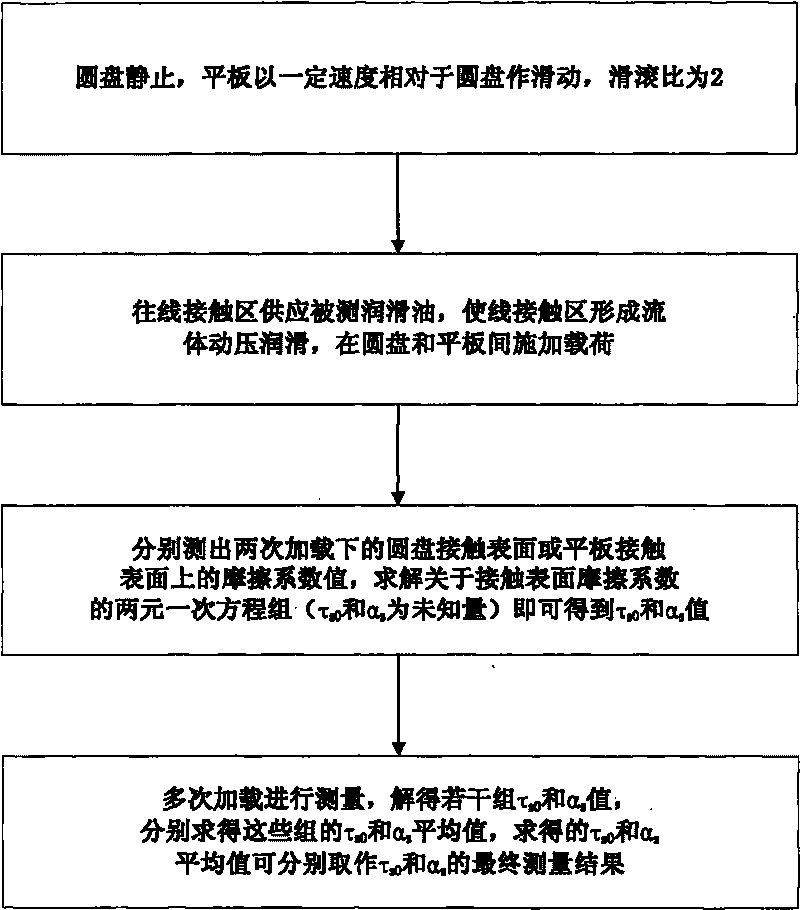

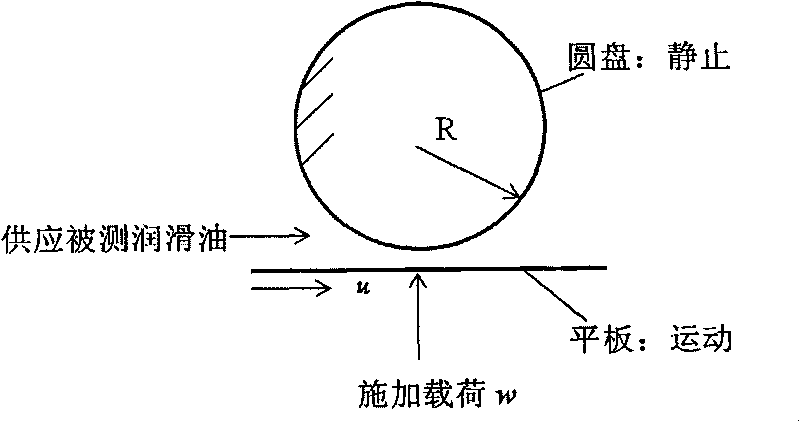

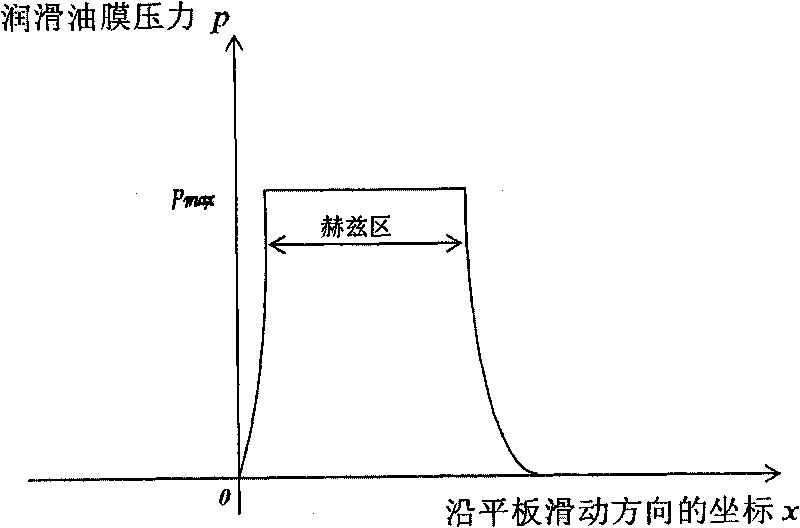

Method and device for measuring interfacial shearing strength under the connection of disc and flat plate

ActiveCN101701901ASimple structureEasy to manufactureUsing mechanical meansMaterial analysisStrength parameterMeasurement device

The invention relates to a method and a device for measuring interfacial shearing strength under the connection of a disc and a flat plate. The method comprises the following steps: A, the flat plate slides relative to the static disc at a speed u, with the slide-roll ratio being 2; B, the measured lubricating oil is fed to a line contact area, so as to form the hydrodynamic lubrication in the line contact area, and load is applied between the disc and the flat plate to ensure that the maximum Hertzian contact pressure of the line contact is larger than 0.4GPa; and C, the friction coefficients of the contact surface of the disc or the flat plate under the load are measured twice, and the binary linear equations for the friction coefficients of the contact surface are solved. By using the method and the device, the invention has significant technical effect and has the advantages of larger pressure measurement range of lubricating oil, simple and compact structure, easy implementation, lower manufacturing and servicing cost, easy measurement and higher measurement accuracy; moreover, the device of the invention is capable of measuring the shearing strength parameters of two interfaces at the same time, therefore, the invention is of significant practical value. The device of the invention can substitute for the high-pressure chamber measurement device and other measurement devices.

Owner:JIANGSU FEIER ELECTRICAL TECH

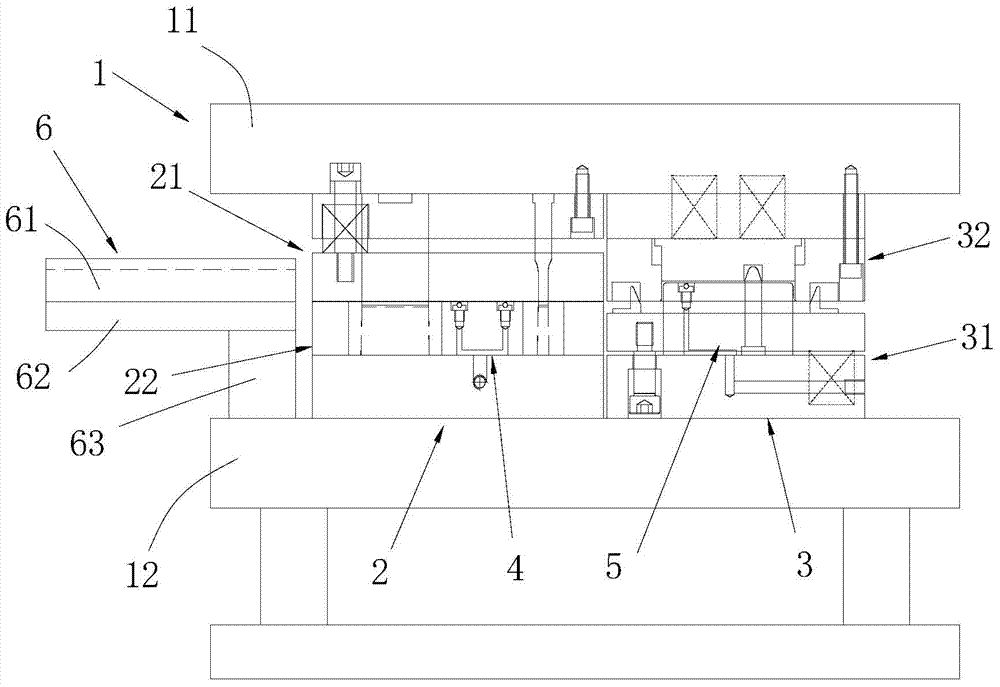

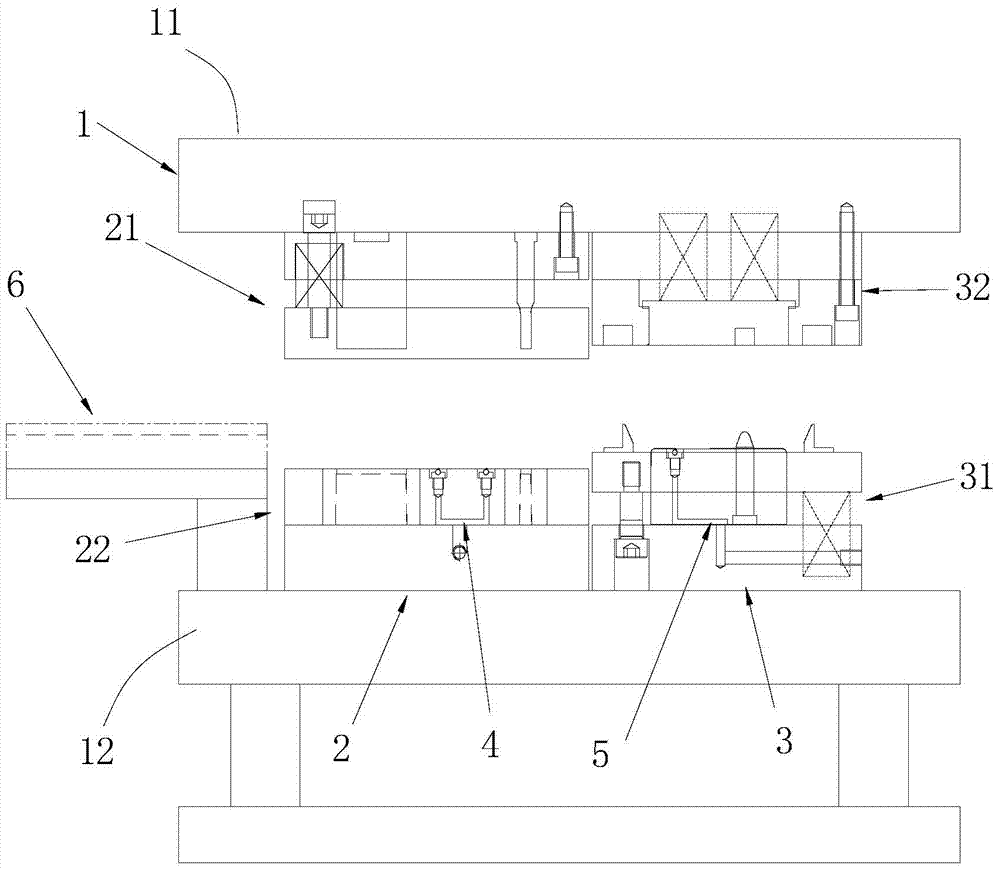

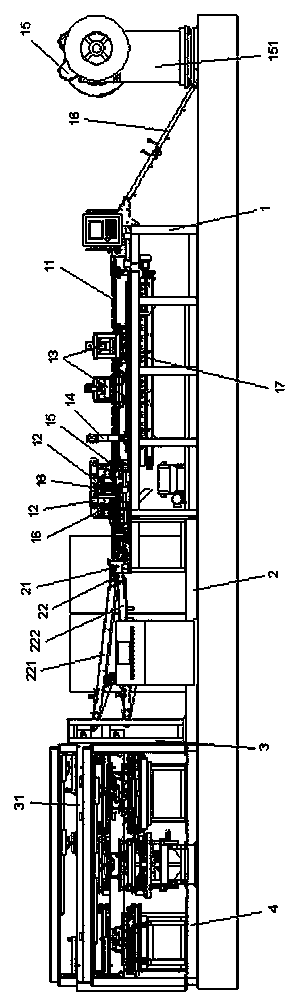

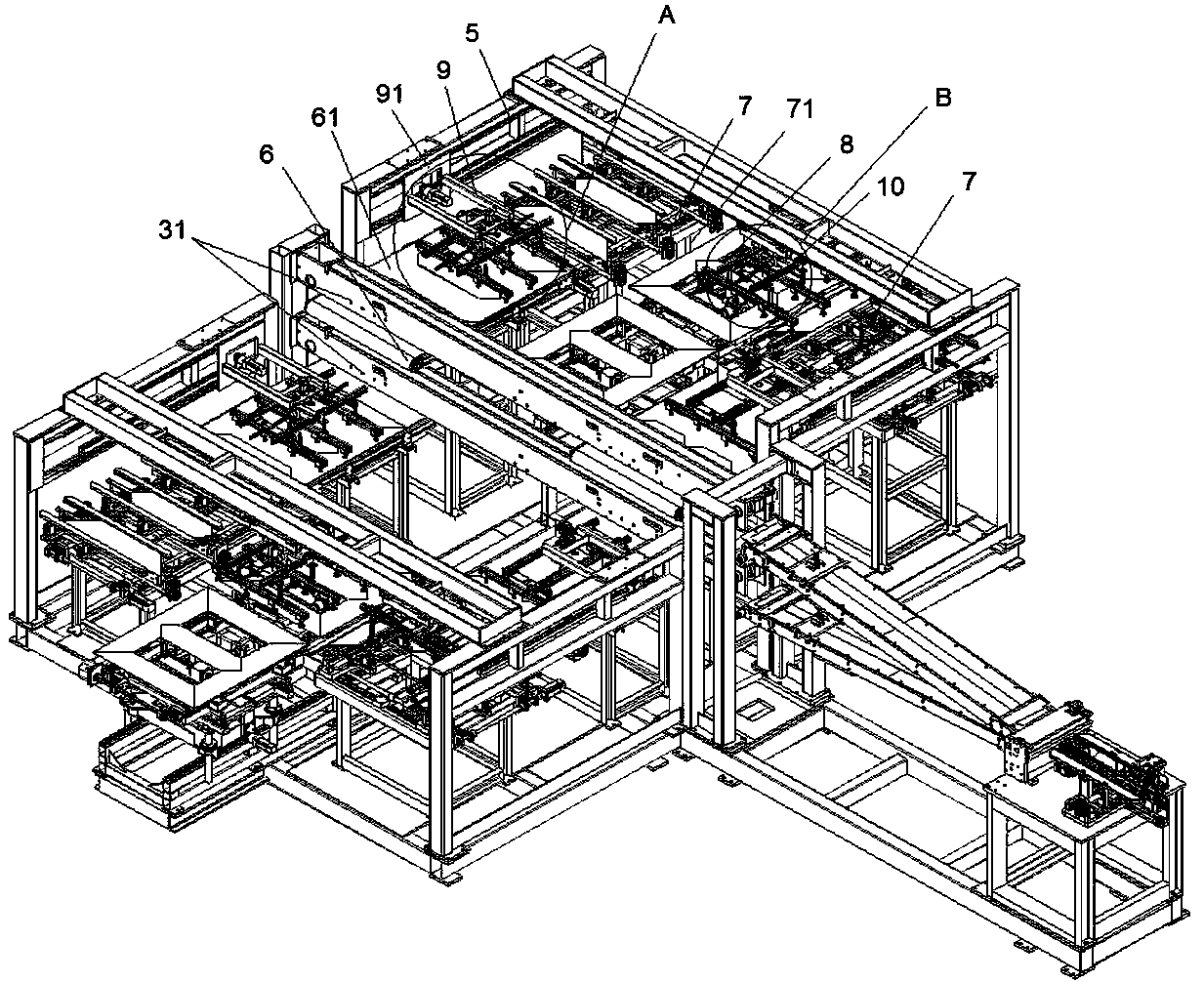

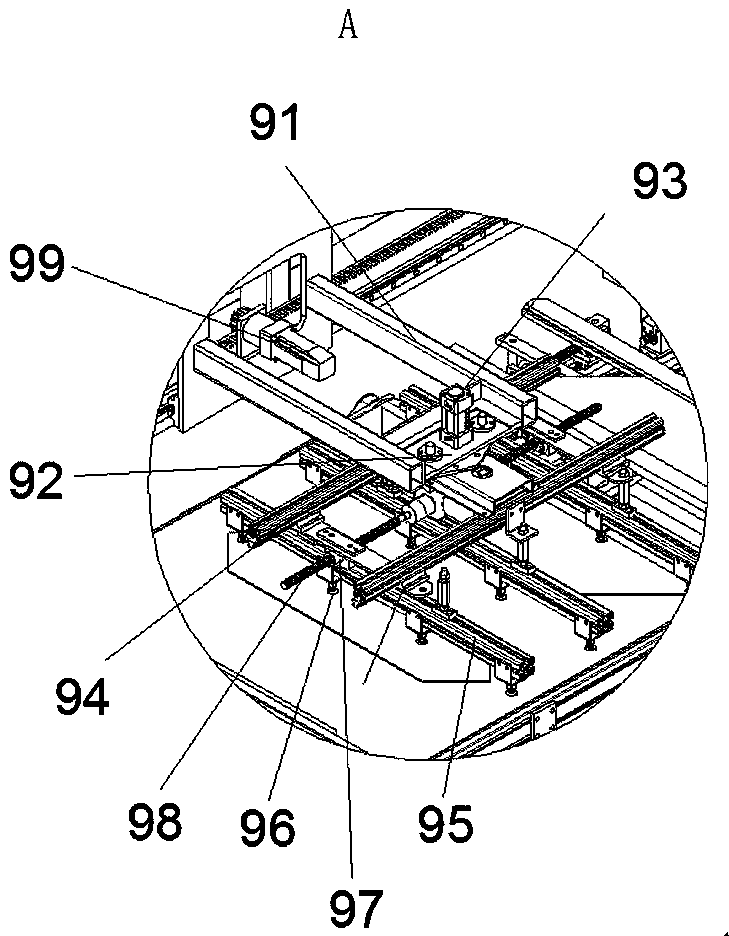

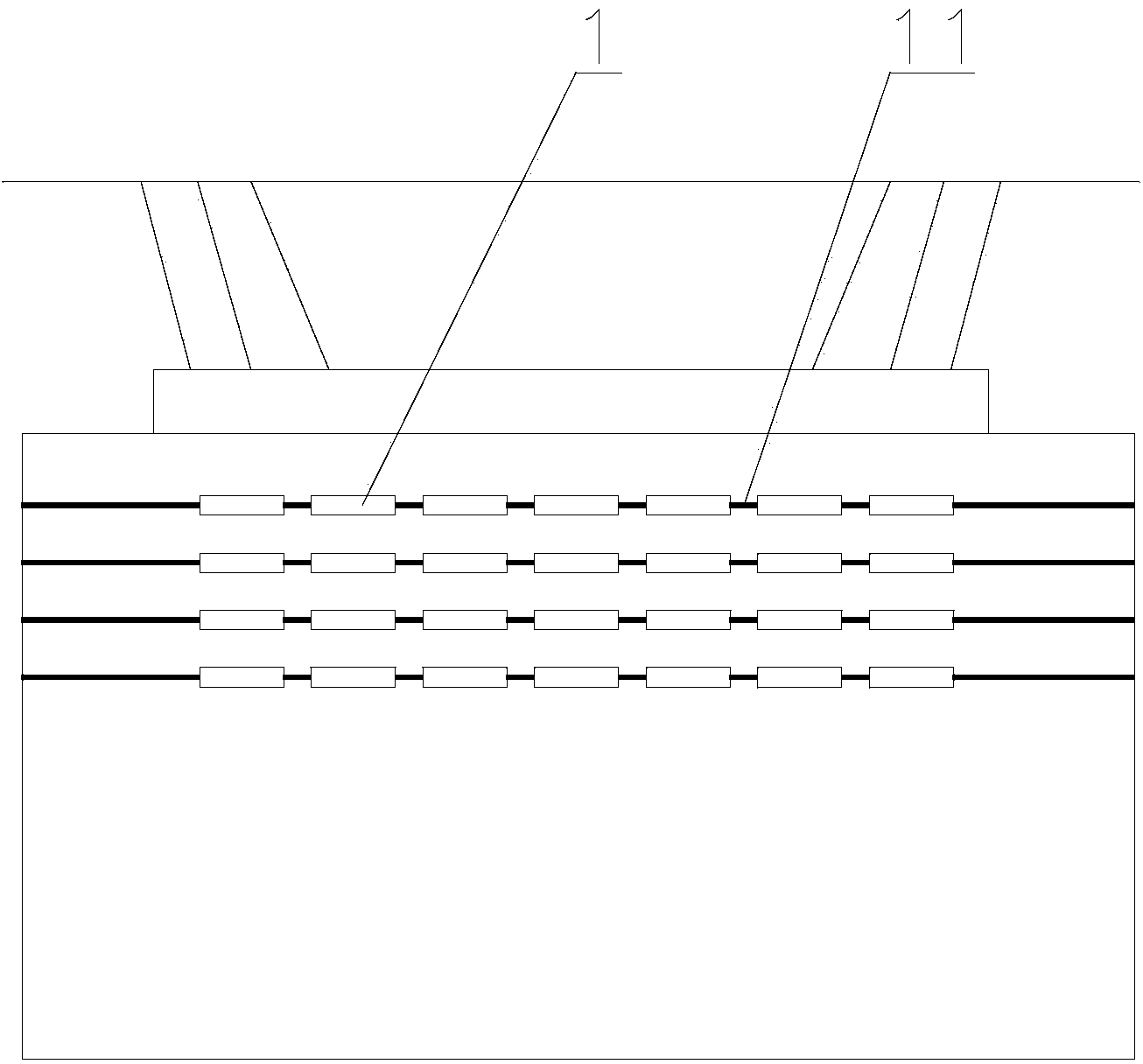

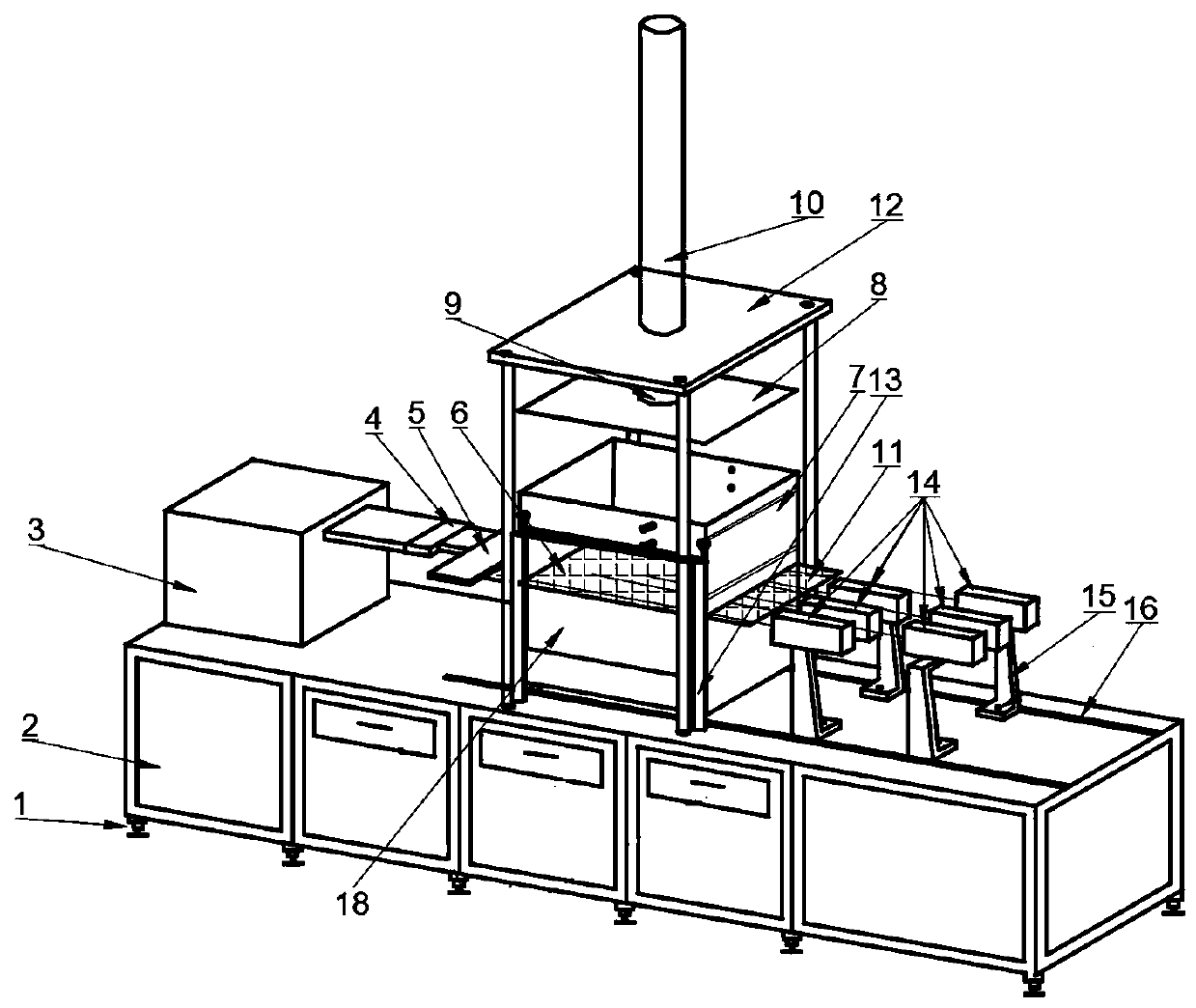

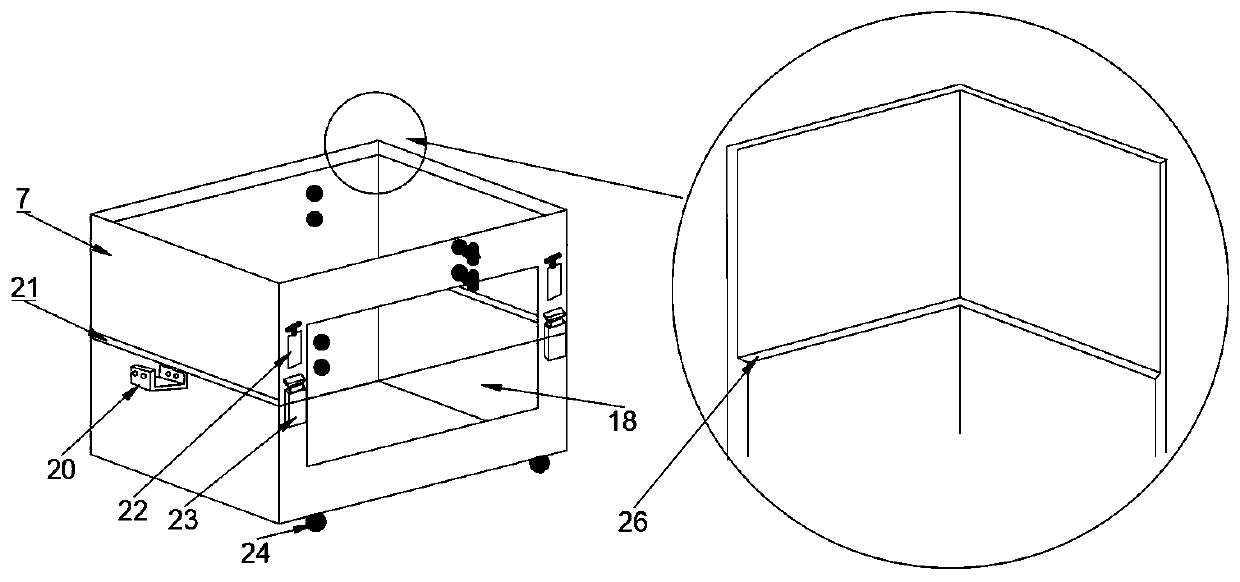

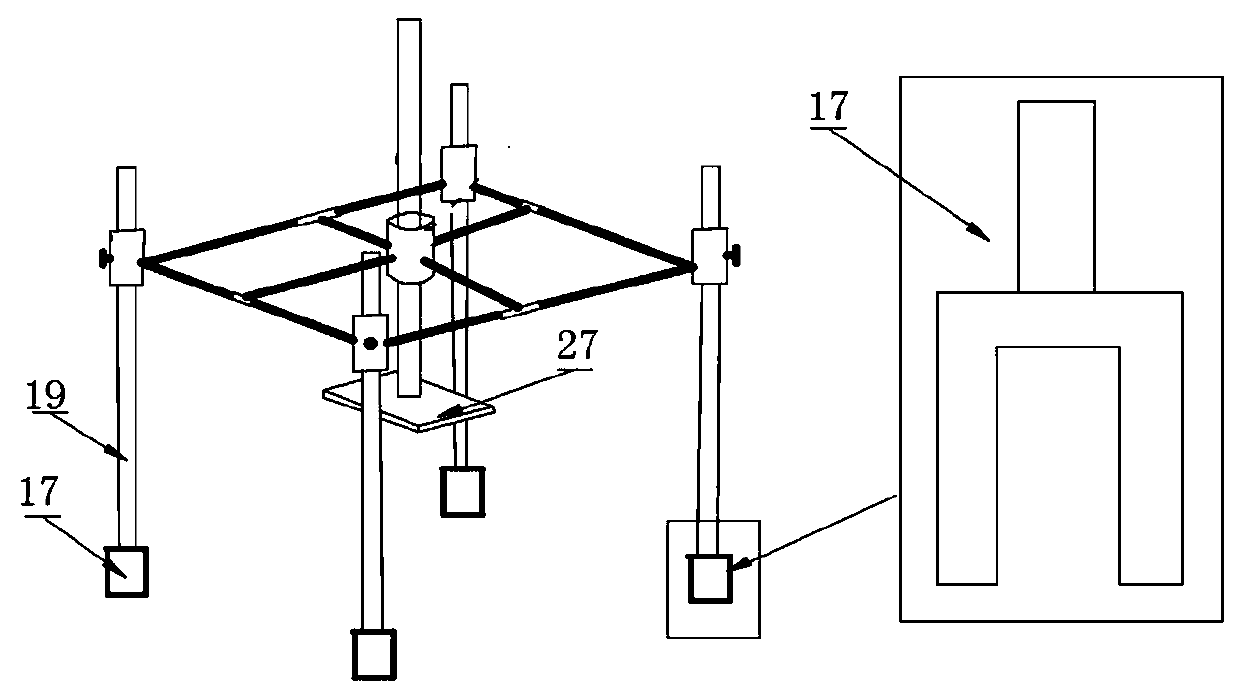

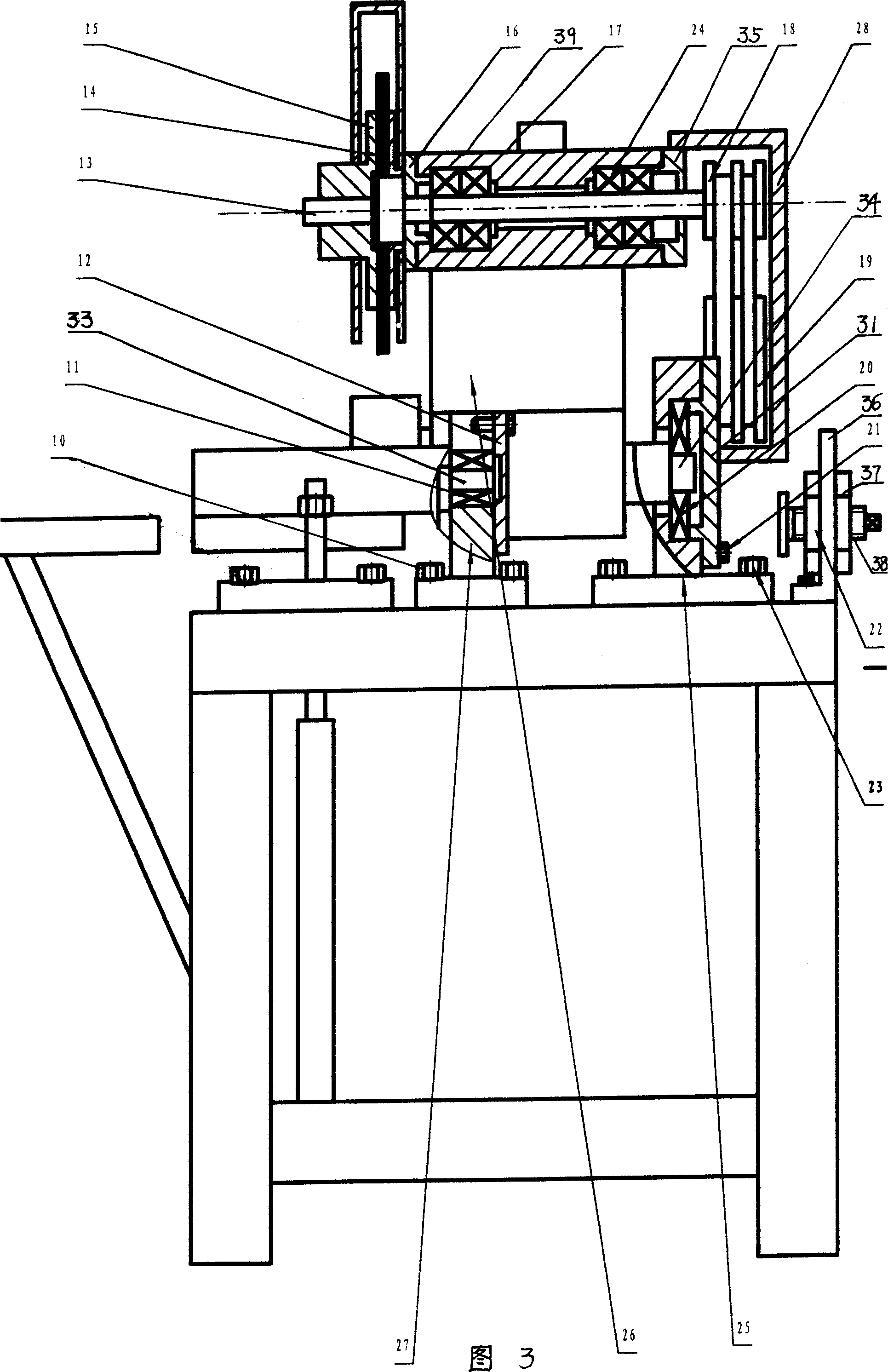

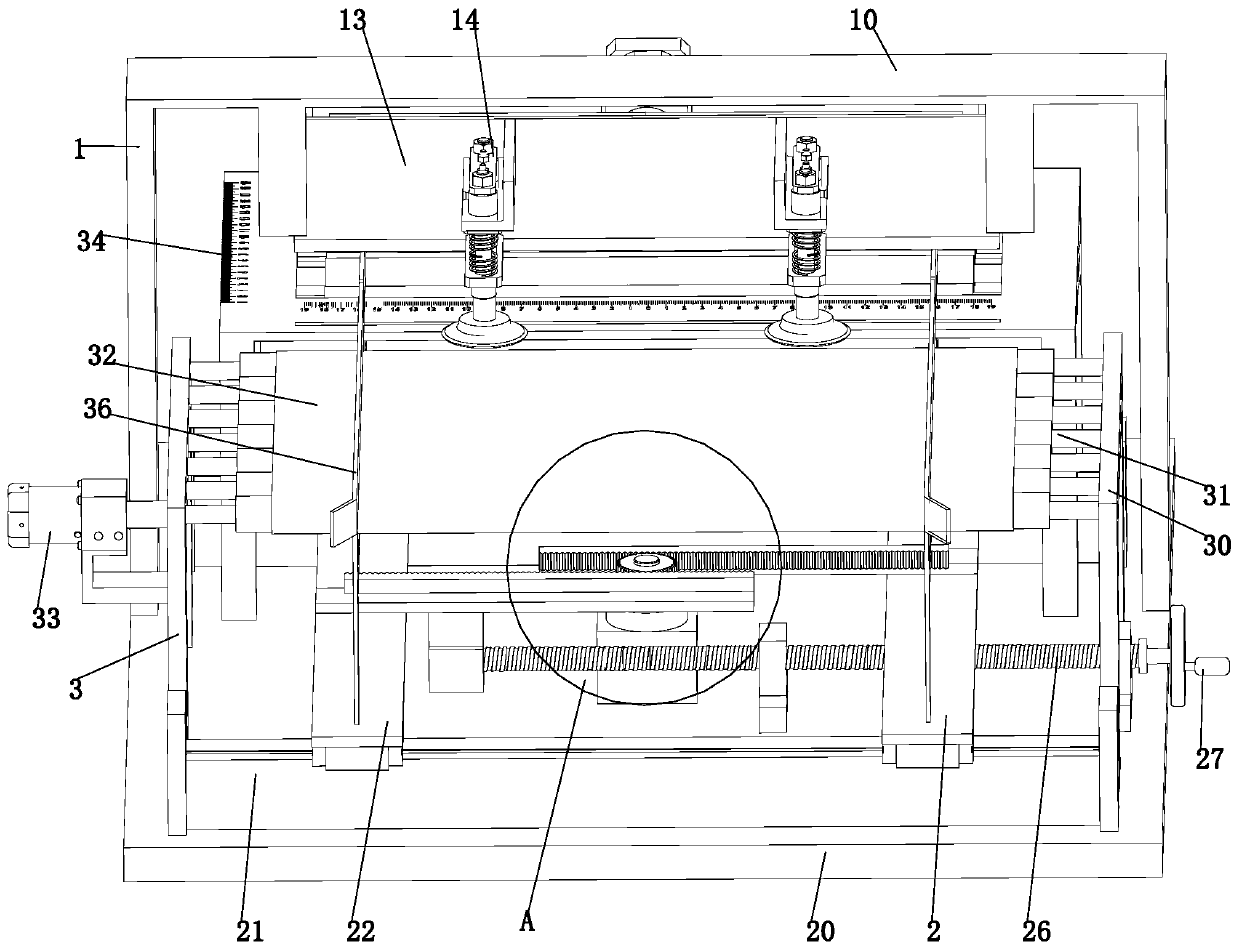

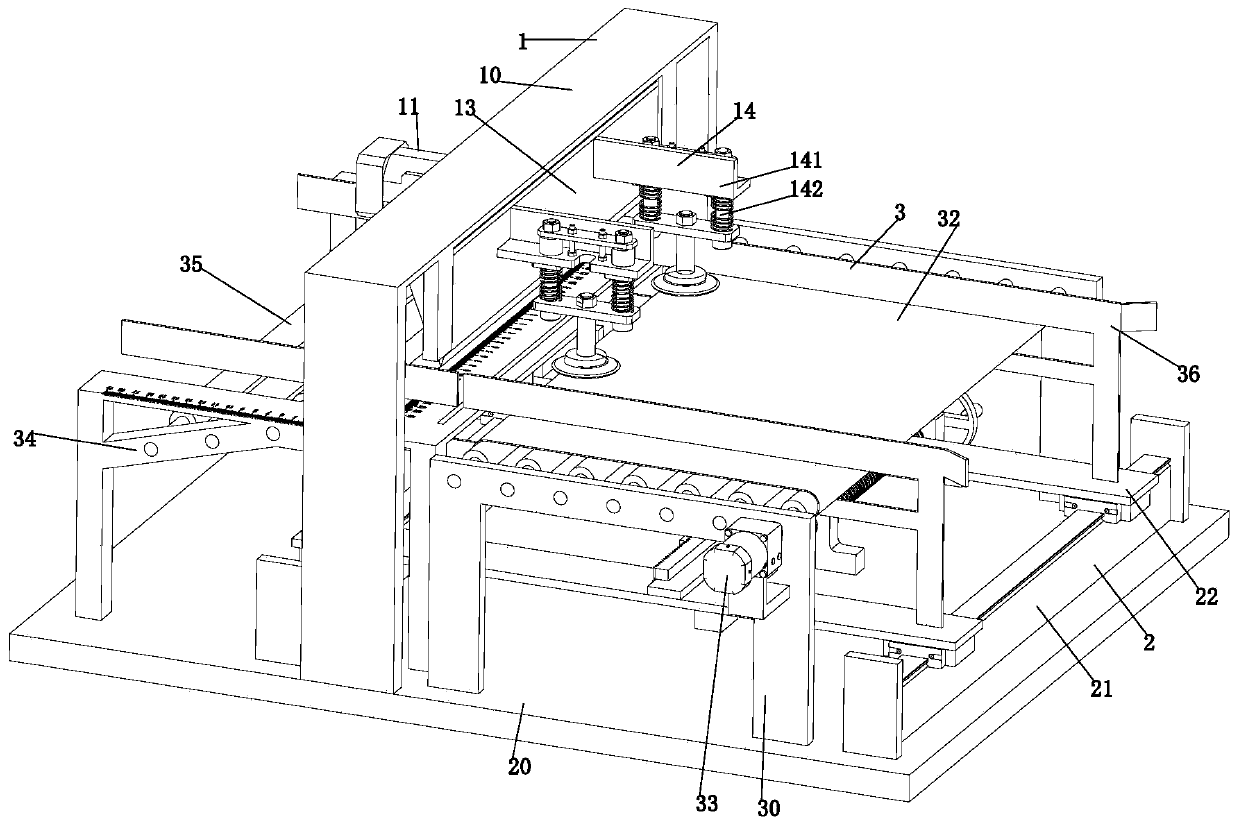

Transformer silicon steel sheet shearing and stacking machine

PendingCN110722359AEasy to assemble directlyAdjustable distanceOther manufacturing equipments/toolsMetal working apparatusPunchingTransformer

The invention discloses a transformer silicon steel sheet shearing and stacking machine, and relates to the technical field of transformer silicon steel sheet manufacturing equipment. An unwinding device, a supporting device and a conveying guide channel of the machine are sequentially connected, and the conveying guide channel is provided with a transverse shearing device, a V-shaped shearing device and a punching device. The conveying guide channel is connected with reverse suction and material arranging devices, and initial positioning devices and fine positioning devices are arranged on the lateral sides of the reverse suction and material arranging devices. Carrying devices are arranged above the initial positioning devices and the fine positioning devices, and a stacking table deviceis arranged between the fine positioning devices. The machine has the advantages that after silicon steel sheets are cut, the assembling process is directly started, the intermediate manual carryingand material arranging procedures are omitted, the labor intensity is reduced, few circulation links are needed, the damage to the silicon steel sheets is reduced, the placement time is short, rust isavoided, shearing, stacking and assembling are integrated, the production floor area is reduced, the energy consumption is reduced, the production efficiency is improved, corresponding distance adjustment can be carried out on silicon steel sheet iron cores with different specifications, and the application range is wider.

Owner:NANTONG SIRUI ENG

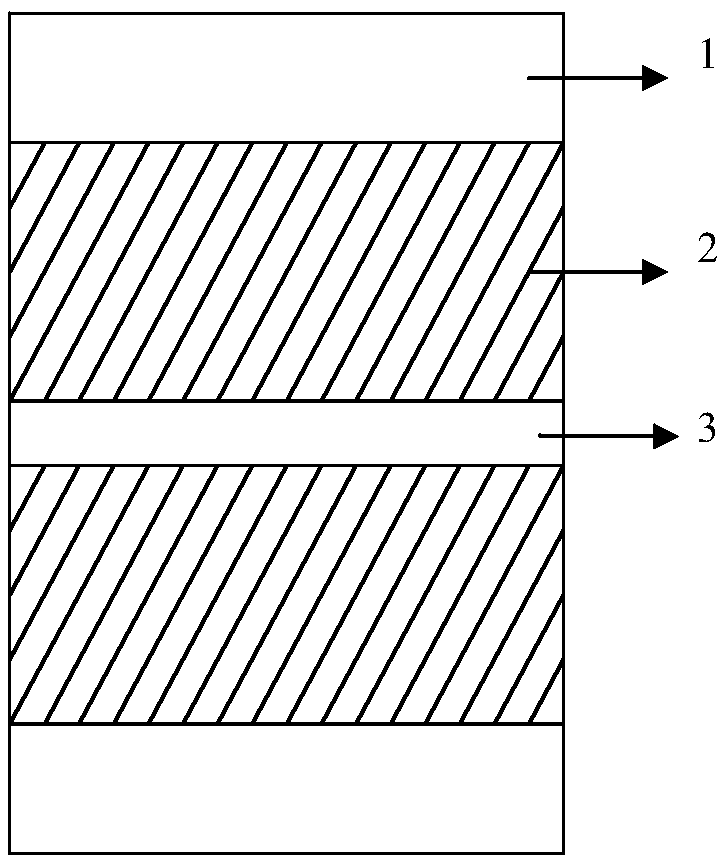

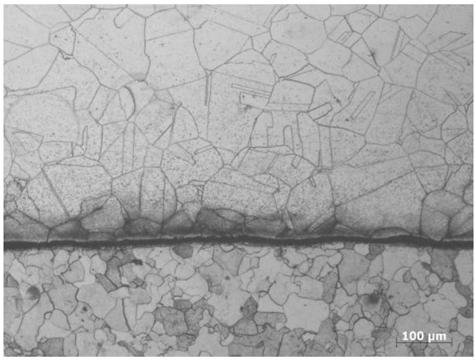

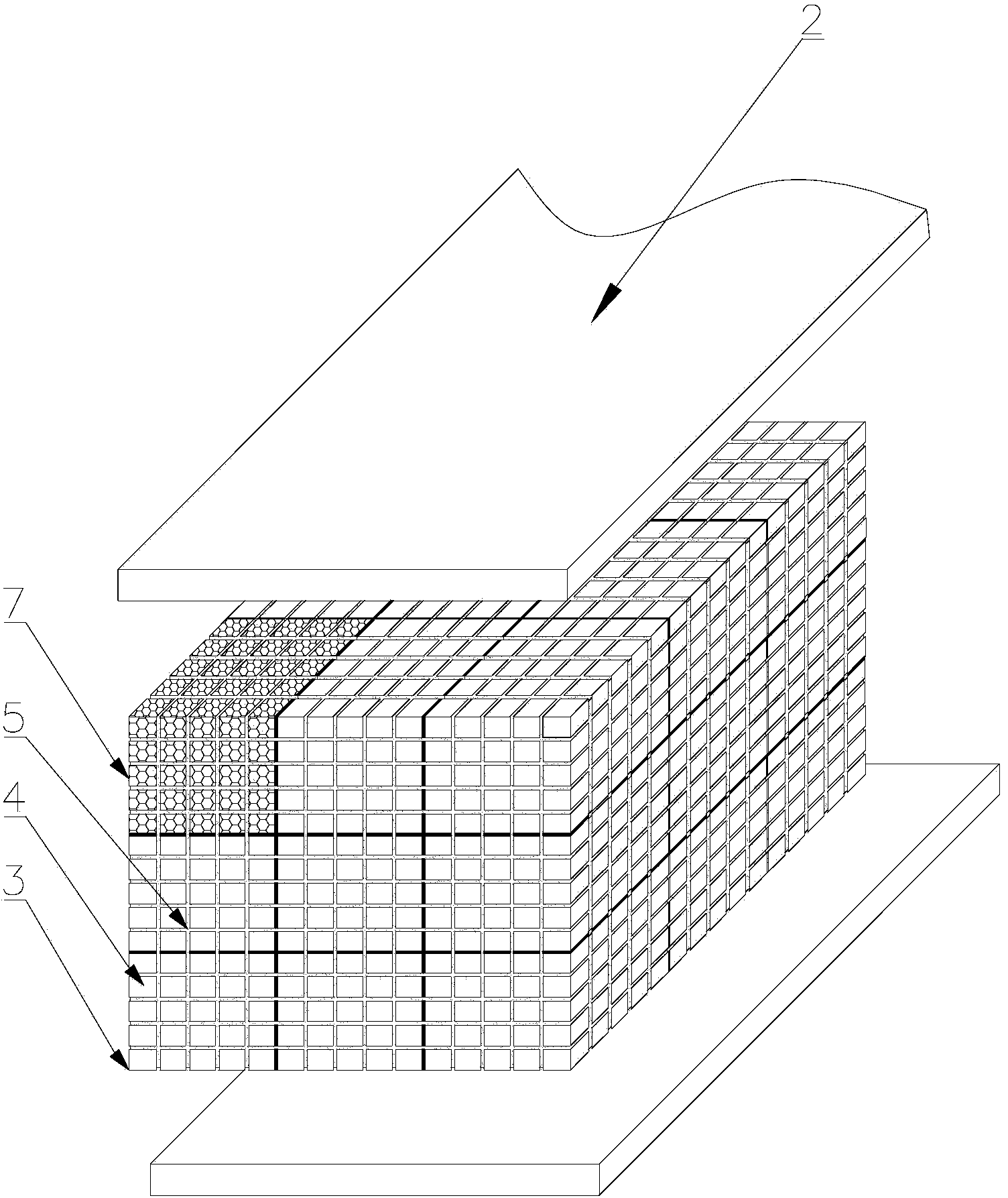

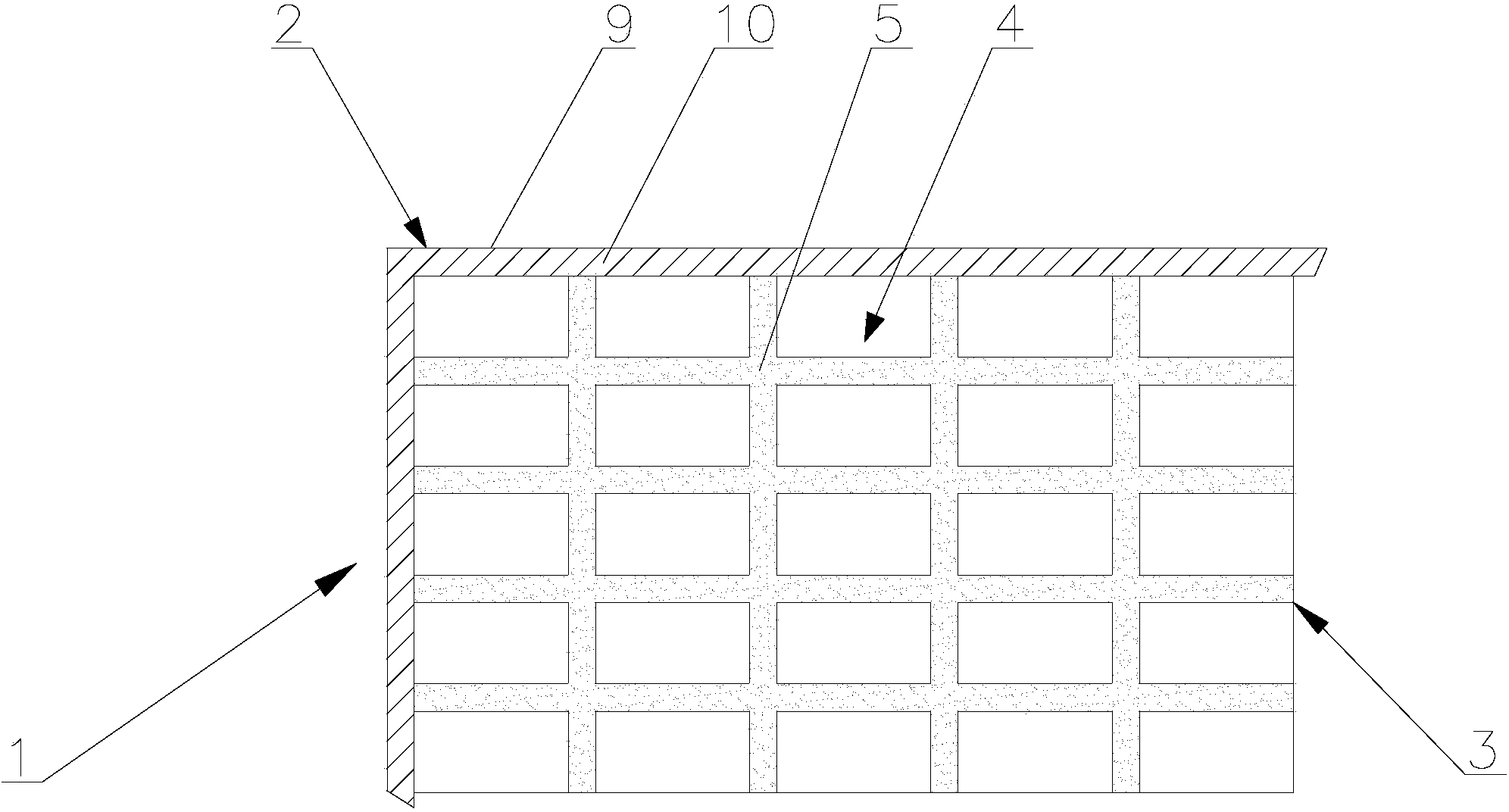

High-shear-strength super-thick composite steel plate for generation III nuclear power station and manufacturing method of composite steel plate

ActiveCN108995323AComposite effect is goodHigh mechanical properties and resistance to intergranular corrosionLaminationLamination apparatusAustenitic stainless steelReduction rate

The invention discloses a high-shear-strength super-thick composite steel plate for a generation III nuclear power station and a manufacturing method of the composite steel plate. The composite steelplate consists of steel-plate carbon steel and 304L austenitic stainless steel. The assembly sequence is as the follows from top to bottom: stainless steel, carbon steel, an isolating agent, carbon steel and stainless steel. Edge sealing is carried out on four edges of a combined billet by welding, vacuumizing treatment is carried out, and the vacuum degree is 100 Pa or lower. The heating temperature of the combined billet is 1200-1270 DEG C, the heating time is 10-15 hours, the single-stroke reduction rate is 5%-15%, the final rolling temperature is controlled to be 1050 DEG C or above, tempering heat treatment is carried out after rolling, the quenching temperature is 870-930 DEG C, the heat preservation time is 2-4 min / mm, and the heating rate is 1.0-1.5 min / mm. The tempering temperature is 620-660 DEG C, the heat preservation time is 3-6 min / mm, and the heating rate is 1.5-2.0 min / mm. The thickness of a finished composite steel plate is 29-110 mm, the shearing strength is good, andthe requirement of steel for composite boards of a nuclear power station is met.

Owner:ANGANG STEEL CO LTD

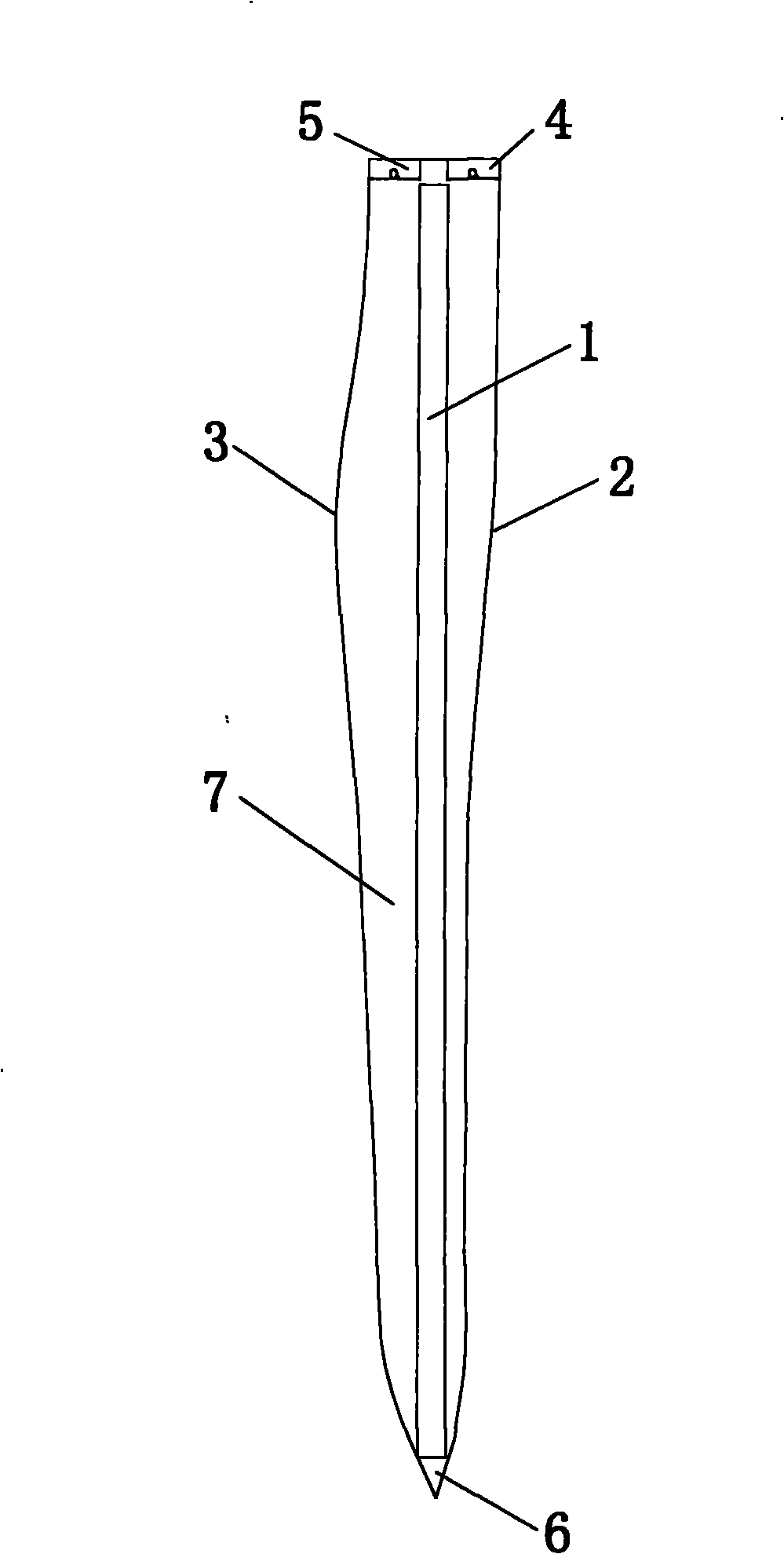

Composite-material energy-dissipation fender and manufacturing process of composite-material energy-dissipation fender

ActiveCN103510491AWide applicabilityProtection securityClimate change adaptationBridge structural detailsShearing deformationEngineering

The invention provides a composite-material energy-dissipation fender which comprises a shell and an energy-dissipation filling body wrapped inside the shell. The energy-dissipation filling body comprises energy-dissipation materials and a plurality of energy-dissipation ribs, the energy-dissipation ribs are distributed inside the energy-dissipation materials and / or between the energy-dissipation materials and the shell, and the energy-dissipation ribs are connected with the shell into a whole. The energy-dissipation ribs of the composite-material energy-dissipation fender form a longitudinally-transversely staggered net structure, the high shearing strength and the certain elastic deformation buffering capacity are achieved, the shell can be protected from large shearing deformation, and the composite-material energy-dissipation fender is good in overall collision avoidance effect, low in manufacturing cost, long in service life and convenient to maintain and repair.

Owner:JIANGSU HONGYUAN TECHNOLOGY ENGINEERING CO LTD

Direct shearing and drawing dual-purpose testing machine for geosynthetics

InactiveCN110967249AUpper case length adjustableRealize integrationPreparing sample for investigationMaterial analysis by optical meansElectric machineryTest chamber

The invention belongs to the field of direct shearing and drawing integrated test equipment, in particular to a direct shearing and drawing dual-purpose testing machine for geosynthetics. The machineis characterized by comprising a test bench, slideway and a test box, a vertical loading system, a horizontal drawing system and compaction equipment, the test box comprises an upper box, a lower box,pulleys arranged at the bottom of the lower box, a narrow slit arranged between the side walls of one sides of the upper box and the lower box in the drawing direction, and tempered glass. the horizontal drawing system comprises a drawing and pressing motor, a tension sensor, a clamp, a geosynthetics material and a plurality of displacement sensors II, and the vertical loading system comprises ahydraulic jack, a vertical counter-force frame, a horizontal pressurizing plate and a displacement sensor I. The upper box is adjustable, the integration of a direct shearing test box and a drawing test box is realized, the conversion is convenient and time-saving, the manufacturing cost is reduced, and the space is saved; the size of the test equipment is larger than that of most existing test equipment, the requirements of relevant specifications can be well met, and the influence of the size effect is reduced as much as possible.

Owner:ANSTEEL GRP MINING CO LTD

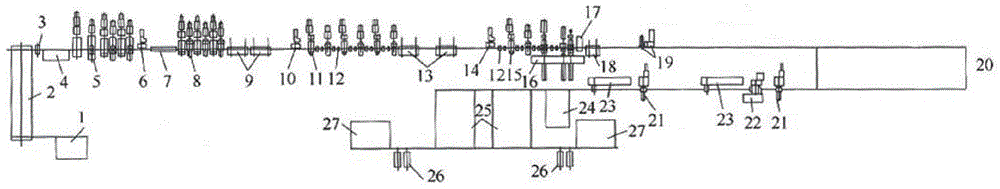

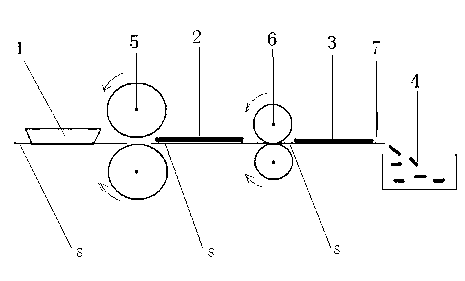

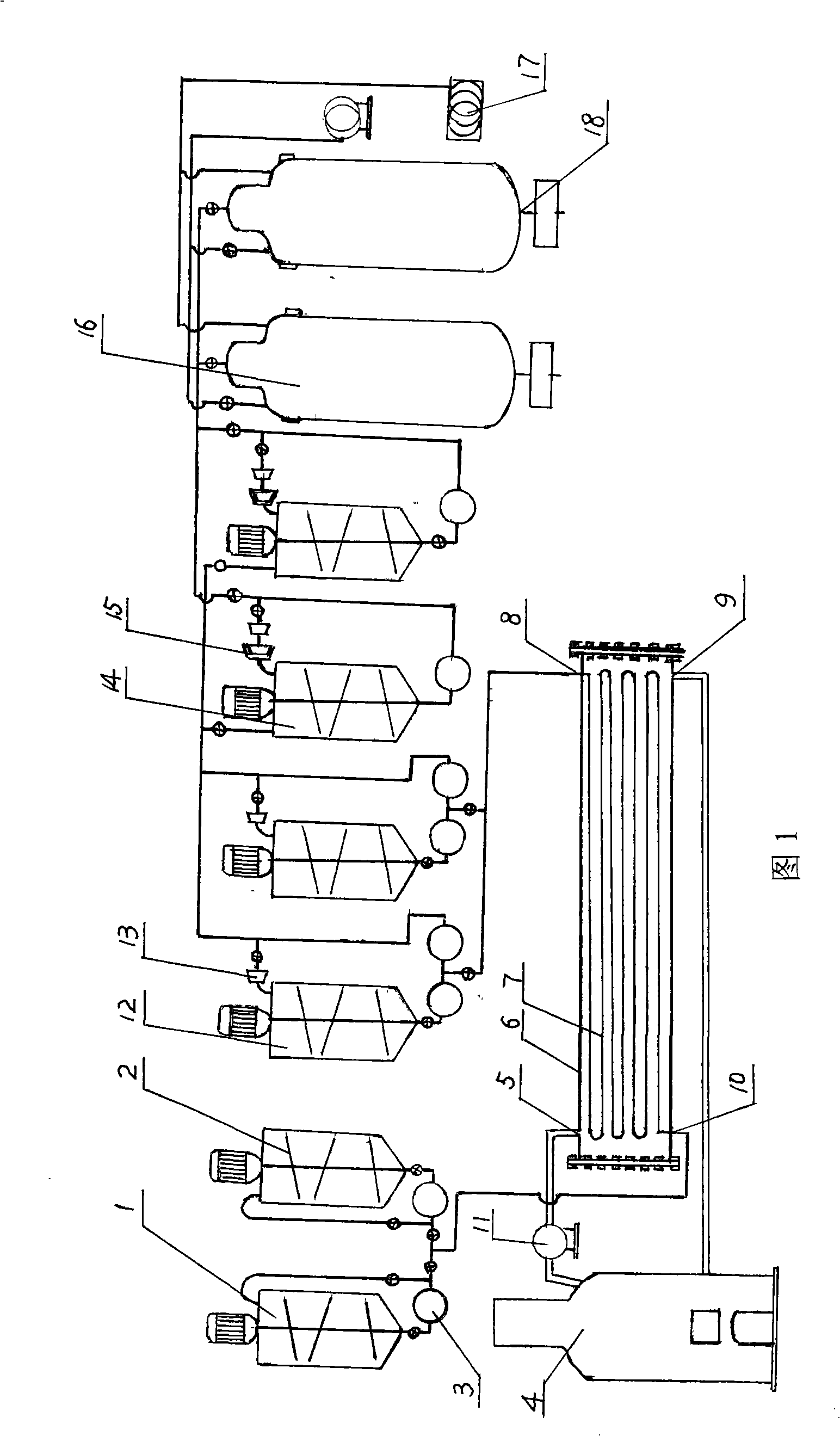

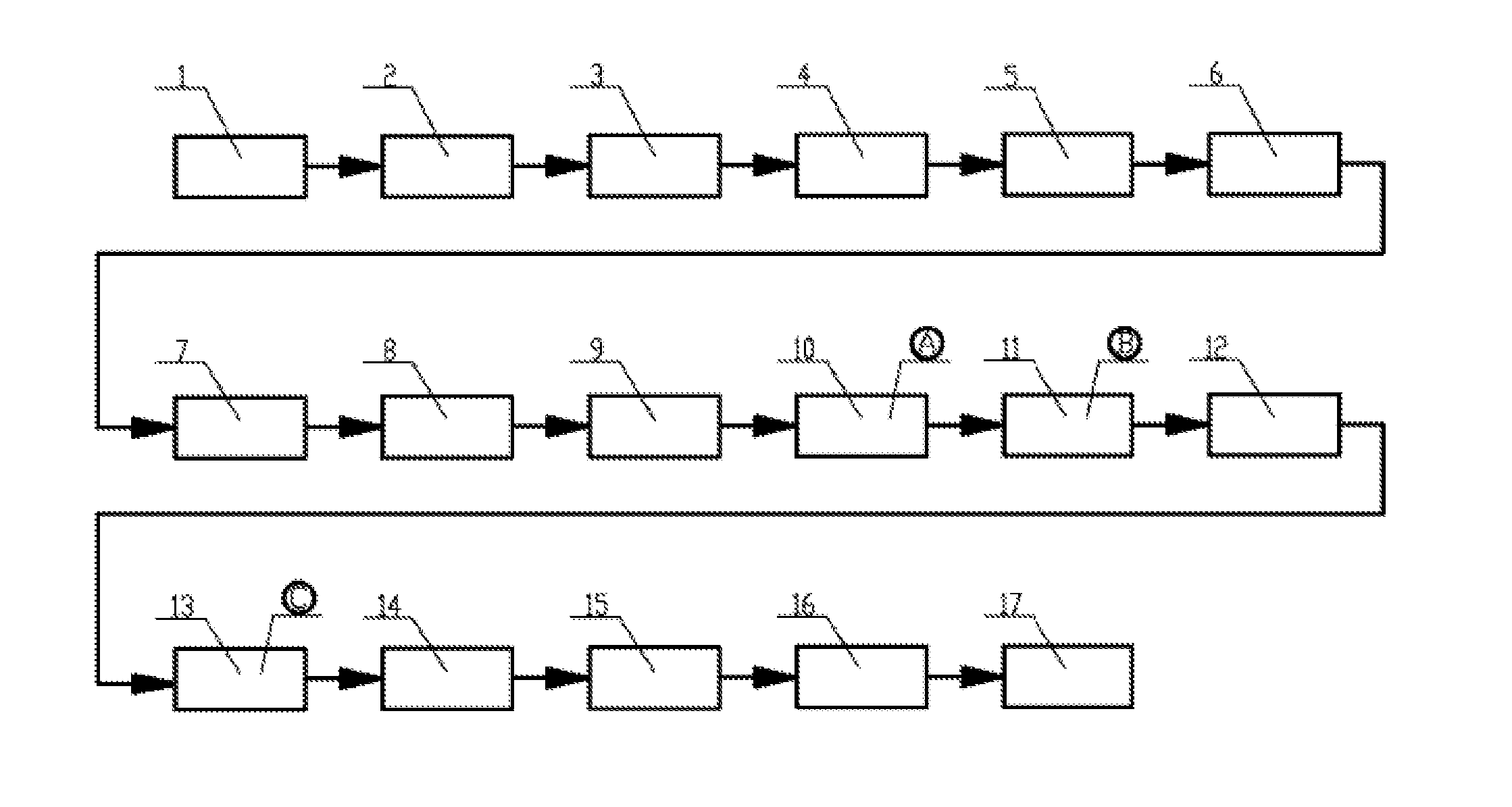

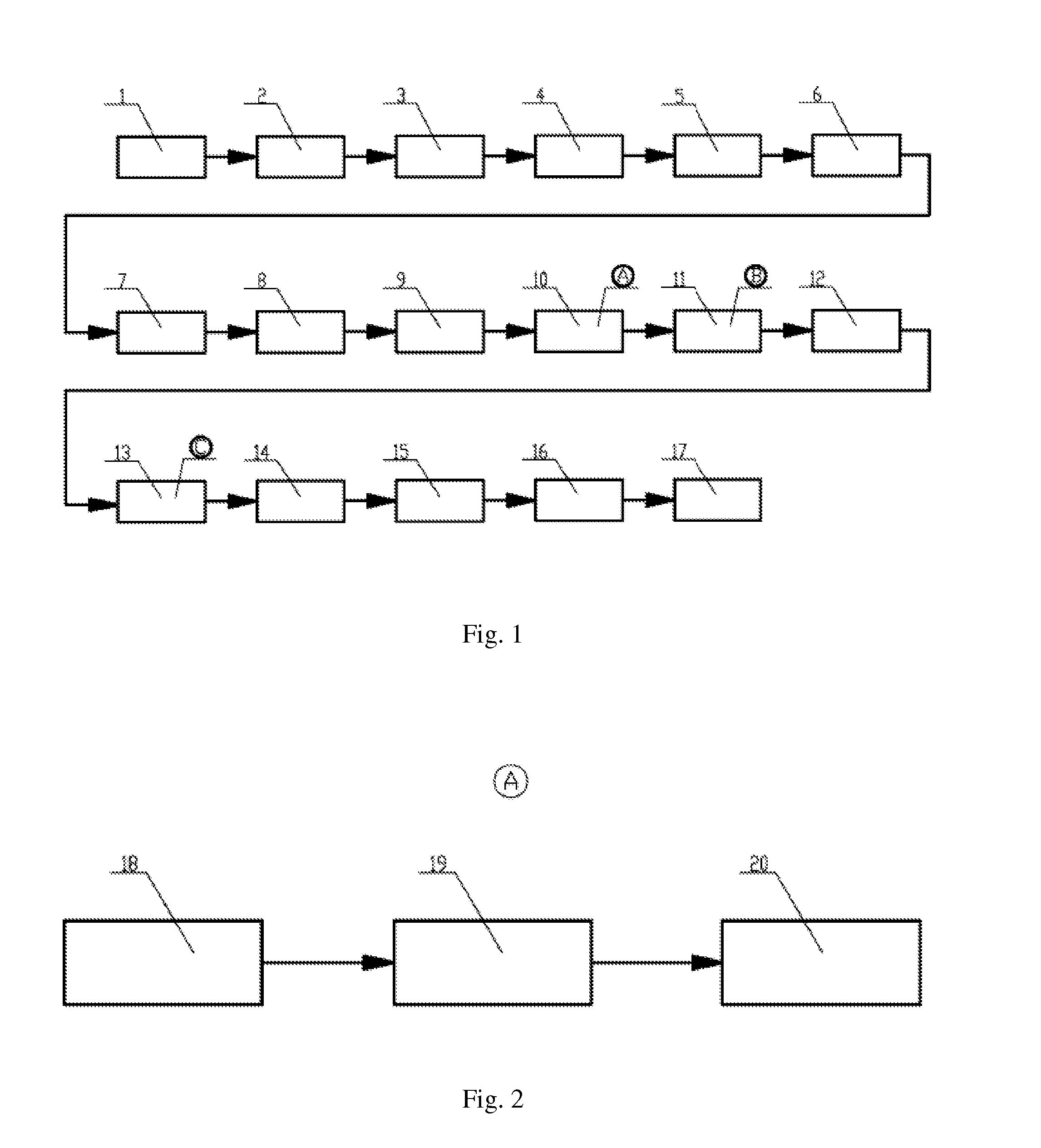

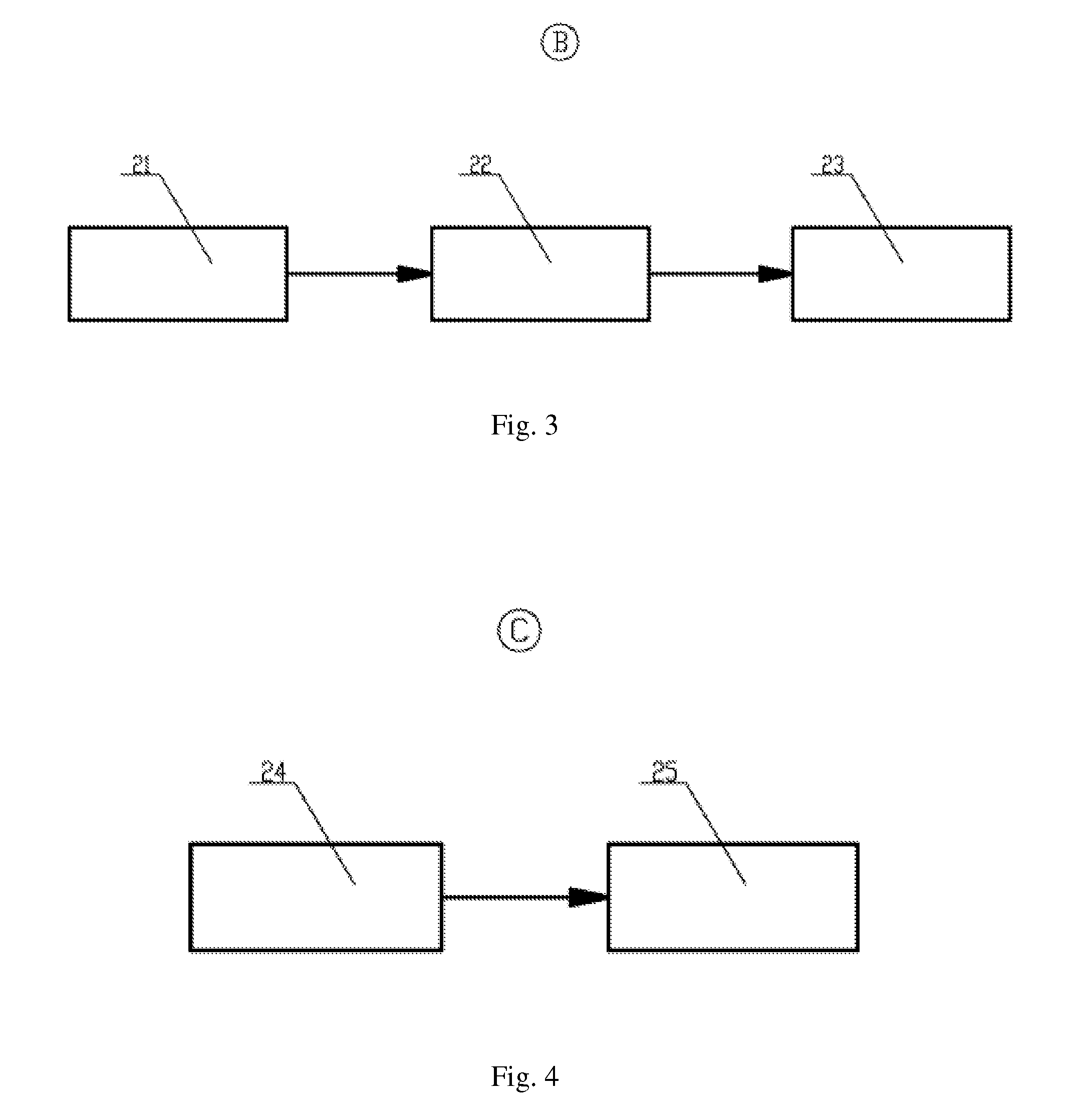

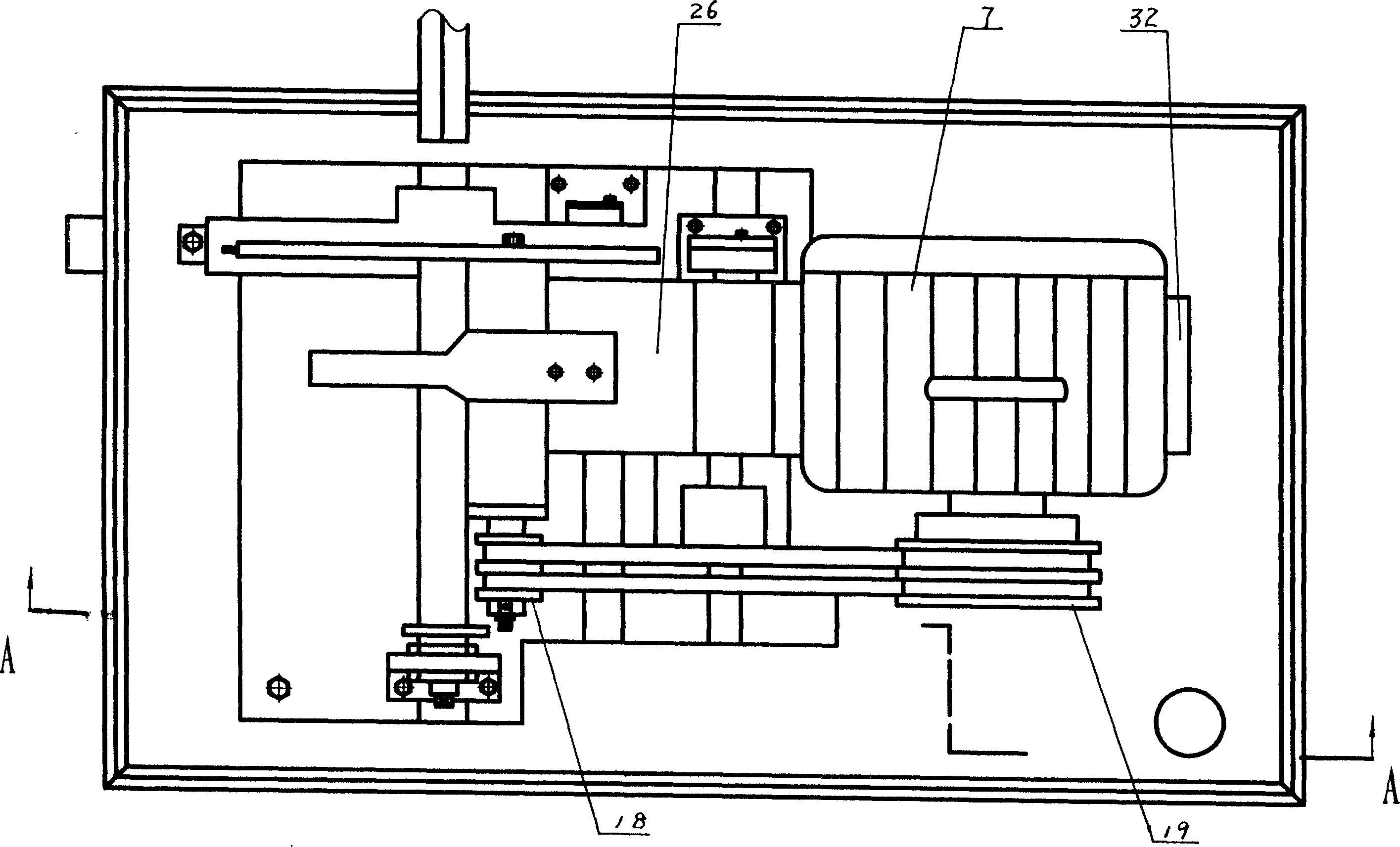

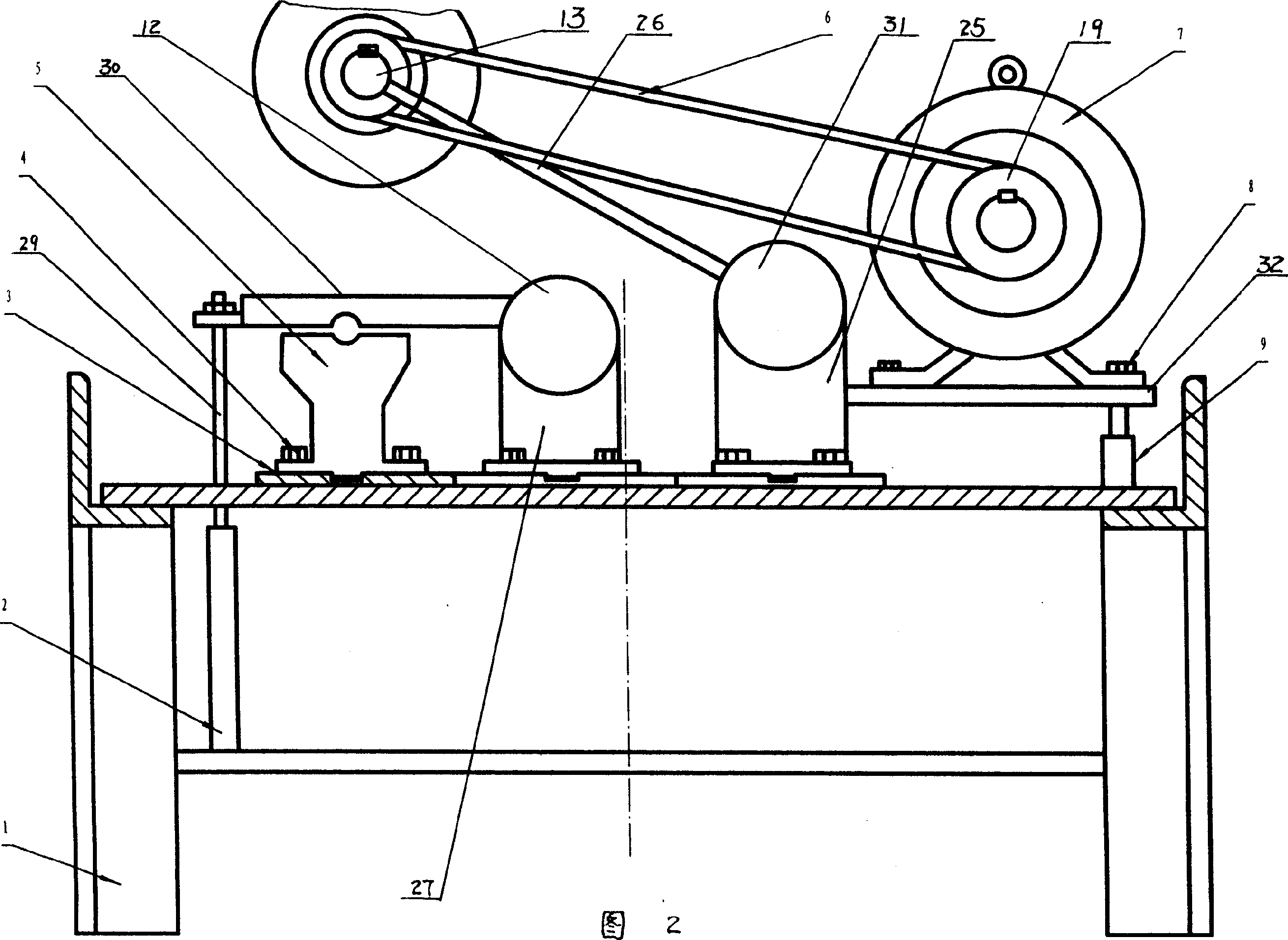

Production line of large diameter longitudinal welded pipe

A production line of large diameter longitudinal welded pipe comprises a material storage table (1), a charging trolley (2), an uncoiler (3), a leveler (4), a shearing and butt welding machine (5), a movable sleeve (6), an edge milling machine (7), a steel plate flaw detector (8), a lifting table (9), a steel pipe forming machine (10), a welding device (11), a pulling device (12), a heat treatment device (13), a cooling device (14), a rigid rolling machine (15), a cut-to-length cutting machine (16) and a discharging rack (17). The production line in the present invention has the advantages including high production efficiency, stable product quality, low manufacturing cost, as well as reliable and convenient operation.

Owner:DALIAN SAGE GROUP

Method for manufacturing stainless steel tail gas pipe of car, and automatic cutter for cutting stainless steel pipe

A technology for manufacturing the stainless steel pipe used as the tail gas pipe of car includes examining raw material, shearing, welding to become pipe, drawing, pressure test, washing, annealing, straightening, sizing, cutting off, straightening, reducing diameter, sizing, cutting off, washing and refining. Its automatic cutter is composed of machine frame, base plate, fixature, small bearing holder and pressing plate, intermediate bearing holder, rotary plate, abrasive dis, and its mainshaft, motor, sizing unit, etc. The finished pipe features high size precision, smooth surface, and hith uniformity in hardness.

Owner:锦州秀亭制管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com