Transformer silicon steel sheet shearing and stacking machine

A technology of silicon steel sheets and transformers, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems that the distance of silicon steel sheets cannot be adjusted accurately, the production area is large, and the production efficiency is low, so as to reduce labor intensity and reduce turnover. The effect of fewer links and less storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0052] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

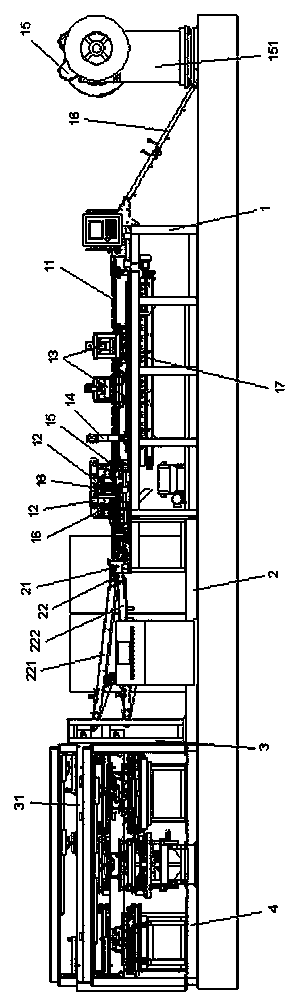

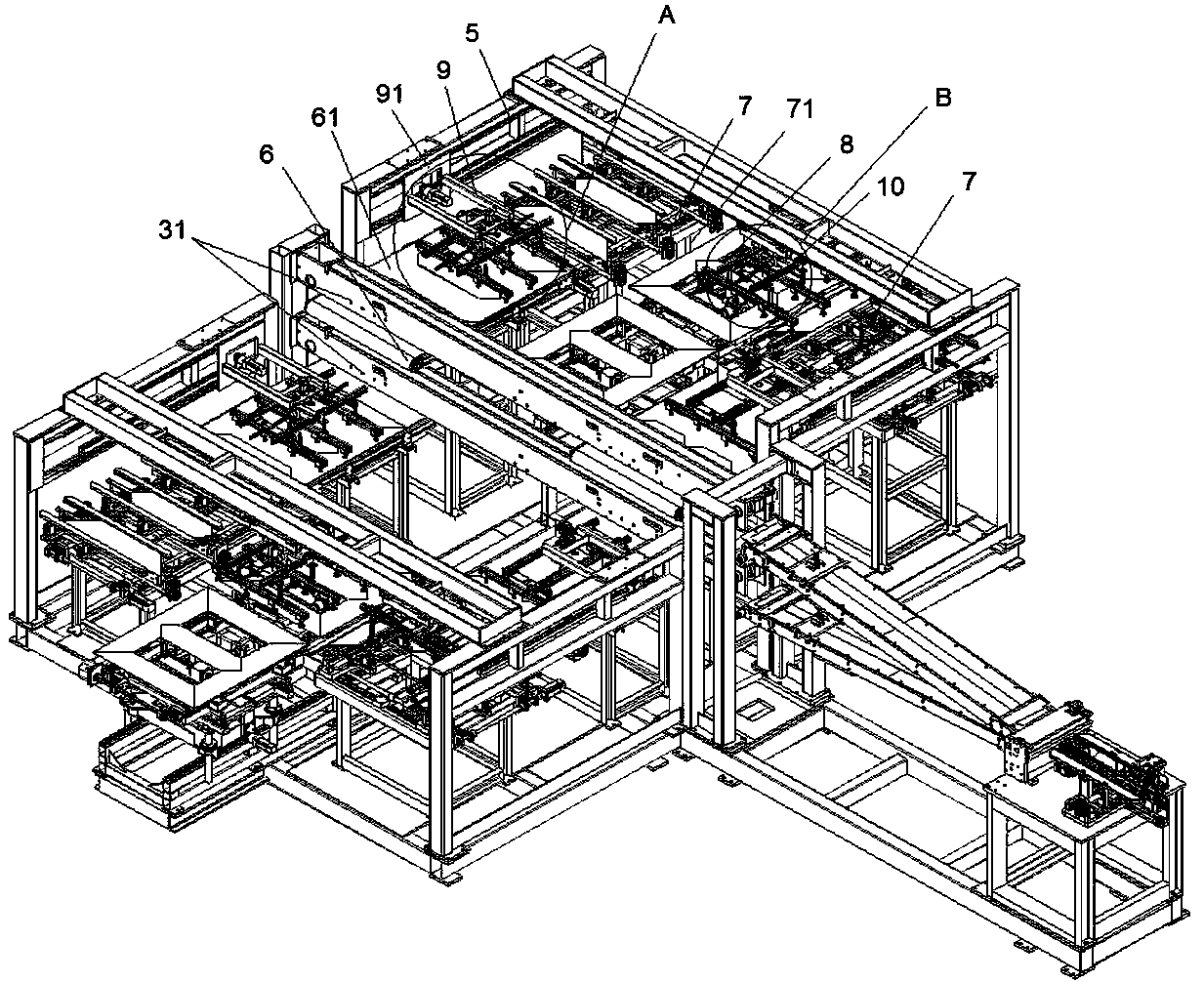

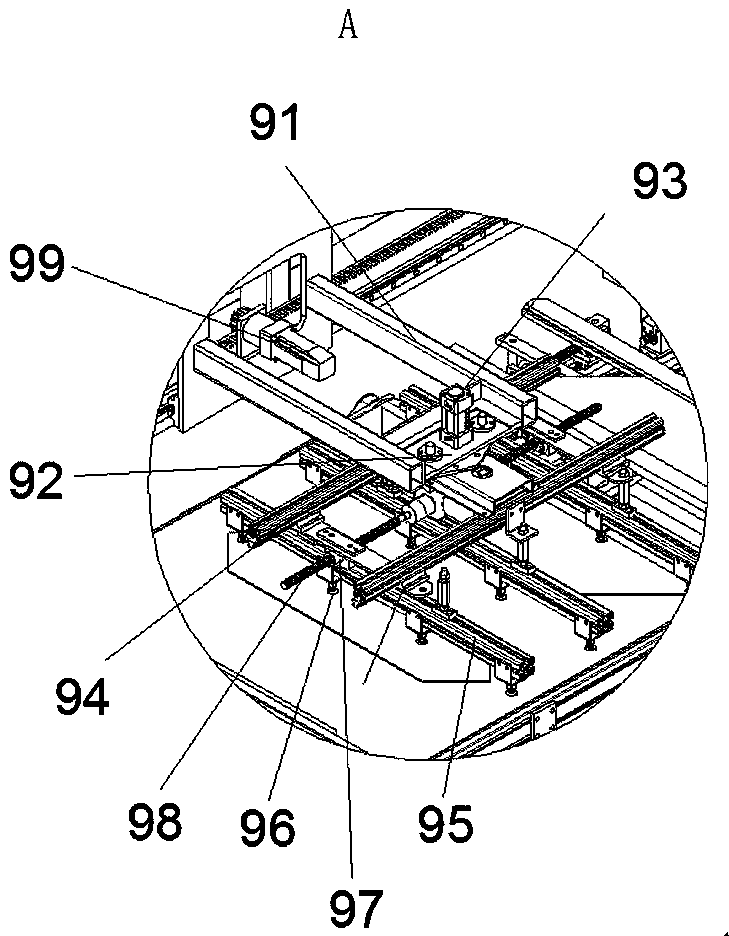

[0053] like figure 1 and figure 2 As shown, the specific implementation mode adopts the following technical solutions: including

[0054] A cross-cutting system 1, a conveying system 2, a suction system 3, a stacking system 4;

[0055] The cross-shear system 1 has a cross-shear support, on which a material-carrying guide channel 11 is arranged, and a transverse-shear device 12, a V-shear device 13, and a punching device 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com