Integrated electric wheel system with de-energized electromagnetic parking brake

A braking device and electromagnetic brake technology, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems that the electromagnetic brake is connected with the outer rotor motor, etc., so as to avoid parking brake failure, avoid motor heat damage, eliminate the effect of mechanical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

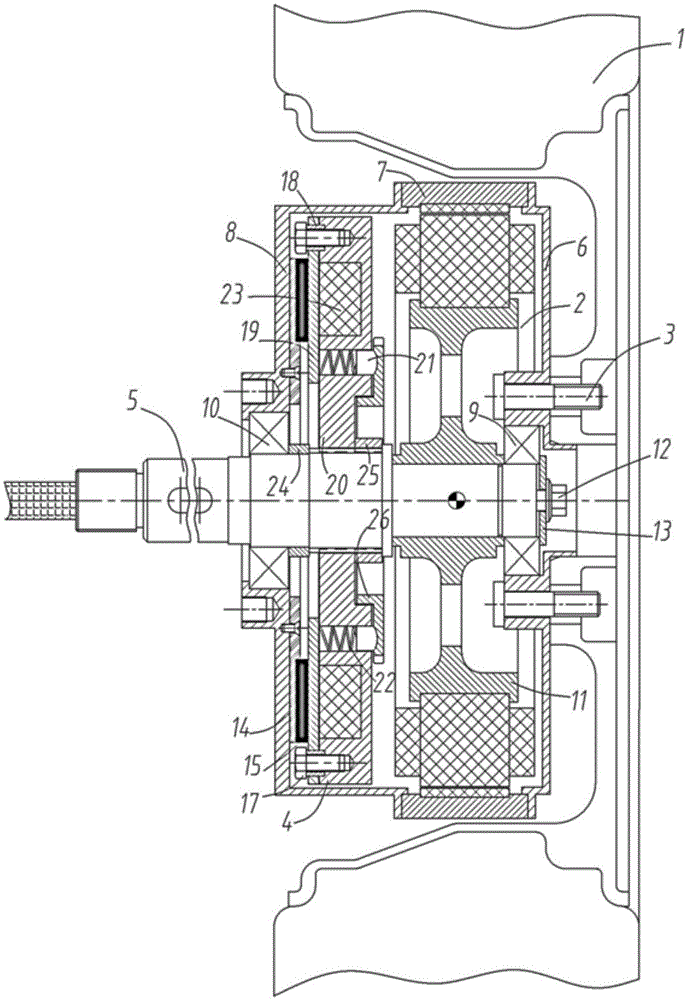

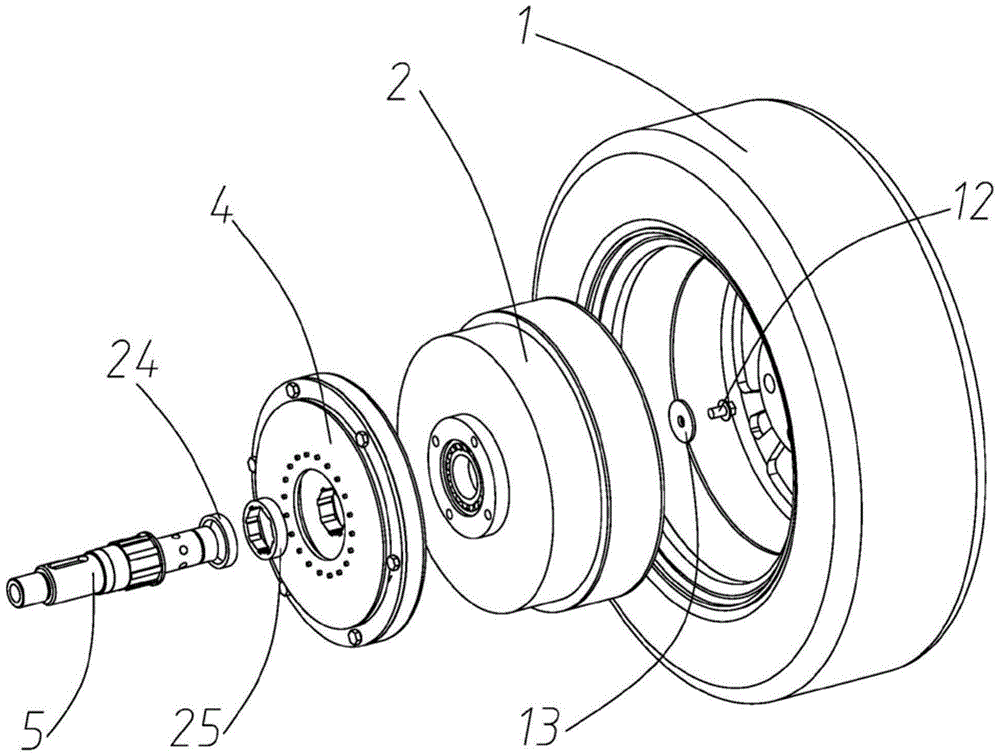

[0027] The overall structure of the integrated electric wheel system with non-excitation electromagnetic parking brake device is as follows:

[0028] refer to figure 1 and figure 2 , The integrated electric wheel system with a non-excitation electromagnetic parking brake device has a wheel 1, a hub motor 2, 5 rim bolts 3, an integrated electromagnetic brake 4, a No. 1 bushing 24, and a No. 2 bushing 25.

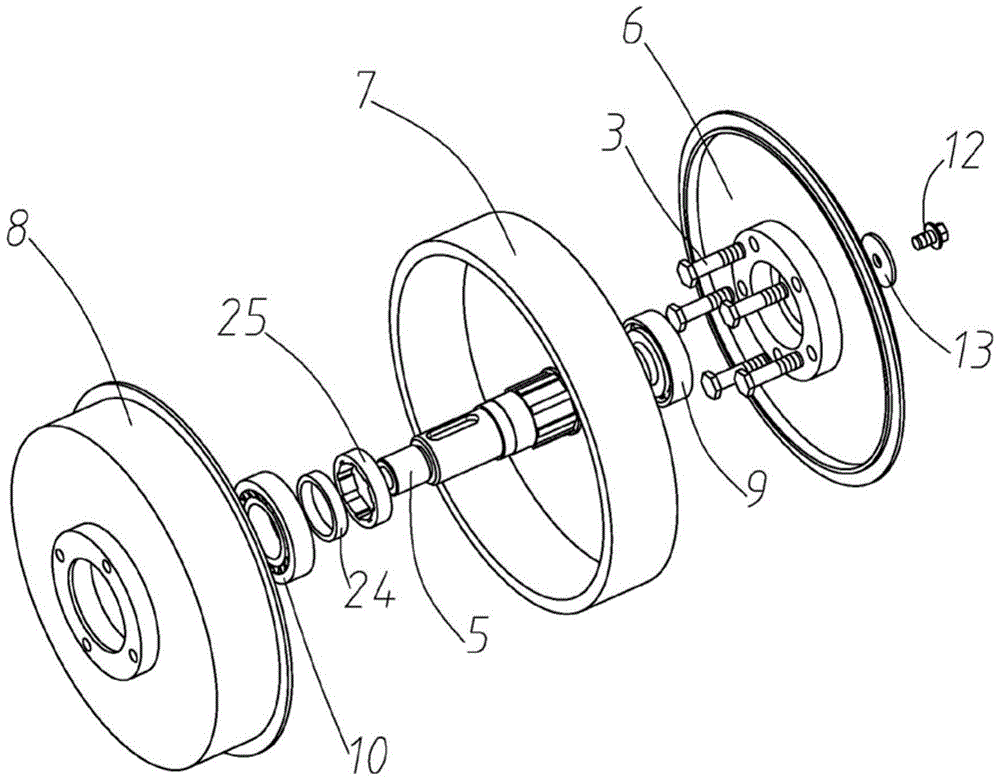

[0029] refer to image 3 , the hub motor 2 has a motor shaft 5, an outer shell of the hub motor 6, an annular shell of the hub motor with permanent magnets embedded in the inner wall 7, an inner shell of the hub motor 8, a tapered roller bearing outside the motor 9, and a tapered roller inside the motor Bearing 10, hub motor stator assembly 11, shaft end bolt 12, shaft end retaining ring 13.

[0030] refer to Figure 4 5, the integrated electromagnetic brake 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com