Thermal protection plate

A heat protection and cover plate technology, which is applied in the direction of thin plate connection, aerospace vehicle heat protection devices, nuts, etc., can solve the problems of thermal stress fatigue damage, poor overheating capacity, large metal thermal expansion coefficient, etc., and achieve high-rise inter-layer shear strength , Excellent thermal insulation performance, good interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

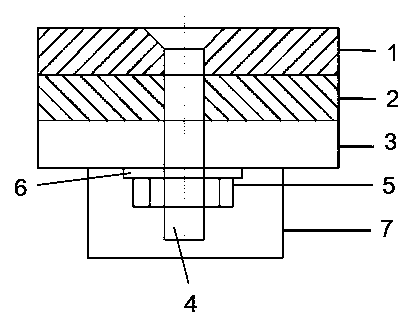

[0028] Such as figure 1 As shown, a heat protection plate includes a cover plate 1, a heat insulating layer 2, and an inner panel 3 from outside to inside in sequence. The outer surface of the cover plate 1 is provided with a SiC coating (not shown), and the cover plate 1 Bolts 4 are installed through the direction of the inner panel 3, and the ends of the bolts 4 extend out of the inner wall of the inner panel 3 and are fixed with nuts 5, and a spring washer 6 is arranged between the inner panel 3 and the nut 5; on the inner wall of the inner panel 3, bolts 4 An airgel heat shield 7 is provided on the outer periphery of the position where the nut 5 is located, and the airgel heat shield 7 and the inner panel 3 are bonded with an inorganic high-temperature adhesive with a heat-resistant temperature not lower than 1000 °C;

[0029] Wherein, the cover plate 1 is a woven structure carbon fiber reinforced ceramic matrix composite material cover plate; the heat insulation layer 2 i...

Embodiment 2

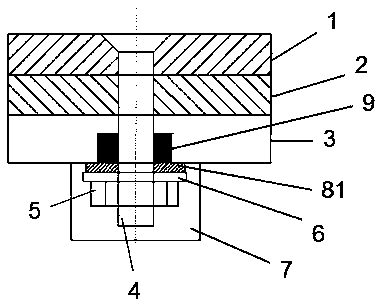

[0031] Such as figure 2 As shown, a heat protection plate includes a cover plate 1, a heat insulating layer 2, and an inner panel 3 from outside to inside in sequence. The outer surface of the cover plate 1 is provided with a SiC coating (not shown), and the cover plate 1 Bolts 4 are provided through the direction of the inner panel 3, the ends of the bolts 4 extend out of the inner wall of the inner panel 3 and are fixed with nuts 5, and the inner wall of the inner panel 3 is provided with airgel heat insulation on the outer periphery where the bolts 4 and nuts 5 are located cover 7, the airgel heat shield 7 and the inner panel 3 are bonded with an inorganic high-temperature adhesive with a heat-resistant temperature not lower than 1000 ° C; the bolt 4 between the inner panel 3 and the nut 5 is sleeved with a first air The gel heat insulation pad 81, the spring washer 6 is arranged between the first airgel heat insulation pad 81 and the nut 5; the bolt 4 located inside the inn...

Embodiment 3

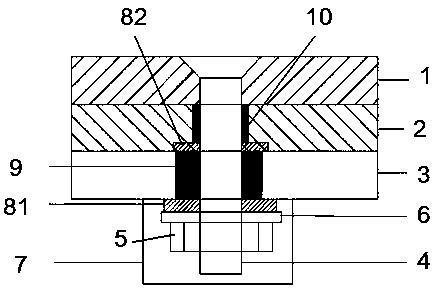

[0034] Such as image 3 As shown, a heat protection plate includes a cover plate 1, a heat insulating layer 2, and an inner panel 3 from outside to inside in sequence. The outer surface of the cover plate 1 is provided with a SiC coating (not shown), and the cover plate 1 Bolts 4 are provided through the direction of the inner panel 3, the ends of the bolts 4 extend out of the inner wall of the inner panel 3 and are fixed with nuts 5, and the inner wall of the inner panel 3 is provided with airgel heat insulation on the outer periphery where the bolts 4 and nuts 5 are located cover 7, the airgel heat shield 7 and the inner panel 3 are bonded with an inorganic high-temperature adhesive with a heat-resistant temperature not lower than 1000 ° C; the bolt 4 between the inner panel 3 and the nut 5 is sleeved with a first air A gel heat insulating pad 81, a spring washer 6 is arranged between the first airgel heat insulating pad 81 and the nut 5; an airgel heat insulating ring 9 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com