Patents

Literature

72results about How to "Guaranteed temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

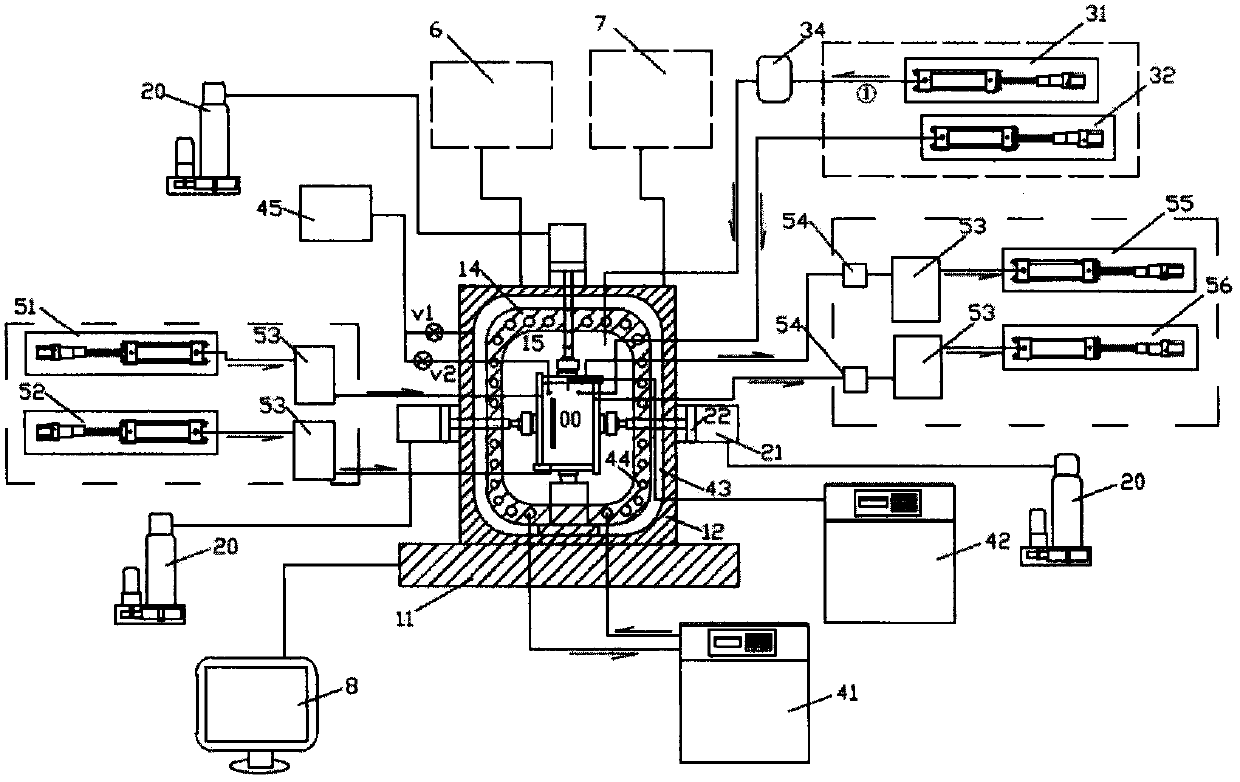

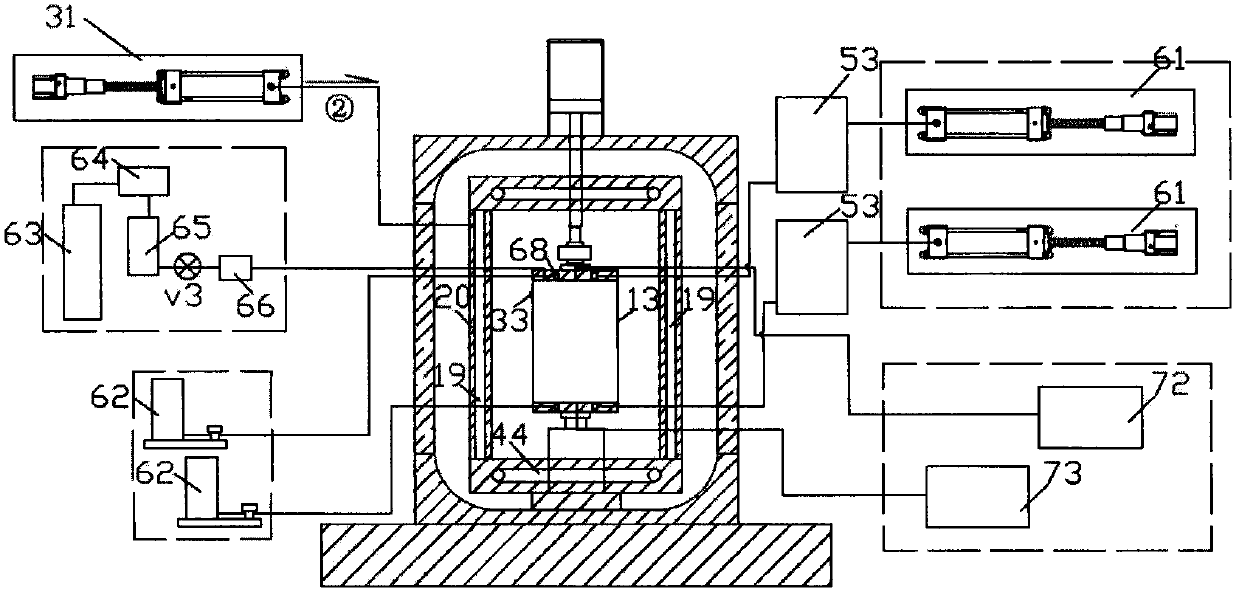

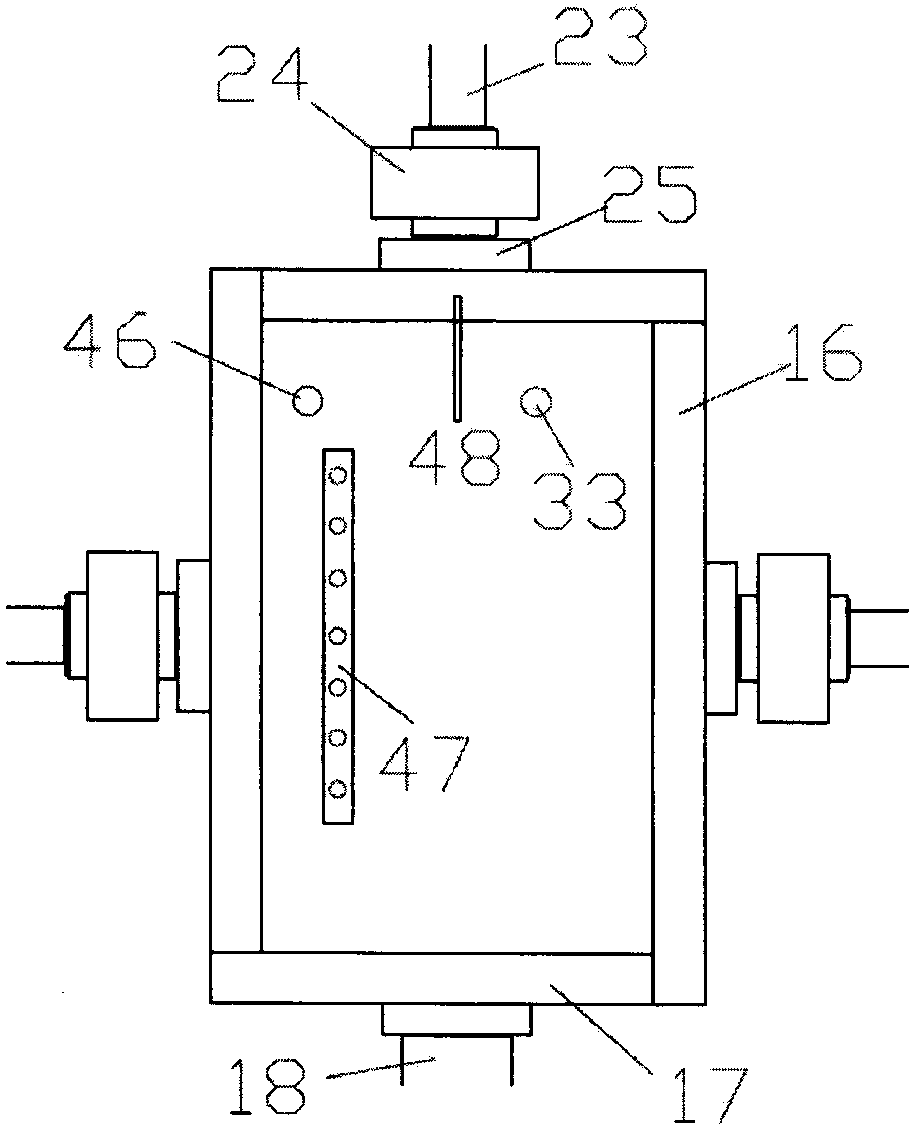

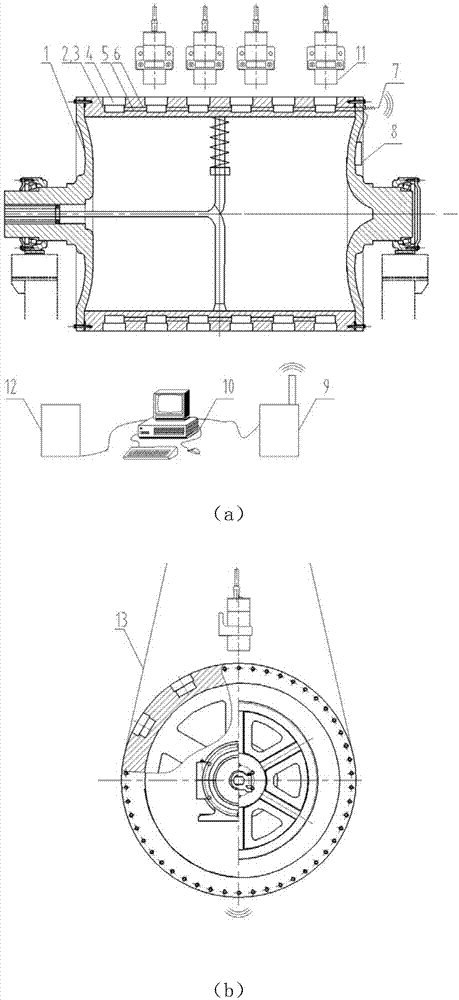

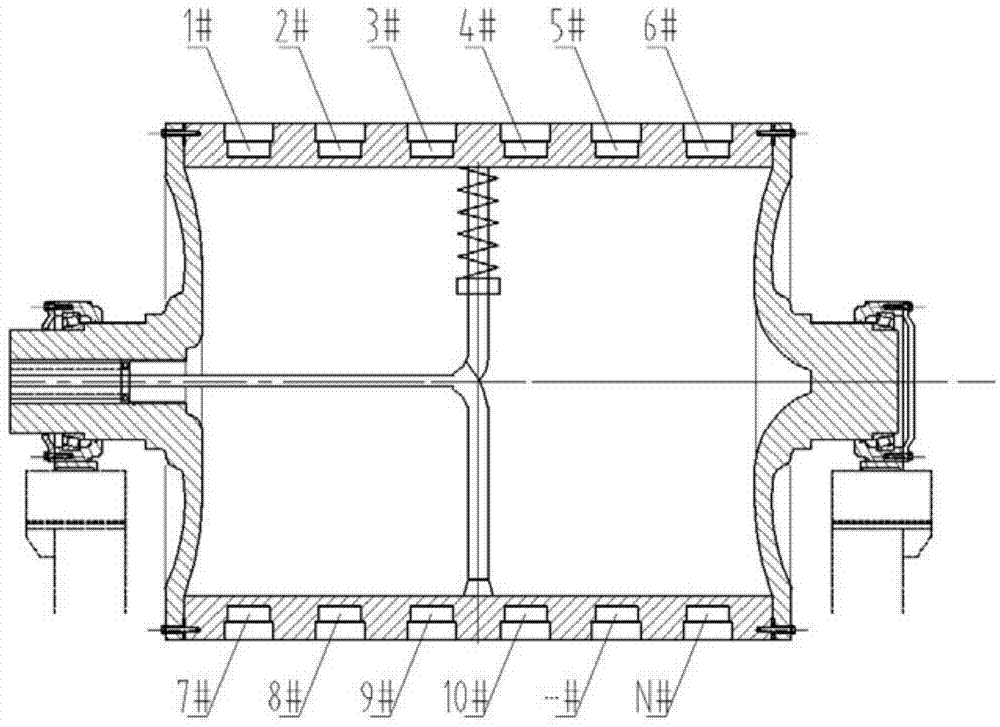

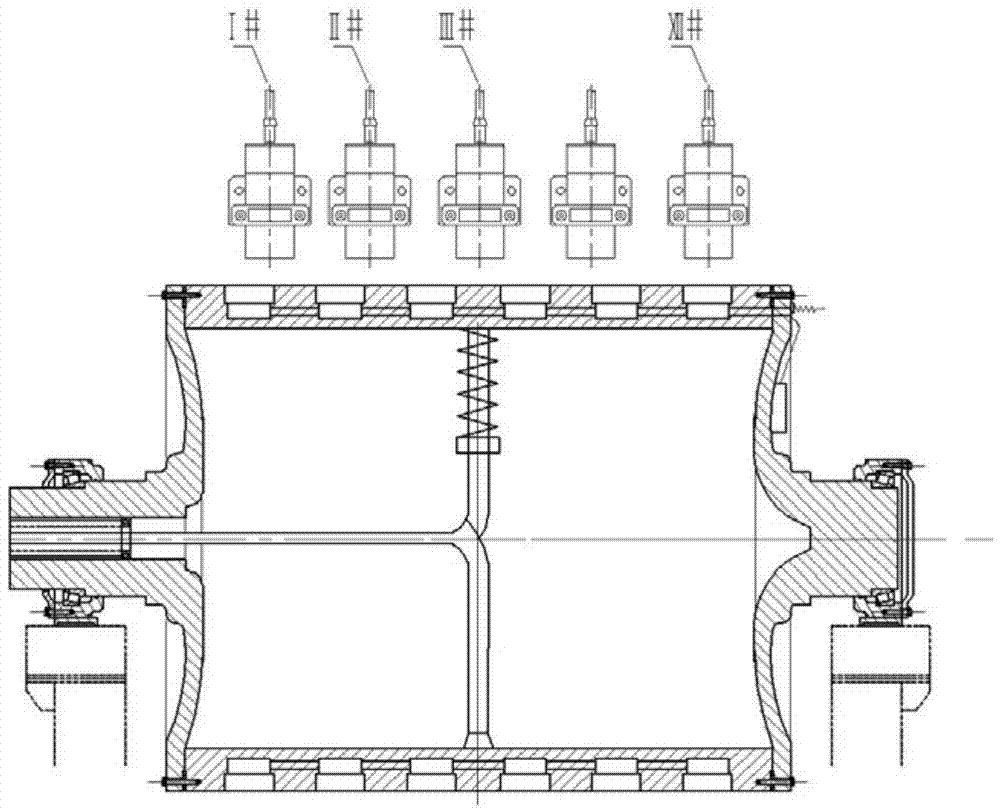

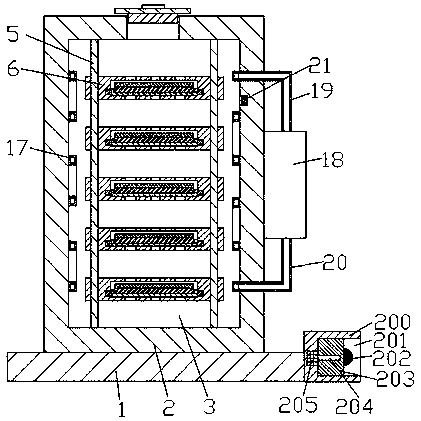

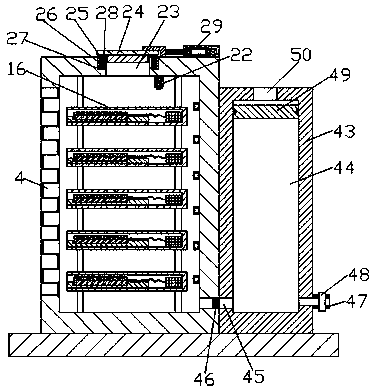

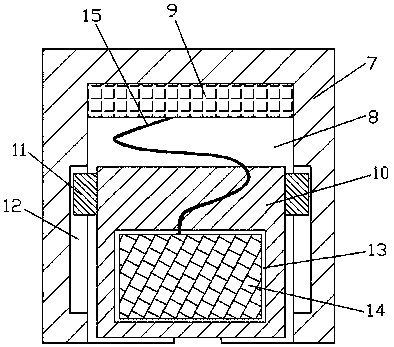

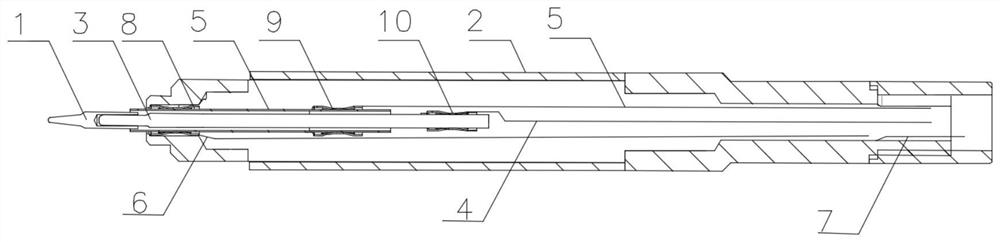

Multi-field coupling true triaxial test system and experiment method implemented by same

ActiveCN107576562AImprove accuracyRealize dockingMaterial strength using tensile/compressive forcesPermeability/surface area analysisDecompositionMulti field

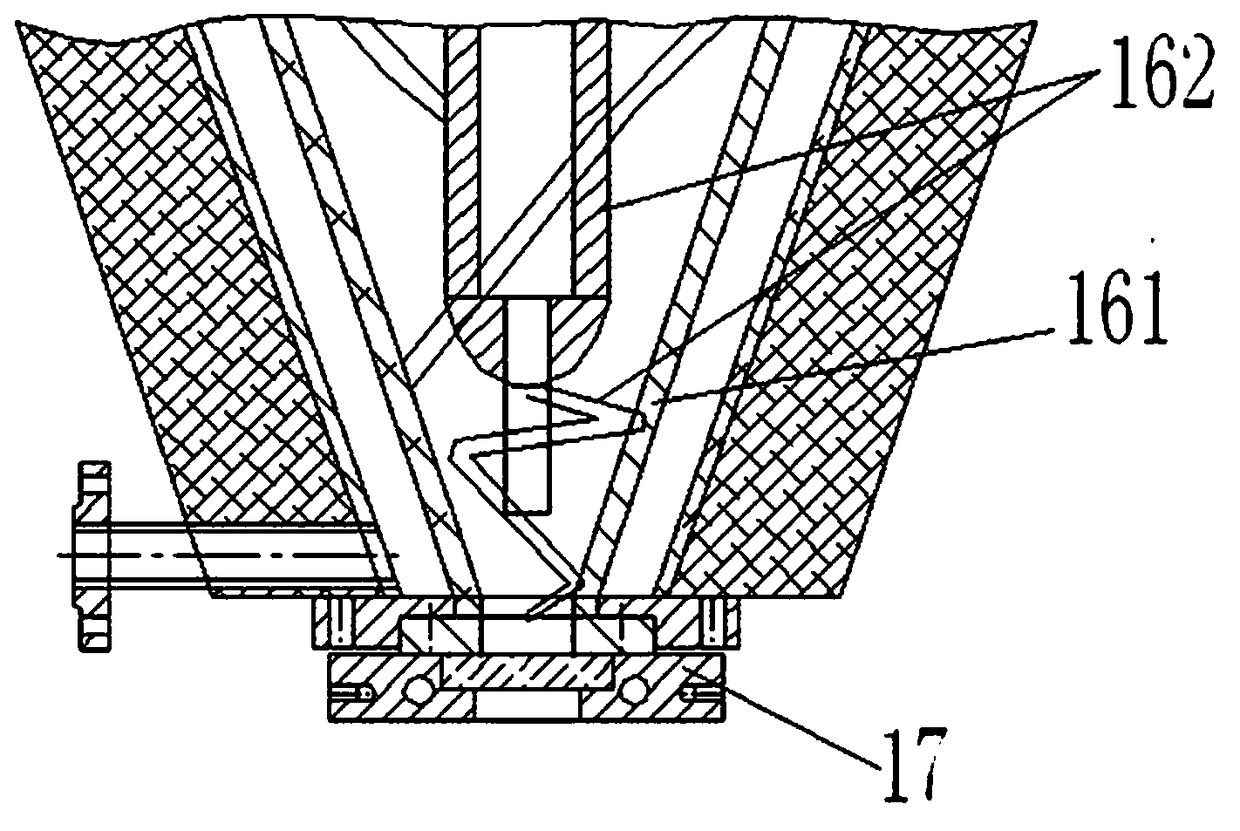

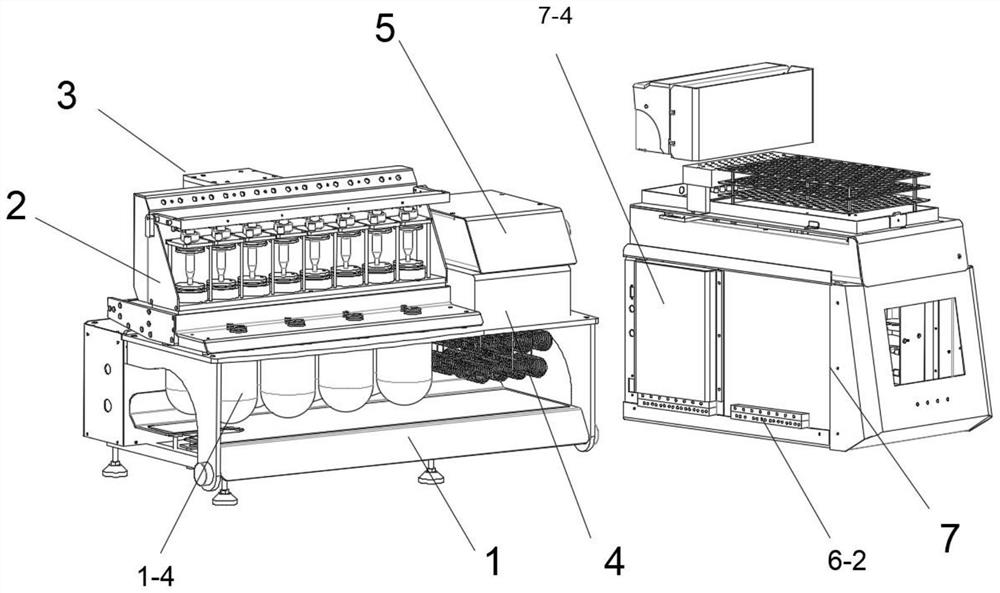

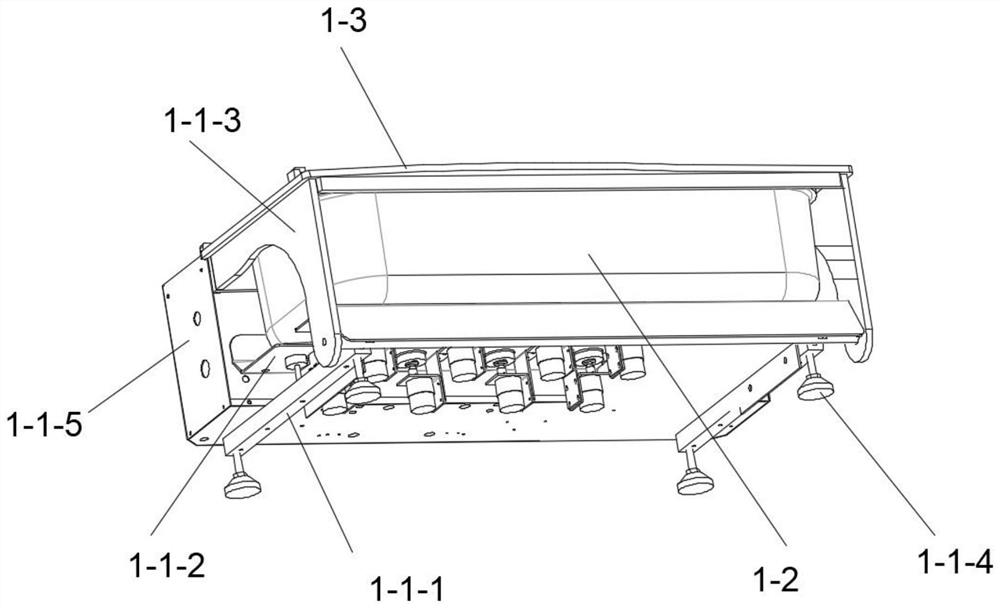

The invention discloses a multi-field coupling true triaxial test system and an experiment method implemented by the same. The multi-field coupling true triaxial test system is characterized by comprising a true triaxial double-cavity pressure chamber (1), an axial loading system (2), a confining pressure / back pressure loading system (3), a temperature control system (4), a permeation control system (5), a gas loading system (6), a bending element experiment system (7) and a computer (8). The multi-field coupling true triaxial test system and the experiment method have the advantages that stress fields and seepage fields are controlled, and accordingly simulation research can be carried out on seepage anisotropy of rock and soil mass; influence of environmental factors on freezing nucleusor frozen soil samples can be simulated under the effects of temperature fields, the seepage fields and the stress fields; research can be carried out on the physical and mechanical properties of unsaturated frozen soil under the effects of the temperature fields and the stress fields; simulation research can be carried out on change of the physical and earth properties of sediments in generationand decomposition procedures of natural hydrates under multi-field coupling conditions, and simulation research can be carried out on mutual displacement effects between hydrate gas in the sediments and underground water; simulation research can be carried out on the physical and mechanical properties of unsaturated soil under the multi-field coupling conditions.

Owner:南京泰克奥科技有限公司

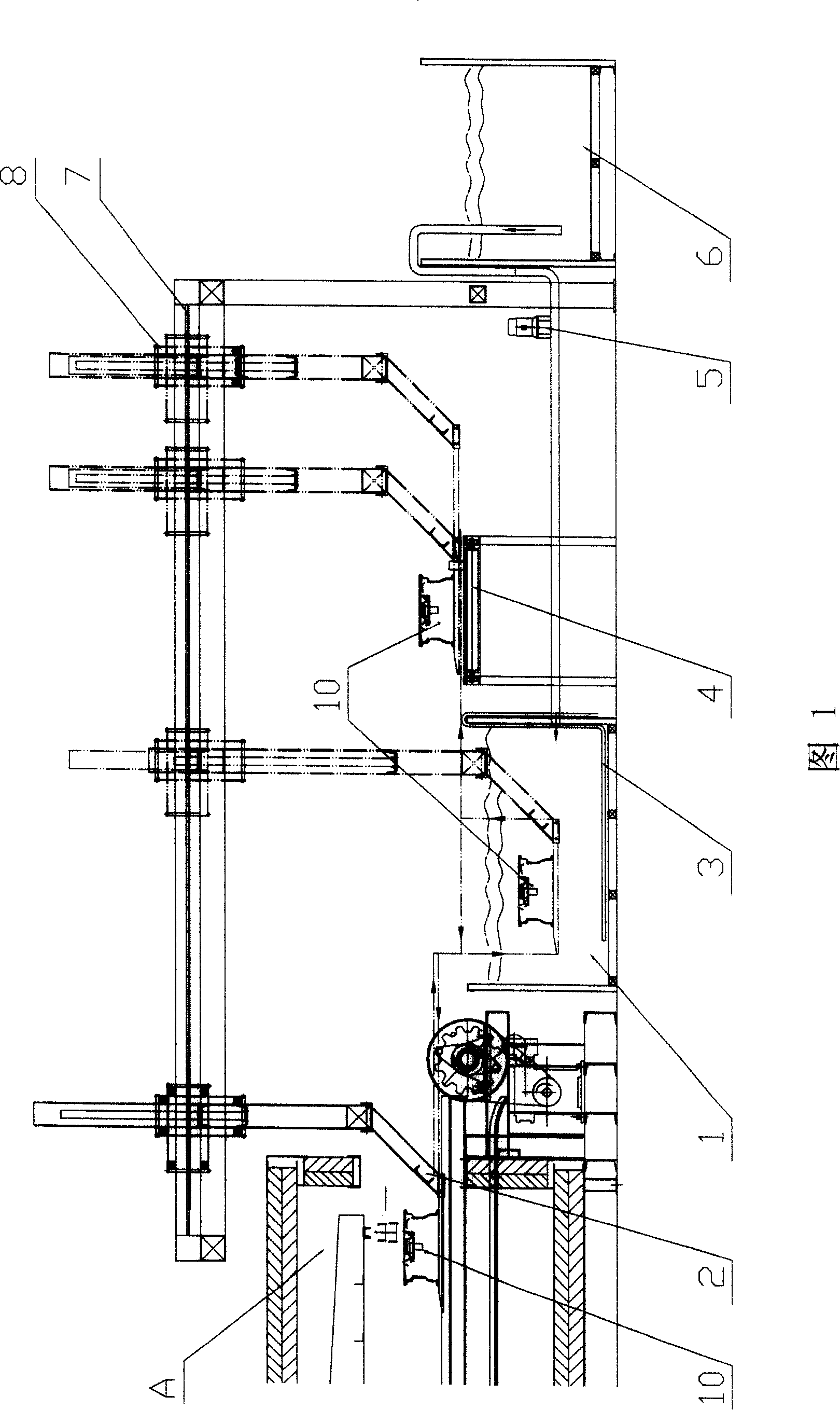

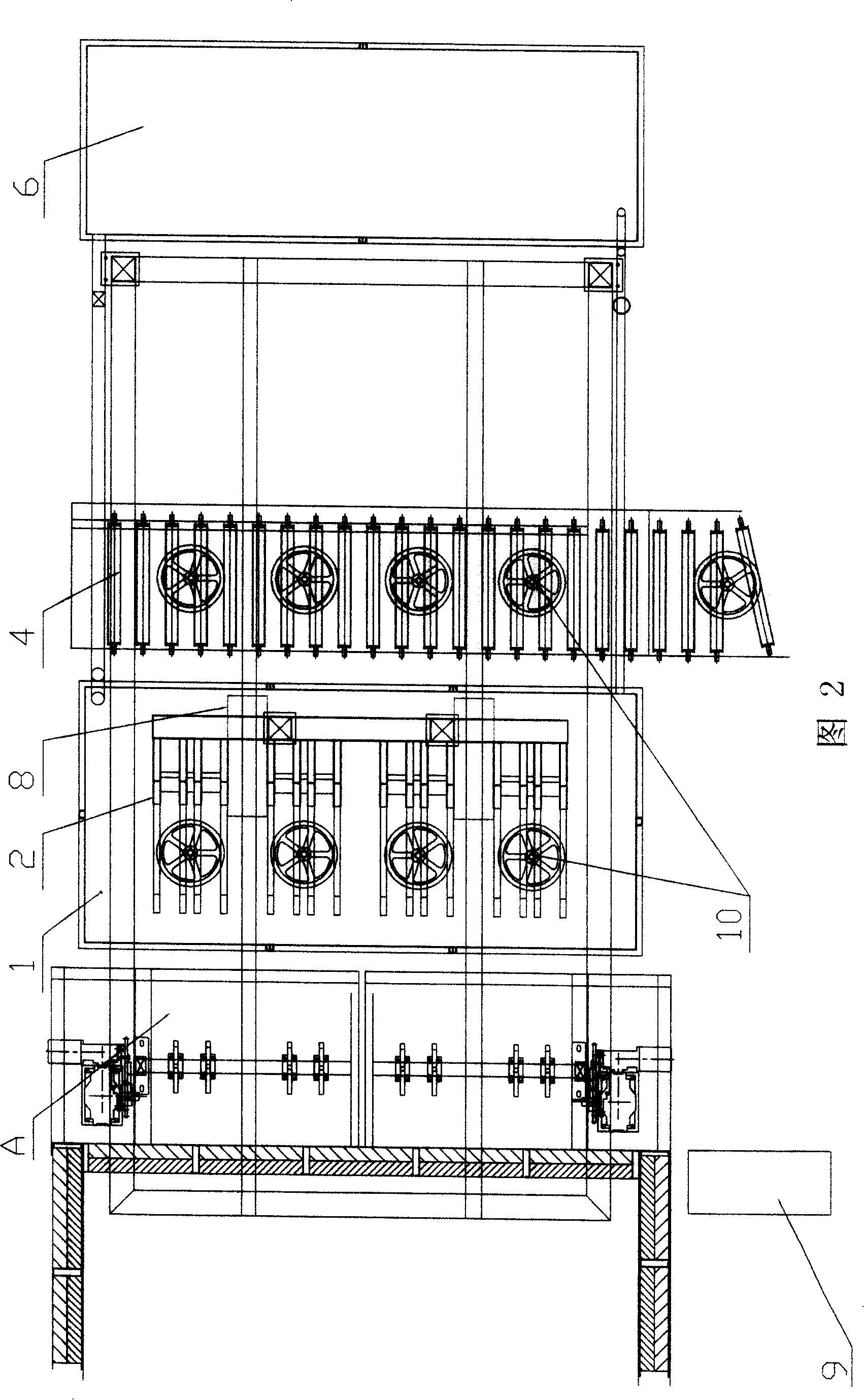

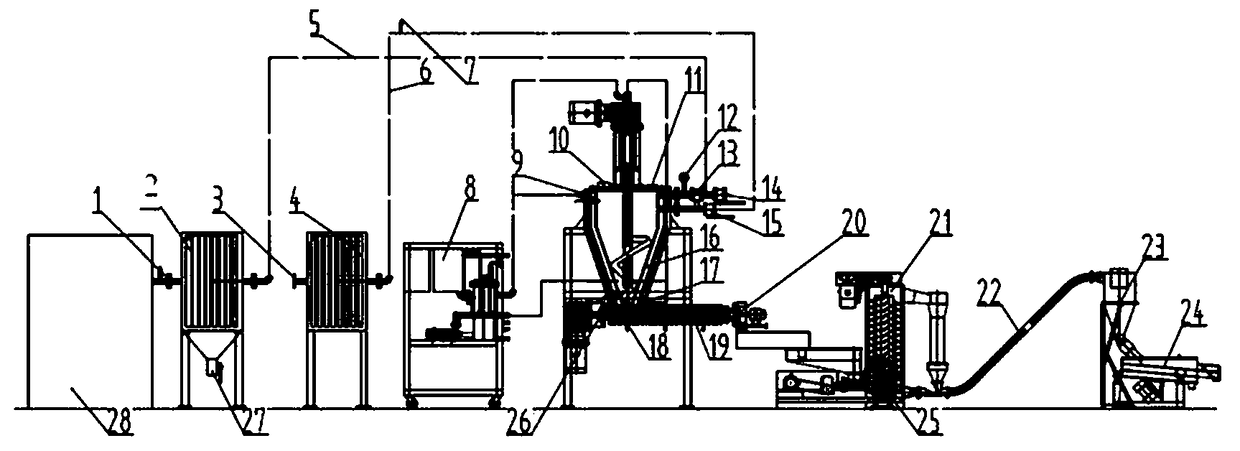

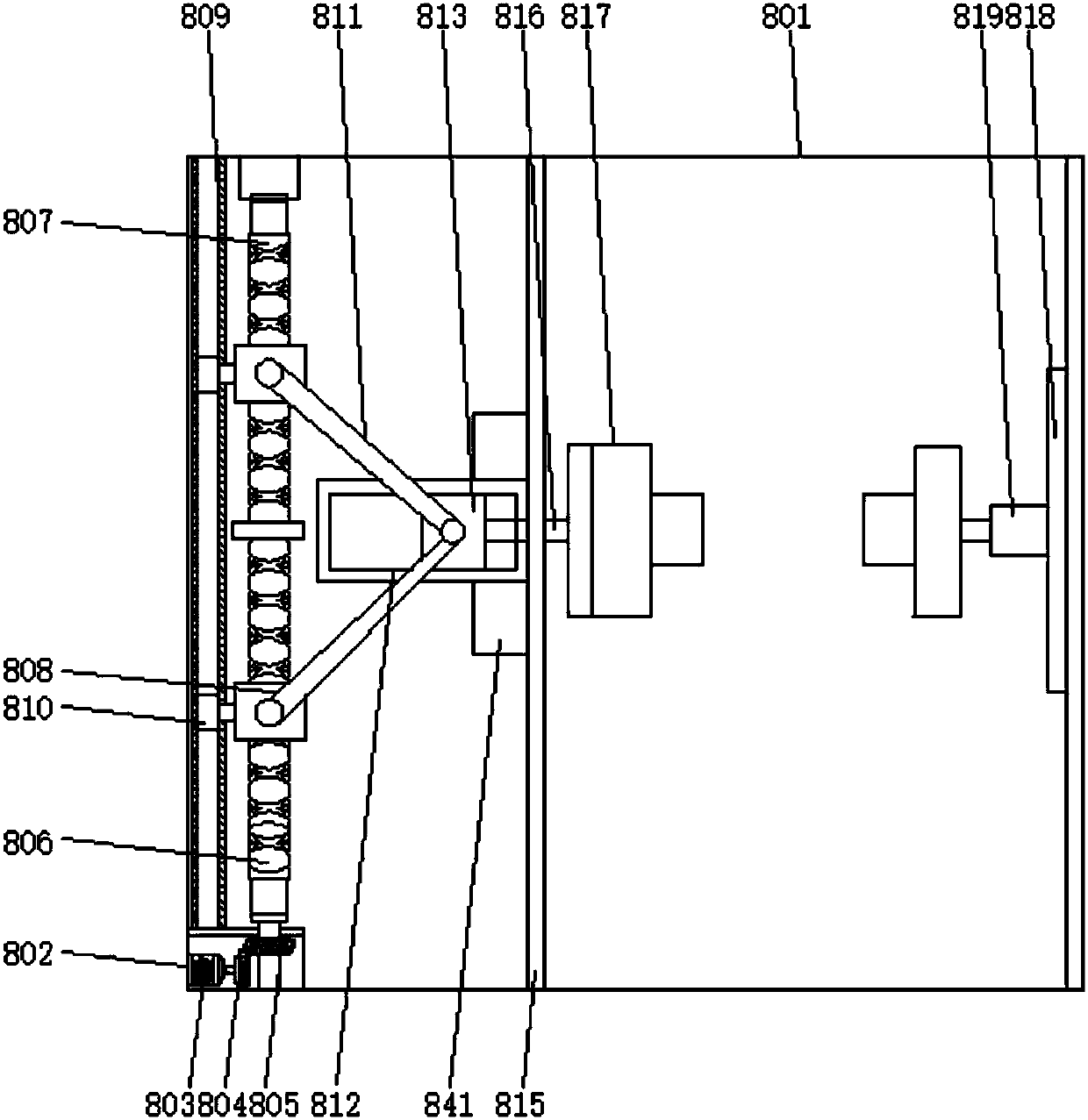

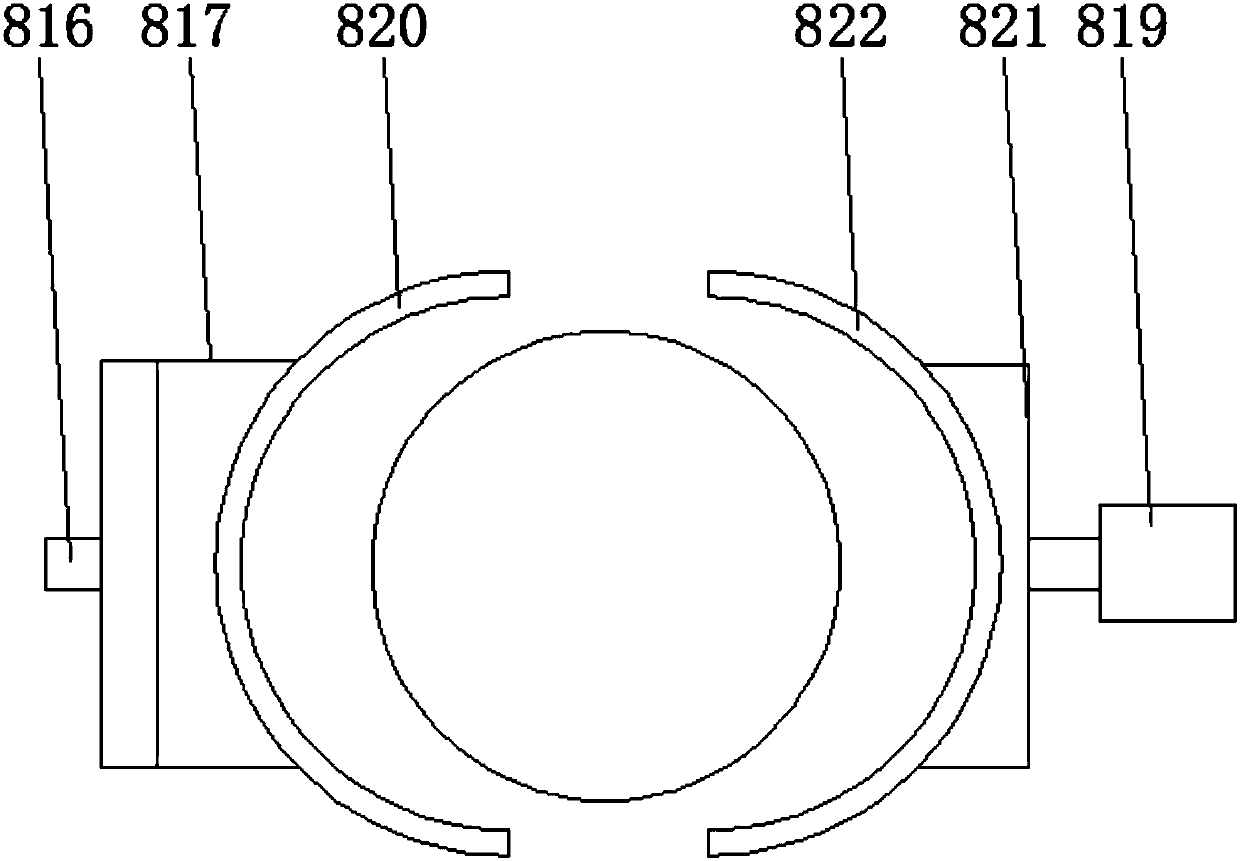

Automobile wheel hub continuous automatic quenching device

InactiveCN101225461AGuaranteed temperature controlFurnace typesHeat treatment process controlSemi automaticManipulator

The invention relates to a continuous automatic quenching device for automobile wheel hubs, which comprises a quenching water tank 1 abutting on a heat treatment furnace, a plurality of fork tines 2 instead of manipulators arranged above the quenching water tank 1, a positioning mechanism 7 and a brake arranged on each fork tine, a water temperature equalizing tube arranged at the bottom of the quenching water tank 1, an automatic discharge roll table 4 arranged close to the upper mouth rim of the quenching water tank 1, and a cooling and circulating water tank 6 provided with a water temperature exchange water pump 5. The continuous automatic quenching device for automobile wheel hubs has the advantages that the defects common in the prior quenching process, such as large workload of manual or semi-automatic operating modes, inability to guarantee the continuousness, stability and accuracy in the quenching of mass products with high quality and requirements, thus providing a continuous automatic quenching device capable of performing precise temperature fixation and timing.

Owner:蒋斐祥

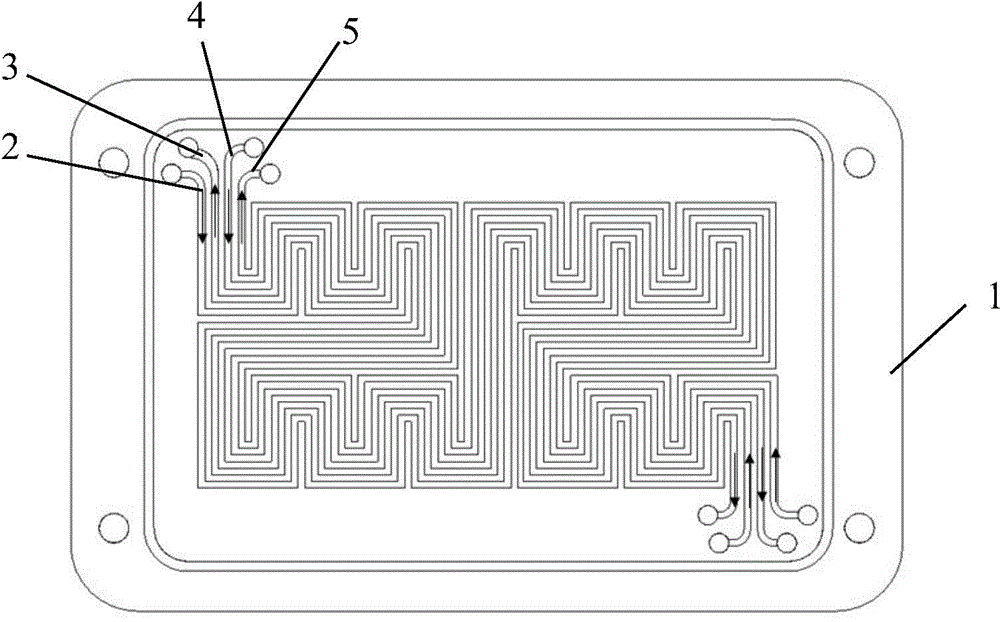

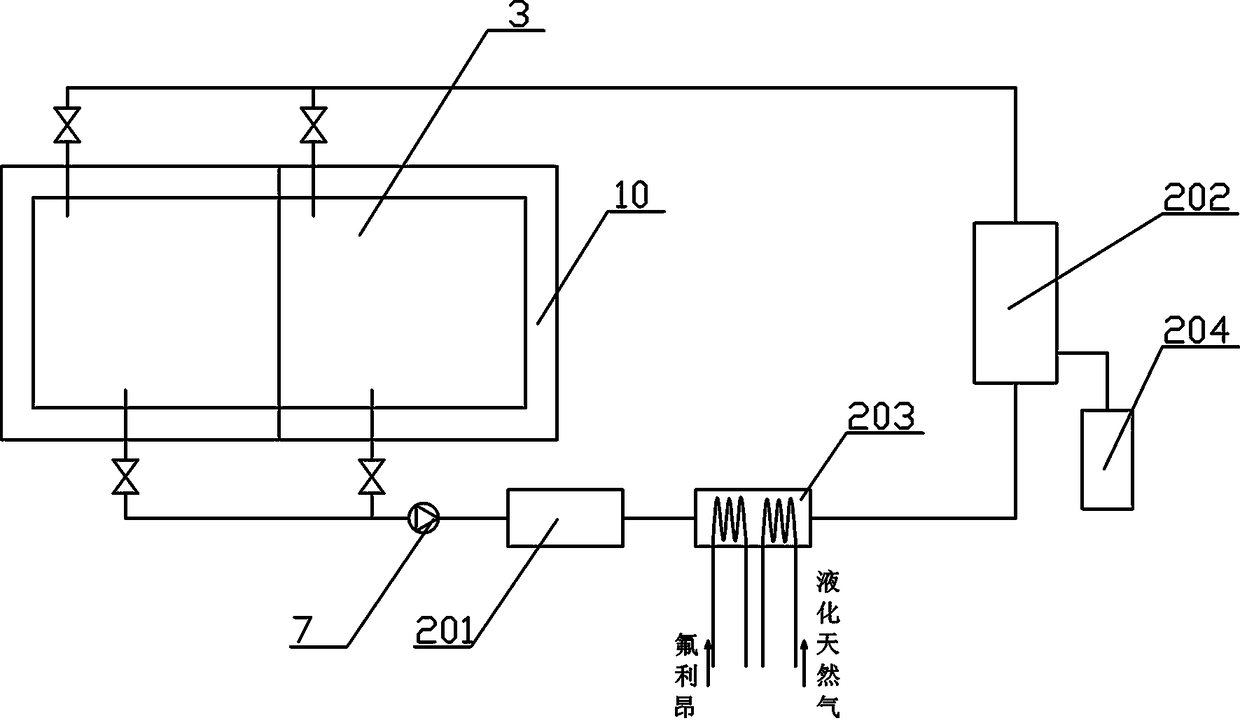

Cooling system with heat transfer enhancement effect and capable of effectively maintaining temperature uniformity of galvanic pile

ActiveCN104538664AImprove heat transfer effectGuaranteed temperature controlFuel cell heat exchangeFinal product manufactureInlet channelFuel cells

The invention discloses a cooling system with a heat transfer enhancement effect and capable of effectively maintaining the temperature uniformity of a galvanic pile. A seal groove is machined on the surface of a cooling plate, and the seal groove, a rubber sealing ring, and a cover plate of the cooling plate are combined so as to form a sealing structure. Cell units are stacked, one side of each cell unit is connected with an upper fixing structure, the other side of the cell unit is connected with a lower fixing structure, the upper fixing structure and the lower fixing structure are fixedly combined by four pairs of symmetrical bolts and nuts so as to jointly form a fuel cell pile. Liquid inlet channels and liquid outlet channels form a crossed layout structure, the liquid inlet channels and the liquid outlet channels are respectively of a bent continuous structure, and the flow directions of cooling liquid in every adjacent liquid inlet channel and liquid outlet channel are opposite. For preventing the occurrence of a situation that the temperature of the cooling plate at the cooling liquid inlet end is too low and the temperature of the cooling plate at the cooling liquid outlet end is too high, the flow directions of cooling liquid in adjacent cooling channels in the cooling plate are arranged oppositely so as to ensure the temperature uniformity of the inside of the cooling plate.

Owner:BEIJING UNIV OF TECH

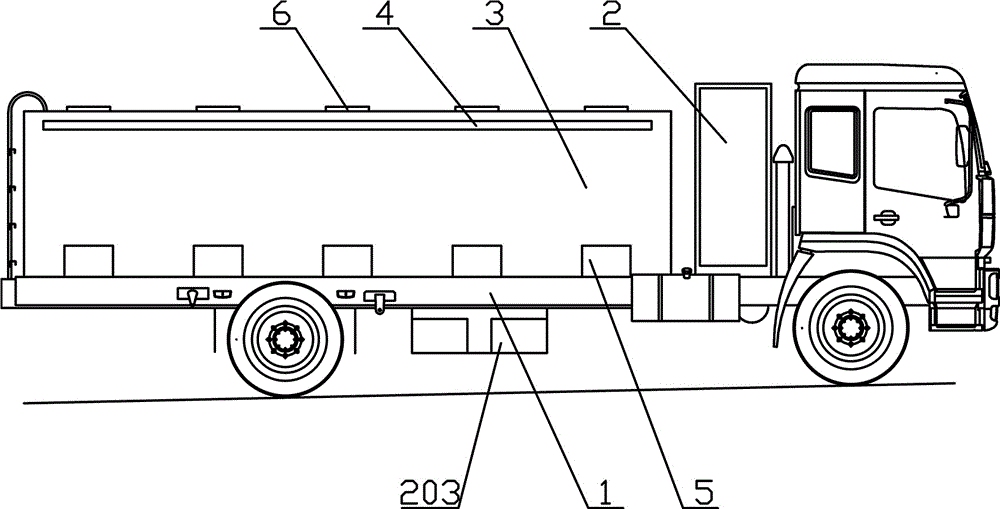

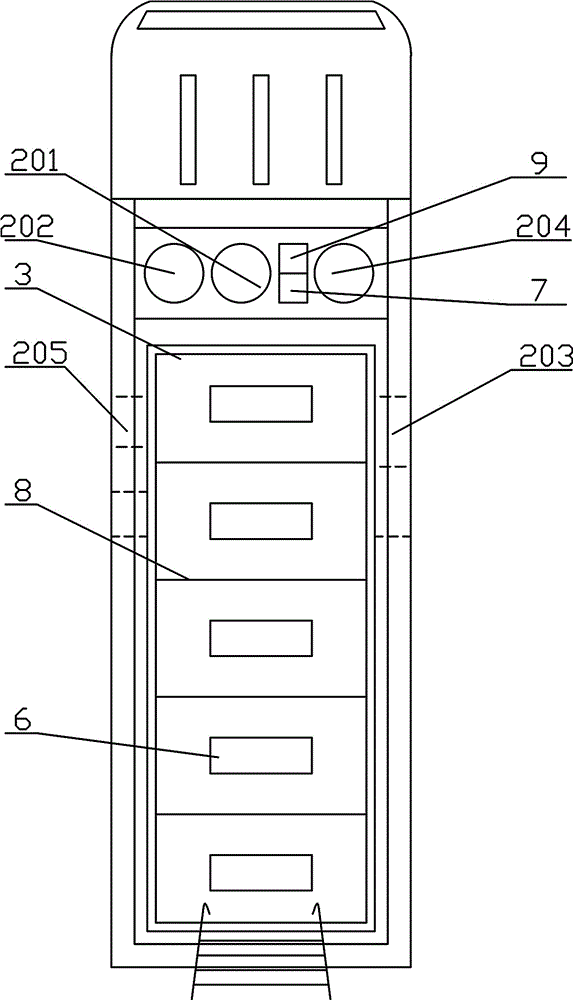

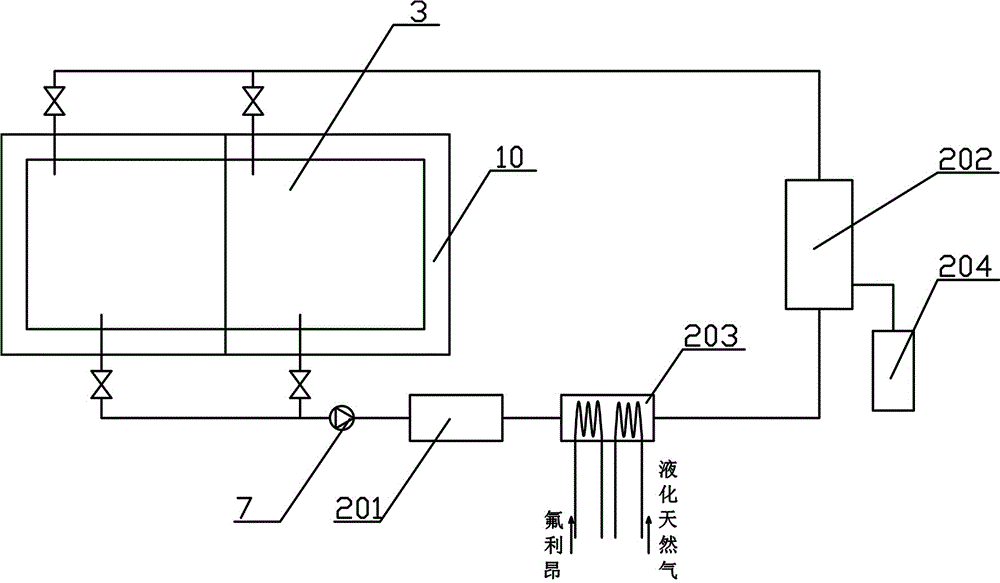

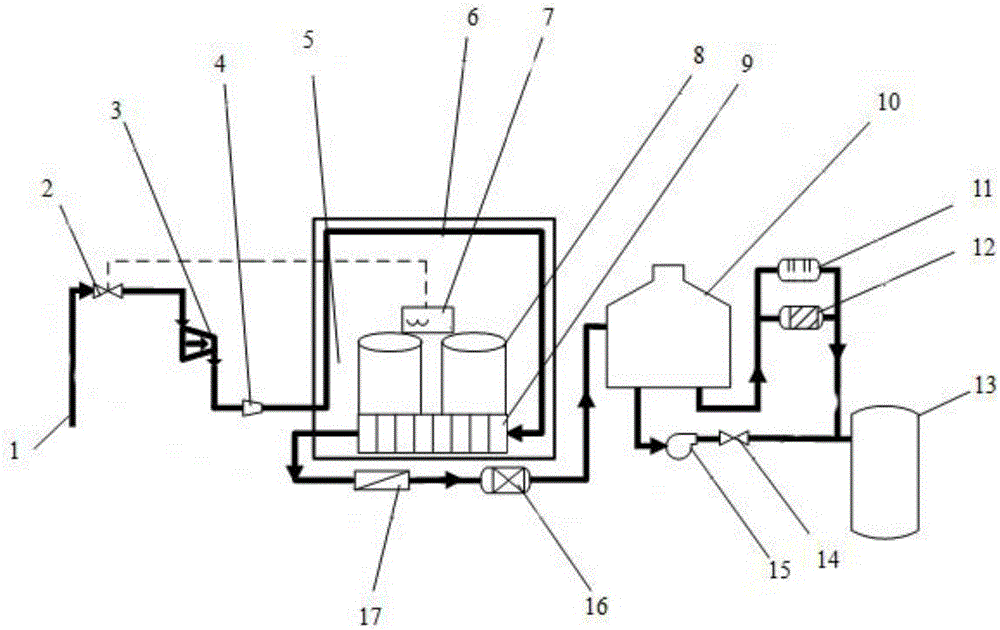

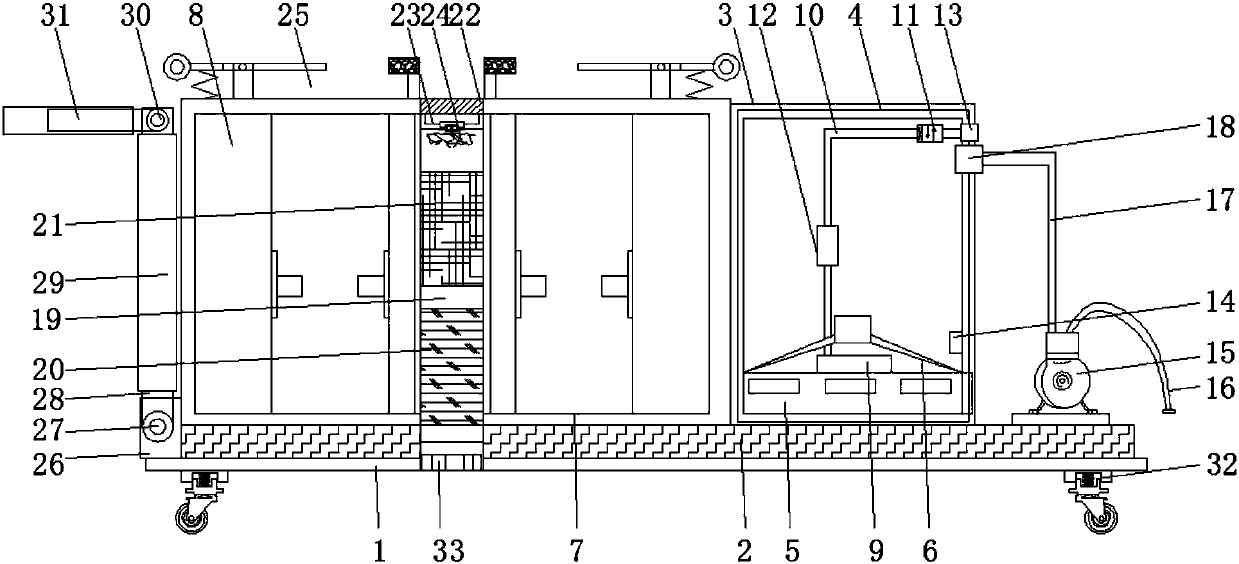

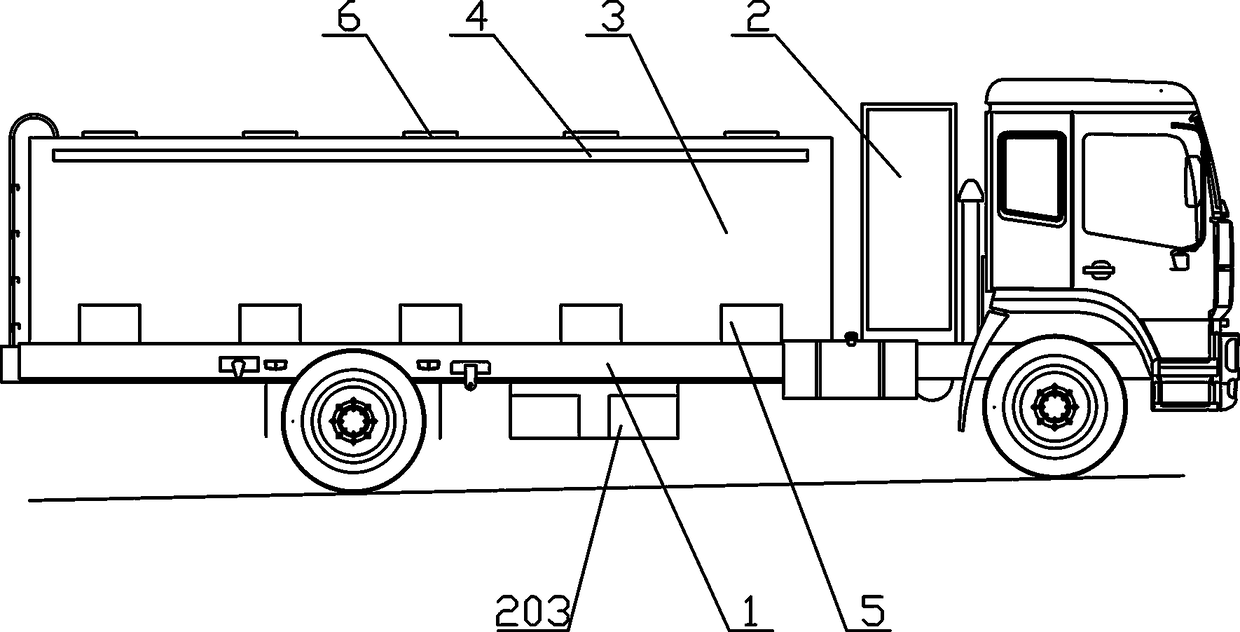

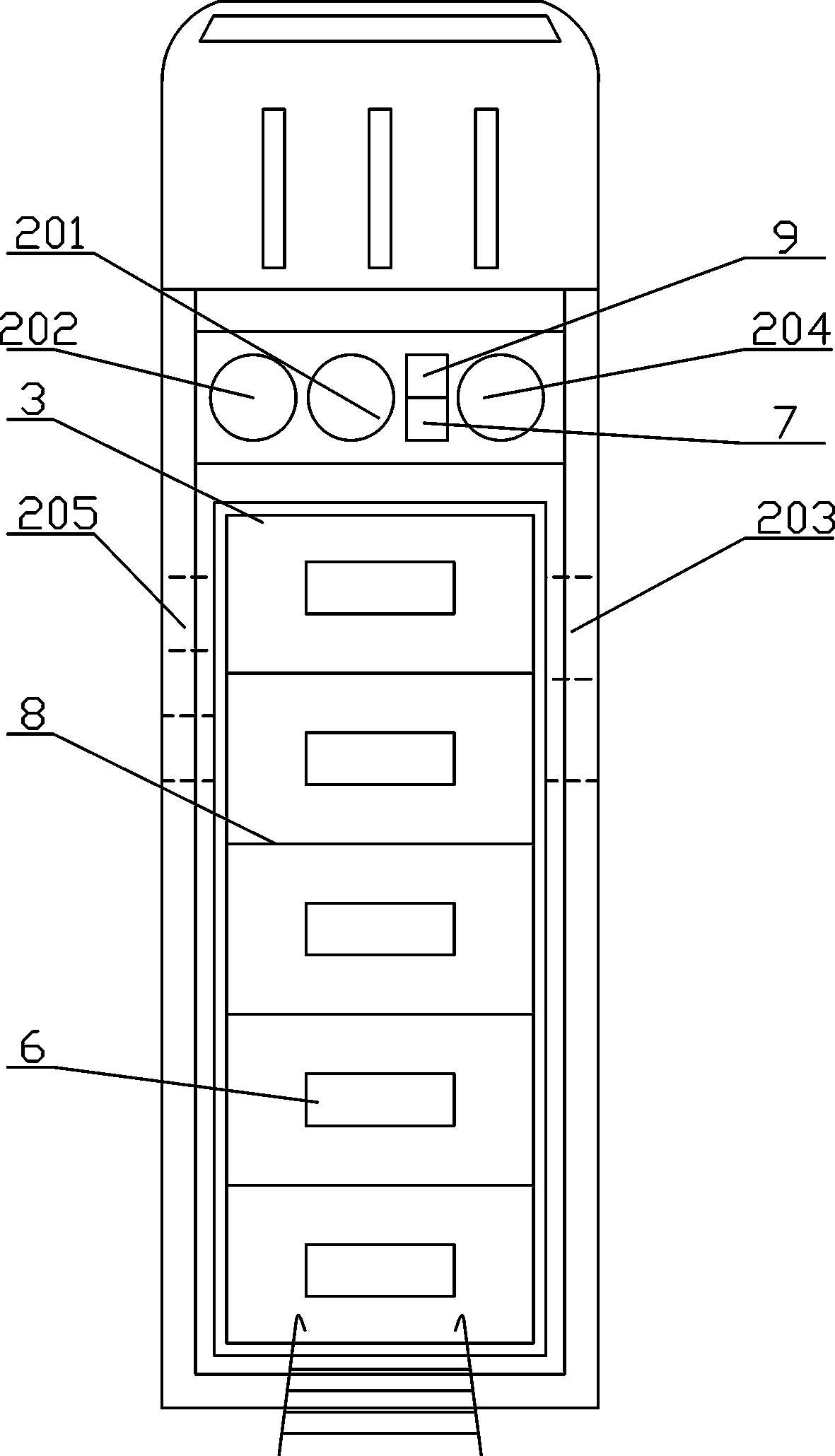

High-density living fish transporting vehicle and transporting method thereof

ActiveCN105660511AWater and oxygen cycle guaranteeGuaranteed oxygen supplyPisciculture and aquariaAnimal transportationRefrigeration compressorAutomatic control

The invention discloses a high-density living fish transporting vehicle and a transporting method thereof. The high-density living fish transporting vehicle comprises a vehicle body, a water oxygen circulation system and a fish tank, wherein the fish tank and the water oxygen circulation system are fixedly arranged on the vehicle body; the fish tank is internally provided with partitions; the outer wall of the fish tank is a sandwiched hollow heat-preservation layer; a fish feeding hole is formed in the top surface of each compartment; a fish discharge hole is formed in a side surface of each compartment; the water oxygen circulation system comprises a filtering device, an oxygen enriching device and a heat exchanger which are serially connected with the fish tank through a water pump, pipelines and valves; water dissolved oxygen and temperature are automatically controlled; the pump and a refrigeration compressor are driven by a vehicle-mounted engine; before being loaded, living fishes are subjected to dormancy pretreatment and water quality conditioning firstly, and circulation, temperature and oxygen dissolution control on a water body are implemented in the transportation process. By adoption of the structure and the method, the temperature inside the fish tank is controlled to be higher than the physiological ice temperature of 0.5-8 DEG C of the living fishes, and the water dissolved oxygen is controlled to be approximate to the physiological oxygen requirement, so that physiological metabolism of the living fishes can be reduced to the minimum level, the living fish transportation time can be prolonged, the survival rate can be increased, and the oxygen consumption can be reduced.

Owner:HUAZHONG AGRI UNIV

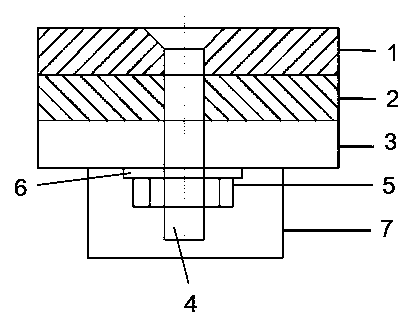

Thermal protection plate

The invention belongs to the technical field of thermal protection systems, and discloses a thermal protection plate. The thermal protection plate sequentially comprises a cover plate, a heat insulation layer and an inner panel from outside to inside, a bolt is arranged in the direction from the cover plate to the inner panel in a penetrating mode, and the tail end of the bolt extends out of the inner wall of the inner panel and is fixed through a nut; an aerogel heat shield is arranged on the periphery of the positions, where the bolt and the nut are located, of the inner wall of the inner panel; the cover plate is a carbon fiber reinforced ceramic based composite material cover plate; the heat insulation layer is an aerogel felt layer; the inner panel is a resin-based composite materialinner panel; the bolt is a carbon fiber reinforced ceramic based composite material bolt, and the nut is a carbon fiber reinforced ceramic matrix composite material nut. The thermal protection plate is excellent in performance and can meet the requirement that the surface temperature of an aircraft is within the range of 900 DEG C or below.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Wireless detection system for papermaking machine dryer surface temperature

ActiveCN104264524AGuaranteed temperature controlSolve the problem of damaging the surface finish of the drying cylinderDryer sectionRadio frequency signalWireless data

The invention discloses a wireless detection system for papermaking machine dryer surface temperature. The wireless detection system comprises a plurality of wireless temperature sensors, a radio frequency antenna, a wireless data receiver and an industrial personal computer, the wireless temperature sensors are embedded into a working wall of a dryer, a radio frequency signal wire is connected between every two wireless temperature sensors, an output end of each radio frequency signal wire is connected with the radio frequency antenna, the radio frequency antenna is mounted on the side wall of the dryer and transmits temperature data to the wireless data receiver, the wireless data receiver is connected with the industrial personal computer through a communication cable, the wireless temperature sensors transmit the temperature data on the wall of the dryer to the wireless data receiver, the wireless data receiver transmits the received temperature data to the industrial personal computer, the detected data are read by the industrial personal computer, and real-time online measurement of the dryer surface temperature is realized.

Owner:SHAANXI UNIV OF SCI & TECH

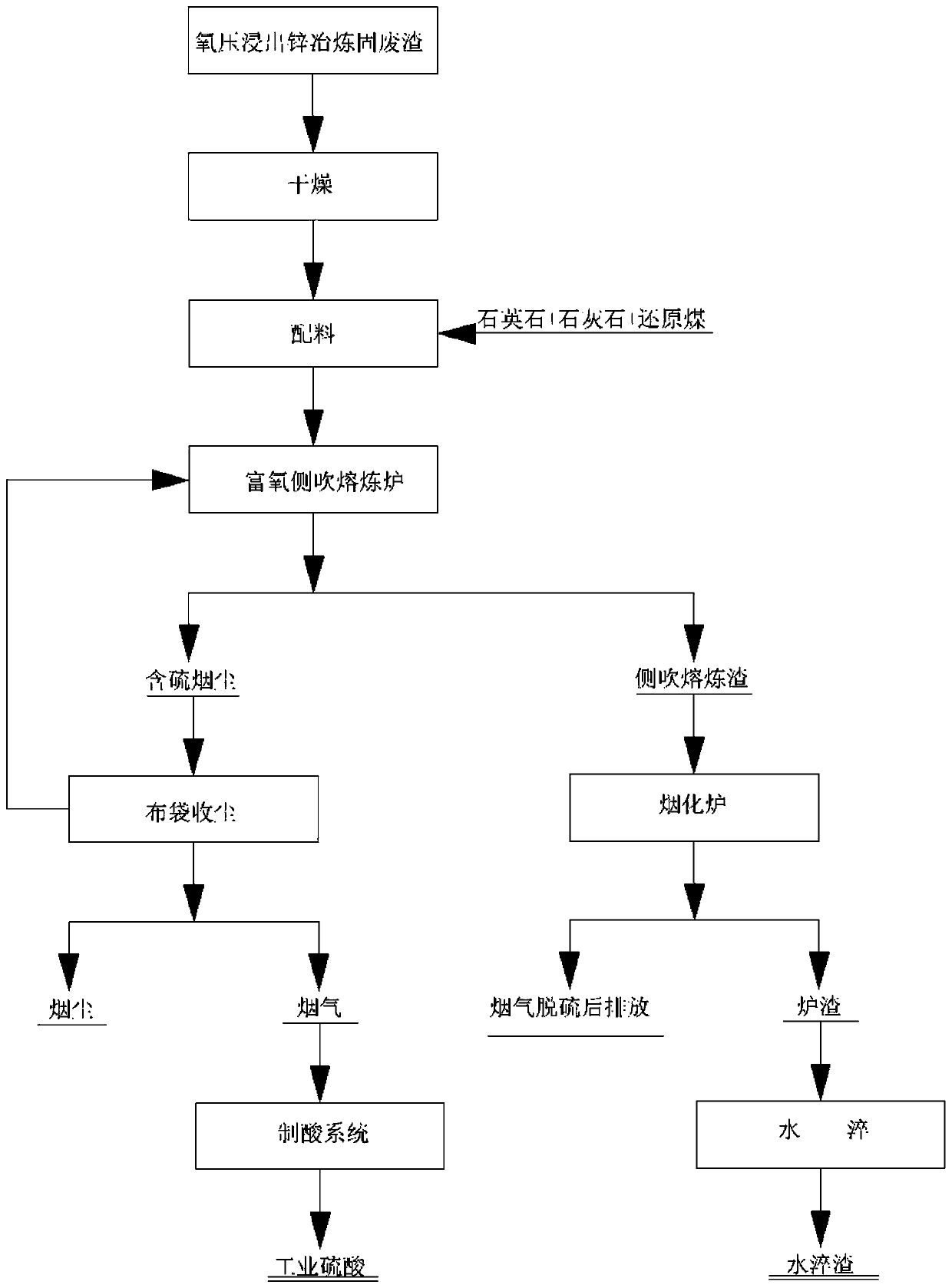

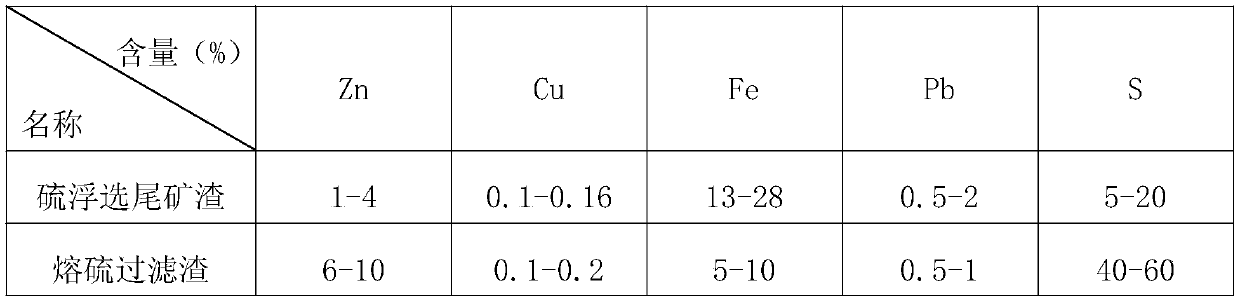

Method for preparing secondary zinc oxide from oxygen pressure leached zinc smelting solid waste residues

InactiveCN111118303ASolve problems such as intractableReduce energy consumptionProcess efficiency improvementIndiumChemical reaction

The invention discloses a method for preparing secondary zinc oxide from oxygen pressure leached zinc smelting solid waste residues. The method comprises the following steps that oxygen pressure leached zinc smelting solid waste residues are dried until the water content is 15% or below, and the solid waste residues are granulated by using a granulator; the solid waste residues are mixed with limestone, quartz stone and reducing coal, and are sent to an oxygen-enriched side-blown furnace; oxygen-enriched air is blown into a furnace during smelting, and chemical reactions such as sulfur makingand slagging are completed; sulfur in the slag generates SO2, and the SO2 enters an acid making system through a flue gas pipeline to produce industrial sulfuric acid; the molten slag is blown by a fuming furnace, secondary zinc oxide products are produced from smoke dust, and the fuming furnace slag is subjected to innocent treatment. According to the method, the problems that the smelting solidwaste produced in the zinc-oxygen pressure leaching process is difficult to stack and transport, valuable metal in the leaching residues cannot be recycled and the like are solved, and harmless treatment of the zinc-oxygen pressure leaching smelting solid waste is achieved. The method has the advantages that valuable metals such as lead, zinc, indium, germanium and silver can be recovered, industrial-grade secondary zinc oxide products can be prepared, the technological process is simple, the recovery rate of the valuable metals is high, and the energy consumption is low.

Owner:WESTERN MINING CO LTD +3

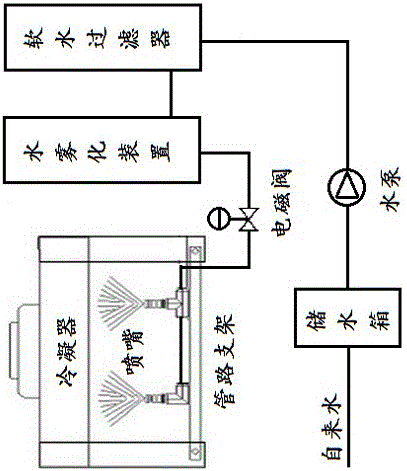

Spray cooling system for condensers of air conditioners of machine rooms

InactiveCN106403398ASolve the problem of high temperature coolingImprove energy efficiencyEvaporators/condensersTrickle coolersElectricitySolenoid valve

The invention discloses a spray cooling system for condensers of air conditioners of machine rooms. The system comprises a water storage tank, a water pump, a water atomization device, a soft water filter, a solenoid valve and nozzles, wherein water in the water storage tank enters the soft water filter through the water pump and is softened and filtered in the soft water filter, and the softened and filtered water is sprayed on air suction sides of the condensers from the nozzles through the solenoid valve after atomized by the water atomization device to cool the condensers of the air conditioners of the machine rooms. The system is simple in design and practical, realizes high-temperature cooling of the condensers of outdoor air cooling machines of data centers and improves the energy efficiency of refrigerating systems. Water mist is used for cooling the condensers of air-conditioning systems, the power loads of the air conditioners can be lowered, the refrigerating capacity can be improved, the electricity can be saved on the premise of guaranteeing the refrigerating capacity of the air conditioners, the temperature of air outlets of the air conditioners can be lowered, and therefore the energy can be saved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

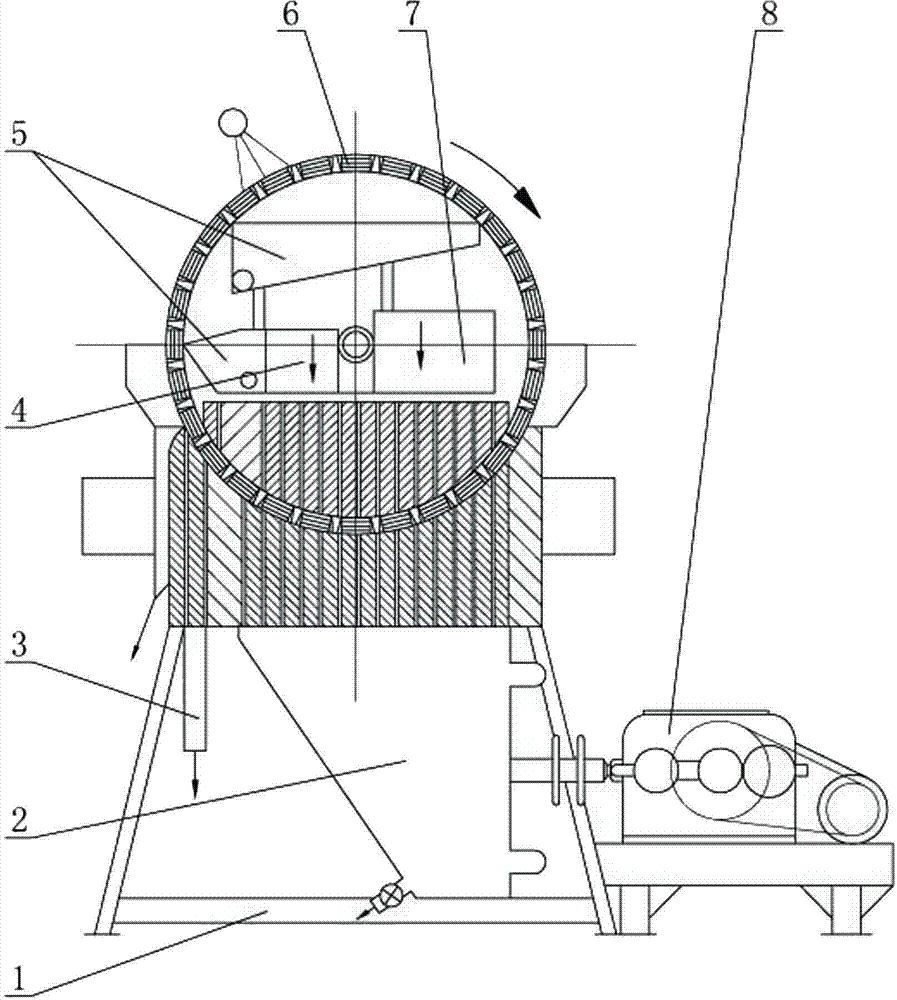

Water-cooled pulse-vibrating vertical ring high-gradient magnetic separator

InactiveCN102728462ALong term workStable jobHigh gradient magnetic separatorsRinse waterMagnetic separator

The invention relates to a water-cooled pulse-vibrating vertical ring high-gradient magnetic separator, which comprises a supporting steel frame, an electromagnet and a magnetic swivel, wherein a tailing hopper and a drainage hopper are arranged below the electromagnet, one side of the tailing hopper is connected with an electric pulse-vibrating mechanism and an ore feeding hopper, a rinsing water hopper, a concentrate hopper and a swivel driving mechanism are arranged above the electromagnet. The magnetic swivel is arranged on the swivel driving mechanism and driven by the swivel driving mechanism to absorb the magnetic concentrate in the working magnetic field, and a concentrate washing device is also arranged on the upper part of the magnetic swivel. The electromagnet is of a C-shaped varied electromagnet encircled by a magnetic yoke and one or at least two sets of water-cooled coils. The water-cooled coils comprise a shell body, a coil winding, a cooling agent and a cooling water container, wherein cooling water capable of absorbing the heat of the cooling agent is arranged in the cooling water container. The water-cooled pulse-vibrating vertical ring high-gradient magnetic separator can be used for the combination of magnetic distribution modes and coil winding modes of various different types, and the special coil water-cooled mode enables the power consumption of the electromagnet to be decreased and the working magnetic field to be increased.

Owner:岳阳鸿升电磁科技有限公司

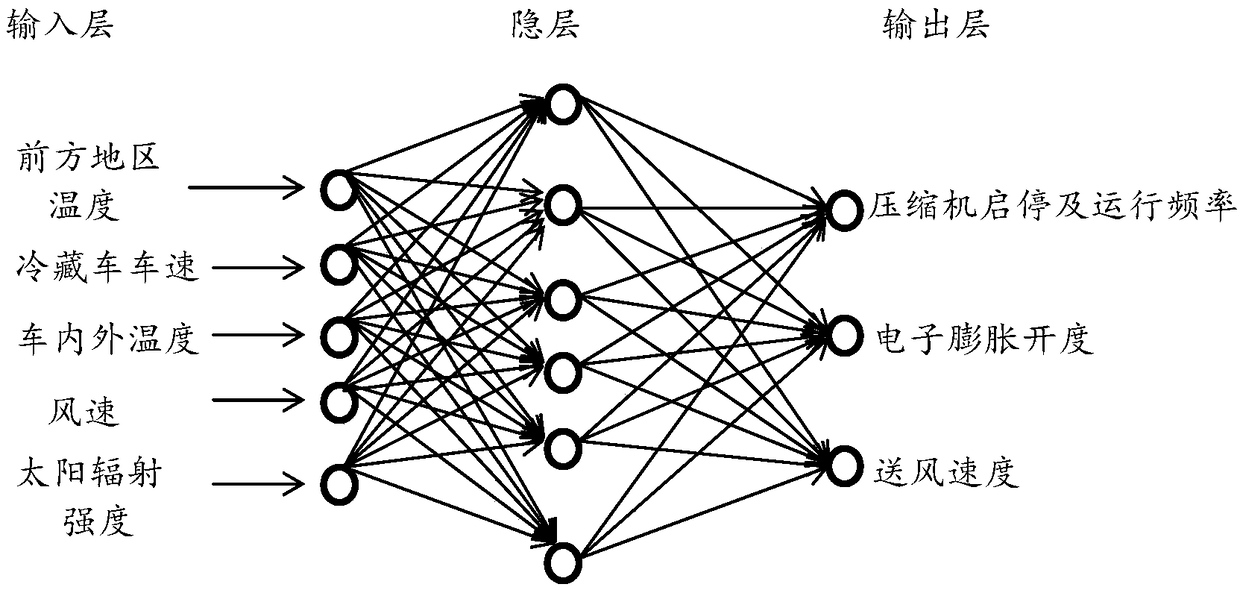

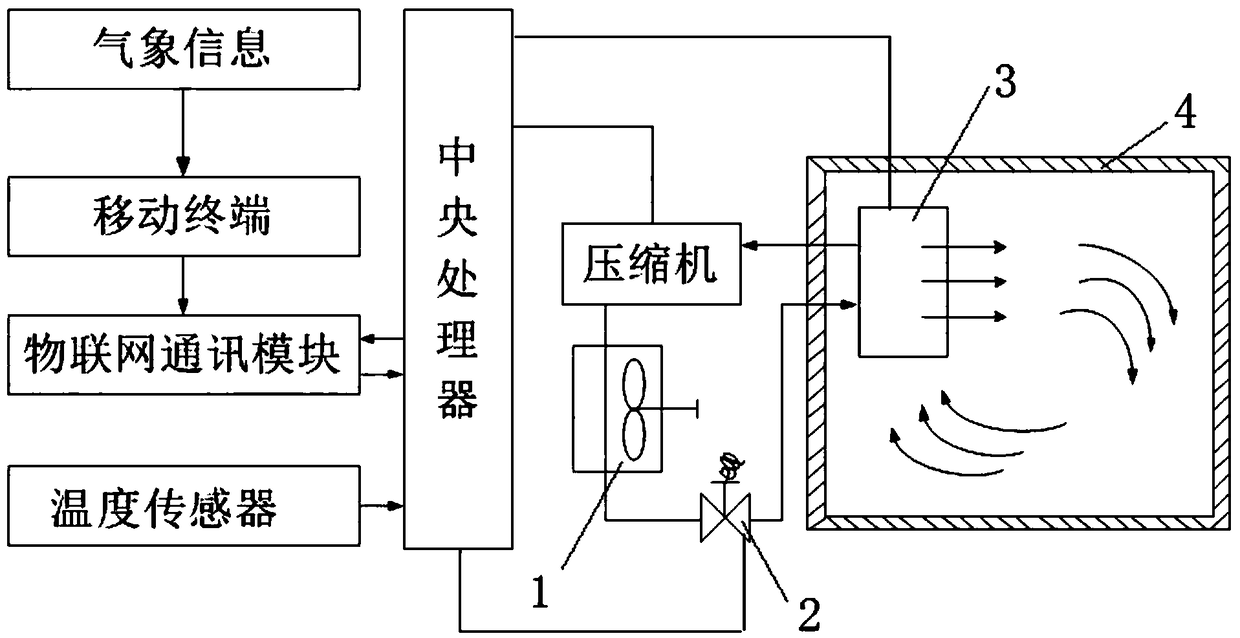

Intelligent temperature-controlled refrigerated vehicle based on real-time weather information

InactiveCN108773315AReduce energy lossGuaranteed temperature controlAir-treating devicesRefrigerated goods vehicleTime informationTemperature control

The invention discloses an intelligent temperature-controlled refrigerated vehicle based on real-time weather information. The intelligent temperature-controlled refrigerated vehicle based on real-time weather information comprises a weather information obtaining system, a temperature monitoring system and a central processor, wherein the weather information obtaining system is used for obtainingthe real-time weather information of a location in a refrigerated vehicle running line; the temperature monitoring system is used for monitoring environment temperatures inside and outside a compartment of the refrigerated vehicle in real time; the central processor is used for intelligently controlling a working state of a refrigerating system of the refrigerated vehicle by using a neural networkalgorithm according to the received real-time weather information, the environment temperatures inside and outside the compartment and a vehicle speed so as to intelligently adjust the temperature inthe compartment of the refrigerated vehicle. According to the intelligent temperature-controlled refrigerated vehicle based on the real-time weather information, the working condition of the refrigerating system can be adjusted according to a local weather condition in the running line, a lot of energy loss caused by unnecessary operation of the refrigerating system can be reduced, and the intelligent temperature-controlled refrigerated vehicle based on the real-time weather information is more energy-saving and environmentally friendly while high-accuracy temperature control is guaranteed.

Owner:TIANJIN UNIV OF COMMERCE

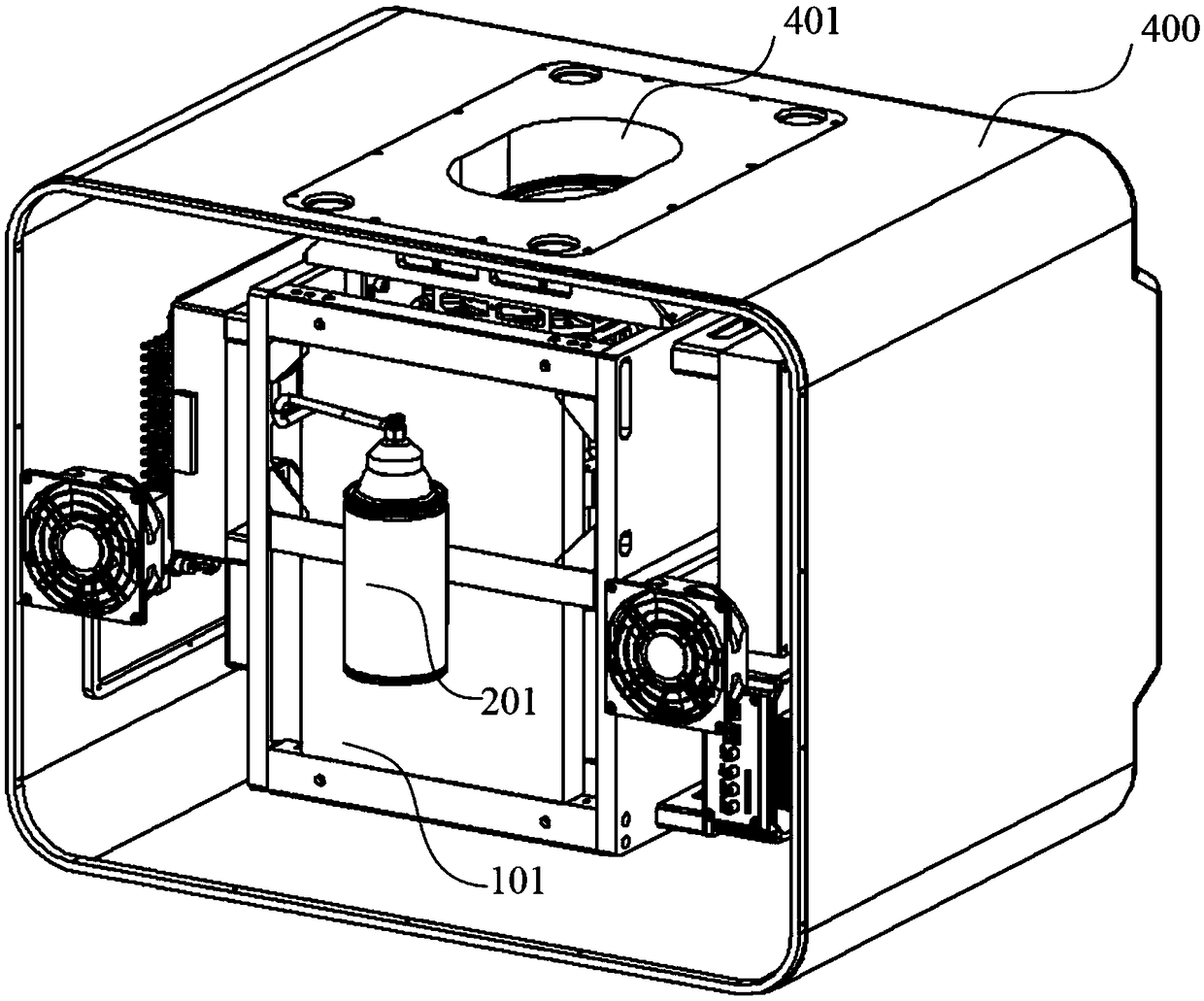

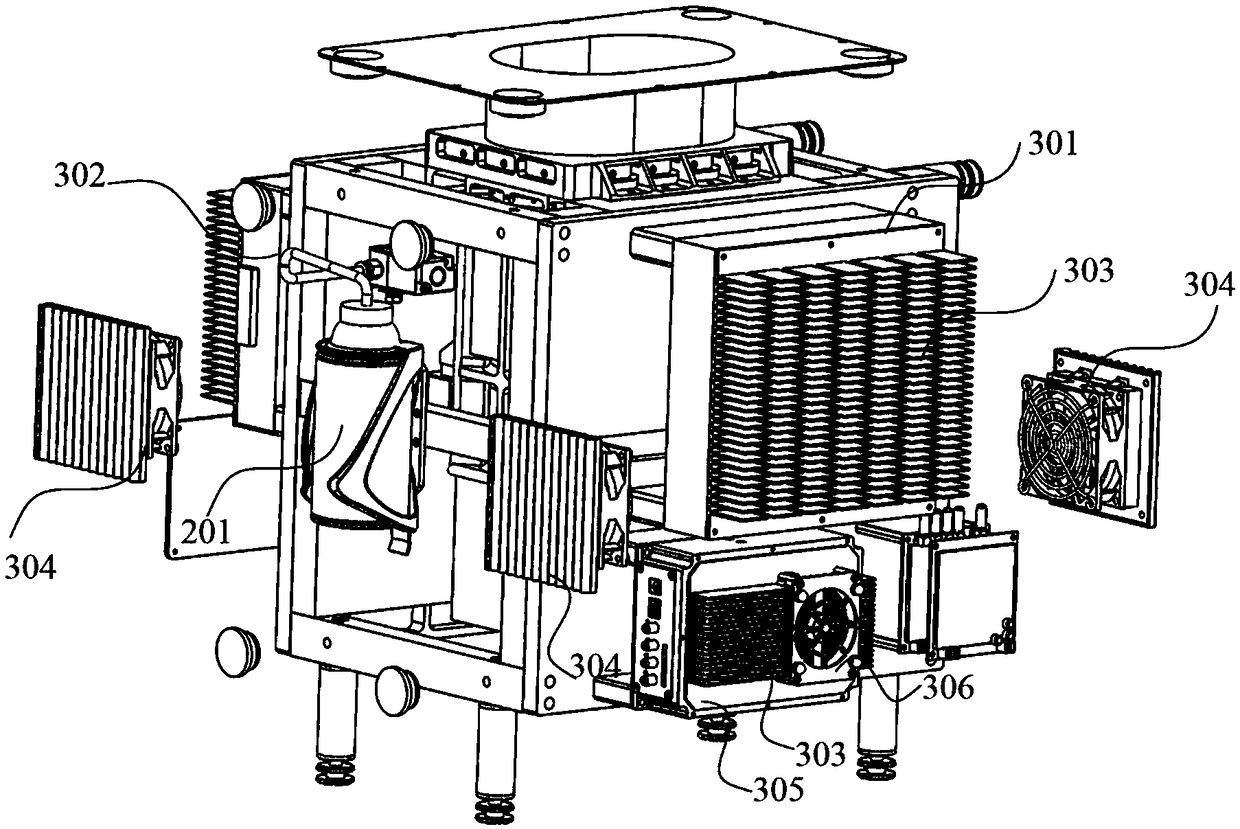

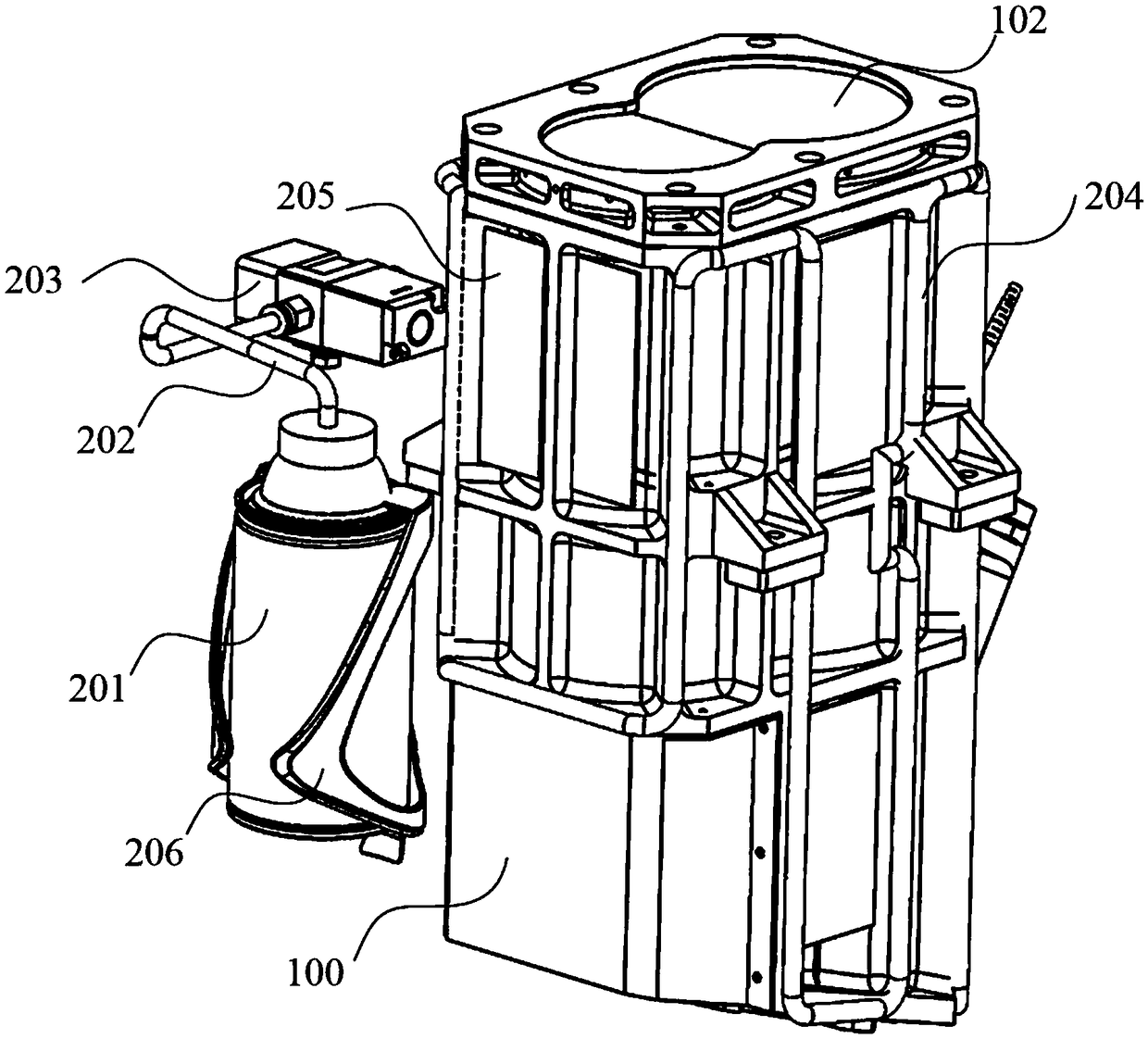

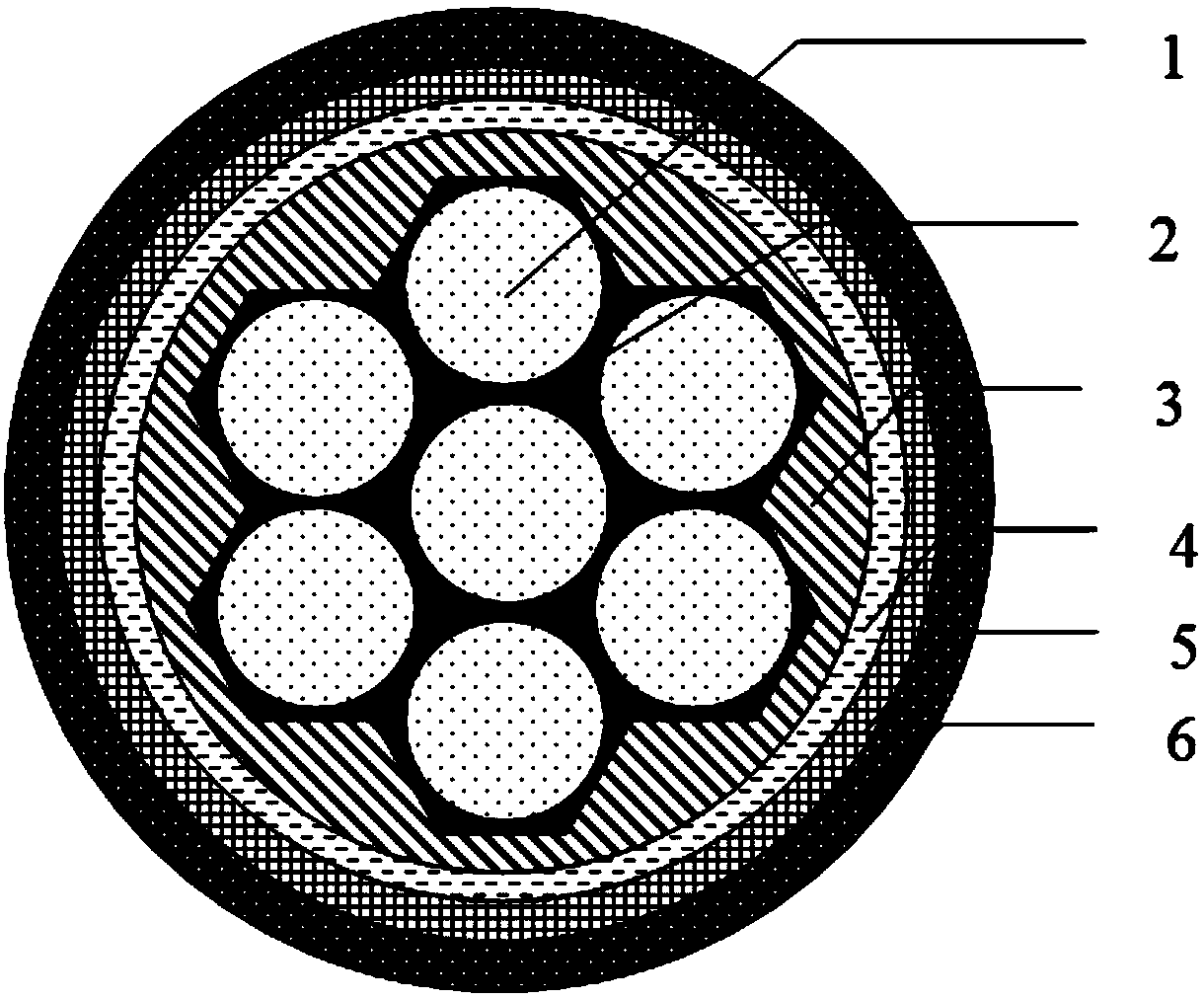

Airborne lidar system based on unmanned aerial vehicle

PendingCN109239690ARapid coolingNo power consumptionWave based measurement systemsThermal insulationCore component

The invention discloses an airborne lidar system based on an unmanned aerial vehicle. According to the system, a telescope module and a plurality of passive lidar optical-components are disposed in anoptical thermal-insulation chamber, and a temperature control module is disposed for precise and organic temperature control on a passive optical module, a laser source, a detector, a data collectionmodule and a main control module of the whole lidar system. According to the system, a cold gas bottle storing compressed gas is adopted as a core component of a refrigeration unit, and rapid and effective cooling is carried out on the passive optical module of lidar, and normal working of core components of the lidar is guaranteed; and the compressed gas in the cold gas bottle carries out rapidrefrigeration in a releasing process, the whole process does completely not consume battery power of the lidar or even the whole unmanned aerial vehicle, and the contradiction between limited batterypower supplying of the unmanned aerial vehicle and strict temperature control of the lidar is ingeniously solved.

Owner:山东国耀量子雷达科技有限公司

Flowering phase regulation method for camellia flowers

InactiveCN107484607ABreak dormancyPromote growthFertilising methodsCultivating equipmentsCamellia sinensisNutrient

The invention relates to a flowering phase regulation method for camellia flowers. The method comprises hormone regulation, temperature and humidity management, nutrient and water management, illumination management and the like. Accordingly, the natural laws of growth and development and blooming of the camellia flowers can be broken through, the flowering phase of the camellia flowers is effectively regulated, and meanwhile effective nutrient and water management and hormone regulation are effectively conducted on the camellia flowers; on the basis that the flowering phase of the camellia flowers is ensured to be consistent, the flowering phase is effectively controlled, blooming in counter-season of the camellia flowers is achieved, growth and cultivation of the camellia flowers adapt to market requirements, and the benefit of camellia flower growers is greatly increased.

Owner:GUANGXI SHATIAN XIANRENTAN AGRI INVESTMENT CO LTD

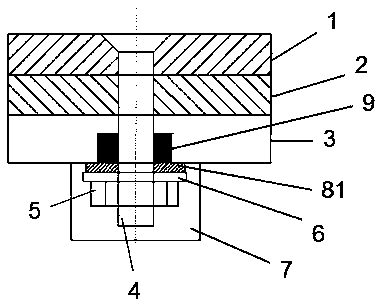

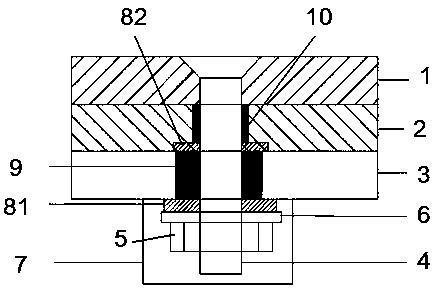

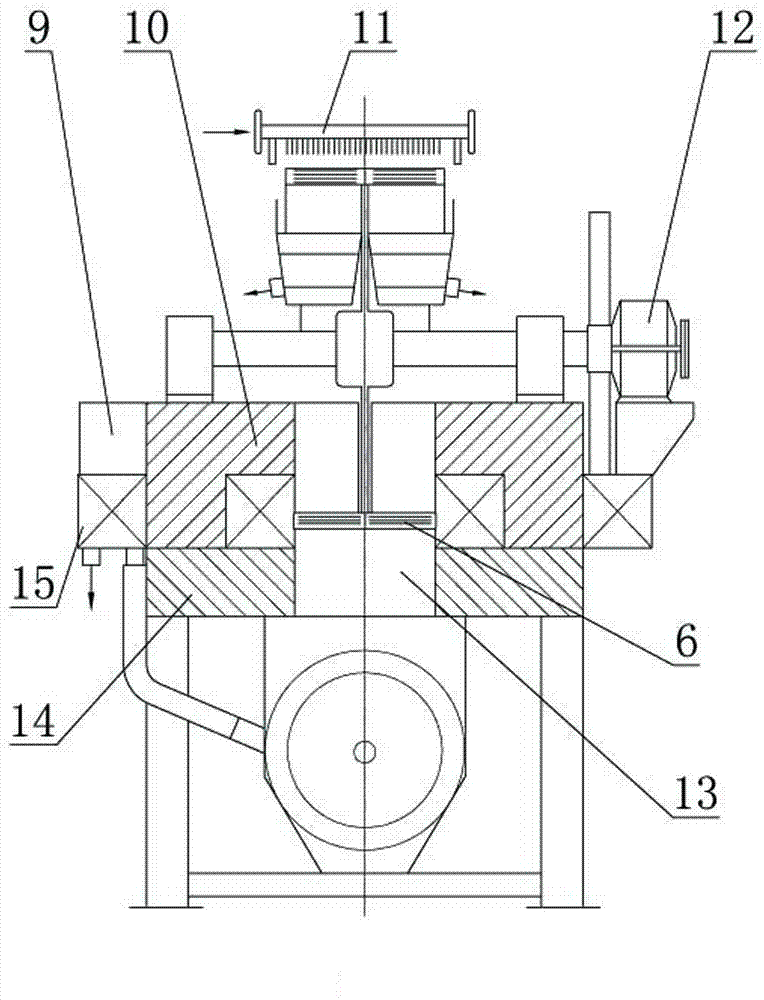

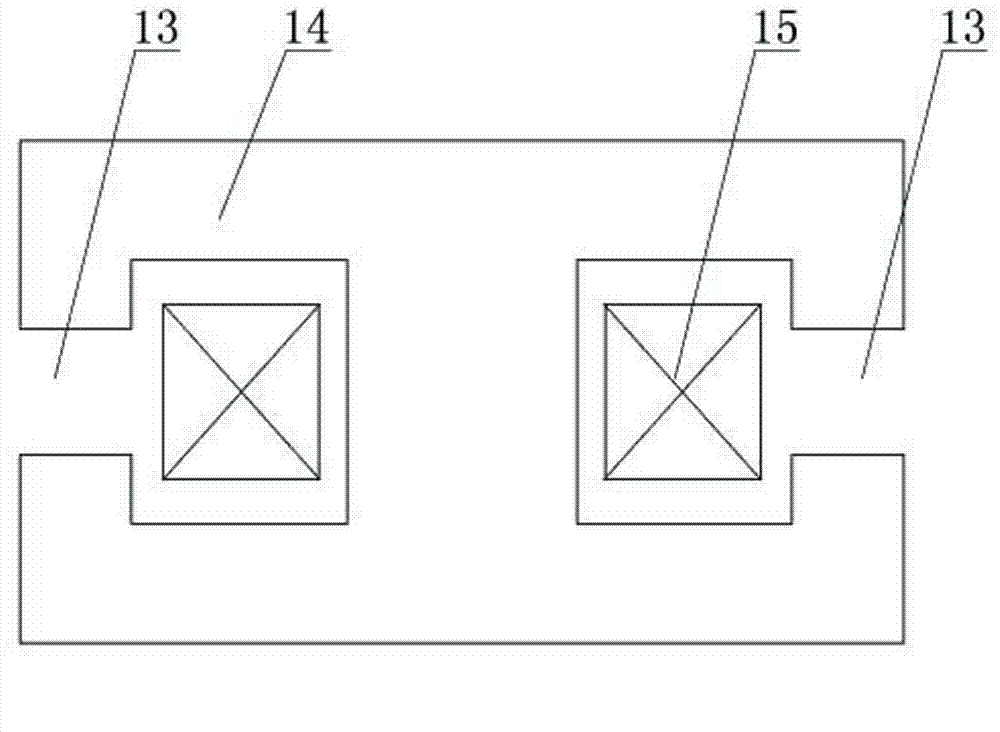

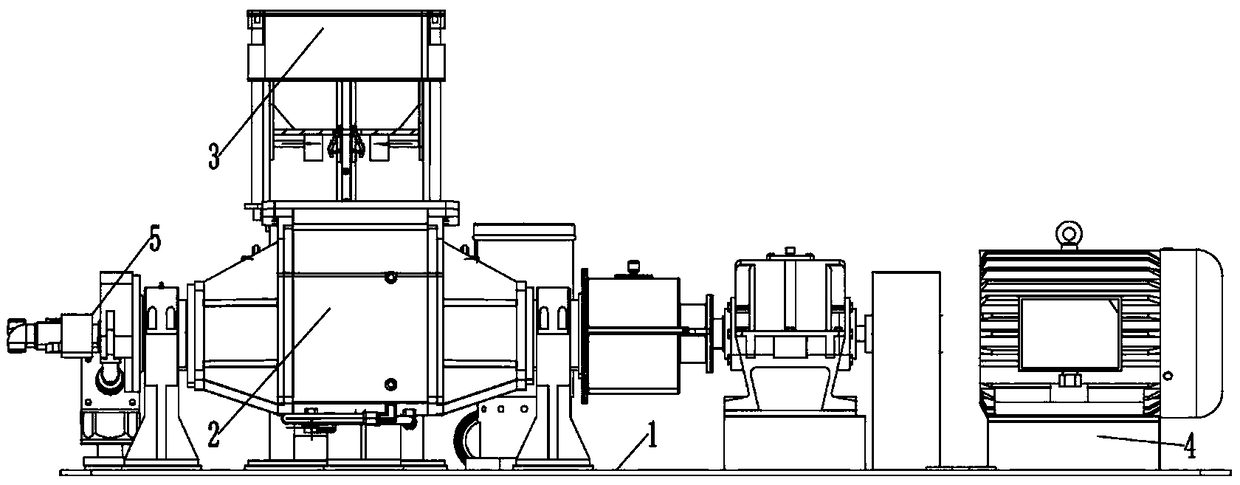

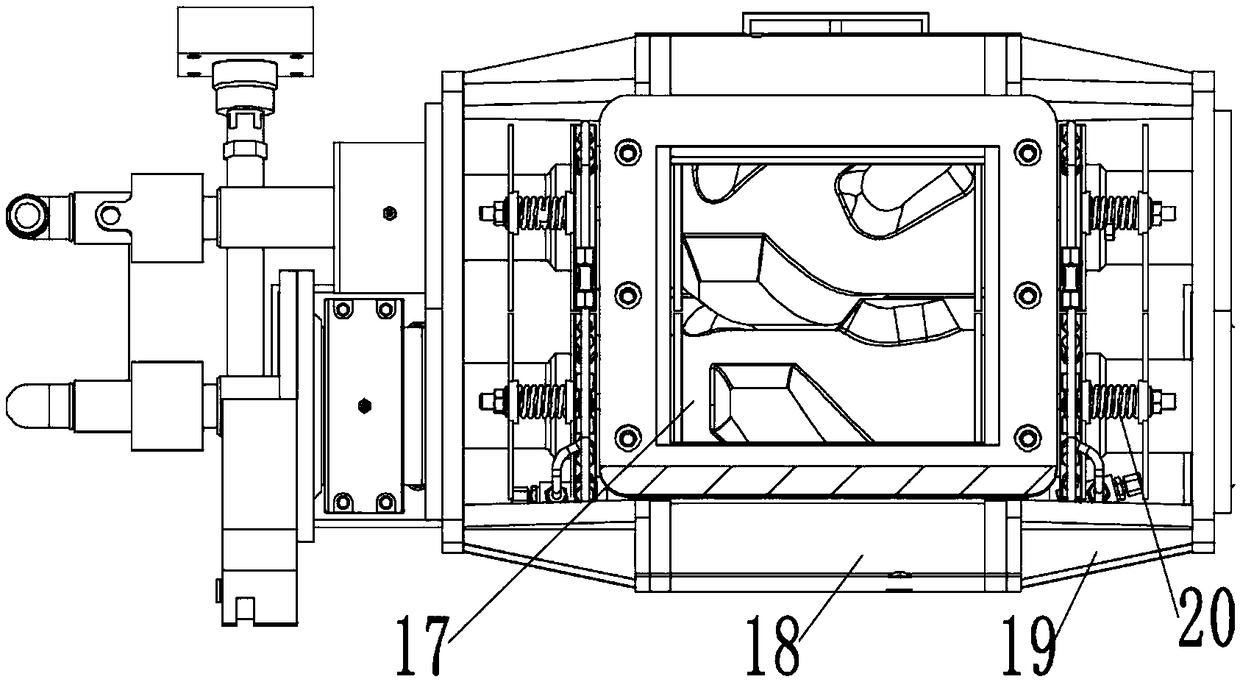

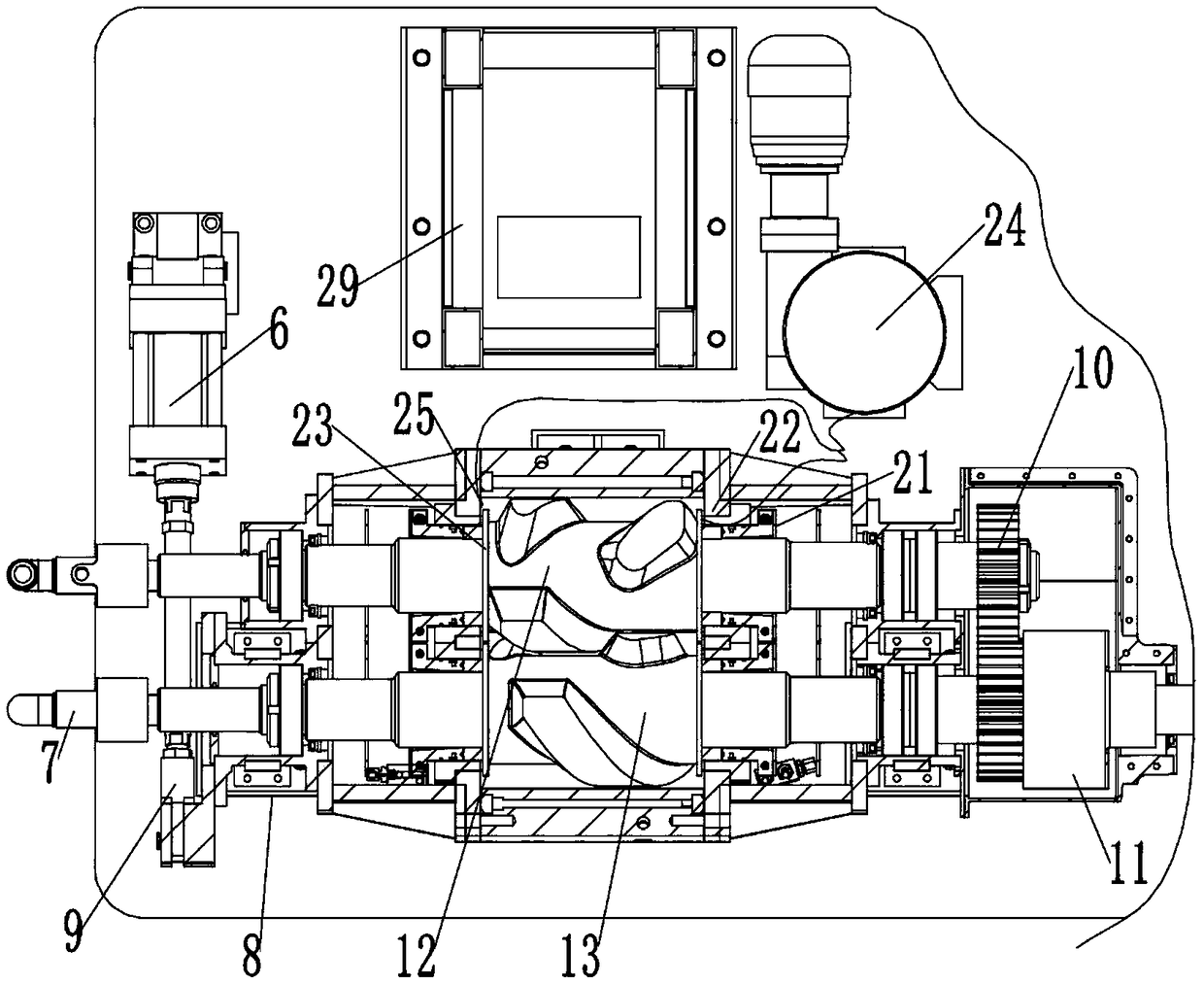

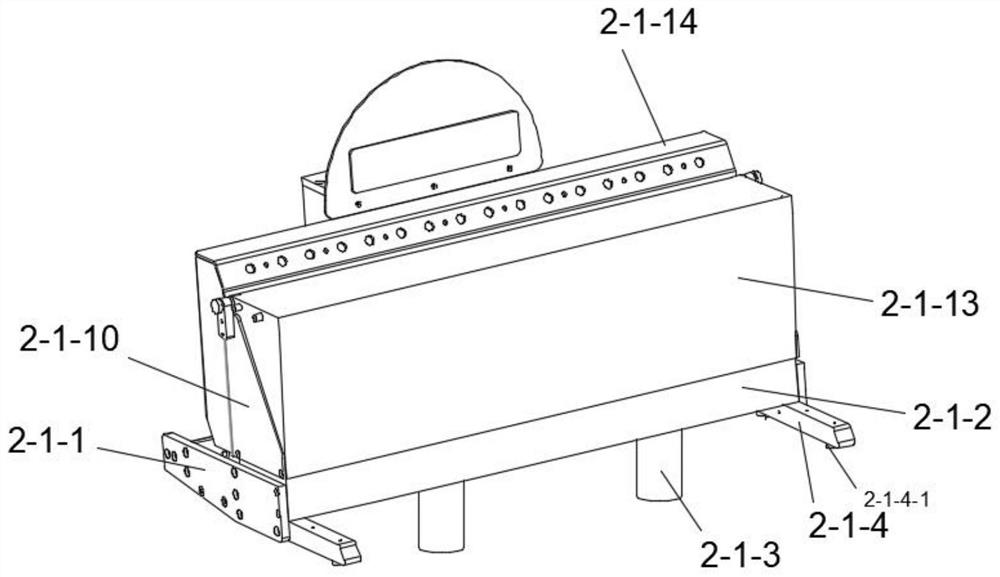

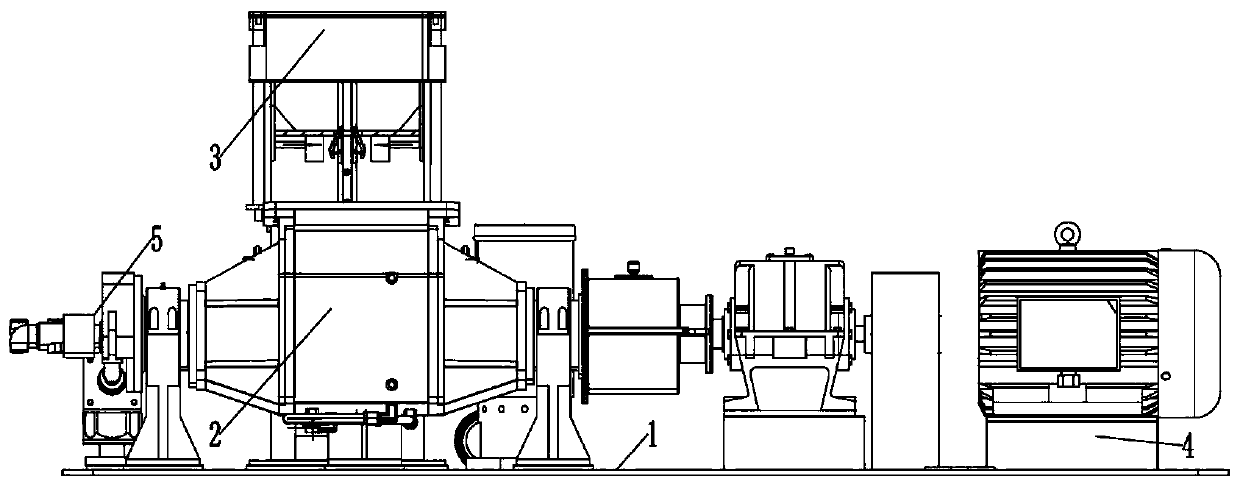

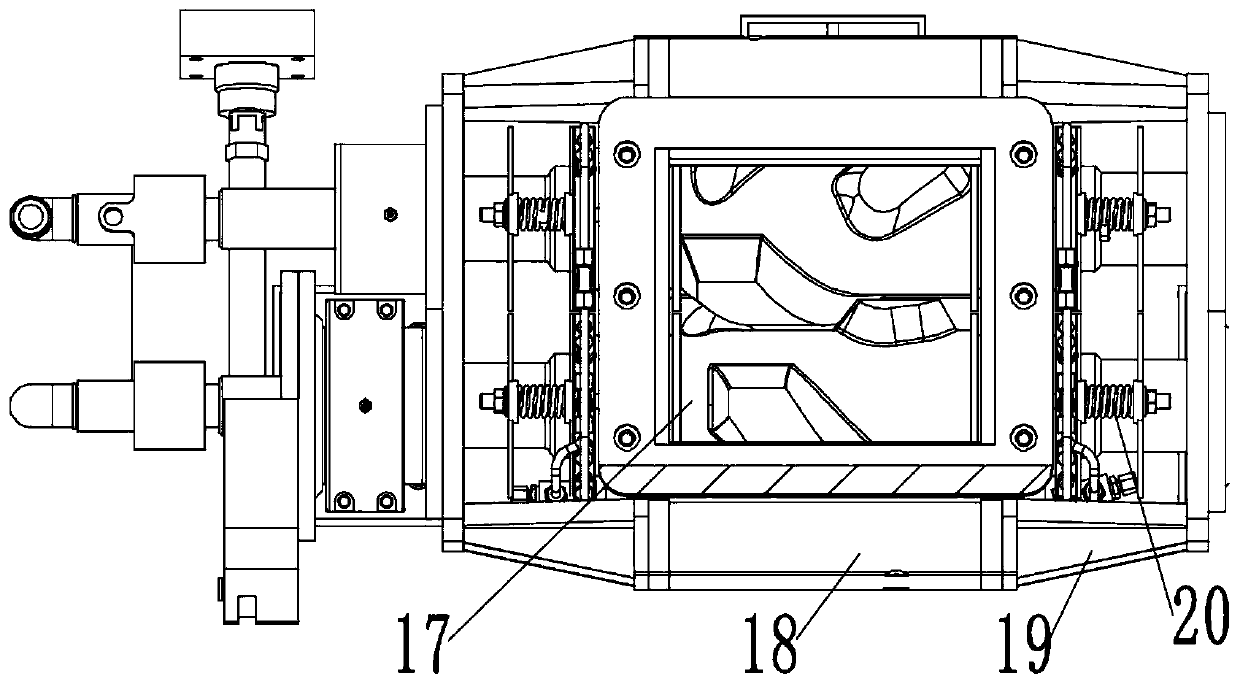

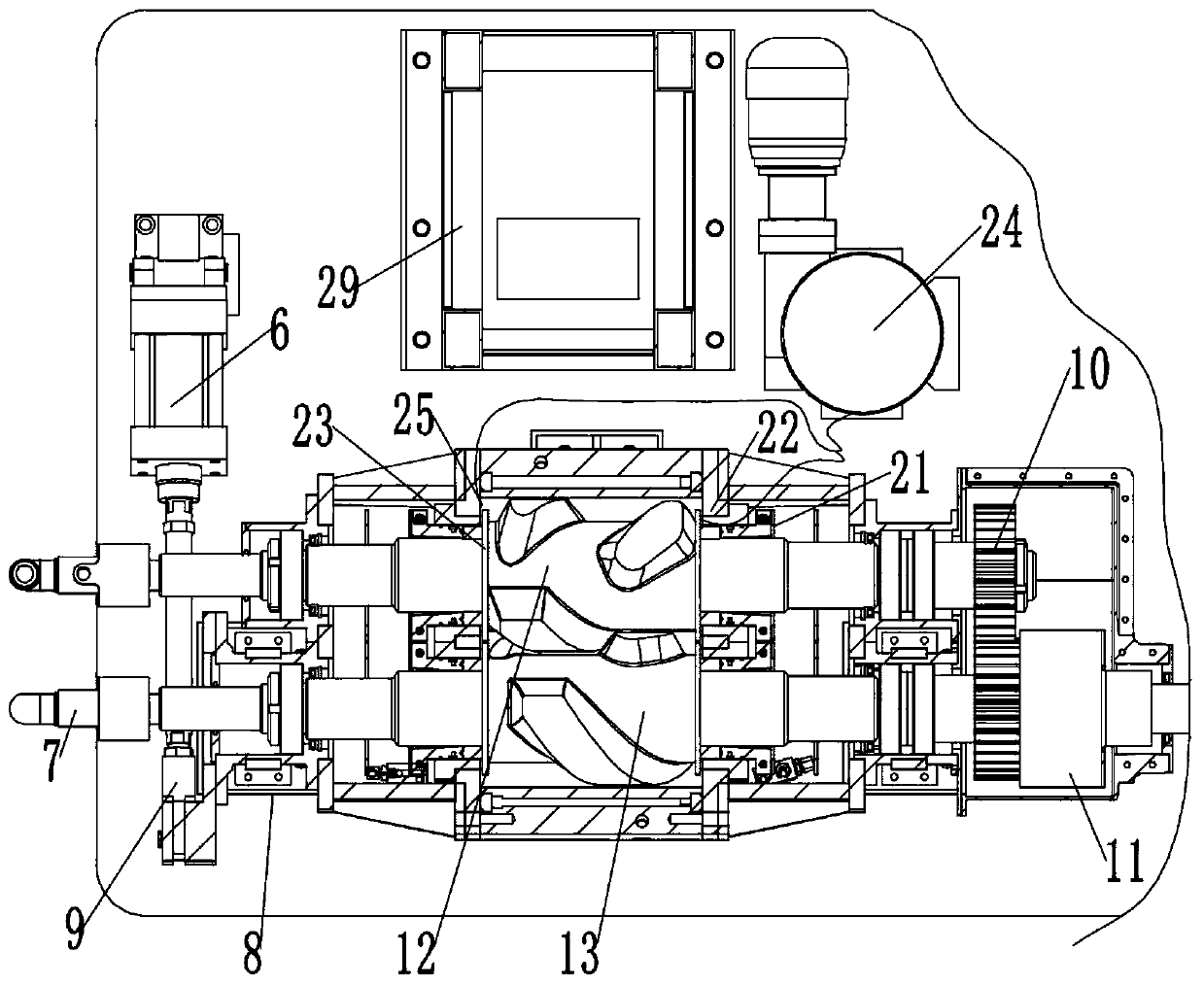

Improved internal mixer and internal mixing method

The invention relates to an improved internal mixer and an internal mixing method. The improved internal mixer comprises a main base, an internal mixing device arranged on the main base, an upper ejecting device arranged on the main base and used for sealing and downwards ejecting the internal mixing device, a driving device arranged on the main base and used for driving the internal mixing deviceto mix rubber, and an overturning system arranged on the main base and used for driving the internal mixing device to discharge through overturning. The internal mixing device comprises an internal mixing box body used for storing the mixed rubber, an internal mixing material opening formed in the internal mixing box body and used for adding and outputting the rubber, an internal mixing right side plate arranged on the internal mixing box body, an internal mixing sealing adjusting spring of which the right end is fixed on the left side surface of the internal mixing right side plate, internalmixing sealing outer spacer sleeves movably arranged left and right in the internal mixing box body and connected with the left end of the internal mixing sealing adjusting spring, an after-engagingrotor and a before-engaging rotor rotationally arranged on the internal mixing box body in the reverse direction. The structure of the after-engaging rotor is the same as that of the before-engaging rotor. The improved internal mixer is reasonable in design, compact in structure and convenient to use.

Owner:JIANGSU TIANYUAN TEST EQUIP

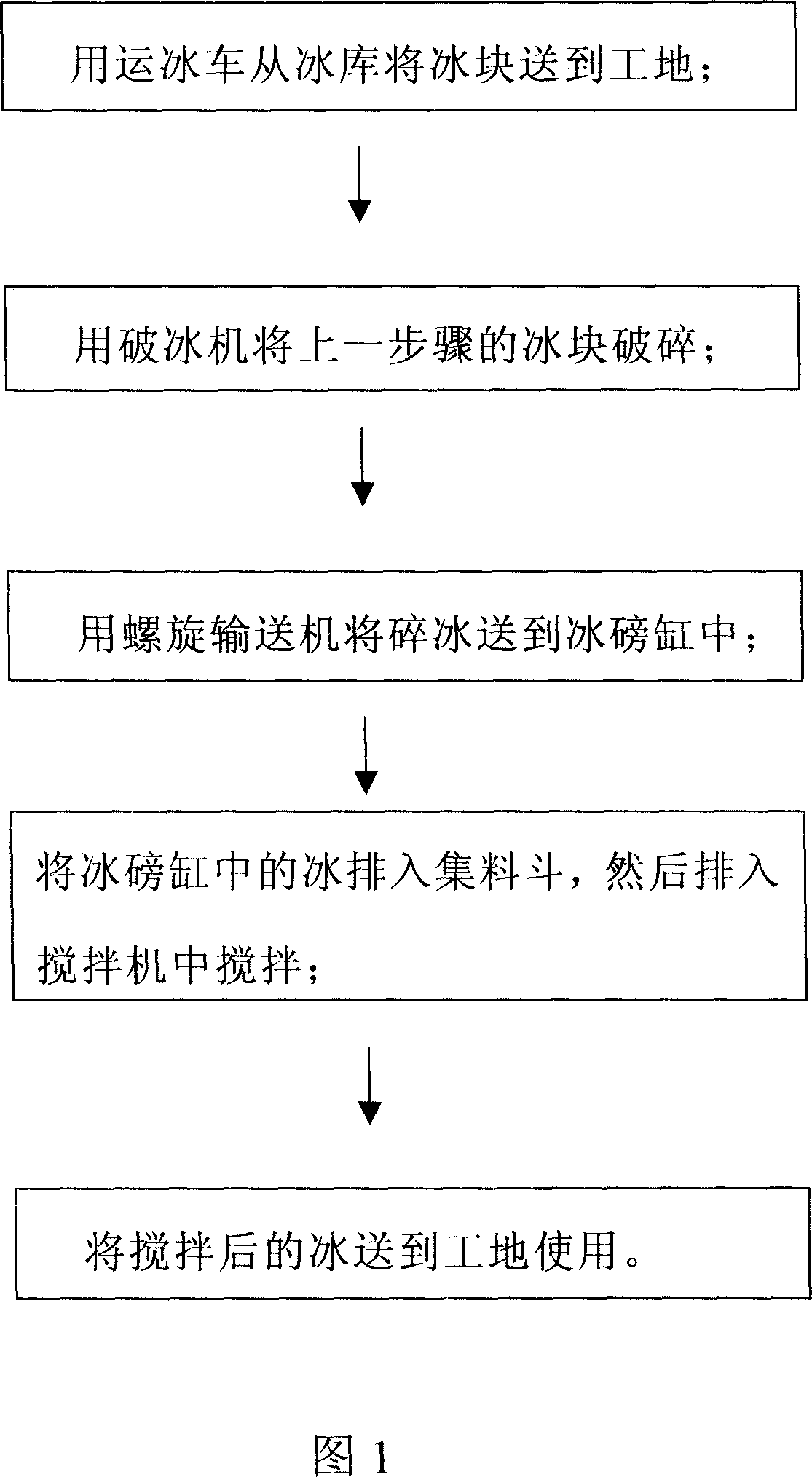

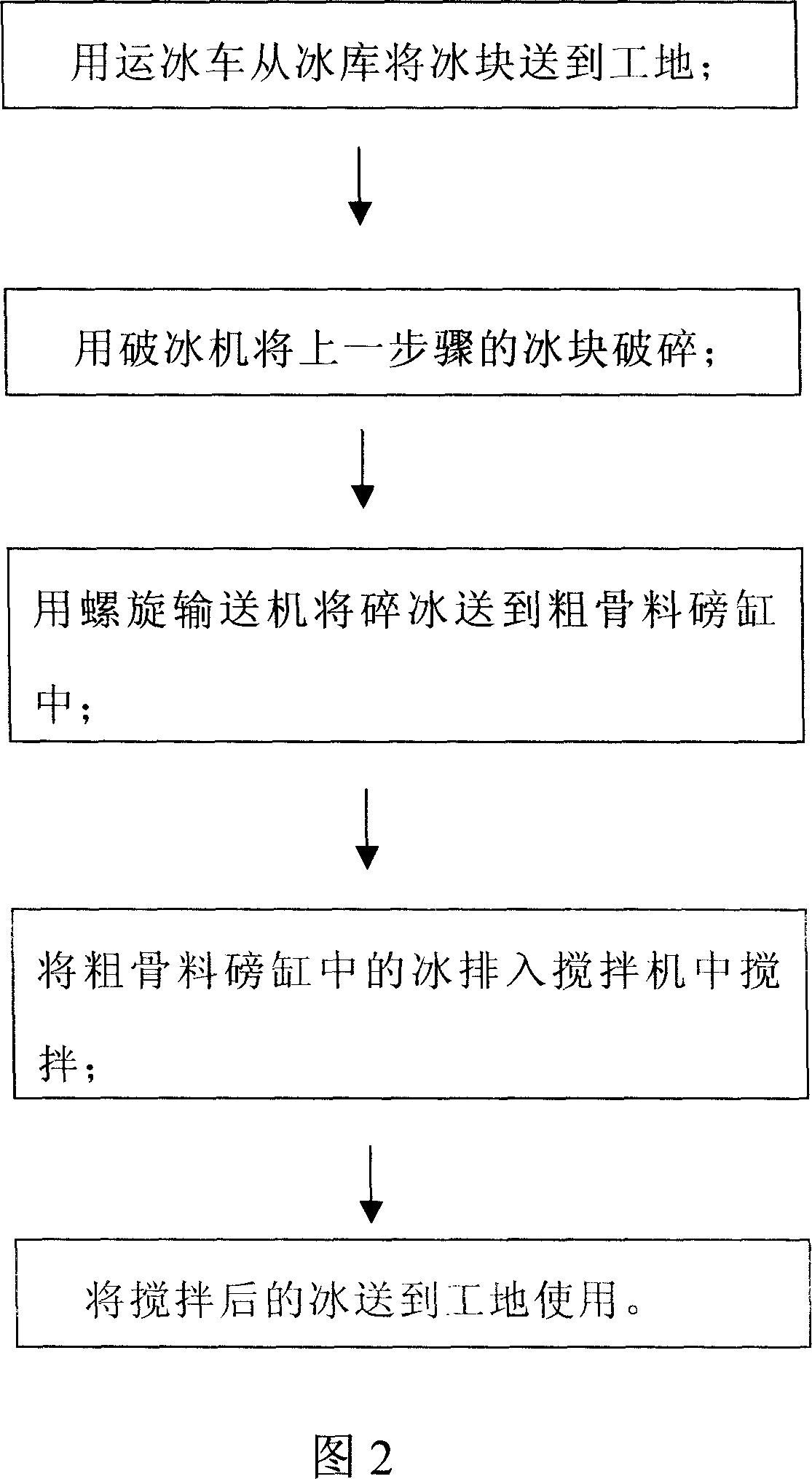

Ice adding system and method for stirring station

InactiveCN101020343AGuaranteed temperature controlLow costCement mixing apparatusMixing operation plantEngineeringTruck

The ice adding system for stirring station includes one hoister, one refrigerator, one ice breaker, one ice weigher, one material bin, one stirrer, and one agitating truck. The ice adding operation with the ice adding system includes the following steps: conveying ice block from ice warehouse to the site, breaking ice block with the ice breaker, weighing the crushed ice, feeding ice to the material bin and the stirrer, and feeding stirred ice to the construction site for use. The present invention has lowered cost, high reliability and effective control of the concrete temperature.

Owner:梁锡武

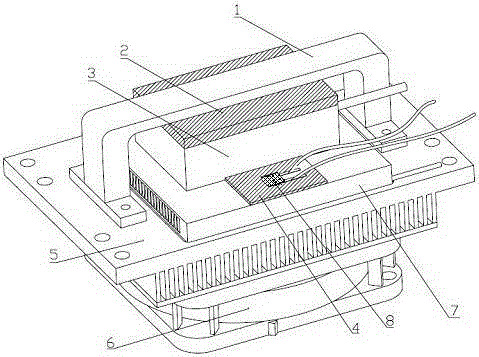

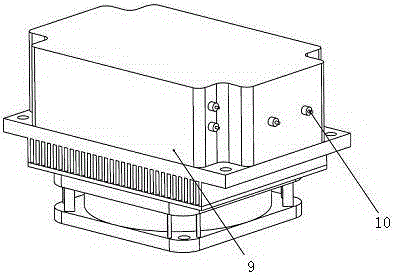

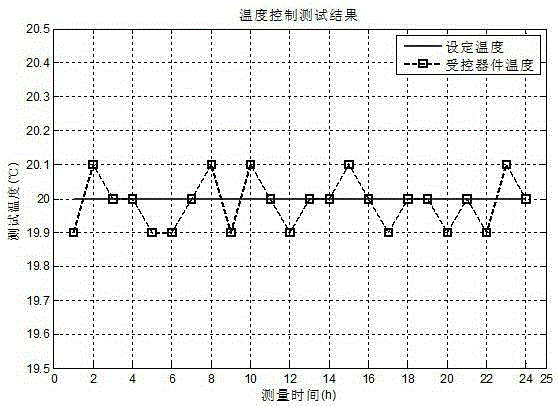

Temperature control structure

ActiveCN105278576AGuaranteed CompatibilityGuaranteed accuracyTemperatue controlTemperature controlElectrical resistance and conductance

Provided in the invention is a temperature control structure comprising a heat radiation structure, a temperature control execution unit and a temperature detection unit. The temperature control execution unit includes a semiconductor refrigeration plate; and the temperature detection unit includes a thermistor. The temperature control structure is characterized in that the lower surface of the semiconductor refrigeration plate is a thermal surface and is in conduction contact with the heat radiation structure; and the upper surface of the semiconductor refrigeration plate is a cold surface and is in conduction contact with a temperature controlled element. And thermal transmission between the semiconductor refrigeration plate and the thermistor is realized by an aluminium nitride circuit wafer. Under the circumstance that compatibility of the semiconductor refrigeration plate and the thermistor is guaranteed, accuracy of temperature detection of the semiconductor refrigeration plate by the thermistor is guaranteed, thereby guaranteeing high-precision temperature control.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Multifunctional computer terminal apparatus

The invention discloses a multifunctional computer terminal apparatus. The multifunctional computer terminal apparatus comprises a fixed base; a sealed machine cabinet is arranged on the front side ofthe upper end plane of the fixed base; a storage space is arranged in the sealed machine cabinet; a sealed closed door is arranged on the front end wall of the storage space; a plurality of terminalcontrol apparatuses are arranged in the storage space; heat dissipation tubes are uniformly distributed on the left and right end walls and the back end wall of the storage space; a refrigerator is fixedly arranged in the middle position of the right end plane of the sealed machine cabinet; a locking apparatus is fixedly arranged on the back side of the upper end plane of the sealed machine cabinet; and a high-pressure nitrogen box is fixedly arranged on the back side of the upper end plane of the fixed base. In operation of the multifunctional computer terminal apparatus, nitrogen enters thestorage space through air inlet holes to discharge air from the storage space, so that quick cooling and fire extinguishing can be realized; and in addition, a sealed weight-balancing block is declined along with discharging of nitrogen in the high-pressure nitrogen storage space, so that nitrogen in the high-pressure nitrogen storage space is extruded and the nitrogen discharging speed is accelerated.

Owner:阜阳市科技型中小企业生产力促进中心有限公司

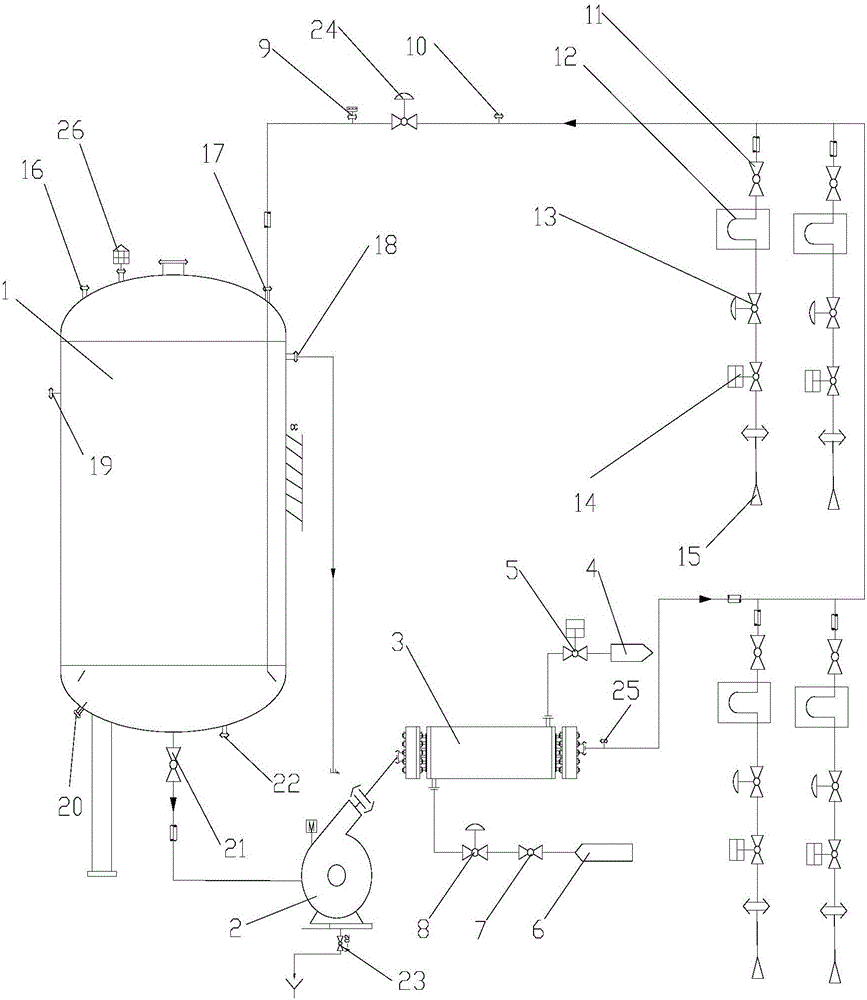

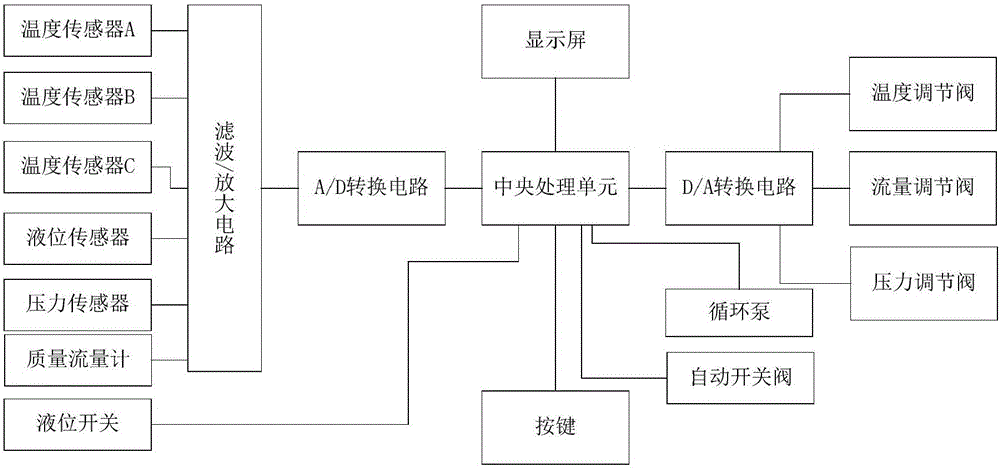

Automatic cycling liquid adding system

ActiveCN106000148ASimplified dosing processEasy to operateFlow mixersTransportation and packagingLiquid storage tankEngineering

The invention discloses an automatic cycling liquid adding system. The automatic cycling liquid adding system comprises a liquid storage tank, a heat exchanger, a circulating pump, a liquid consuming branch and a controller. The liquid inlet of the circulating pump communicates with the liquid outlet of the liquid storage tank, the liquid outlet of the circulating pump communicates with the inlet of the heat exchanger, and the outlet of the heat exchanger is connected with the circulating liquid inlet of the liquid storage tank through a pipeline. The liquid storage tank is provided with a temperature sensor A, a liquid level sensor and a liquid level switch. The liquid consuming branch is connected to the connection pipeline between the outlet of the heat exchanger and the circulating liquid inlet of the liquid storage tank. A temperature sensor B is arranged on a connection pipeline between the outlet of the heat exchanger and the liquid consuming branch. A temperature sensor C, a pressure sensor and a pressure adjusting valve are arranged on a connection pipeline between the liquid consuming branch and the circulating liquid inlet of the liquid storage tank. The automatic cycling liquid adding system is high in automation degree, and the product quality and the efficiency can be improved.

Owner:CHENGDU RONGSHENG PHARMA

Cooling system of equipment compartment of deep-sea space station and control method thereof

ActiveCN106545934AImprove self-sustainabilitySufficient energy supplyLighting and heating apparatusSeawater treatmentEngineeringHigh pressure

The invention provides a cooling system of an equipment compartment of a deep-sea space station. The cooling system comprises a seawater power generation system, a seawater cooling system and a seawater processing system. According to the cooling system of the equipment compartment of the deep-sea space station provided by the invention, temperature control of the equipment compartment of the deep-sea space station can be guaranteed, high-pressure seawater outside the station can be used to generate electricity so as to improve electric energy reserve in the station, and seawater which enters the station can be prepared into fresh water so as to replenish limited producing and living use water in the station. Therefore, self-supportability of the deep-sea space station can be improved. Sufficient energy supply of the deep-sea space station is scientifically and reliably guaranteed, the deep-sea space station has a strong life supporting system, and more people can be contained to carry out scientific research of long operation time in deep sea.

Owner:JIANGSU UNIV OF SCI & TECH

Integrated complete equipment for TLCP (thermotropic liquid crystal polymer) polymerization granulation

ActiveCN109227998AImprove the production capacity of mechanized integrationReduce labor intensityEngineeringOil temperature

The invention provides integrated complete equipment for TLCP (thermotropic liquid crystal polymer) polymerization granulation. The equipment comprises a reaction kettle, a material extruder, a waterring hot cutting granulator and an oil temperature machine, wherein the reactor is provided with a first feeding port and a first discharging port; the material extruder is provided with a second feeding port and a second discharging port; the first discharging port is connected with the second feeding port through an inserting plate valve, and the inserting plate valve controls the first discharging port to be communicated with or isolated from the second feeding port; the water ring hot cutting granulator is provided with a third feeding port and a third discharging port, and the third feeding port is connected with the second discharging port. According to the integrated complete equipment for TLCP polymerization granulation, the TLCP polymerization granulation process flow has a highermechanical integration level, process complexity and labor intensity of workers are reduced, and quality of produced granules can be improved.

Owner:黄献中

Closed-loop sampling system for flow-cell-process drug dissolution and use method thereof

PendingCN112113800AGuaranteed functionalityCompact structureWithdrawing sample devicesTesting medicinal preparationsCirculator pumpWater circulation

The invention discloses a closed-loop sampling system for flow-cell-process drug dissolution and a use method thereof. The closed-loop sampling system comprises a constant-temperature water area system, a flow cell system, a lifting mechanism, a circulating heating system, a solvent monitoring system, a solvent circulating system and a sampling system, wherein the constant-temperature water area system comprises a constant-temperature water tank rack, a constant-temperature water tank, a solvent cup holder, a solvent cup and a solvent cup cover; the flow cell system is arranged at the top endof the constant-temperature water area system; the lifting mechanism is arranged on one side of the constant-temperature water tank rack; the circulating heating system comprises a heating device anda water circulating pump; the circulating inlet end of the solvent monitoring system communicates with the heating device, and the circulating outlet end of the solvent monitoring system respectivelycommunicates with the solvent cup and a flow cell; the solvent circulating system comprises a solvent circulating pump and a pulse valve; and the sampling system comprises a sampling mechanism, a sampling pipeline, a sampling valve and a sampling pump. The system is compact in structure, the heating efficiency of the heating device is high, water area temperature distribution is uniform, water temperature control is accurate, and temperature and pressure of a solvent are monitored.

Owner:禄亘(上海)生命科技有限公司

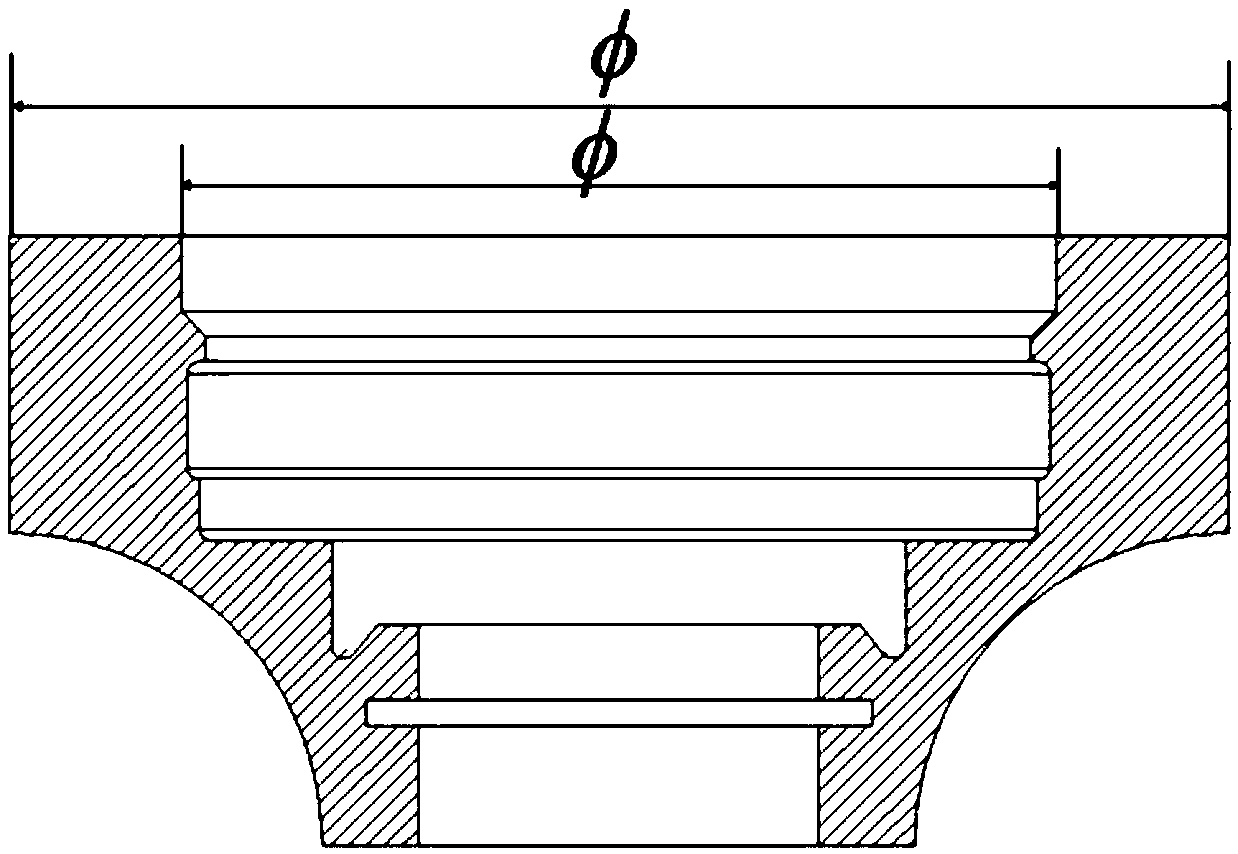

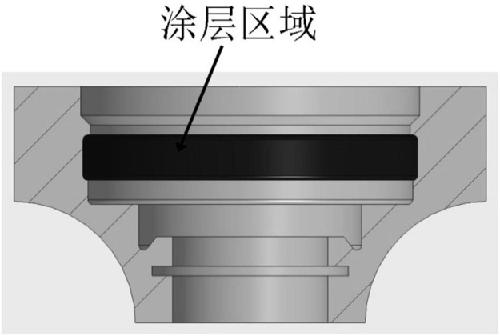

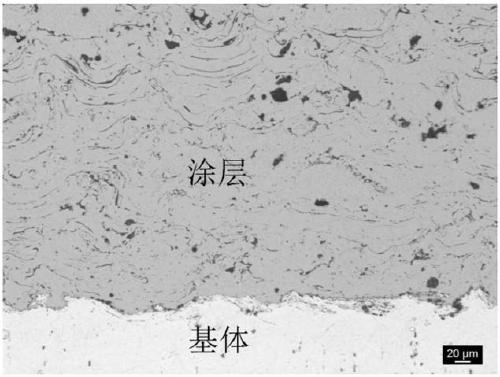

Method for partial plasma spraying of NiCrAlY coating on inner wall of aluminum alloy crankcase with boss, and application of method

ActiveCN109055883AMeet service conditionsImprove processing yieldMolten spray coatingTemperature controlCrankcase

The invention relates to a method for partial plasma spraying of NiCrAlY coating on inner wall of aluminum alloy crankcase with a boss, and application of the method, and belongs to the technical field of material surface treatment. The method comprises the following steps: performing dust removal and degreasing treatment on the crankcase, protecting a non-spraying area, performing surface sandingroughening treatment on an area to be sprayed, placing the crankcase in a fixture, fixing the fixture on a turntable, and spraying the spraying area with a NiCrAlY coating. During the spraying process, when the temperature of the area to be sprayed exceeds 150 DEG C, the spraying stops; and the spraying continues until the temperature drops below 100 DEG C; and the spraying is repeated until thethickness meets the requirements. The method ensures the temperature control of the spraying process and effectively controls the degree of deformation of the crankcase. The coated crankcase preparedby the invention is assembled on an aeroengine to achieve stable operation, so the application prospect is broad.

Owner:GUANGDONG INST OF NEW MATERIALS

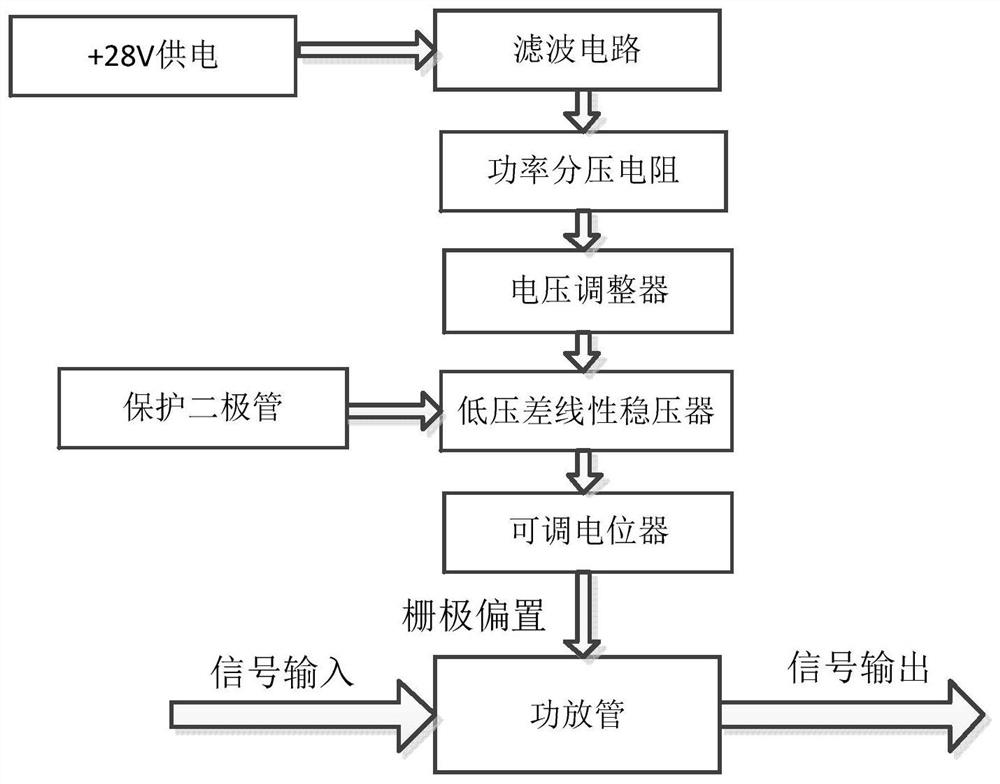

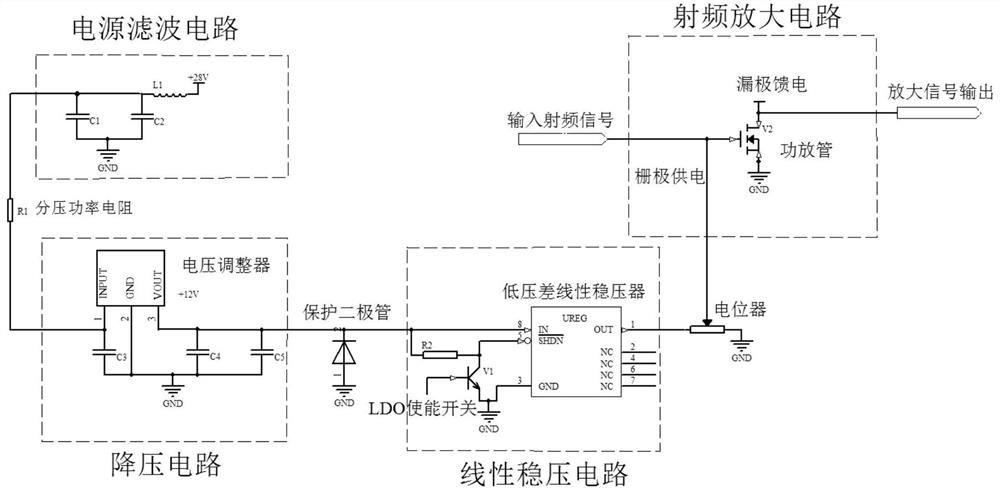

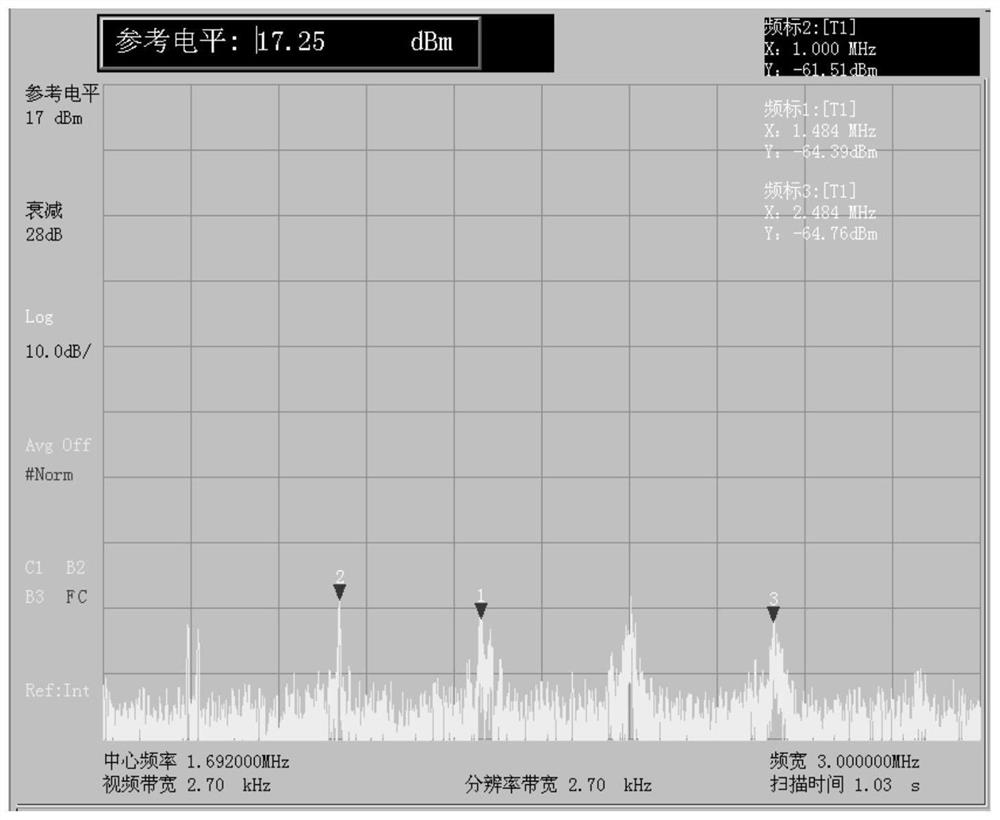

Grid voltage stabilizing circuit of LDMOS power amplifier tube

InactiveCN112631358AGuaranteed temperature controlGuaranteed stabilityElectric variable regulationCapacitanceLDMOS

The invention discloses a grid voltage stabilizing circuit of an LDMOS power amplifier tube. The grid voltage stabilizing circuit comprises a power supply filter circuit, a step-down circuit and a linear voltage stabilizing circuit, the power supply filter circuit is used for filtering ripples of power supply voltage and signal crosstalk of other units, and the output end of the power supply filter circuit is connected with the input end of the voltage reduction circuit through the voltage division power resistor; the step-down circuit comprises a voltage regulator and a plurality of rectifying and filtering capacitors; the linear voltage stabilizing circuit comprises an enable switch circuit and a low-dropout linear voltage stabilizer, and the enable switch circuit is used for controlling opening and closing of the low-dropout linear voltage stabilizer; and an enable pin of the low-dropout linear voltage stabilizer is connected with the switching circuit, and an output pin of the low-dropout linear voltage stabilizer is connected to a grid electrode of the LDMOS power amplifier tube through a potentiometer. According to the invention, the radio frequency amplification index of the LDMOS power amplifier tube can be remarkably improved, and meanwhile, the overall stability and good linearity of the radio frequency amplification circuit are realized.

Owner:SHAANXI FENGHUO ELECTRONICS

Chemical product and chemical pipe transportation device

ActiveCN107839727ATransport stableGuaranteed temperature controlHand carts with multiple axesTemperature controlLiquid storage tank

The invention discloses a chemical product and a chemical pipe transportation device. The device comprises a base plate, a damper is fixedly connected with the top of the base plate, a chemical liquidstorage tank is fixedly connected with one side of the top of the damper, a heating electromagnetic coil is installed on the inner wall of the chemical liquid storage tank, a power supply installation box is fixedly connected with the bottom of the inner wall of the chemical liquid storage tank, a subulate heater is fixedly connected with the top of the power supply installation box, a liquid guiding pump is fixedly connected with the top of the power supply installation box, and a liquid guiding pipe is communicated with the liquid outlet of the liquid guiding pump. The invention relates tothe technical field of chemical processing. The chemical product and the chemical pipe transportation device achieve stable transportation of the chemical liquid and clamping transportation of the chemical pipe, can guarantee the stabilization of the transportation process temperature control during use, flow rate, and rapid and convenient starting and closing, and can guarantee the stabilizationof the chemical pipe in the transportation process and the chemical pipe not being humid during the transportation so as to reduce unnecessary losses.

Owner:南通睿基自动化技术有限公司

A high-density live fish transport vehicle and transport method thereof

ActiveCN105660511BWater and oxygen cycle guaranteeGuaranteed oxygen supplyPisciculture and aquariaAnimal transportationRefrigeration compressorAutomatic control

The invention discloses a high-density living fish transporting vehicle and a transporting method thereof. The high-density living fish transporting vehicle comprises a vehicle body, a water oxygen circulation system and a fish tank, wherein the fish tank and the water oxygen circulation system are fixedly arranged on the vehicle body; the fish tank is internally provided with partitions; the outer wall of the fish tank is a sandwiched hollow heat-preservation layer; a fish feeding hole is formed in the top surface of each compartment; a fish discharge hole is formed in a side surface of each compartment; the water oxygen circulation system comprises a filtering device, an oxygen enriching device and a heat exchanger which are serially connected with the fish tank through a water pump, pipelines and valves; water dissolved oxygen and temperature are automatically controlled; the pump and a refrigeration compressor are driven by a vehicle-mounted engine; before being loaded, living fishes are subjected to dormancy pretreatment and water quality conditioning firstly, and circulation, temperature and oxygen dissolution control on a water body are implemented in the transportation process. By adoption of the structure and the method, the temperature inside the fish tank is controlled to be higher than the physiological ice temperature of 0.5-8 DEG C of the living fishes, and the water dissolved oxygen is controlled to be approximate to the physiological oxygen requirement, so that physiological metabolism of the living fishes can be reduced to the minimum level, the living fish transportation time can be prolonged, the survival rate can be increased, and the oxygen consumption can be reduced.

Owner:HUAZHONG AGRI UNIV

Ceramic electric soldering iron

PendingCN113695701AMeet weldingAvoid damageSoldering ironElectrical resistance and conductanceGrounding resistance

The invention relates to the technical field of heating equipment, and discloses a ceramic electric soldering iron. The ceramic electric soldering iron comprises a soldering bit, a handle, a ceramic heating body, a positive wire and a negative wire, and is characterized by further comprising a wire and a ground wire, wherein the negative wire is connected to the soldering bit, the positive wire is connected to the ceramic heating body, the wire is connected to the cathode wire at the front end of the ceramic heating body, the wire is connected with a control detection center (capable of detecting grounding voltage and grounding resistance), and the ground wire is connected with the handle. The ceramic electric soldering iron has the advantage of determining whether the grounding voltage is less than 2 mV and the grounding resistance is less than 2 Ohm.

Owner:CHONGQING LE MARK CERAMIC TECH CO LTD

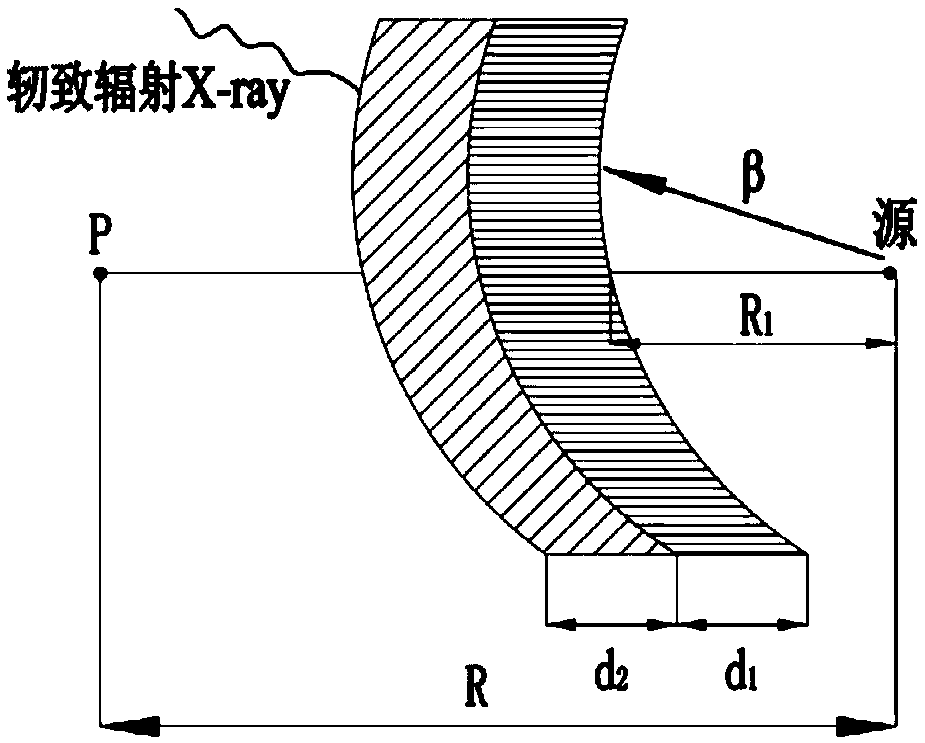

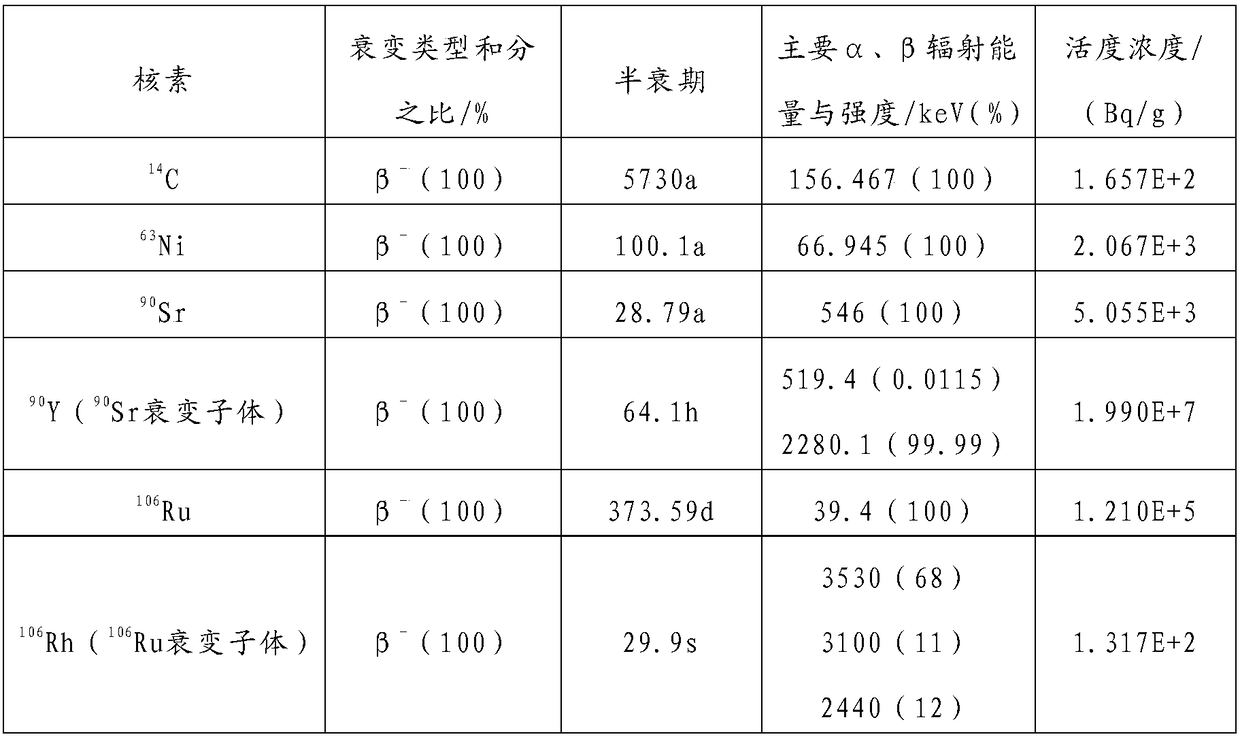

Shielding structure of isotope battery

ActiveCN109166643AImprove mechanical propertiesReduce intensityRadiation electrical energyRadio isotopesElectrical battery

The invention belongs to the technical field of radiation shielding design of radionuclide of an isotope battery, and particularly relates to a shielding structure of an isotope battery. The shieldingstructure is used for shielding a radioisotope (1) in the isotope battery, and comprises a graphene carbon-based material layer (2) coating the outer surface of the radioisotope (1), a grid (3) whichis made from a light nuclei material and used for placing the radioisotope (1), an inner shield layer (5) made from a light nuclei material, an outer shield layer (6) made from a heavy nuclei material and an outer shell (7) made from an alloy material, and the inner shield layer (5), the outer shield layer (6) and the outer shell (7) are sequentially disposed on the periphery of the grid (3). Through the shielding structure of the isotope battery, the bremsstrahlung photon intensity is reduced to 20% of that of an original design scheme, the radiation dose of workers is reduced by about 20-80%, and on the premise of no influences on other properties, the power generation efficiency of the isotope battery can be improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

After-ripening treatment method of incised notopterygium seeds

InactiveCN109041629AMaintain humidityMaintain temperatureSeed and root treatmentNotopterygium incisumEmbryo

The invention discloses an after-ripening treatment method of incised notopterygium seeds. The after-ripening treatment method comprises the following steps: carrying out gibberellin solution imbibition treatment, open-air hillside land burying and low-temperature wet storage operation on the incised notopterygium seeds in sequence and promoting incised notopterygium embryo development and differentiation to finish after-ripening, so as to improve the sprouting rate of the incised notopterygium seeds to be 90 percent or more. Natural sprouting conditions of the incised notopterygium seeds aresimulated through open-air hillside land burying, so as to finish shape after-ripening of incised notopterygium embryos and the quality of germchits is easy to improve after the incised notopterygiumseeds are sprouted.

Owner:四川千草生物科技股份有限公司

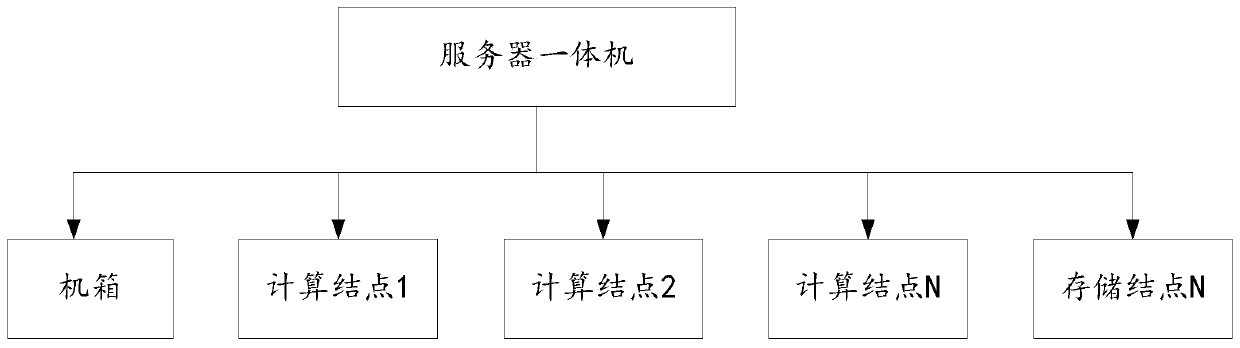

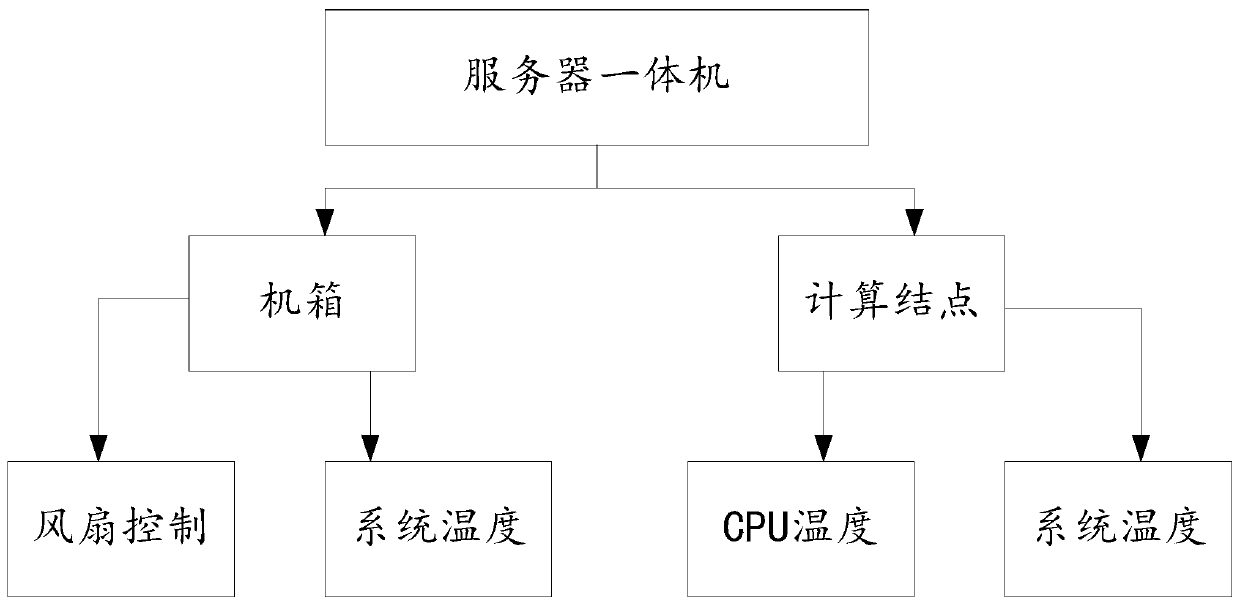

Temperature control method, system and device of server all-in-one machine and storage medium

InactiveCN110134210AGuaranteed temperature controlSafe and stable operationDigital data processing detailsHardware monitoringComputer caseEngineering

The invention provides a temperature control method, system and device of a server all-in-one machine and a storage medium. The temperature control method comprises the temperature obtaining step thata case BMC obtains the temperature of a computing node and the system temperature of a case; a calculation step: the case BMC calculates a predetermined rotating speed which a corresponding fan neesto reach through a temperature control calculation method; and a control step: the fan rotating speed is controlled to reach a preset rotating speed by the case BMC to realize temperature control. The temperature control method has the advantages that the temperature of the computing node and the system temperature of the case are obtained through the case BMC to achieve temperature control, thetemperature of the computing node is effectively monitored, temperature control over the computing node and the case is guaranteed, and the all-in-one machine system can operate more safely and stably.

Owner:深圳市国鑫恒宇科技有限公司

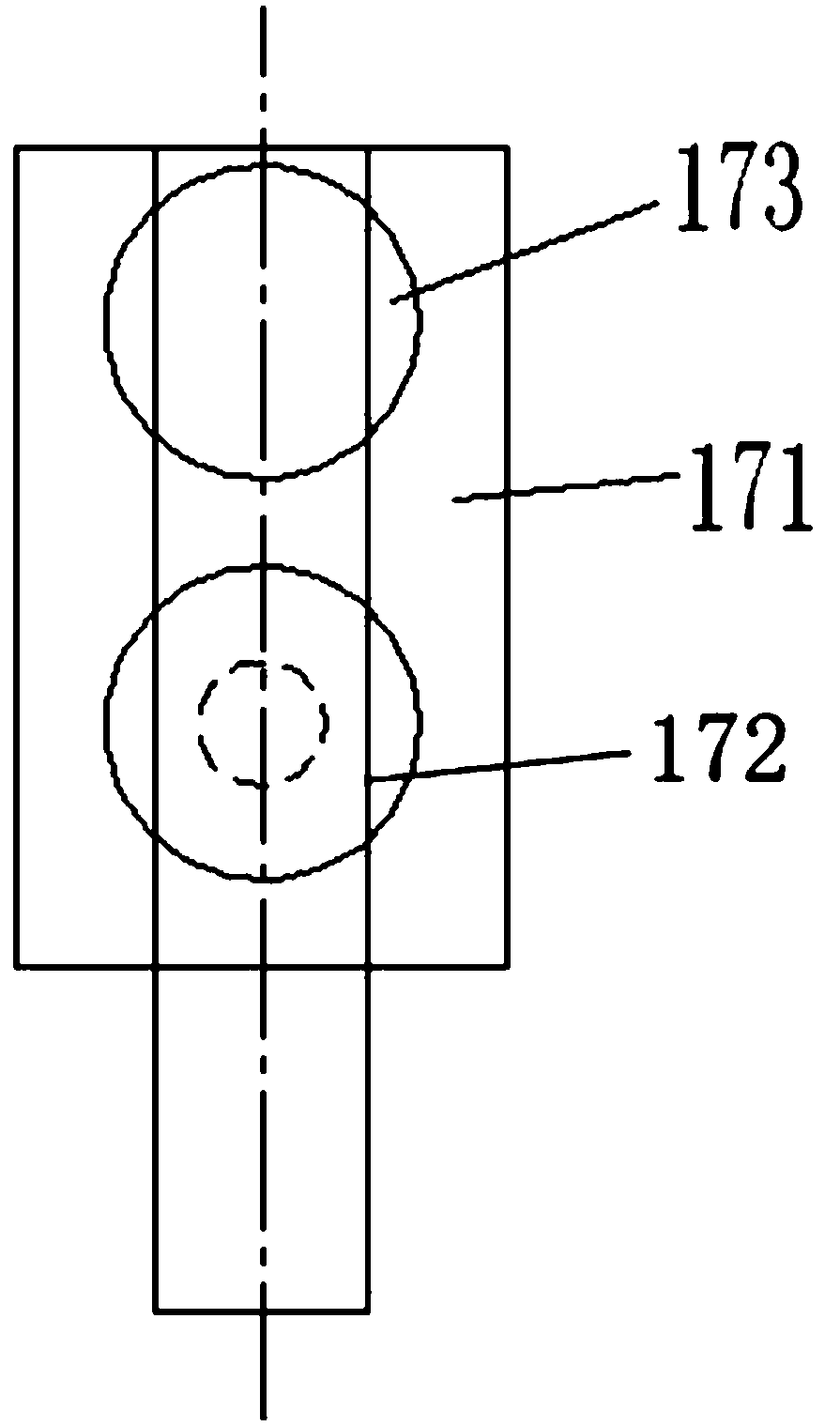

Turnover system and feeding device of improved type banbury mixer and method

The invention relates to a turnover system and a feeding device of an improved type banbury mixer and a method. The turnover system comprises a turnover gas cylinder (6), a root part of which is arranged on a main base (1), a turnover bearing base (8) which is arranged between the main base (1) and a banbury box body (18) of a banbury device (2), a turnover drive arm (9) which is connected betweenthe turnover gas cylinder (6) and the banbury box body (18), and turnover rotary joints (7) which are separately arranged at the two ends of the banbury box body (18); an engaged cooling water outlet(16) and an engaged cooling center hole (15) are separately connected to the corresponding turnover rotary joints (7); and a drive device (4) comprises a drive motor arranged on the main base (1), adrive motor which is in transmission connection to a transmission tooth type shaft coupler (11), and a transmission speed ratio gear (10) which is in key connection to the end part of an engaged rotor(12). The turnover system is reasonable in design, is compact in structure and is convenient in use.

Owner:QINGDAO UNIV OF SCI & TECH +1

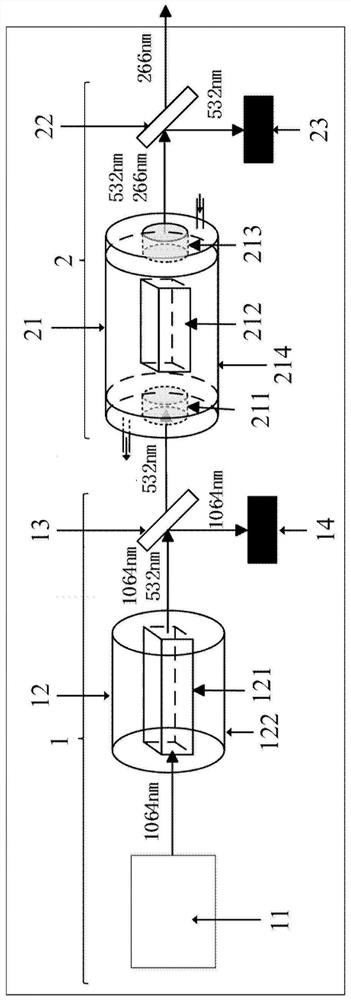

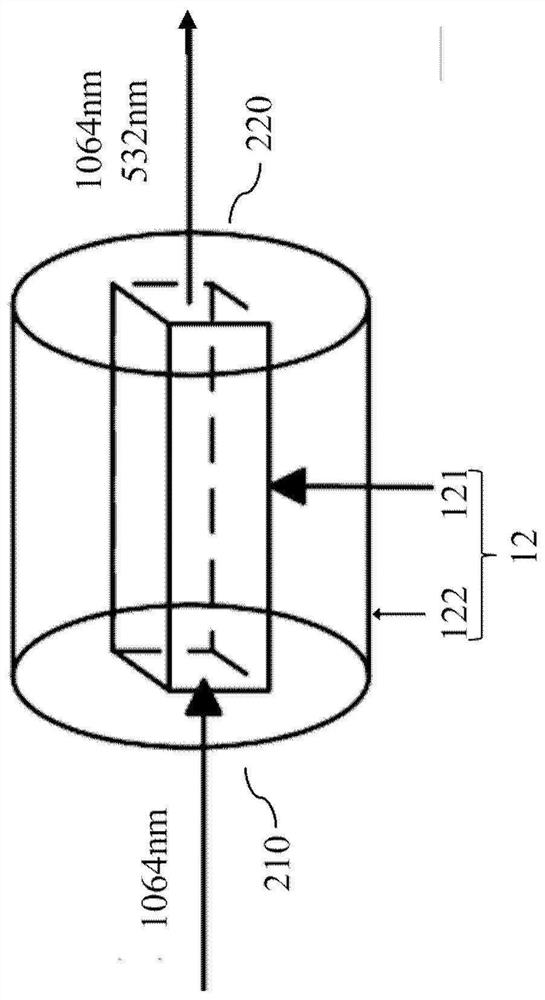

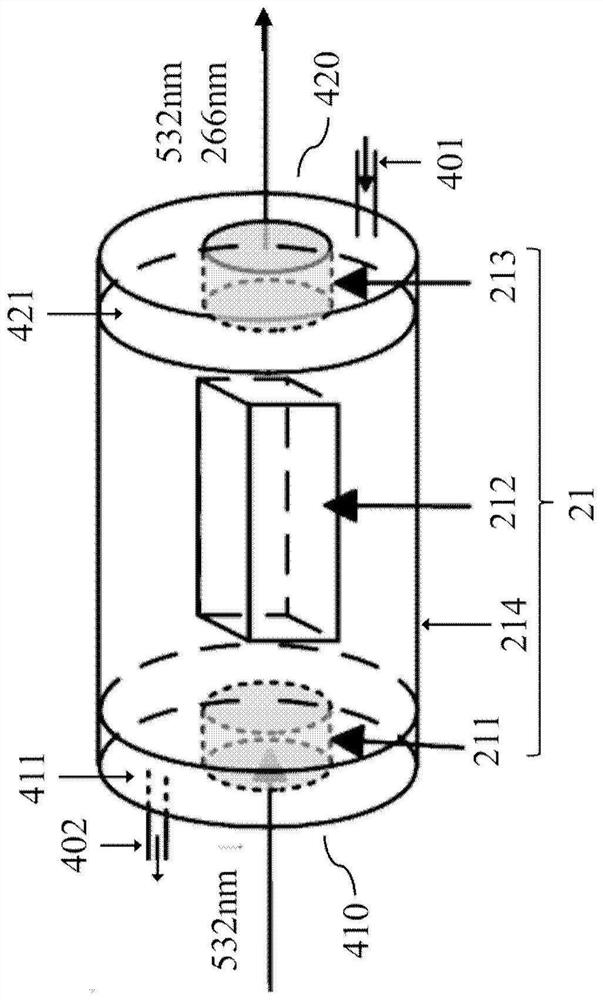

266nm solid-state laser and its beam quality optimization method

ActiveCN112510476BLow costGuaranteed tightnessActive medium shape and constructionSolid state laser constructional detailsUltravioletLight beam

The invention provides a 266nm solid-state laser and a beam quality optimization method thereof, wherein the 266nm solid-state laser includes a first frequency doubling structure and a second frequency doubling structure; After the first frequency doubling structure, it is used to receive the 532nm laser beam formed by the first frequency doubling structure and convert it into a 266nm high-power ultraviolet laser beam; wherein, the second frequency doubling structure includes a quadruple frequency doubling crystal component, and the quadruple frequency doubling crystal The component is composed of a combination of the first BBO crystal, CLBO crystal and the second BBO crystal arranged in sequence along the laser exit optical path, and is used for frequency doubling conversion of the 532nm laser beam exiting along the laser exit optical path to obtain 266nm high-power ultraviolet Laser beam. Therefore, based on the 266nm solid-state laser of the present invention, under the condition that the 266nm laser power output is guaranteed, two nonlinear crystal cascading methods of BBO crystal and CLBO crystal are used to improve the output beam quality and prolong the service life of the crystal at the same time and reduced laser cost.

Owner:RAINBOW SOURCE LASER RSLASER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com