Water-cooled pulse-vibrating vertical ring high-gradient magnetic separator

A technology of high-gradient magnetic separator and pulse vibration, which is applied in the direction of high-gradient magnetic separator, etc., can solve the problems of high operating cost, insufficient use of cooling water, complex cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

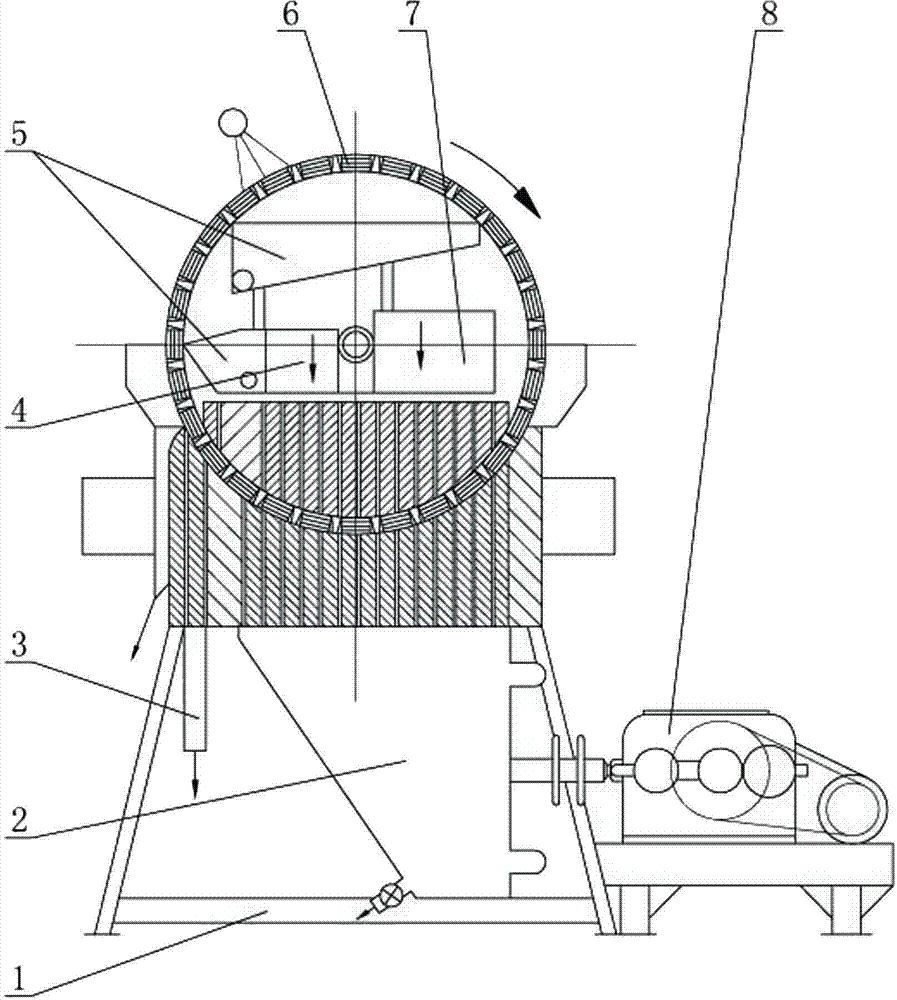

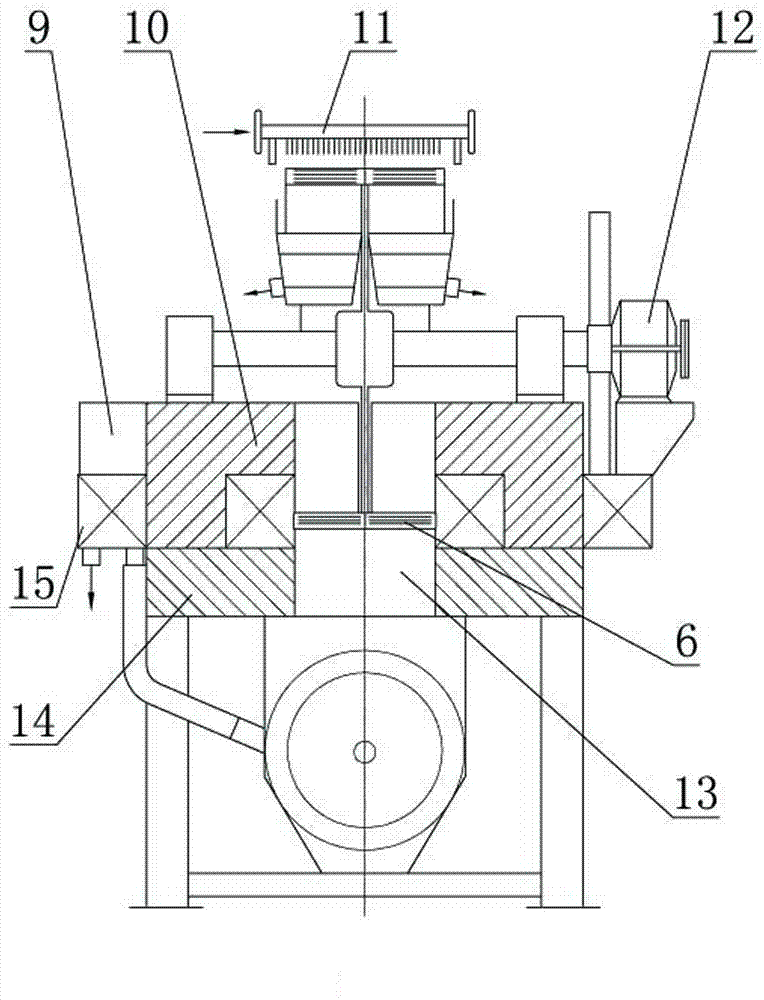

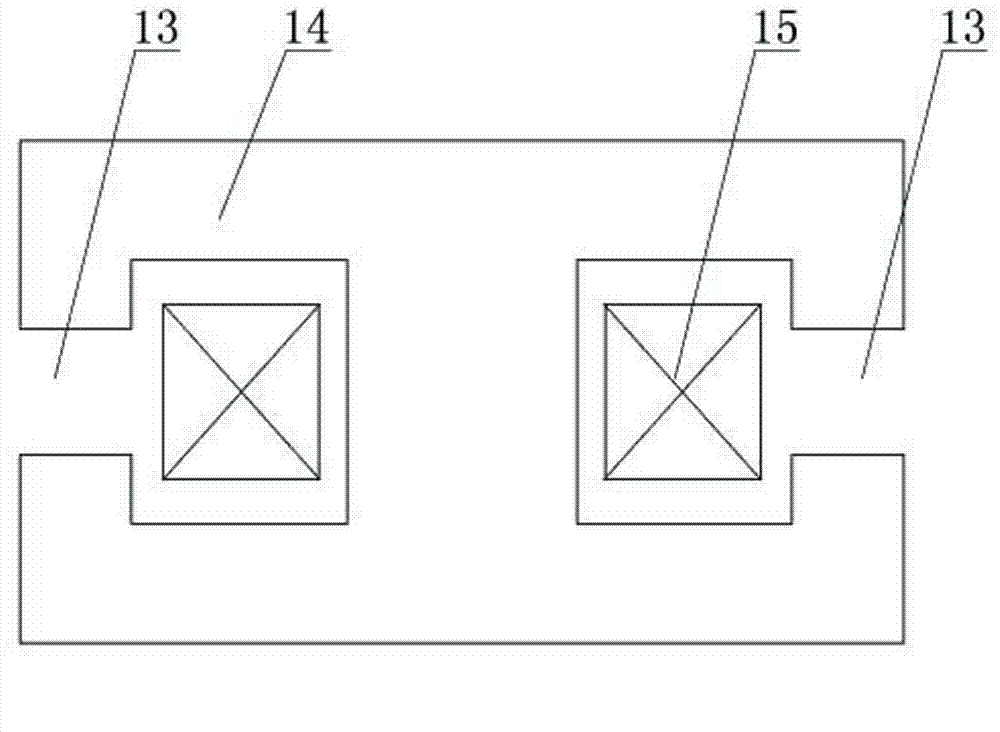

[0026] Depend on Figures 1 to 16 It can be seen that the present invention includes a supporting steel frame 1, an electromagnet 10 fixedly arranged on the supporting steel frame 1, and a magnetically conductive swivel 6 arranged above the electromagnet 10 and rotating in the working magnetic field 13 of the electromagnet 10, wherein :

[0027] Below the electromagnet 10 are provided a tailings bucket 2 and a drainage bucket 3, and one side of the tailings bucket 2 is connected with an electric pulse vibration mechanism 8 for controlling the vibration of the mineral material of the magnetic separator; Bucket 4, concentrate bucket 5 and swivel drive mechanism 12, the magnetic conduction swivel 6 is arranged on the swivel drive mechanism 12, and driven by the swivel drive mechanism 12, it rotates in the working magnetic field 13 to hold the magnetic concentrate; The upper part of the magnetic swivel 6 is also provided with a concentrate washing device 11 .

[0028] The electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com