Reinforcing ring for reversing device and preparation method thereof

A technology for reinforcing rings and commutators, applied in the field of commutators, can solve problems such as affecting the service life of the commutator, shortening the use of reinforcing rings, losing fixing effect, etc., to prevent mutual slippage and wear, and improve heat resistance. , the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

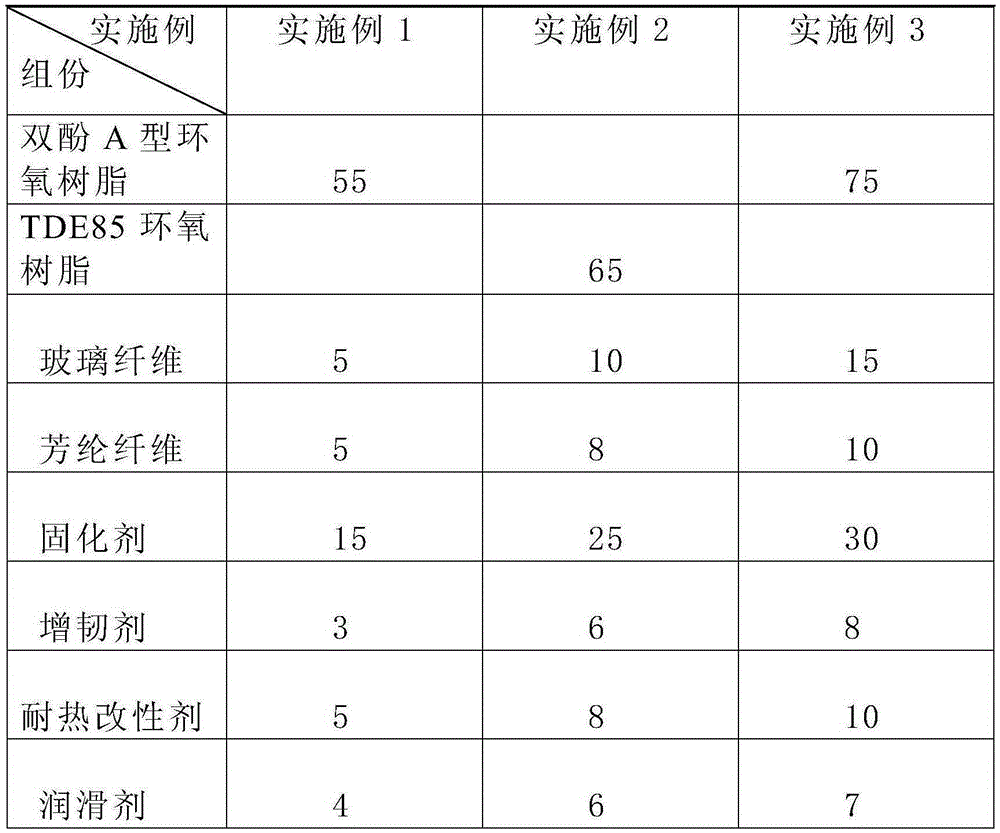

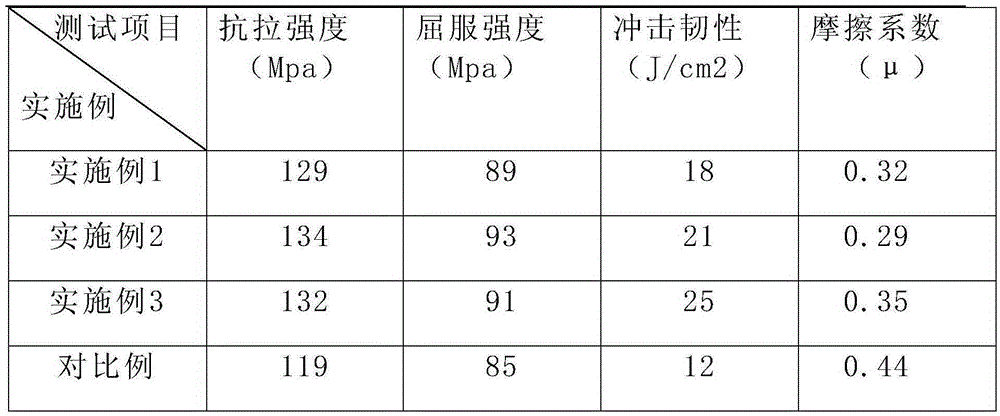

Embodiment 1

[0046] S1, take 55 parts by weight of bisphenol A epoxy resin and put it into a baking oven to preheat first, the preheating temperature is 60 degrees, and stop after preheating for 5 minutes;

[0047] S2. After the viscosity of the epoxy resin drops, take 15 parts by weight of the curing agent and add it to the bisphenol A epoxy resin, and then fully stir to fully integrate the bisphenol A epoxy resin and the curing agent to obtain a mixed liquid;

[0048] S3, heating the prepared mixed liquid, the heating temperature is 80 degrees, and the heating time is 2 minutes;

[0049]S4. During the heating process, sequentially add 3 parts by weight of a toughening agent, 5 parts by weight of a heat-resistant modifier and 4 parts by weight of a lubricant, and fully stir it to obtain a mother liquor;

[0050] S5, immerse 5 parts by weight of glass fiber and 5 parts by weight of aramid fiber in the mother liquor, fully stir for 3 minutes, make the glass fiber and aramid fiber evenly di...

Embodiment 2

[0054] S1. Take 65 parts by weight of TDE85 epoxy resin and put it into a baking oven to preheat, the preheating temperature is 65 degrees, and stop after preheating for 7 minutes;

[0055] S2. After the viscosity of the TDE85 epoxy resin drops, take 25 parts by weight of the curing agent and add it to the epoxy resin, and then fully stir to fully integrate the TDE85 epoxy resin and the curing agent to obtain a mixed liquid;

[0056] S3, heating the prepared mixed liquid, the heating temperature is 90 degrees, and the heating time is 2.5 minutes;

[0057] S4. During the heating process, sequentially add 6 parts by weight of a toughening agent, 8 parts by weight of a heat-resistant modifier and 6 parts by weight of a lubricant, and fully stir it to obtain a mother liquor;

[0058] S5. Immerse 10 parts by weight of glass fiber and 8 parts by weight of aramid fiber in the mother liquor, fully stir for 3-5 minutes, so that the glass fiber and aramid fiber are evenly distributed, a...

Embodiment 3

[0062] S1. Take 75 parts by weight of bisphenol A type epoxy resin and put it into a baking oven to preheat first. The preheating temperature is 70 degrees, and stop after preheating for 8 minutes;

[0063] S2. After the viscosity of the epoxy resin drops, take 30 parts by weight of the curing agent and add it to the bisphenol A epoxy resin, and then fully stir it to fully integrate the bisphenol A epoxy resin and the curing agent to obtain a mixed liquid;

[0064] S3, heating the prepared mixed liquid, the heating temperature is 100 degrees, and the heating time is 3 minutes;

[0065] S4. During the heating process, sequentially add 8 parts by weight of a toughening agent, 10 parts by weight of a heat-resistant modifier and 7 parts by weight of a lubricant, and fully stir it to obtain a mother liquor;

[0066] S5, immerse the glass fiber and the aramid fiber in the mother liquor, fully stir for 5 minutes, so that the glass fiber and the aramid fiber are evenly distributed, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com