Ceramic electric soldering iron

A technology of electric soldering iron and ceramics, which is applied in the direction of soldering iron, metal processing equipment, welding equipment, etc. It can solve the problems of unguaranteed grounding voltage, damage to internal equipment of electric soldering iron, and shortened service life. It achieves low price, eliminates static electricity, and avoids damage. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

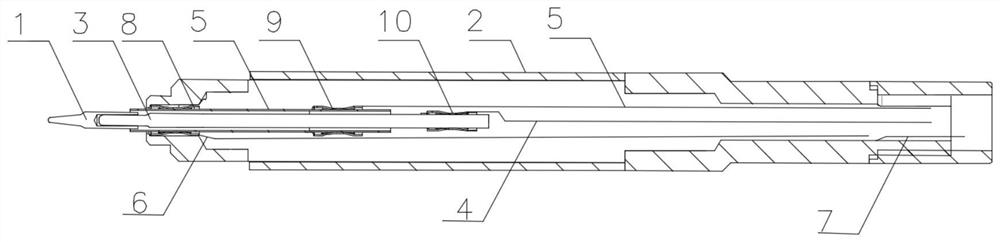

[0018] Such as figure 1 As shown, a ceramic electric soldering iron includes a soldering iron head 1, a handle 2, a ceramic heating element 3, a positive lead 4, a negative lead 5, a lead 6 and a ground wire 7, and the front end of the ceramic heating element 3 is connected to the soldering iron tip 1 , the handle 2 wraps the ceramic heating element 3 and the soldering iron tip 1, the soldering iron tip 1 passes through the front end of the handle 2, the negative lead 5 is connected to the soldering iron tip 1, the negative lead 5 Lead out from the middle of the ceramic heating element 3, the negative electrode lead 5 and the positive electrode lead 4 form a loop in the ceramic heating element 3, and heat the ceramic heating element 3, the front end of the ceramic heating element 3 The lead wire 6 is drawn from the negative lead wire 5, and the lead wire 6 is connected to the control and detection center to detect the grounding voltage and grounding resistance. The closer the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com