Patents

Literature

44results about How to "Easy arc start" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-protection core welding stick used for underwater wet welding

ActiveCN103084761AGood mechanical propertiesEasy arc startWelding/cutting media/materialsSoldering mediaManganeseMechanical property

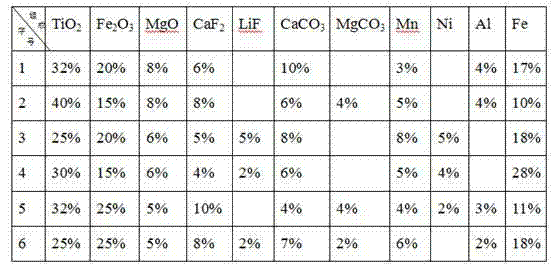

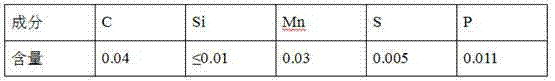

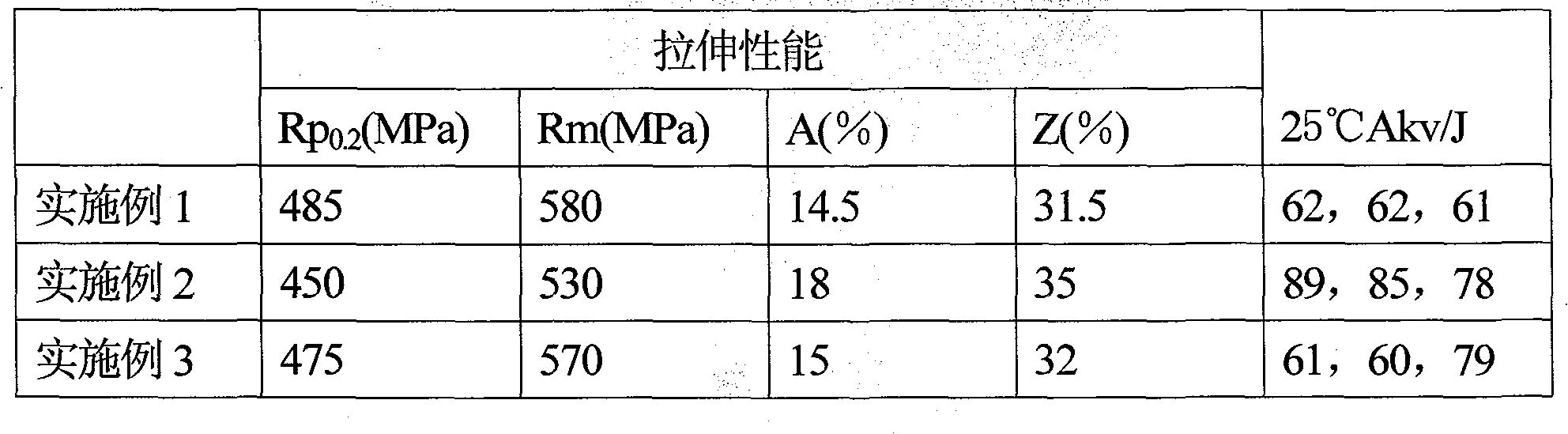

The invention provides a self-protection core welding stick used for underwater wet welding. The self-protection core welding stick used for underwater wet welding comprises two parts including a protection covering and a core wire and is characterized in that the protection covering is formed by rolling up a low-carbon steel belt, wherein the low-carbon steel belt comprises, by weight, 0.03% to 0.08% of carbon (C), 0.03% of manganese (Mn), <=0.02% of sulfur (S) and <=0.02% of phosphorus (P). The core is composed of oxide, fluoride, carbonate, manganese powder, nickel powder, aluminum powder and iron powder. The components comprises, by mass, 50%-63% of oxide, 5%-10% of fluoride, 5%-10% of carbonate, 3%-8% of manganese powder, 0%-5% of nickel powder, 0%-4% of aluminum powder and 10%-30% of iron powder. The self-protection core welding stick used for underwater wet welding is not only good in mechanical property, but also simple in arc starting in welding, stable in electric arc combustion, good in arc restarting capacity, and beautiful in appearance of a gained welding joint. The strength of extension of a butt joint can reach 500 Mpa. The self-protection core welding stick used for underwater wet welding can be used for welding of the underwater structure of low-carbon and low-alloy steel.

Owner:HARBIN INST OF TECH AT WEIHAI

Self-protection flux-cored wire for underwater wet-method welding

ActiveCN104057214AEasy arc startGood mechanical propertiesWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a self-protection flux-cored wire for underwater wet-method welding. The self-protection flux-cored wire is characterized in that a N6 nickel band is used as a metal covering of the wire, an alkaline calcium fluoride-aluminum oxide slag system is used as a flux-cored basic slag system, the internal flux core consists of calcium fluoride, aluminum powder, iron powder, magnesium oxide, silicon iron, lithium fluoride, manganese powder and metal chromium, and the weight percent of each component is as follows: 40 to 55 percent of calcium fluoride, 8 to 13 percent of aluminum powder, 5 to 9 percent of iron powder, 0.5 to 5 percent of magnesium oxide, 3 to 7 percent of silicon iron, 3 to 9 percent of lithium fluoride, 6 to 11 percent of manganese powder and 4 to 10 percent of metal chromium. When the flux-cored wire is used for the underwater wet-method welding, arc is likely to start, the electric arc is stable in combustion, the restarting arc is good in performance, the forming property of the weld seam is good, the tensile strength of the weld metal after being welded is not lower than 460MPa, and the underwater welding of the medium-low carbon steel and low-alloy high-strength steel structure of ordinary strength requirement can be satisfied.

Owner:HARBIN INST OF TECH AT WEIHAI

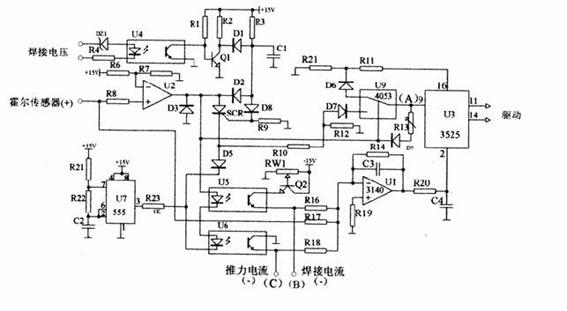

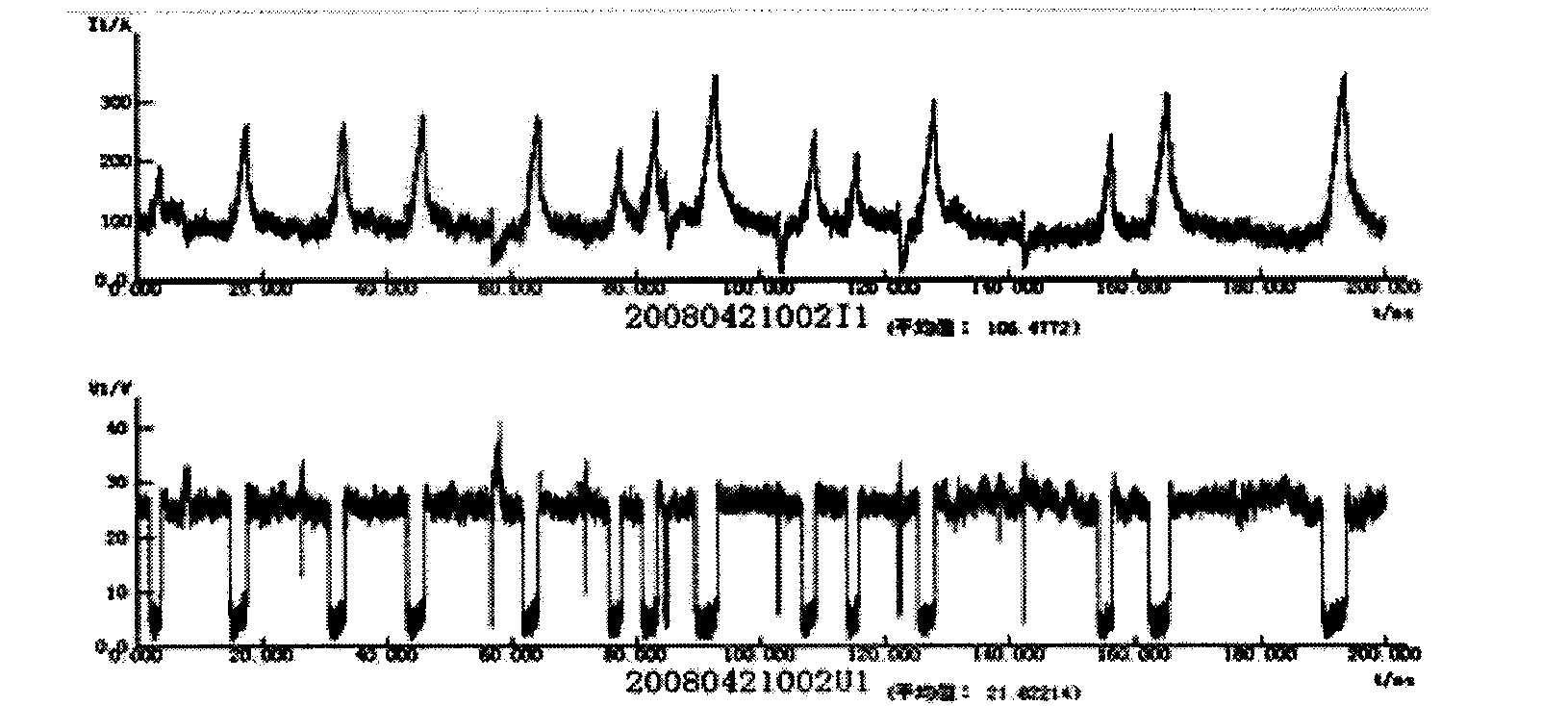

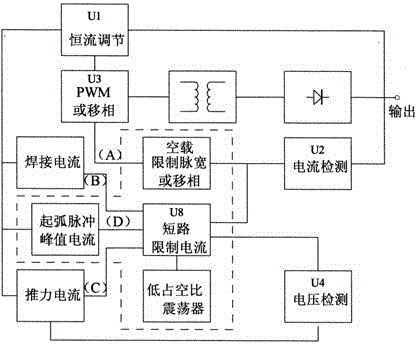

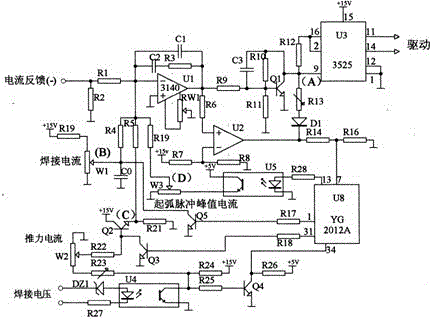

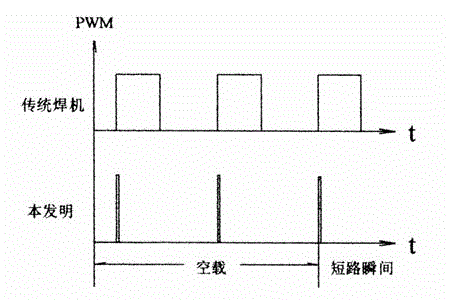

Touch arc striking electric welding machine and electric welding touch arc striking control method

InactiveCN102672308AEliminate overshoot currentEliminate stickingArc welding apparatusWelding power supplyElectric current flow

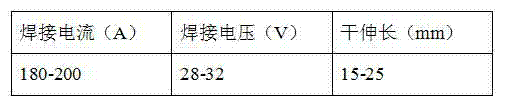

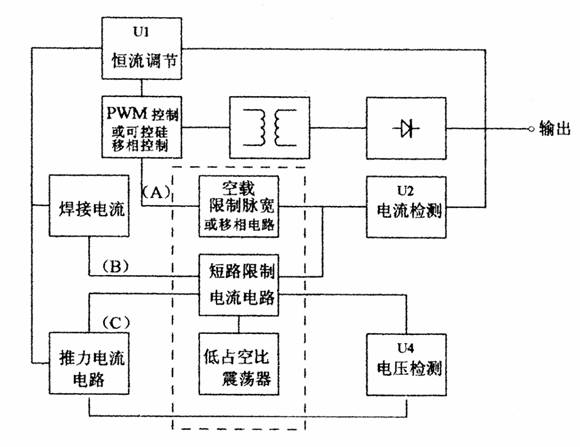

The invention belongs to the field of electric welding, and particularly relates to a touch arc striking electric welding machine and an electric welding touch arc striking control method. By applying pulse current of low frequency and low duty ratio during short circuit of the electric welding machine, frequent overshoot current of the electric welding machine is eliminated, the reliability of a welding power source is greatly improved, and a welding rod adhesion phenomenon is eliminated to easily strike arc.

Owner:刘裕国

High-strength underwater welding electrodes

InactiveCN1939649AEasy arc startStable arc burningWelding/cutting media/materialsSoldering mediaUnderwater weldingHigh intensity

A high-strength wet welding electrode for underwater welding is composed of the core made of H08E steel wire a coated surficial water-proof layer, and a coated sandwich layer containing rutile (42-54 Wt%), potash feldspar (12-20), talc (6-14), cellulose (4-12), ferromanganese (6-14), Ni powder (0-4), Fe powder (3-12) and Al-Mg alloy (0-4).

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Self-protective flux-cored wire for all-position underwater wet welding in deep water environment

ActiveCN106964918AMeet weldingEasy arc startWelding/cutting media/materialsSoldering mediaSlagFilling rate

The invention belongs to the technical field of welding materials and discloses a self-protective flux-cored wire for all-position underwater wet welding in a deep water environment. The self-protective flux-cored wire comprises a metal skin and a flux core. The metal skin is formed by rolling an N6 nickel strip. The basic slag system of the flux core is an alkaline calcium fluoride-aluminum-magnesium slag system. The N6 nickel strip comprises, by weight, no smaller than 99.5% of Ni and Co in total, no larger than 0.06% of Cu, no larger than 0.10% of Fe, no larger than 0.05% of Mn, no larger than 0.10% of C, no larger than 0.10% of Si and no larger than 0.005% of S. The flux core comprises, by mass, 52-67% of fluoride, 14-20% of aluminum-magnesium alloy powder, 5-10% of calcium carbonate, 5-15% of ferromanganese, 3-10% of chromium, 4-10% of titanium and 1.5-5% of rare earth. The filling rate of the flux core in the flux-core wire is 24-32%. According to the scheme provided by the invention, the self-protective flux-cored wire can be used for welding under water by 100-200 meters, arcing is easy during welding, arc burning is stable, no arc blowout or breaking phenomenon occurs, an obtained welding seam is attractive in forming, the tensible strength of deposited metal after welding is larger than 500 MPa, and the self-protective flux-cored wire has good impact toughness and meets the all-position welding requirements of medium and low carbon steel and low alloy high strength steel in the deepwater environment.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

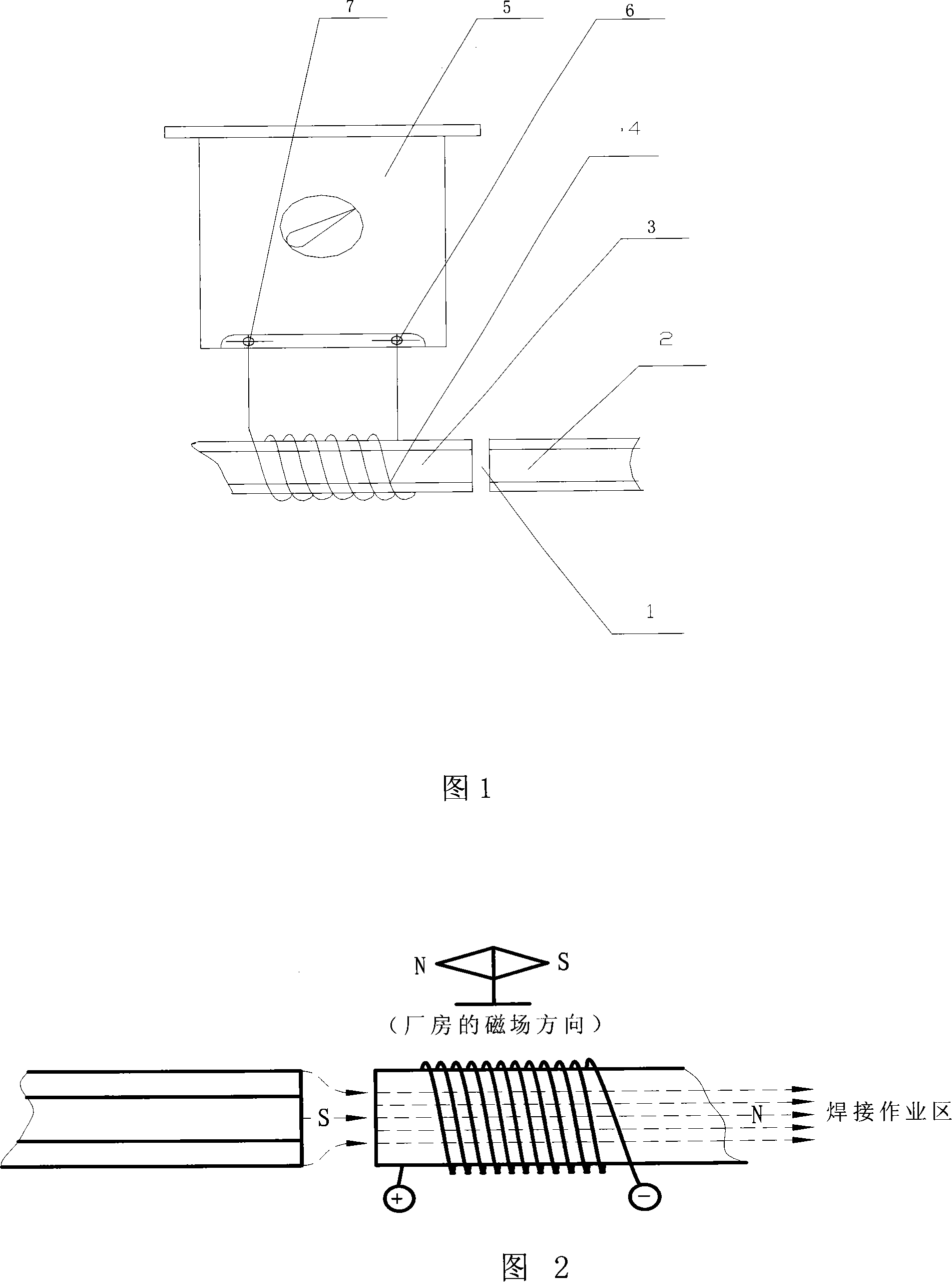

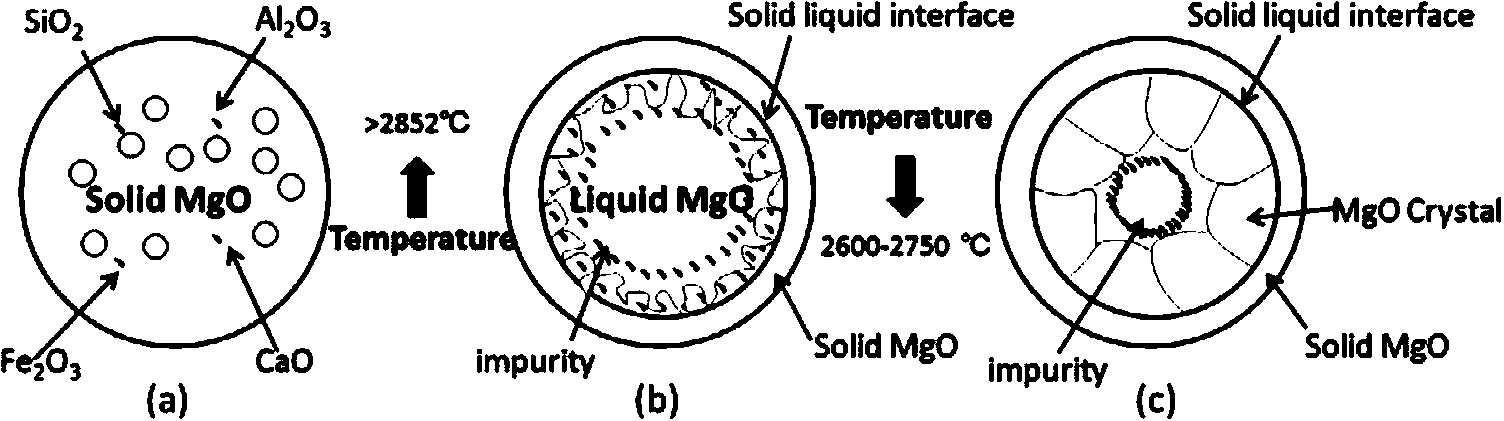

Method for welding metal under strong magnetic field circumstance

InactiveCN101148009ASolve welding difficultiesReduce welding defectsMagnetic bodiesWelding/cutting auxillary devicesElectricityWeld seam

The present invention relates to welding technology, and is especially metal welding method in strong magnetic field environment. The metal welding method in strong magnetic field environment includes measuring the strength and direction of the environmental magnetic field with special instrument, forming one coil of certain turn number and winding direction and connecting the coil to one metal workpiece to be welded, connecting the coil to one DC welder to generate one magnetic field in the same strength as and reverse direction to the environmental magnetic field, and welding with one other welder in no or weak magnetic field condition. The method of the present invention can result in high welding quality, weld seam strength reaching 80 % of mother material strength and tensile strength of the weld seam up to 700 MPa.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

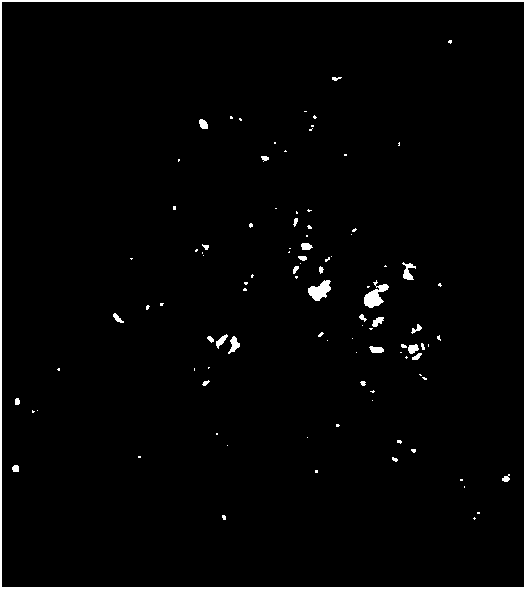

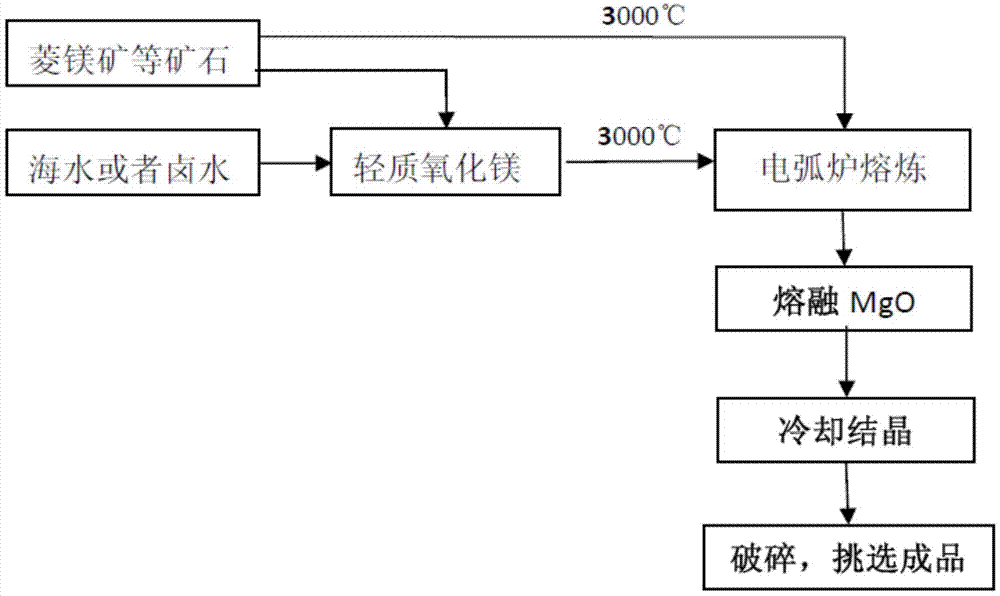

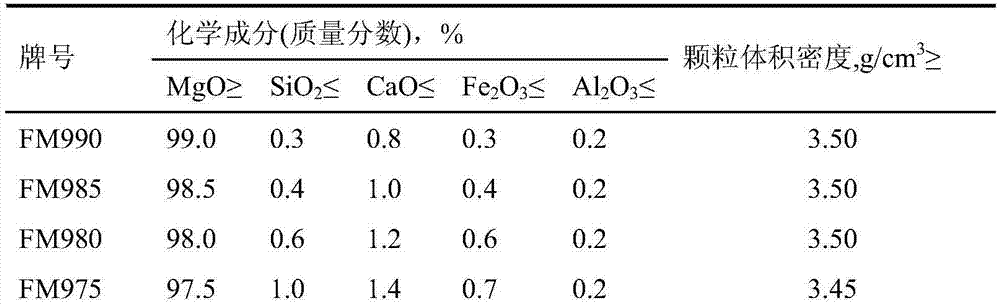

Additive for producing macrocrystalline fused magnesite

The invention relates to an additive for producing macrocrystalline fused magnesite. Main components of the additive are high purity graphite powder, rare earth oxide composition and zirconium oxide. The additive is characterized in that the addition mass of the high purity graphite powder accounts for 0.5-5% of the mass of magnesium oxide, the addition mass of the rare earth oxide accounts for 0.01-1.5% of the mass of magnesium oxide, and the addition mass of zirconium oxide accounts for 0.1-3% of the mass of magnesium oxide. The massive white transparent high purity fused magnesite is obtained by pointedly adding corresponding impurity removal materials according to the type and content of impurities in the magnesium oxide raw material in combination with an appropriate technological process; the technological process is simple; the dosage of the additive is small, but the additive has an obvious effect. Due to optimization of the additive and the technology, the melting power and time are reduced, the utilization rate of raw materials is increased, and the effects of energy conservation and emission reduction are achieved. The additive is easy to obtain, simple in process, low in cost and suitable for large-scale industrial production and application; requirements for required equipment are low.

Owner:EAST CHINA UNIV OF SCI & TECH

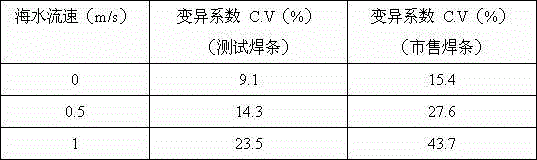

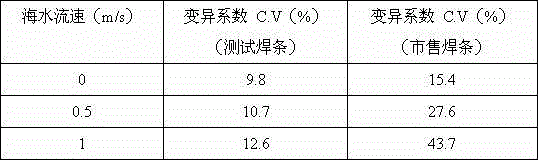

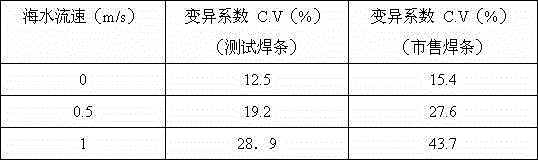

High-stability coating for underwater wet welding rod

InactiveCN104874939ASmooth startStable arc burningWelding/cutting media/materialsSoldering mediaSolid componentCoating

The invention discloses a high-stability coating for an underwater wet welding rod. The coating is prepared by mixing a solid component and a liquid component, wherein the mass of the added liquid component is 15%-20% of that of the solid component; the solid component is prepared from raw materials in percentage by mass as follows: 45%-55% of rutile, 10%-16% of fluorite, 5%-8% of marble, 4%-8% of ferromanganese, 8%-15% of nickel powder, 8%-10% of cryolite and 0%-2% of cesium nitrate; the liquid component adopts potassium-sodium water glass with the potassium-sodium ratio being 3:1 at the temperature of 20 DEG C. According to the high-stability coating for the underwater wet welding rod, arc strike can be performed smoothly under the conditions that the water depth doesn't exceed 20 meters and the water velocity is not higher than 1.2 m / s, continuous stable combustion is realized, an electric arc extinguishing phenomenon is avoided, the strength is higher than or equal to 400 MPa, and the welding requirements of a non-structural member are basically met.

Owner:青岛哈工海洋工程技术有限公司

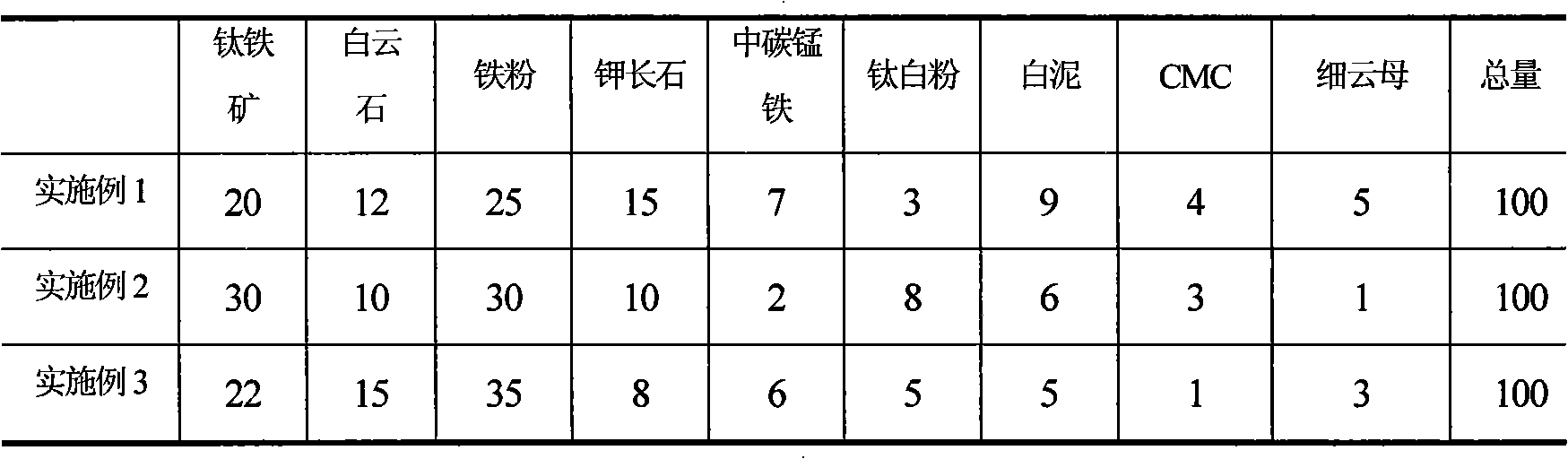

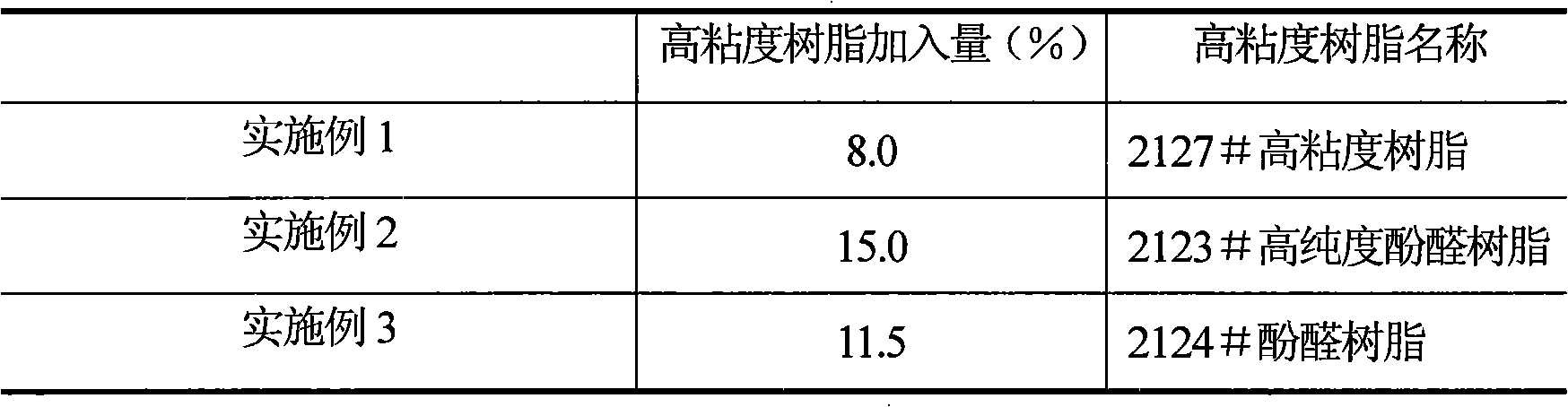

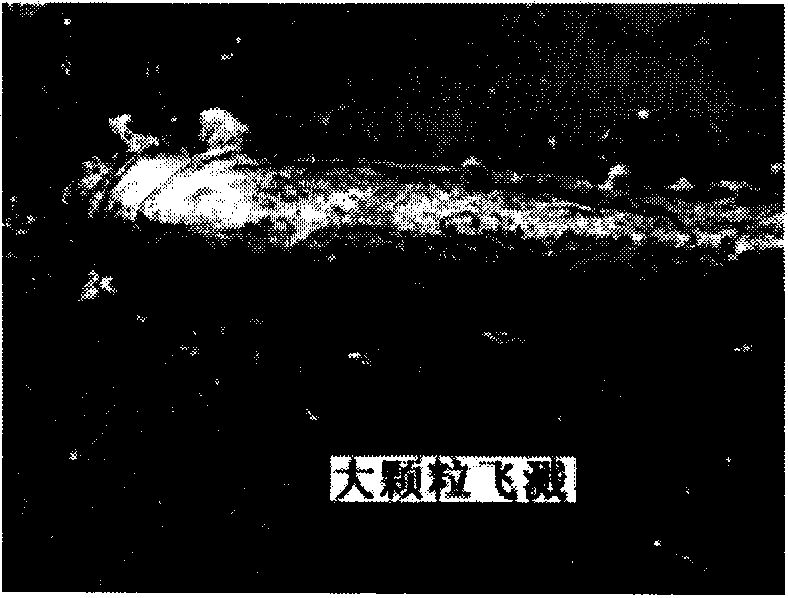

Low-cost wet method underwater welding rods

InactiveCN101347873ASimple production processIncrease productivityWelding/cutting media/materialsSoldering mediaSlagPotassium

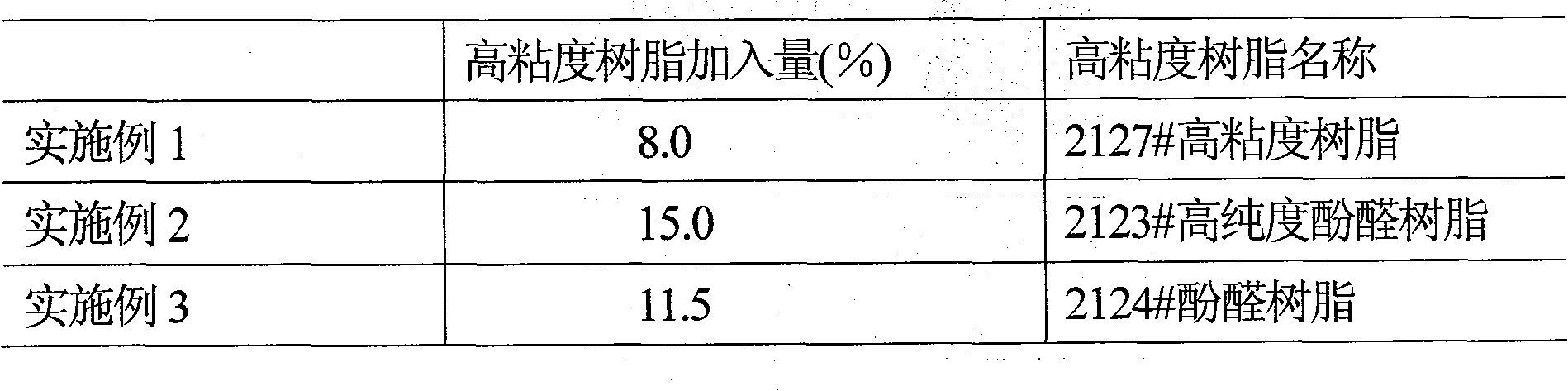

The invention provides a low-cost underwater wet welding rod which adopts a commercial H08E welding wire as a welding core; the main components and weight proportion of coating are as follows: 20-30% of ilmenite, 10-15% of dolomite, 25-35% of ferrous powder, 8-15% of potassium feldspar, 2-7% of medium-carbon ferromanganese, 5-9% of white slime, 3-8% of titanium pigment, 1-4% of CMC and 1-5% of fine mica; the high viscosity resin which accounts for 8-15% of the total weight of the coating components is added. By adopting the high viscosity resin as an adhesion agent, the welding rod of the invention can be directly applied to underwater wet welding after extrusion and does not need to be coated with a waterproof coating on the surface, thus simplifying production technique, improving production efficiency and reducing production cost; the invention can ensure that after the welding rod is soaked in water for a long time, the coating dose not go bad and drop off, and welding operation can still be carried out. When used in underwater welding, the welding rod has the advantages of easy arc striking, stable combustion of electric arc, good performance of restarting, easy slag detachability, good weld forming and fine processing property of underwater welding.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

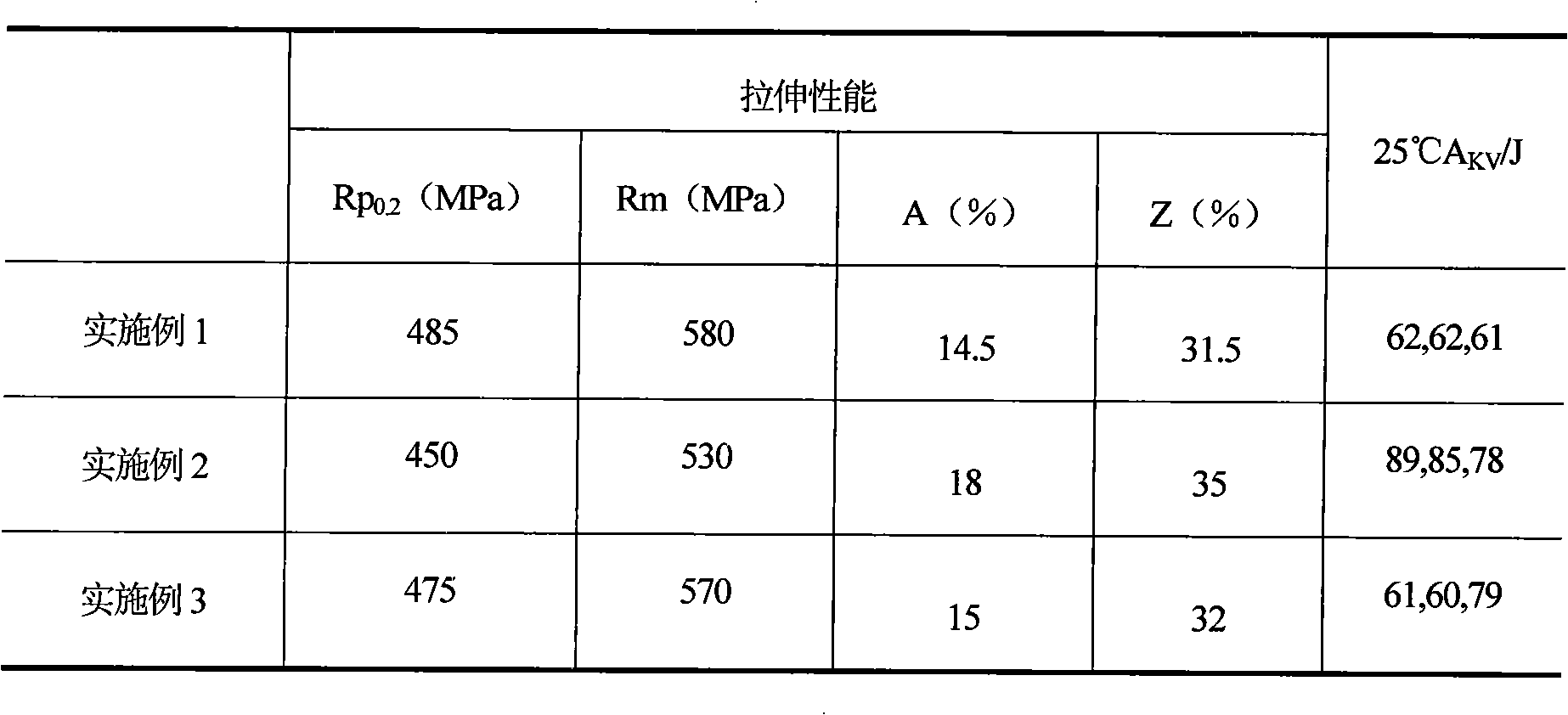

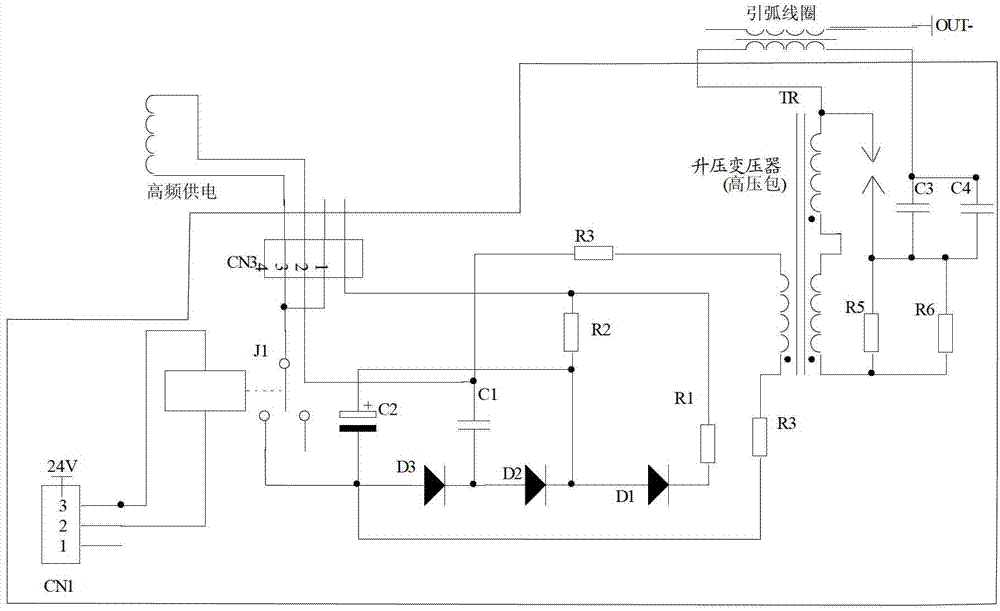

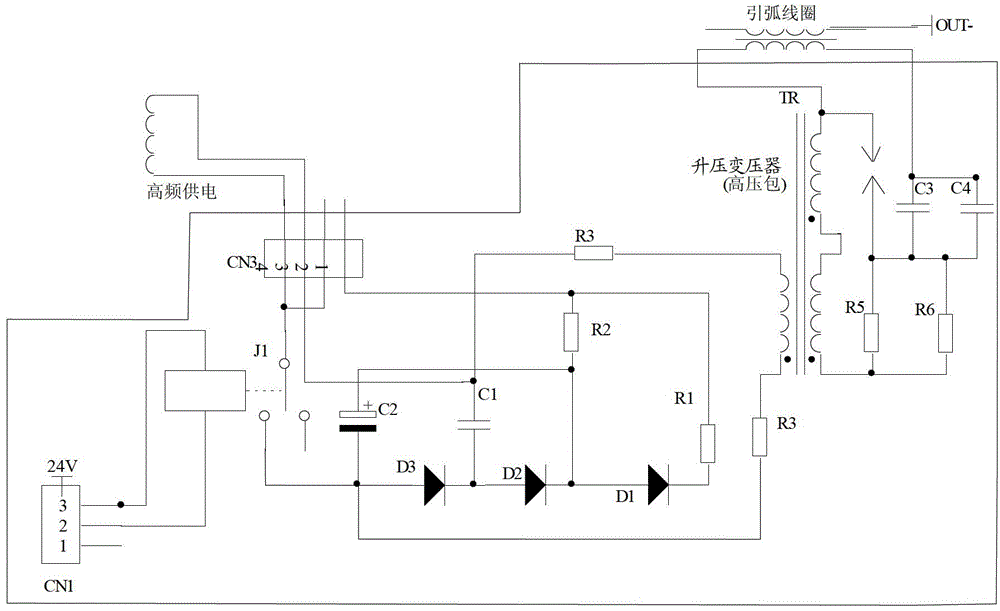

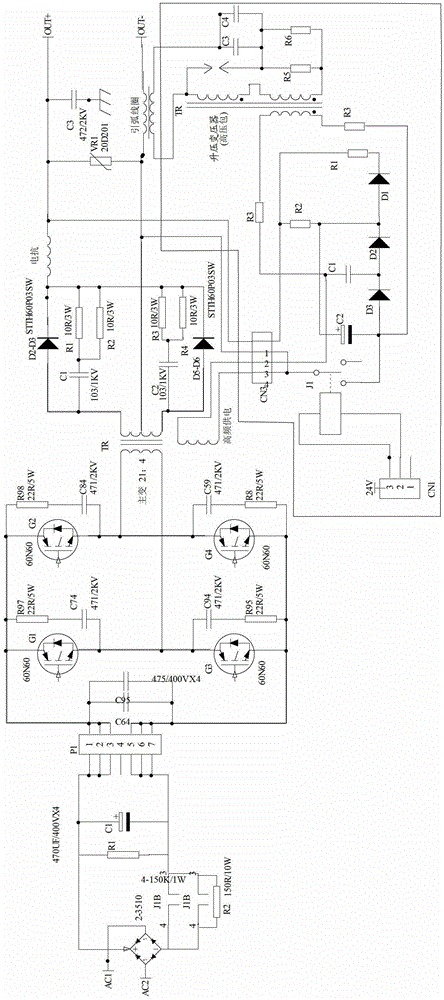

High frequency arc ignition circuit with direct current voltage output

InactiveCN103111719AEasy breakdownIncrease success rateArc welding apparatusEngineeringHigh pressure

The invention relates to a high frequency arc ignition circuit with direct current voltage output. The high frequency arc ignition circuit with direct current voltage output comprises a high frequency signal source, a relay, a high frequency voltage booster circuit and a voltage doubling circuit. The high frequency signal source is respectively connected with the input end of the voltage doubling circuit and the input end of the high frequency voltage booster circuit through the relay. The output end of the voltage doubling circuit outputs direct current voltage to secondary positive and negative electrodes of a welding machine main circuit. The high frequency voltage booster circuit produces high frequency high voltage signals and the high frequency high voltage signals are coupled to the secondary negative electrode of the welding machine main circuit and outputted. With the aid of the voltage doubling circuit, the direct current voltage is added to the high frequency arc ignition circuit with direct current voltage output on the condition of high frequency arc starter, air can be punctured more easily at the time of high frequency arc starter, arcing is easier, and success rate of arcing and arcing performance of the welding machine can be improved.

Owner:广东世博科焊接工程技术有限公司

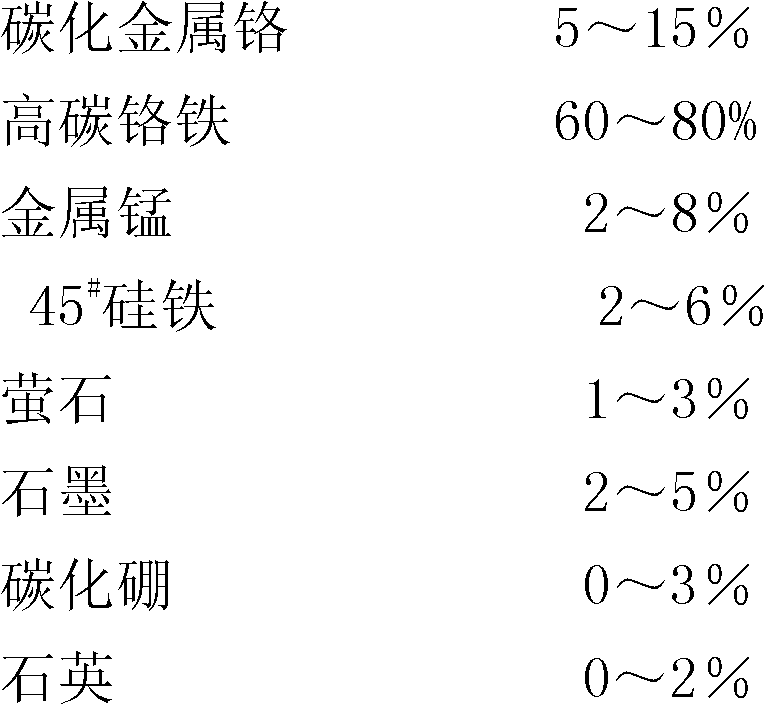

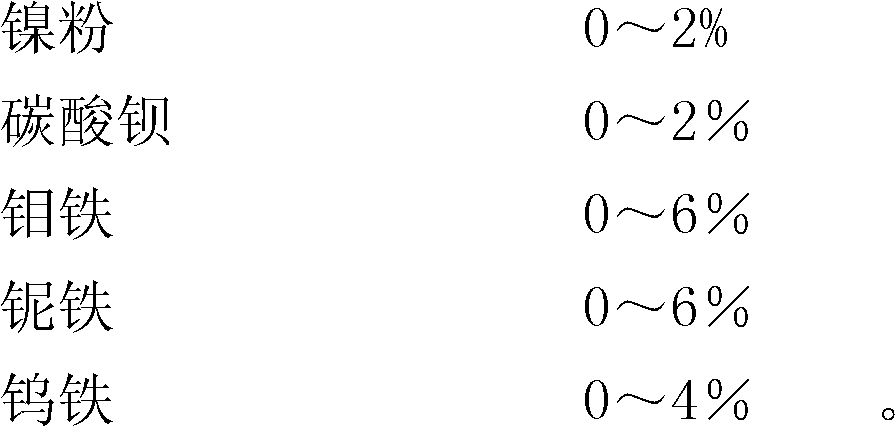

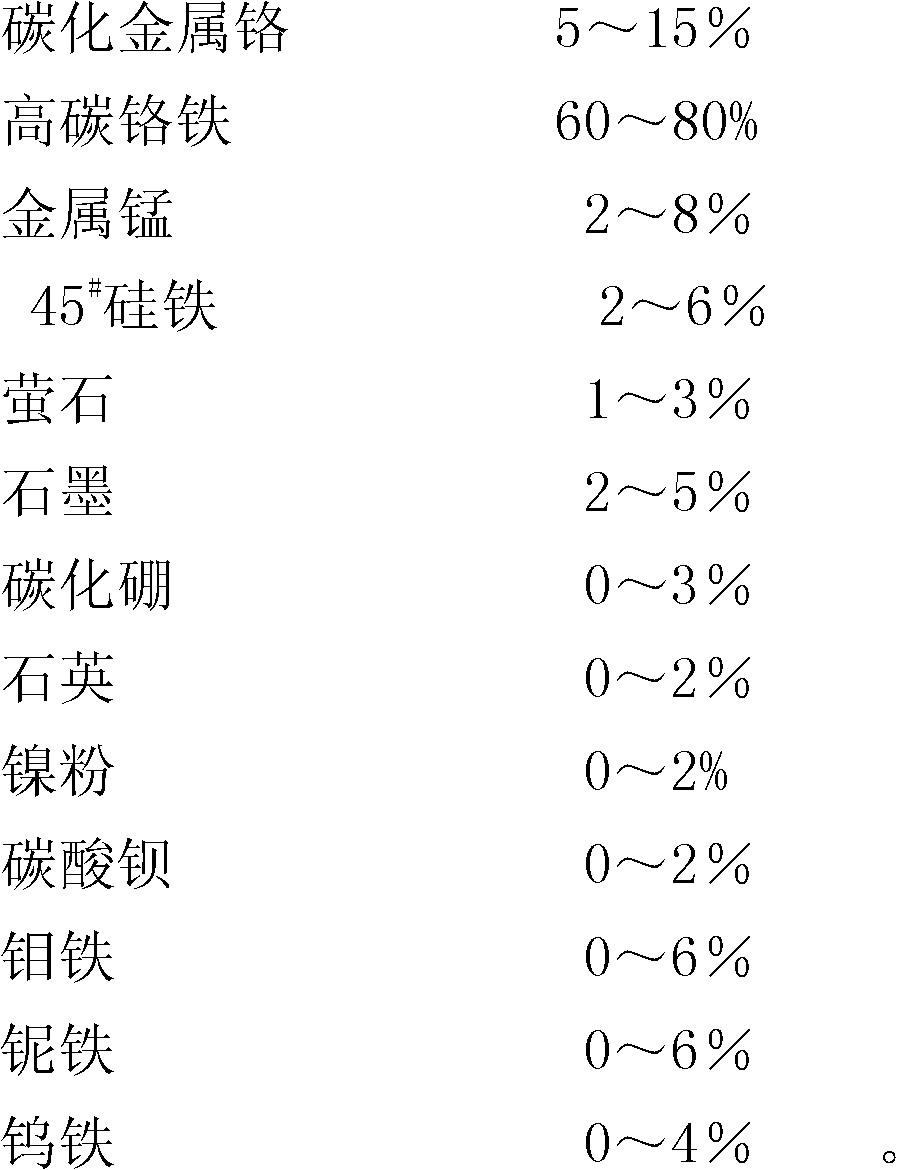

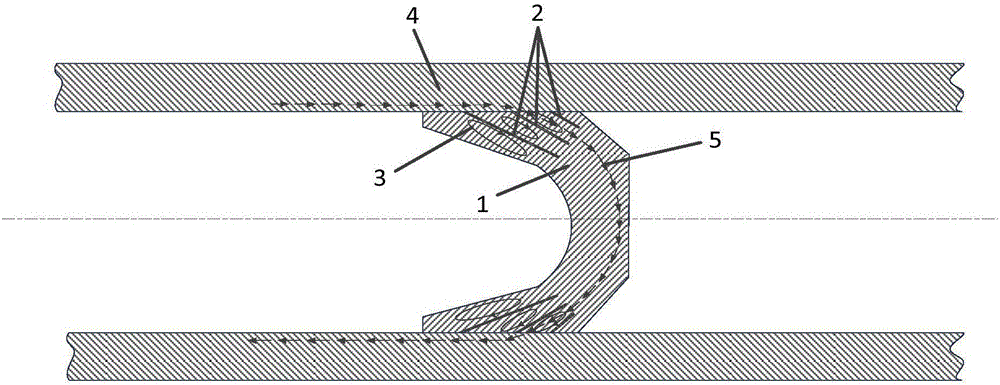

Slag-free surfacing welding rod

ActiveCN102416531AImprove deposition efficiencyEasy arc startWelding/cutting media/materialsSoldering mediaHigh carbonNiobium

The invention relates to a slag-free surfacing welding rod, which comprises a welding core (using an H08A welding core) and a coating. Powdered raw materials, including carbonized chromium, high carbon ferrochrome, manganese, No. 45 ferrosilicon, fluorspar, graphite, boron carbide, quartz, nickel powder, barium carbonate, molybdenum iron, niobium iron and tungsten iron are mixed to obtain the coating; potassium-sodium water glass with the weight being 5 percent of the weight of the coating powder and the modulus being 45 is slowly added into the prepared coating powder and then mixed; the coating is uniformly and concentrically extruded on the H08A welding core with the diameter being 4.0mm to obtain the surfacing welding rod according to a mass ratio of the coating which is added with the water glass: the welding core being 2:1. . When the slag-free surfacing welding rod with high wear resistance is applied in surfacing, continuous surfacing can be realized with no need to knock off slag, the deposition efficiency is high, arcs can be easily formed, no red tails can be formed in the continuous surfacing, and the hardness of deposited metal can reach above HRc65. The slag-free surfacing welding rod can be applied in composite manufacturing and repair of various products subject to intermediate and low stress and serious abrasive wear.

Owner:中机焊业科技(福建)有限公司

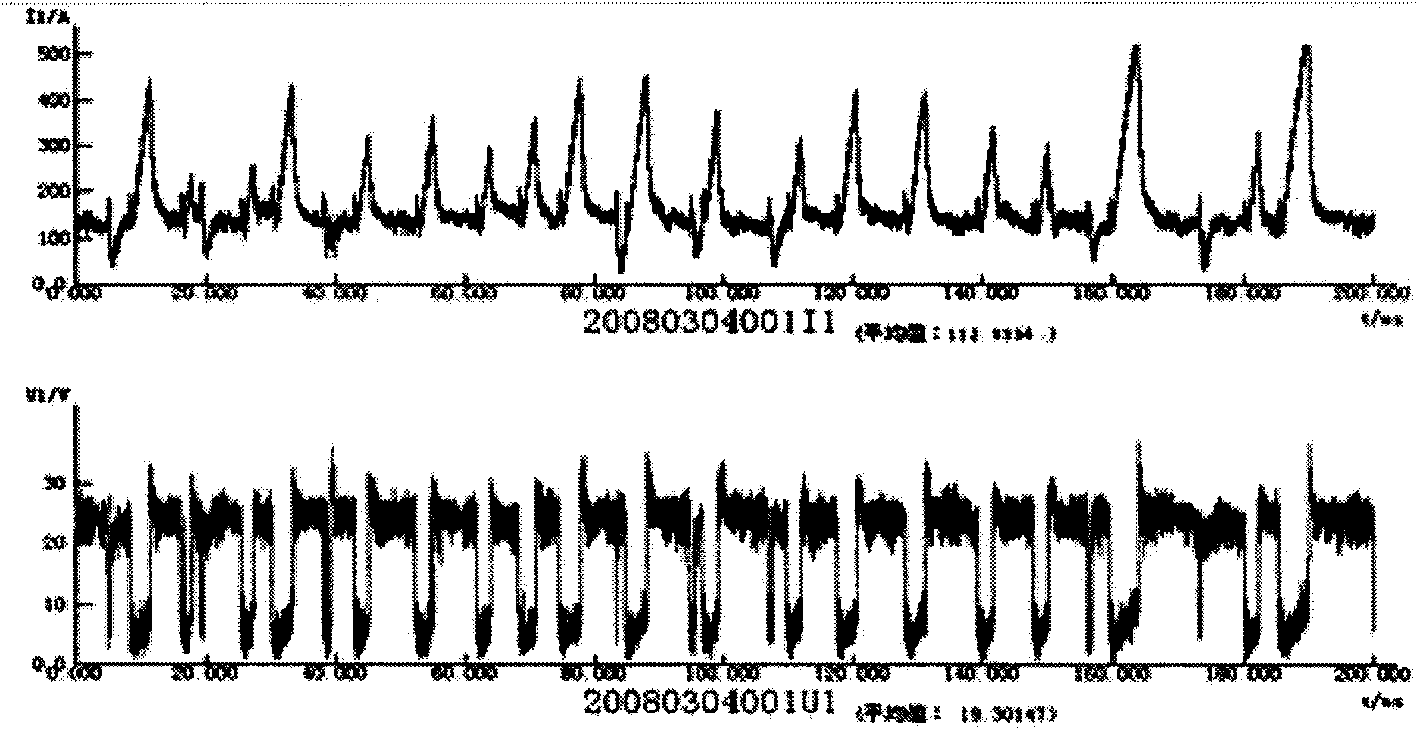

Method for inhibiting armature transition through reducing vortex based on empennage layering

The invention discloses a method for inhibiting armature transition of an electromagnetic rail launching device. The method is characterized in that the strength of a vortex in an armature empennage of a drive current falling section of the electromagnetic rail launching device can be reduced, and armature transition is inhibited; empennage layering is designed, and spaces between the layers are filled with C-shaped armatures made from an insulating high temperature resistant material; main structures of the armatures are processed and manufactured through 6061 aluminium alloy and are used for conducting a drive current; the interlayer insulating material is made from an epoxy resin glass fiber material, and is used for blocking the flowing path of the vortex; relative to single C-shaped armatures frequently utilized at present, the armatures have relatively large vortex impedance; and at the drive current falling section, the strength of the vortex in the armature empennage is effectively reduced, the falling speed of contact force of the armatures and rails is decreased, the armatures and the rails can keep a good electric contact state, and armature transition is inhibited. The method is high in applicability and easy to achieve, and an effective solution is provided for inhibiting transition inhibition of the electromagnetic rail launching device.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Additive for producing high-purity fused magnesite

The invention relates to an additive for producing high-purity fused magnesite. The main components of the additive are high-purity graphite powder, rare earth oxide and titanium oxide. The additive is characterized in that the adding dosage of the high-purity graphite powder is 0.5-5% of the mass of magnesium oxide; the adding dosage of the rare earth oxide is 0.01-0.5% of the mass of magnesium oxide; the adding dosage of titanium oxide is 0.1-5% of the mass of magnesium oxide. In the additive provided by the invention, the chemical form oxides are used for replacing an expensive rear earth alloy material, the main components of the additive are high-purity graphite powder, such rare earth oxide combinations as lanthanum oxide, cerium oxide and the like and titanium oxide, and the components are added in the raw material in different smelting stages; impurity removal and purification are performed by means of the excellent properties of the rare earth oxide and titanium oxide, and massive white transparent high-purity fused magnesia is obtained by appropriate process flows.

Owner:EAST CHINA UNIV OF SCI & TECH

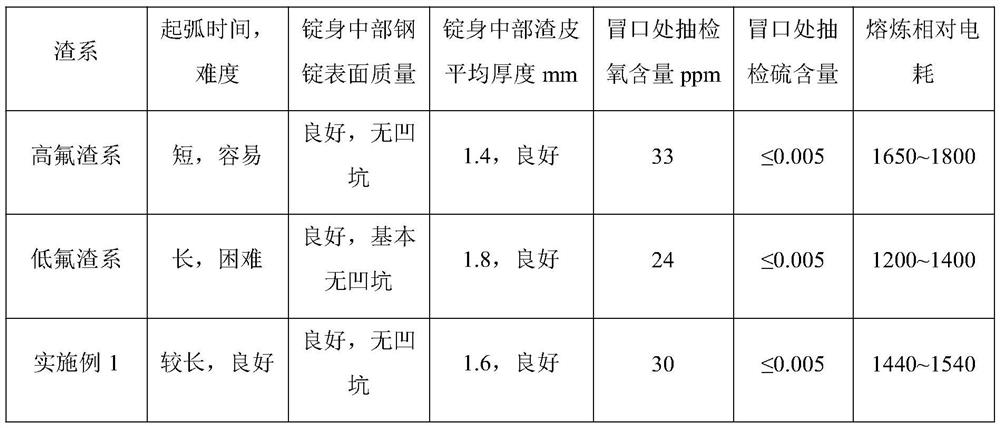

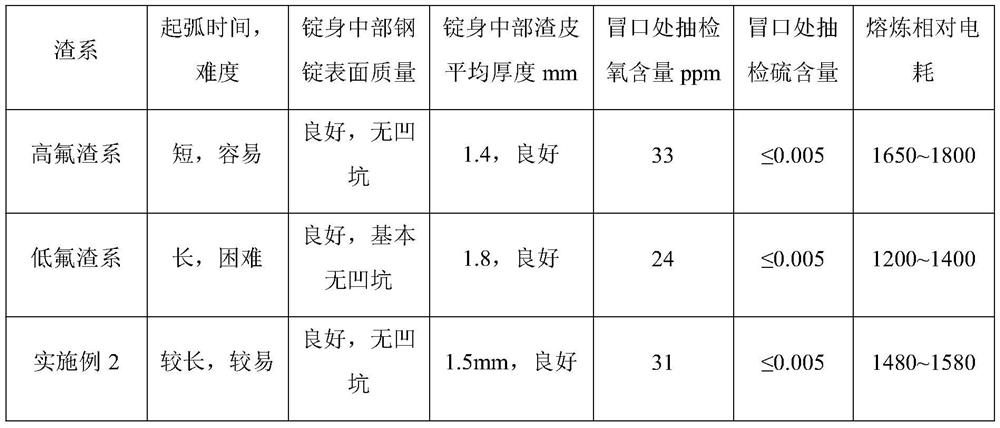

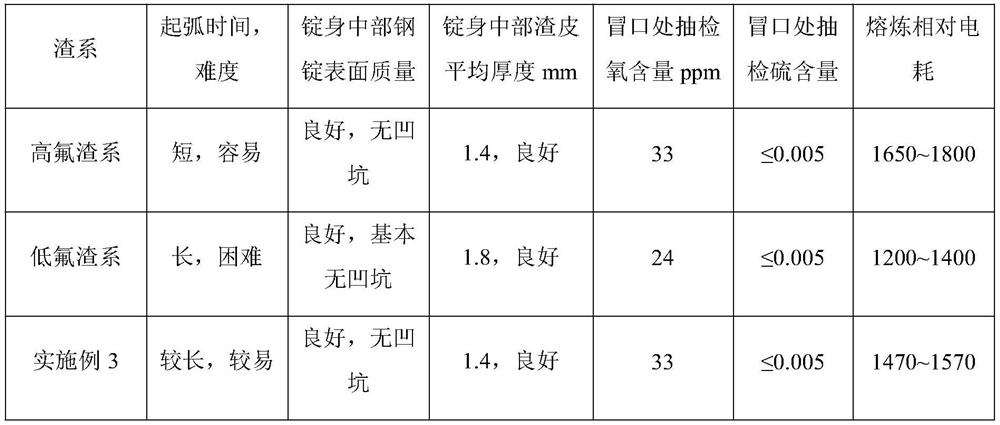

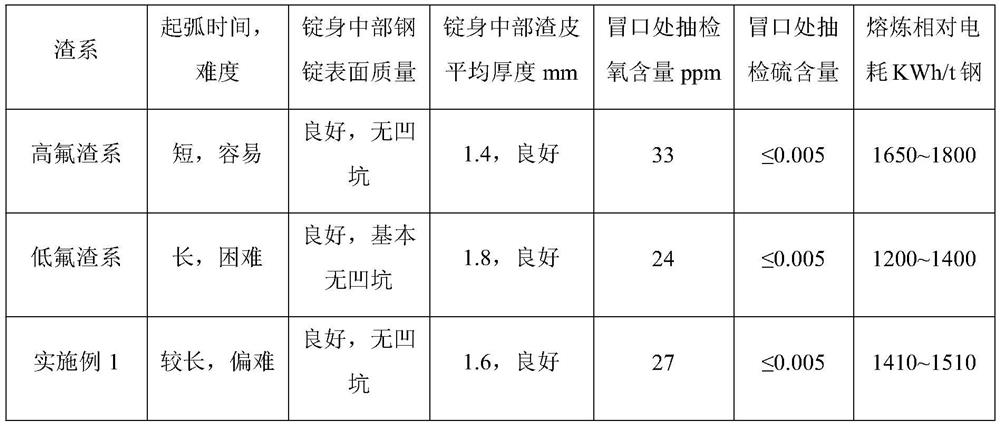

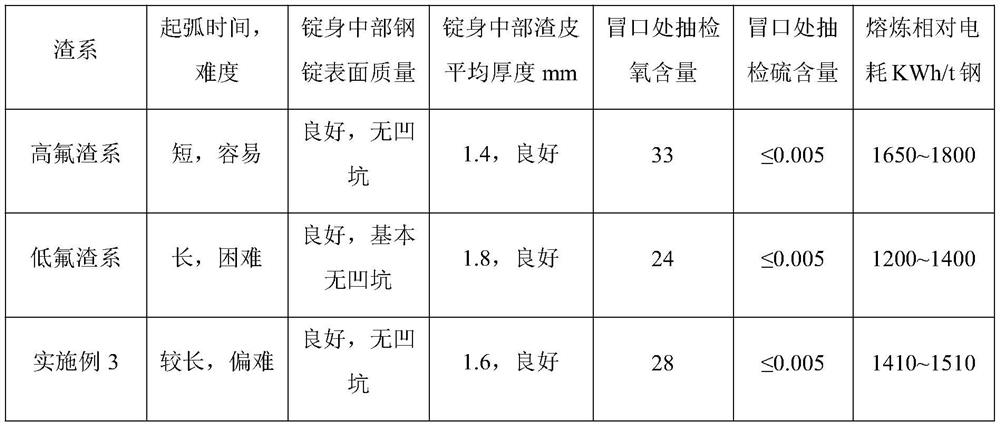

Medium-high fluorine slag system for electroslag remelting of B-containing rotor steel ingot and use method

The invention relates to a medium-high fluorine slag system for electroslag remelting of a B-containing rotor steel ingot and a use method, belongs to the technical field of electroslag special metallurgy, and is used for solving the problems of high energy consumption and high fluorine slag volatilization pollution of an existing B-containing electroslag remelting slag system. The medium-high fluorine slag system comprises the following components in percentage by mass: 40.26-46.79% of CaF2, 23.07-33.99% of Al2O3, 22.25-24.83% of CaO, 3-5% of MgO, 0.5-1.5% of B2O3 and the balance impurities, wherein SiO2 in the impurities is less than 0.5%. The medium-high fluorine slag system reduces the high fluorine slag volatilization pollution, and is low in power consumption and excellent in comprehensive metallurgical performance in use.

Owner:CENT IRON & STEEL RES INST

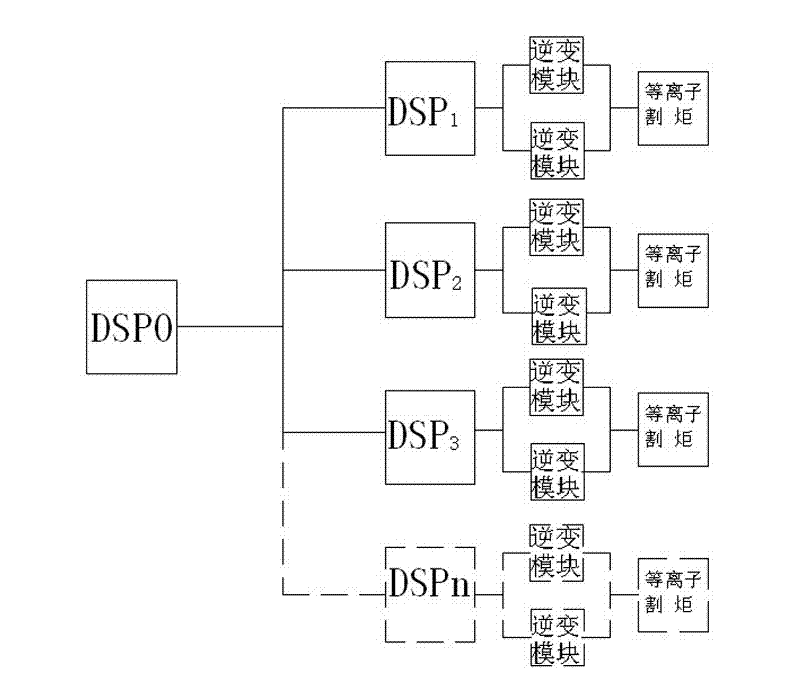

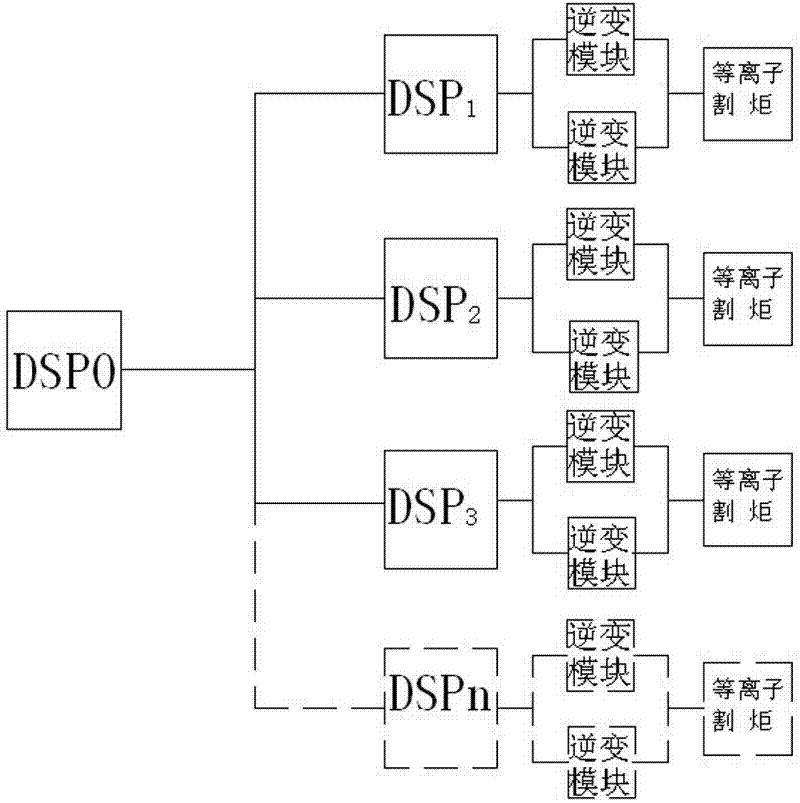

Numerical-control plasma power source with multiple plasma cutting torches

InactiveCN102380698AOutput for easy controlSave resourcesPlasma welding apparatusNumerical controlArea network

The invention discloses a numerical-control plasma power source with multiple plasma cutting torches. The plasma power source is connected with a main DSP (digital signal processor) digital signal controller, the main DSP digital signal controller is further connected with input ends of multiple sub DSP signal controllers through control lines, each sub DSP digital signal controller is connected with one plasma cutting torch through at least two inverter modules, and each inverter module is connected with a CAN (controller area network) bus. According to the technical scheme, the numerical-control plasma power source adopts simple principles, one plasma power source can be distributed to multiple plasma cutting torches so as to facilitate constant-current power output control, and accordingly, the multiple plasma cutting torches can be subjected to completely synchronous arc striking and complicated cutting of grooves can be completed at one step. In addition, the numerical-control plasma power source with the multiple plasma cutting torches has the advantages of high cutting precision and capability of improving operation efficiency and saving resources.

Owner:安徽西锐重工科技有限公司

Active additive used for solid welding wire free of plated copper and preparation method thereof

ActiveCN103394825AArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaVegetable oilCopper plating

The invention relates to the technical field of chemical engineering, and particularly discloses an active additive used for a solid welding wire free of plated copper and a preparation method thereof. The active additive used for the solid welding wire free of the plated copper comprises, by weight, 90-93 parts of vegetable oil, 3-5 parts of cesium powder, 0.8-2 parts of tellurium powder, 2-3 parts of lithium hydrate and 0.2-0.8 part of sodium hydroxide. The active additive used for the solid welding wire free of the plated copper and the preparation method thereof have the advantages that preparation can be achieved easily, environment friendliness and safety are guaranteed, pollution, caused by copper plating liquid and acid and alkali liquid, to the environment is avoided, cost for subsequent sewage treatment is reduced, and injury of dust containing copper to a welder is also avoided; the rust-proof effect and the lubrication effect are good, an electric arc of the manufactured solid welding wire free of the plated copper can be kept stable in a welding process, splashing is reduced, arcing is easy, stability is good, the welding efficiency, the welding performance and the melting depth are improved, the melting depth is large, and a welding line is smooth and attractive.

Owner:德州市立尊焊丝有限公司

Method for manufacturing fused magnesia and pig iron by using waste magnesia carbon bricks and rolled steel sheets

The invention relates to a method for manufacturing fused magnesia and pig iron by using waste magnesia carbon bricks and rolled steel sheets. The method comprises the steps that (1) the waste magnesia carbon bricks and the rolled steel sheets are broken to form magnesia carbon brick powder and rolled steel sheet powder respectively; (2) the magnesia carbon brick powder is mixed with the rolled steel sheet powder after water is added to the magnesia carbon brick powder to enable the magnesia carbon brick powder to be wet; (3) adhesion agents are added to enable mixed materials to be pressed so as to form iron carbon magnesium pellets; (4) the iron carbon magnesium pellets containing water are dried; (5) the iron carbon magnesium pellets and magnesite are fed into a high-capacity magnesium electrofusion furnace in a layered material distribution mode, and the iron carbon magnesium pellets serve as the first layer of raw materials; (6) the iron carbon magnesium pellets are distributed in the central region of the magnesium electrofusion furnace, and the magnesite is distributed on the periphery of the iron carbon magnesium pellets, so that the second layer of raw materials is formed by the iron carbon magnesium pellets and the magnesite together; and (7) the step (5) and the step (6) are repeatedly conducted, various layers of raw materials are distributed in sequence, refining and precipitation are conducted, and finally the fused magnesia and the pig iron are obtained. The method for manufacturing the fused magnesia and the pig iron by using the waste magnesia carbon bricks and the rolled steel sheets achieves comprehensive and efficient utilization of the industrial waste.

Owner:鞍山澳海耐火材料有限公司

Low-cost wet method underwater welding rods

InactiveCN101347873BSimple production processIncrease productivityWelding/cutting media/materialsSoldering mediaSlagPotassium

The invention provides a low-cost underwater wet welding rod which adopts a commercial H08E welding wire as a welding core; the main components and weight proportion of coating are as follows: 20-30% of ilmenite, 10-15% of dolomite, 25-35% of ferrous powder, 8-15% of potassium feldspar, 2-7% of medium-carbon ferromanganese, 5-9% of white slime, 3-8% of titanium pigment, 1-4% of CMC and 1-5% of fine mica; the high viscosity resin which accounts for 8-15% of the total weight of the coating components is added. By adopting the high viscosity resin as an adhesion agent, the welding rod of the invention can be directly applied to underwater wet welding after extrusion and does not need to be coated with a waterproof coating on the surface, thus simplifying production technique, improving production efficiency and reducing production cost; the invention can ensure that after the welding rod is soaked in water for a long time, the coating dose not go bad and drop off, and welding operation can still be carried out. When used in underwater welding, the welding rod has the advantages of easy arc striking, stable combustion of electric arc, good performance of restarting, easy slag detachability, good weld forming and fine processing property of underwater welding.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

A self-shielded flux-cored wire for underwater wet welding

ActiveCN104057214BNot easy to arcEasy arc startWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a self-protection flux-cored wire for underwater wet-method welding. The self-protection flux-cored wire is characterized in that a N6 nickel band is used as a metal covering of the wire, an alkaline calcium fluoride-aluminum oxide slag system is used as a flux-cored basic slag system, the internal flux core consists of calcium fluoride, aluminum powder, iron powder, magnesium oxide, silicon iron, lithium fluoride, manganese powder and metal chromium, and the weight percent of each component is as follows: 40 to 55 percent of calcium fluoride, 8 to 13 percent of aluminum powder, 5 to 9 percent of iron powder, 0.5 to 5 percent of magnesium oxide, 3 to 7 percent of silicon iron, 3 to 9 percent of lithium fluoride, 6 to 11 percent of manganese powder and 4 to 10 percent of metal chromium. When the flux-cored wire is used for the underwater wet-method welding, arc is likely to start, the electric arc is stable in combustion, the restarting arc is good in performance, the forming property of the weld seam is good, the tensile strength of the weld metal after being welded is not lower than 460MPa, and the underwater welding of the medium-low carbon steel and low-alloy high-strength steel structure of ordinary strength requirement can be satisfied.

Owner:HARBIN INST OF TECH AT WEIHAI

High-strength underwater welding electrodes

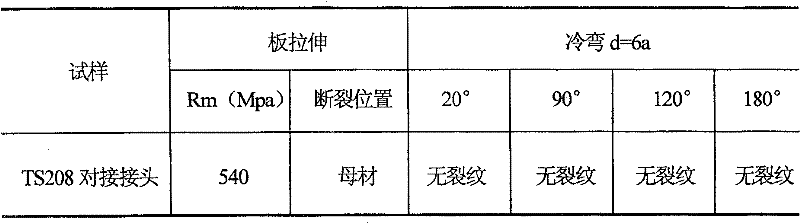

InactiveCN1939649BEasy arc startStable arc burningWelding/cutting media/materialsSoldering mediaCelluloseButt joint

A high-strength wet welding electrode for underwater welding is composed of the core made of H08E steel wire a coated surficial water-proof layer, and a coated sandwich layer containing rutile (42-54 Wt%), potash feldspar (12-20), talc (6-14), cellulose (4-12), ferromanganese (6-14), Ni powder (0-4), Fe powder (3-12) and at least one kind of Nickel powder (2-4) and Al-Mg alloy (2-4).

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Welding electrode and coating for welding under wading environment, and preparation methods of welding electrode and coating

ActiveCN108515288ASimple preparation processEasy arc startWelding/cutting media/materialsSoldering mediaYttriumFerrosilicon

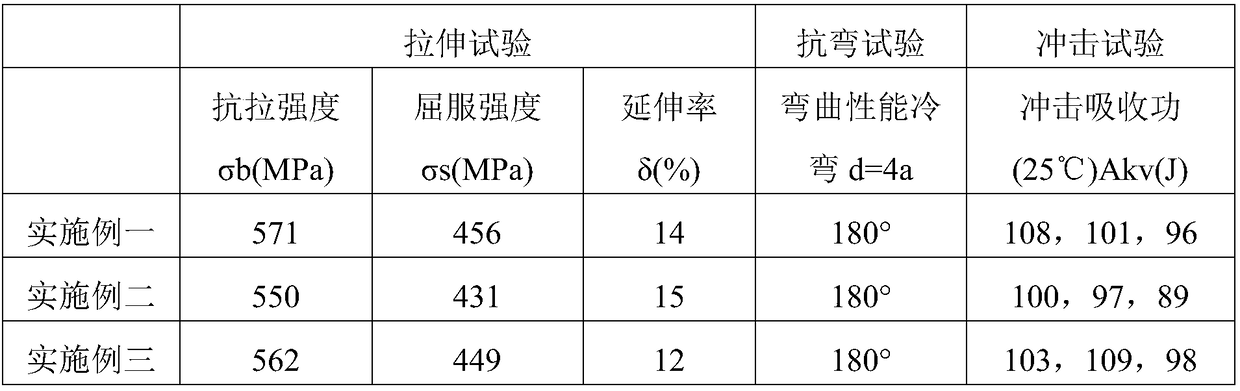

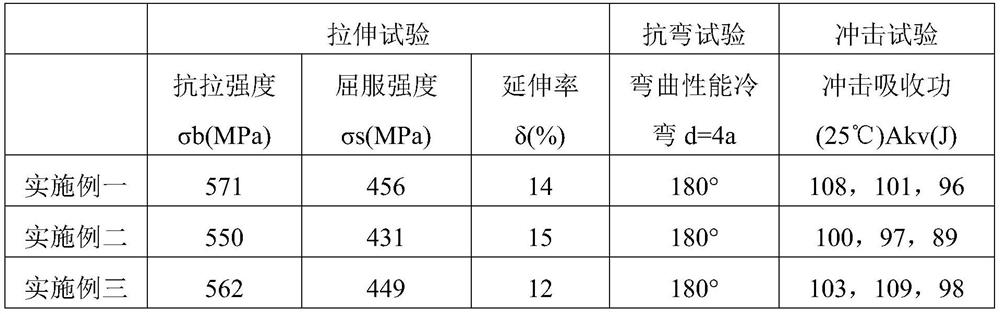

The invention discloses a welding electrode and a coating for welding under a wading environment, and preparation methods of the welding electrode and the coating. The coating comprises the followingcomponent raw materials of, by weight, 35-50% of rutile, 10-20% of calcium carbonate, 5-15% of fluorite, 7-18% of mica, 2-9% of ferrosilicon, 3-9% of ferromanganese, 4-10% of titanium and 1.5-5% of yttrium. Potassium sodium water glass with the weight being 18-30% of the total weight of the coating is further added into the coating, and the mass ratio of potassium oxide to sodium oxide in the potassium sodium water glass is 2:1. Meanwhile, the invention further discloses the preparation methods of the welding electrode and the coating. The preparation process is simple, arcing is easy during welding, electric arc combustion is stable, the phenomena of arc quenching and breaking are avoided, an obtained welded seam is attractive in forming, the tensile strength of a butt-joint connector canreach 550 MPa, the thickness of the butt-joint connector is four times that of a plate, cracks are avoided when the cold bending angle is 180 degrees, the advantages of good welding manufacturability, convenient test operation, high welding efficiency and the like are achieved, and welding of workpieces under the wading environment can be met.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

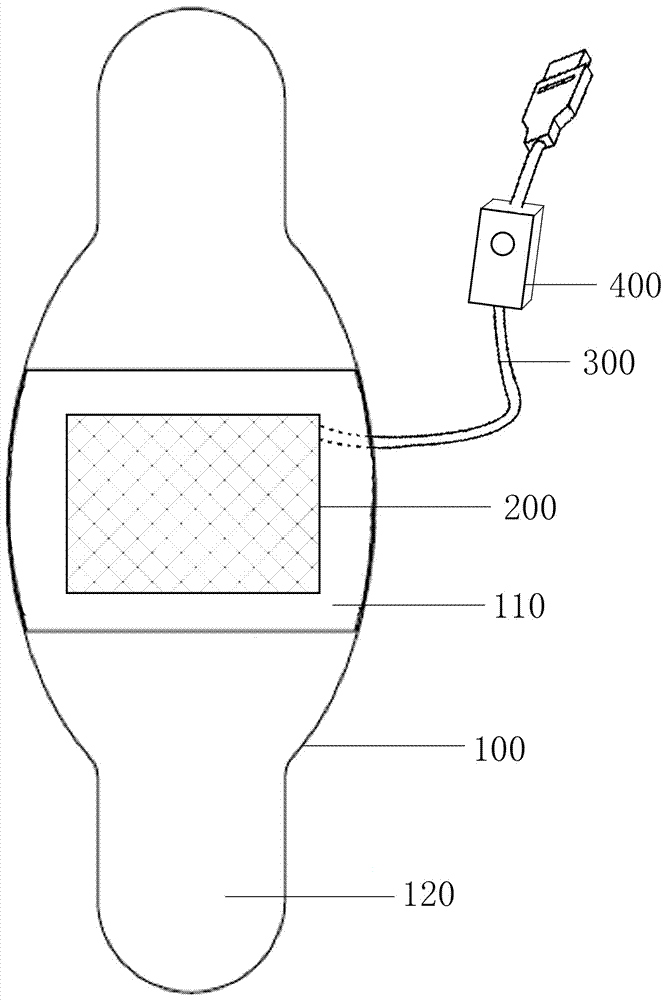

Pillow towel having health-care function

InactiveCN107259900APromote thermoregulation effectFacilitate the resonance effectElectrotherapyBlanketHuman bodyCarbon fibers

The invention relates to the field of auxiliary supplies for cervical vertebra rehabilitation and prevention and discloses a pillow towel having a health-care function. The pillow towel comprises a pillow towel body and connecting bodies located on two sides of the pillow towel body, wherein the connecting bodies on two sides are mutually and movably connected, a heating piece is arranged in the pillow towel body, and a material for the pillow towel body includes bamboo charcoal powder, tourmaline powder and germanium powder according to the weight part ratio of 10-30 to 7-9 to 2. The heating piece adopts a carbon fiber woven net structure. The pillow towel integrates the heating piece and the tourmaline powder and the germanium powder, the infrared ray transmitting rate, the negative air ion releasing amount and an ion permeation effect are improved through the joint effect of temperature rise and human body extrusion, the blood circulation and metabolism of the human body are further promoted, and the pillow towel has an excellent thermal-therapy health-care effect.

Owner:广东安胜仪器有限公司

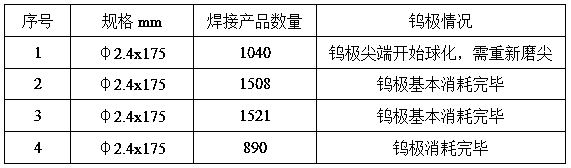

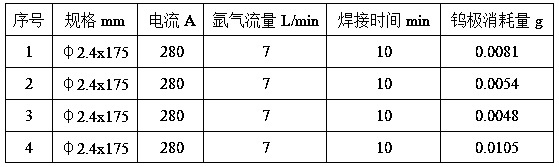

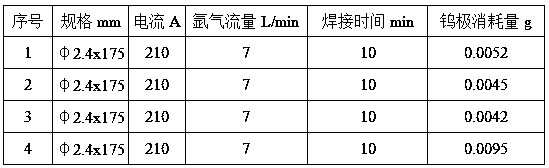

Quaternary composite rare earth tungsten alloy electrode material and preparation method thereof

The invention relates to a quaternary composite rare earth tungsten alloy electrode material. The material comprises the following raw material of, in percentage by weight, 1.0% to 1.5% of lanthanum oxide, 0.1% to 0.3% of zirconium oxide and yttrium oxide, 0.3% to 0.5% of cerium oxide, 2% to 2.5% of rare earth oxide and the balance tungsten oxide. The specific preparation method comprises the procedures of solid-liquid doping, secondary reduction, isostatic cool pressing, sintering, rotary swaging, wire drawing, straightening, cutting, and polishing and burnishing. According to the method, thequaternary rare earth tungsten electrode is prepared by considering the excellent properties of low electron work function, easiness in arcing, slow growth of tip grains, long service life, large bearing current and the like of a lanthanum tungsten electrode and also considering the characteristics of slender arc beam, deeper fusion depth and high welding strength during medium and large currentwelding of the yttrium-tungsten electrode, and due to the good corrosion resistance of zirconium and the small arcing current and easy arcing of cerium tungsten, lanthanum, yttrium, zirconium and cerium are mutually considered in the electrode, so that good comprehensive performance is obtained.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

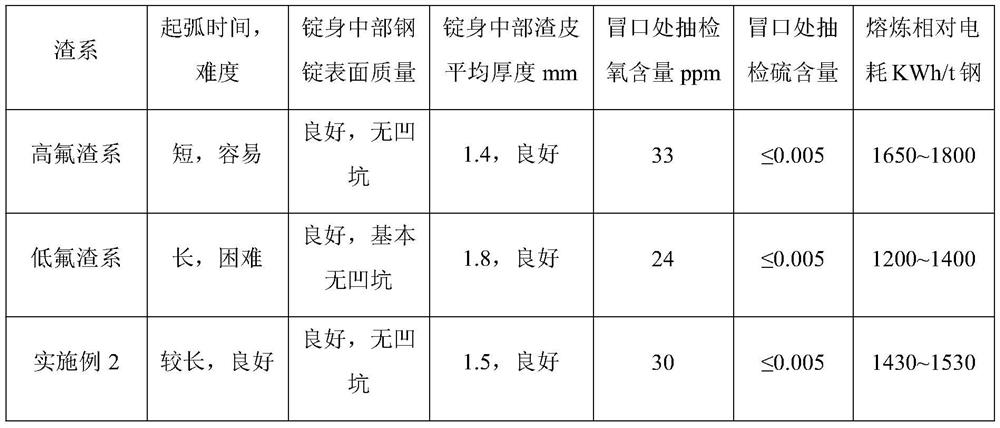

Medium-low fluorine slag system for electroslag remelting B-containing rotor steel ingot and use method

The invention relates to a medium-low fluorine slag system for electroslag remelting of a B-containing rotor steel ingot and a using method, belongs to the technical field of electroslag special metallurgy, and aims to solve the problems that an existing B-containing electroslag melting slag system is high in energy consumption and high-fluorine slag volatilizes to cause pollution. The medium-low fluorine slag system comprises the components in percentage by mass: 30.06%-39.30% of CaF2, 34.02%-43.79% of Al2O3, 18.31%-22.72% of CaO, 3%-5% of MgO, 0.10%-3.50% of B2O3 and the balance impurities, wherein the content of SiO2 in the impurities is less than 0.5%, and the range of CaO / (SiO2 + 0.5 * Al2O3) is from 0.7 to 1.4. The medium-low fluorine slag system reduces volatilization pollution of high-fluorine slag, and is low in power consumption during use and good in comprehensive metallurgical performance.

Owner:CENT IRON & STEEL RES INST

Permanent magnet hall thruster ignition device

PendingCN109779865AEasy arc startConvenience to lead the beamMachines/enginesUsing plasmaControl cellEngineering

The invention discloses a permanent magnet hall thruster ignition device comprises an outer ceramic ring, an inner ceramic ring, an anode assembly, magnetic steel, a magnetic conductive base, a magnetic steel sleeve, excitation coils and a magnetic conductive ferrule; the magnetic conductive ferrule is installed on the outer wall of the magnetic steel in a sleeved manner; the magnetic conductive ferrule and the magnetic steel are installed in an annular positioning ring on the magnetic conductive base; and the excitation coils are installed between the inner wall of a magnetic steel sleeve andthe outer wall of the magnetic conductive ferrule through positioning of the annular positioning ring. In the ignition process, the excitation coils, a power supply of which is supplied by a cathodeheating power supply, generate a magnetic field with a direction opposite to a direction of an inherent magnetic field of the magnetic steel, and the intensity of the magnetic field at an outlet of adischarge channel is weakened, so that primary electrons emitted by a cathode can successfully enter the discharge channel, and arcing ignition of the thruster is facilitated; and after ignition of the thruster is finished, power supply of the excitation coils is cut off. By adopting the permanent magnet hall thruster ignition device, the ignition difficulty of a permanent magnet hall thruster canbe remarkably lowered, and extra burden caused to components such as a power supply processing unit, a propellant storage unit and a control unit cannot be generated at the same time.

Owner:NANHUA UNIV

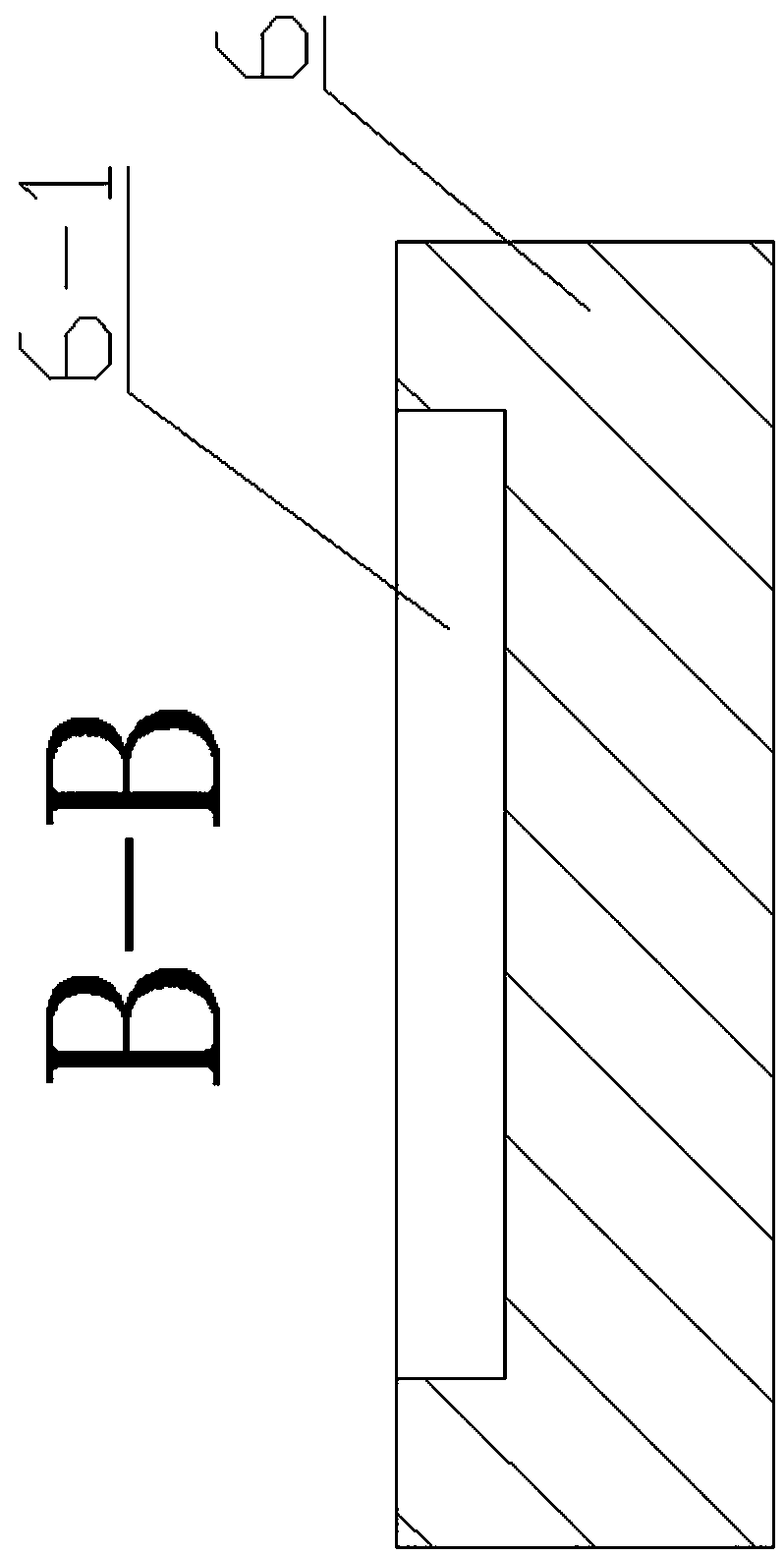

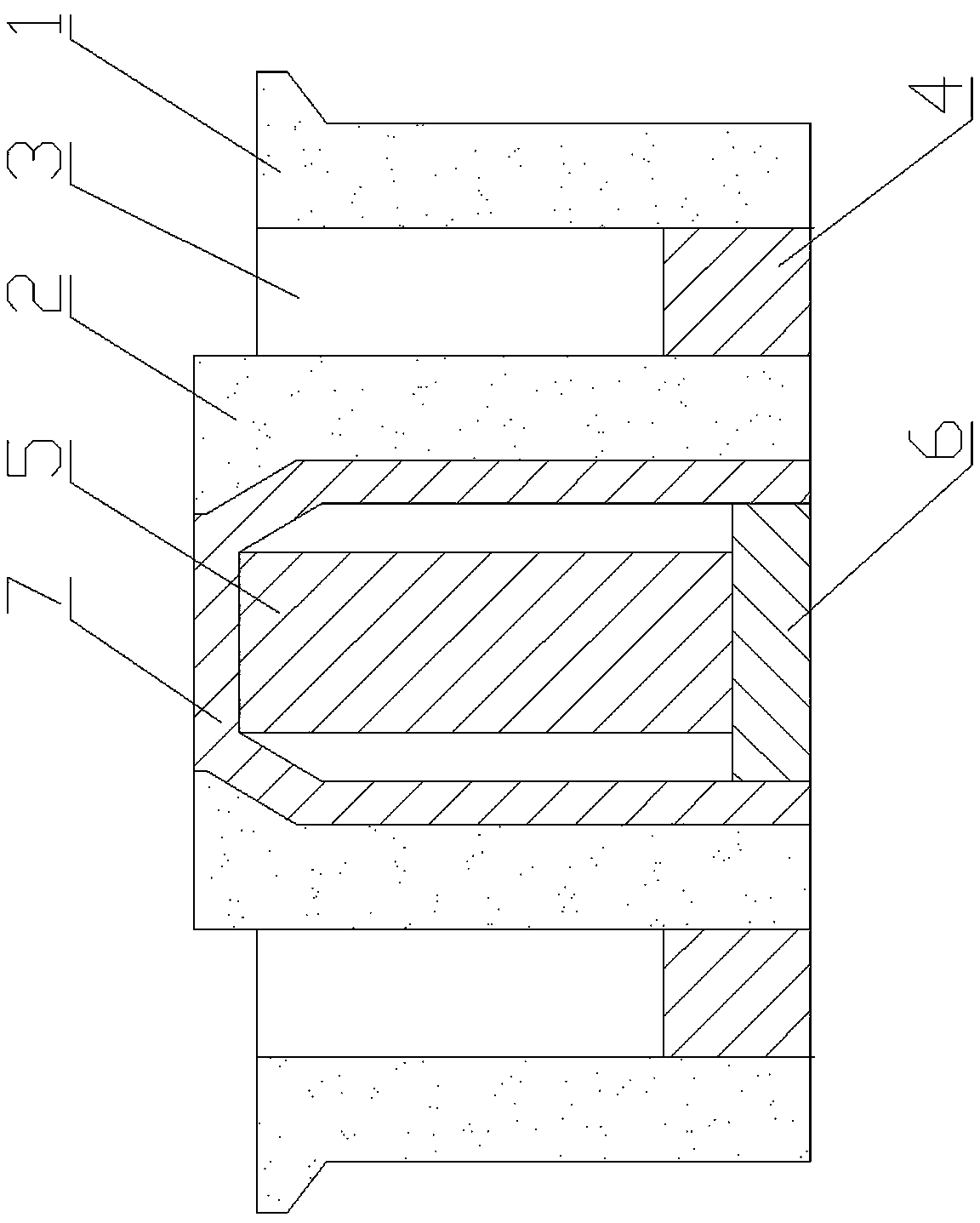

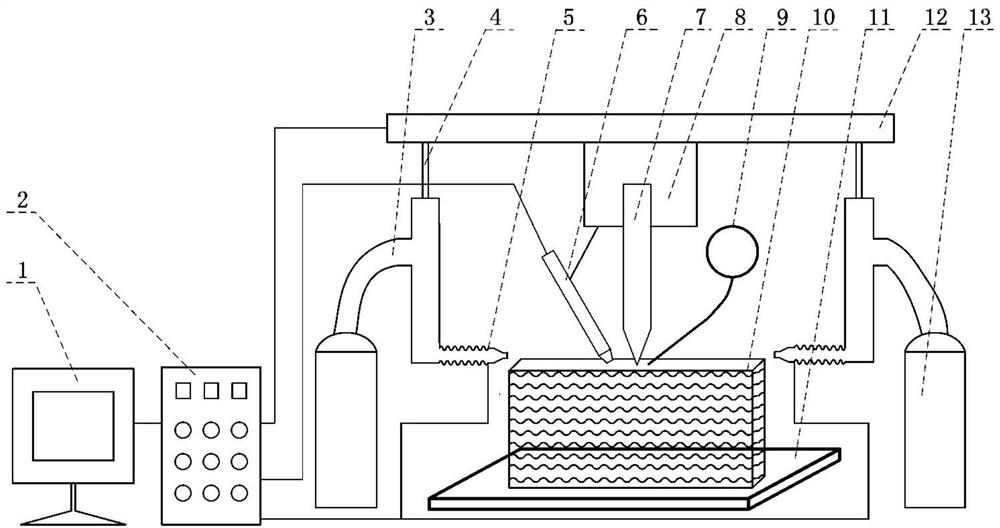

Part surface temperature control device and control method in electric arc additive manufacturing process

PendingCN112975054AImprove cooling effectReduce waiting time between layersWelding accessoriesTemperature controlControl system

The invention belongs to the field of additive manufacturing, and relates to a part surface temperature control device and control method in the electric arc additive manufacturing process, and the part surface temperature control device comprises a control system, a welding gun, a servo motor, an air blowing device and a machine tool moving system. The control system is connected with the machine tool moving system. The machine tool moving system is connected with the welding gun through the servo motor. The air blowing device is connected with the machine tool moving system and moves synchronously with the welding gun. The bottom of the air blowing device and the bottom of the welding gun are on the same plane. According to the part surface temperature control device and control method in the electric arc additive manufacturing process, the interlayer waiting time can be shortened, and the mechanical property and the forming efficiency of the electric arc additive forming part can be improved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

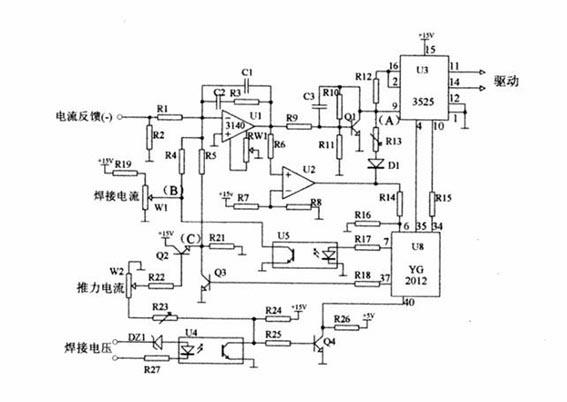

Arc striking pulse peak current control electric welding machine and control method thereof

The invention belongs to the field of electric welding and particularly relates to an arc striking pulse peak current control electric welding machine and a control method thereof. The electric welding machine applies a low-frequency low-duty-ratio pulse current during short circuit, and an arc striking pulse peak current of the low-frequency low-duty-ratio pulse current ranges from a 30A welding current to a triplex welding current. Therefore, the arc striking pulse peak current can be higher than the welding current during the low welding current, and arc striking is facilitated; and the arc striking pulse peak current can be lower than the welding current during the high welding current, a short-circuit limit output circuit is cut off after arc striking in welding is successful, the welding current slowly rises from the minimum current to the welding current, and the striking current can be reduced by the means.

Owner:刘裕国

A kind of electrode and coating for welding in wading environment, and preparation method thereof

ActiveCN108515288BMeet weldingSimple preparation processWelding/cutting media/materialsSoldering mediaFerrosiliconYttrium

The invention discloses a welding electrode and a coating for welding under a wading environment, and preparation methods of the welding electrode and the coating. The coating comprises the followingcomponent raw materials of, by weight, 35-50% of rutile, 10-20% of calcium carbonate, 5-15% of fluorite, 7-18% of mica, 2-9% of ferrosilicon, 3-9% of ferromanganese, 4-10% of titanium and 1.5-5% of yttrium. Potassium sodium water glass with the weight being 18-30% of the total weight of the coating is further added into the coating, and the mass ratio of potassium oxide to sodium oxide in the potassium sodium water glass is 2:1. Meanwhile, the invention further discloses the preparation methods of the welding electrode and the coating. The preparation process is simple, arcing is easy during welding, electric arc combustion is stable, the phenomena of arc quenching and breaking are avoided, an obtained welded seam is attractive in forming, the tensile strength of a butt-joint connector canreach 550 MPa, the thickness of the butt-joint connector is four times that of a plate, cracks are avoided when the cold bending angle is 180 degrees, the advantages of good welding manufacturability, convenient test operation, high welding efficiency and the like are achieved, and welding of workpieces under the wading environment can be met.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

High frequency arc ignition circuit with direct current voltage output

InactiveCN103111719BEasy breakdownIncrease success rateArc welding apparatusEngineeringHigh pressure

The invention relates to a high frequency arc ignition circuit with direct current voltage output. The high frequency arc ignition circuit with direct current voltage output comprises a high frequency signal source, a relay, a high frequency voltage booster circuit and a voltage doubling circuit. The high frequency signal source is respectively connected with the input end of the voltage doubling circuit and the input end of the high frequency voltage booster circuit through the relay. The output end of the voltage doubling circuit outputs direct current voltage to secondary positive and negative electrodes of a welding machine main circuit. The high frequency voltage booster circuit produces high frequency high voltage signals and the high frequency high voltage signals are coupled to the secondary negative electrode of the welding machine main circuit and outputted. With the aid of the voltage doubling circuit, the direct current voltage is added to the high frequency arc ignition circuit with direct current voltage output on the condition of high frequency arc starter, air can be punctured more easily at the time of high frequency arc starter, arcing is easier, and success rate of arcing and arcing performance of the welding machine can be improved.

Owner:广东世博科焊接工程技术有限公司

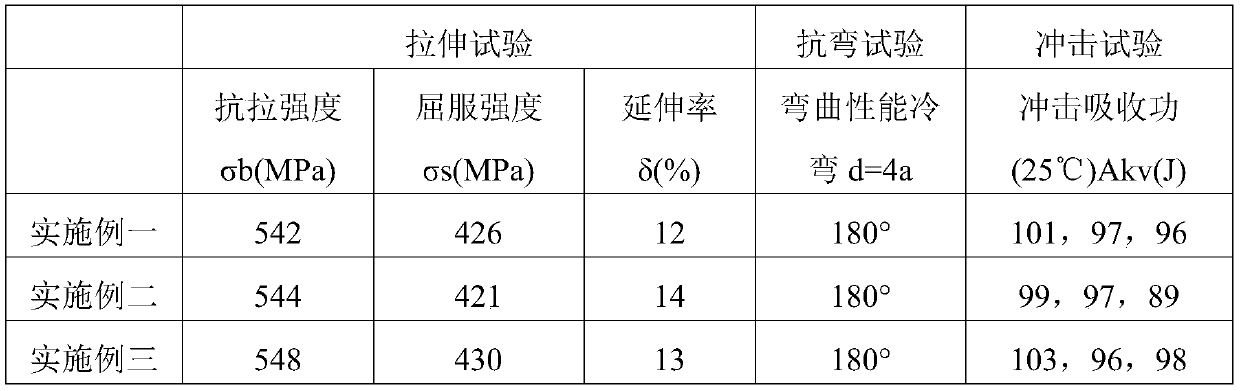

A self-shielding flux-cored welding wire for welding in wading environment

ActiveCN108526752BGuaranteed arc stabilityImprove deposition efficiencyWelding/cutting media/materialsSoldering mediaAlloyImpact toughness

The invention discloses a self-protection flux-cored wire for welding under a water environment. The self-protection flux-cored wire for welding under the water environment comprises a metal skin anda flux core. The flux core comprises components including, by mass percent, 35%-55% of rutile, 10%-20% of ferric oxide, 5%-12% of aluminum oxide, 5%-10% of calcium carbonate, 3%-8% of fluoride, 2%-5%of titanium powder, 4%-8% of nickel powder, 1%-2% of molybdenum powder and 15%-25% of iron powder. The self-protection flux-cored wire can be used for carrying out welding under the water environment,arc starting is easy during welding, arc combustion is stable, excellent welding process performance is achieved, obtained welding lines are attractive in forming, the extension strength of depositedmetal after welding is larger than 540 MPa, no cracks appear when a butt joint is 4 times the thickness of a plate and the cold bending angle is 180 degrees, good impact toughness is achieved, and welding of low-carbon and medium-carbon steel and low-alloy high-strength steel under the water environment is met.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com