A kind of electrode and coating for welding in wading environment, and preparation method thereof

A coating and electrode technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve problems such as difficulties, excessive smoke and gas, and hidden dangers in service safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

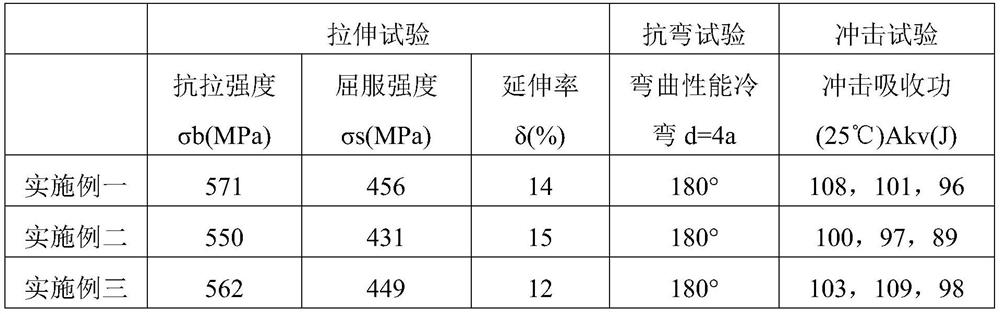

Embodiment 1

[0023] Embodiment 1: Adopt commercially available H08E steel wire as welding core, the composition and weight percent of coating are: rutile 37%, calcium carbonate 20%, fluorite 13%, mica 12%, ferrosilicon 5%, ferromanganese 5% , titanium 6%, yttrium 2%. Potassium-sodium water glass with a potassium-sodium ratio of 2:1 is used as the binder of the coating, and the addition amount is 20% of the total weight of the coating.

Embodiment 2

[0024] Embodiment two: adopt commercially available H08E steel wire as welding core, the composition and weight percent of coating are: rutile 45%, calcium carbonate 15%, fluorite 8%, mica 10%, ferrosilicon 6%, ferromanganese 6% , titanium 5%, yttrium 5%. Potassium-sodium water glass with a potassium-sodium ratio of 2:1 is used as the binder of the coating, and the addition amount is 25% of the total weight of the coating.

Embodiment 3

[0025] Embodiment three: adopt commercially available H08E steel wire as welding core, the composition and weight percent of coating are: rutile 50%, calcium carbonate 10%, fluorite 10%, mica 8%, ferrosilicon 5%, ferromanganese 8% , titanium 4%, yttrium 5%. Potassium-sodium water glass with a potassium-sodium ratio of 2:1 is used as the binder of the coating, and the addition amount is 28% of the total weight of the coating.

[0026] Weigh the above-mentioned component raw materials respectively by weight, put them into a mixing tank, and dry mix for 3-6 hours; then add potassium sodium water glass as a binder, and wet mix and stir for 1-2 hours. Apply the wet-mixed and uniform coating on the steel wire, the diameter of the steel wire is 4mm, and the outer diameter of the welding rod is 6.2-6.7mm. After grinding out the clamping end and arc striking end, the electrode is dried in three stages in the electrode drying furnace: low temperature 40-80°C, medium temperature 100-160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com