Method for preparing new copper-iron welding wires

A copper-iron and welding wire technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as large differences in expansion coefficient, large welding residual stress and deformation of welded joints, and complicated welding, so as to achieve uniform overall structure of the alloy, Guaranteed no doping of impurities and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

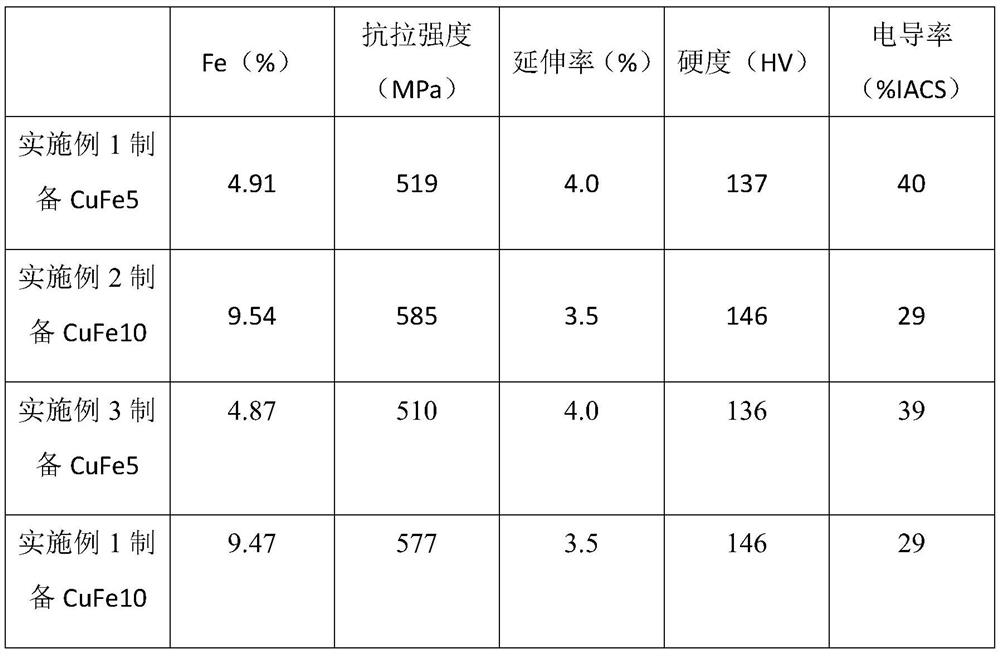

Examples

Embodiment 1

[0031] Embodiment 1: a kind of preparation method of novel copper-iron welding wire is characterized in that, specifically comprises:

[0032] Step 1: Ingredients

[0033] In terms of percentage content, the percentage content of Fe element in the raw material is 5%, and the remainder is Cu element; the Fe element is added in the form of CuFe master alloy, and the remaining Cu element is added in the form of electrolytic copper plate;

[0034] Step 2: Smelting

[0035] Vacuum smelting is used for smelting; the specific steps of smelting are: put the prepared raw materials into the vacuum smelting furnace, when the vacuum degree reaches 2Pa, heat up, increase the heating power to 20KW, keep warm for 3min; then use 1KW Raise the heating power to 40KW at a rising rate of / s, and keep it warm for 12 minutes; then raise the heating power to 80KW at a rising rate of 2KW / s, and keep it until the raw materials in the crucible are uniform up and down, reduce the power to 10KW, and ope...

Embodiment 2

[0046] Embodiment 2: a kind of preparation method of novel copper-iron welding wire, is characterized in that, specifically comprises:

[0047] Step 1: Ingredients

[0048] In terms of percentage content, the percentage content of Fe element in the raw material is 10%, and the remainder is Cu element; the Fe element is added in the form of CuFe master alloy, and the remaining Cu element is added in the form of electrolytic copper plate;

[0049] Step 2: Smelting

[0050] Vacuum smelting is used for smelting; the specific steps of smelting are: put the prepared raw materials into the vacuum smelting furnace, when the vacuum degree reaches 4Pa, heat up, increase the heating power to 30KW, keep warm for 4min; then use 1KW Raise the heating power to 50KW at a rising rate of / s and keep it warm for 15 minutes; then raise the heating power to 90KW at a rising rate of 2KW / s and keep it until the raw materials in the crucible are evenly up and down, then reduce the power to 20KW and ...

Embodiment 3

[0061] Embodiment 3: This embodiment is basically the same as Embodiment 1, the difference is:

[0062] Step 2: Smelting

[0063] Vacuum smelting is used for smelting; the specific steps of smelting are: put the prepared raw materials into the vacuum smelting furnace, when the vacuum degree reaches 2Pa, heat up, increase the heating power to 20KW, and keep warm for 5min; then heat Increase the power to 40KW and keep it warm for 5 minutes; then increase the heating power to 60KW and keep it until the raw materials in the crucible are uniform up and down, then reduce the power to 5KW, open the inert gas valve, and then slowly fill the furnace with inert gas. When it rises to 0.08Mpa, close the inert gas valve, increase the power to 70KW±5KW, and refine for 1min; among them, the inert gas uses high-purity argon with a concentration of 99.999%;

[0064] Step Three: Casting

[0065] Reduce the power of the vacuum melting furnace from 70KW±5KW to 40KW±5KW, keep it for 20s and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com