Patents

Literature

61results about How to "Stable arc burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-protection core welding stick used for underwater wet welding

ActiveCN103084761AGood mechanical propertiesEasy arc startWelding/cutting media/materialsSoldering mediaManganeseMechanical property

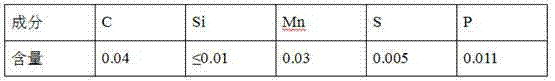

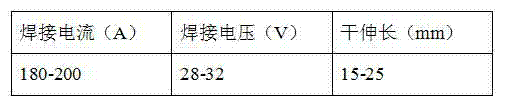

The invention provides a self-protection core welding stick used for underwater wet welding. The self-protection core welding stick used for underwater wet welding comprises two parts including a protection covering and a core wire and is characterized in that the protection covering is formed by rolling up a low-carbon steel belt, wherein the low-carbon steel belt comprises, by weight, 0.03% to 0.08% of carbon (C), 0.03% of manganese (Mn), <=0.02% of sulfur (S) and <=0.02% of phosphorus (P). The core is composed of oxide, fluoride, carbonate, manganese powder, nickel powder, aluminum powder and iron powder. The components comprises, by mass, 50%-63% of oxide, 5%-10% of fluoride, 5%-10% of carbonate, 3%-8% of manganese powder, 0%-5% of nickel powder, 0%-4% of aluminum powder and 10%-30% of iron powder. The self-protection core welding stick used for underwater wet welding is not only good in mechanical property, but also simple in arc starting in welding, stable in electric arc combustion, good in arc restarting capacity, and beautiful in appearance of a gained welding joint. The strength of extension of a butt joint can reach 500 Mpa. The self-protection core welding stick used for underwater wet welding can be used for welding of the underwater structure of low-carbon and low-alloy steel.

Owner:HARBIN INST OF TECH AT WEIHAI

Self-protection flux-cored wire for underwater wet-method welding

ActiveCN104057214AEasy arc startGood mechanical propertiesWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a self-protection flux-cored wire for underwater wet-method welding. The self-protection flux-cored wire is characterized in that a N6 nickel band is used as a metal covering of the wire, an alkaline calcium fluoride-aluminum oxide slag system is used as a flux-cored basic slag system, the internal flux core consists of calcium fluoride, aluminum powder, iron powder, magnesium oxide, silicon iron, lithium fluoride, manganese powder and metal chromium, and the weight percent of each component is as follows: 40 to 55 percent of calcium fluoride, 8 to 13 percent of aluminum powder, 5 to 9 percent of iron powder, 0.5 to 5 percent of magnesium oxide, 3 to 7 percent of silicon iron, 3 to 9 percent of lithium fluoride, 6 to 11 percent of manganese powder and 4 to 10 percent of metal chromium. When the flux-cored wire is used for the underwater wet-method welding, arc is likely to start, the electric arc is stable in combustion, the restarting arc is good in performance, the forming property of the weld seam is good, the tensile strength of the weld metal after being welded is not lower than 460MPa, and the underwater welding of the medium-low carbon steel and low-alloy high-strength steel structure of ordinary strength requirement can be satisfied.

Owner:HARBIN INST OF TECH AT WEIHAI

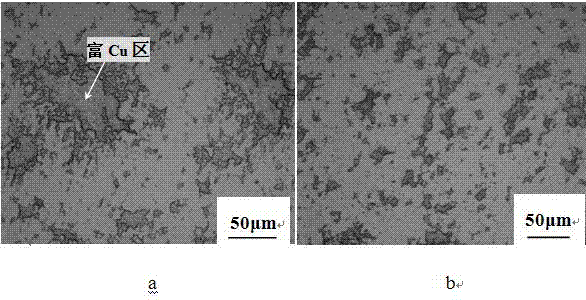

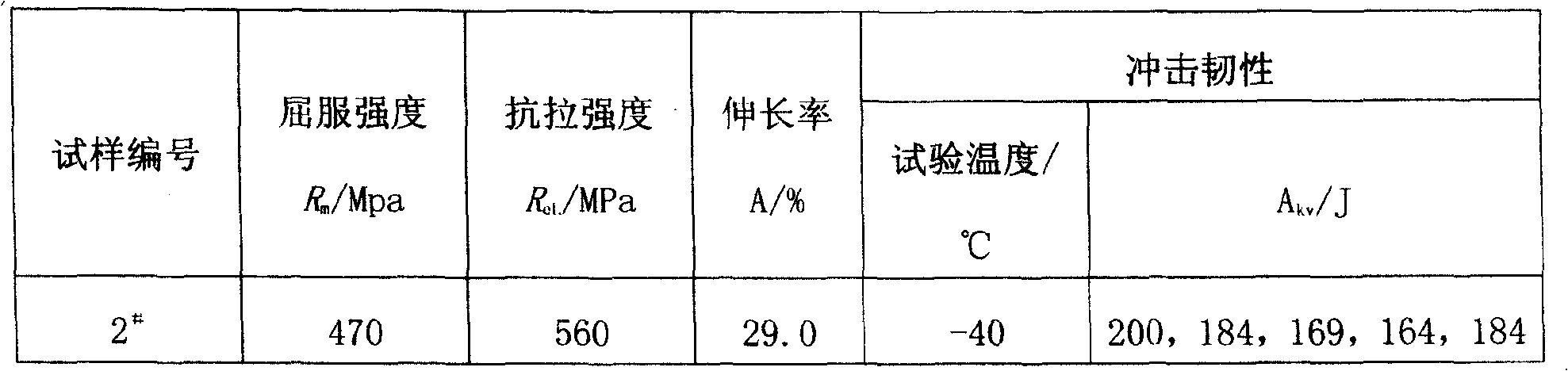

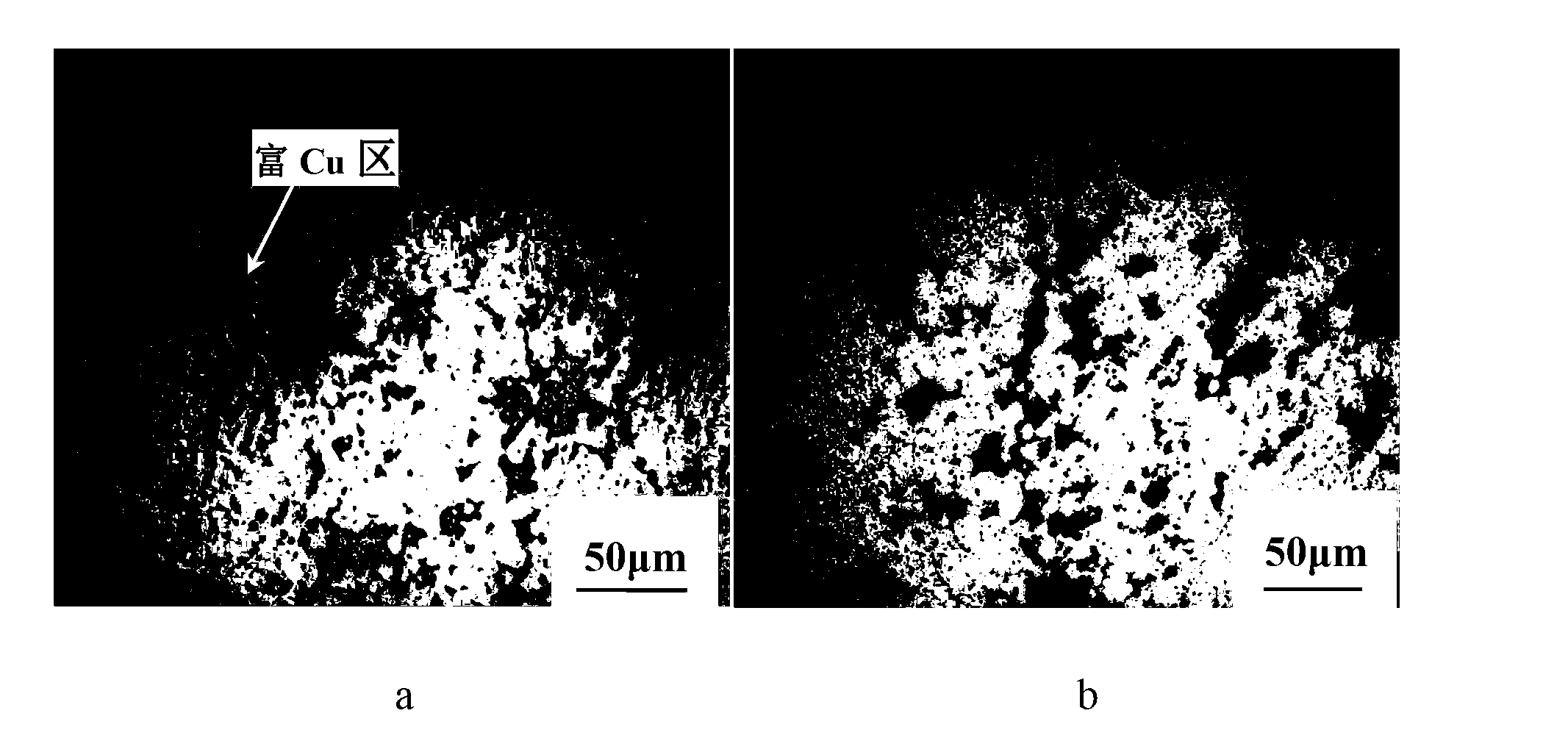

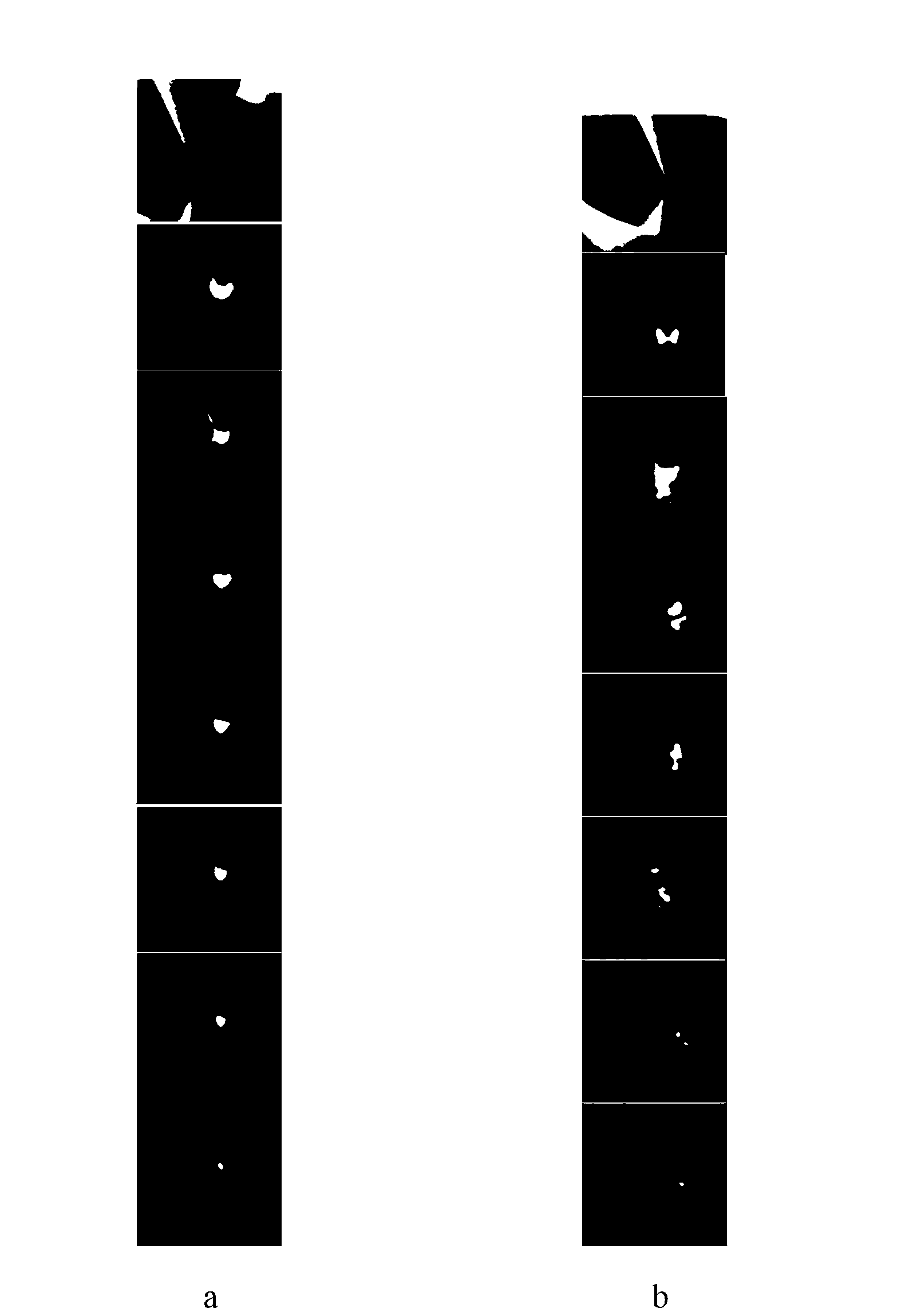

Preparation method of CuW70 contact material

The invention discloses a preparation method of a CuW70 contact material, comprising the steps of: adding inducing copper powder into tungsten powder in certain proportion and mixing them well, putting the mixed powder into a rubber sheath which is then placed in the high pressure cylinder of a cold isostatic pressing machine so as to be pressed into a skeleton green body, and then preparing the CuW70 contact material through copper infiltration of the sintered skeleton. Due to disappeared copper-rich area and uniform two-phase distribution of the prepared CuW70 contact material by the methodof the invention, the material has rapidly moving cathode spot on the surface, effectively dispersed electric arc, less copper phase splashing, and improved ablation resistance.

Owner:XIAN UNIV OF TECH

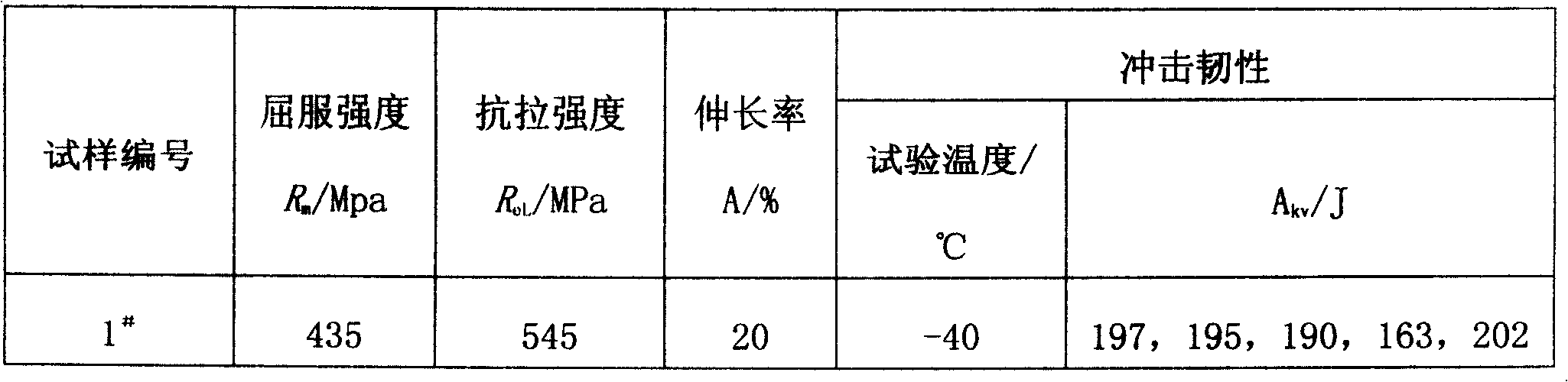

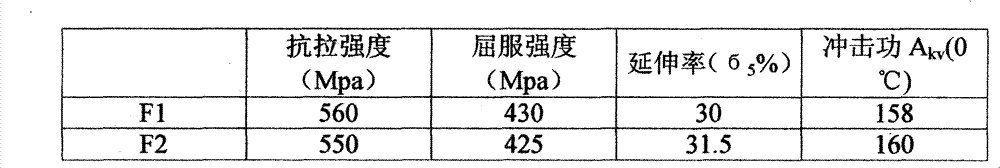

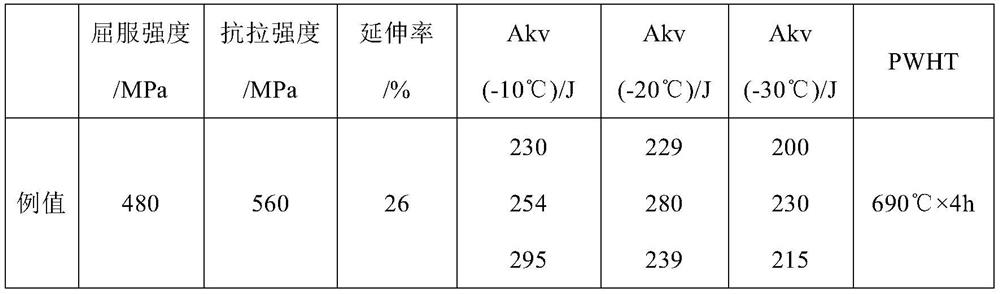

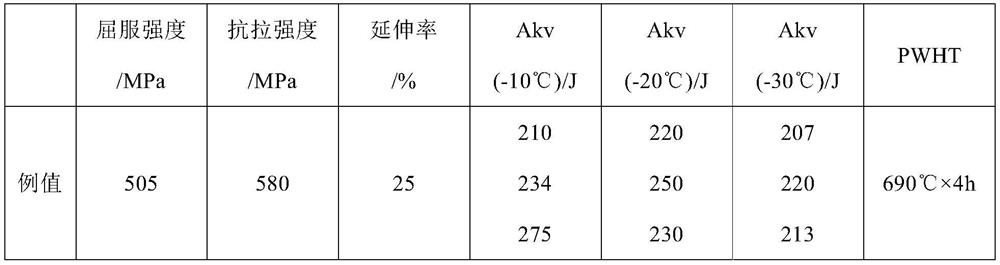

High-strength high-ductility fluorine alkalescent sintered flux

InactiveCN101314200AAdapt to melting pointAdapt to viscosityWelding/cutting media/materialsSoldering mediaAlkalinityHigh intensity

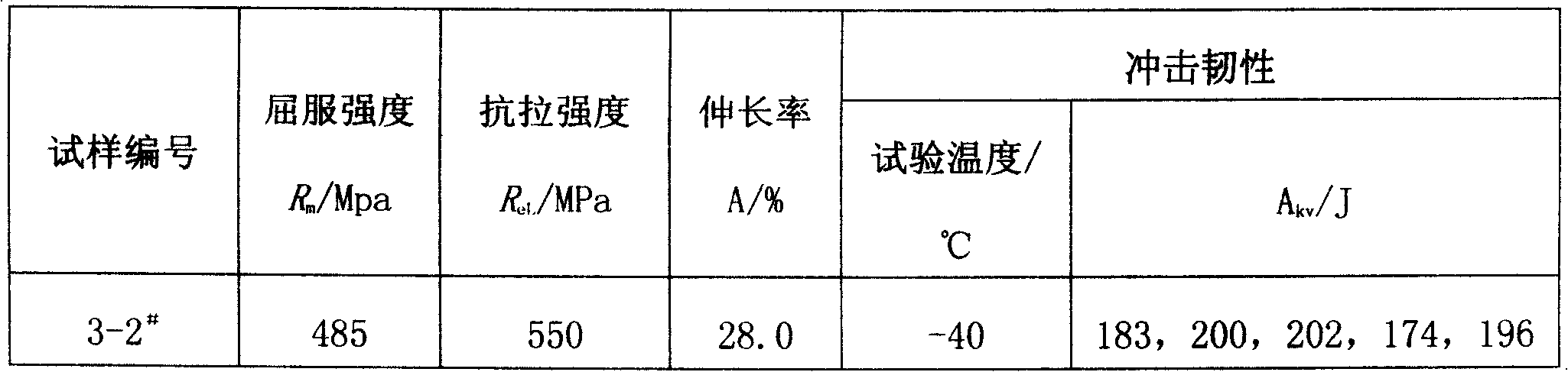

The invention relates to a high-strength high-toughness fluoride-basic type sintered flux. The high-strength high-toughness fluoride-basic type sintered flux consists of the following compositions in percentage by weight: 22 to 26 percent of MgO, 25 to 27 percent of CaF2, 21 to 23 percent of Al2O3, 14 to 16 percent of SiO2, 4 to 7 percent of CaO, 3 to 5 percent of MnO, 0.3 to 0.6 percent of Na2, less than or equal to 3 percent of FeO, less than or equal to 0.03 percent of S and less than or equal to 0.04 percent of P. Through controlling a basicity (BI1W) scope of the sintered flux, the oxygen content and the impurity content in the sintered flux are reduced, thereby ensuring the purity of weld metal and improving low-temperature impact toughness of the weld metal. The high-strength high-toughness fluoride-basic type sintered flux is matched with a YS-H08D welding wire to weld a high-strength Q420q bridge structure steel; the weld metal has high low-temperature impact toughness, yield strength and tensile strength; a Charpy impact absorption work Akv(40 DEG C below zero) is between 169 and 202J; and the impact absorption power has small dispersion degree. The high-strength high-toughness fluoride-basic type sintered flux can be matched with a plurality of welding wires and can be used for welding a plurality of low alloy steels such as a spiral seam hidden arc welding steel tube of an X80 steel grade, which also has high low-temperature impact toughness.

Owner:BAOJI YUSHENG WELDING MATERIAL

High-strength underwater welding electrodes

InactiveCN1939649AEasy arc startStable arc burningWelding/cutting media/materialsSoldering mediaUnderwater weldingHigh intensity

A high-strength wet welding electrode for underwater welding is composed of the core made of H08E steel wire a coated surficial water-proof layer, and a coated sandwich layer containing rutile (42-54 Wt%), potash feldspar (12-20), talc (6-14), cellulose (4-12), ferromanganese (6-14), Ni powder (0-4), Fe powder (3-12) and Al-Mg alloy (0-4).

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Self-protective flux-cored wire for all-position underwater wet welding in deep water environment

ActiveCN106964918AMeet weldingEasy arc startWelding/cutting media/materialsSoldering mediaSlagFilling rate

The invention belongs to the technical field of welding materials and discloses a self-protective flux-cored wire for all-position underwater wet welding in a deep water environment. The self-protective flux-cored wire comprises a metal skin and a flux core. The metal skin is formed by rolling an N6 nickel strip. The basic slag system of the flux core is an alkaline calcium fluoride-aluminum-magnesium slag system. The N6 nickel strip comprises, by weight, no smaller than 99.5% of Ni and Co in total, no larger than 0.06% of Cu, no larger than 0.10% of Fe, no larger than 0.05% of Mn, no larger than 0.10% of C, no larger than 0.10% of Si and no larger than 0.005% of S. The flux core comprises, by mass, 52-67% of fluoride, 14-20% of aluminum-magnesium alloy powder, 5-10% of calcium carbonate, 5-15% of ferromanganese, 3-10% of chromium, 4-10% of titanium and 1.5-5% of rare earth. The filling rate of the flux core in the flux-core wire is 24-32%. According to the scheme provided by the invention, the self-protective flux-cored wire can be used for welding under water by 100-200 meters, arcing is easy during welding, arc burning is stable, no arc blowout or breaking phenomenon occurs, an obtained welding seam is attractive in forming, the tensible strength of deposited metal after welding is larger than 500 MPa, and the self-protective flux-cored wire has good impact toughness and meets the all-position welding requirements of medium and low carbon steel and low alloy high strength steel in the deepwater environment.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

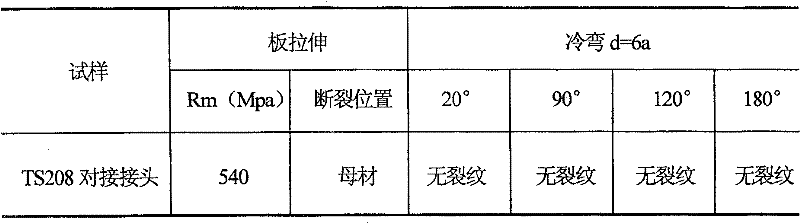

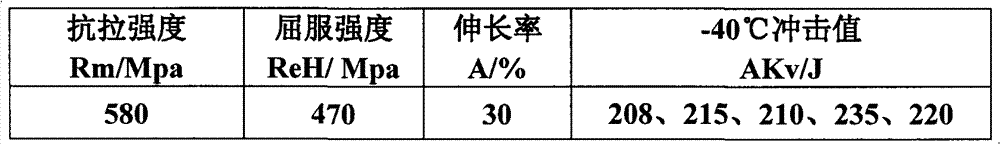

Weather-resistant submerged arc welding wire for free-coating weather-resistant steel bridge

ActiveCN106001987AGood weld formabilityImprove metallurgical qualityArc welding apparatusWelding/cutting media/materialsChemical compositionAtmospheric corrosion

The invention discloses a weather-resistant submerged arc welding wire for a free-coating weather-resistant steel bridge, and belongs to the field of welding materials. According to the technical scheme, the weather-resistant submerged arc welding wire for the free-coating weather-resistant steel bridge comprises a basic chemical component Fe and the following chemical components in percentage by mass: 0.03 to 0.10% of C, 0.10 to 0.28% of Si, 1.15 to 1.55% of Mn, not greater than 0.012% of P, not greater than 0.005% of S, 0.25 to 0.55% of Cr, 0.25 to 0.55% of Ni, 0.20 to 0.50% of Cu, 0.005 to 0.025% of Ca, and 0.005 to 0.05% of Re. The welding wire is applied to the welding of Q345qENH-Q460qENH serial weather-resistant bridge steel, and is outstanding in atmospheric corrosion resistance, high in process performance, stable in quality, and suitable for large-scale popularization and application.

Owner:YANSHAN UNIV

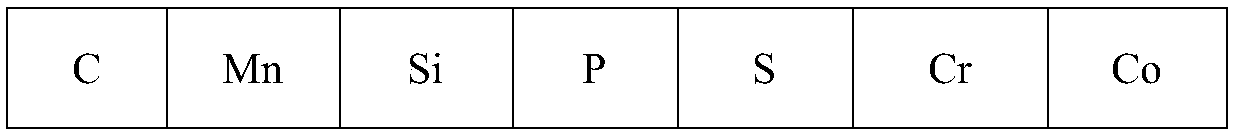

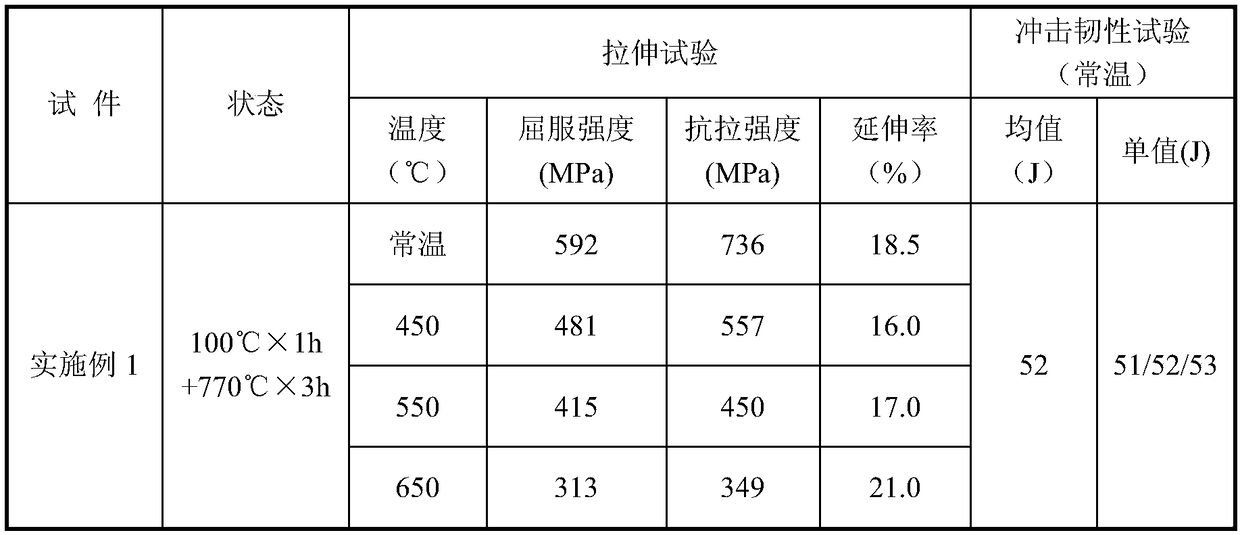

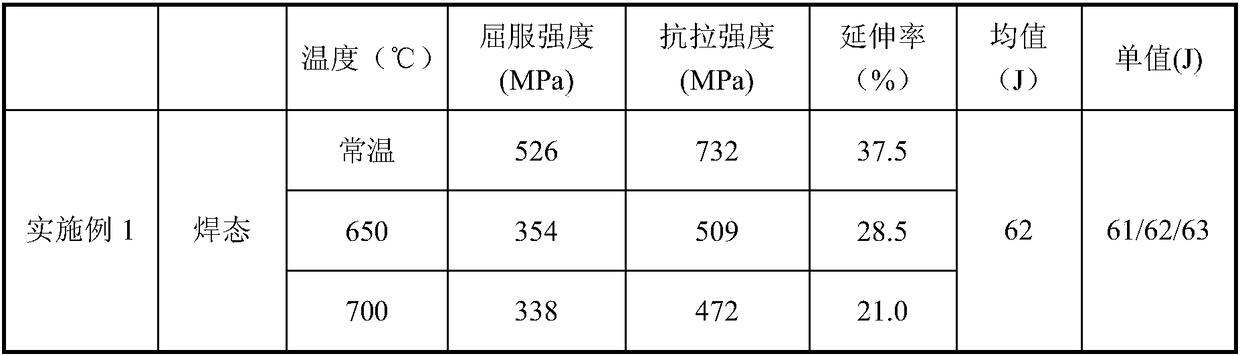

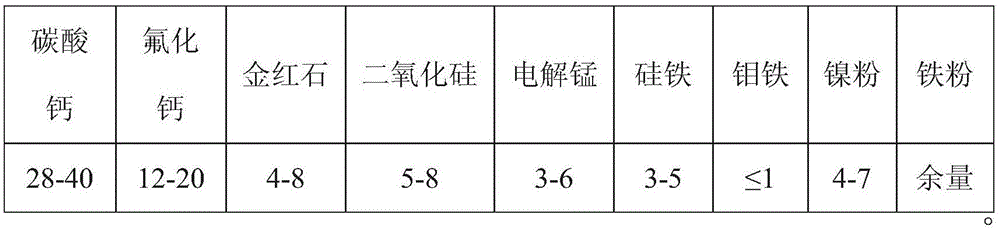

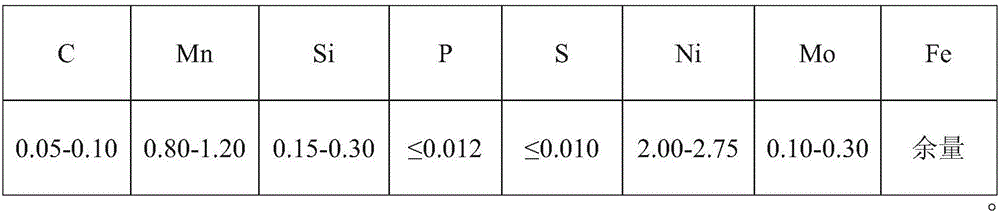

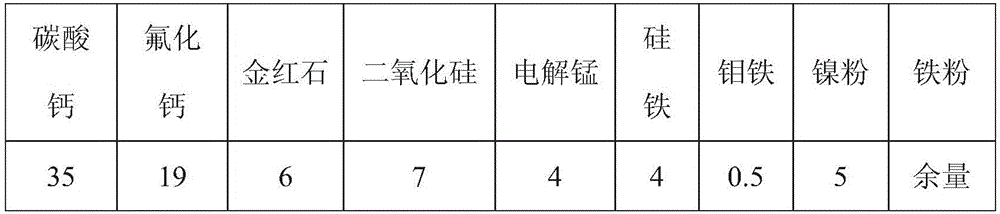

Coating transition type heat resistance steel welding rod for 650 DEG C ultra-supercritical thermal power generating unit

InactiveCN108188614AGood workmanshipStable arc burningWelding/cutting media/materialsSoldering mediaSlagHeat resistance

The invention provides a coating transition type heat resistance steel welding rod for a 650 DEG C ultra-supercritical thermal power generating unit. A CaO-CaF2-SiO2 slag system formula is adopted, atrace of alloy elements are added, the main components of deposited metal are 9%Cr-3%W-3%Co, and the welding technology performance is good. Under the heat treatment condition of 100 DEG C x 1h+780 DEG C x 3h, the tensile strength Rm of the deposited metal is larger than or equal to 680 MPa, and the normal temperature KV2 is larger than or equal to 50 J; and the tensile strength Rm of a welding connector of the deposited metal is larger than or equal to 680 MPa, the normal temperature KV2 is larger than or equal to 50 J, and the low-alloy steel electric welding rod is suitable for the 650 DEGC steam temperature ultra-supercritical thermal power generating unit.

Owner:KUSN GINTUNE WELDING

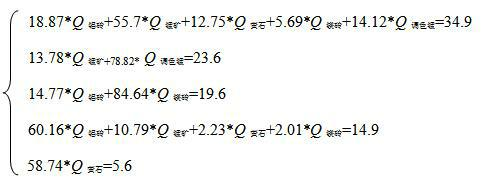

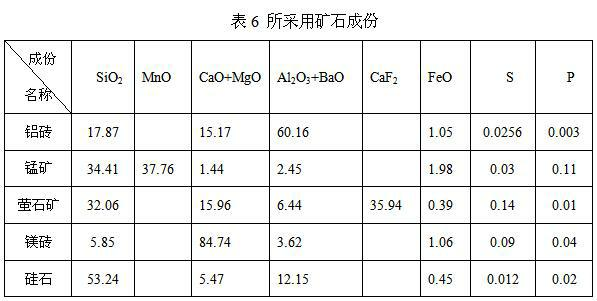

Automatic submerged arc welding flux and preparation method thereof

ActiveCN102632349AAchieve recyclingStable arc burningWelding/cutting media/materialsSoldering mediaLiquid stateMaterials science

The invention provides an automatic submerged arc welding flux and a preparation method of the automatic submerged arc welding flux. The preparation method of the automatic submerged arc welding flux comprises the following steps that: industrial residues which contain beneficial elements of a certain grade are mixed with a specific proportion and taken as main raw materials of the automatic submerged arc welding flux, and then placed into a melting furnace for melting; after the raw materials are meted to liquid state, hypervalent manganese ores are added for restoring and color matching, after the water cooling and granulation, the semi-finished products of the welding flux is produced; the melted semi-finished products of the welding flux are dried, screened and packaged, and finally the finished products of the welding flux is produced. The automatic submerged arc welding flux comprises the following components in percentage by weight: SIO233-39%, MnO23-30%, MgO+CaO8-20%, Al2O3+BaO10-15%, Caf22-6.5%, FeO less than or uqual to 2%, S less than or equal to 0.03%, P less than or equal to 0.009%. The automatic submerged arc welding flux has the advantages that the energy consumption is low, the cost is low, the purification of the deposited metal is favorable, the oxidizability is low, the tensile strength is high, and the low temperature impact toughness is high.

Owner:蒋才银

All-position flux-cored wire for alkaline gas protection

InactiveCN102785041ALess welding spatterProtection transitionArc welding apparatusWelding/cutting media/materialsCrack resistanceHydrogen

The invention discloses an all-position flux-cored wire for alkaline gas protection, which has both strong impact toughness and strong crack resistance and is suitable for protection of gas such as CO2 or CO2+Ar. The flux-cored wire is manufactured by drawing SPCC (steel plate cold commercial) steel strips or similar mild-carbon steel strips wrapping flux core in specific component proportion. By adopting an alkaline slag system, weld metal can be purified, hydrogen and oxygen contents of the weld metal can be reduced, so that excellent impact toughness and cracking resistance can be obtained. Desulphuration capacity of the alkaline slag system is utilized so as to further purify the weld metal and improve the cracking resistance.

Owner:天津雷公焊接材料有限公司

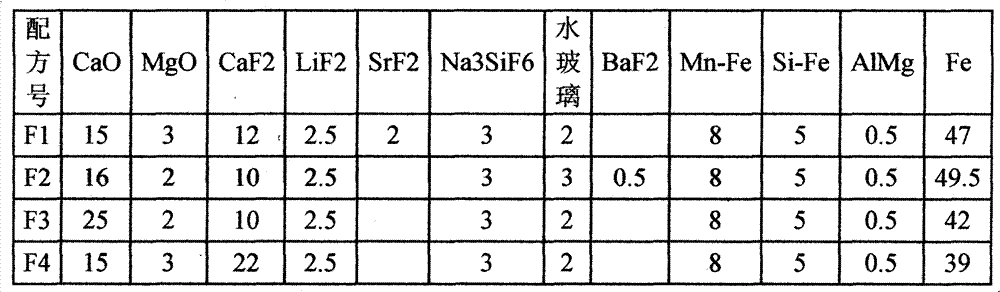

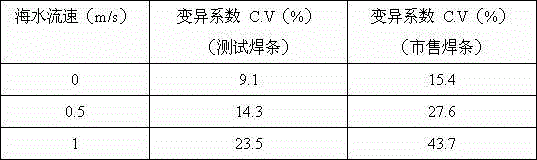

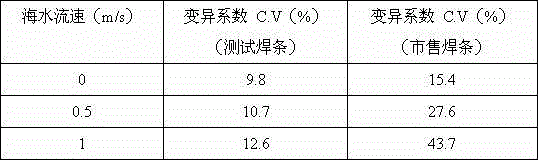

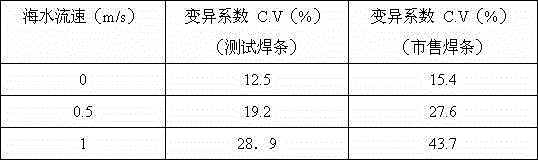

High-stability coating for underwater wet welding rod

InactiveCN104874939ASmooth startStable arc burningWelding/cutting media/materialsSoldering mediaSolid componentCoating

The invention discloses a high-stability coating for an underwater wet welding rod. The coating is prepared by mixing a solid component and a liquid component, wherein the mass of the added liquid component is 15%-20% of that of the solid component; the solid component is prepared from raw materials in percentage by mass as follows: 45%-55% of rutile, 10%-16% of fluorite, 5%-8% of marble, 4%-8% of ferromanganese, 8%-15% of nickel powder, 8%-10% of cryolite and 0%-2% of cesium nitrate; the liquid component adopts potassium-sodium water glass with the potassium-sodium ratio being 3:1 at the temperature of 20 DEG C. According to the high-stability coating for the underwater wet welding rod, arc strike can be performed smoothly under the conditions that the water depth doesn't exceed 20 meters and the water velocity is not higher than 1.2 m / s, continuous stable combustion is realized, an electric arc extinguishing phenomenon is avoided, the strength is higher than or equal to 400 MPa, and the welding requirements of a non-structural member are basically met.

Owner:青岛哈工海洋工程技术有限公司

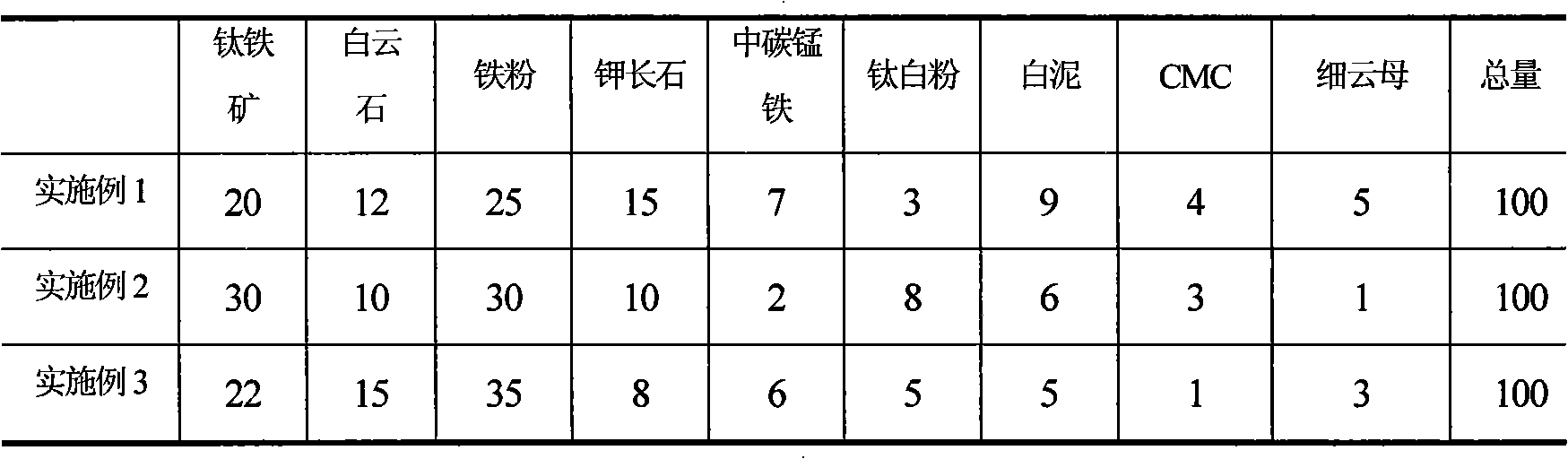

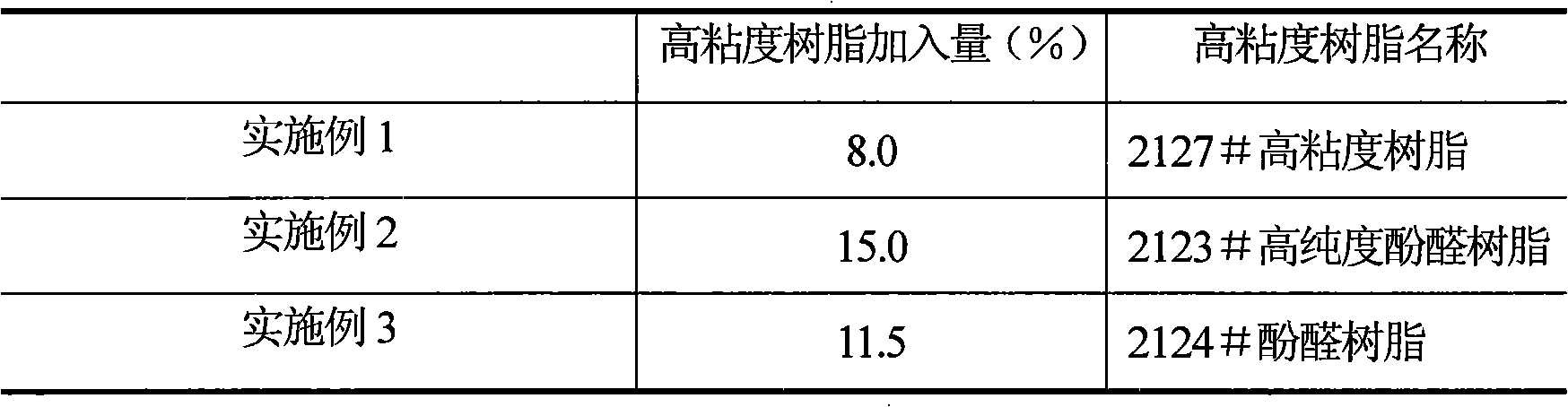

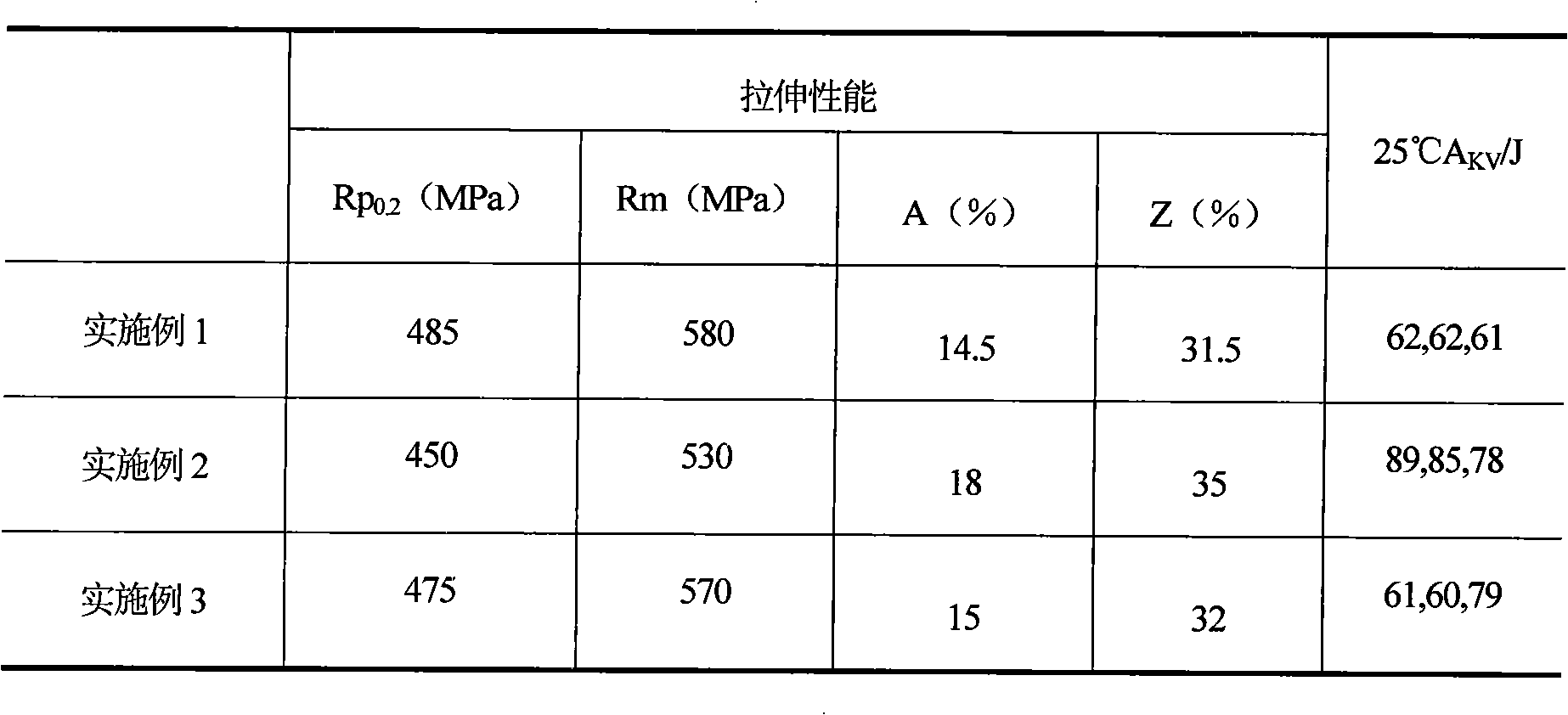

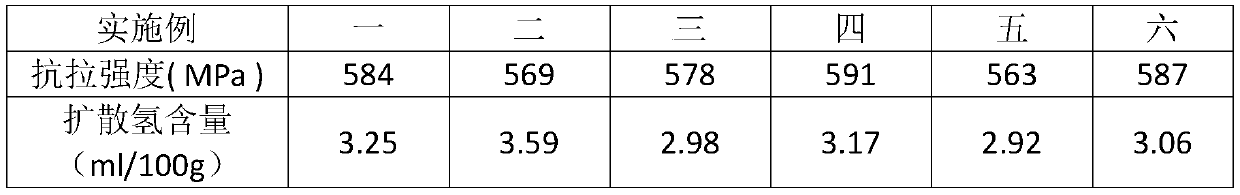

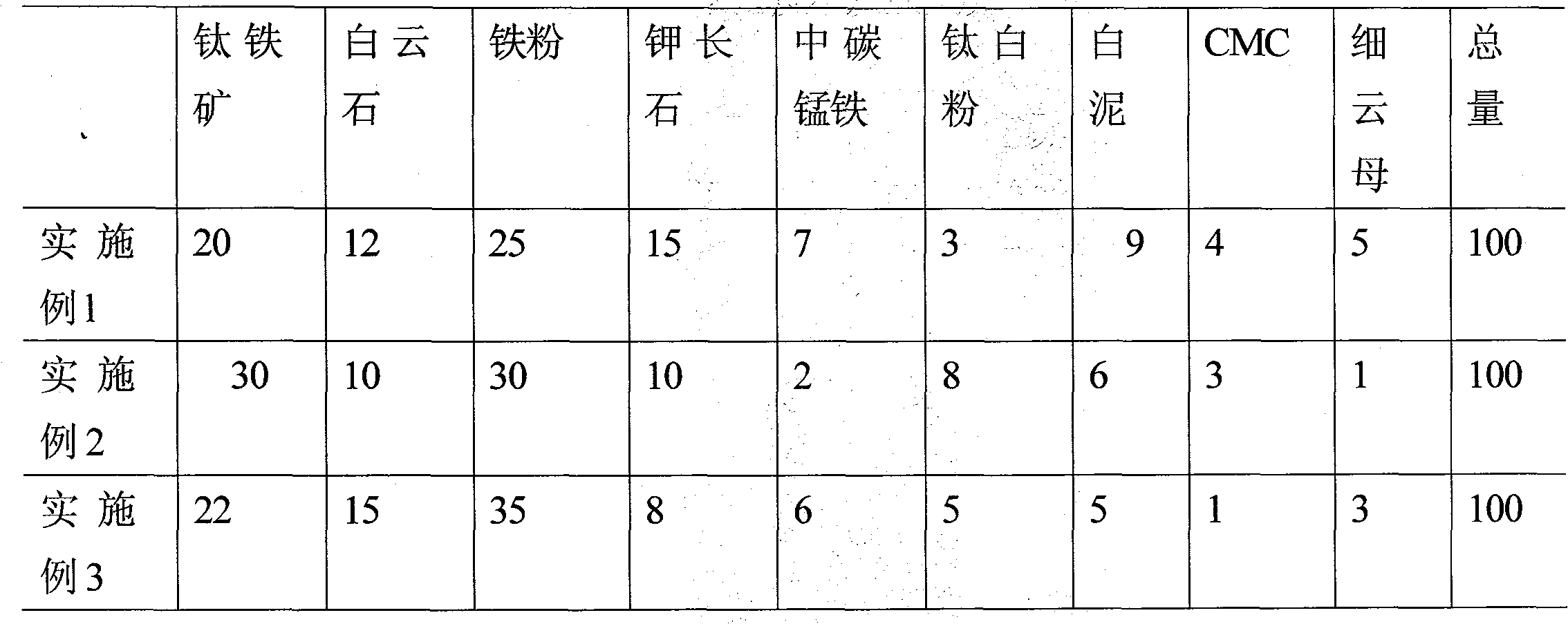

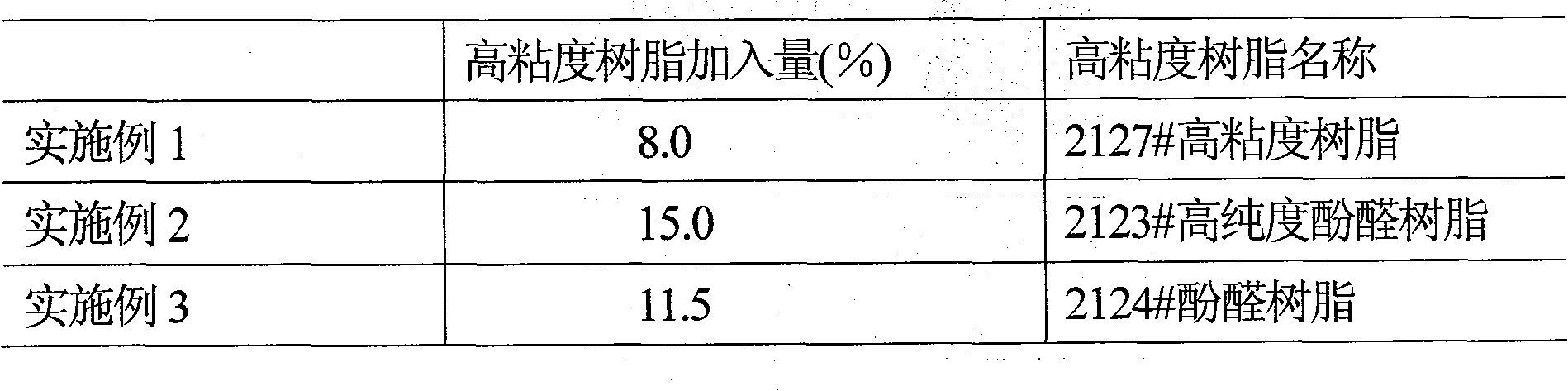

Low-cost wet method underwater welding rods

InactiveCN101347873ASimple production processIncrease productivityWelding/cutting media/materialsSoldering mediaSlagPotassium

The invention provides a low-cost underwater wet welding rod which adopts a commercial H08E welding wire as a welding core; the main components and weight proportion of coating are as follows: 20-30% of ilmenite, 10-15% of dolomite, 25-35% of ferrous powder, 8-15% of potassium feldspar, 2-7% of medium-carbon ferromanganese, 5-9% of white slime, 3-8% of titanium pigment, 1-4% of CMC and 1-5% of fine mica; the high viscosity resin which accounts for 8-15% of the total weight of the coating components is added. By adopting the high viscosity resin as an adhesion agent, the welding rod of the invention can be directly applied to underwater wet welding after extrusion and does not need to be coated with a waterproof coating on the surface, thus simplifying production technique, improving production efficiency and reducing production cost; the invention can ensure that after the welding rod is soaked in water for a long time, the coating dose not go bad and drop off, and welding operation can still be carried out. When used in underwater welding, the welding rod has the advantages of easy arc striking, stable combustion of electric arc, good performance of restarting, easy slag detachability, good weld forming and fine processing property of underwater welding.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

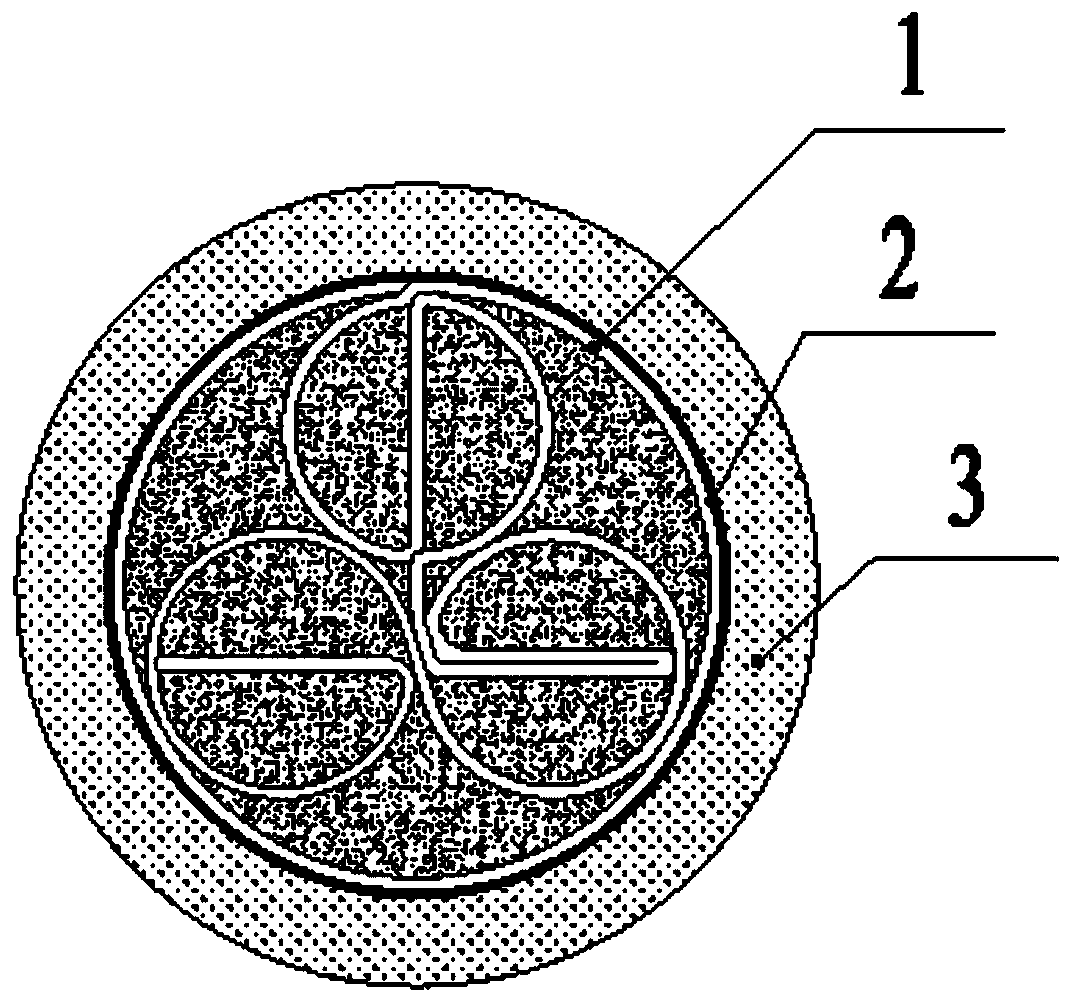

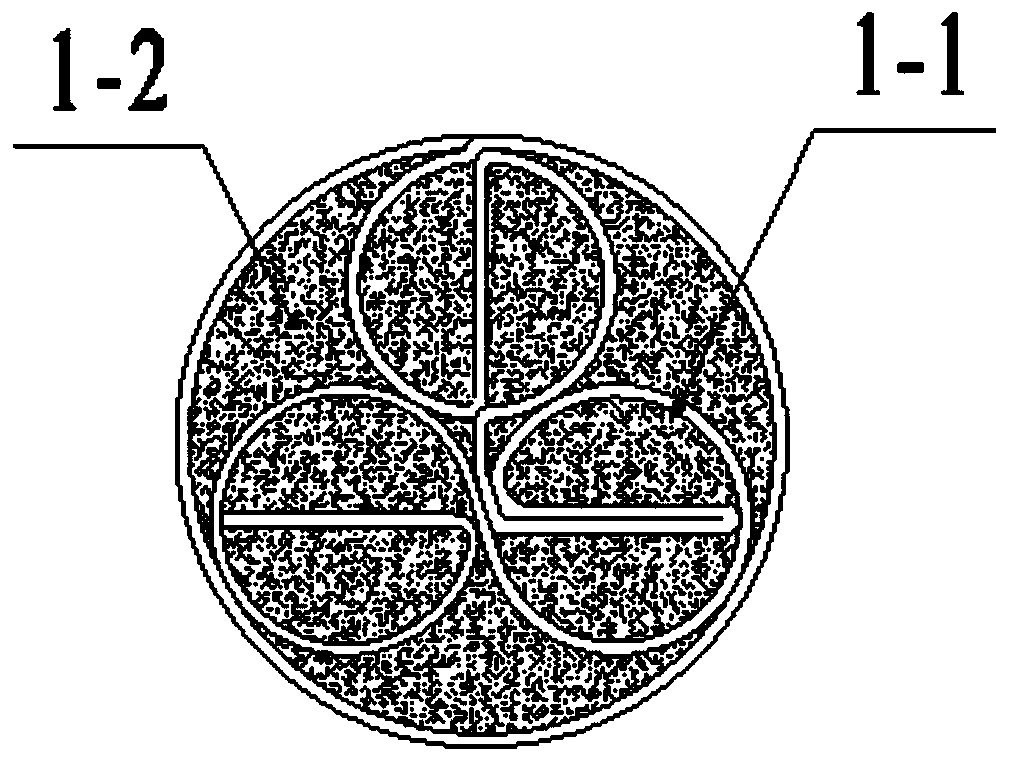

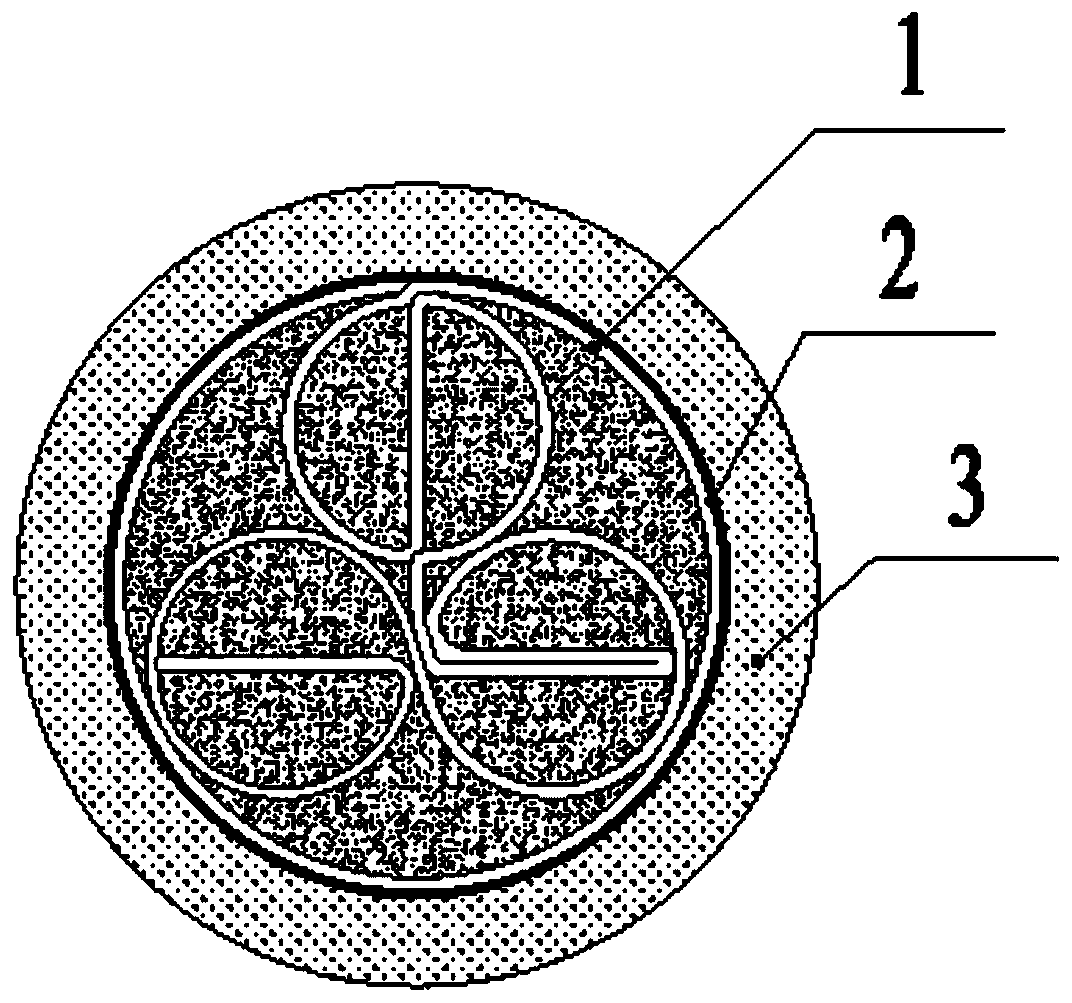

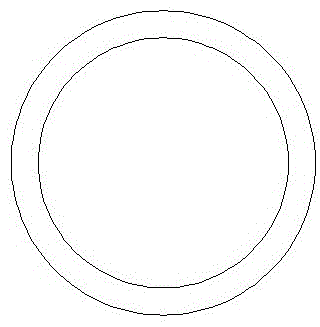

Flux-cored welding rod for stainless steel welding

ActiveCN111168273AImprove conductivityStrong resistance to moisture absorptionWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceCrack resistance

The invention belongs to the field of welding materials, and particularly relates to a flux-cored welding rod for stainless steel welding. The flux-cored welding rod comprises a flux-cored welding core, a nano graphene coating and a coating from inside to outside, the flux-cored welding core is of a structure similar to a cable, a nickel strip is sequentially bent into three e-shaped circles whichare externally tangent pairwise and are equal in diameter, then is wound into a circular ring which is internally tangent to the e-shaped circles, and is closed to form the flux-cored welding core, gaps in the closed circular ring are filled with flux core, and modified potassium titanate is adopted in the flux core to serve as an arc stabilizer. According to the welding rod, during welding, thecenter of the welding core is high in electrical conductivity and stable in electric arc, resistance heat generated by the flux-cored welding core is small, the heat conduction performance of the welding core is high, the volume expansion of the welding core is small, and the reddening and cracking resistance of the coating is good. The use length of the welding rod is 88% or above of the length of the coating, the utilization rate of the welding rod is increased, deposited metal is uniform in chemical component, the comprehensive mechanical property is good, and the welding rod is an innovation in the aspect of flux-cored welding rods for stainless steel welding.

Owner:ZHENGZHOU UNIV

Submerged arc sintered flux for stainless steel at low temperature

ActiveCN109175788AAdjustable viscositySmooth transitionWelding/cutting media/materialsSoldering mediaAlloyWollastonite

The invention relates to a submerged arc sintered flux for stainless steel at the low temperature. The submerged arc sintered flux is prepared from dry powder with various components and binder sodiumsilicate and is characterized in that the dry powder is prepared from, by weight, 15-30 parts of fluorite, 15-30 parts of white corundum, 20-35 parts of magnesia, 10-25 parts of wollastonite and 1-5parts of alloy powder. The flux is prepared by a method comprising the following steps that dry powder materials are evenly mixed according to the matching ratios, sodium silicate is added, wet mixingis carried out, then granulation is carried out, the granules are dried at the low temperature of 200-330 DEG C for 30-50 min, screened, sintered at the high temperature of 700-800 DEG C for 45-60 min, cooled and screened, and therefore the submerged arc sintered flux is obtained. The submerged arc sintered flux has the excellent effects shown in the description.

Owner:BEIJING JINWEI WELDING MATERIAL +1

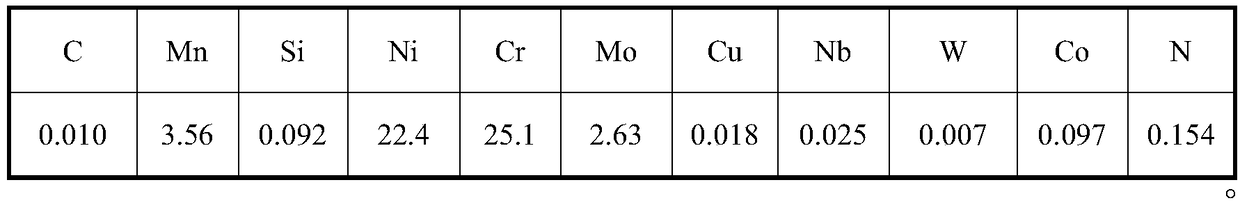

Austenitic heat-resisting stainless steel welding electrode for ultra-supercritical thermal power units

ActiveCN108098187ASuitable for all position weldingSimple welding processWelding/cutting media/materialsSoldering mediaSlagAustenite

The invention provides an austenitic heat-resisting stainless steel welding electrode for ultra-supercritical thermal power units, comprising deposited metals, to be specific, 0.03-0.10% of C, 1.0-2.5% of Mn, < / =0.80% of Si, 24.0-26.0% of Ni, 21.5-23.5% of Cr, 1.5-2.5% of Mo, 2.5-3.5% of Cu, 0.30-0.60% of Nb, 3.0-4.0% of W, 1.0-2.0% of Co, 0.15-0.30% of N and the balance of Fe and impurities. TheCaO-CaF2-SiO2 slag system formulation is used herein, trace alloy elements are added, the main deposited metals include 25% of Ni, 22% of Cr, 3% of Cu, 3% of W and 1% of Co, welding processibility isgood, deposited metal tensile strength Rm is > / =720 MPa, ductility is > / =35%, and normal-temperature KV2 is > / =50 J.

Owner:KUSN GINTUNE WELDING

High-strength steel electrode used for minus 50 DEG C low temperature spherical tank

InactiveCN106425164AGood process performanceStable arc burningWelding/cutting media/materialsSoldering mediaSlagMetal

The invention provides a high-strength steel electrode used for a minus 50 DEG C low temperature spherical tank. According to the high-strength steel electrode, a CaO-TiO2-CaF2 slag system formula is adopted, and microcrystalline alloying elements are added into a deposited metal on the basis of 2.5% Ni, so that the welding technology property of the electrode is good, when welded under a heat input of 30-40 KJ / cm and under a heat treatment condition of 580 DEG C*4 h, the deposited metal has tensile strength Rm of 630 MPA or above, minus 60 DEG C KV2 is 60 J or above, and the welded joint of the deposited metal has the tensile strength Rm of 610 MPa or above, minus 50 DEG C KV2 is 70 J or above, therefore, the high-strength steel electrode is very applicable to weld and construction of the minus 50 DEG C low temperature ethylene / propylene spherical tank.

Owner:KUSN GINTUNE WELDING

Welding electrode coating and method of preparing same into welding electrode

ActiveCN105798483ALow priceLow costWelding/cutting media/materialsSoldering mediaSilicic acidKaolin clay

The invention discloses a welding electrode coating. The welding electrode coating is composed of, by weight, 5-7 parts of diamond, 18-22 parts of reduced ilmenite, 4-6 parts of kaolin, 13-16 parts of light calcium powder, 22-25 parts of iron red, 2-4 parts of talcum powder, 10-14 parts of aluminum powder, 1-3 parts of sodium carbonate, 4-6 parts of wood meal, 4-7 parts of titanium dioxide and 3-6 parts of ferromanganese. A binder of the welding electrode coating is sodium silicate or potassium silicate water glass, and 30-36 g of water glass is added into each100 g of the welding electrode coating. Raw materials are low in price, so that the coating prepared is low in cost. When the welding electrode prepared by the welding electrode coating is used for welding, welding defects like air holes, slag inclusion and cracks do not appear on the welding surface, and welding seam forming is smooth; an electric arc is stable in burning, splashing particles are small, slag removing is easy after welding, and the coating is uniform in melting and free of caking and shedding; a conventional knife and conventional cutting parameters are adopted to machine a welding joint, knife beating in the machining process is avoided, no knife relieving trace is formed on a cut surface, and machining performance is good.

Owner:HENAN POLYTECHNIC

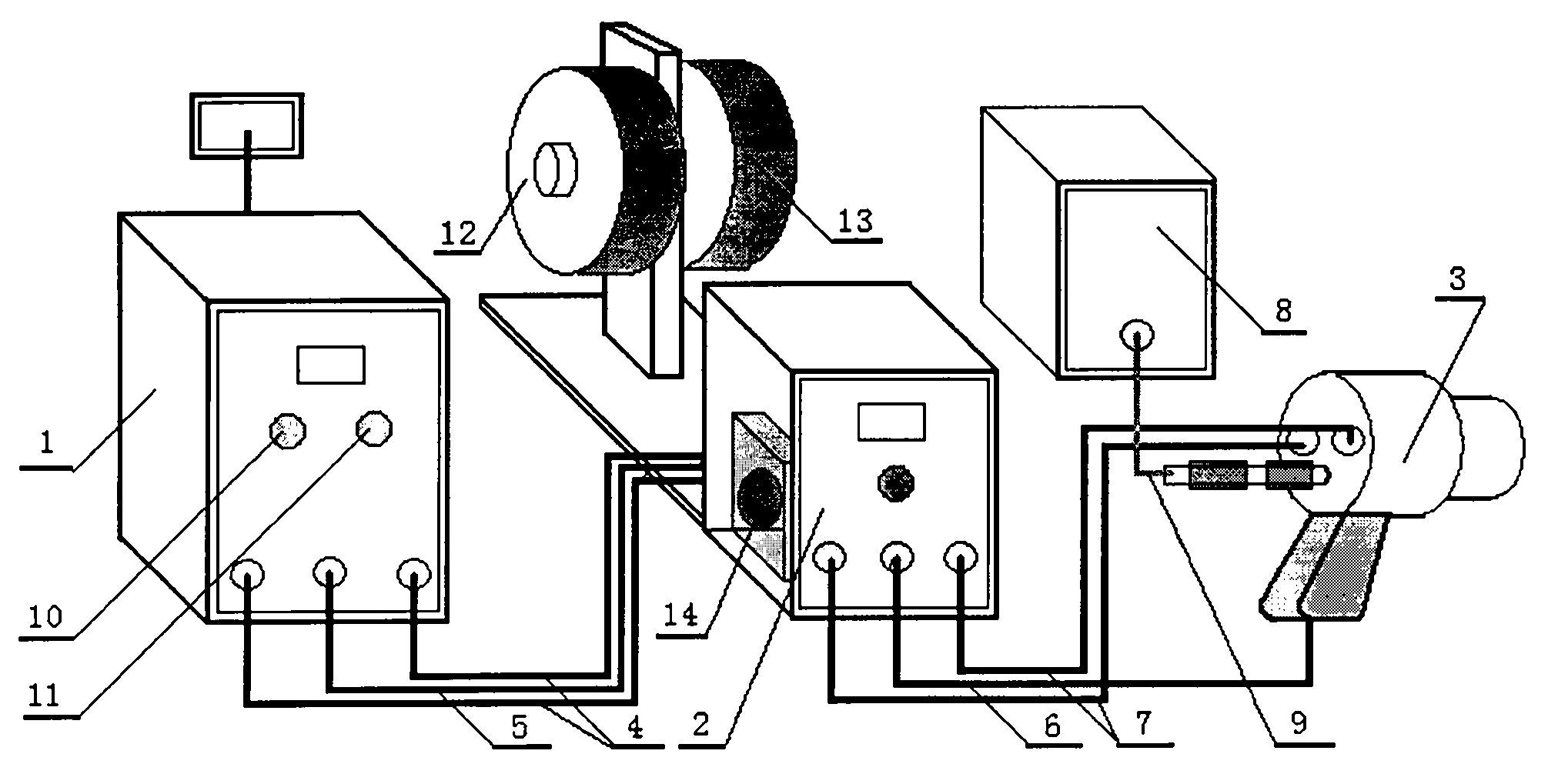

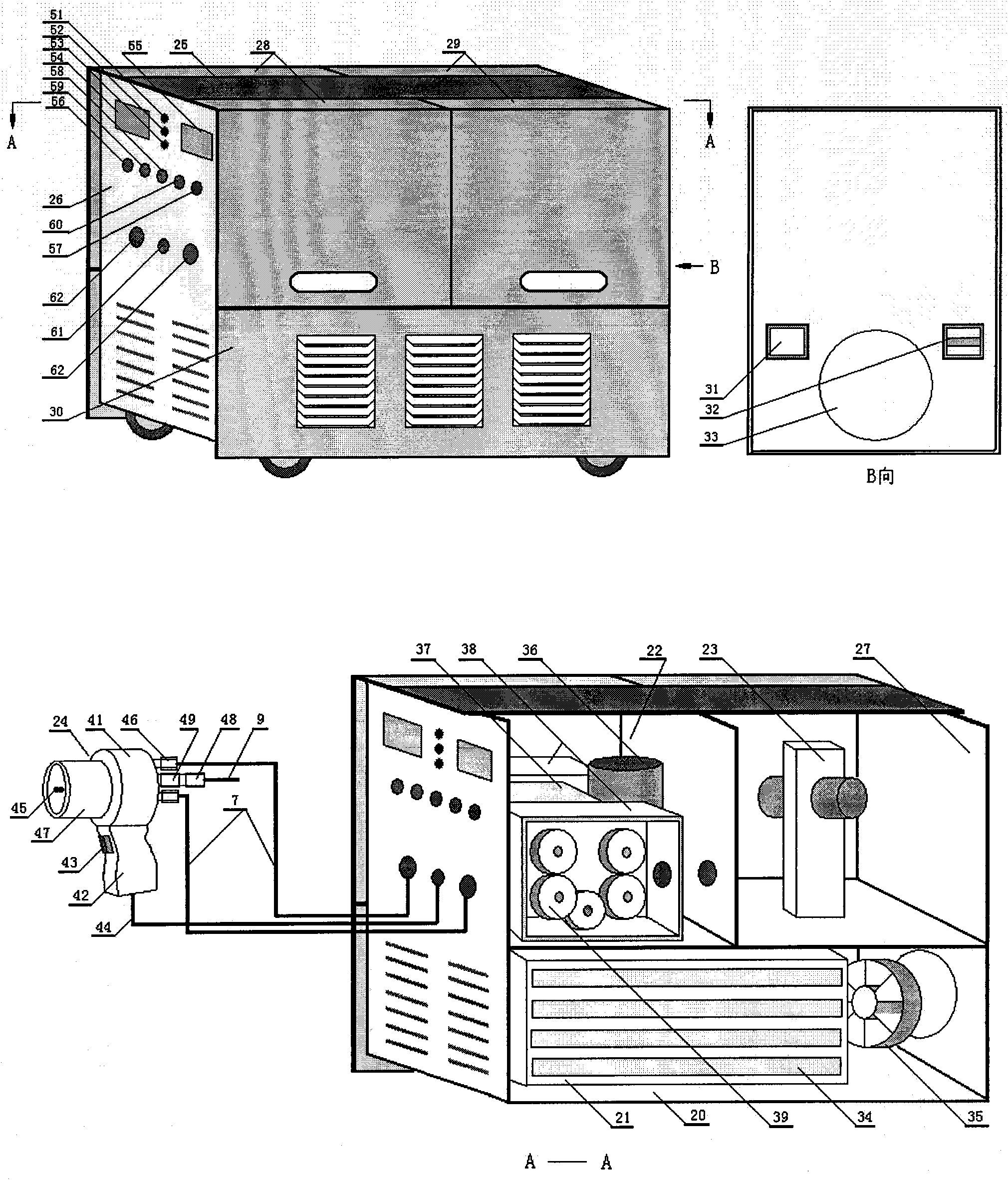

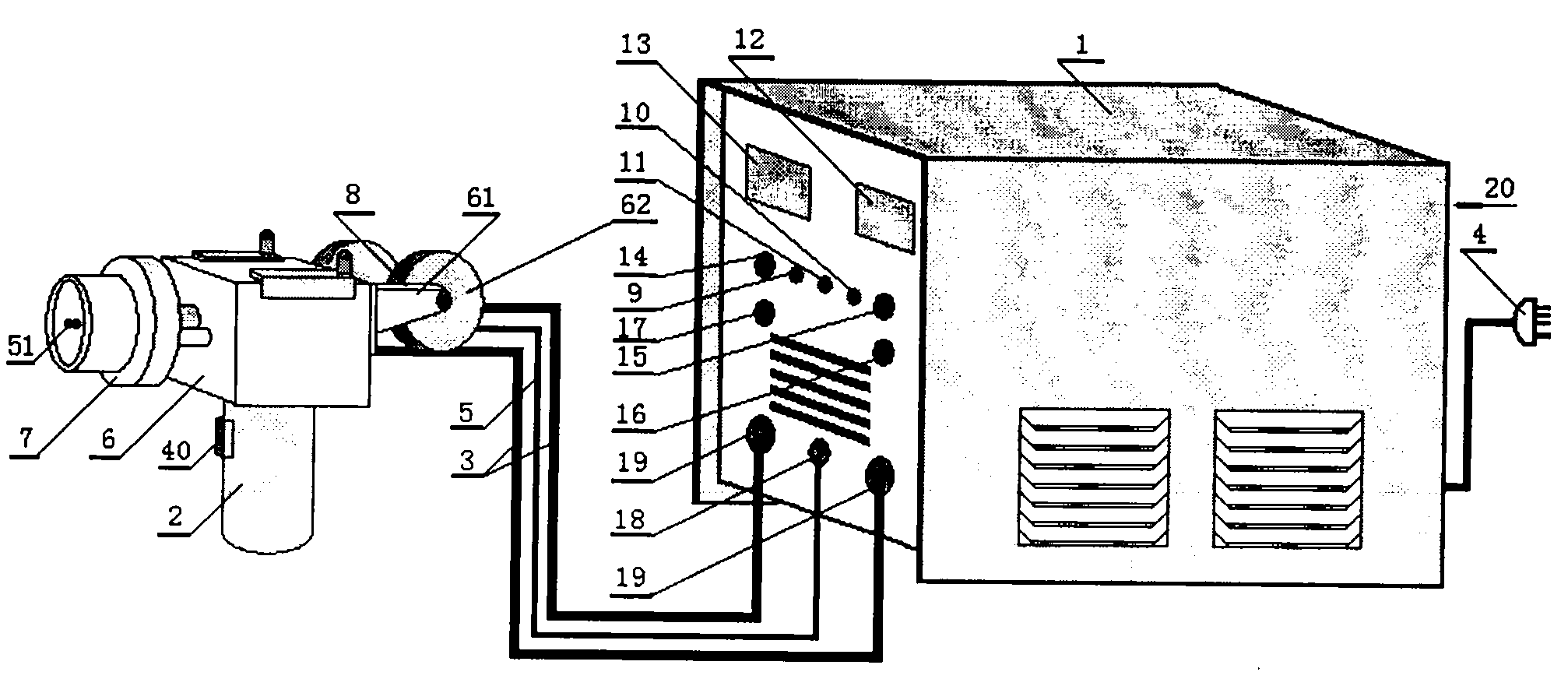

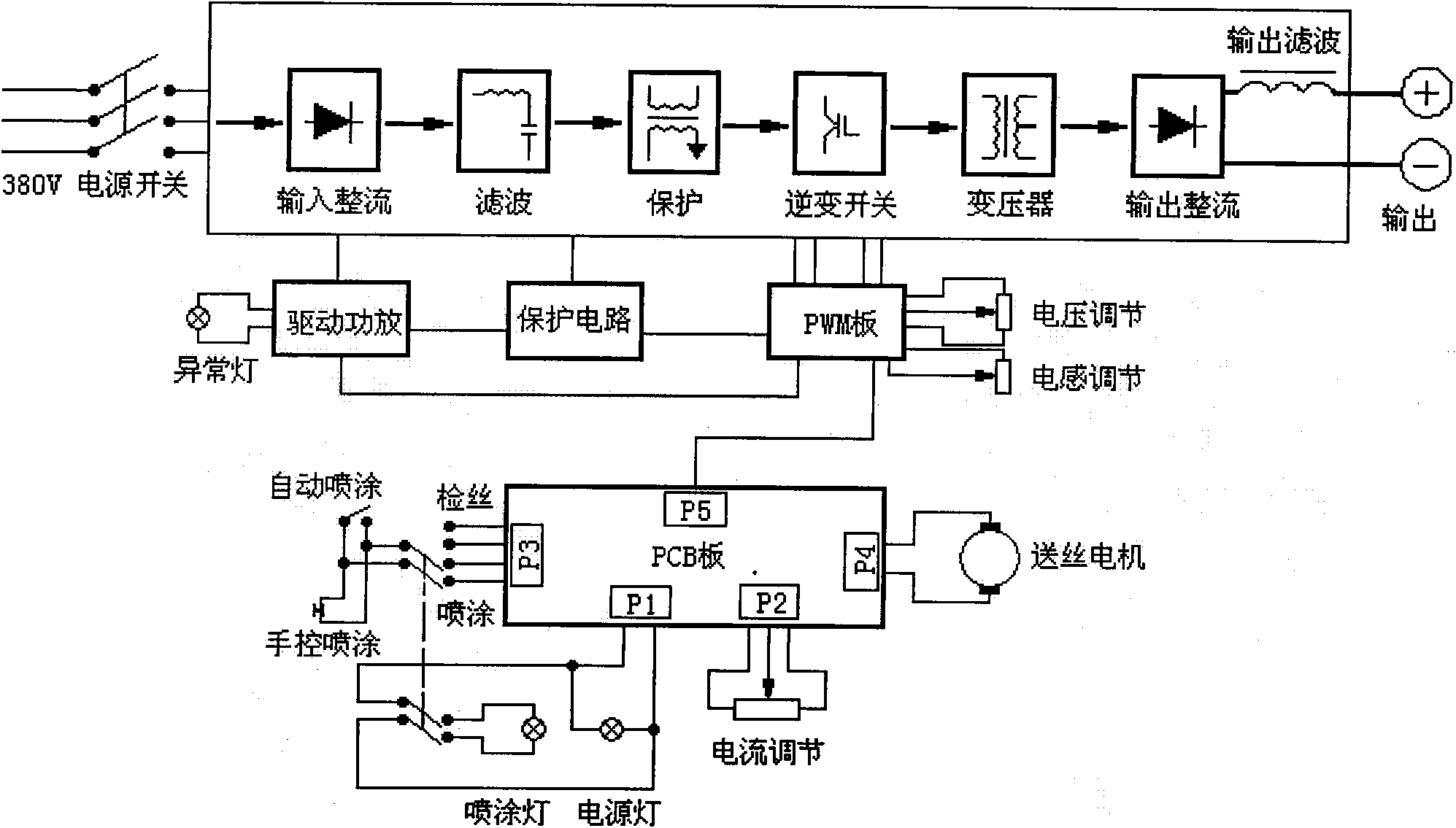

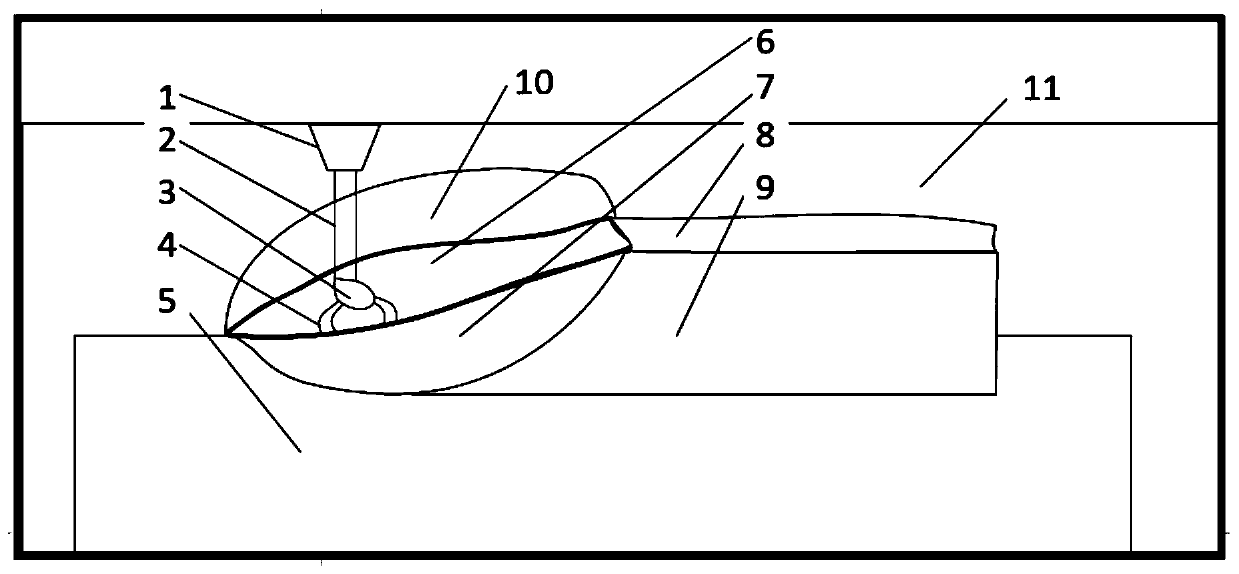

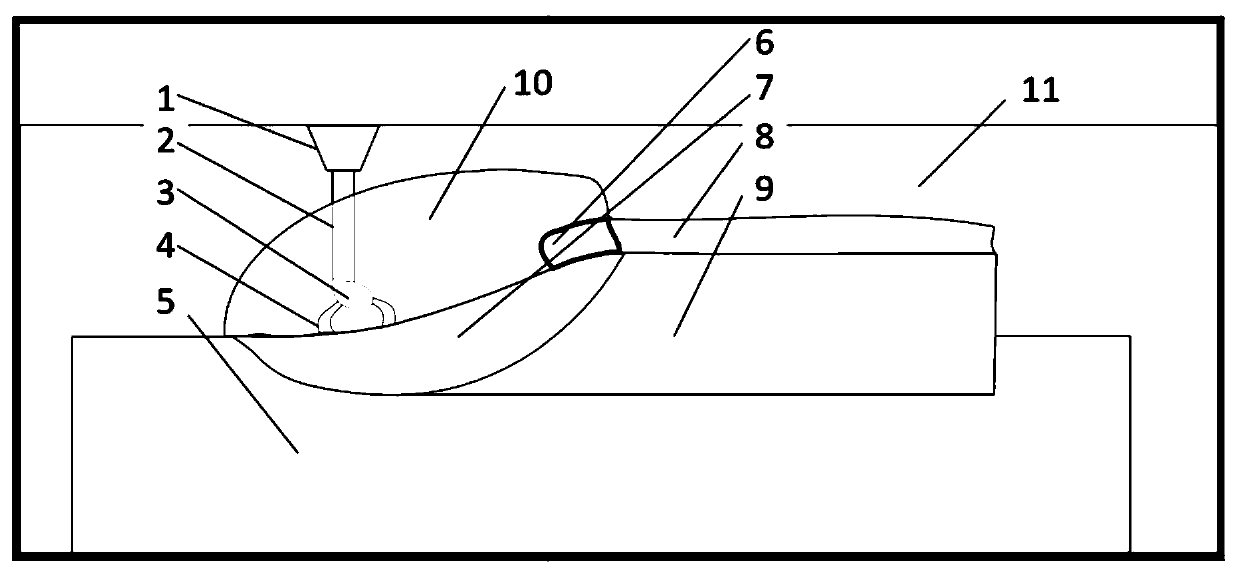

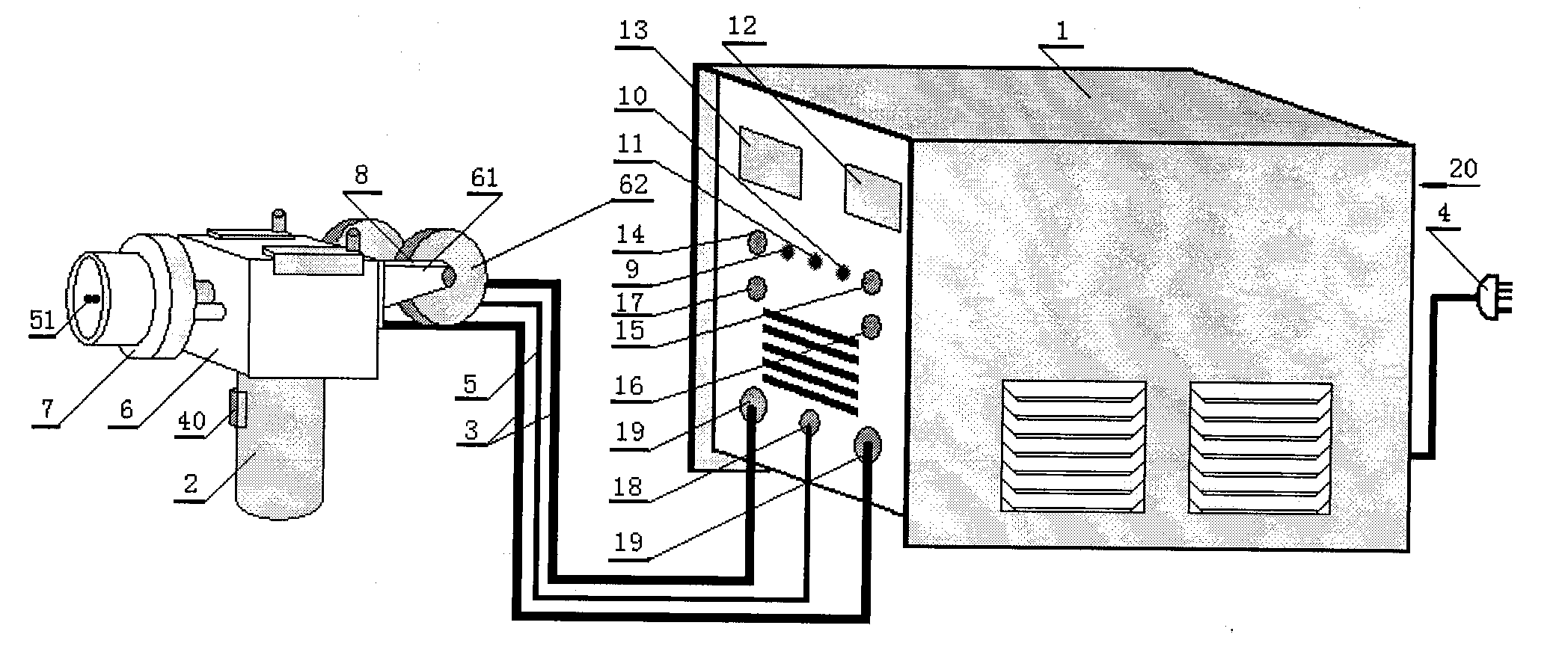

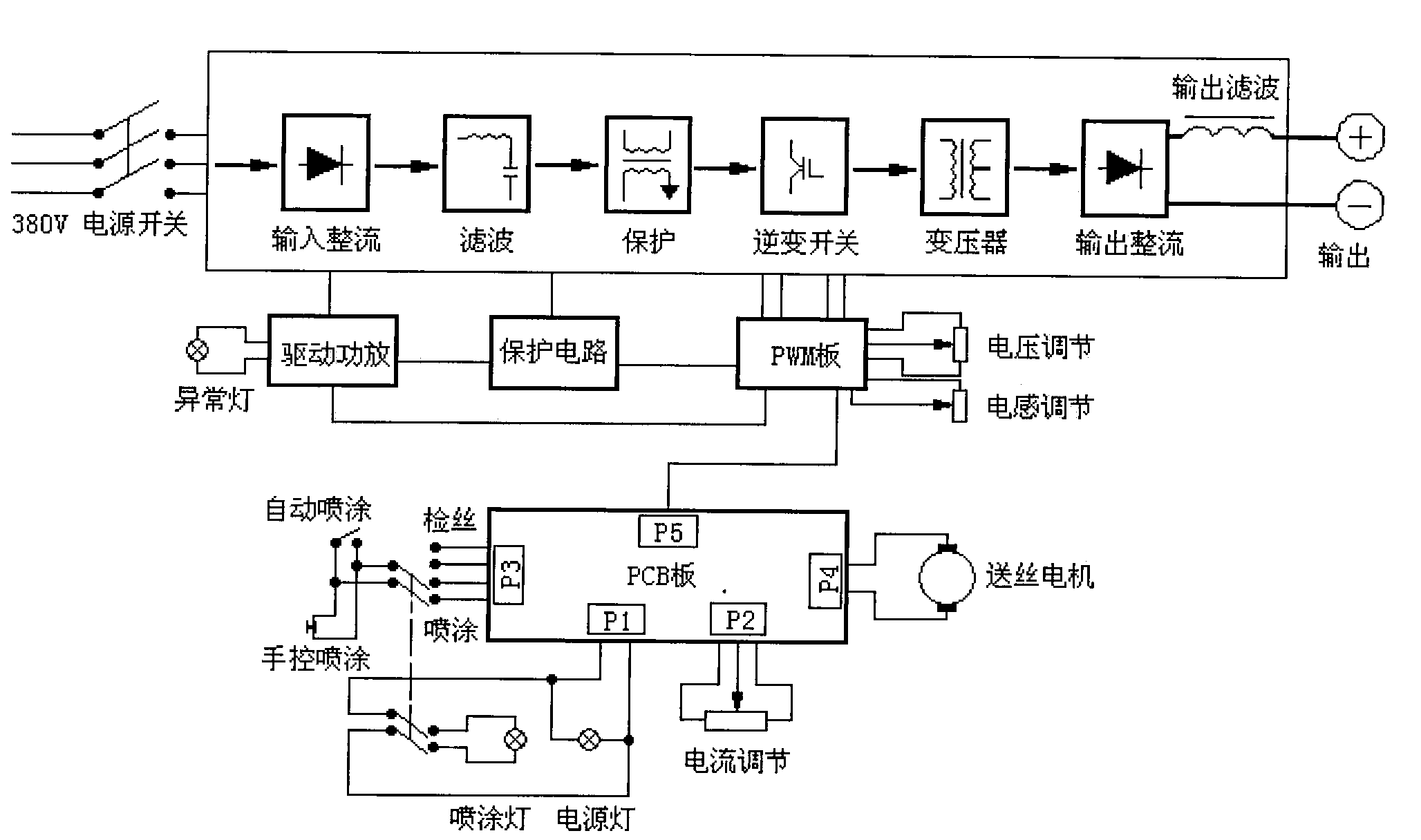

Integral push-wire-type electric arc spraying equipment

InactiveCN101864550AReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingWhole body

The invention relates to an integral push-wire-type electric arc spraying equipment used for thermal spraying, which can be seen in an attached figure of the abstract. The equipment adopt an inverter-type spraying power supply, has the technical scheme of combining and closing the spraying power supply, a wire feed device and a wire reel bracket (including a wire reel) into a whole body, and is matched with a home-made electric arc spray gun. The integral push-wire-type electric arc spraying equipment solve the problems of heavy weight, large volume, dispersed devices, more externally connected cables and the like of the push-wire-type electric arc spraying equipment. The equipment have the function of stepless regulation for output voltage within the range of 10-50V, and can freely adjust the parameters without stopping a machine in the spraying process; the equipment is provided with a manual / automatic spraying and wire detection / spraying switch, thus being convenient for the selection of operation way and preventing electric arc from hurting people and damaging equipment when in the process of installing, adjusting and checking spraying wires; and due to the full-closed structure, the blockage phenomenon of a wire guide pipe is avoided. The equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like.

Owner:慈溪光华金属复合材料有限公司

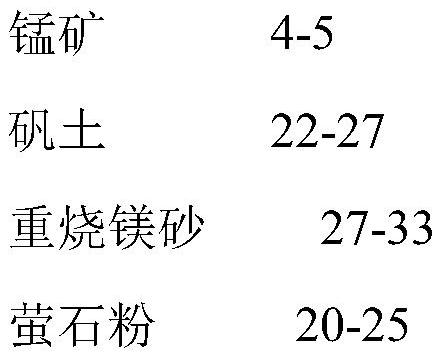

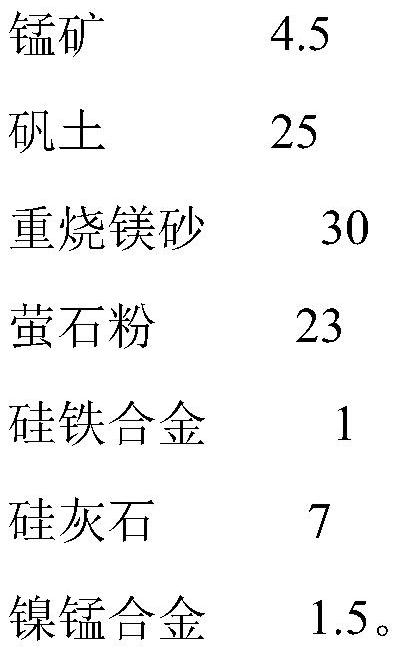

Fluorine alkaline sintered flux and preparation method and application thereof

InactiveCN111673316AImprove performanceEasy to prepareWelding/cutting media/materialsSoldering mediaPotassium silicateFerrosilicon

The invention discloses a fluorine alkaline sintered flux. The fluorine alkaline sintered flux is formed in the manner that the raw materials comprising, by weight, 4-5 parts of manganese ores, 22-27parts of alumina, 27-33 parts of dead-burned magnesia, 20-25 parts of fluorite powder, 1-2 parts of ferrosilicon and 5-10 parts of wollastonite are added to 21-27 parts of sodium potassium silicate and undergo sintering. The prepared fluorine alkaline sintered flux has excellent low-temperature impact resistance. The invention also provides a specific preparation method of the fluorine alkaline sintered flux and the application of the fluorine alkaline sintered flux to X70 pipeline steel welding. The fluorine alkaline sintered flux prepared through sintering can be completely applied to X70 pipeline steel.

Owner:济南市金材焊接材料有限公司

Steel gas protection welding wire for railway vehicle welding

InactiveCN107350657AImprove corrosion resistanceSolve the strength problemWelding/cutting media/materialsSoldering mediaImpact energyGas protection

The invention discloses a steel gas protection welding wire for railway vehicle welding. The steel gas protection welding wire comprises chemical components, by mass, of 0.04-0.10% of C, 0.35-0.65% of Si, 1.30-1.60% of Mn, 0.020% or less of P, 0.010% or less of S, 0.20-0.50% of Cr, 0.30-0.80% of Ni, 0.19-0.40% of Cu and the balance Fe and inevitable impurities. According to the steel gas protection welding wire, the comprehensive property is good, the tensile strength is 620 MPa or over, impact energy of minus 40 DEG C is 124 J or over, and the anti-corrosion property is outstanding.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

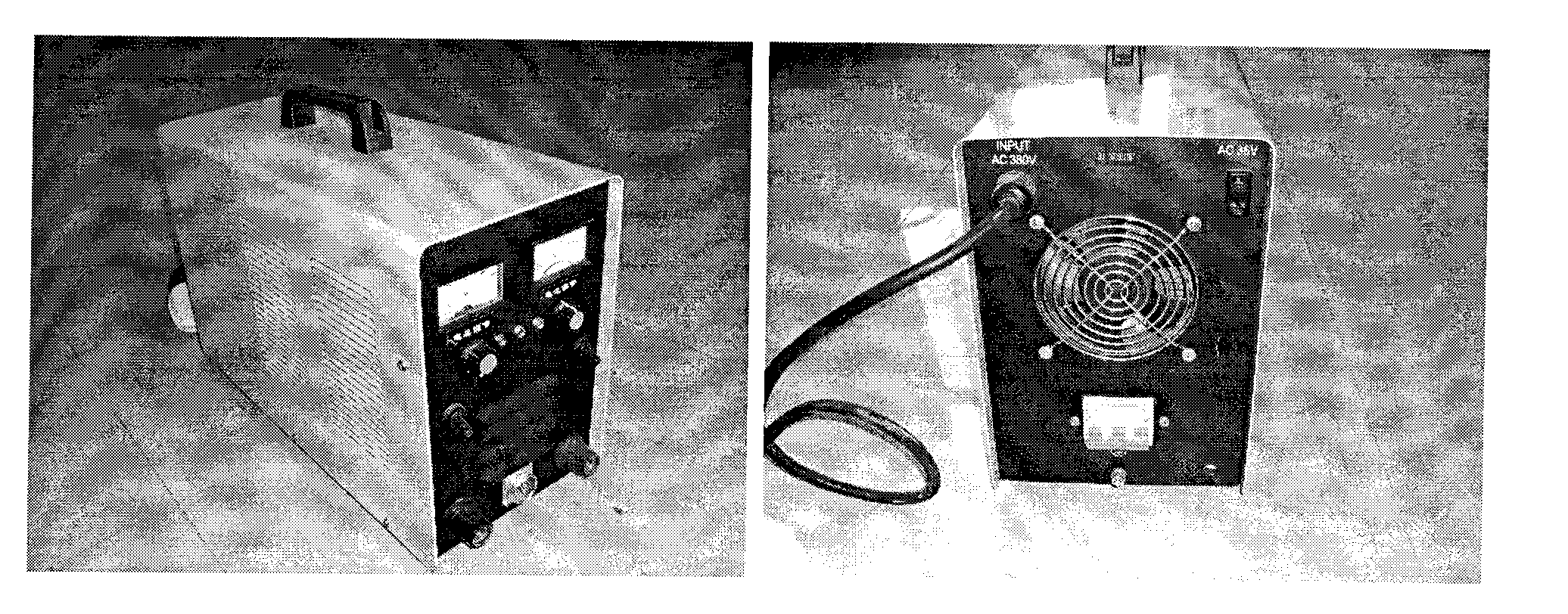

Small-sized wire drawing type electric arc spraying equipment

ActiveCN101864549AReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingPower flow

The invention relates to small-sized wire drawing type electric arc spraying equipment used for hot spraying, which is shown in the attached drawing of the abstract. The equipment adopts the technical scheme of an inversion type spraying power supply and a wire drawing type spraying gun, the output voltage of 10 to 40V is regulated in a stepless way, and the voltage can be regulated in the spraying process without stop; a manual / automatic spraying and wire inspection / spraying switch is arranged, which is convenient to select an operation mode and avoid the occurrence of the condition that electric arcs injure people and damage equipment because of the short circuit of a wire material when the spraying wire material is installed, regulated and inspected; the spraying wire material is limited to be phi 1.0 to phi 1.6mm, the maximum spraying current is 250A, the load duration rate is 100 percent, and continuous spraying is permitted; the weight of the spraying power supply is 15kg, and the weight of the spraying gun is 1.5kg; and the equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like, is suitable for the field operation and the use in an occasion with small spraying space and is suitable for spraying a component with a fine and small structure and a product with a fine coating.

Owner:慈溪光华金属复合材料有限公司

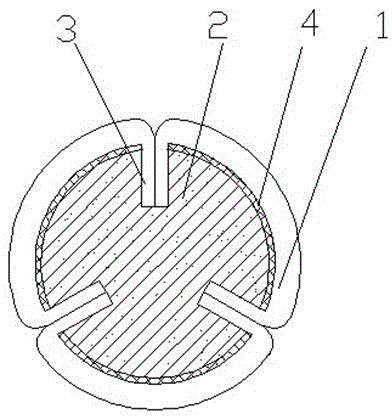

Flux-cored wire

InactiveCN104668805AEvenly distributedEvenly meltedWelding/cutting media/materialsSoldering mediaElectric arcEngineering

The invention relates to the field of welding material, in particular to a flux-cored wire. The flux-cored wire comprises sheet iron and core flux packaged by the sheet iron; the section formed by using the sheet iron to package the core flux is plum blossom-shaped, wherein the outer sheet iron is divided equally, two ends of each section of the equally divided sheet iron extend towards the center of the section to form petals of the plum blossom-shaped structure, and the petals contact closely to form the plum blossom shape. After using said structure, because the sheet iron is uniformly distributed on the whole section, the core of the flux-cored wire with the plum blossom-shaped section is conductive, the electric arc combustion is stable, the flux-cored wire melting is uniform, and the metallurgic reaction is complete.

Owner:何朋飞

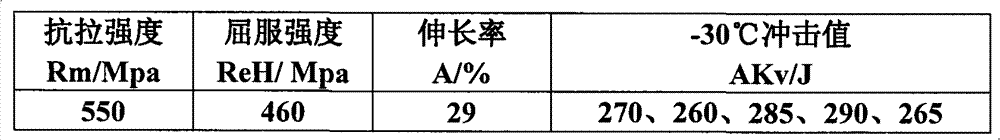

Novel self-shielded flux-cored wire for submerged arc welding

ActiveCN110293330AGood welding performanceLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaWeld seamRutile

The invention provides a novel self-shielded flux-cored wire for submerged arc welding. The self- shielded flux-cored wire is characterized in that liquid slag completely covers electric arcs, moltendrops and molten pools in the welding process, and the self-shielded flux-cored wire comprises a metal sheath and a flux core, wherein the metal sheath is an N6 nickel strip, and the neutral fluoride-rutile slag system is taken as a basic slag system of the flux core. The formula of the flux core comprises the following components of, in mass percent, 10%-35% of rutile, 20%-40% of fluoride, 10%-20% of manganese powder, 3%-10% of aluminum powder, 5%-15% of molybdenum powder, 0%-5% of chromium powder and balance iron powder. According to the flux-cored wire, electric arc combustion is stable inthe welding process, the phenomenon of arc breaking is avoided, the spatter rate is low, the forming performance of welding seams is good, the tensile strength of welded joints is up to 550 Mpa, the diffusible hydrogen content of the joints is lower than 5 ml / 100 g, and the standard of ultra-low hydrogen welding materials is reached.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Low-cost wet method underwater welding rods

InactiveCN101347873BSimple production processIncrease productivityWelding/cutting media/materialsSoldering mediaSlagPotassium

The invention provides a low-cost underwater wet welding rod which adopts a commercial H08E welding wire as a welding core; the main components and weight proportion of coating are as follows: 20-30% of ilmenite, 10-15% of dolomite, 25-35% of ferrous powder, 8-15% of potassium feldspar, 2-7% of medium-carbon ferromanganese, 5-9% of white slime, 3-8% of titanium pigment, 1-4% of CMC and 1-5% of fine mica; the high viscosity resin which accounts for 8-15% of the total weight of the coating components is added. By adopting the high viscosity resin as an adhesion agent, the welding rod of the invention can be directly applied to underwater wet welding after extrusion and does not need to be coated with a waterproof coating on the surface, thus simplifying production technique, improving production efficiency and reducing production cost; the invention can ensure that after the welding rod is soaked in water for a long time, the coating dose not go bad and drop off, and welding operation can still be carried out. When used in underwater welding, the welding rod has the advantages of easy arc striking, stable combustion of electric arc, good performance of restarting, easy slag detachability, good weld forming and fine processing property of underwater welding.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Small-sized wire drawing type electric arc spraying equipment

ActiveCN101864549BReduce volumeReduce weightMolten spray coatingElectric arc sprayingThermal sprayingOperation mode

The invention relates to small-sized wire drawing type electric arc spraying equipment used for hot spraying, which is shown in the attached drawing of the abstract. The equipment adopts the technical scheme of an inversion type spraying power supply and a wire drawing type spraying gun, the output voltage of 10 to 40V is regulated in a stepless way, and the voltage can be regulated in the spraying process without stop; a manual / automatic spraying and wire inspection / spraying switch is arranged, which is convenient to select an operation mode and avoid the occurrence of the condition that electric arcs injure people and damage equipment because of the short circuit of a wire material when the spraying wire material is installed, regulated and inspected; the spraying wire material is limited to be phi 1.0 to phi 1.6mm, the maximum spraying current is 250A, the load duration rate is 100 percent, and continuous spraying is permitted; the weight of the spraying power supply is 15kg, and the weight of the spraying gun is 1.5kg; and the equipment has the characteristics of small volume, light weight, convenient carrying, safe and reliable equipment performance, convenient use, simple operation, stable spraying quality and the like, is suitable for the field operation and the use in an occasion with small spraying space and is suitable for spraying a component with a fine and small structure and a product with a fine coating.

Owner:慈溪光华金属复合材料有限公司

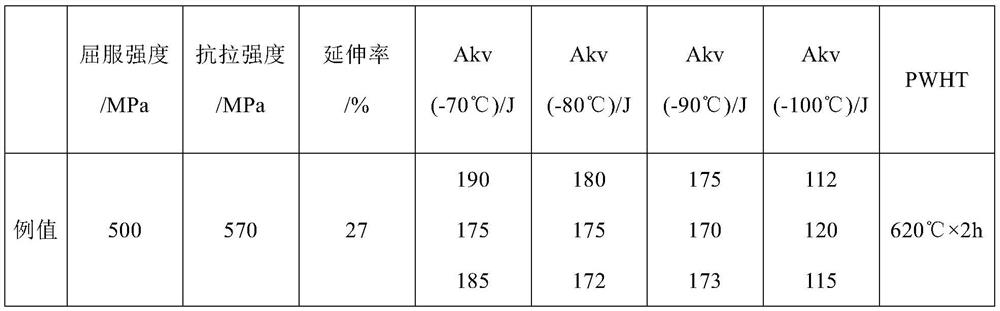

Ultralow-hydrogen type high-alkalinity high-toughness sintered flux

PendingCN112059473AGood technical effectFormulated scientifically and convenientlyWelding/cutting media/materialsSoldering mediaFerro-manganese alloyIron alloys

The invention relates to an ultralow-hydrogen high-alkalinity high-toughness sintered flux. The sintered flux is specifically prepared from dry powder of multiple components and binder water glass, and the dry powder comprises the following components in parts by weight: 12-23 parts of MgO, 15-25 parts of CaF2, 16-26 parts of Al2O3, 10-20 parts of CaCO3, 1-8 parts of SiO2, 1-5 parts of BaCO3, 1-5parts of Li2CO3, 2-5 parts of K2O+Na2O, and 1-5 parts of silicon-manganese-iron alloy. The ultralow-hydrogen type high-alkalinity high-toughness sintered flux is prepared through the method includingthe following steps that the dry powder materials are evenly mixed according to the proportions, the water glass is added, wet mixing is conducted, then granulation is conducted, drying is conducted at the temperature of 280-380 DEG C to remove the moisture, screening is conducted, high-temperature sintering is conducted at the temperature of 750-850 DEG C, cooling and screening are conducted, andthe ultralow-hydrogen type high-alkalinity high-toughness sintered flux is obtained. The ultralow-hydrogen type high-alkalinity high-toughness sintered flux has the excellent technical effects as shown in the specification.

Owner:BEIJING JINWEI WELDING MATERIAL +1

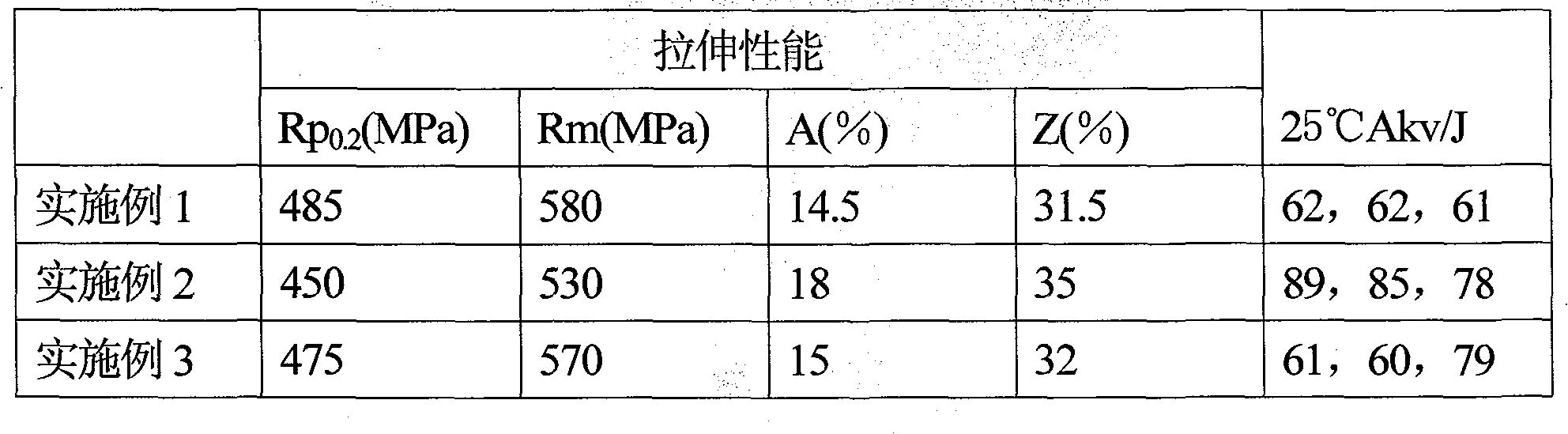

A self-shielded flux-cored wire for underwater wet welding

ActiveCN104057214BNot easy to arcEasy arc startWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a self-protection flux-cored wire for underwater wet-method welding. The self-protection flux-cored wire is characterized in that a N6 nickel band is used as a metal covering of the wire, an alkaline calcium fluoride-aluminum oxide slag system is used as a flux-cored basic slag system, the internal flux core consists of calcium fluoride, aluminum powder, iron powder, magnesium oxide, silicon iron, lithium fluoride, manganese powder and metal chromium, and the weight percent of each component is as follows: 40 to 55 percent of calcium fluoride, 8 to 13 percent of aluminum powder, 5 to 9 percent of iron powder, 0.5 to 5 percent of magnesium oxide, 3 to 7 percent of silicon iron, 3 to 9 percent of lithium fluoride, 6 to 11 percent of manganese powder and 4 to 10 percent of metal chromium. When the flux-cored wire is used for the underwater wet-method welding, arc is likely to start, the electric arc is stable in combustion, the restarting arc is good in performance, the forming property of the weld seam is good, the tensile strength of the weld metal after being welded is not lower than 460MPa, and the underwater welding of the medium-low carbon steel and low-alloy high-strength steel structure of ordinary strength requirement can be satisfied.

Owner:HARBIN INST OF TECH AT WEIHAI

High-strength underwater welding electrodes

InactiveCN1939649BEasy arc startStable arc burningWelding/cutting media/materialsSoldering mediaCelluloseButt joint

A high-strength wet welding electrode for underwater welding is composed of the core made of H08E steel wire a coated surficial water-proof layer, and a coated sandwich layer containing rutile (42-54 Wt%), potash feldspar (12-20), talc (6-14), cellulose (4-12), ferromanganese (6-14), Ni powder (0-4), Fe powder (3-12) and at least one kind of Nickel powder (2-4) and Al-Mg alloy (2-4).

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Preparation method of CuW70 contact material

InactiveCN102312146BUniform network structureImprove conductivityElectric switchesCopperHigh pressure

The invention discloses a preparation method of a CuW70 contact material, comprising the steps of: adding inducing copper powder into tungsten powder in certain proportion and mixing them well, putting the mixed powder into a rubber sheath which is then placed in the high pressure cylinder of a cold isostatic pressing machine so as to be pressed into a skeleton green body, and then preparing the CuW70 contact material through copper infiltration of the sintered skeleton. Due to disappeared copper-rich area and uniform two-phase distribution of the prepared CuW70 contact material by the methodof the invention, the material has rapidly moving cathode spot on the surface, effectively dispersed electric arc, less copper phase splashing, and improved ablation resistance.

Owner:XIAN UNIV OF TECH

Low-alkalinity and high-toughness sintered flux

ActiveCN102363252BStable arc burningAdjustable viscosityWelding/cutting media/materialsSoldering mediaAlkalinityMetal

The invention provides a low-alkalinity and high-toughness sintered flux, which comprises the components in part by weight: 35-55 parts of CaF2, 35-50 parts of Al2O3, 1-5 parts of MgO, 1-5 parts of CaO, 2-6 parts of SiO2, 1-5 parts of Si-Fe, 1-5 parts of Mn-Fe and 2-5 parts of K2O+Na2O. After the sintered flux is adopted, on the premise of guaranteeing higher low-temperature impact toughness of weld metal, the alkalinity of the flux is reduced, and the welding technological performance of the flux is improved.

Owner:BEIJING JINWEI WELDING MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com