Automatic submerged arc welding flux and preparation method thereof

An automatic submerged arc welding and flux technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as unstable product process performance and mechanical performance, shortage of high-grade ore raw material resources, and restrictions on large-scale production of smelting flux , to achieve the effect of solving resource consumption, surface corrugation rules, and weld metal brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The selected flux components are shown in Table 1:

[0022]

[0023] Take 4-8 mesh manganese-rich slag particles, water slag particles, manganese ore tailings, fluorite particles, and magnesia brick particles as raw materials. The ingredients are shown in Table 2:

[0024]

[0025] The required ore composition is calculated according to the following formula:

[0026]

[0027] Q: The percentage of the ore composition is required, but it is not the percentage of the flux formula.

[0028] a: Composition (%) of the specified compound in the selected DY-30 flux.

[0029] b: The composition of the compound in the selected ore (%).

[0030] The composition of ore and flux satisfies the following equations:

[0031]

[0032] Solve the equations to get the ratio of each ore:

[0033] Q 富锰渣 =54.21%, Q 水渣 =19.26%, Q 锰矿 =25.37%, Q 萤石 =5.96%, Q 镁砖 =7.26%.

[0034] The above results are normalized and converted to percentage content, and the percentage co...

Embodiment 2

[0044] The selected flux components are shown in Table 5:

[0045]

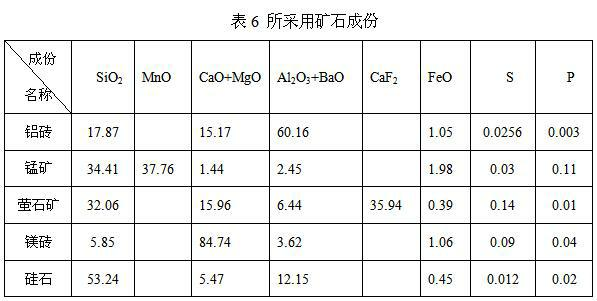

[0046] Take 4-8 mesh aluminum brick particles, manganese ore tailings, fluorite particles, magnesia brick particles and other raw materials, and the ingredients are shown in Table 6:

[0047]

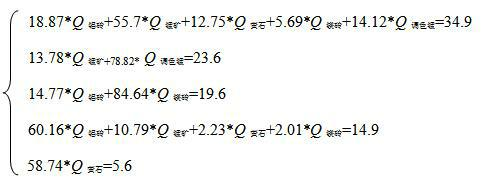

[0048] The composition of ore and flux satisfies the following equations:

[0049]

[0050] After solving the equations and normalizing the results, the ratio of each ore is obtained:

[0051] Q 铝砖 =13.87, Q 锰矿 =55.56, Q 萤石 =9.07, Q 镁砖 =10.57, Q 硅石 =10.95.

[0052] Finally check the impurity content in the formula:

[0053] ΣS%=0.04%<0.06%, ΣP%=0.068%<0.08%, ΣFeO%=1.44%<1.8%.

[0054] The following steps are the same as in Example 1.

Embodiment 3

[0056] The selected flux components are shown in Table 7:

[0057]

[0058] Take 4-8 mesh aluminum brick particles, manganese ore tailings, fluorite particles, magnesia brick particles and other raw materials, and the ingredients are shown in Table 8:

[0059]

[0060] The composition of ore and flux satisfies the following equations:

[0061]

[0062] After solving the equations and normalizing the results, the ratio of each ore is obtained:

[0063] Q 铝砖 =13.23, Q 锰矿 =41.71, Q 萤石 =8.32, Q 镁砖 =17.90, Q 调色锰 =18.84.

[0064] Finally check the impurity content in the formula:

[0065] ΣS%=0.046%<0.06%, ΣP%=0.079%<0.08%, ΣFeO%=1.33%<1.8%.

[0066] The following steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com